Greenhouse Thermal Effectiveness to Produce Tomatoes Assessed by a Temperature-Based Index

Abstract

:1. Introduction

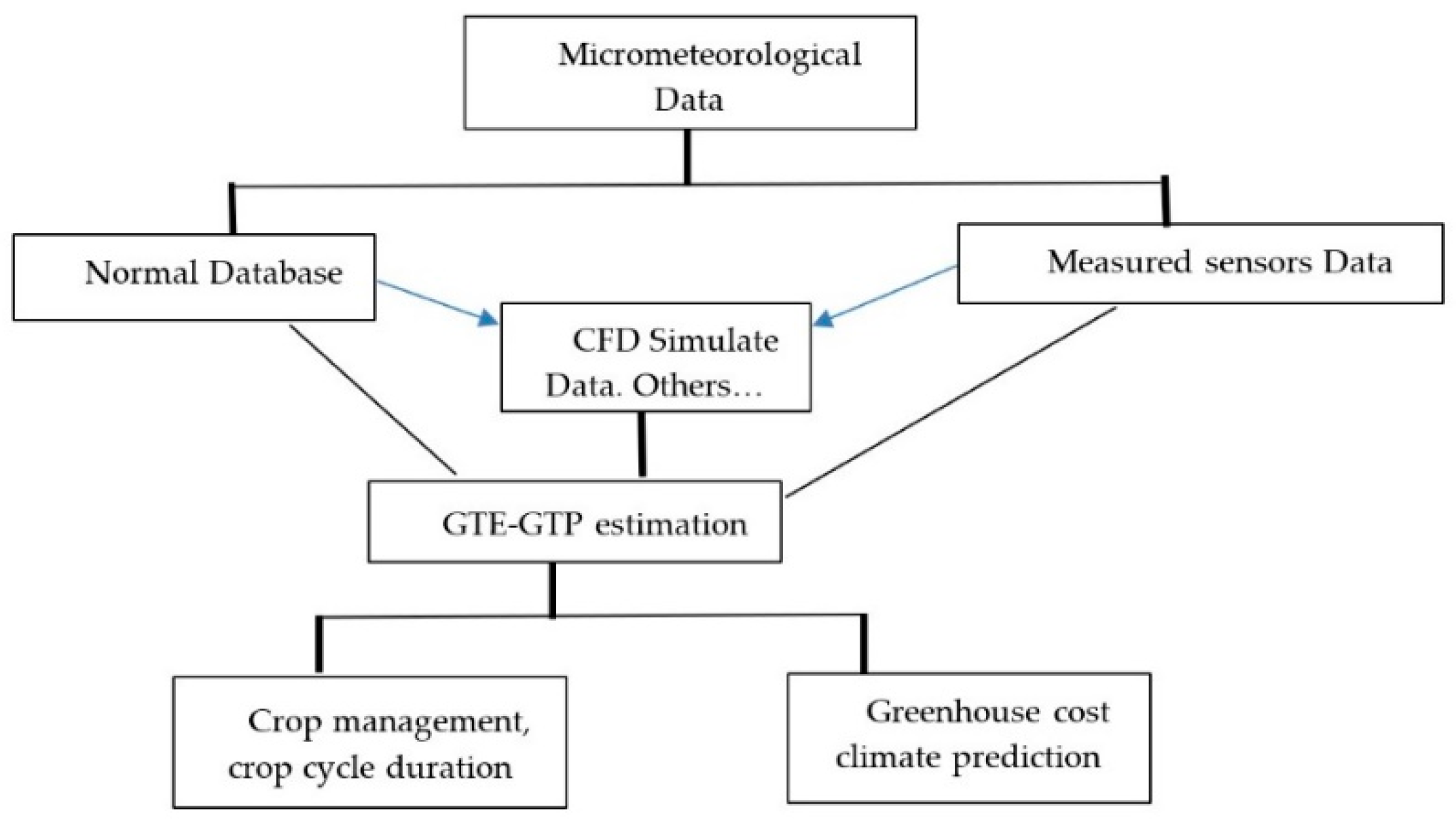

2. Materials and Methods

2.1. Theory of the Thermal Index in Crops

2.2. Error Function Complementary (erfc) Conceptual Applications

2.3. Temperature Database Used to Estimate GTE

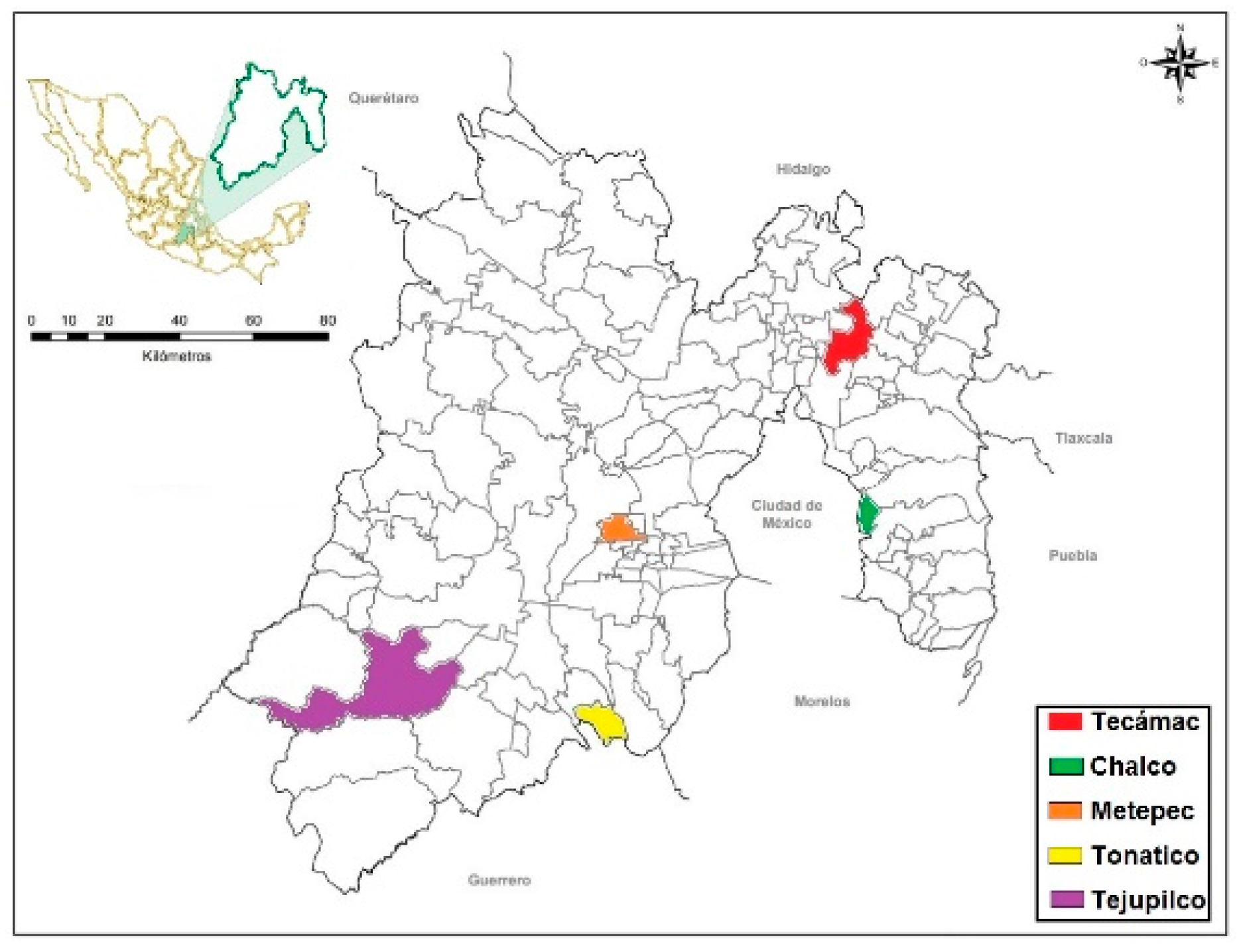

2.4. Estimation of GTE and Extrapolation to the State of Mexico (Central Mexico)

