Characteristics on the Spatial Distribution of Droplet Size and Velocity with Difference Adjuvant in Nozzle Spraying

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

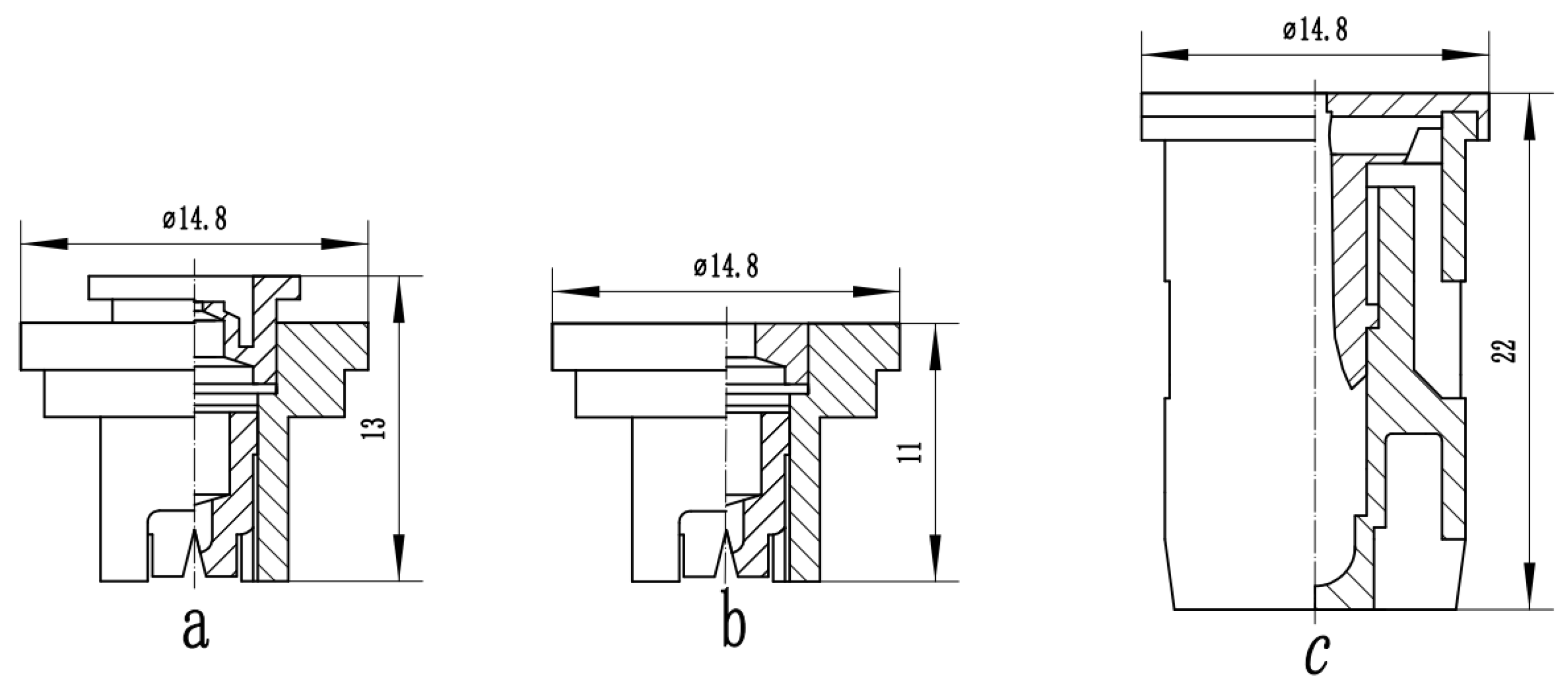

