Resource Use and Environmental Impacts of Seed and Vegetative Globe Artichoke Production in Mediterranean Environments: A Cradle-to-Farm Gate Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. LCA Framework

2.1.1. Goal, Scope, Functional Unit, System Boundaries, and Assumptions

2.1.2. Inventory Data

2.1.3. Life Cycle Impact Assessment (LCIA)

3. Results

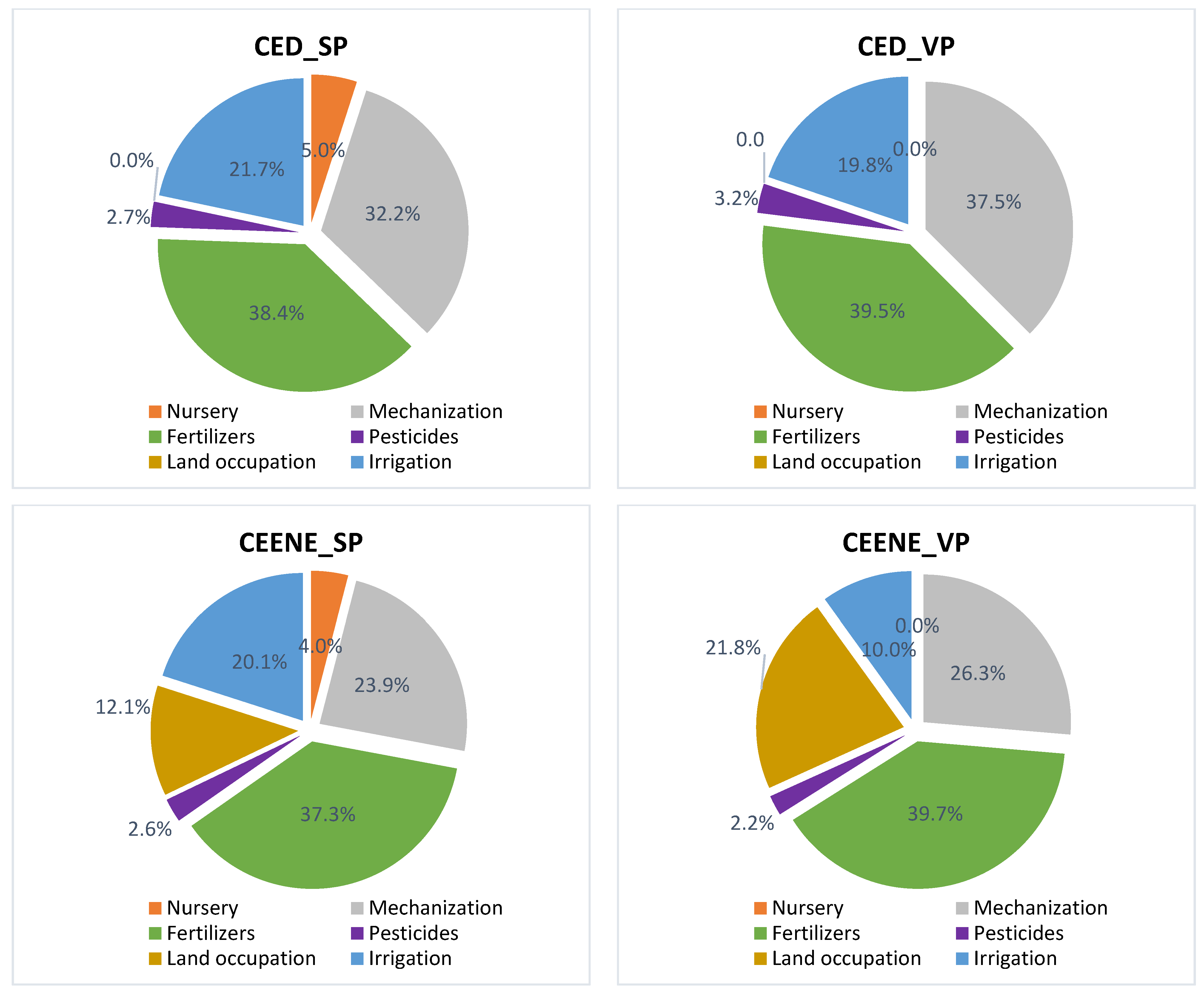

