Analysis of Mechanical Characteristics of Stereolithography Soft-Picking Manipulator and Its Application in Grasping Fruits and Vegetables

Abstract

:1. Introduction

2. Materials and Methods

2.1. SLA Printing System Setup

2.2. Structure Design of Soft-Picking Manipulator

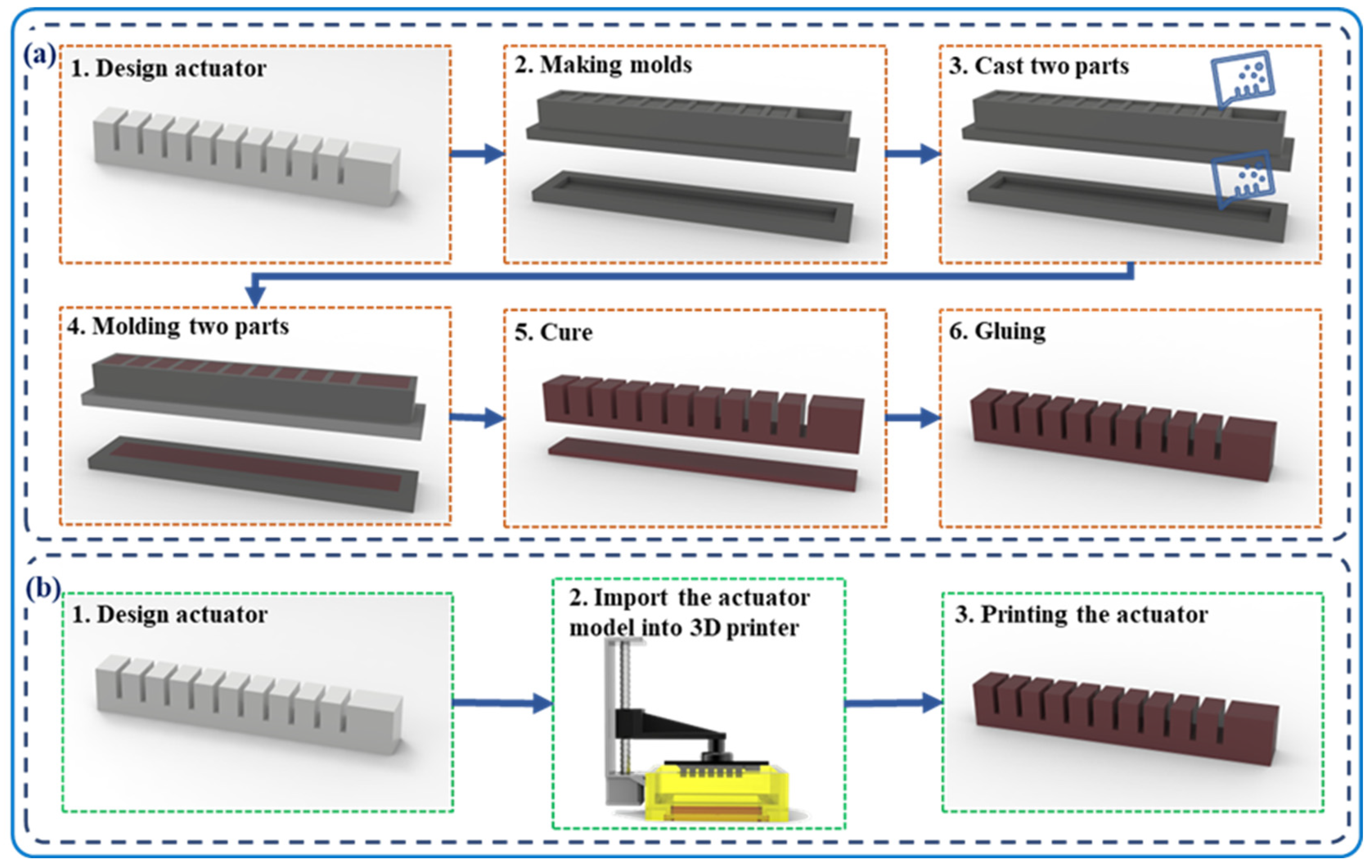

2.3. Preparation of Soft Actuators

2.4. Finite Element Analysis of the Soft Actuator

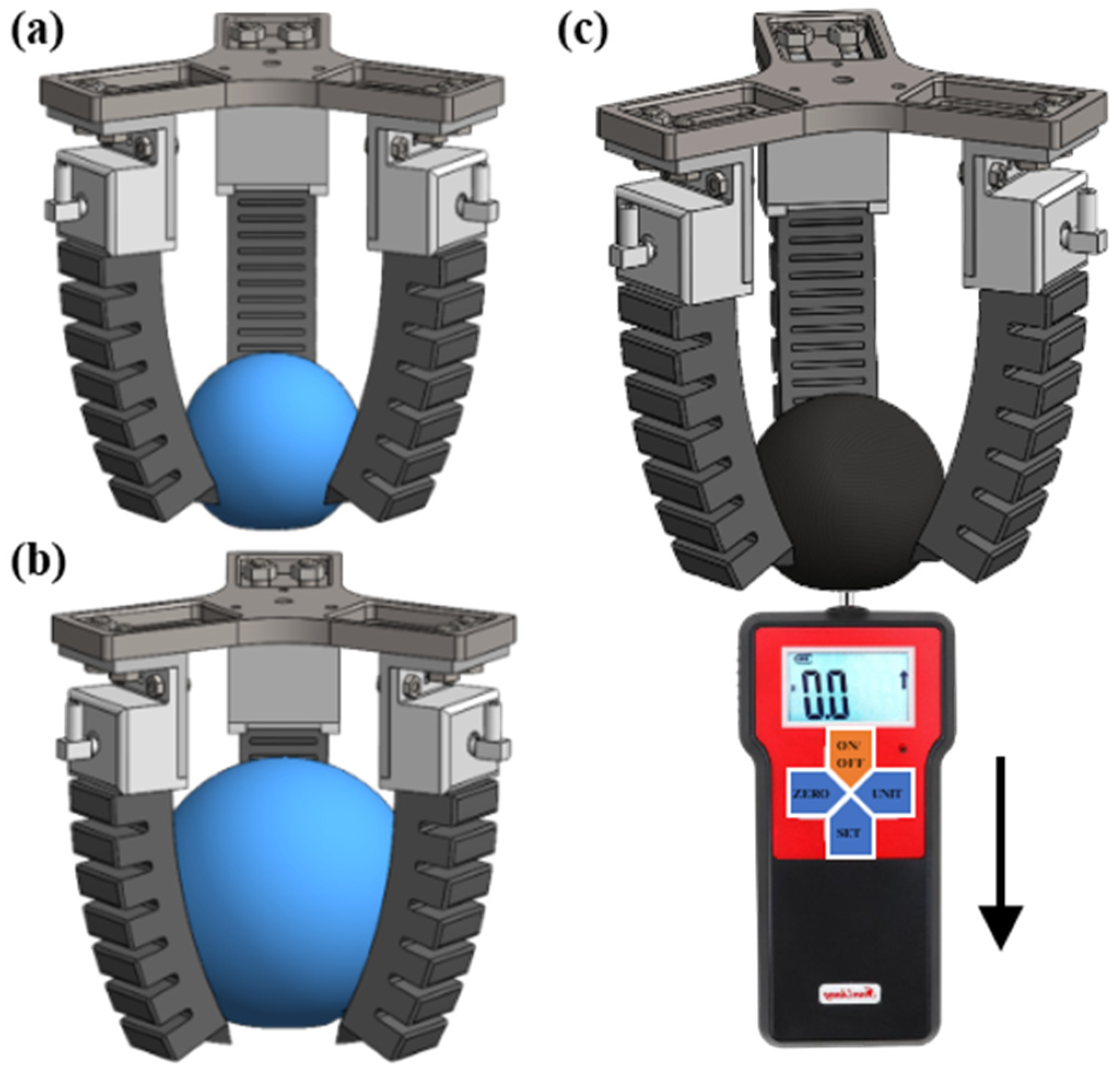

2.5. Soft Actuator Output Force Test

2.6. Test Platform Design

2.7. The Soft Manipulator Grasping Mode

3. Results

3.1. Grasping Experiments of Different Grasping Modes

3.2. Fruit and Vegetable Grasping Experiments

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ding, B.; Zhao, J.; Li, Y. Design of a spatial constant-force end-effector for polishing/deburring operations. Int. J. Adv. Manuf. Technol. 2021, 116, 3507–3515. [Google Scholar] [CrossRef]

- Ding, B.; Li, X.; Chen, S.-C.; Li, Y. Modular quasi-zero-stiffness isolator based on compliant constant-force mechanisms for low-frequency vibration isolation. J. Vib. Control 2023, 1–15. [Google Scholar] [CrossRef]

