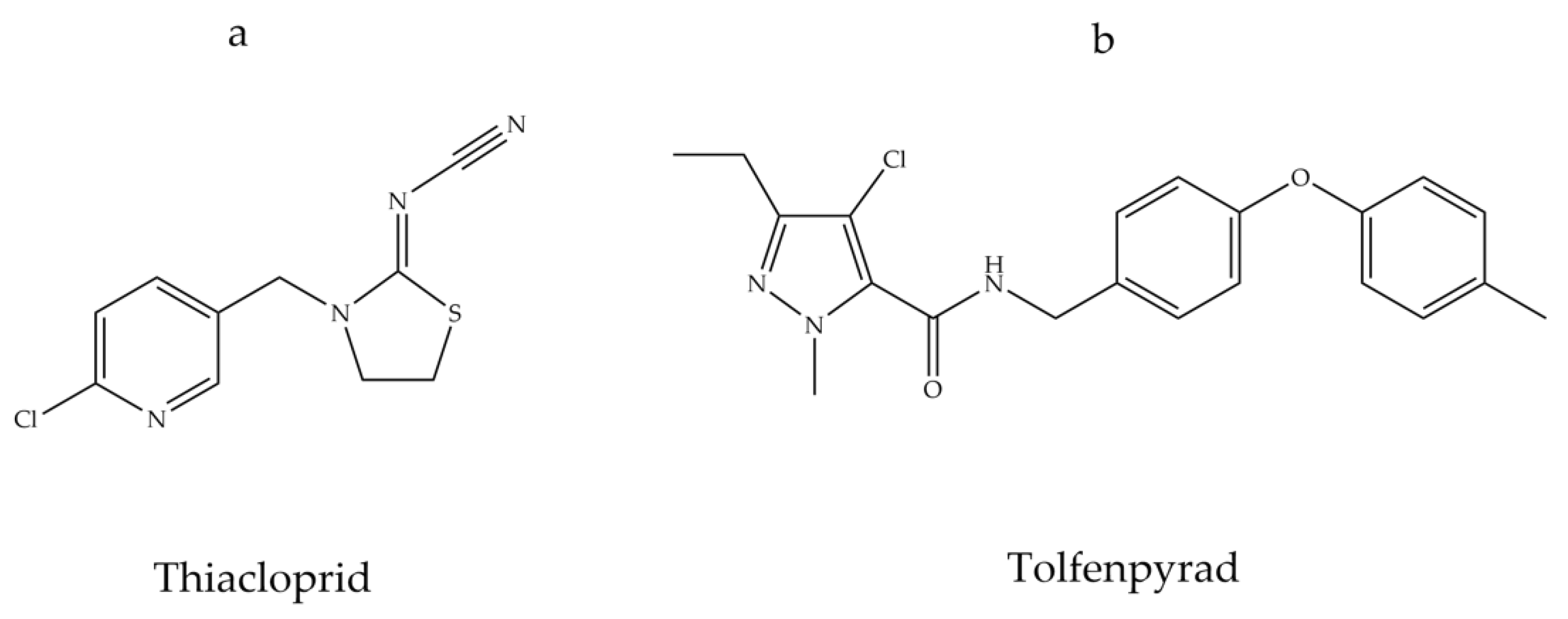

Dissipation and Dietary Risk Assessment of Thiacloprid and Tolfenpyrad in Tea in China

Abstract

:1. Introduction

2. Materials and Methods

2.1. Mateirals and Reagents

2.2. Field Trials

2.3. Preparation of the Tea Samples

2.4. UHPLC–MS/MS Analysis

2.5. Method Validation

2.6. Dissipation Dynamics of Thiacloprid and Tolfenpyrad

2.7. Dietary Risk Assessment

3. Results and Discussion

3.1. Validation of the Method

3.1.1. Matrix Effect, Linearity, and LOQ Values

3.1.2. Accuracy and Precision

3.2. Dissipation Dynamics of Thiacloprid and Tolfenpyrad

3.3. Terminal Residues of Thiacloprid and Tolfenpyrad in Tea

3.4. Dietary Exposure Risk Assessment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yan, P.; Shen, C.; Zou, Z.; Fan, L.; Li, X.; Zhang, L.; Zhang, L.; Dong, C.; Fu, J.; Han, W. Increased soil fertility in tea gardens leads to declines in fungal diversity and complexity in subsoils. Agronomy 2022, 12, 1751. [Google Scholar] [CrossRef]