3.1. Energetic and Exergitic Performance

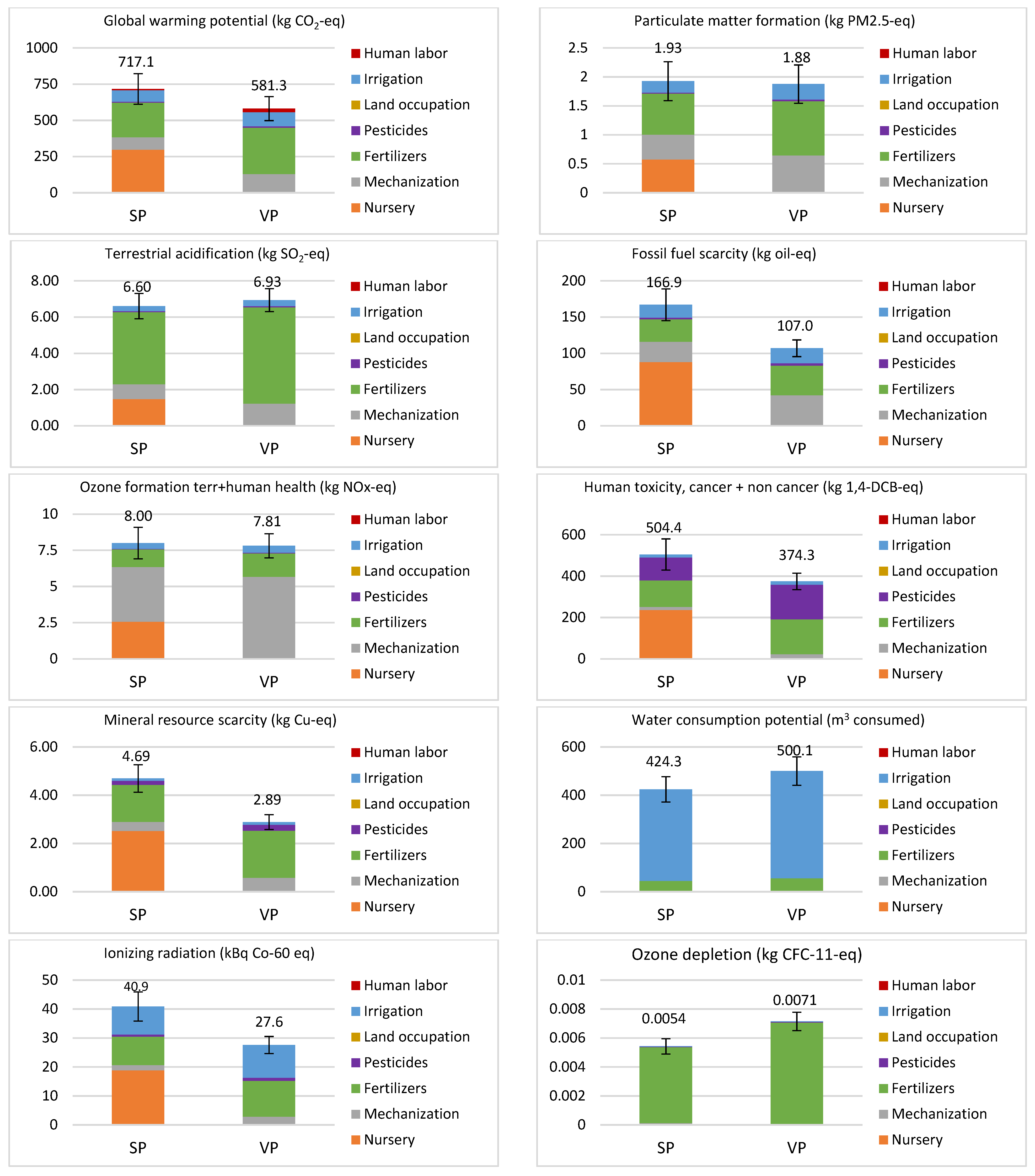

3.2. Environmental Performance

4. Discussion and Concluding Remarks

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lattanzio, V.; Kroon, P.A.; Linsalata, V.; Cardinali, A. Globe artichoke: A functional food and source of nutraceutical ingredients. J. Funct. Foods 2009, 1, 131–144. [Google Scholar] [CrossRef]