2.1.1. Nozzle and Adjuvants

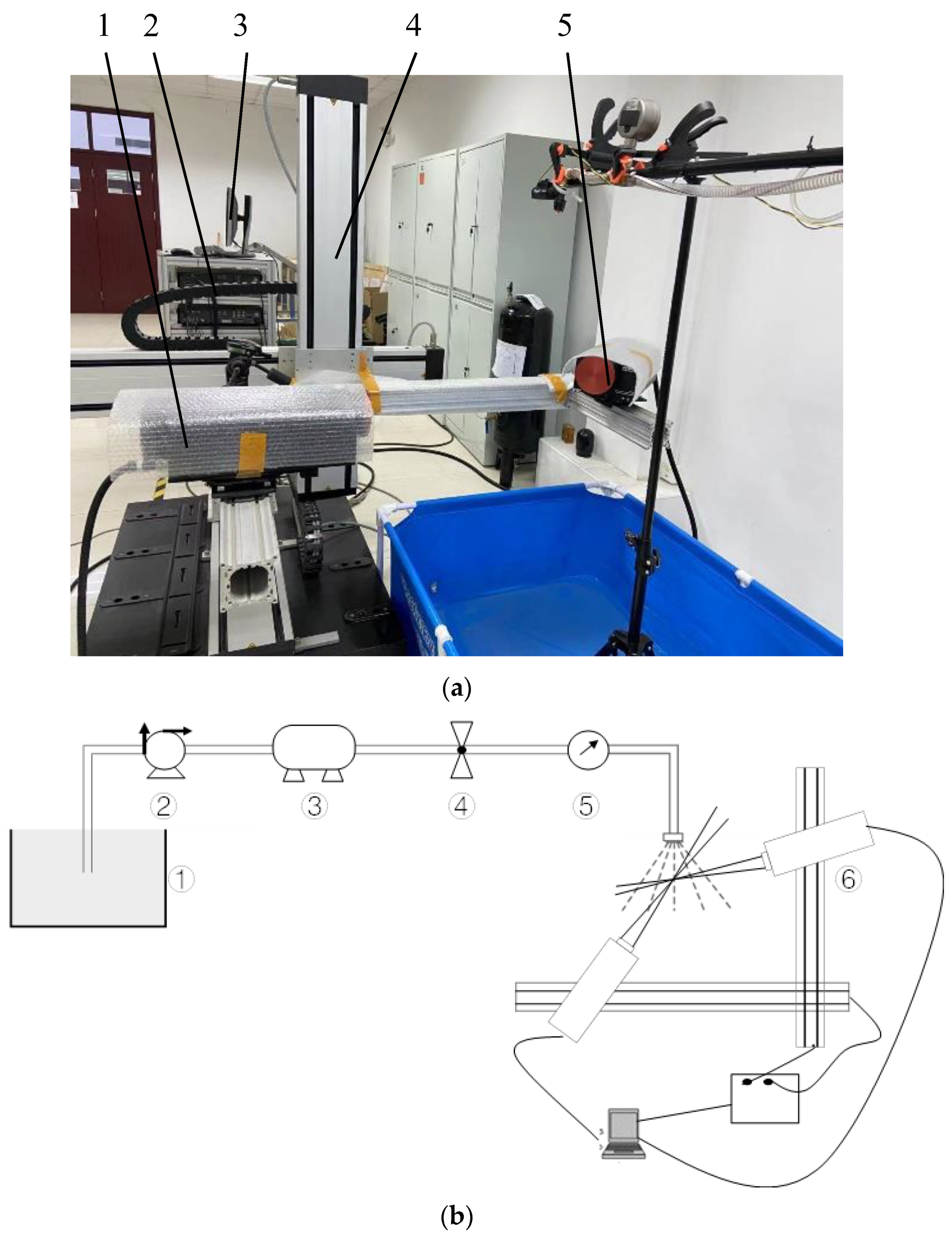

2.1.2. Experimental Equipment

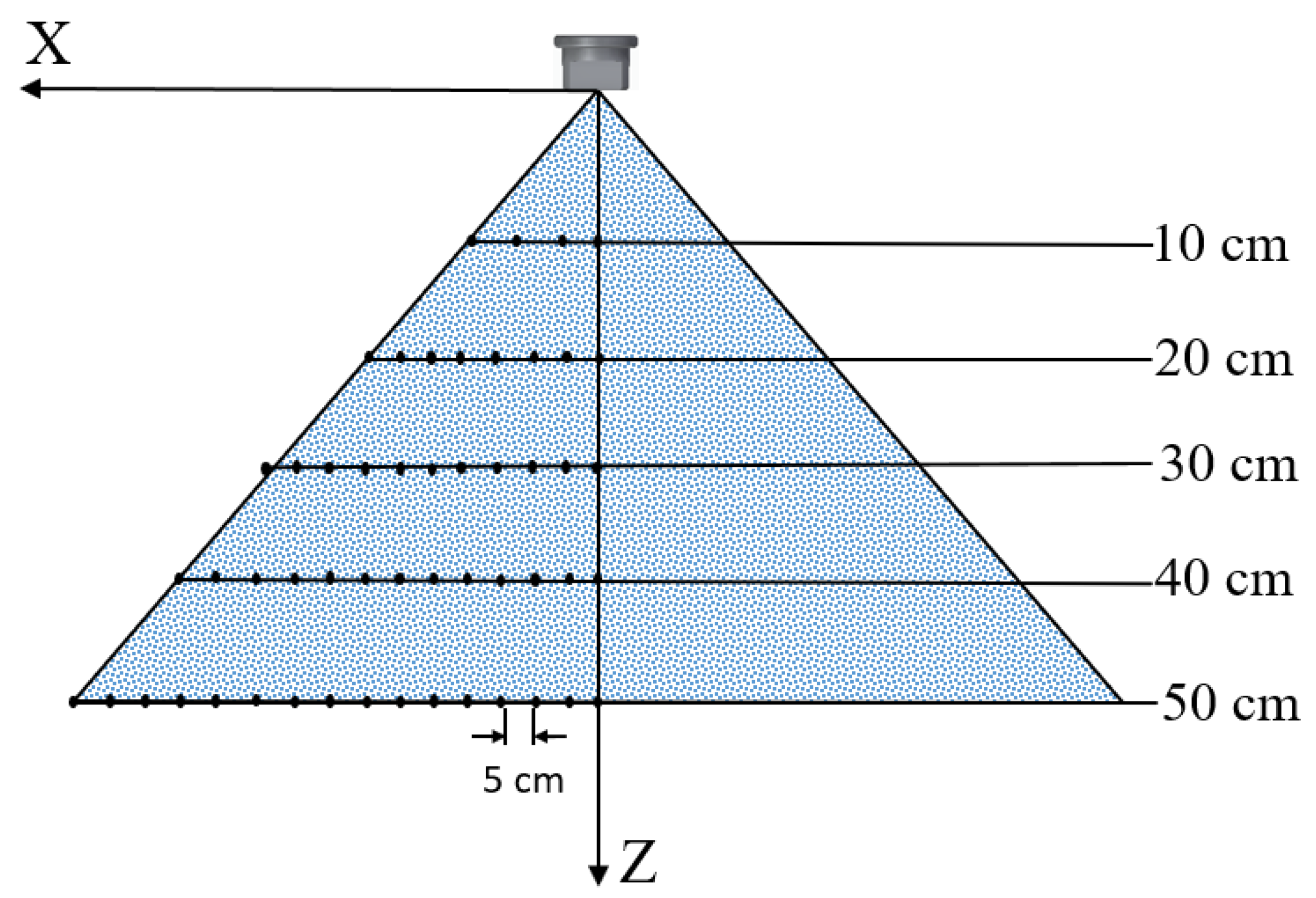

2.2. Test Method

2.3. Basic Theory