3. Results

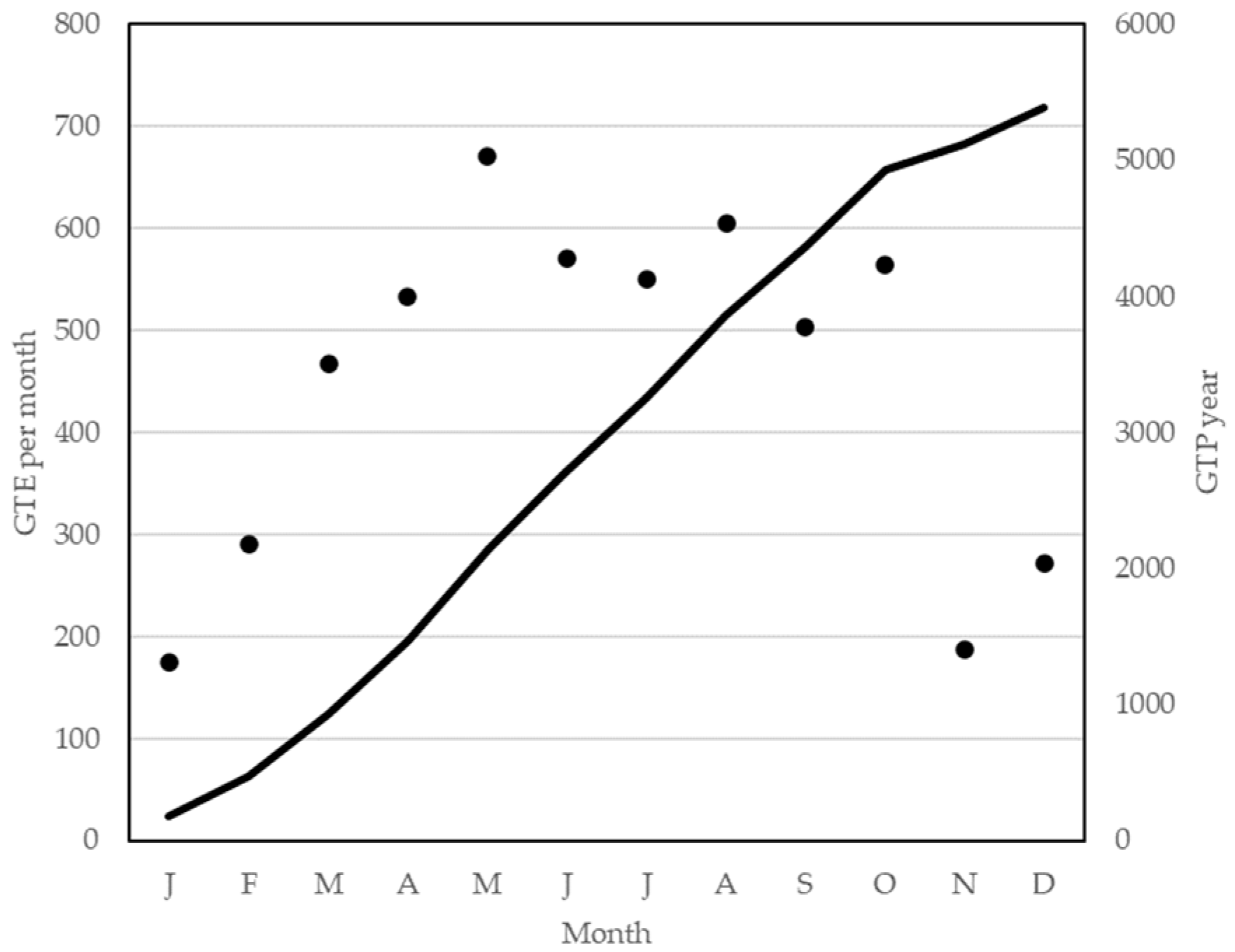

3.1. Greenhouse Thermal Effectiveness Estimation and Comparative Results

3.2. Greenhouse Thermal Effectiveness by Using the Database of Temperature

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

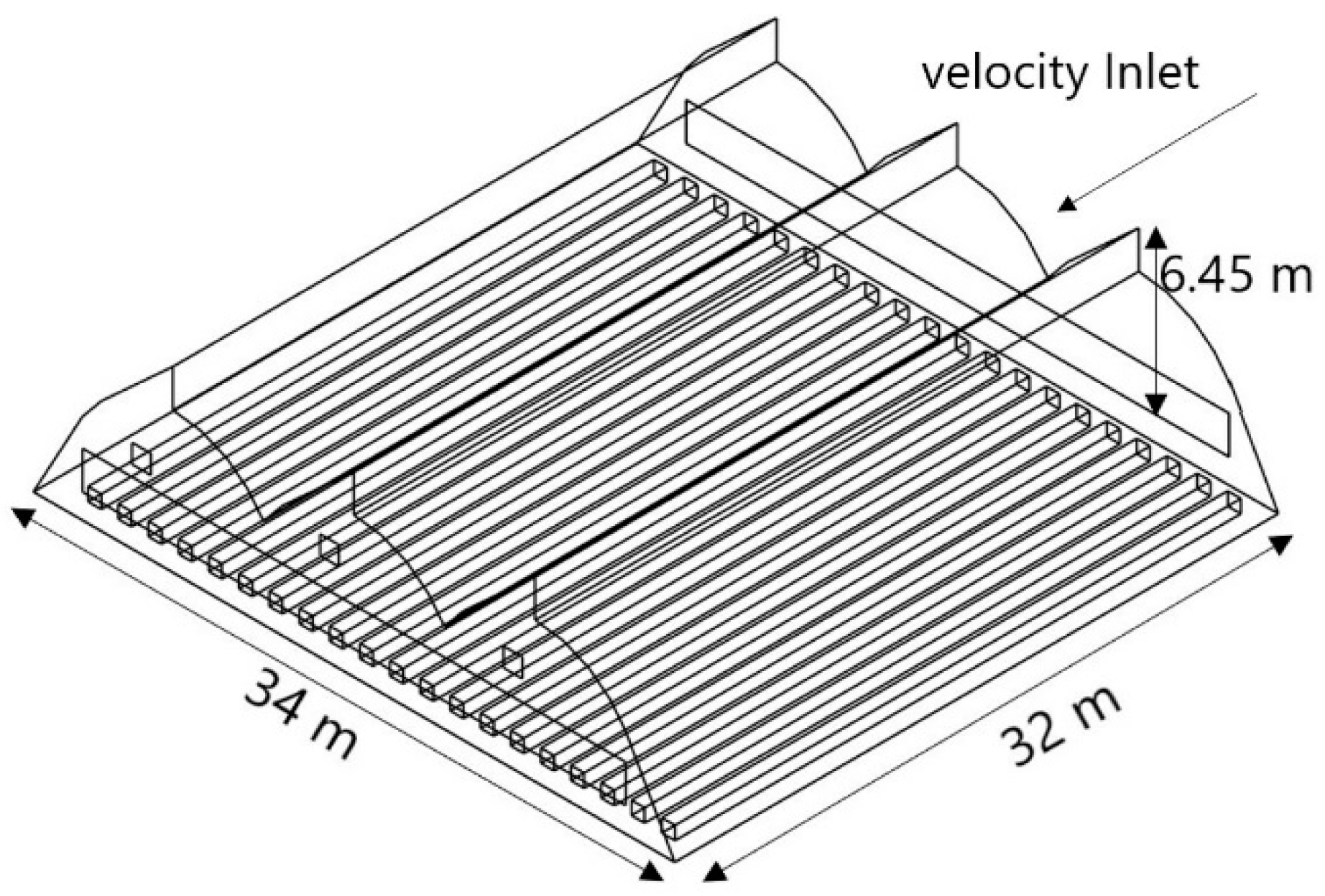

Appendix A. CFD Model

| Boundary Conditions | Method |

|---|---|

| Solver | Pressure-based |

| State | Steady |

| Viscosity function | k-ε Standard |

| Energy equation | Activated |

| Entry | Velocity inlet |

| Output | Pressure outlet |

| Air temperature | Constant (22.55 °C) |

| Wind speed | Constant (2.41 m s−1) |

| Porous jump | Permeability face |

| Thin porous media | |

| Drag coefficient | |

| Heat source | Boussinesq’s hypothesis |

| Soil thermal condition | Constant (200 W m−2) |

| Sensors | Experimental | Simulated |

|---|---|---|

| 1 | 25.5 | 24.9 |

| 2 | 25.7 | 25.5 |

| 3 | 28.5 | 25.1 |

| 4 | 26.3 | 23.9 |

| 5 | 25.7 | 26.6 |

References

- Moreno, R.A.; Aguilar, D.J.; Luévano, G.A. Características de la agricultura protegida y su entorno en México. Rev. Mex. Agroneg. 2011, 15, 763–774. [Google Scholar]

- Doan, C.C.; Tanaka, M. Relationships between Tomato Cluster Growth Indices and Cumulative Environmental Factors during Greenhouse Cultivation. Sci. Hortic. 2022, 295, 110803. [Google Scholar] [CrossRef]