- Liu, K.; Chen, W.; Yang, W.; Jiao, Z.; Yu, Y. Review of the Research Progress in Soft Robots. Appl. Sci. 2022, 13, 120. [Google Scholar] [CrossRef]

- Xiong, Y.; Peng, C.; Grimstad, L.; From, P.J.; Isler, V. Development and field evaluation of a strawberry harvesting robot with a cable-driven gripper. Comput. Electron. Agr. 2019, 157, 392–402. [Google Scholar] [CrossRef]

- Li, J.; Dai, C.; Wang, Y.; Cha, F.; Miao, W. Structure design and experiment of three finger flexible pneumatic gripper. J. Harbin Inst. Technol. 2022, 54, 105–113. [Google Scholar]

- Homberg, B.S.; Katzschmann, R.K.; Dogar, M.R.; Rus, D. Robust proprioceptive grasping with a soft robot hand. Auton. Robot. 2019, 43, 681–696. [Google Scholar] [CrossRef]

- Navas, E.; Fernandez, R.; Armada, M.A.; Santos, P.G.D. Diaphragm-Type Pneumatic-Driven Soft Grippers for Precision Harvesting. Agronomy 2021, 11, 1727. [Google Scholar] [CrossRef]

- Liu, C.; Dong, E.; Xu, M.; Alici, G.; Yang, J. Locomotion analysis and optimization of actinomorphic robots with soft arms actuated by shape memory alloy wires. Int. J. Adv. Robot. Syst. 2018, 15, 467–475. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kaynak, A.; Yang Khoo, S.; Zhang, J.; Nahavandi, S.; Kouzani, A. Control-Oriented Modelling of a 3D-Printed Soft Actuator. Materials 2018, 12, 71. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Shea, H.; Floreano, D. Soft Biomimetic Fish Robot Made of Dielectric Elastomer Actuators. Soft Robot. 2018, 5, 466–474. [Google Scholar] [CrossRef]

- Martinez, R.V.; Branch, J.L.; Fish, C.R.; Jin, L.; Shepherd, R.F.; Nunes, R.M.D.; Suo, Z.; Whitesides, G.M. Composite Materials: Robotic Tentacles with Three-Dimensional Mobility Based on Flexible Elastomers. Adv. Mater. 2013, 25, 153. [Google Scholar] [CrossRef]

- Jia, J.; Ye, Y.; Cheng, P.; Hu, R.; Wu, C. Design and parameter optimization of soft pneumatic gripper for slender fruits and vegetables picking. Trans. Chin. Soc. Agric. Mach. 2021, 52, 26–34. [Google Scholar]

- Fei, Y.; Pang, W.; Yu, W. Movement of air-driven soft robot. J. Mech. Eng. 2017, 53, 14–18. [Google Scholar] [CrossRef]

- Daerden, F.; Lefeber, D. In Pneumatic Artificial Muscles: Actuators for robotics and automation. In Proceedings of the International Conference in AI, London, UK, 31 July 2018. [Google Scholar]

- Marchese, A.D.; Katzschmann, R.K.; Rus, D. A Recipe for Soft Fluidic Elastomer Robots. Soft Robot. 2015, 2, 7–25. [Google Scholar] [CrossRef]

- Onal, C.D.; Rus, D. Autonomous undulatory serpentine locomotion utilizing body dynamics of a fluidic soft robot. Bioinspiration Biomim. 2013, 8, 026003. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, N.; Hingorani, H.; Ding, N.; Wang, D.; Yuan, C.; Zhang, B.; Gu, G.; Ge, Q. Fast-Response, Stiffness-Tunable Soft Actuator by Hybrid Multimaterial 3D Printing. Adv. Funct. Mater. 2019, 15, 1806698. [Google Scholar] [CrossRef]

- Zhuang, Y.; Guo, Y.; Li, J.; Jiang, K.; Yu, Y.; Zhang, H.; Liu, D. Preparation and laser sintering of a thermoplastic polyurethane carbon nanotube composite-based pressure sensor. RSC Adv. 2020, 10, 23644. [Google Scholar] [CrossRef] [PubMed]

- Anver, H.M.C.M.; Mutlu, R.; Alici, G. 3D printing of a thin-wall soft and monolithic gripper using fused filament fabrication. In Proceedings of the IEEE International Conference on Advanced Intelligent Mechatronics, Munich, Germany, 3–7 July 2017. [Google Scholar]