3. Results and Discussion

3.1. Droplet Size Distribution of Droplets

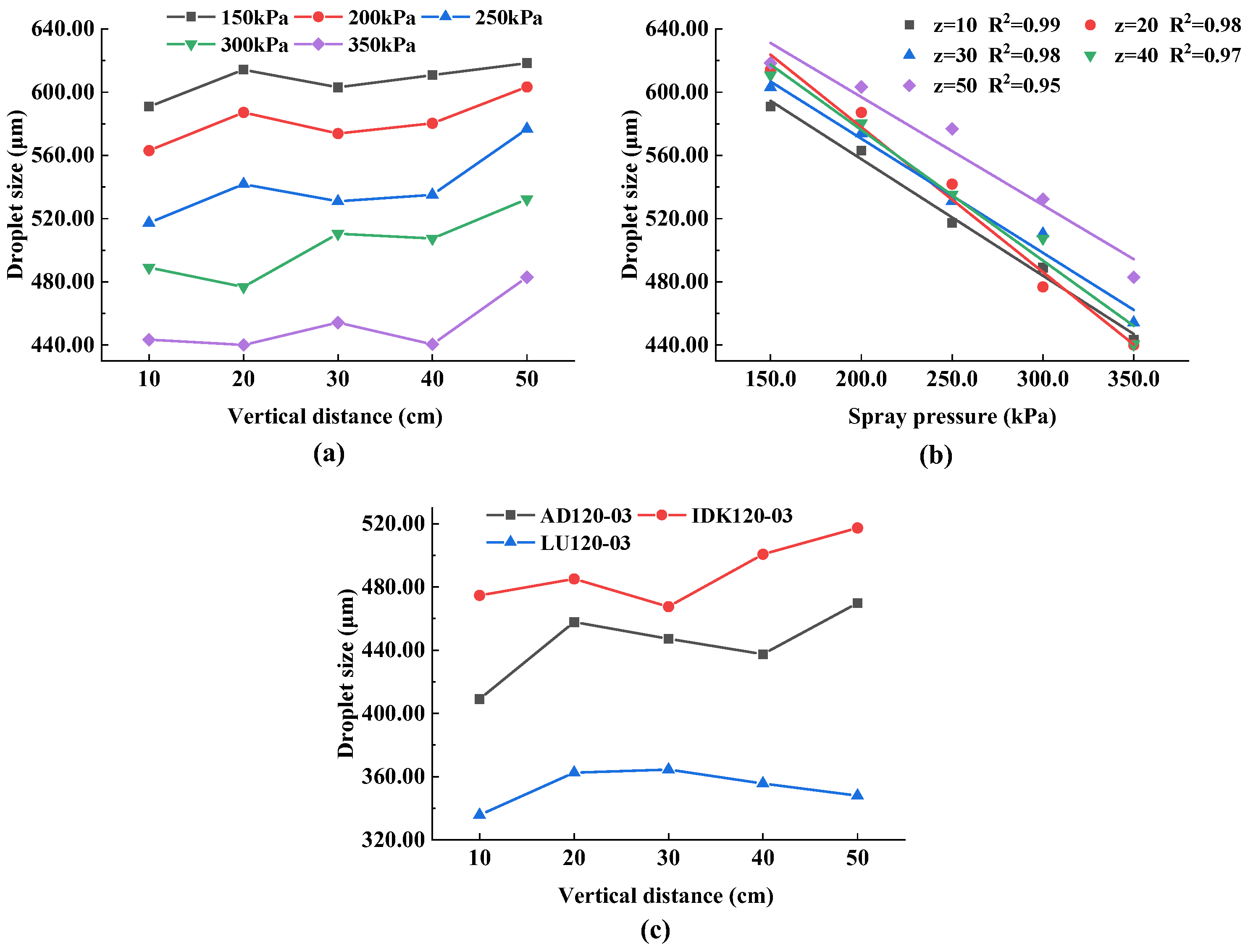

3.1.1. Vertical Z-Axis Droplet Size DZ Distribution

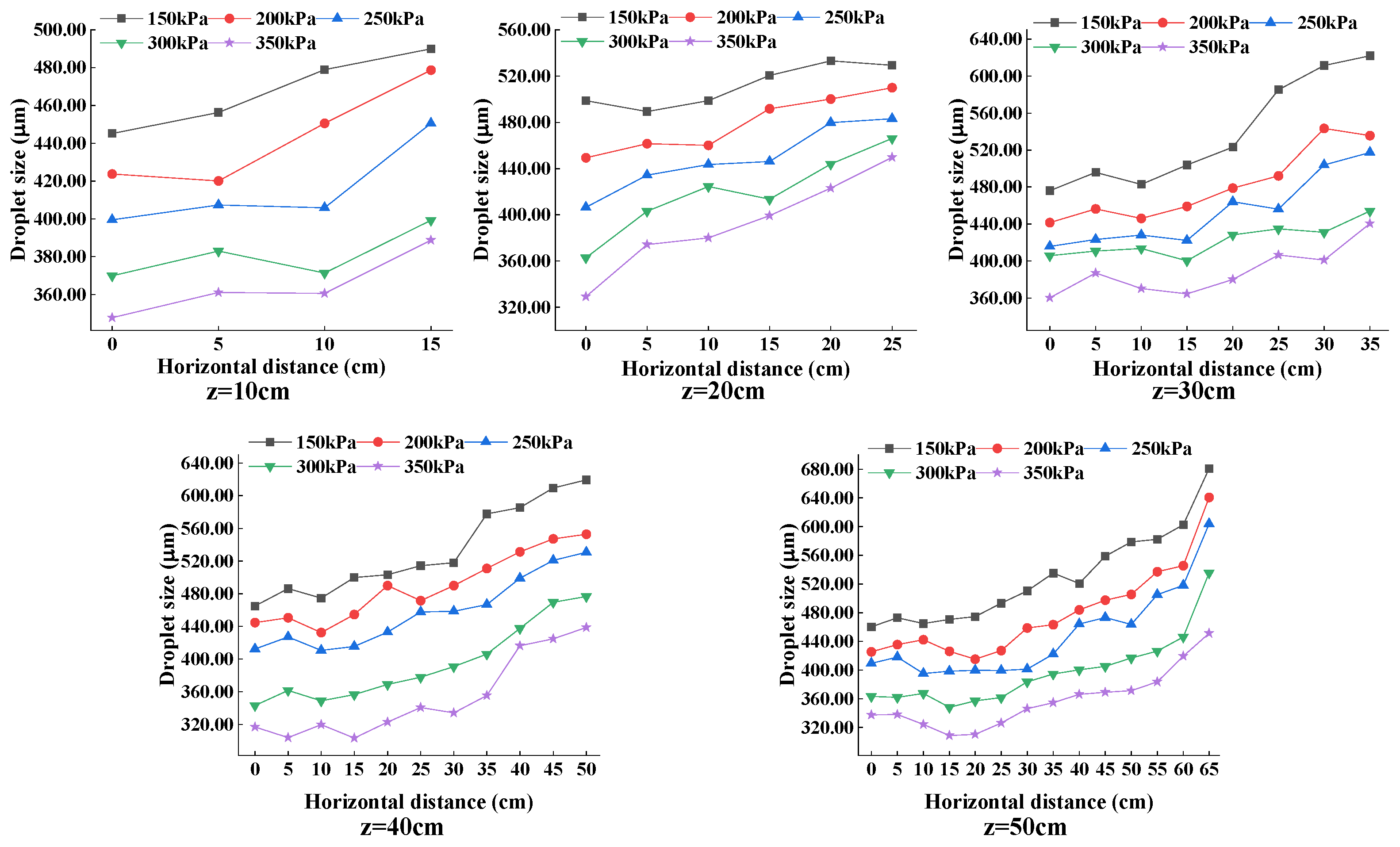