- Xing, W.; Zhou, C.; Li, J.; Wang, W.; He, J.; Tu, Y.; Cao, X.; Zhang, Y. Suitability evaluation of tea cultivation using machine learning technique at town and village scales. Agronomy 2022, 12, 2010. [Google Scholar] [CrossRef]

- Bag, S.; Mondal, A.; Majumder, A.; Banik, A. Tea and its phytochemicals: Hidden health benefits & modulation of signaling cascade by phytochemicals. Food Chem. 2022, 371, 131098. [Google Scholar] [PubMed]

- Abunofal, O.; Mohan, C. Salubrious effects of green tea catechins on fatty liver disease: A systematic review. Medicines 2022, 9, 20. [Google Scholar] [CrossRef] [PubMed]

- Paiva, L.; Rego, C.; Lima, E.; Marcone, M.; Baptista, J. Comparative analysis of the polyphenols, caffeine, and antioxidant activities of green tea, white tea, and flowers from azorean camellia sinensis varieties affected by different harvested and processing conditions. Antioxidants 2021, 10, 183. [Google Scholar] [CrossRef]

- Prema, P.; Boobalan, T.; Arun, A.; Rameshkumar, K.; Babu, R.S.; Veeramanikandan, V.; Nguyen, V.-H.; Balaji, P. Green tea extract mediated biogenic synthesis of gold nanoparticles with potent anti-proliferative effect against pc-3 human prostate cancer cells. Mater. Lett. 2022, 306, 130882. [Google Scholar] [CrossRef]

- Wan, J.; Feng, M.; Pan, W.; Zheng, X.; Xie, X.; Hu, B.; Teng, C.; Wang, Y.; Liu, Z.; Wu, J. Inhibitory effects of six types of tea on aging and high-fat diet-related amyloid formation activities. Antioxidants 2021, 10, 1513. [Google Scholar] [CrossRef]

- Qi, Y.; Zhang, H.; Zhang, H.; Wu, G.; Wang, L.; Qian, H.; Qi, X. Epicatechin adducting with 5-hydroxymethylfurfural as an inhibitory mechanism against acrylamide formation in maillard reactions. J. Agric. Food Chem. 2018, 66, 12536–12543. [Google Scholar] [CrossRef]

- Tu, A.; Lin, J.; Lee, C.; Chen, Y.; Wu, J.; Tsai, M.; Cheng, K.; Hsieh, C.-W. Reduction of 3-deoxyglucosone by epigallocatechin gallate results partially from an addition reaction: The possible mechanism of decreased 5-hydroxymethylfurfural in epigallocatechin gallate-treated black garlic. Molecules 2021, 26, 4746. [Google Scholar] [CrossRef]

- Lee, S.H.; Lin, S.R.; Chen, S.F. Identification of tea foliar diseases and pest damage under practical field conditions using a convolutional neural network. Plant Pathol. 2020, 69, 1731–1739. [Google Scholar] [CrossRef]

- Zhong, Q.; Li, H.; Wang, M.; Luo, F.; Wang, X.; Yan, H.; Cang, T.; Zhou, L.; Chen, Z.; Zhang, X. Enantioselectivity of indoxacarb during the growing, processing, and brewing of tea: Degradation, metabolites, and toxicities. Sci. Total Environ. 2022, 823, 153763. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.; Duan, T.; Kaium, A.; Li, X. Dissipation and dietary risk assessment of carbendazim and epoxiconazole in citrus fruits in china. J. Sci. Food Agric. 2022, 102, 1415–1421. [Google Scholar] [CrossRef]

- Kabir, M.H.; Abd El-Aty, A.; Rahman, M.M.; Kim, S.W.; Choi, J.H.; Lee, Y.J.; Truong, L.T.; Lee, K.B.; Kim, M.R.; Shin, H.C. The disappearance rate and risk assessment of thiacloprid residues in asian pear using liquid chromatography confirmed with tandem mass spectrometry. Biomed. Chromatogr. 2017, 31, e3861. [Google Scholar] [CrossRef]

