Abstract

Recently, technological development has become increasingly pronounced, with great advances in all production areas, including agriculture. In the agricultural sector, improvements in machinery and the study of new techniques have resulted in the increased efficiency and productivity of different crops. In particular, UAVs (unmanned aerial vehicles) are increasingly used in agriculture. Among the latest utilities is the application of phytosanitary products. The use of small UAVs retrofitted with spraying systems make it possible to treat large surfaces in short periods of time, achieving a reduction in inputs and time compared to conventionally used methods (trailed sprayers). The aim of this work was to compare conventional sprayers and UAV sprayers on a farm in Spain, with olive and vineyard crops. The determining factors in the choice of one or another alternative were studied, such as the economic requirements and efficiency of different alternatives. The results show that a large investment is required to acquire a UAV sprayer, while operating costs are higher for conventional sprayers versus UAV sprayers. Efficiency (ha/h) is much higher for UAV sprayers. In addition to these advantages, UAV sprayers require a lower cost of water and products. However, different factors could make conventional sprayers a better choice.

1. Introduction

An unmanned aerial vehicle (UAV), commonly known as a drone, is an aircraft without any human pilot, crew or passengers on board. UAVs are a component of an unmanned aircraft system (UAS), which additionally includes a ground-based controller and a system of communications with the UAV [1,2].

Although the first UAV models emerged in the first decade of the last century, the development of UAVs began at the conclusion of World War II, when they were used exclusively for military use. Nowadays, UAVs have gained applications in the civil field. One of the most interesting applications, the reason for this work, is its foray into agricultural activity, where UAVs are used to control the variables that most affect the correct development of crops [3]. UAVs have also been used to help with the problem of hydric resources in Spain [4,5]. Goldman Sachs predicts that the agricultural sector will be the second-largest user of drones in the world in the next 5 years [6]. Among the main agricultural applications, the following can be highlighted:

- -

- Crop monitoring. Crop monitoring involves using high-definition cameras that work in sync with a global positioning system (GPS). These cameras take photos that are synchronized with their position, subsequently analyzing the data obtained with other software [7]. This application is useful in crops such as corn, because in advanced stages, when the plant is developed, corn reaches a height that is impossible to track on foot [8]. The cameras commonly used for this type of work provide RGB images, from which indices, such as the foliar area and spectral indices, including excess green, are obtained [8,9].

- -

- Detection of water stress in crops. The location of crops experiencing water stress can be determined using the thermal cameras of UAVs. With this information, the water needs of each plant can be established, and the water can be used in a more efficient way, preventing localized risks [10,11].

- -

- Detection of nutritional stress in crops. The detection of nutritional stress involves detecting, from the vegetative state, possible nutritional deficiencies of the plants [12]. Subsequently, with these data, the exact fertilization needs can be calculated [13,14].

- -

- Early detection of diseases and pests and application of phytosanitary products. The observation of changes produced in crops can be detected using UAVs such that diseases are easily located. Subsequently, phytosanitary products can be applied in affected areas with precision [15].

- -

- Plant count. An exact count of the plants on a farm, avoiding extrapolations, can be achieved using UAVs. This application is especially useful for locating problems in crops, as well as for assessing damage to plots due to different phenomena such as fires [15,16].

The implementation of large numbers of cameras and sensors, such as thermal, LiDAR and hyperspectral [16,17], has led to an increase in the agricultural applications of aerial vehicles. Today, UAVs are used in a wide range of agricultural applications, such as crop protection, specifically in the spraying of products to protect plants [18,19]. Several brands have started to manufacture sprayer models using more advanced technology, posing a real alternative to the conventionally used methods.

Unlike the treatments applied with conventional trailed sprayers, the use of UAVs in spraying applications makes sense when ultra-low volume (ULV) doses are used [20]. This factor together with the ability to penetrate the plants are decisive for this technology, making it impossible to use it for all plant conditions [20].

Many authors have studied the efficiency of these aerial treatments in horticultural crops and fruit trees and have achieved promising results [21,22,23]. However, there are not many comparisons between the machinery used for crop protection and the newly developed UAV sprayer models. For this reason, the objectives of this work are the following: (1) economic study on the application of phytosanitary products with conventional trailed sprayers and the new models of UAV sprayers; (2) to conduct an efficiency study of the same models, checking the labor savings with one or another alternative (these analyses will be associated with the crops of a farm in Badajoz, making the study as real as possible); and (3) to develop a SWOT (strengths, weaknesses, opportunities, and threats) matrix with the principal characteristics of new UAV sprayers.

2. Materials and Methods

- -

- UAV and conventional sprayer models

In this study, three rotary-wing UAV sprayer models (UAV 1, UAV 2, UAV 3) and two trailed conventional sprayers were selected for their price and features. All of them were made by the most advanced agricultural brands in the market. The specifications and datasheets of the UAV sprayer models (Table 1) and conventional sprayers (Table 2) were provided by the manufacturers. The model specifications and datasheets were also provided by two distributors in Castilla-La Mancha (Spain).

Table 1.

Characteristics and specifications of the selected UAV sprayer models.

Table 2.

Characteristics and specifications of the selected conventional sprayer (CS) models.