- Grabowska, A.; Caruso, G.; Mehrafarin, A.; Kalisz, A.; Gruszecki, R.; Kunicki, E.; Sękara, A. Application of modern agronomic and biotechnological strategies to valorise worldwide globe artichoke (Cynara cardunculus L.) potential—An analytical overview. Ital. J. Agron. 2018, 13, 279–289. [Google Scholar] [CrossRef]

- Scavo, A.; Rial, C.; Molinillo, J.M.G.; Varela, R.M.; Mauromicale, G.; Macías, F.A. Effect of shading on the sesquiterpene lactone content and phytotoxicity of cultivated cardoon leaf extracts. J. Agric. Food Chem. 2020, 68, 11946–11953. [Google Scholar] [CrossRef] [PubMed]

- Restuccia, C.; Lombardo, M.; Scavo, A.; Mauromicale, G.; Cirvilleri, G. Combined application of antagonistic Wickerhamomyces anomalus BS91 strain and Cynara cardunculus L. leaf extracts for the control of postharvest decay of citrus fruit. Food Microbiol. 2020, 92, 103583. [Google Scholar] [CrossRef]

- Atlasbig World Artichoke Production by Country. Available online: https://www.atlasbig.com/en-us/countries-artichoke-production (accessed on 4 June 2022).

- Calabrese, N.; Cravero, V.; Pagnotta, M.A. Cynara cardunculus Propagation. In The Globe Artichoke Genome (Compendium of Plant Genomes); Springer: Cham, Switzerland, 2019; pp. 21–40. [Google Scholar]

- Mazzeo, G.; Scavo, A.; Lo Monaco, A.; Longo, S.; Mauromicale, G. Insect pollinators improve seed production in globe artichoke (Cynara cardunculus var. scolymus). Ann. Appl. Biol. 2020, 176, 241–248. [Google Scholar] [CrossRef]

- Riahi, J.; Nicoletto, C.; Bouzaein, G.; Sambo, P.; Khalfallah, K.K. Effect of vegetative propagation materials on globe artichoke production in semi-arid developing countries: Agronomic, marketable and qualitative traits. Agronomy 2017, 7, 65. [Google Scholar] [CrossRef] [Green Version]

- García, S.M.; Cointry, E.; Anido, F.L.; Firpo, I.T.; Cravero, V.P.; Rotondo, R. Evaluation of two propagation systems in globe artichoke. Acta Hortic. 2012, 942, 147–152. [Google Scholar] [CrossRef]

- Calabrese, N.; Carito, A. Yield evaluation of new seed propagated artichoke cultivars. Acta Hortic. 2013, 983, 393–397. [Google Scholar] [CrossRef]

- Lahoz, I.; Macua, J.I.; Urmeneta, I.; Juanena, A. ‘Blanca de Tudela’ and seed artichoke in Navarre. Acta Hortic. 2020, 71–76. [Google Scholar] [CrossRef]

- Giménez, M.J.; Giménez-Berenguer, M.; García-Pastor, M.E.; Parra, J.; Zapata, P.J.; Castillo, S. The influence of flower head order and gibberellic acid treatment on the hydroxycinnamic acid and luteolin derivatives content in globe artichoke cultivars. Foods 2021, 10, 1813. [Google Scholar] [CrossRef]

- Landis, T. Chapter 7. Nursery Practices. In The Woody Plant Seed Manual, Agriculture Handbook; USDA Forest Service: Washington, DC, USA, 2008; pp. 125–145. [Google Scholar]

- Lazzerini, G.; Merante, P.; Lucchetti, S.; Nicese, F.P. Assessing environmental sustainability of ornamental plant production: A nursery level approach in Pistoia District, Italy. Agroecol. Sustain. Food Syst. 2018, 42, 911–932. [Google Scholar] [CrossRef]

- Bojacá, C.R.; Wyckhuys, K.A.G.; Schrevens, E. Life cycle assessment of Colombian greenhouse tomato production based on farmer-level survey data. J. Clean. Prod. 2014, 69, 26–33. [Google Scholar] [CrossRef]