- Wang, X.; Anadón, A.; Wu, Q.; Qiao, F.; Ares, I.; Martínez-Larrañaga, M.-R.; Yuan, Z.; Martínez, M.-A. Mechanism of neonicotinoid toxicity: Impact on oxidative stress and metabolism. Annu. Rev. Pharm. Toxicol. 2018, 58, 471–507. [Google Scholar] [CrossRef]

- Morrissey, C.A.; Mineau, P.; Devries, J.H.; Sanchez-Bayo, F.; Liess, M.; Cavallaro, M.C.; Liber, K. Neonicotinoid contamination of global surface waters and associated risk to aquatic invertebrates: A review. Environ. Int. 2015, 74, 291–303. [Google Scholar] [CrossRef]

- Crosby, E.B.; Bailey, J.M.; Oliveri, A.N.; Levin, E.D. Neurobehavioral impairments caused by developmental imidacloprid exposure in zebrafish. Neurotoxicol. Teratol. 2015, 49, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Hikiji, W.; Yamaguchi, K.; Saka, K.; Hayashida, M.; Ohno, Y.; Fukunaga, T. Acute fatal poisoning with tolfenpyrad. J. Forensic. Leg. Med. 2013, 20, 962–964. [Google Scholar] [CrossRef]

- Tang, T.; Zhao, M.; Wang, P.; Xiao, Y.; Huang, S.; Fu, W. Field efficacies and joint actions of beta-cyfluthrin mixed with thiamethoxam or tolfenpyrad against diaphorina citri (hemiptera: Liviidae). J. Environ. Entomol. 2020, 113, 2793–2799. [Google Scholar] [CrossRef]

- Stara, A.; Pagano, M.; Albano, M.; Savoca, S.; Di Bella, G.; Albergamo, A.; Koutkova, Z.; Sandova, M.; Velisek, J.; Fabrello, J.; et al. Effects of long-term exposure of mytilus galloprovincialis to thiacloprid: A multibiomarker approach. Environ. Pollut. 2021, 289, 117892. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, Z.; Li, J.; Wang, N.; Xue, C. Sublethal effects of tolfenpyrad on the development, reproduction, and predatory ability of chrysoperla sinica. Ecotoxicol. Environ. Saf. 2022, 236, 113482. [Google Scholar] [CrossRef]

- Salvaggio, A.; Antoci, F.; Messina, A.; Ferrante, M.; Copat, C.; Ruberto, C.; Scalisi, E.M.; Pecoraro, R.; Brundo, M.V. Teratogenic effects of the neonicotinoid thiacloprid on chick embryos (gallus gallus domesticus). Food Chem. Toxicol. 2018, 118, 812–820. [Google Scholar] [CrossRef] [PubMed]

- Hou, R.; Jiao, W.; Qian, X.; Wang, X.; Xiao, Y.; Wan, X. Effective extraction method for determination of neonicotinoid residues in tea. J. Agric. Food Chem. 2013, 61, 12565–12571. [Google Scholar] [CrossRef] [PubMed]

- Jiao, W.; Xiao, Y.; Qian, X.; Tong, M.; Hu, Y.; Hou, R.; Hua, R. Optimized combination of dilution and refined quechers to overcome matrix effects of six types of tea for determination eight neonicotinoid insecticides by ultra performance liquid chromatography–electrospray tandem mass spectrometry. Food Chem. 2016, 210, 26–34. [Google Scholar] [CrossRef] [PubMed]

- Ikenaka, Y.; Fujioka, K.; Kawakami, T.; Ichise, T.; Bortey-Sam, N.; Nakayama, S.M.M.; Mizukawa, H.; Taira, K.; Takahashi, K.; Kato, K.; et al. Contamination by neonicotinoid insecticides and their metabolites in sri lankan black tea leaves and japanese green tea leaves. Toxicol. Rep. 2018, 5, 744–749. [Google Scholar] [CrossRef] [PubMed]

- Sharma, N.; Banerjee, H.; Pal, S.; Sharma, K. Persistence of thiacloprid and deltamethrin residues in tea grown at different locations of north-east india. Food Chem. 2018, 253, 88–92. [Google Scholar] [CrossRef]

- Li, S.; Ren, J.; Li, L.; Chen, R.; Li, J.; Zhao, Y.; Chen, D.; Wu, Y. Temporal variation analysis and risk assessment of neonicotinoid residues from tea in china. Environ. Pollut. 2020, 266, 115119. [Google Scholar] [CrossRef]