- Peele, B.N.; Wallin, T.J.; Zhao, H.; Shepherd, R.F. 3D printing antagonistic systems of artificial muscle using projection stereolithography. Bioinspiration Biomim. 2015, 10, 055003. [Google Scholar] [CrossRef] [PubMed]

- Junghwan, B.; Yoontaek, L.; Jaeyoung, Y.; Byeongmoon, L.; Eunho, O.; Seungjun, C.; Takhee, L.; Kyu-Jin, C.; Jaeha, K.; Yongtaek, H. Electronic skins for soft, compact, reversible assembly of wirelessly activated fully soft robots. Sci. Robot. 2018, 3, eaas9020. [Google Scholar]

- Schaffner, M.; Faber, J.A.; Pianegonda, L.; Rühs, P.A.; Coulter, F.; Studart, A.R. 3D printing of robotic soft actuators with programmable bioinspired architectures. Nat. Commun. 2018, 9, 878. [Google Scholar] [CrossRef]

- Yap, H.K.; Ng, H.Y.; Yeow, C.H. High-Force Soft Printable Pneumatics for Soft Robotic Applications. Soft Robot. 2016, 3, 144–158. [Google Scholar] [CrossRef]

- Mutlu, R.; Alici, G.; Panhuis, M.; Spinks, G.M. 3D printed flexure hinges for soft monolithic prosthetic fingers. Soft Robot. 2016, 3, 120–133. [Google Scholar] [CrossRef]

- Wallin, T.J.; Pikul, J.; Shepherd, R.F. 3D printing of soft robotic systems. Nat. Rev. Mater. 2018, 3, 84–100. [Google Scholar] [CrossRef]

- Li, W.; Zhou, H.; Liu, W.; Yu, H.; Wang, J.; Gong, L.; Xing, Z. Research progress in ceramic slurries and rheology via photopolymerization based 3D printing. J. Mater. Eng. 2022, 50, 40–50. [Google Scholar]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212. [Google Scholar] [CrossRef]

- Zirak, N.; Shirinbayan, M.; Benfriha, K.; Deligant, M.; Tcharkhtchi, A. Stereolithography of (meth)acrylate-based photocurable resin: Thermal and mechanical properties. J. Appl. Polym. Sci. 2022, 139, 52248. [Google Scholar] [CrossRef]

- Wallin, T.J.; Pikul, J.H.; Bodkhe, S.; Peele, B.N.; Murray, B.C.M.; Therriault, D. Click chemistry stereolithography for soft robots that self-heal. J. Mater. Chem. B 2017, 31, 6249–6255. [Google Scholar] [CrossRef]

- Feng, X.; Yang, Z.; Wang, S. The reinforcing effect of lignin-containing cellulose nanofibrils in the methacrylate composites produced by stereolithography. Polym. Eng. Sci. 2022, 9, 2968–2976. [Google Scholar] [CrossRef]

- Choi, J.W.; Macdonald, E.; Wicker, R. Multi-material microstereolithography. Int. J. Adv. Manuf. Technol. 2010, 49, 543–551. [Google Scholar] [CrossRef]

- Lan, P.X.; Lee, J.W.; Seol, Y.J.; Cho, D.W. Development of 3D PPF/DEF scaffolds using micro-stereolithography and surface modification. J. Mater. Sci. Mater. Med. 2009, 20, 271–279. [Google Scholar] [CrossRef]

- Hua, C.; Chu, K.; Chen, X.; Zhu, Y. Design, analysis and experimental study of soft picking manipulator system for fruit harvesting. J. For. Eng. 2021, 6, 127–132. [Google Scholar]

- Thrasher, C.J.; Schwartz, J.J.; Boydston, A.J. Modular Elastomer Photoresins for Digital Light Processing Additive Manufacturing. ACS Appl. Mater. Interfaces 2017, 9, 39708–39716. [Google Scholar] [CrossRef] [PubMed]

- Heung, K.H.L.; Tang, Z.Q.; Ho, L.; Tung, M.; Li, Z.; Tong, R.K.Y. Design of a 3D Printed Soft Robotic Hand for Stroke Rehabilitation and Daily Activities Assistance. In Proceedings of the 2019 IEEE 16th International Conference on Rehabilitation Robotics (ICORR), Toronto, ON, Canada, 24–28 June 2019; pp. 65–70. [Google Scholar]