- Park, S.; Shim, J.; Song, D. Issues in calculation of balance-point temperatures for heating degree-days for the development of building-energy policy. Renew. Sustain. Energy Rev. 2021, 135, 110211. [Google Scholar] [CrossRef]

- Aguilar-Rodriguez, C.E.; Flores-Velazquez, J.; Ojeda-Bustamante, W.; Rojano, F.; Iñiguez-Covarrubias, M. Valuation of the Energy Performance of a Greenhouse with an Electric Heater Using Numerical Simulations. Processes 2020, 8, 600. [Google Scholar] [CrossRef]

- Flores-Velázquez, J.; Vega-García, M. Regional management of the environment in a zenith greenhouse with computational fluid dynamics (CFD). Ing. Agríc. Biosist. 2019, 11, 3–20. [Google Scholar] [CrossRef]

- Decano-Valentin, C.; Lee, I.B.; Yeo, U.H.; Lee, S.Y.; Kim, J.G.; Park, S.J.; Choi, Y.B.; Cho, J.H.; Jeong, H.H. Integrated Building Energy Simulation–Life Cycle Assessment (BES–LCA) Approach for Environmental Assessment of Agricultural Building: A Review and Application to Greenhouse Heating Systems. Agronomy 2021, 11, 1230. [Google Scholar] [CrossRef]

- Villagran, E.; Bojacá, C.; Akrami, M. Contribution to the Sustainability of Agricultural Production in Greenhouses Built on Slope Soils: A Numerical Study of the Microclimatic Behavior of a Typical Colombian Structure. Sustainability 2021, 13, 4748. [Google Scholar] [CrossRef]

- Rabbi, B.; Chen, Z.H.; Sethuvenkatraman, S. Protected Cropping in Warm Climates: A Review of Humidity Control and Cooling Methods. Energies 2019, 12, 2737. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.Y.; Lee, I.B.; Lee, S.N.; Yeo, U.H.; Kim, J.G.; Kim, R.W.; Decano-Valentin, C. Dynamic Energy Exchange Modelling for a Plastic-Covered Multi-Span Greenhouse Utilizing a Thermal Effluent from Power Plant. Agronomy 2021, 11, 1461. [Google Scholar] [CrossRef]

- Reza, H.; Morteza, T.; Rostam, F.; Mehrdad, H.; Anthony, H. Energy-economic-environmental cycle evaluation comparing two polyethylene and polycarbonate plastic greenhouses in cucumber production (from production to packaging and distribution). Sci. Total Environ. 2022, 828, 154232. [Google Scholar]

- Latin American and Caribbean Demographic Centre CELADE. World Population and Latin America and the Caribbean Population: Changes and New (Im) Balances; Astrolabio, Universidad Nacional de Cordoba. Argentina No. 8; Universidad Nacional de Córdoba: Córdoba, Argentina, 2012. [Google Scholar]

- Nurdan, Y.; Levent, B. Evaluation of a hybrid system for a nearly zero energy greenhouse. Energy Convers. Manag. 2017, 148, 1278–1290. [Google Scholar]

- Mukesh, K.; Didier, H.; Stéphane, G. Survey and evaluation of solar technologies for agricultural greenhouse application. Sol. Energy 2022, 232, 18–34. [Google Scholar]

- Farzin, G.; Niko, H.; Stefanie, H.; Ramin, R. A novel integrated framework to evaluate greenhouse energy demand and crop yield production. Renew. Sustain. Energy Rev. 2018, 96, 487–501. [Google Scholar]

- Shen, Y.; Wei, R.; Xu, L. Energy Consumption Prediction of a Greenhouse and Optimization of Daily Average Temperature. Energies 2018, 11, 65. [Google Scholar] [CrossRef] [Green Version]

- Naderi, S.A.; Dehkordi, A.L.; Taki, M. Energy and Environmental Evaluation of Greenhouse Bell Pepper Production with Life Cycle Assessment Approach. Environ. Sustain. Indic. 2019, 3, 100011. [Google Scholar] [CrossRef]

- Samaranayake, P.; Liang, W.; Chen, Z.-H.; Tissue, D.; Lan, Y.-C. Sustainable Protected Cropping: A Case Study of Seasonal Impacts on Greenhouse Energy Consumption during Capsicum Production. Energies 2020, 13, 4468. [Google Scholar] [CrossRef]

