Alternative Mulches for Sustainable Greenhouse Tomato Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Location and Experimental Greenhouse

2.2. Plant Material and Cropping Details

2.3. Soil Mulches Materials and Experimental Design

2.4. Analyzed Variables

2.4.1. Soil Matric Potential

2.4.2. Soil Temperature

2.4.3. Physical and Chemical Variables of Soil Samples

2.4.4. Crop Yield

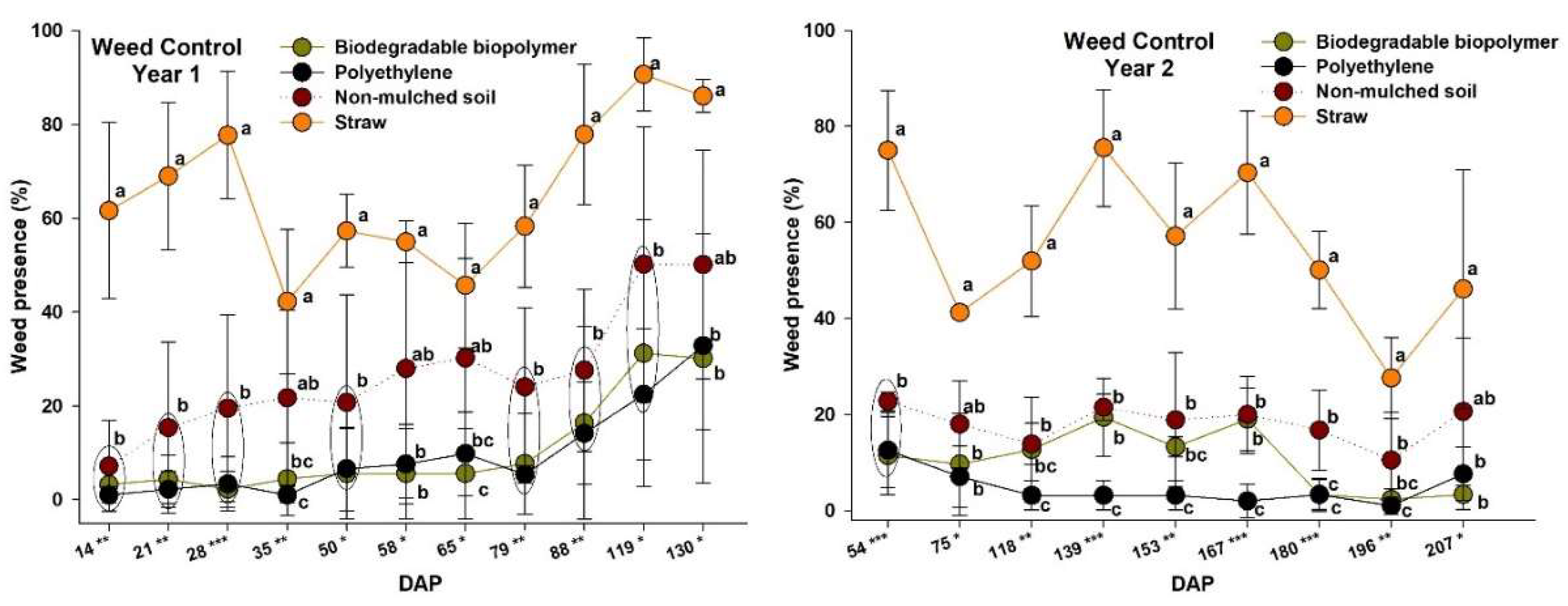

2.4.5. Weed Assessments

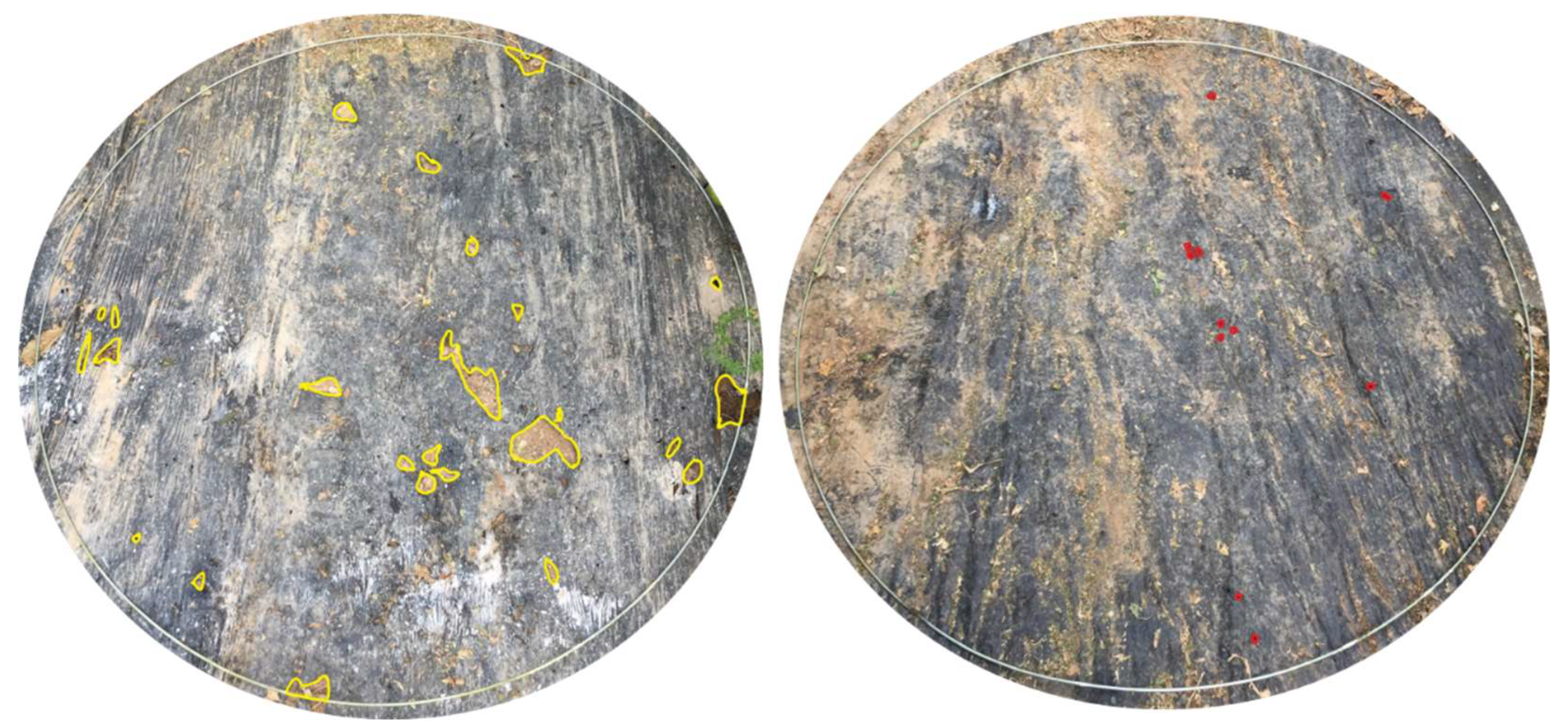

2.4.6. Plastic Mulch Deterioration (Polyethylene and Biodegradable Films)

2.5. Statistical Analysis

3. Results and Discussion