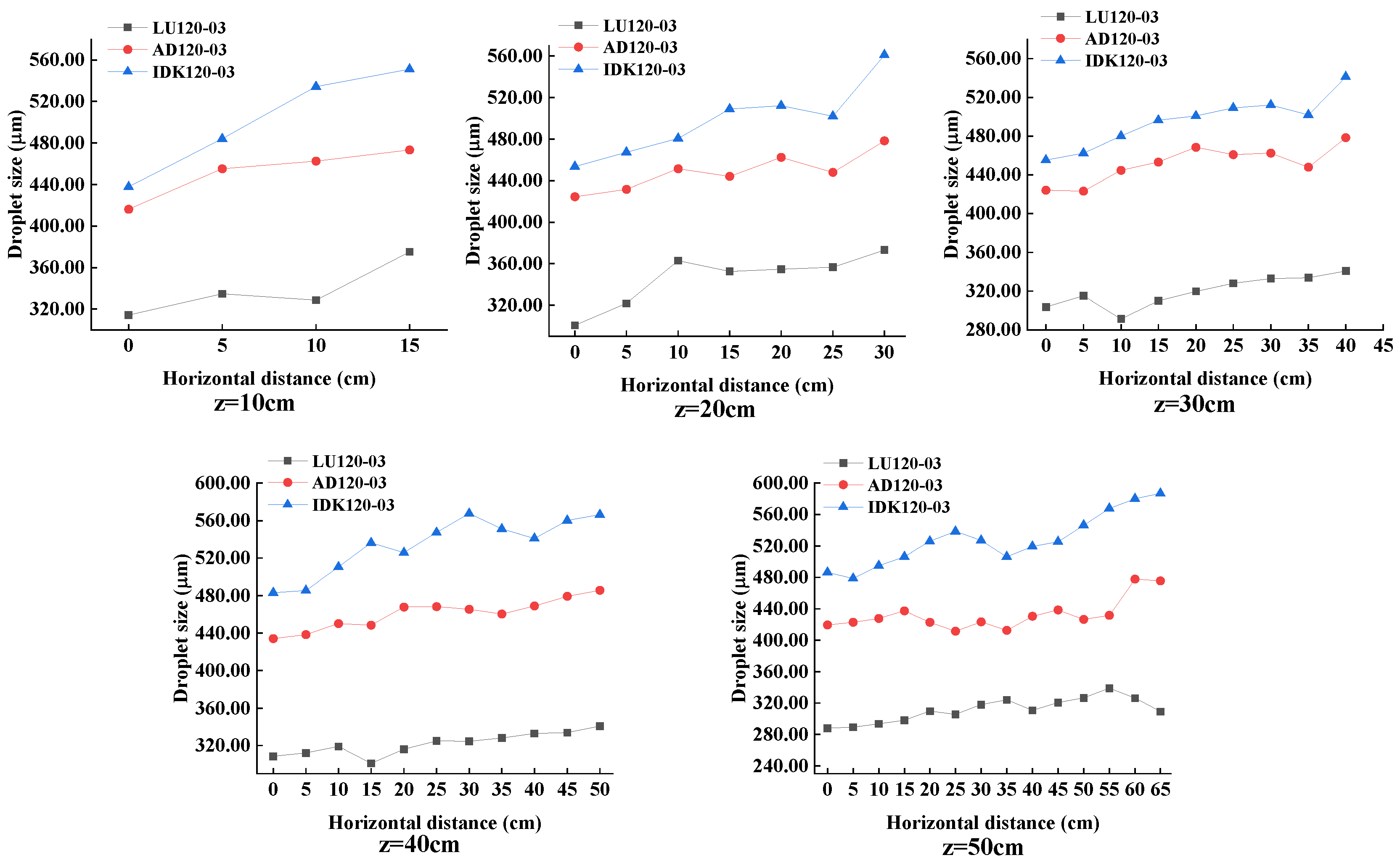

3.1.2. Horizontal X-Axis Droplet Size DX Distribution

3.2. Droplet Velocity Distribution of Droplets

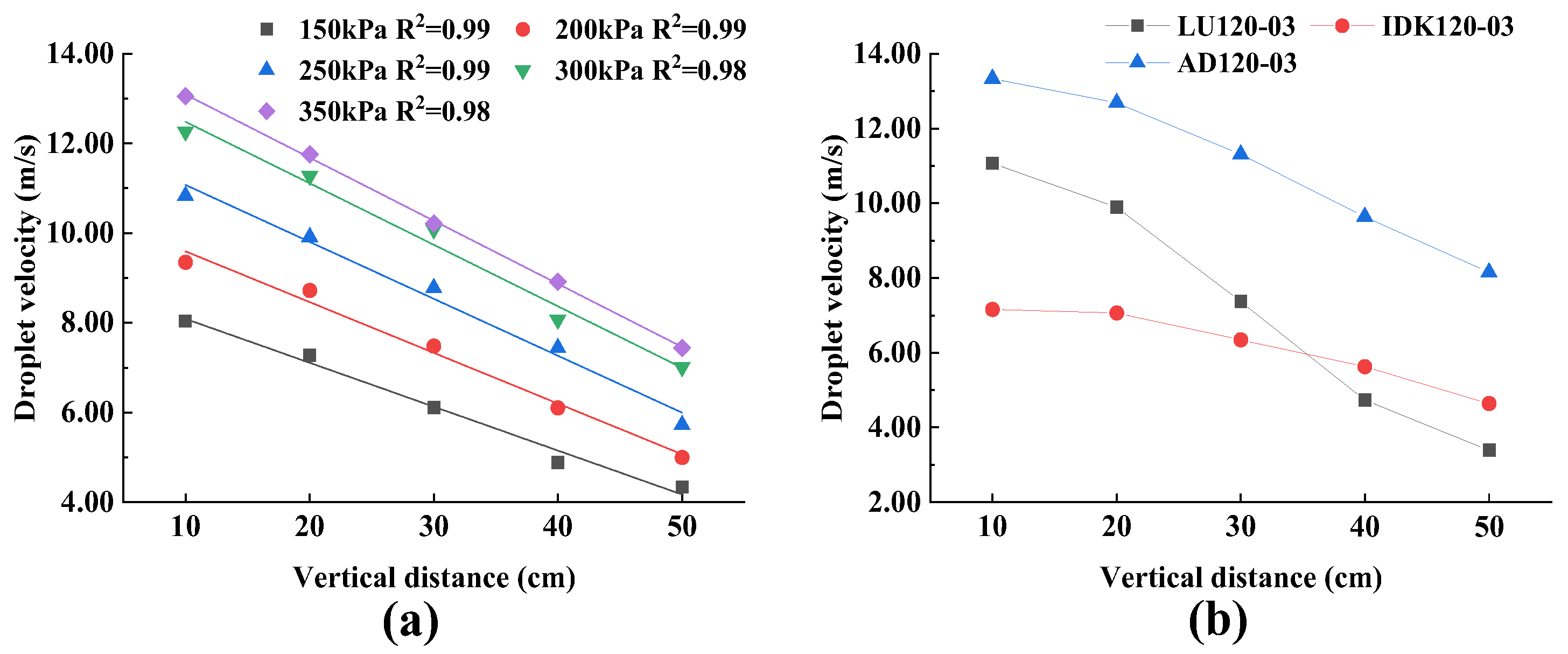