- Al-Kodmany, K. The Vertical Farm: A Review of Developments and Implications for the Vertical City. Buildings 2018, 8, 24. [Google Scholar] [CrossRef] [Green Version]

- Flores-Velazquez, J.; Aguilar, R.C.E.; Ojeda, W.; Rojano, F. CFD index for temperature greenhouse characterization. In Proceedings of the 2018 ASABE Annual International Meeting, Detroit, MI, USA, 29 July–1 August 2018. [Google Scholar]

- Armendáriz-Erives, S. Desafíos y riesgos agrícolas ante el calentamiento global. In Oportunidades y Retos de la Ingeniería Agrícola Ante la Globalización y el Cambio Climático; UACH-URUZA: Durango, Mexico, 2007; pp. 73–79. [Google Scholar]

- Thom, H.C.S. Seasonal Degree-day statistic for the United States. Mon. Weather Rev. 1952, 80, 143–149. [Google Scholar] [CrossRef] [Green Version]

- Thom, H.C.S. The rational relationship between heating degree-day and Temperature. Mon. Weather Rev. 1954, 82, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Thom, H.C.S. Some Methods of Climatological Analysis; WMO Technical Note Number 81; Secretariat of the World Meteorological Organization: Geneva, Switzerland, 1956; p. 53. [Google Scholar]

- Shamshiri, R.; Jones, J.W.; Thorp, K.; Ahmad, D.; Man, H.; Taheri, S. Microclimate evaluation and control in greenhouse cultivation of tomato: A review. Int. Agrophys. 2018, 32, 287–302. [Google Scholar] [CrossRef]

- Lin, D.; Wei, R.; Xu, L. An integrated yield prediction model for greenhouse tomato. Agronomy 2019, 9, 873. [Google Scholar] [CrossRef] [Green Version]

- Marcelis, L.F.M.; Buwalda, F.; Dieleman, J.A.; Dueck, T.A.; Elings, A.; de Gelder, A.; Hemming, S.; Kempkes, F.L.K.; Li, T.; van Noort, F.; et al. Innovations in crop production: A matter of physiology and technology. Acta Hortic. 2014, 1037, 39–45. [Google Scholar] [CrossRef]

- Almanza-Merchán, P.J.; Arévalo, Y.A.; Cely, R.G.E.; Pinzón, E.H.; Serrano, C.P.A. Caracterización del crecimiento del fruto de tomate (Solanum lycopersicum L.) híbrido ‘Ichiban’ cultivado bajo cubierta. Agron. Colomb. 2016, 34, 155–162. [Google Scholar] [CrossRef]

- Ardila, G.; Fischer, G.; Balaguera-López, H.E. Caracterización del Crecimiento del Fruto y Producción de Tres Híbridos de Tomate (Solanum lycopersicum L.) en Tiempo Fisiológico Bajo Invernadero. Rev. Colomb. Cienc. Hortíc. 2011, 5, 44–56. [Google Scholar] [CrossRef] [Green Version]

- Holmes, C.; Tett, S.; Butler, A. What is the uncertainty in degree-day projections due to different calibration methodologies? J. Clim. 2017, 30, 9059–9075. [Google Scholar] [CrossRef]

- Ojeda-Bustamante, W.; Sifuentes-Ibarra, E.; Slack, D.C.; Carrillo, M. Generalization of Irrigation Scheduling Parameters Using the Growing Degree Days Concept: Application to a Potato Crop. Irrig. Drain. 2004, 53, 251–261. [Google Scholar] [CrossRef]

- Aguilar-Rodriguez, C.E.; Flores-Velazquez, J.; Rojano-Aguilar, F.; Ojeda-Bustamante, W.; Iñiguez-Covarrubias, M. Crop cycle estimation in greenhouse, based on degree day heat (GDC) simulated in CFD. Tecnol. Cienc. Agua 2020, 11, 27–57. [Google Scholar]

- Atilgan, A.; Tezcan, A. Evaluation of Temperature Data Usage the Method of Degree-Hour in Greenhouses: Pepper Plant Case. Sci. Pap. Ser. B Hortic. J. 2017, 61, 287–292. [Google Scholar]

- Mourshed, M. Relationship Between Annual Mean Temperature and Degree-Days. Energy Build. 2012, 54, 418–425. [Google Scholar] [CrossRef] [Green Version]

- Coskun, C.; Ertürk, M.; Oktay, Z.; Hepbasli, A. A new approach to determine the outdoor temperature distributions for building energy calculations. Energy Convers. Manag. 2014, 78, 165–172. [Google Scholar] [CrossRef]