As can be seen in Table 1, the first and third UAV sprayer models are similar in terms of tank volume, with 10 L for both models. The second UAV sprayer model is the successor of the first one, with better characteristics such as a bigger treatment diameter and tank volume. In addition, the battery life of the third model is the highest followed by the second model. The maximum speed is the same to UAV 1 and UAV 2, higher than UAV 3.

Conventional trailed sprayer models have similar characteristics (Table 2). The dimensions and tank volumes are similar due to the crop specifications because the machinery must be able to cross crop streets. The conventional sprayer 1 (CS1) applied phytosanitary products using air blasts produced by pneumatic equipment, allowing for smaller droplet size. In the case of the conventional sprayer 2 (CS2), the spraying was made by a hydraulic system.

- -

- Hire a UAV sprayer company

After consulting different companies, the average price was taken from the companies that use the same UAV sprayer models defined above or with the same characteristics as those evaluated in this article.

- -

- Crops and land properties

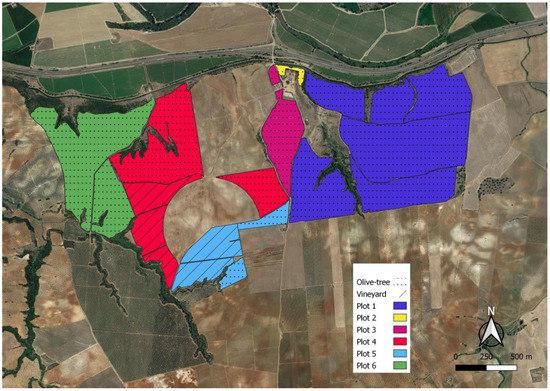

The study area was located in Spain, specifically between the cities of Merida and Badajoz, Extremadura province (38°51′37.7″ N, 6°32′35.794″ W). The crops are represented in Figure 1 and are detailed in Table 3.

Figure 1.

Cultivation areas studied of the farm.

Table 3.

Details of crops, areas and slopes of each plot studied.

The study was carried out with the farm’s main crops, namely:

- (a)

- Olive. There were three varieties on the farm, accounting for 248.13 ha: Picual, Arbequina and Morisca, with three different types of plantation schemes: 7 × 7, 7 × 6 and 7 × 5 m with 204, 238 and 285 olive trees per hectare, respectively. That information is important for flight planning, as well as the spray width of the UAV. Plagues and diseases that attack olive in the zone are Bactrocera oleae, Prays oleae and Fusicladium oleaginum.

- (b)

- Vine. The farm had trellised vineyards, with Syrah and Petit verdot varieties. The total area was 38.38 ha. The distance between the vines was 1.5 m, and the row spacing was 3 m. The main disease affecting the vine at the farm is Uncinula necator. The remaining diseases do not produce significant economic losses and do not require treatment in the farm.

2.1. Economic Analysis

2.1.1. Fixed Costs

First, it was necessary to compare the different prices of selling for each conventional sprayer and UAV sprayer selected models. For this comparison, different companies were contacted to determine the best offers. In addition to these starting costs, each alternative requires other initial costs:

- (a)

- Conventional sprayers:

- -

- Professional qualification for plant protection products handling.

- (b)

- UAV sprayers:

- -

- Theoretical online training course for a professional drone pilot;

- -

- Practices and practical exam fees;

- -

- LAPL medical certificate;

- -

- Class 2 medical certificate;

- -

- Phytosanitary product applicator pilot course;

- -

- Two extra batteries and charger.

To overcome the problem of long charging times, a charger and two additional batteries must be purchased and swapped between flights, minimizing the downtime.

The necessary requirements to manage both alternatives must be added to these costs. In the case of conventional alternatives, a professional qualification for plant protection products handling is necessary. For the UAV sprayers, more requirements are needed to manage this type of aerial applications.

2.1.2. Variable Costs

The operating costs were also studied. For the economic evaluation of the use of conventional trailed sprayers, the calculations were based on the technical considerations proposed by the ASABE (American Society of Agricultural and Biological Engineers) and MAPA (Spanish Ministry of Agriculture, Fisheries and Food) [24,25]. These factors are different from the two alternatives:

- (a)

- Conventional sprayer alternative: depreciation of tractor, depreciation of trailed sprayer, fuel, lubricant oils, insurance, hydraulic oils, shed and worker. The depreciation of the tractor and sprayer was calculated using the next formula:

This equation is based on the purchase price, the selling price after a period of time and the hours worked per year.

The fuel cost has been calculated by applying the following formula:

The most important factors to calculate fuel costs were the velocity, the power of machinery and the local price of fuel. As can be seen, the necessary conversions have been applied to obtain a EUR/h value for conventional machinery use.

Lubricants oils, insurance, hydraulic oils, shed and worker were estimated by ASABE and spreadsheets given by MAPA (Spanish Ministry of Agriculture, Fisheries and Food), which make it possible to estimate some costs depending on the technical characteristics of the machinery used.

- (b)

- UAV sprayer alternative: depreciation of UAV, energy costs, insurance and worker.

The depreciation costs were obtained following the next equation:

The energy costs were calculated with the next equation:

To estimate the costs of this equation, the amperage and voltage of the batteries, the number of batteries and the price of energy have been considered, obtaining a value of cost in EUR/h. The price of the insurance was offered by national insurance companies.

- (c)

- Hire a UAV Company: A third alternative has also been included, which is to subcontract a UAV sprayers company that will carry out the appropriate treatments.