3.2.1. Vertical Z-Axis Droplet Velocity VZ Distribution

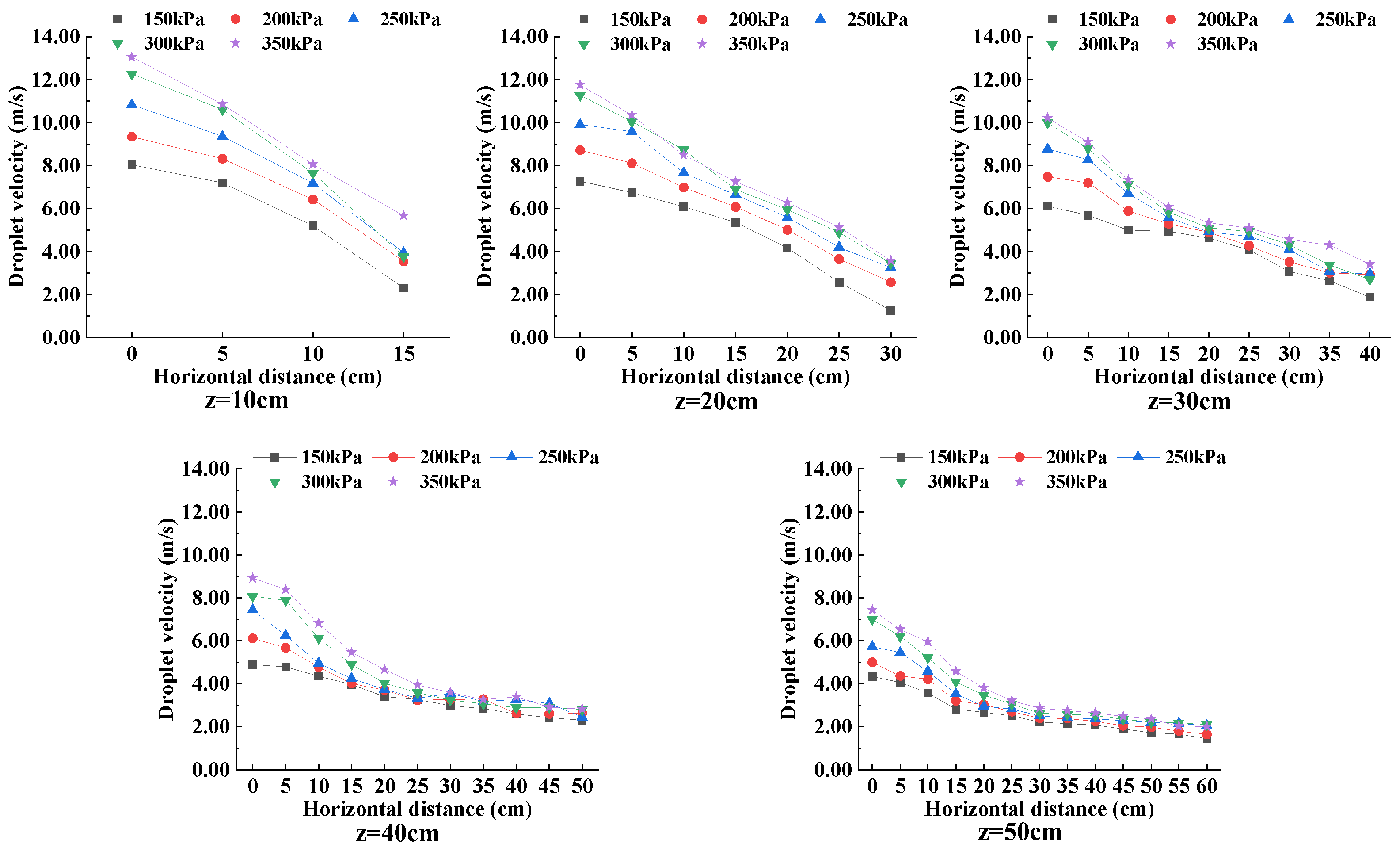

3.2.2. Horizontal X-Axis Droplet Velocity VX Distribution

4. Conclusions

- (1)