- Djebli, A.; Hanini, S.; Badaoui, O.; Haddad, B.; Benhamou, A. Modeling and comparative analysis of solar drying behavior of potatoes. Renew. Energy 2020, 145, 1494–1506. [Google Scholar] [CrossRef]

- Yildiz, I.; Sosaoglu, B. Spatial Distributions of Heating, Cooling, and Industrial Degree-Days in Turkey. Theor. Appl. Climatol. 2007, 90, 249–261. [Google Scholar] [CrossRef] [Green Version]

- Jones, J.W.; Kenig, A.; Vallejos, C.E. Reduced state–Variable tomato growth model. ASABE 1999, 42, 255–265. [Google Scholar] [CrossRef]

- Atherton, J.G.; Rudich, J. The Tomato Crop; Chapman and Hall: London, UK; New York, NY, USA, 1986; p. 661. [Google Scholar]

- Heuvelink, E. Influence of day and night temperature on the growth of young tomato plants. Sci. Hortic. 1989, 38, 11–22. [Google Scholar] [CrossRef]

- De Koning, A.N.M. Long term temperature integration of tomato. Growth and development under alternating temperature regimes. Sci. Hortic. 1990, 45, 117–127. [Google Scholar] [CrossRef]

- Körner, O.; Challa, H. Design for an improved temperature integration concept in greenhouse cultivation. Comput. Electron. Agric. 2003, 39, 39–59. [Google Scholar] [CrossRef]

- Tesi, R. Medios de Protección Para la Hortofloro Fruticultura y el Viverismo; Mundi-Prensa: Madrid, Spain, 2001; p. 288. [Google Scholar]

- Anandhi, A. Growing degree days—Ecosystem indicator for changing diurnal temperatures and their impact on corn growth stages in Kansas. Ecol. Indic. 2016, 61, 149–158. [Google Scholar] [CrossRef] [Green Version]

- Pathak, T.B.; Stoddard, C.S. Climate change effects on the processing tomato growing season in California using growing degree day model. Model. Earth Syst. Environ. 2018, 4, 765–775. [Google Scholar] [CrossRef]

- Grigorieva, E.; Matzarakis, A.; De Freitas, C. Analysis of growing degree-days as climate impact indicator in a region with extreme annual air temperature amplitude. Clim. Res. 2010, 42, 143–154. [Google Scholar] [CrossRef] [Green Version]

- Semple, L.; Carriveau, R.; Ting, D. Assessing heating and cooling demands of closed greenhouse systems in a cold climate. Int. J. Energy Res. 2017, 41, 1903–1913. [Google Scholar] [CrossRef]

- Soussi, M.; Chaibi, M.T.; Buchholz, M.; Saghrouni, Z. Comprehensive Review on Climate Control and Cooling Systems in Greenhouses under Hot and Arid Conditions. Agronomy 2022, 12, 626. [Google Scholar] [CrossRef]

- Kraemer, M.E.; Mullins, C.D.; Nidziela, C.E., Jr. Effect of greenhouse temperature on tomato yield and ripening. Va. J. Sci. 2012, 63, 4–14. [Google Scholar]

- Deaño, A.; Temme, N.M. Analytical and numerical aspects of a generalization of the complementary error function. Appl. Math. Comput. 2010, 216, 3680–3693. [Google Scholar] [CrossRef] [Green Version]

- Li, S.W.; Li, H.; Han, X.; Ma, Y. Development and validation of a model for whole course aging of nickel added to a wide range of soils using a complementary error function. Geoderma 2019, 348, 54–59. [Google Scholar] [CrossRef]

- Faridi, H.; Arabhosseini, A.; Zarei, G.; Okos, M. Degree-Day Index for Estimating the Thermal Requirements of a Greenhouse Equipped with an Air-Earth Heat Exchanger System. J. Agric. Mach. 2021, 11, 83–95. [Google Scholar]

- Lebedev, N.N. Special Functions and their Applications. Am. Math. Mon. 1966, 1, 308. [Google Scholar] [CrossRef]

- Chevillard, S. The functions erf and erfc computed with arbitrary precision and explicit error bounds. Inf. Comput. 2012, 216, 72–95. [Google Scholar] [CrossRef] [Green Version]