- Beccaro, G.L.; Cerutti, A.K.; Vandecasteele, I.; Bonvegna, L.; Donno, D.; Bounous, G. Assessing environmental impacts of nursery production: Methodological issues and results from a case study in Italy. J. Clean. Prod. 2014, 80, 159–169. [Google Scholar] [CrossRef]

- Martin-Gorriz, B.; Gallego-Elvira, B.; Martínez-Alvarez, V.; Maestre-Valero, J.F. Life cycle assessment of fruit and vegetable production in the Region of Murcia (south-east Spain) and evaluation of impact mitigation practices. J. Clean. Prod. 2020, 265, 121656. [Google Scholar] [CrossRef]

- Notarnicola, B.; Sala, S.; Anton, A.; McLaren, S.J.; Saouter, E.; Sonesson, U. The role of life cycle assessment in supporting sustainable agri-food systems: A review of the challenges. J. Clean. Prod. 2017, 140, 399–409. [Google Scholar] [CrossRef]

- Pelletier, N. Life Cycle Assessment in Agriculture. Potential Applications, Social License and Market Access, Alberta Agriculture and Rural Development; Alberta Government: Stony Plain, AB, Canada, 2014; pp. 1–32.

- Caffrey, K.R.; Veal, M.W. Conducting an agricultural life cycle assessment: Challenges and perspectives. Sci. World J. 2013, 2013, 472431. [Google Scholar] [CrossRef] [Green Version]

- Todorović, M.; Mehmeti, A.; Cantore, V. Impact of different water and nitrogen inputs on the eco-efficiency of durum wheat cultivation in Mediterranean environments. J. Clean. Prod. 2018, 183, 1276–1288. [Google Scholar] [CrossRef]

- Meisterling, K.; Samaras, C.; Schweizer, V. Decisions to reduce greenhouse gases from agriculture and product transport: LCA case study of organic and conventional wheat. J. Clean. Prod. 2009, 17, 222–230. [Google Scholar] [CrossRef]

- Zarei, M.J.; Kazemi, N.; Marzban, A. Life cycle environmental impacts of cucumber and tomato production in open-field and greenhouse. J. Saudi Soc. Agric. Sci. 2018, 8, 249–255. [Google Scholar] [CrossRef]

- Shen, J.; Zhang, P.; Chang, Y.; Zhang, L.; Hao, Y.; Tang, S.; Xiong, X. The environmental performance of greenhouse versus open-field cherry production systems in China. Sustain. Prod. Consum. 2021, 28, 736–748. [Google Scholar] [CrossRef]

- Evangelista, A.; Lan, Y.C.; Chen, Z.; Tam, V.W.Y.; Datt, R. Adopting Life Cycle Assessment for Various Greenhouse Typologies in Multiple Cropping Environment in Australia. In Sustainable Production, Life Cycle Engineering and Management; Springer: Singapore, 2021. [Google Scholar]

- Lo Giudice, A.; Mbohwa, C.; Clasadonte, M.T.; Ingrao, C. Life Cycle Assessment interpretation and improvement of the Sicilian artichokes production. Int. J. Environ. Res. 2014, 8, 305–316. [Google Scholar] [CrossRef]

- Canaj, K.; Mehmeti, A.; Berbel, J. The economics of fruit and vegetable production irrigated with reclaimed water incorporating the hidden costs of life cycle environmental impacts. Resources 2021, 10, 90. [Google Scholar] [CrossRef]

- IndexBox. World-Artichokes-Market Analysis, Forecast, Size, Trends and Insights Update: COVID-19 Impact; IndexBox Inc.: Dublin, Ireland, 2021. [Google Scholar]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; IPCC: Geneva, Switzerland, 2006; Volume 3, pp. 1–40.