- In the spatial distribution of droplet volume median diameter Dv0.5, in the vertical direction of the nozzle center, the droplet size Dv0.5 has no significant change with the Z axis vertical distance. Compared with water, the distribution of the adjuvants on the droplet volume median diameter Dv0.5 was as follows: the average increase proportion of droplet volume median diameter was the largest by Maidao and Maisi, which increased by about 12%, followed by Surun by 10%, and the minimum was 9% of Adsee AB-600. Among the three nozzles, IDK120-03 nozzle produced the largest droplet volume median diameter Dv0.5 and the smallest droplet volume median diameter LU120-03. In the horizontal direction, the droplet volume median diameter Dv0.5 increases with the increase of horizontal distance, and the droplet size at the edge is the largest. The droplet size Dv0.5 increased with the increase of Maisi, Surun, AdseeAB-600 and Maidao adjuvants. The increase of droplet size Dv0.5 with Maisi adjuvants is the largest, while that with AdseeAB-600 and Maidao adjuvants was close to each other, and the smallest was the Surun adjuvants.

- (2)

- In the droplet velocity spatial distribution, at the vertical direction of the nozzle center, the droplet velocity decreases with the increase of the vertical distance Z axis after the liquid is forced to atomize by the nozzle. The droplet velocity increases with pressure at the same position. In the four kinds of adjuvants solutions, the droplet velocity of Maisi, Maidao, Surun and AdseeAB-600 adjuvants increased by 13%, 9%, 8% and 4%, respectively, relative to water at the vertical direction of the nozzle center. In the three types of nozzles, the droplet velocity produced by the AD120-03 nozzle at the vertical direction of the nozzle center is greater than that of the IDK120-03 and LU120-03 nozzles. In the horizontal direction of atomization area, the droplet velocity decreases with the increase of horizontal distance of X axis. Compared with the droplet velocity distribution of the adjuvant solution, the droplet velocity of the Maisi is the largest in the horizontal direction, followed by the Surun, followed by the Maidao, and the smallest is the AdseeAB-600 adjuvant solution. Compared with the three types of nozzles, the droplet velocity VZ of AD120-03 is the largest and the whole stage velocity is the largest in the horizontal direction. LU120-03 droplet velocity decreased most obviously, IDK120-03 droplet velocity decreased relatively slowly.

- (3)

- Among the four types of adjuvants, it was found that the oil adjuvant Maisi could increase the droplet size and velocity, because the concentration of surfactant on the oil-water interface decreased with the stretching of the liquid sheet during the atomization of oil adjuvants, resulting in an increase in hydrophobicity. The hydrophobic oil droplets were easier to move to the gas-liquid interface to form holes, resulting in a large degree of droplet rupture. Due to the thick liquid sheet at the nozzle outlet, shift of emulsified droplet VMD to increasing VMD during breakage. When the droplet size needs to be increased, the oil-based silk adjuvants can be selected.

- (4)

- Spraying different adjuvant solutions with different nozzles under different pressures can change the droplet size and velocity distribution, and the spatial distribution of droplet velocity and droplet size is different. The adjuvant in this paper can increase the droplet size, provide reference, and reduce the drift caused by small droplets to a certain extent, which has important research significance for improving the target rate and pesticide adhesion rate, and further improving the quality of pesticide application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Faical, B.S.; Freitas, H.; Gomes, P.H.; Mano, L.Y.; Pessin, G.; de Carvalho, A.C.P.L.F.; Krishnamachari, B.; Ueyama, J. An adaptive approach for UAV-based pesticide spraying in dynamic environments. J. Comput. Electron. Agric. 2017, 138, 210–223. [Google Scholar] [CrossRef]

- Focks, A.; ter Horst, M.; van den Berg, E.; Baveco, H.; van den Brink, P.J. Integrating chemical fate and population-level effect models for pesticides at landscape scale: New options for risk assessment. J. Ecol. Model. 2014, 280, 102–116. [Google Scholar] [CrossRef]

- Spanoghe, P.; De, S.M.; Van, M.P.; Steurbaut, W. Influence of agricultural adjuvants on droplet spectra. Pest Manag. Sci. Former. Pestic. Sci. 2007, 63, 4–16. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Zhu, H.; Ozkan, H.E.; Derksen, R.C.; Krause, C.R. Evaporation and deposition coverage area of droplets containing insecticides and spray additives on hydrophilic, hydrophobic, and crabapple leaf surfaces. J. Trans. ASABE 2009, 52, 39–49. [Google Scholar] [CrossRef]

- Tuck, C.R.; Ellis, M.C.B.; Miller, P.C.H. Techniques for measurement of droplet size and velocity distributions in agricultural sprays. J. Crop Prot. 1997, 16, 619–628. [Google Scholar] [CrossRef]

- Bozdogan, N.Y.; Bozdogan, A.M. Comparison of field and model percentage drift using different types of hydraulic nozzles in pesticide applications. Int. J. Environ. Sci. Technol. 2009, 6, 191–196. [Google Scholar] [CrossRef]

- Cao, J. Liquid Atomization; Peking University Press: Beijing, China, 2013. [Google Scholar]

- Huseyin, G.; Heping, Z.; Erdal, O.; Peter, L. Characterization of hydraulic nozzles for droplet size and spray coverage. J. At. Sprays 2012, 22, 627–645. [Google Scholar]

- Emilia, H.; Arnoldus, W.P.V. Spray drift review: The extent to which a formulation can contribute to spray drift reduction. J. Crop Prot. 2013, 44, 75–83. [Google Scholar]