- Scharff, R.B.N.; Doubrovski, E.L.; Poelman, W.A.; Jonker, P.P.; Wang, C.C.L.; Geraedts, J.M.P. Towards behavior design of a 3D-printed soft robotic hand. In Soft Robotics: Trends, Applications and Challenges; Springer International Publishing: Berlin/Heidelberg, Germany, 2017; pp. 23–29. [Google Scholar]

- Homberg, B.S.; Katzschmann, R.K.; Dogar, M.R.; Rus, D. Haptic identification of objects using a modular soft robotic gripper. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015. [Google Scholar]

- Zhuang, Y.; Guo, Y.; Li, J.; Yu, Y.; Jiang, K.; Zhang, H.; Guo, S. Study on the forming and sensing properties of laser-sintered TPU/CNT composites for plantar pressure sensors. Int. J. Adv. Manuf. Technol. 2021, 112, 2211–2222. [Google Scholar] [CrossRef]

| Fruit and Vegetable Categories | Weight/g | Height/mm | Mean Diameter/mm | Pressure/kPa | Success Rate/% |

|---|---|---|---|---|---|

| Cherry tomato | 41.23 | 50.65 | 38.97 | 22 | 85 |

| Orange | 70.86 | 44.74 | 58.59 | 20 | 100 |

| Tomato | 214.60 | 66.71 | 75.54 | 26 | 100 |

| Pear | 283.68 | 73.66 | 79.51 | 36 | 100 |

| Apple | 253.49 | 75.53 | 84.33 | 32 | 100 |

| Banana | 143.79 | 161.25 | 37.07 | 30 | 80 |

| Cucumber | 188.47 | 151.53 | 44.39 | 38 | 75 |

| Manufacturing Method | Output Force | Materials | Manufacturing Process | Manufacturing Costs | Characteristics | Ref. Number |

|---|---|---|---|---|---|---|

| Fused Filament Fabrication (FFF) | 4.4 N/100 kPa | Thermoplastic elastomer (TPE) | Simple | Low cost | Rough surfaces; High temperature process; High pressure; | [19] |

| FDM | 17.79 N/300 kPa | TPE | Simple | Low cost | Easy to deform during molding; High pressure; | [23] |

| DLP | – | Hexane-1,6-diol diacrylate/HEA mixture | Medium complexity | Expensive equipment | Excellent surface quality; Increased performance with multiple materials; | [34] |

| 3D printing | 2.45 N/160 kPa | ShOreA30 | Simple | – | High pressure; Large bending angle; | [35] |

| SLS | 2.9 N/400 kPa | TPU92A-1 | Simple | Expensive equipment and materials | High pressure; Long manufacturing time; | [36] |

| Molding | – | Dragonskin 10 A/20 A | Complexity | Low cost | More material available; Long manufacturing time; Complex manufacturing process; | [6] |

| Molding | – | Ecoflex 00-10 | Complexity | Low cost | Long manufacturing time; Complex manufacturing process; | [37] |

| SLA | 1.9 N/60 kPa | Silicone rubber resin | Simple | Low cost | Excellent surface quality and precision; Easy to age in the sun. | This paper |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhuang, Y.; Guo, Y.; Li, J.; Shen, L.; Wang, Z.; Sun, M.; Wang, J. Analysis of Mechanical Characteristics of Stereolithography Soft-Picking Manipulator and Its Application in Grasping Fruits and Vegetables. Agronomy 2023, 13, 2481. https://doi.org/10.3390/agronomy13102481

Zhuang Y, Guo Y, Li J, Shen L, Wang Z, Sun M, Wang J. Analysis of Mechanical Characteristics of Stereolithography Soft-Picking Manipulator and Its Application in Grasping Fruits and Vegetables. Agronomy. 2023; 13(10):2481. https://doi.org/10.3390/agronomy13102481

Chicago/Turabian StyleZhuang, Yu, Yanling Guo, Jian Li, Liuyang Shen, Zhentao Wang, Maoxiang Sun, and Jinfeng Wang. 2023. "Analysis of Mechanical Characteristics of Stereolithography Soft-Picking Manipulator and Its Application in Grasping Fruits and Vegetables" Agronomy 13, no. 10: 2481. https://doi.org/10.3390/agronomy13102481

APA StyleZhuang, Y., Guo, Y., Li, J., Shen, L., Wang, Z., Sun, M., & Wang, J. (2023). Analysis of Mechanical Characteristics of Stereolithography Soft-Picking Manipulator and Its Application in Grasping Fruits and Vegetables. Agronomy, 13(10), 2481. https://doi.org/10.3390/agronomy13102481