- Yao, Q.; Yan, S.-A.; Li, J.; Huang, M.; Lin, Q. Health risk assessment of 42 pesticide residues in tieguanyin tea from Fujian, China. Drug Chem. Toxicol. 2022, 45, 932–939. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, X.; Wang, Z.; Zhou, L.; Luo, F.; Chen, Z. Dissipation behavior and risk assessment of tolfenpyrad from tea bushes to consuming. Sci. Total Environ. 2022, 806, 150771. [Google Scholar] [CrossRef]

- Bai, A.; Chen, A.; Chen, W.; Liu, S.; Luo, X.; Liu, Y.; Zhang, D. Residue behavior, transfer and risk assessment of tolfenpyrad, dinotefuran and its metabolites during tea growing and tea brewing. J. Sci. Food Agric. 2021, 101, 5992–6000. [Google Scholar] [CrossRef]

- Tong, Z.; Duan, J.; Wu, Y.; Liu, Q.; He, Q.; Shi, Y.; Yu, L.; Cao, H. A survey of multiple pesticide residues in pollen and beebread collected in china. Sci. Total Environ. 2018, 640–641, 1578–1586. [Google Scholar] [CrossRef]

- van Klaveren, J.D.; Boon, P.E. Probabilistic risk assessment of dietary exposure to single and multiple pesticide residues or contaminants: Summary of the work performed within the safe foods project. Food Chem. Toxicol. 2009, 47, 2879–2882. [Google Scholar] [CrossRef]

- Man, Y.; Zheng, Y.; Liu, X.; Dong, F.; Xu, J.; Wu, X.; Zheng, Y. Simultaneous determination of isofetamid and its two metabolites in fruits and vegetables using ultra-performance liquid chromatography with tandem mass spectrometry. Food Anal. Methods 2019, 12, 1487–1496. [Google Scholar] [CrossRef]

- Li, K.; Chen, W.; Xiang, W.; Chen, T.; Zhang, M.; Ning, Y.; Liu, Y.; Chen, A. Determination, residue analysis and risk assessment of thiacloprid and spirotetramat in cowpeas under field conditions. Sci. Rep. 2022, 12, 3470. [Google Scholar] [CrossRef]

- Dong, M.; Wen, G.; Tang, H.; Wang, T.; Zhao, Z.; Song, W.; Wang, W.; Zhao, L. Dissipation and safety evaluation of novaluron, pyriproxyfen, thiacloprid and tolfenpyrad residues in the citrus-field ecosystem. Food Chem. 2018, 269, 136–141. [Google Scholar] [CrossRef]

- Fang, Q.; Shi, Y.; Cao, H.; Tong, Z.; Xiao, J.; Liao, M.; Wu, X.; Hua, R. Degradation dynamics and dietary risk assessments of two neonicotinoid insecticides during lonicera japonica planting, drying, and tea brewing processes. J. Agric. Food Chem. 2017, 65, 1483–1488. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, S.; Huang, C.; Fu, J.; Huang, R.; Li, Z.; Zhang, Z. Dissipation and residue of clothianidin in granules and pesticide fertilizers used in cabbage and soil under field conditions. Environ. Sci. Pollut. Res. 2018, 25, 27–33. [Google Scholar] [CrossRef]

- Delcour, I.; Spanoghe, P.; Uyttendaele, M. Literature review: Impact of climate change on pesticide use. Food Res. Int. 2015, 68, 7–15. [Google Scholar] [CrossRef]

- JMPR (The Joint FAO/WHO Meeting on Pesticide Residues), JMPR Report Thiacloprid, No. 223. Available online: https://www.fao.org/fileadmin/templates/agphome/documents/Pests_Pesticides/JMPR/JMPRrepor2006.pdf (accessed on 15 October 2022).