- Bradley, K.; Fritz, W.; Clint, H.; Wale, B.; Greg, R.; Kruger, R.S.H. Measuring droplet size of agricultural spray nozzles−measurement distance and airspeed effects. J. At. Sprays 2014, 24, 747–760. [Google Scholar]

- Zyl, S.; Brink, J.C.; Calitz, F.J.; Fourie, H.P. Effects of adjuvants on deposition efficiency of fenhexamid sprays applied to Chardonnay grapevine foliage. J. Crop Prot. 2010, 29, 843–852. [Google Scholar]

- Wang, S.; Dorr, G.J.; Khashehchi, M.; Xiongkui, H. Performance of selected agricultural spray nozzles using particle image velocimetry. J. Agric. Sci. Technol. 2015, 17, 601–613. [Google Scholar]

- Nita, M.; Ellis, M.A.; Wilson, L.L.; Madden, L.V. Evaluation of the curative and protectant activity of fungicides and fungicide–adjuvant mixtures on Phomopsis cane and leaf spot of grape: A controlled environment study. J. Crop Prot. 2007, 26, 1377–1384. [Google Scholar] [CrossRef]

- Samuel, A.; Weidong, J.; Mingxiong, O.; Pei, W.; Eric, A.A. Analysis of potential impaction and phytotoxicity of surfactant-plant surface interaction in pesticide application. Crop Prot. 2020, 127, 104961. [Google Scholar]

- Joseph, E.H.; Travis, W.G.; Robert, J.R.; Fred, H.Y.; Ramon, G.L. Coverage and drift potential associated with nozzle and speed selection for herbicide applications using an unmanned aerial sprayer. J. Weed Technol. 2020, 34, 235–240. [Google Scholar]

- Zhang, W.; He, X.; Song, J.; Wang, C.; Herbst, A. Effect of additive S240 on atomization of water dispersible granule and emulsion medicine. J. Trans. Chin. Soc. Agric. Eng. 2014, 30, 61–67. [Google Scholar]

- Zhao, H.; Song, J.; Zeng, A.; He, X. Relationship between dynamic surface tension of spray liquid and droplet size. J. Trans. Chin. Soc. Agric. Mach. 2009, 40, 74–79. [Google Scholar]

- Robert, N.K.; Jeffrey, A.G. The effect of spray particle size and distribution on drift and efficacy of herbicides. J. Asp. Appl. Biol. Int. Adv. Pestic. Appl. 2004, 71, 44–51. [Google Scholar]

- Ferguson, J.C.; O’Donnell, C.C.; Chauhan, B.S.; Adkins, S.W.; Kruger, G.R.; Wang, R.B.; Ferreira, P.H.U.; Hewitt, A.J. Determining the uniformity and consistency of droplet size across spray drift reducing nozzles in a wind tunnel. J. Crop Prot. 2015, 76, 1–6. [Google Scholar] [CrossRef]

- Wang, X.; He, X.; Song, J.; Herbst, A. Effect of additives type and concentration on droplet drift of different nozzles. J. Trans. Chin. Soc. Agric. Eng. 2015, 31, 49–55. [Google Scholar]

- Zhang, R.; Zhang, Z.; Xu, G.; Chen, L.; Hewitt, A.J. Effect of spray auxiliaries type and concentration on spray nozzle atomization effect. J. Trans. Chin. Soc. Agric. Eng. 2018, 34, 36–43. [Google Scholar]

- Tian, Z.; Yuan, G.; Gao, P.; Shen, G. Study of effects of different spray fertilizer on rice paddy herbicide reduction. J. Plant Prot. 2020, 46, 297–302. [Google Scholar]

- Liu, Y.; Zhang, G.; Zhou, C.; Wang, W.; Hu, Y.; Mu, W. Synergistic effects of cationic auxiliaries 1227 and C(8-10) and organosilicon auxiliaries Breakthru S240 on three insecticides. J. Insects 2011, 54, 902–909. [Google Scholar]

- Xie, C.; He, X.; Song, J.; Herbst, A. Comparative study on atomization process of two types of fan fog heads. J. Trans. Chin. Soc. Agric. Eng. 2013, 29, 25–30. [Google Scholar]

- Tang, Q.; Chen, L.; Zhang, R.; Zhang, B.; Yi, T.; Xu, M.; Xu, G. Atomization characteristics of standard fan nozzle and air induced nozzle under high speed airflow. J. Trans. Chin. Soc. Agric. Eng. 2016, 32, 121–128. [Google Scholar]

- Zhang, J.; Song, J.; He, X.; Zeng, A.; Liu, Y. Droplet motion characteristics in the process of fan-shaped spray nozzle atomization. J. Trans. Chin. Soc. Agric. Mach. 2011, 42, 66–69. [Google Scholar]

- Li, S.; Chen, C.; Wang, Y.; Kang, F.; Li, W. Study on the Atomization Characteristics of Flat Fan Nozzles for Pesticide Application at Low Pressures. J. Agric. 2021, 11, 309. [Google Scholar] [CrossRef]

- Chen, C.; Li, S.; Wu, X.; Wang, Y.; Kang, F. Analysis of droplet size uniformity and selection of spray parameters based on the biological optimum particle size theory. J. Environ. Res. 2021, 11, 109. [Google Scholar] [CrossRef]

- Vallet, A.; Tinet, C. Characteristics of droplets from single and twin jet air induction nozzles: A preliminary investigation. J. Crop Prot. 2013, 48, 63–68. [Google Scholar] [CrossRef]

- ASAE Standards S572; Spray Nozzle Classification by Droplet Spectra. ASAE: St. Joseph, MI, USA, 2004.