- Nemecek, T.; Kagi, T. Life cycle inventories of Agricultural Production Systems, Ecoinvent report No. 15. Final Rep. Ecoinvent V2.0 2007, 15, 1–360. [Google Scholar]

- Ordikhani, H.; Parashkoohi, M.G.; Zamani, D.M.; Ghahderijani, M. Energy-environmental life cycle assessment and cumulative exergy demand analysis for horticultural crops (Case study: Qazvin province). Energy Rep. 2021, 7, 2899–2915. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Hellweg, S.; Frischknecht, R.; Hendriks, H.W.M.; Hungerbühler, K.; Hendriks, A.J. Cumulative energy demand as predictor for the environmental burden of commodity production. Environ. Sci. Technol. 2010, 44, 2189–2196. [Google Scholar] [CrossRef] [Green Version]

- Dewulf, J.; Bösch, M.E.; De Meester, B.; Van Der Vorst, G.; Van Langenhove, H.; Hellweg, S.; Huijbregts, M.A.J. Cumulative exergy extraction from the natural environment (CEENE): A comprehensive life cycle impact assessment method for resource accounting. Environ. Sci. Technol. 2007, 41, 8477–8483. [Google Scholar] [CrossRef] [PubMed]

- Huijbregts, M.A.J.; Steinmann, Z.J.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Zijp, M.; van Zelm, R. ReCiPe 2016: A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level—Report 1: Characterization; RIVM Report 2016-0104; National Institute for Public Health and the Environment: Bilthoven, The Netherlands, 2016; p. 194.

- Ecoinvent Database: Quality Control and User Interfaces for a Web-Based Life Cycle Assessment Database. In Information Systems for Sustainable Development; IGI Global: Hershey, PA, USA, 2005. [CrossRef]

- Martin-Gorriz, B.; Martínez-Alvarez, V.; Maestre-Valero, J.F.; Gallego-Elvira, B. Influence of the water source on the carbon footprint of irrigated agriculture: A regional study in south-eastern Spain. Agronomy 2021, 11, 351. [Google Scholar] [CrossRef]

- Solinas, S.; Tiloca, M.T.; Deligios, P.A.; Cossu, M.; Ledda, L. Carbon footprints and social carbon cost assessments in a perennial energy crop system: A comparison of fertilizer management practices in a Mediterranean area. Agric. Syst. 2021, 186, 102989. [Google Scholar] [CrossRef]

- Fang, Y.R.; Liu, J.A.; Steinberger, Y.; Xie, G.H. Energy use efficiency and economic feasibility of Jerusalem artichoke production on arid and coastal saline lands. Ind. Crops Prod. 2018, 117, 131–139. [Google Scholar] [CrossRef]

- Canaj, K.; Mehmeti, A.; Morrone, D.; Toma, P.; Todorović, M. Life cycle-based evaluation of environmental impacts and external costs of treated wastewater reuse for irrigation: A case study in southern Italy. J. Clean. Prod. 2021, 293, 126142. [Google Scholar] [CrossRef]

- Bacenetti, J.; Paleari, L.; Tartarini, S.; Vesely, F.M.; Foi, M.; Movedi, E.; Ravasi, R.A.; Bellopede, V.; Durello, S.; Ceravolo, C.; et al. May smart technologies reduce the environmental impact of nitrogen fertilization? A case study for paddy rice. Sci. Total Environ. 2020, 715, 136956. [Google Scholar] [CrossRef]

- Fotia, K.; Mehmeti, A.; Tsirogiannis, I.; Nanos, G.; Mamolos, A.P.; Malamos, N.; Barouchas, P.; Todorovic, M. LCA-Based Environmental Performance of Olive Cultivation in Northwestern Greece: From Rainfed to Irrigated through Conventional and Smart Crop Management Practices. Water 2021, 13, 1954. [Google Scholar] [CrossRef]

- Canaj, K.; Parente, A.; D’Imperio, M.; Boari, F.; Buono, V.; Toriello, M.; Mehmeti, A.; Montesano, F.F. Can Precise Irrigation Support the Sustainability of Protected Cultivation? A Life-Cycle Assessment and Life-Cycle Cost Analysis. Water 2021, 14, 6. [Google Scholar] [CrossRef]

- Balafoutis, A.; Koundouras, S.; Anastasiou, E.; Fountas, S.; Arvanitis, K. Life Cycle Assessment of Two Vineyards after the Application of Precision Viticulture Techniques: A Case Study. Sustainability 2017, 9, 1997. [Google Scholar] [CrossRef] [Green Version]

- Maureira, F.; Rajagopalan, K.; Stöckle, C.O. Evaluating tomato production in open-field and high-tech greenhouse systems. J. Clean. Prod. 2022, 337, 130459. [Google Scholar] [CrossRef]