- JMPR (The Joint FAO/WHO Meeting on Pesticide Residues), JMPR Report Tolfenpyrad, No. 269. Available online: https://www.fao.org/fileadmin/templates/agphome/documents/Pests_Pesticides/JMPR/Report2016/TOLFENPYRAD.pdf (accessed on 15 October 2022).

| Pesticide | Linear Range (mg/L) | Matrix | Regression Equation | R2 | ME (%) | LOQ (mg/kg) |

|---|---|---|---|---|---|---|

| Thiacloprid | 0.001–1.2 | Solvent | y = 246,672.429762 x + 701.808469 | 0.99074 | – | – |

| Fresh tea | y = 76,095.679815 x + 40.610964 | 0.99975 | −69 | 0.01 | ||

| Dry tea | y = 182,759.029991 x + 310.853573 | 0.99567 | −26 | 0.01 | ||

| Tolfenpyrad | Solvent | y = 401,114.462560 x + 141.779780 | 0.99985 | – | – | |

| Fresh tea | y = 350,454.841273 x + 64.389752 | 0.99952 | −13 | 0.01 | ||

| Dry tea | y = 425,190.369489 x − 152.466303 | 0.99684 | 6 | 0.01 |

| Spiked Concentrations (mg/kg) | Thiacloprid | Tolfenpyrad | ||||||

|---|---|---|---|---|---|---|---|---|

| Fresh Tea | Dry Tea | Fresh Tea | Dry Tea | |||||

| Recovery | RSD | Recovery | RSD | Recovery | RSD | Recovery | RSD | |

| 0.01 | 73 | 4.0 | 78 | 6.6 | 95 | 5.1 | 105 | 7.3 |

| 0.05 | 88 | 8.3 | 92 | 0.8 | 75 | 3.4 | 93 | 2.1 |

| 0.5 | 90 | 5.4 | 97 | 1.2 | 79 | 3.1 | 92 | 6.1 |

| 10 | 82 | 5.5 | 92 | 2.0 | – | – | – | – |

| 50 | – | – | – | – | 86 | 0.7 | 93 | 1.7 |

| 100 | 82 | 4.6 | 94 | 2.7 | 79 | 1.8 | 99 | 5.1 |

| Location | Collecting Time | Dry Tea | Fresh Tea | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Thiacloprid (mg/kg) | Degradation Rate (%) | Tolfenpyrad (mg/kg) | Degradation Rate (%) | Thiacloprid (mg/kg) | Degradation Rate (%) | Tolfenpyrad (mg/kg) | Degradation Rate (%) | ||

| Anhui | 0 d | 1.815 ± 0.027 | - | 7.963 ± 0.013 | - | 6.359 ± 0.350 | - | 3.266 ± 0.084 | - |

| 7 d | 0.205 ± 0.001 | 88.7 | 1.534 ± 0.027 | 80.7 | 0.444 ± 0.002 | 93.0 | 0.341 ± 0.009 | 89.6 | |

| 14 d | 0.175 ± 0.002 | 90.4 | 0.684 ± 0.002 | 91.4 | 0.356 ± 0.009 | 94.4 | 0.121 ± 0.006 | 96.3 | |

| 21 d | 0.179 ± 0.005 | 90.1 | 0.218 ± 0.018 | 97.3 | 0.053 ± 0.001 | 99.2 | 0.010 ± 0.001 | 99.7 | |

| 28 d | 0.015 ± 0.001 | 99.2 | 0.033 ± 0.001 | 99.6 | 0.010 ± 0.001 | 99.8 | <0.01 a | >99.7 | |

| Dissipation kinetic equations | Ct = 1.2333e−0.138t | Ct = 7.5532e−0.184t | Ct = 4.4789e−0.215t | Ct = 2.5008e−0.236t | |||||

| R2 | 0.9136 | 0.9915 | 0.9749 | 0.9920 | |||||

| Half-lives (days) | 5.02 | 3.76 | 3.22 | 2.94 | |||||

| Hubei | 0 d | 3.374 ± 0.002 | - | 15.977 ± 0.234 | - | 4.535 ± 0.022 | - | 2.792 ± 0.074 | - |

| 7 d | 0.701 ± 0.018 | 79.2 | 9.412 ± 0.088 | 41.1 | 2.289 ± 0.099 | 49.5 | 2.255 ± 0.020 | 19.2 | |

| 14 d | 0.334 ± 0.002 | 90.1 | 3.997 ± 0.092 | 75.0 | 0.444 ± 0.005 | 90.2 | 0.266 ± 0.010 | 90.5 | |

| 21 d | 0.162 ± 0.001 | 95.2 | 2.292 ± 0.051 | 85.6 | 0.317 ± 0.023 | 93.0 | 0.401 ± 0.017 | 85.6 | |