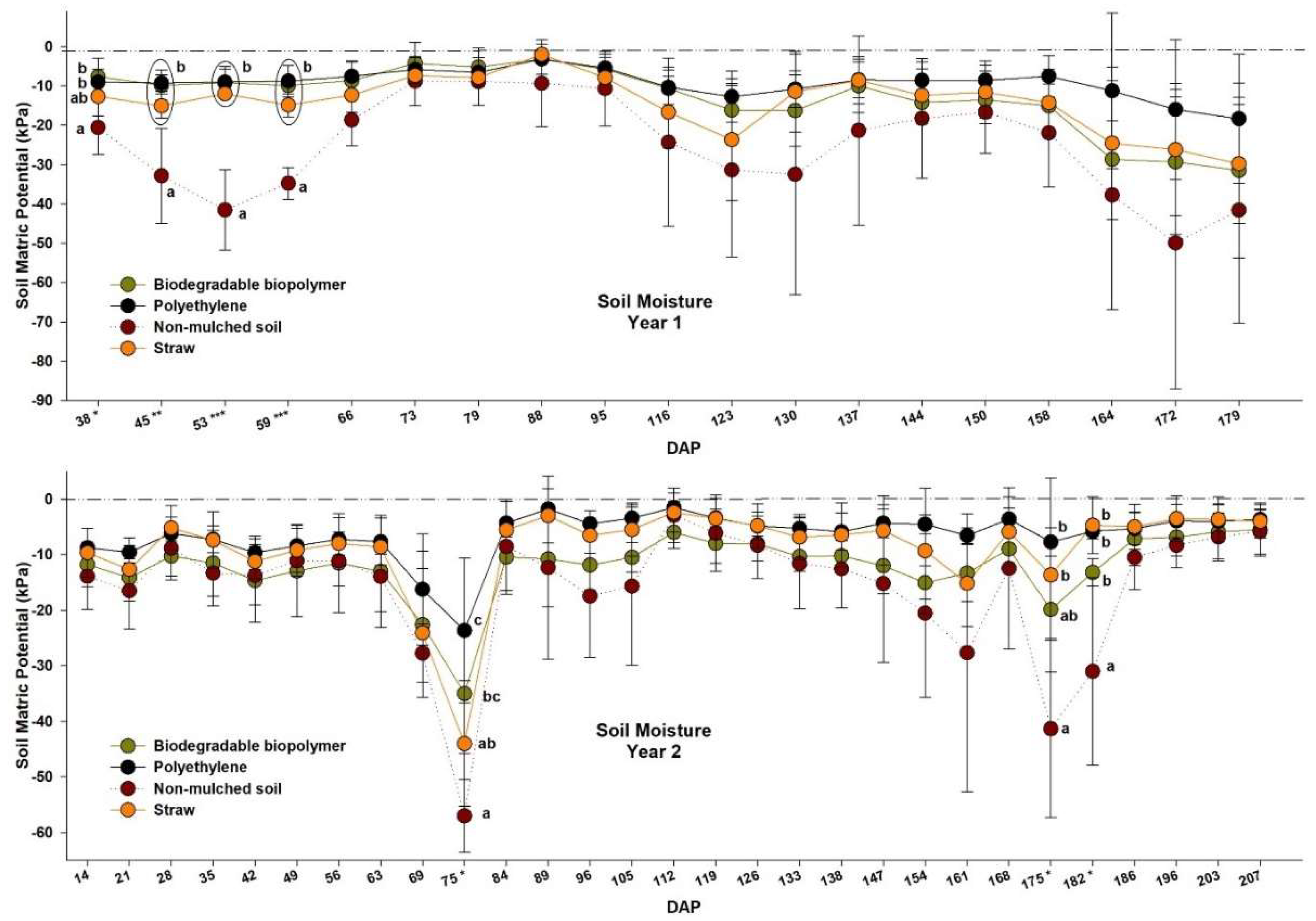

3.1. Soil Matric Potential

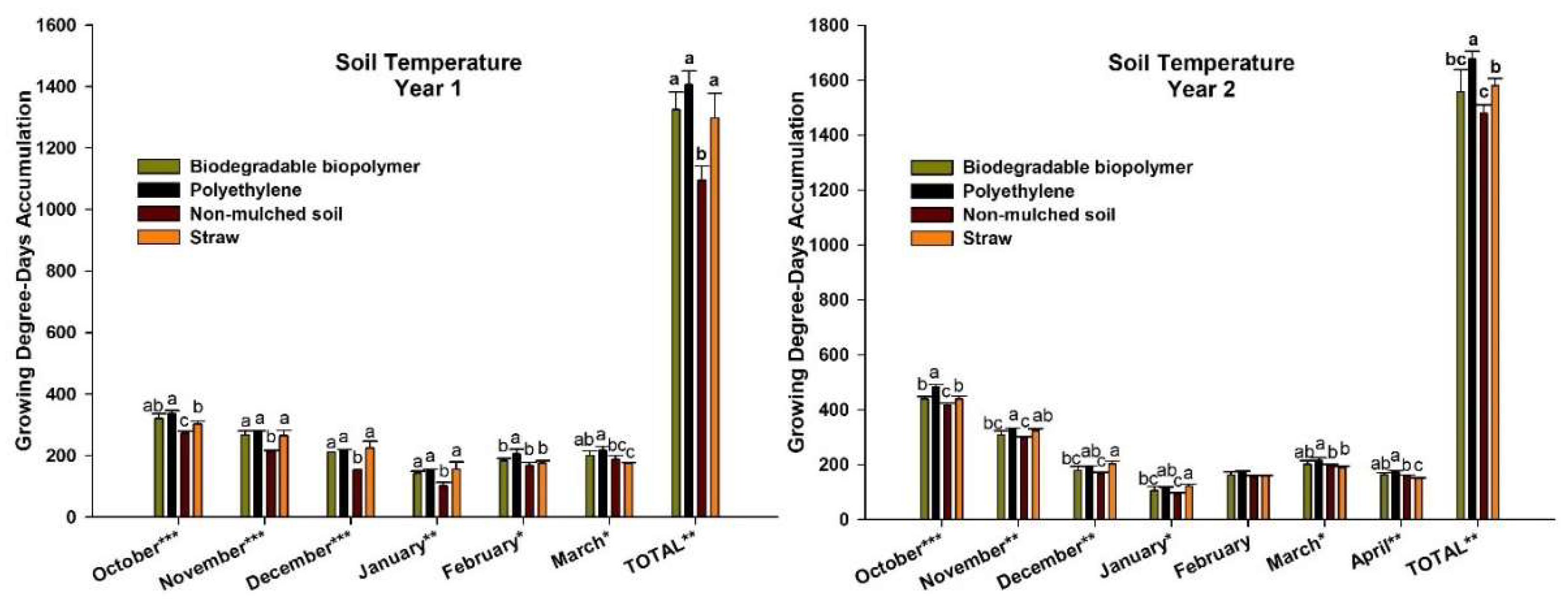

3.2. Soil Temperature

3.3. Physical and Chemical Variables of Soil Samples

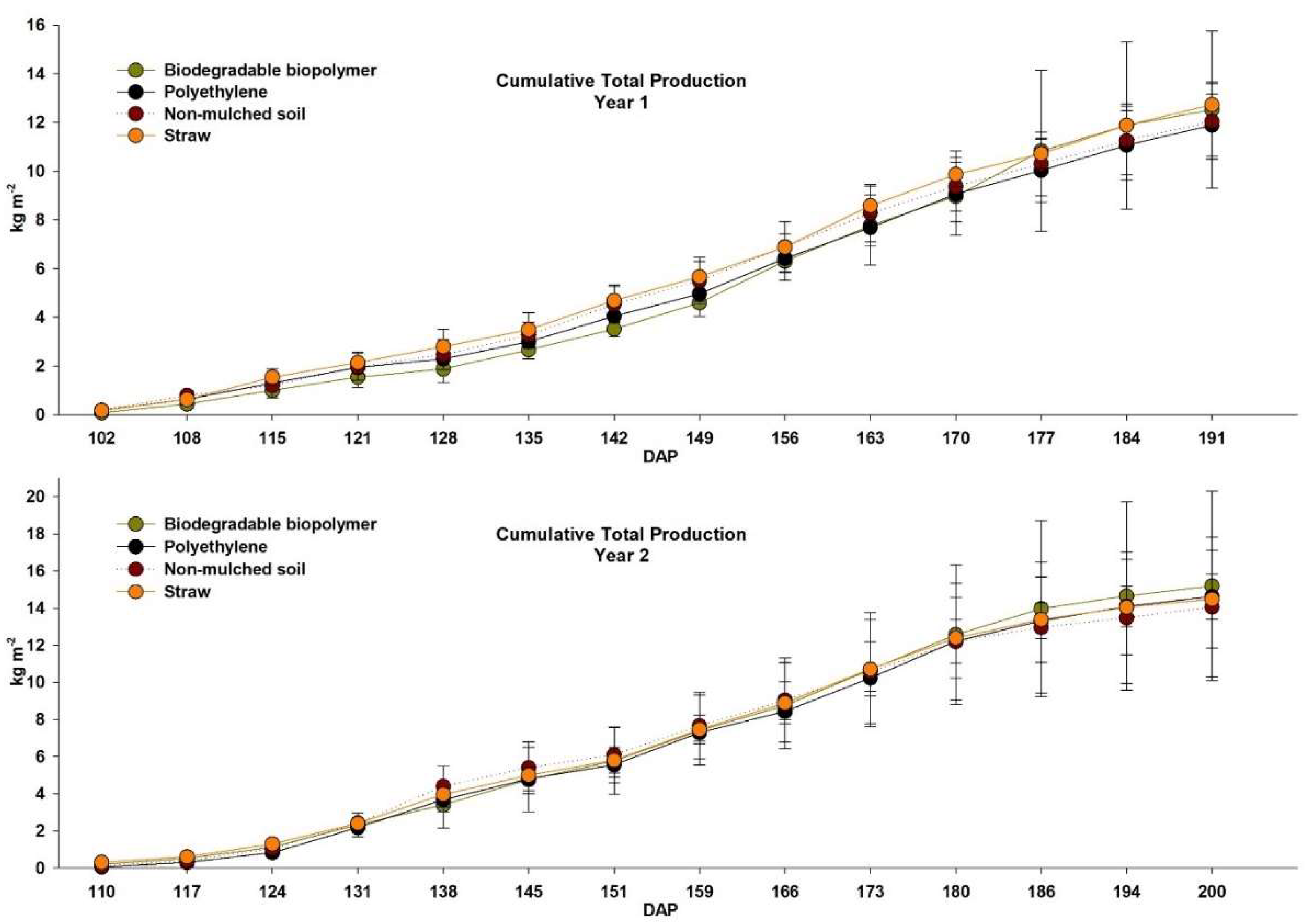

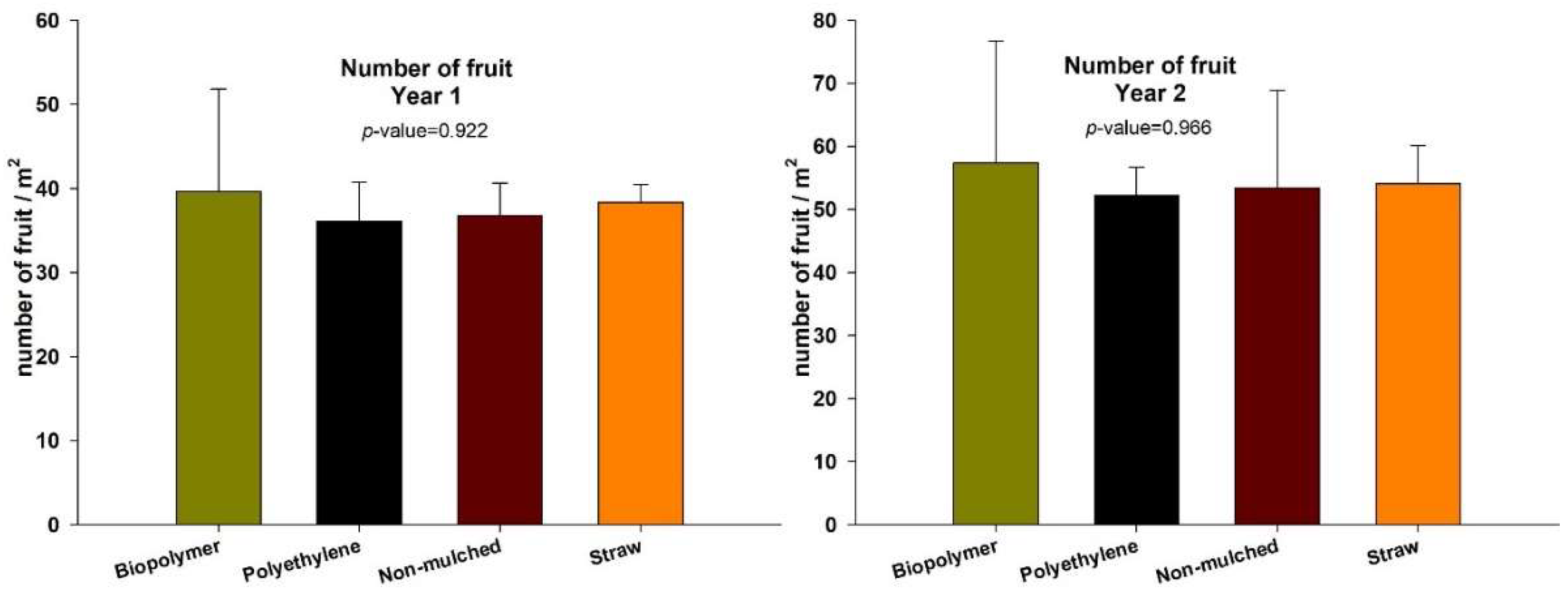

3.4. Crop Yield

3.5. Weed Control

3.6. Deterioration of Plastic Mulches (Biodegradable Biopolymer and Polyethylene)

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cabernard, L.; Pfister, S.; Oberschelp, C.; Hellweg, S. Growing environmental footprint of plastics driven by coal combustion. Nat. Sustain. 2022, 5, 139–148. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Jia, L.; Evans, S.; van der Linden, S. Motivating actions to mitigate plastic pollution. Nat. Commun. 2019, 10, 4582. [Google Scholar] [CrossRef] [PubMed]

- European Commission. A European Strategy for Plastics in a Circular Economy. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52018DC0028&from=PT (accessed on 16 March 2022).

- Cajamar. Análisis de la Campaña Hortofrutícola de Almería. Campaña 2020/2021. 2021. Available online: https://publicacionescajamar.es/series-tematicas/informes-coyuntura-analisis-de-campana/analisis-de-la-campana-hortofruticola-de-almeria-campana-2020-2021 (accessed on 10 March 2022).

- Sayadi-Gmada, S.; Rodríguez-Pleguezuelo, C.R.; Rojas-Serrano, F.; Parra-López, C.; Parra-Gómez, S.; García-García, M.C.; García-Collado, R.; Lorbach-Kelle, M.B.; Manrique-Gordillo, T. Inorganic management in greenhouse agriculture in Almeria (SE Spain): Towards a circular system in intensive horticultural production. Sustainability 2019, 11, 3782. [Google Scholar] [CrossRef]

- Castillo-Díaz, F.J.; Belmonte-Ureña, L.J.; Camacho-Ferre, F.; Tello-Marquina, J.C. The management of agriculture plastic waste in the framework of circular economy. Case of the Almeria greenhouse (Spain). Int. J. Environ. Res. Public Health 2021, 18, 12042. [Google Scholar] [CrossRef]