2.1.3. Equation Costs

Third, all costs were used to form linear equations to compare different alternatives, including the running costs of each option. These equations allowed us to compare which option is better from an economical point of view. The equations were composed first of a fixed factor, linked to Fixed Costs and corresponding to the starting point on the ordinate axis, and a variable factor on the abscissa axis, linked to Variable Costs.

As can be seen in the equation, this variation was calculated as a function of time, checking how final costs increase as a function of time worked. Finally, the equations were plotted on a graph, in order to compare which option was the most profitable in terms of working days.

2.2. Efficiency Analysis

The work done per unit of time is a determining factor when choosing the best alternative.

2.2.1. UAV Sprayer Models

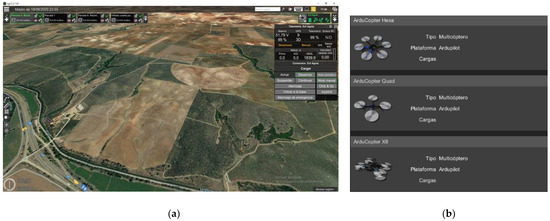

In this section, a flight planning software was used to calculate the necessary time to spray each plot. Numerous applications, such as Mission Planner, UgCS, DJI GS Pro, 3DSurvey Pilot and Pix4Dcapture, offer automated mission flying. The chosen software was UgCS (SPH Engineering SIA UgCS Mission Planning Software for UAV Professionals. The software is available online at https://www.ugcs.com/ (accessed on 4 August 2021). According to a previous study [26], UgCS provides the possibility to include an external digital elevation model (DEM) to compute a more accurate 3D flight plan (Figure 2a).

Figure 2.

(a) UgCS software interface. (b) Emulators of the different UAV sprayer models.

With this software, emulators of selected UAV sprayer models were created (Figure 2b), adapting characteristics such as treatment speed and battery life, as well as the pass width of each model, the main factor of treatment. The flight height is also an important factor in the application of the treatment, being able to modify the deposition density and penetration of the phytosanitary product [20,22,27,28,29]. After that, routes were planned following the steps described below:

- -

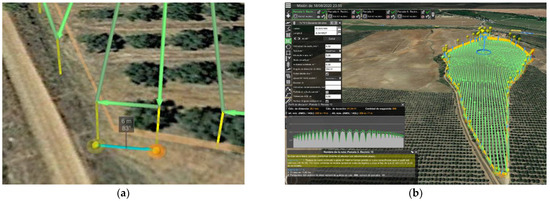

- Delimit the limits of each of the farm parcels. These limits should settle with precision, avoiding waste of time during the flight (Figure 3a).

Figure 3. (a) Delimitation of each of the farm parcels and setting the flight orientation. (b) Setting the treatment width for each UAV sprayer model.

Figure 3. (a) Delimitation of each of the farm parcels and setting the flight orientation. (b) Setting the treatment width for each UAV sprayer model. - -

- Establish the pass width depending on the model for each parcel. The determining technology for this step is the UAV’s spray system and its working diameter (Figure 3b). For this study, the pass width was 0.5 m less than the working diameter of each model, ensuring the application of plant protection products on the crop.

- -

- Set the flight orientation, looking for the shortest route time. Usually, the shortest route time will correspond to the one in which the least changes in direction are made (Figure 3a). The flight path was planned to optimize battery usage, which does not necessarily optimize the application of the plant protection product.

- -

- Establish the UAV velocity during the treatment. The value chosen was 6 m/s, similar to the velocity adopted in previous studies [23,30].

The program calculates the estimated flight time, including those points where it will be necessary to change the battery. The dead times were calculated by multiplying the number of battery changes per 5 min estimated for each change. Fifteen percent of the value of this multiplication was added to dead times in order to include the filling of the tank.

2.2.2. Conventional Sprayer Models

In the case of conventional sprayers, the efficiency data have been obtained based on the records of the farm managers, considering the geography and topography, as well as the location of the supply wells. The average work value for the olive tree and vineyard obtained from the records is 1.6 hectares per hour, including, in this efficiency, the necessary times to fill the sprayer tank and the travel time to supplies of water. Although the treatment velocity of the olive trees was faster, it was necessary to go through all the cultivation rows, while in the vineyard, it was allowed to treat four rows of vines per pass.

2.3. SWOT Matrix

With the results obtained in two previous sections and considering some additional factors, a SWOT matrix was developed, showing the general advantages and disadvantages of this technology.

3. Results and Discussion

3.1. Economic Analysis

3.1.1. Fixed Costs

UAV sprayer acquisition costs were collected from different companies, including costs for the UAV sprayer model, extra battery charger and four batteries required by each model. The costs of all models after taxes are shown in Table 4.

Table 4.

Acquisition and requirement prices of the different UAV sprayer models selected.

As it can be seen, UAV 2 is the most expensive of the shortlisted models, followed by UAV 3. UAV 1 is the cheapest of the three models. In the last column, the costs of the requirements in the base of actual normative can be seen:

- -

- Theoretical online training course for a professional drone pilot: EUR 500;

- -

- Practices and practical exam fees: EUR 300;

- -

- LAPL medical certificate: EUR 80;

- -

- Class 2 medical certificate: EUR 120;

- -

- Phytosanitary product applicator pilot course: EUR 1100.