- Zhang, H.; Zhou, H.; Zheng, Z.; Liao, J.; Hewitt, A.J. Effects of pesticide auxiliaries on aerosol droplet size for airborne and ground control of forest pests. J. Sci. Silvae Sin. 2020, 56, 118–129. [Google Scholar]

- Makhnenko, I.; Alonzi, E.R.; Fredericks, S.A.; Colby, C.M.; Dutcher, C.S. A review of liquid sheet breakup: Perspectives from agricultural sprays. J. Aerosol Sci. 2021, 157, 105805. [Google Scholar] [CrossRef]

| Adjuvants | Type | Manufacturer |

|---|---|---|

| Surun | Agricultural silicone synergist | Qingdao Hairunhe Biotechnology Co., Ltd., Qingdao, China |

| Adsee AB-600 | Mixed water-based and cationic surfactants | Akzo Nobel N. V, Amsterdam, The Netherlands |

| Maidao | Improved mixture of vegetable oil and emulsifier | China National Chemical Corporation, Beijing, China |

| Maisi | Improved mixing of mineral oil and emulsifier | China National Chemical Corporation, Beijing, China |

| Specification | Parameter |

|---|---|

| Drop size measurement range | 0.3 to >8000 μm (spherical or near-spherical particles) |

| Size dynamic range | 50:1 |

| Estimated size accuracy | ±0.5 μm or 0.5% of full size range |

| Estimated size resolution | ±0.5 μm or 0.5% of full size range |

| Velocity measurement range | −600 to 1000 m/s |

| Velocity accuracy | ±0.1% |

| Volume flux accuracy | ±10% |

| Laser type | Diode pumped solid state (DPSS) |

| Wavelength | 491 nm, 532 nm, 561 nm, 660 nm |

| Measure Position | Fitting Relationship | R2 |

|---|---|---|

| Z = 10 cm | DZ = −0.74p + 705.23 | 0.99 |

| Z = 20 cm | DZ = −0.92p + 761.31 | 0.98 |

| Z = 30 cm | DZ = −0.72p + 715.12 | 0.98 |

| Z = 40 cm | DZ = −0.83p + 741.57 | 0.97 |

| Z = 50 cm | DZ = −0.68p + 733.74 | 0.95 |

| Adjuvant Types | Parameter | Vertical Distance (cm) | ||||

|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | ||

| Water | Volume Median Diameter (VMD)/μm | 387.7 | 409.2 | 426.8 | 426.8 | 410.5 |

| Maisi | Volume Median Diameter (VMD)/μm | 456.1 | 478.6 | 484.2 | 459.1 | 449.3 |

| Rate of change relative to tap water/% | 17.64 | 16.96 | 13.08 | 7.57 | 9.45 | |

| Surun | Volume Median Diameter (VMD)/μm | 447.9 | 474.2 | 464.5 | 447.4 | 440.6 |

| Rate of change relative to tap water/% | 15.53 | 15.88 | 8.48 | 4.83 | 7.33 | |

| Adsee AB-600 | Volume Median Diameter (VMD)/μm | 437.1 | 470.1 | 462.0 | 444.4 | 453.1 |

| Rate of change relative to tap water/% | 12.74 | 14.88 | 7.89 | 4.12 | 10.38 | |

| Maidao | Volume Median Diameter (VMD)/μm | 466.6 | 474.6 | 476.7 | 448.6 | 459.1 |

| Rate of change relative to tap water/% | 20.35 | 15.98 | 11.33 | 5.11 | 11.84 | |

| Spray Pressure | Fitting Relationship | R2 |

|---|---|---|

| 150 kPa | VZ = −0.09 Z + 9.07 | 0.99 |

| 200 kPa | VZ = −0.11 Z + 10.73 | 0.99 |

| 250 kPa | VZ = −0.12 Z + 12.34 | 0.99 |

| 300 kPa | VZ = −0.13 Z + 13.85 | 0.98 |

| 350 kPa | VZ = −0.14 Z + 14.50 | 0.98 |

| Adjuvant Types | Parameter | Vertical Distance (cm) | ||||

|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | ||

| Water | Droplet velocity/m·s−1 | 5.727 | 5.578 | 5.271 | 4.500 | 4.029 |

| Maisi | Droplet velocity/m·s−1 | 6.643 | 6.215 | 5.793 | 5.127 | 4.584 |

| Rate of change relative to tap water/% | 16.00 | 11.42 | 9.90 | 13.95 | 13.75 | |

| Surun | Droplet velocity/m·s−1 | 6.617 | 5.951 | 5.607 | 4.887 | 4.309 |

| Rate of change relative to tap water/% | 15.54 | 6.69 | 6.36 | 8.62 | 6.95 | |

| Adsee AB-600 | Droplet velocity/m·s−1 | 5.966 | 5.998 | 5.586 | 4.631 | 4.137 |

| Relative rate of change to tap water/% | 4.18 | 7.53 | 5.97 | 2.90 | 2.69 | |

| Maidao | Droplet velocity/m·s−1 | 6.501 | 5988 | 5.594 | 5.096 | 4.351 |

| Rate of change relative to tap water/% | 13.51 | 7.36 | 6.12 | 13.26 | 7.99 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Chen, L.; Tang, Q.; Li, L.; Cheng, W.; Hu, P.; Zhang, R. Characteristics on the Spatial Distribution of Droplet Size and Velocity with Difference Adjuvant in Nozzle Spraying. Agronomy 2022, 12, 1960. https://doi.org/10.3390/agronomy12081960

Li X, Chen L, Tang Q, Li L, Cheng W, Hu P, Zhang R. Characteristics on the Spatial Distribution of Droplet Size and Velocity with Difference Adjuvant in Nozzle Spraying. Agronomy. 2022; 12(8):1960. https://doi.org/10.3390/agronomy12081960

Chicago/Turabian StyleLi, Xinpeng, Liping Chen, Qin Tang, Longlong Li, Wu Cheng, Peng Hu, and Ruirui Zhang. 2022. "Characteristics on the Spatial Distribution of Droplet Size and Velocity with Difference Adjuvant in Nozzle Spraying" Agronomy 12, no. 8: 1960. https://doi.org/10.3390/agronomy12081960

APA StyleLi, X., Chen, L., Tang, Q., Li, L., Cheng, W., Hu, P., & Zhang, R. (2022). Characteristics on the Spatial Distribution of Droplet Size and Velocity with Difference Adjuvant in Nozzle Spraying. Agronomy, 12(8), 1960. https://doi.org/10.3390/agronomy12081960