- Ntinas, G.K.; Neumair, M.; Tsadilas, C.D.; Meyer, J. Carbon footprint and cumulative energy demand of greenhouse and open-field tomato cultivation systems under Southern and Central European climatic conditions. J. Clean. Prod. 2017, 142, 3617–3626. [Google Scholar] [CrossRef]

- Balmford, A.; Amano, T.; Bartlett, H.; Chadwick, D.; Collins, A.; Edwards, D.; Field, R.; Garnsworthy, P.; Green, R.; Smith, P.; et al. The environmental costs and benefits of high-yield farming. Nat. Sustain. 2018, 1, 477–485. [Google Scholar] [CrossRef]

| Stage | Definition | This Study |

|---|---|---|

| Goal and scope definition | Specifies the intended purpose of the study, the targeted audience, the application, and the methods and databases. |

|

| Life cycle Inventory | The life cycle inventory (LCI) represents a compilation of resource use and emissions related to the functional unit. |

|

| Life cycle impact assessment (LCIA). | Assess all potential effects of material usage, water, and energy within the environmental releases. |

|

| LCA interpretation | Identify, quantify, check, and evaluate information from the results of the LCI and/or the LCIA. | Insights into production efficiency and production intensity of globe artichoke propagation techniques following a cradle-to-farm gate perspective. |

| Input-Output | Unit | Seed- Propagated (SP) | Vegetative Propagated (VP) |

|---|---|---|---|

| Seedlings | n. | 388 | 833 |

| Aluminum | kg | 0.43 | - |

| Concrete | m3 | 6.11 × 10−4 | - |

| Stainless steel | kg | 2.19 | - |

| Solar glass for the greenhouse structure (4 mm) | kg | 1.17 | - |

| Low-density polyethylene (LDPE) | kg | 0.08 | - |

| Polyvinyl chloride (PVC) | kg | 1.67 × 10−3 | |

| Polyester | kg | 0.006 | - |

| Peat moss, horticultural use | m3 | 0.023 | - |

| Polystyrene foam for trays | kg | 0.972 | - |

| Transport, freight, light commercial vehicle | ton km−1 | 0.389 | - |

| Irrigation water, groundwater | m3 | 500 | 583 |

| Electricity irrigation, Italian grid network | kWh | 94 | 109 |

| Nitrogen-based fertilizers | kg N | 15.1 | 20 |

| Urea, as N | kg N | 6.0 | 8 |

| Ammonium nitrate, as N | kg N | 4.5 | 6 |

| Nitrogen fertiliser, as N | kg N | 4.5 | 6 |

| Phosphorus-based fertilizers | kg P2O5 | 8.3 | 10 |

| Potassium-based fertilizers | kg K2O | 8.3 | 12.5 |

| Fuel for farm operations | MJ | 1074.3 | 1289.2 |

| Pesticides, unspecified (mix of fungicides, herbicides, and insecticides) | kg | 0.56 | 0.8 |

| Human labor | hour | 13.6 | 35 |

| Output | Unit | SP | VP |

|---|---|---|---|

| Fertilizer emissions | |||

| Ammonia, to air | kg | 1.82 | 1.52 |

| Dinitrogen monoxide, to air | kg | 0.295 | 0.245 |

| Nitrogen oxides, to air | kg | 0.049 | 0.041 |

| Carbon dioxide, fossil, to air (urea) | kg | 9.42 | 12.56 |

| Phosphates, to water | kg | 0.0178 | 0.0148 |

| Phosphorus, to water | kg | 0.1005 | 0.081 |

| Nitrates, to water | kg | 13.2 | 11 |

| Diesel fuel emissions | |||

| Ammonia, to air | kg | 5.02 × 10−4 | 6.02 × 10−4 |

| Benzo(a)pyrene, to air | kg | 7.53 × 10−7 | 9.04 × 10−7 |

| Cadmium, to air | kg | 2.51 × 10−7 | 3.02 × 10−7 |

| Carbon dioxide, fossil, to air | kg | 78.4 | 94.1 |

| Carbon monoxide, fossil, to air | kg | 0.286 | 0.343 |

| Chromium, to air | kg | 1.26 × 10−6 | 1.51 × 10−6 |

| Copper, to air | kg | 4.26 × 10−5 | 5.12 × 10−5 |

| Dinitrogen monoxide, to air | kg | 3.01 × 10−3 | 3.61 × 10−3 |

| Dioxins, measured as 2,3,7,8-tetrachlorodibenzo-p-dioxin, to air | kg | 1.50 × 10−12 | 1.80 × 10−12 |