The differences in requirement costs between the analyzed models are fundamentally based on the medical certificate. UAV 2 is a drone with a weight exceeding 20 kg. Thus, a Class 2 medical certificate is required. The other models are under 20 kg; thus, an LAPL medical certificate is required.

The final investment necessary for the acquisition of each model is approximately EUR 20,000, except for the second model, which is around EUR 22,000. This implies a huge economic acquisition cost of UAV sprayers, which provides a low benefit/cost ratio to small farms, as stated by Matese et al. [31]. This investment is suitable for large farms, which can use the UAV for other tasks, such as 3D mapping of vegetation, in order to save crop protection products and remote sensing techniques [32]. The trailed sprayers acquisition costs are compiled in Table 5.

Table 5.

Acquisition and requirement prices of the different conventional trailed sprayers selected.

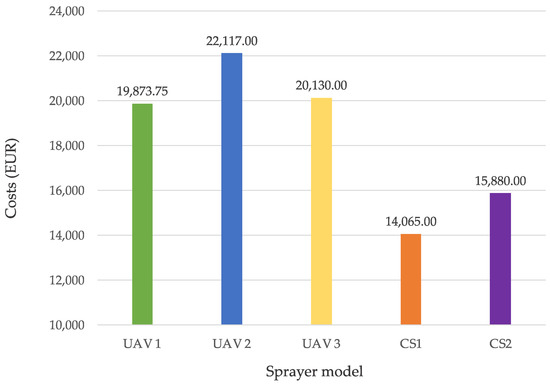

As it can be seen, UAV sprayer models are more expensive than conventional sprayer models. The median price of UAV sprayers is 42.8% more expensive than the median price of conventional sprayers. These offers were proposed by Castilla-La Mancha’s companies, located in Ciudad Real (Spain). In the last column, requirement costs are reflected, showing that sprayer requirement costs are more expensive than UAV sprayers requirement costs. The conventional sprayer costs are based on the requirement of a professional qualification for plant protection products handling. As is shown in Figure 4, UAV sprayers are much more expensive to purchase than conventional sprayers, being the UAV 2 the most expensive alternative. For conventional sprayers, the cheapest option was the CS1, approximately EUR 5000 less than the UAV 1.

Figure 4.

Total acquisition costs for all alternatives.

3.1.2. Amortization Costs

First, the amortization costs of conventional sprayers, tractor and UAV sprayers were calculated as described in the “Materials and Methods” section. The values are compiled in Table 6, representing each alternative with its data, including the acquisition costs and the residual prices of different alternatives after their useful life.

Table 6.

Amortizations costs of the different models analyzed.

Residual prices were estimated using different offers of secondhand models. The more expensive the equipment, the higher its residual selling price. To calculate the hours of work per year, spreadsheets from the MAPA (Ministerio de Agricultura, Pesca y Alimentación) were used. The MAPA spreadsheet set the time work bands of different categories. As machinery is expected to provide significant use, values higher than the highest established by the MAPA have been taken. In the last column, amortizations of each alternative were calculated. If the amortization cost of the tractor is added to that of the trailed sprayer, it is similar to the amortization cost of UAV sprayer.

3.1.3. Variable Costs

Variable costs are different depending on each alternative and model. Conventional sprayers use a different power source than UAVs sprayers and require other spare parts and supplies. The running costs of sprayers are as follows:

- Fuel. The fuel cost of conventional sprayers and tractors was considered. At the study farm, treatment velocity with sprayers has been 7 km/h for some years. With this velocity, the treated area per hour is 1.6 ha, the fuel consumption of the tractor (73.6 kW) is 6 L/h, and the increase in consumption with the trailed sprayer is 4 L/ha. These data and the fuel price in the region (0.704 EUR/L) were used to calculate the fuel costs:

- Hydraulic and lubricant oils. To estimate the consumption of hydraulic and lubricant oils, the methodology set forth by the authors of [24] was considered while also observing the technical sheet of the machinery. The cost amounts to EUR 0.3/h for hydraulic oil and EUR 0.21/h for lubricant oil.

- Breakdowns and mechanical inspection. This value was estimated to be between EUR 1/h and 1.5/h, taking the value of EUR 1.08/h.

- Machinery insurance. After consulting some insurance companies, the best offer covering both devices (tractor and sprayer) amounted to EUR 225/year, that is, EUR 0.225/h.

- Machinery storage. Machinery storage was estimated to be approximately EUR 225/year, that is, EUR 0.225/h.

- Worker: The estimated cost per worker was 70 EUR/day (8 h).

The running costs of the UAV models were also considered:

- Energy costs. Energy costs varies based on the battery voltage and amperage of each model:

For UAV 1: Battery of 12 Amps and 22.2 Volts

For UAV 2: Battery of 17.5 Amps and 51.8 Volts

For UAV 3: Battery of 18 Amps and 52.5 Volts

- Insurance taxes. The main insurance companies that cover this type of vehicle made offers ranging from EUR 200/year to 400/year. The value of EUR 360/year was taken, with each model’s hourly rate totaling:

UAV 1: 360/250 = 1.44 EUR/h

UAV 2: 360/220 = 1.64 EUR/h

UAV 3: 360/245 = 1.47 EUR/h

- Worker: The cost was estimated to be the same as the conventional sprayer alternative, being the same employee.