- Schonbeck, M.W.; Evanylo, G.K. Effects of mulches on soil properties and tomato production I. soil temperature, soil moisture and marketable yield. J. Sustain. Agric. 1998, 13, 1. [Google Scholar] [CrossRef]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Qin, W.; Hu, C.S.; Oenema, O. Soil mulching significantly enhances yields and water and nitrogen use efficiencies of maize and wheat: A metaanalysis. Sci. Rep. 2015, 5, 16210. [Google Scholar] [CrossRef]

- Serrano-Ruíz, H.; Martin-Closas, L.; Pelacho, A.M. Biodegradable plastic mulches: Impact on the agricultural biotic environment. Sci. Total Environ. 2020, 750, 141228. [Google Scholar] [CrossRef]

- Bonachela, S.; Granados, M.R.; López, J.C.; Hernández, J.; Magan, J.J.; Baeza, E.J.; Baille, A. How plastic mulches affect the thermal and radiative microclimate in an unheated low-cost greenhouse. Agric. For. Meteorol. 2012, 152, 65–72. [Google Scholar] [CrossRef]

- Cowan, J.S.; Miles, C.A.; Andrews, P.K.; Inglis, D.A. Biodegradable mulch performed comparably to polyethylene in high tunnel tomato (Solanum lycopersicum L.) production. J. Sci. Food Agric. 2014, 94, 1854–1864. [Google Scholar] [CrossRef] [PubMed]

- López-Marín, J.; Abrusci, C.; González, A.; Fernández, J.A. Study of degradable materials for soil mulching in greenhouse-grown lettuce. Acta Hortic. 2012, 952, 393–398. [Google Scholar] [CrossRef]

- Yan, C.; He, W.; Turner, N.C.; Liu, E.; Liu, Q.; Liu, S. Plastic-film mulch in Chinese agriculture: Importance and problems. World Agric. 2014, 4, 32–36. Available online: http://www.world-agriculture.net/article/plastic-film-mulch-in-chinese-agriculture-importance-and-problems (accessed on 21 February 2022).

- Steinmetz, Z.; Wollman, C.; Schaefer, M.; Buchman, C.; David, J.; Tröger, J.; Muñoz, K.; Frör, O.; Schaumann, G.E. Plastic mulching in agriculture. Trading short-term agronomic benefits for long-term soil degradation? Sci. Total Environ. 2016, 550, 690–705. [Google Scholar] [CrossRef] [PubMed]

- Di Mola, I.; Cozzolino, E.; Ottaiano, L.; Duri, L.; Riccardi, R.; Spigno, P.; Leone, V.; Mori, M. The effect of novel biodegradable films on agronomic performance of zucchini squash grown under open-field and greenhouse conditions. Aust. J. Crop Sci. 2019, 13, 1810–1818. [Google Scholar] [CrossRef]

- Guo, J.; Huang, X.; Xiang, L.; Wang, Y.; Li, Y.; Li, H.; Cai, Q.; Mo, C.; Wong, M. Source, migration and toxicology of microplastics in soil. Environ. Int. 2020, 137, 105263. [Google Scholar] [CrossRef]

- Serrano-Ruíz, H.; Martín-Closas, L.; Pelacho, M. Application of an in vitro plant ecotoxicity test to unused biodegradable mulches. Polym. Degrad. Stab. 2018, 158, 102–110. [Google Scholar] [CrossRef]

- Sintim, H.Y.; Flury, M. Is biodegradable plastic mulch the solution to agriculture’s plastic problem? Environ. Sci.Technol. 2017, 51, 1068–1069. [Google Scholar] [CrossRef]

- Sintim, Y.; Bandopadhyay, S.; English, M.; Bary, A.; Liquet y Gonzalez, J.E.; DeBruyn, J.M.; Flury, M. Four years of continuous use of soil-biodegradable plastic mulch: Impact on soil and groundwater quality. Geoderma 2021, 381, 114665. [Google Scholar] [CrossRef]

- EIP-AGRI Focus Group on Reducing the Plastic Footprint of Agriculture: Final Report. Available online: https://ec.europa.eu/eip/agriculture/en/publications/eip-agri-focus-group-plastic-footprint-final (accessed on 16 March 2022).

- Larkin, R.P. Effects of selected soil amendments and mulch type on soil properties and productivity in organic vegetable production. Agronomy 2020, 10, 795. [Google Scholar] [CrossRef]

- Krzan, A.; Hemjinda, S.; Miertus, S.; Corti, A.; Chiellini, E. Standardization and certification in the area of environmentally degradable plastics. Polym. Degrad. Stab. 2006, 91, 2819–2833. [Google Scholar] [CrossRef]

- Muñoz, K.; Thiele-Bruhn, S.; Kenngott, K.G.J.; Meyer, M.; Diehl, D.; Steinmetz, Z.; Schaumann, G.E. Effects of plastic versus straw mulching systems on soil microbial community structure and enzymes in strawberry cultivation. Soil Syst. 2022, 6, 21. [Google Scholar] [CrossRef]

- Valera, D.L.; Belmonte, L.J.; Molina-Aiz, F.D.; López, A.; Camacho, F. The greenhouses of Almería, Spain: Technological analysis and profitability. Acta Hortic. 2017, 1170, 219–226. [Google Scholar] [CrossRef]

- Baeza, E.; Pérez-Parra, J.; López, J.C.; Gázquez, J.C. Ventilación natural. In Manejo del Clima en el Invernadero Mediterráneo; Sánchez-Guerrero, M.C., Lorenzo, P., Alonso, F.J., Medrano, E., Eds.; Instituto de Investigación y Formación Agraria y Pesquera de Andalucía: Almería, Spain, 2010; pp. 13–32. [Google Scholar]

- BOE núm. 78. España, Orden de 5 de diciembre de 1975 por la que se aprueban como oficiales los métodos de análisis de suelos y aguas. Boletín Oficial del Estado 1976, 78, 6458–6491. [Google Scholar]