| 28 d | 0.164 ± 0.008 | 95.1 | 0.890 ± 0.035 | 94.4 | 0.701 ± 0.003 | 84.6 | 0.664 ± 0.002 | 76.2 | |

| Dissipation kinetic equations | Ct = 2.0766e−0.107t | Ct = 17.459e−0.103t | Ct = 3.1489e−0.082t | Ct = 2.1347e−0.066t | |||||

| R2 | 0.9271 | 0.9879 | 0.9312 | 0.8126 | |||||

| Half-lives (days) | 6.48 | 6.73 | 8.45 | 10.50 | |||||

| Guangxi | 0 d | 4.467 ± 0.080 | - | 23.032 ± 0.059 | - | 12.049 ± 0.207 | - | 6.623 ± 0.002 | - |

| 7 d | 0.316 ± 0.004 | 92.9 | 2.954 ± 0.039 | 87.2 | 0.932 ± 0.040 | 92.3 | 0.596 ± 0.017 | 91.0 | |

| 14 d | 0.182 ± 0.003 | 95.9 | 0.986 ± 0.020 | 95.7 | 0.569 ± 0.003 | 95.3 | 0.136 ± 0.001 | 97.9 | |

| 21 d | 0.074 ± 0.001 | 98.3 | 0.299 ± 0.008 | 98.7 | 0.527 ± 0.041 | 95.6 | 0.103 ± 0.002 | 98.4 | |

| 28 d | 0.059 ± 0.002 | 98.7 | 0.176 ± 0.003 | 99.2 | 0.203 ± 0.001 | 98.3 | 0.030 ± 0.001 | 99.5 | |

| Dissipation kinetic equations | Ct = 1.9412e−0.144t | Ct = 14.302e−0.172t | Ct = 5.3193e−0.129t | Ct = 3.4155e−0.179t | |||||

| R2 | 0.9198 | 0.9716 | 0.8892 | 0.9634 | |||||

| Half-lives (days) | 4.81 | 4.03 | 5.54 | 3.87 | |||||

| Fujian | 0 d | 1.921 ± 0.003 | - | 7.292 ± 0.083 | - | 6.595 ± 0.156 | - | 3.358 ± 0.162 | - |

| 7 d | 0.239 ± 0.007 | 87.6 | 1.371 ± 0.003 | 81.2 | 0.757 ± 0.052 | 88.5 | 0.387 ± 0.006 | 88.5 | |

| 14 d | 0.069 ± 0.001 | 96.4 | 0.196 ± 0.005 | 97.3 | 0.103 ± 0.009 | 98.4 | 0.021 ± 0.001 | 99.4 | |

| 21 d | 0.042 ± 0.001 | 97.8 | 0.078 ± 0.001 | 98.9 | 0.076 ± 0.002 | 98.9 | 0.010 ± 0.001 | 99.7 | |

| 28 d | 0.026 ± 0.001 | 98.6 | 0.041 ± 0.002 | 99.4 | 0.025 ± 0.001 | 99.6 | <0.01 a | >99.7 | |

| Dissipation kinetic equations | Ct = 1.0103e−0.147t | Ct = 5.1161e−0.189t | Ct = 3.6697e−0.192t | Ct = 1.8904e−0.238t | |||||

| R2 | 0.9479 | 0.9938 | 0.9794 | 0.9950 | |||||

| Half-lives (days) | 4.72 | 3.67 | 3.61 | 2.91 | |||||

| Location | Matrix | 14 d | 21 d | Matrix | 14 d | 21 d | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Thiacloprid (mg/kg) | Tolfenpyrad (mg/kg) | Thiacloprid (mg/kg) | Tolfenpyrad (mg/kg) | Thiacloprid (mg/kg) | Tolfenpyrad (mg/kg) | Thiacloprid (mg/kg) | Tolfenpyrad (mg/kg) | |||

| Anhui | Dry tea | 0.175 ± 0.002 | 0.684 ± 0.002 | 0.179 ± 0.005 | 0.218 ± 0.018 | Fresh tea | 0.356 ± 0.009 | 0.121 ± 0.006 | 0.053 ± 0.001 | 0.010 ± 0.001 |