3.1.4. Total Costs and Equations

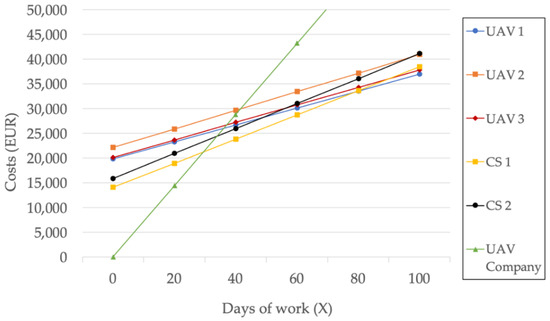

The last component of the economic analysis is the elaboration of the equational models, which allows the final cost comparison of each alternative studied. In these equations, fixed costs and variable costs have been included. The equations obtained according to previously calculated the data are shown in Figure 5, which demonstrate the working days (8 h) for better visibility and clarity. The represented equations show the total costs as a function of working time with each of the alternatives studied. As seen from the equations, the running costs for conventional sprayers are EUR 244–252/day, while the running costs for UAV sprayers are EUR 171–188/day. If it is compared with other author’s work [20], a similarity is evident in the result of the economic analysis of these alternatives, in which conventional sprayers have a running cost of EUR 208/day, that is, a cost lower than EUR 36–44/day compared with the costs obtained in this work. Conversely, UAV sprayers had a running cost of EUR 98/day without considering the costs of the employee, approximately the same costs that we have obtained (a difference of EUR 3–20/day).

Figure 5.

Representation of the cost equations for each model analyzed. Worktime of 8 h per day. UAV 1: 19,873.75 + 171.28 X; UAV 2: 22,117 + 188.36 X; UAV 3: 20,130 + 176.88 X; CS 1: 14,065 + 244.16 X; CS 2: 15,880 + 252.48 X; UAV COMPANY: 720 X.

Figure 5 shows that the option of hiring a UAV sprayer company is the most economically recommended for up to 30 working days, at which point the CS 1 option becomes the most beneficial. After 80 working days, the best option is the UAV 1. This means that for larger farms, the lower operating cost can make the large initial investment in this equipment profitable. The other options, as shown in the graph, will never be better options if only the economical point of view is considered.

3.2. Efficiency Analysis

The results obtained by the UgCS control software, including the flight time of the three different UAV sprayer models, are shown in Table 7, Table 8 and Table 9. The flight speed range was between 5 and 6 meters per second for all plots, depending on the route planning and the number of directional changes of the UAV sprayer. The flying altitude was 7 meters from the ground above olive trees and 2.5 m from the ground above the vineyards (approximately 1 m above the crop canopy).

Table 7.

Efficiency results of UAV 1.

Table 8.

Efficiency results of UAV 2.

Table 9.

Efficiency results of UAV 3.

The efficiency results are compiled in the next boxplot to better reflect the obtained results (Figure 6).

Figure 6.

Efficiencies of different UAV sprayers.

The efficiency values confirm that UAV 2 is the most efficient option, with values 2 ha/h higher than the other two models. Specifically, the value achieved by UAV 2 ranges from 6.6 to 8.2 ha/h. The other two models have similar efficiencies, with the UAV 3 being higher due to its long battery life, demonstrating work values ranging from 4.5 to 6 ha/h. The boxplot shows some points that are outside the forks. These points correspond to the parcels for which the efficiency value is considerably affected by geometry (its size entails a higher or lower number of battery changes and their corresponding dead times). These values were obtained for a working speed of 5–6 m/s, which could affect the effectiveness of treatments with these devices [33]. Although UAV sprayers reach up to 12 m/s, the flight speed could have a significant effect on spray drift characteristics for UAV aerial applications, and reducing flight speed could increase the potential for drift effectively [34]. The values of efficiency obtained (5–7 ha/h) were similar to those of the work of other authors such as Martinez-Guanter et. al, with values of 5.6 ha/h of treated crop [20].

It should be noted the importance of the flight orientation of UAV sprayers. It was decided to be an orientation that would allow greater efficiency in flight time. This does not necessarily imply a better optimization in the application of the product, as part of the phytosanitary product may not fall on the crop. It would be interesting to program the proximity sensor for the application of the product, optimizing its application and solving the problem. Another option would be to establish the flight path over the crops rows, but this was not considered because of the flight time required.

To conclude, when comparing the efficiency values of the UAV sprayer models with the average values obtained by the conventional sprayers, the UAV sprayer model with the worst values is up to 3 times higher than the conventional sprayers, which can only treat 1.6 ha/h (Figure 7).

Figure 7.

Comparison of average efficiencies of the analyzed models.

3.3. SWOT Matrix

The SWOT matrix is shown below:

3.3.1. Strengths

- Detection of disease outbreaks or pests [35];

- Efficiency in the use of phytosanitary products [20];

- Reduction of water consumption in the application of products due to the characteristics of ultra-low volume treatments;

- Continuous contact of workers with phytosanitary products [36,37];

- Lower operating costs than conventional methods;

- Automatic flight with prior programming without the need of piloting [10];

- Compaction of the soil profiles does not occur, unlike conventional methods [38].