- Hannan, J.J. Greenhouses, Advanced Technology for Protected Horticulture; CRC Press: Boca Raton, FL, USA, 1997; 708p. [Google Scholar]

- Sato, S.; Peet, M.M.; Thomas, J.F. Physiological factors limit fruit set tomate (Lycopersicon esculentum Mill.) under chronic, mild heat stress. Plant Cell Environ. 2000, 23, 719–726. [Google Scholar] [CrossRef]

- Abramowitz, M.; Stegun, I. Handbook of Mathematical Function; Dover: New York, NY, USA, 1972; p. 299. [Google Scholar]

- Flores-Velazquez, J.; Ojeda-Bustamante, W.; Salazar, I.; Rojano, A.; López, I. Water Requirements for Greenhouse Tomato. Terra Latinoam. 2007, 25, 127–134. [Google Scholar]

- SAGARPA-SIAP. Superficie Agrícola Protegida. 2017. Available online: http://www.sagarpa.gob.mx/quienesomos/datosabiertos/siap/Paginas/superficie_agricola_protegida.aspx (accessed on 10 November 2018).

- Silva, R.C.D.; Cordeiro, J.J.; Pandorfi, H.; Vigoderis, R.B.; Guiselini, C. Simulation of ventilation systems in a protected environment using computational fluid dynamics. Eng. Agrıc. 2017, 37, 414–425. [Google Scholar] [CrossRef]

- Saberian, A.; Sajadiye, S.M. The effect of dynamic solar heat load on the greenhouse microclimate using CFD simulation. Renew. Energy 2019, 138, 722–737. [Google Scholar] [CrossRef]

| Climatic Station | Temperature (°C) | Calculated GTP by Period | |||

|---|---|---|---|---|---|

| Annual Mean | Monthly Maximum | Monthly Minimum | Spring– Summer | Autumn– Winter | |

| Chalco | 14.1 | 25.2 | 1.4 | 2361 | 437 |

| Tecamac | 15.6 | 26.9 | 1.8 | 2952 | 972 |

| Tonatico | 20.0 | 32.4 | 8.3 | 4463 | 2468 |

| Metepec | 13.2 | 25 | −1.7 | 1783 | 352 |

| Tejupilco | 20.9 | 32.6 | 10.6 | 4579 | 2798 |

| GTE (%) | Chalco | Tecamac | Tonatico | Metepec | Tejupilco | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| S–S | A–W | S–S | A–W | S–S | A–W | S–S | A–W | S–S | A–W | |

| 0–20 | - | 78 | - | 1 | - | - | - | 102 | - | - |

| 20–40 | - | 49 | - | 75 | - | - | 24 | 39 | - | - |

| 40–60 | 29 | 37 | 14 | 35 | - | - | 111 | 10 | - | - |

| 60–80 | 147 | - | 32 | 28 | - | 7 | 79 | - | - | 4 |

| 80–100 | 38 | - | 168 | 10 | 214 | 144 | - | - | 214 | 147 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Flores-Velázquez, J.; Rojano, F.; Aguilar-Rodríguez, C.E.; Villagran, E.; Villarreal-Guerrero, F. Greenhouse Thermal Effectiveness to Produce Tomatoes Assessed by a Temperature-Based Index. Agronomy 2022, 12, 1158. https://doi.org/10.3390/agronomy12051158

Flores-Velázquez J, Rojano F, Aguilar-Rodríguez CE, Villagran E, Villarreal-Guerrero F. Greenhouse Thermal Effectiveness to Produce Tomatoes Assessed by a Temperature-Based Index. Agronomy. 2022; 12(5):1158. https://doi.org/10.3390/agronomy12051158

Chicago/Turabian StyleFlores-Velázquez, Jorge, Fernando Rojano, Cruz Ernesto Aguilar-Rodríguez, Edwin Villagran, and Federico Villarreal-Guerrero. 2022. "Greenhouse Thermal Effectiveness to Produce Tomatoes Assessed by a Temperature-Based Index" Agronomy 12, no. 5: 1158. https://doi.org/10.3390/agronomy12051158

APA StyleFlores-Velázquez, J., Rojano, F., Aguilar-Rodríguez, C. E., Villagran, E., & Villarreal-Guerrero, F. (2022). Greenhouse Thermal Effectiveness to Produce Tomatoes Assessed by a Temperature-Based Index. Agronomy, 12(5), 1158. https://doi.org/10.3390/agronomy12051158