- Miles, C.; Wallace, R.; Wszelaki, A.; Martin, J.; Cowan, J.; Walters, T.; Inglis, D. Deterioration of potentially biodegradable alternatives to black plastic mulch in three tomato production regions. HortScience 2012, 47, 1270–1277. [Google Scholar] [CrossRef]

- Cowan, J.S.; Inglis, D.A.; Miles, C.A. Deterioration of three potentially biodegradable plastic mulches before and after soil incorporation in a broccoli field production system in Northwestern Washington. HortTechnology 2013, 23, 849–858. [Google Scholar] [CrossRef]

- Othman, Y.A.; Leskovar, D.I. Degradable mulch as an alternative to polyethilene for watermelon production. HortTechnology 2022, 32, 226–233. [Google Scholar] [CrossRef]

- Immirzi, A.; Santagata, G.; Vox, G.; Schettini, E. Preparation, characterisation and field-testing of a biodegradable sodium alginate-based spray mulch. Biosyst. Eng. 2009, 102, 461–472. [Google Scholar] [CrossRef]

- Cirujeda, A.; Aibar, J.; Anzalone, A.; Martín-Closas, L.; Meco, R.; Moreno, M.; Pardo, A.; Pelacho, A.M.; Rojo, F.; Royo-Esnal, A.; et al. Biodegradable mulch instead of polyethylene for weed control of processing tomato production. Agron. Sustain. Dev. 2012, 32, 889–897. [Google Scholar] [CrossRef]

- Cruz-Romero, G. Manejo de suelos en condiciones de escasez de agua. In Actas del I y II Seminario del Agua; Instituto de Estudios Almerienses: Almería, Spain, 1997; pp. 145–166. [Google Scholar]

- Lei, Y.; Takahashi, H.; Li, W. Effects of concrete mulch on soil thermal and moisture regimes. J. Agric. Meteorol. 2004, 60, 17–23. [Google Scholar] [CrossRef][Green Version]

- Maurya, P.R.; Lal, R. Effect of different mulch materials on soil and on root growth and yield of maize and cowpea. Field Crops Res. 1981, 4, 33–45. [Google Scholar] [CrossRef]

- Jia, Y.; Li, F.M.; Wang, X.L.; Yang, S.M. Soil water and alfalfa yields as affected by alternating ridges and furrows in rainfall harvest in a semiarid environment. Field Crops Res. 2006, 97, 167–175. [Google Scholar] [CrossRef]

- Ramakrishna, A.; Tam, H.M.; Wani, S.P.; Long, T.D. Effect of mulch on soil temperature, moisture, weeds infestation and yield of groundnut in northern Vietnam. Field Crops Res. 2006, 95, 115–125. [Google Scholar] [CrossRef]

- Li, M.Z.; Li, F.M.; Jin, S.L.; Song, Y. How two ridges and the furrow mulched with plastic film affect soil water, soil temperature and yield of maize on the semiarid Loess Plateau of China. Field Crops Res. 2009, 113, 41–47. [Google Scholar]

- Yang, Y.M.; Liu, X.J.; Li, W.Q.; Li, C.Z. Effect of different mulch materials on winter wheat production in desalinized soil in Heilonggang region of North China. J. Zhejiang Univ. Sci. B 2006, 7, 858–867. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, P.K.; Dayal, D.; Bandyopadhyay, K.K.; Mohanty, M. Evaluation of straw and polythene mulch for enhancing productivity of irrigated summer groundnut. Field Crops Res. 2006, 99, 76–86. [Google Scholar] [CrossRef]

- Duppong, L.M.; Delate, K.; Liebman, M.; Horton, R.; Romero, F.; Kraus, G.; Petrich, J.; Chowdbury, P.K. The effect of natural mulches on crop performance, weed suppression and bio-chemical constituents of Cantip and St. John’s Wort. Crop Sci. 2004, 44, 861–869. [Google Scholar] [CrossRef]

- Kosterna, E. The effect of covering and mulching on the temperature and moisture of soil and broccoli yield. Acta Agrophys. 2014, 21, 165–178. [Google Scholar]

- Stinson, J.; Brinen, G.M.; Connell, D.; Black, R. Evaluation of landscape mulches. HortScience 1990, 103, 372–377. [Google Scholar]

- Moreno, M.M.; Moreno, A. Effect of different biodegradable and polyethylene mulches on soil properties and production in a tomato crop. Sci. Hortic. 2008, 116, 256–263. [Google Scholar] [CrossRef]

- Tofanelli, M.; Wortman, S. Benchmarking the agronomic performance of biodegradable mulches against polyethylene mulch film: A meta-analysis. Agronomy 2020, 10, 1618. [Google Scholar] [CrossRef]

- Cárdenas, F.; González, J.; Hernández, M. El Cultivo Protegido del Tomate. In Técnicas de Producción en Cultivos Protegidos; Camacho-Ferre, F., Ed.; Caja Rural Intermediterránea, Cajamar; Instituto de estudios Cajamar: Almería, Spain, 2003; Volume 2, pp. 481–537. [Google Scholar]

- Cozzolino, E.; Sekara, A.; Pokluda, R.; del Piano, L.; Cuciniello, A.; Caruso, G. Plant growth, yield, fruit quality and residual biomass composition of tomato as affected by mulch type. Acta Hortic. 2020, 1271, 465–472. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, R.H.; Wang, X.J.; Wang, J.P.; Zhang, C.P.; Tian, C.Y. Carbon dioxide fluxes and concentrations in a cotton field in north western China: Effects of plastic mulching and drip irrigation. Pedosphere 2011, 21, 178. [Google Scholar] [CrossRef]

- Tindall, J.A.; Beverly, R.B.; Radcliffe, D.E. Mulch effect on soil properties and tomato growth using micro-irrigation. Agron. J. 1991, 83, 1028–1034. [Google Scholar] [CrossRef]