3.3.2. Weaknesses

- Current regulations restrict the use of UAVs [39];

- Short flight time. The duration of the batteries is short, making it necessary to purchase some of them in order to work without dead times;

- High initial investment;

- UAVs cannot fly on windy days due to air resistance and the loss of phytosanitary product by drift [37];

- Generation of turbulence in the spray if the treatment height is not sufficient [18,37];

- Flight restriction in certain areas of the country, according to AESA (Agencia Estatal de Seguridad Aérea);

- Difficulties in work with certain products, especially highly concentrated ultra-volume treatments [33];

- Difficulty in the effectiveness of the treatments due to poor penetration, as some authors have reported [20,27].

3.3.3. Opportunities

- Change in the UAV management regulations in 2021 allowing more flexible and permissive use;

- Great opportunities for research and development in agriculture;

- Currently, more and more entities are publishing articles about these vehicles, with up to 160 articles published in 2018 [35];

- Expanding technology, increasing its reception in the agricultural field [10].

3.3.4. Threats

- Loss of efficacy in treatment due to an incorrect method of application;

- Cost of possible breakdowns. With expensive equipment, breakdowns can represent a high operational cost.

4. Conclusions

In this work, economic and efficiency analyses of conventional sprayers and new UAV sprayers were conducted, with the aim of determining which alternative is most recommended to perform phytosanitary applications.

After evaluating the models and gathering the corresponding data to carry out the study, the following conclusions were reached:

- -

- The acquisition of UAV sprayers supposes a huge economic inversion, up to almost double that of conventional sprayers. Of the models studied, the most expensive UAV sprayer model had a price exceeding EUR 20000, while the most expensive conventional sprayer cost approximately EUR 15000—25% less. This difference is significant and determines whether the advantages that these devices have can help to justify the price variation.

- -

- The cost of requirements must also be added to this initial investment because these are necessary to start its use. For UAVs sprayers, it is necessary to invest in more resources than for conventional sprayers, both in time and money. Comparing numbers, UAVs sprayers need an extra investment of about EUR 2000, while conventional sprayers only need a phytosanitary applicator course, which costs about EUR 150.

- -

- The running cost of conventional sprayers is between EUR 244/day and 252/day, which is 38% more expensive than UAV operations (EUR 171/day to 188/day). This means that, despite the investment in UAVs sprayers being substantially higher, the continued use of equipment can make it more convenient, from an economic point of view, to opt for the UAV sprayer option. Thus, the cheapest option would be to buy the UAV 1.

- -

- From the equational models, it can be verified that the most profitable option for a few days of work is hiring a UAV sprayer company that makes it not necessary to buy a device. From 30 to 80 days of work, the best option is to buy sprayer 1 (CS1). For larger farms similar to the one treated in this study, purchasing a UAV sprayer may be the best option.

- -

- The work efficiency obtained with UgCS software ranged from 5 to 7 ha/h, while the real work experience on the farm showed average sprayer work values of 1.6 ha/h. The result is clear, considering that UAVs do not have the same downtime as sprayers and do not need to maneuver between crops.

Based on these conclusions and after reviewing the existing bibliography, we conclude that from an efficiency point of view, UAV sprayers are an interesting option for working on large farms. UAV sprayers are also a suitable alternative to conventional methods considering their associated water savings, especially in countries as dry as Spain.

However, it is necessary to improve other factors, such as UAV sprayer efficacy and prices, to make UAV sprayers an even more attractive alternative to conventional sprayers.

Finally, the best option is the combination of sprayers and UAV sprayers, taking advantage of the benefits of both alternatives, being complementary in precision agriculture.

Author Contributions

Conceptualization, P.A.M.-R.; methodology, P.A.M.-R. and E.C.C.; software, E.C.C.; writing—original draft preparation, P.A.M.-R. and E.C.C.; writing—review and editing, P.A.M.-R., E.C.C., J.V. and J.A.L.-P.; visualization, P.A.M.-R. and E.C.C.; supervision, J.A.L.-P.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

Data are not publicly available, though the data may be made available on request from the corresponding author.

Acknowledgments

P.A. Morales-Rodríguez would like to thank the University of Castilla-La Mancha for their financial support through the program “Plan Propio de Investigación” (2020/D/LD/MC/4), cofounded by the European Regional Development Fund (FEDER, UE).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hu, J.; Lanzon, A. An innovative tri-rotor drone and associated distributed aerial drone swarm control. Robot. Auton. Syst. 2018, 103, 162–174. [Google Scholar] [CrossRef] [Green Version]

- Sharma, A.; Vanjani, P.; Paliwal, N.; Basnayaka, C.M.W.; Jayakody, D.N.K.; Wang, H.-C.; Muthuchidambaranathane, P. Communication and Networking Technologies for UAVs: A Survey. 2020. Available online: http://arxiv.org/pdf/2009.02280v1 (accessed on 1 March 2022).