| Methane, fossil, to air | kg | 4.03 × 10−3 | 4.83 × 10−3 |

| Nickel, to air | kg | 1.76 × 10−6 | 2.11 × 10−6 |

| Nitrogen oxides | kg | 1.11 | 1.33 |

| NMVOC, non-methane volatile organic compounds, unspecified origin, to air | kg | 0.13 | 0.156 |

| PAH, polycyclic aromatic hydrocarbons, to air | kg | 8.43 × 10−5 | 1.01 × 10−4 |

| Particulates, <2.5 µm, to air | kg | 0.101 | 0.122 |

| Particulates, >10 µm, to air | kg | 6.75 × 10−3 | 8.10 × 10−3 |

| Particulates, >2.5 µm, and <10 µm, to air | kg | 4.50 × 10−3 | 5.40 × 10−3 |

| Selenium, to air | kg | 2.51 × 10−7 | 3.02 × 10−7 |

| Human labor | |||

| Carbon dioxide, fossil, to air | kg | 9.53 | 24.5 |

| Pesticide emissions | |||

| Avermectin B1, to soil | kg | 0.0040 | 0.0060 |

| Cadusafos, to soil | kg | 5.6 | 8.3 |

| Chlorothalonil, to soil | kg | 9.7 | 14.3 |

| Chlorpyrifos, to soil | kg | 0.84 | 1.25 |

| Diquat dibromide, to soil | kg | 0.42 | 0.63 |

| Emamectin benzoate, to soil | kg | 0.015 | 0.022 |

| Indoxacarb, to soil | kg | 0.11 | 0.16 |

| Mancozeb, to soil | kg | 2.520 | 3.735 |

| Methomyl, to soil | kg | 0.945 | 1.401 |

| Paraquat, to soil | kg | 0.361 | 0.535 |

| Spinosad, to soil | kg | 1.176 | 1.743 |

| Propagation System | CED (MJ) | CEENE (MJex) | ||

|---|---|---|---|---|

| 1 ha | 1 ton | 1 ha | 1 ton | |

| Seedpropagated (SP) | 75,212 [SD 11,285.5] | 4178.5 [SD 675.1] | 106,664 [SD 13,812] | 5927 [SD 826.2] |

| Vegetative propagated (VP) | 64,212 [SD 6820.4] | 5384.4 [SD 586.4] | 88,698 [SD 8530.7] | 7391.5 [SD 711] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehmeti, A.; Canaj, K.; Boari, F.; Cantore, V.; Todorovic, M.; Calabrese, N. Resource Use and Environmental Impacts of Seed and Vegetative Globe Artichoke Production in Mediterranean Environments: A Cradle-to-Farm Gate Analysis. Agronomy 2022, 12, 1605. https://doi.org/10.3390/agronomy12071605

Mehmeti A, Canaj K, Boari F, Cantore V, Todorovic M, Calabrese N. Resource Use and Environmental Impacts of Seed and Vegetative Globe Artichoke Production in Mediterranean Environments: A Cradle-to-Farm Gate Analysis. Agronomy. 2022; 12(7):1605. https://doi.org/10.3390/agronomy12071605

Chicago/Turabian StyleMehmeti, Andi, Kledja Canaj, Francesca Boari, Vito Cantore, Mladen Todorovic, and Nicola Calabrese. 2022. "Resource Use and Environmental Impacts of Seed and Vegetative Globe Artichoke Production in Mediterranean Environments: A Cradle-to-Farm Gate Analysis" Agronomy 12, no. 7: 1605. https://doi.org/10.3390/agronomy12071605

APA StyleMehmeti, A., Canaj, K., Boari, F., Cantore, V., Todorovic, M., & Calabrese, N. (2022). Resource Use and Environmental Impacts of Seed and Vegetative Globe Artichoke Production in Mediterranean Environments: A Cradle-to-Farm Gate Analysis. Agronomy, 12(7), 1605. https://doi.org/10.3390/agronomy12071605