- Mehmood, S.; Zamir, S.; Rasool, T.; Akbar, W. Effect of tillage and mulching on soil fertility and grain yield of sorghum. Sci. Agric. 2014, 8, 31–36. [Google Scholar]

- García-Raya, P.; Ruiz-Olmos, C.; Marín-Guirao, J.I.; Asensio-Grima, C.; Tello-Marquina, J.C.; de Cara-García, M. Greenhouse Soil Biosolarization with Tomato Plant Debris as a Unique Fertilizer for Tomato Crops Greenhouse Soil Biosolarization with Tomato Plant Debris as a Unique Fertilizer for Tomato Crops. Int. J. Environ. Res. Public Health 2019, 16, 279. [Google Scholar] [CrossRef]

- Goldberger, J.; Jones, R.; Miles, C.; Wallace, R.; Inglis, D. Barriers and bridges to the adoption of biodegradable plastic mulches for US specialty crop production. Renew. Agric. Food Syst. 2015, 30, 143–153. [Google Scholar] [CrossRef]

- Sintim, H.Y.; Bandopadhyay, S.; English, M.E.; Bary, A.I.; DeBruyn, J.M.; Schaeffer, S.M.; Miles, C.A.; Reganold, J.P.; Flury, M. Impacts of biodegradable plastic mulches on soil health. Agric. Ecosyst. Environ. 2019, 273, 36–49. [Google Scholar] [CrossRef]

- Bandopadhyay, S.; Martin-Closas, L.; Pelacho, A.M.; DeBruyn, J.M. Biodegradable plastic mulch films: Impacts on soil microbial communities and ecosystem functions. Front. Microbiol. 2018, 9, 819. [Google Scholar] [CrossRef]

- Bandopadhyay, S.; Sintim, H.Y.; DeBruyn, J.M. Effects of biodegradable plastic film mulching on soil microbial communities in two agroecosystems. PeerJ 2020, 8, e9015. [Google Scholar] [CrossRef]

- Nachimuthu, G.; Halpin, N.V.; Bell, M.J. Productivity benefits from plastic mulch in vegetable production likely to limit adoption of alternate practices that deliver water quality benefits: An on-farm case study. Horticulturae 2017, 3, 42. [Google Scholar] [CrossRef]

- Osipitan, O.A.; Mesgaran, M.B.; Hanson, B.D.; Fernandez-Bayo, J.D. Leveraging tomato crop residues and pomace for biosolarization to deplete weed seedbank in tomato fields. Agric. Sci. Technol. 2022, 2, 22–31. [Google Scholar] [CrossRef]

- Minuto, G.; Guerrini, S.; Pini, S.; Capurro, M. Weed control with biodegradable mulch in vegetable crops. Acta Hortic. 2008, 801, 291–297. [Google Scholar] [CrossRef]

- Ngouajio, M.; Ernest, J. Light transmission through colored polyethylene mulches affect weed populations. HortScience 2004, 39, 1302–1304. [Google Scholar] [CrossRef]

- Marí, A.I.; Pardo, G.; Aibar, J.; Cirujeda, A. Purple nutsedge (Cyperus rotundus L.) control with biodegradable mulches and its effect on fresh pepper production. Sci. Hortic. 2020, 263, 109111. [Google Scholar] [CrossRef]

- Alcantara, C.; Jiménez, A.; Balsera, A. Manejo ecológico de hierbas. Influencia sobre la producción de tomate y pimiento. Phytoma España 2007, 194, 44–48. [Google Scholar]

- Woldetsadik, K.; Gertsson, U.; Ascard, J. Response of shallots to mulching and nitrogen fertilization. HortScience 2003, 38, 217–221. [Google Scholar] [CrossRef]

- Zangoueinejad, R.; Alebrahim, M.T. Use of conventional and innovative organic materials as alternatives to black plastic mulch to suppress weeds in tomato production. Biol. Agric. Hortic. 2021, 37, 267–284. [Google Scholar] [CrossRef]

- Cowan, J.S.; Saxton, A.M.; Liu, H.; Leonas, K.K.; Inglis, D.; Miles, C.A. Visual assessments of biodegradable mulch deterioration are not indicative of changes in mechanical properties. HortScience 2016, 51, 245–254. [Google Scholar] [CrossRef]

- Martín-Closas, L.; Pelacho, A.M.; Picuno, P.; Rodriguez, D. Properties of new biodegradable plastics for mulching, and characterization of their degradation in the laboratory and in the field. Acta Hortic. 2008, 801, 275–282. [Google Scholar] [CrossRef]

- Bilck, A.P.; Grossmann, M.V.E.; Yamashita, F. Biodegradable mulch films for strawberry production. Polym. Test. 2010, 29, 471–476. [Google Scholar] [CrossRef]

- Rutiaga, M.O.; Galan, L.J.; Morales, L.H.; Gordon, S.H.; Imam, S.H.; Nino, K. AMechanical property and biodegradability of cast films prepared from blends of oppositely charged biopolymers. J. Polym. Environ. 2005, 13, 185–191. [Google Scholar] [CrossRef]

| Soil Physical and Chemical Variables | Start Season 1 | End Season 1 | Soil Physical and Chemical Variables | End Season 2 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Straw | Polyethylene | Biopolymer | Non-mulched | p-Value | Straw | Polyethylene | Biopolymer | Non-mulched | p-value | |||

| pH | 8.6 ± 0.2 | 8.1 ± 0.1 | 8.1 ± 0.1 | 8.1 ± 0.1 | 8.1 ± 0.1 | 0.821 | pH (Extract 1:2:5 H2O) | 9.2 ± 0.1a | 9.0 ± 0.1b | 9.0 ± 0.1b | 9.0 ± 0.1b | 0.024 |