- Bonanno, S.; Gonzalez, N.; Iaccarino, F. Uso de Tecnología Drone para Controlar Campos Agrícolas; Universidad Argentina de la Empresa: Buenos Aires, Argentina, 2014. [Google Scholar]

- Veroustraete, F. El auge de los drones en la agricultura. EC Agric. 2015, 2, 325–327. [Google Scholar]

- Berner, B.; Chojjnacki, J. Use of Drones in Crop Protection. In Farm Machinery and Processes Management in Sustainable Agriculture, IX International Scientific Symposium, Proceedings of the IX International Scientific Symposium “Farm Machinery and Processes Management in Sustainable Agriculture”, Lublin, Poland, 22–24 November 2017; Departament of Machinery Exploittation and Management of Production Processes, University of Life Sciences in Lublin: Lublin, Poland, 2017; pp. 46–51. ISBN 9788393743322. [Google Scholar]

- Kesteloo, H. Drones Reporting for Work—Goldman Sachs Forecasts $100B Drone Market by 2020; International Drone Racing Association, Inc.: Belleville, MI, USA, 2019. [Google Scholar]

- Mogili, U.R.; Deepak, B.B.V.L. Review on Application of Drone Systems in Precision Agriculture. Procedia Comput. Sci. 2018, 133, 502–509. [Google Scholar] [CrossRef]

- Stehr, N.J. Drones: The Newest Technology for Precision Agriculture. Nat. Sci. Educ. 2015, 44, 89–91. [Google Scholar] [CrossRef]

- Guirola Menéndez, C.L. Detección de Estrés Nutricional con Cámaras Multiespectrales; Universidad Central” Marta Abreu” de Las Villas, Facultad de Ingeniería: Santa Clara, Cuba, 2018. [Google Scholar]

- Otto, A.; Agatz, N.; Campbell, J.; Golden, B.; Pesch, E. Optimization approaches for civil applications of unmanned aerial vehicles (UAVs) or aerial drones: A survey. Networks 2018, 72, 411–458. [Google Scholar] [CrossRef]

- Hassler, S.C.; Baysal-Gurel, F. Unmanned Aircraft System (UAS) Technology and Applications in Agriculture. Agronomy 2019, 9, 618. [Google Scholar] [CrossRef] [Green Version]

- Shendryk, Y.; Sofonia, J.; Garrard, R.; Rist, Y.; Skocaj, D.; Thorburn, P. Fine-scale prediction of biomass and leaf nitrogen content in sugarcane using UAV LiDAR and multispectral imaging. Int. J. Appl. Earth Obs. Geoinf. 2020, 92, 102177. [Google Scholar] [CrossRef]

- Al-Arab, M.; Torres-Rua, A.; Ticlavilca, A.; Jensen, A.; McKee, M. Use of high-resolution multispectral imagery from an unmanned aerial vehicle in precision agriculture. In Proceedings of the 2013 IEEE International Geoscience and Remote Sensing Symposium—IGARSS, Melbourne, Australia, 21–26 July 2013; pp. 2852–7003. [Google Scholar]

- Melis, M.T.; Da Pelo, S.; Erbì, I.; Loche, M.; Deiana, G.; Demurtas, V.; Meloni, M.A.; Dessì, F.; Funedda, A.; Scaioni, M.; et al. Thermal Remote Sensing from UAVs: A Review on Methods in Coastal Cliffs Prone to Landslides. Remote Sens. 2020, 12, 1971. [Google Scholar] [CrossRef]

- Acosta Henríquez, G.F.; Mendoza Torres, C.M. Aplicaciones de los drones en la agricultura. Anu. Investig. 2017, 6, 351–365. [Google Scholar]

- Belcore, E.; Wawrzaszek, A.; Wozniak, E.; Grasso, N.; Piras, M. Individual Tree Detection from UAV Imagery Using Hölder Exponent. Remote Sens. 2020, 12, 2407. [Google Scholar] [CrossRef]

- Proctor, C.; He, Y. Workflow for building a hyperspectral uav: Challenges and opportunities. Int. Arch. Photogramm. Remote Sens. Spatial Inf. Sci. 2015, XL-1/W4, 415–419. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.-Q.; Song, X.-P.; Liang, Y.-J.; Qin, Z.-Q.; Zhang, B.-Q.; Wei, J.-J.; Li, Y.-R.; Wu, J.-M. Effects of Spray Parameters of Drone on the Droplet Deposition in Sugarcane Canopy. Sugar Tech 2020, 22, 583–588. [Google Scholar] [CrossRef]

- Radoglou-Grammatikis, P.; Sarigiannidis, P.; Lagkas, T.; Moscholios, I. A compilation of UAV applications for precision agriculture. Comput. Netw. 2020, 172, 107148. [Google Scholar] [CrossRef]

- Martinez-Guanter, J.; Agüera, P.; Agüera, J.; Pérez-Ruiz, M. Spray and economics assessment of a UAV-based ultra-low-volume application in olive and citrus orchards. Precis. Agric 2020, 21, 226–243. [Google Scholar] [CrossRef]

- Zhu, H.; Li, H.; Zhang, C.; Li, J.; Zhang, H. Performance Characterization of the UAV Chemical Application Based on CFD Simulation. Agronomy 2019, 9, 308. [Google Scholar] [CrossRef] [Green Version]

- Xiao, Q.; Du, R.; Yang, L.; Han, X.; Zhao, S.; Zhang, G.; Fu, W.; Wang, G.; Lan, Y. Comparison of Droplet Deposition Control Efficacy on Phytophthora capsica and Aphids in the Processing Pepper Field of the Unmanned Aerial Vehicle and Knapsack Sprayer. Agronomy 2020, 10, 215. [Google Scholar] [CrossRef] [Green Version]

- Meng, Y.; Su, J.; Song, J.; Chen, W.-H.; Lan, Y. Experimental evaluation of UAV spraying for peach trees of different shapes: Effects of operational parameters on droplet distribution. Comput. Electron. Agric. 2020, 170, 105282. [Google Scholar] [CrossRef]

- Ministerio de Agricultura. Pesca y Alimentación. Plataforma de Conocimiento para el Medio Rural y Pesquero: Atomizador Arrastrado; Ministerio de Agricultura: Madrid, Spain, 2020; Available online: https://bit.ly/38W2RYj (accessed on 25 November 2021).