| Hubei | 0.334 ± 0.002 | 3.997 ± 0.092 | 0.162 ± 0.001 | 2.292 ± 0.051 | 0.444 ± 0.005 | 0.266 ± 0.010 | 0.317 ± 0.023 | 0.401 ± 0.010 | ||

| Guangxi | 0.182 ± 0.003 | 0.986 ± 0.020 | 0.074 ± 0.001 | 0.299 ± 0.008 | 0.569 ± 0.003 | 0.136 ± 0.001 | 0.527 ± 0.041 | 0.103 ± 0.002 | ||

| Fujian | 0.069 ± 0.001 | 0.196 ± 0.005 | 0.042 ± 0.001 | 0.078 ± 0.001 | 0.103 ± 0.009 | 0.021 ± 0.001 | 0.076 ± 0.002 | 0.010 ± 0.001 | ||

| Shandong | 0.360 ± 0.010 | 1.893 ± 0.007 | 0.208 ± 0.008 | 0.478 ± 0.003 | 0.518 ± 0.007 | 0.078 ± 0.006 | 0.038 ± 0.008 | <0.01 a | ||

| Zhejiang | 1.226 ± 0.009 | 1.678 ± 0.005 | 0.927 ± 0.009 | 0.315 ± 0.009 | 1.304 ± 0.016 | 1.379 ± 0.011 | 1.104 ± 0.007 | 0.215 ± 0.006 | ||

| Hunan | 0.944 ± 0.019 | 1.899 ± 0.051 | 0.797 ± 0.011 | 2.347 ± 0.038 | 2.547 ± 0.070 | 0.576 ± 0.008 | 2.549 ± 0.014 | 0.457 ± 0.017 | ||

| Guizhou | 0.104 ± 0.007 | 0.282 ± 0.001 | 0.054 ± 0.001 | 0.080 ± 0.005 | 0.309 ± 0.009 | 0.050 ± 0.001 | 0.203 ± 0.014 | 0.017 ± 0.002 | ||

| Yunnan | 0.687 ± 0.023 | 3.367 ± 0.014 | 0.416 ± 0.001 | 0.497 ± 0.002 | 1.098 ± 0.020 | 1.204 ± 0.021 | 0.702 ± 0.009 | 0.459 ± 0.018 | ||

| Guangdong | 0.094 ± 0.008 | 0.276 ± 0.004 | 0.059 ± 0.006 | 0.075 ± 0.002 | 0.359 ± 0.004 | 0.054 ± 0.001 | 0.159 ± 0.008 | 0.018 ± 0.004 | ||

| Pesticide | PHI (Day) | ARfD (mg/kg bw) | ADI (mg/kg bw) | STMR (mg/kg) | HR (mg/kg) | RQa (%) | RQc (%) |

|---|---|---|---|---|---|---|---|

| Thiacloprid | 14 | 0.03 | 0.01 | 0.26 | 1.23 | 4.94 | 47.4 |

| 21 | 0.17 | 0.93 | 3.74 | 47.2 | |||

| Tolfenpyrad | 14 | 0.01 | 0.006 | 1.34 | 4.00 | 48.2 | 28.6 |

| 21 | 0.31 | 2.35 | 28.3 | 25.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Chen, H.; Gao, D.; Long, J.; Long, H.; Zhang, Y. Dissipation and Dietary Risk Assessment of Thiacloprid and Tolfenpyrad in Tea in China. Agronomy 2022, 12, 3166. https://doi.org/10.3390/agronomy12123166

Wang W, Chen H, Gao D, Long J, Long H, Zhang Y. Dissipation and Dietary Risk Assessment of Thiacloprid and Tolfenpyrad in Tea in China. Agronomy. 2022; 12(12):3166. https://doi.org/10.3390/agronomy12123166

Chicago/Turabian StyleWang, Weitao, Hongping Chen, Di Gao, Jiahuan Long, Hui Long, and Ying Zhang. 2022. "Dissipation and Dietary Risk Assessment of Thiacloprid and Tolfenpyrad in Tea in China" Agronomy 12, no. 12: 3166. https://doi.org/10.3390/agronomy12123166

APA StyleWang, W., Chen, H., Gao, D., Long, J., Long, H., & Zhang, Y. (2022). Dissipation and Dietary Risk Assessment of Thiacloprid and Tolfenpyrad in Tea in China. Agronomy, 12(12), 3166. https://doi.org/10.3390/agronomy12123166