| CE (dS/m) * | 6.19 ± 3.99 | 2.58 ± 0.44 | 2.46 ± 0.62 | 2.28 ± 0.74 | 3.37 ± 0.74 | 0.251 | CE (dS/m) ** | 0.53 ± 0.10 | 0.48 ± 0.04 | 0.69 ± 0.08 | 0.81 ± 0.34 | 0.182 |

| Ca+2 (mg/L) | 1253 ± 117 | 5001 ± 1257 | 5898 ± 869 | 5563 ± 849 | 2927 ± 1756 | 0.071 | Ca+2 (mg/kg sms) | 5753 ± 81 | 5761 ± 31 | 5649 ± 144 | 5678 ± 221 | 0.706 |

| Na+1 (mg/L) | 37 ± 8 | 47 ± 5 | 51 ± 18 | 47 ± 10 | 52 ± 13 | 0.926 | Na+1 (mg/kg sms) | 218 ± 47 | 201 ± 24 | 252 ± 35 | 304 ± 123 | 0.348 |

| Mg+2 (mg/L) | 261 ± 13 | 383 ± 94 | 413 ± 8 | 337 ± 66 | 314 ± 52 | 0.292 | Mg+2 (mg/kg sms) | 348 ± 31 | 339 ± 30 | 333 ± 16 | 384 ± 46 | 0.288 |

| K+1 (mg/L) | 1841 ± 922 | 2796 ± 176ab | 3391 ± 532a | 2573 ± 604ab | 1982 ± 303b | 0.027 | K+1 (mg/kg sms) | 884 ± 144 | 819 ± 62 | 824 ± 105 | 1009 ± 236 | 0.431 |

| Active limestone (%) | 5.7 ± 1.9 | 6.0 ± 1.8 | 4.5 ± 1.7 | 5.8 ± 2.9 | 6.3 ± 1.6 | 0.722 | Active limestone (% sms) | 7.7 ± 0.6 | 7.7 ± 0.6 | 7.7 ± 0.6 | 7.7 ± 0.6 | 1.000 |

| P Olsen (meq/L) | 19 ± 1 | 8 ± 1 | 9 ± 2 | 8 ± 2 | 9 ± 1 | 0.696 | P Olsen (mg/kg sms) | 61.9 ± 8.3 | 59.6 ± 8.6 | 65.0 ± 16.7 | 67,5 ± 6.6 | 0.817 |

| Nitric N (mg/L) | 157 ± 86 | 61 ± 23 | 48 ± 4 | 52 ± 24 | 62 ± 25 | 0.821 | Nitric N (mg/kg sms) | 7.1 ± 0.9 | 7.8 ± 5.4 | 19.0 ± 6.1 | 21.6 ± 17.8 | 0.232 |

| Organic Matter (%) | 1.2 ± 0.5 | 1.1 ± 0.0 | 0.9 ± 0.0 | 1.1 ± 0.1 | 1.0 ± 0.2 | 0.304 | Organic Matter (% sms)) | 2.1 ± 0.1 | 2.4 ± 0.6 | 2.1 ± 0.2 | 2.3 ± 0.2 | 0.563 |

| Total carbonates (%) | 14 ± 4 | 19 ± 4 | 18 ± 3 | 17 ± 5 | 21 ± 6 | 0.728 | CaCO3 equivalent (% sms) | 25.7 ± 1.5 | 25.0 ± 1.0 | 26.7 ± 1.2 | 25.7 ± 0.6 | 0.394 |

| Total N (%) | 0.043 ± 0.015 | 0.050 ± 0.010 | 0.040 ± 0.010 | 0.043 ± 0.006 | 0.037 ± 0.006 | 0.297 | Total N (% sms) | 0.177 ± 0.015 | 0.180 ± 0.036 | 0.180 ± 0.036 | 0.177 ± 0.006 | 0.999 |

| C/N | 20 ± 11 | 16 ± 4 | 16 ± 5 | 17 ± 3 | 20 ± 2 | 0.531 | C/N | 7.02 ± 0.77 | 7.83 ± 0.68 | 6.84 ± 0.70 | 7.47 ± 0.30 | 0.297 |

| Sand % | 68 ± 4 | 56 ± 3 | 59 ± 8 | 59 ± 4 | 60 ± 7 | 0.873 | Sand % | 58 ± 3 | 57 ± 3 | 59 ± 2 | 55 ± 5 | 0.464 |

| Silt % | 13 ± 1 | 21 ± 4 | 17 ± 6 | 20 ± 2 | 19 ± 6 | 0.867 | Silt % | 21 ± 2 | 22 ± 1 | 20 ± 1 | 21 ± 2 | 0.767 |

| Clay % | 19 ± 3 | 23 ± 1 | 24 ± 3 | 21 ± 2 | 21 ± 1 | 0.284 | Clay % | 21 ± 1 | 22 ± 2 | 21 ± 1 | 24 ± 3 | 0.280 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marín-Guirao, J.I.; Martín-Expósito, E.; García-García, M.d.C.; de Cara-García, M. Alternative Mulches for Sustainable Greenhouse Tomato Production. Agronomy 2022, 12, 1333. https://doi.org/10.3390/agronomy12061333

Marín-Guirao JI, Martín-Expósito E, García-García MdC, de Cara-García M. Alternative Mulches for Sustainable Greenhouse Tomato Production. Agronomy. 2022; 12(6):1333. https://doi.org/10.3390/agronomy12061333

Chicago/Turabian StyleMarín-Guirao, Jose Ignacio, Emilio Martín-Expósito, María del Carmen García-García, and Miguel de Cara-García. 2022. "Alternative Mulches for Sustainable Greenhouse Tomato Production" Agronomy 12, no. 6: 1333. https://doi.org/10.3390/agronomy12061333

APA StyleMarín-Guirao, J. I., Martín-Expósito, E., García-García, M. d. C., & de Cara-García, M. (2022). Alternative Mulches for Sustainable Greenhouse Tomato Production. Agronomy, 12(6), 1333. https://doi.org/10.3390/agronomy12061333