- Boto, J.A.; Pastrana, P.; Suárez de Cepeda, M. Consumos energéticos en las operaciones agrícolas en España. Efic. Ahorr. Energético 2005. [Google Scholar]

- Manconi, A.; Ziegler, M.; Blöchliger, T.; Wolter, A. Technical note: Optimization of unmanned aerial vehicles flight planning in steep terrains. Int. J. Remote Sens. 2019, 40, 2483–2492. [Google Scholar] [CrossRef]

- Xiao, J.; Chen, L.; Pan, F.; Deng, Y.; Ding, C.; Liao, M.; Su, X.; Cao, H. Application method affects pesticide efficiency and effectiveness in wheat fields. Pest Manag. Sci. 2020, 76, 1256–1264. [Google Scholar] [CrossRef]

- Wang, J.; Lan, Y.; Wen, S.; Hewitt, A.J.; Yao, W.; Chen, P. Meteorological and flight altitude effects on deposition, penetration, and drift in pineapple aerial spraying. Asia-Pac. J. Chem. Eng. 2020, 15, e2382. [Google Scholar] [CrossRef]

- Li, X.; Giles, D.K.; Niederholzer, F.J.; Andaloro, J.T.; Lang, E.B.; Watson, L.J. Evaluation of an unmanned aerial vehicle as a new method of pesticide application for almond crop protection. Pest Manag. Sci. 2021, 77, 527–537. [Google Scholar] [CrossRef]

- Wang, G.; Han, Y.; Li, X.; Andaloro, J.; Chen, P.; Hoffmann, W.C.; Han, X.; Chen, S.; Lan, Y. Field evaluation of spray drift and environmental impact using an agricultural unmanned aerial vehicle (UAV) sprayer. Sci. Total Environ. 2020, 737, 139793. [Google Scholar] [CrossRef] [PubMed]

- Matese, A.; Toscano, P.; Di Gennaro, S.; Genesio, L.; Vaccari, F.; Primicerio, J.; Belli, C.; Zaldei, A.; Bianconi, R.; Gioli, B. Intercomparison of UAV, Aircraft and Satellite Remote Sensing Platforms for Precision Viticulture. Remote Sens. 2015, 7, 2971–2990. [Google Scholar] [CrossRef] [Green Version]

- Sozzi, M.; Kayad, A.; Gobbo, S.; Cogato, A.; Sartori, L.; Marinello, F. Economic Comparison of Satellite, Plane and UAV-Acquired NDVI Images for Site-Specific Nitrogen Application: Observations from Italy. Agronomy 2021, 11, 2098. [Google Scholar] [CrossRef]

- Abd. Kharim, M.N.; Wayayok, A.; Mohamed Shariff, A.R.; Abdullah, A.F.; Husin, E.M. Droplet deposition density of organic liquid fertilizer at low altitude UAV aerial spraying in rice cultivation. Comput. Electron. Agric. 2019, 167, 105045. [Google Scholar] [CrossRef]

- Wang, C.; Zeng, A.; He, X.; Song, J.; Herbst, A.; Gao, W. Spray drift characteristics test of unmanned aerial vehicle spray unit under wind tunnel conditions. Int. J. Agric. Biol. Eng. 2020, 13, 13–21. [Google Scholar] [CrossRef]

- Filho, F.H.; Heldens, W.B.; Kong, Z.; de Lange, E.S. Drones: Innovative Technology for Use in Precision Pest Management. J. Econ. Entomol. 2020, 113, 1–25. [Google Scholar] [CrossRef] [Green Version]

- Ali, H.; Zaheer, A.; Khan, S.; Ahmed, N.; Fayyaz, A. A hazard-free framework for aerial distribution of pesticides on agricultural land. Mehran Univ. Res. J. Eng. Technol. 2020, 39, 548–553. [Google Scholar] [CrossRef]

- Wen, S.; Han, J.; Ning, Z.; Lan, Y.; Yin, X.; Zhang, J.; Ge, Y. Numerical analysis and validation of spray distributions disturbed by quad-rotor drone wake at different flight speeds. Comput. Electron. Agric. 2019, 166, 105036. [Google Scholar] [CrossRef]

- Sarri, D.; Martelloni, L.; Rimediotti, M.; Lisci, R.; Lombardo, S.; Vieri, M. Testing a multi-rotor unmanned aerial vehicle for spray application in high slope terraced vineyard. J. Agric. Eng. 2019, 50, 38–47. [Google Scholar] [CrossRef]

- Ministerio de la Presidencia. Real Decreto 1036/2017: Por el que se Regula la Utilización Civil de Aeronaves Pilotadas por Control Remoto, y se Modifica el Real Decreto 552/2014; Ministerio de la Presidencia: Madrid, Spain, 2017; Available online: https://www.boe.es/eli/es/rd/2017/12/15/1036 (accessed on 4 December 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).