Assessing the Impact of Different Irrigation Levels on Starch Potato Production

Abstract

1. Introduction

2. Materials and Methods

2.1. Study Site Characterization

2.2. Crop Management

2.3. Experimental Design

2.4. Irrigation Levels

2.5. Harvest Strategy, Yield and Quality Measurements

2.6. Economic Indices and Responses

2.7. Statistical Analyses

3. Results

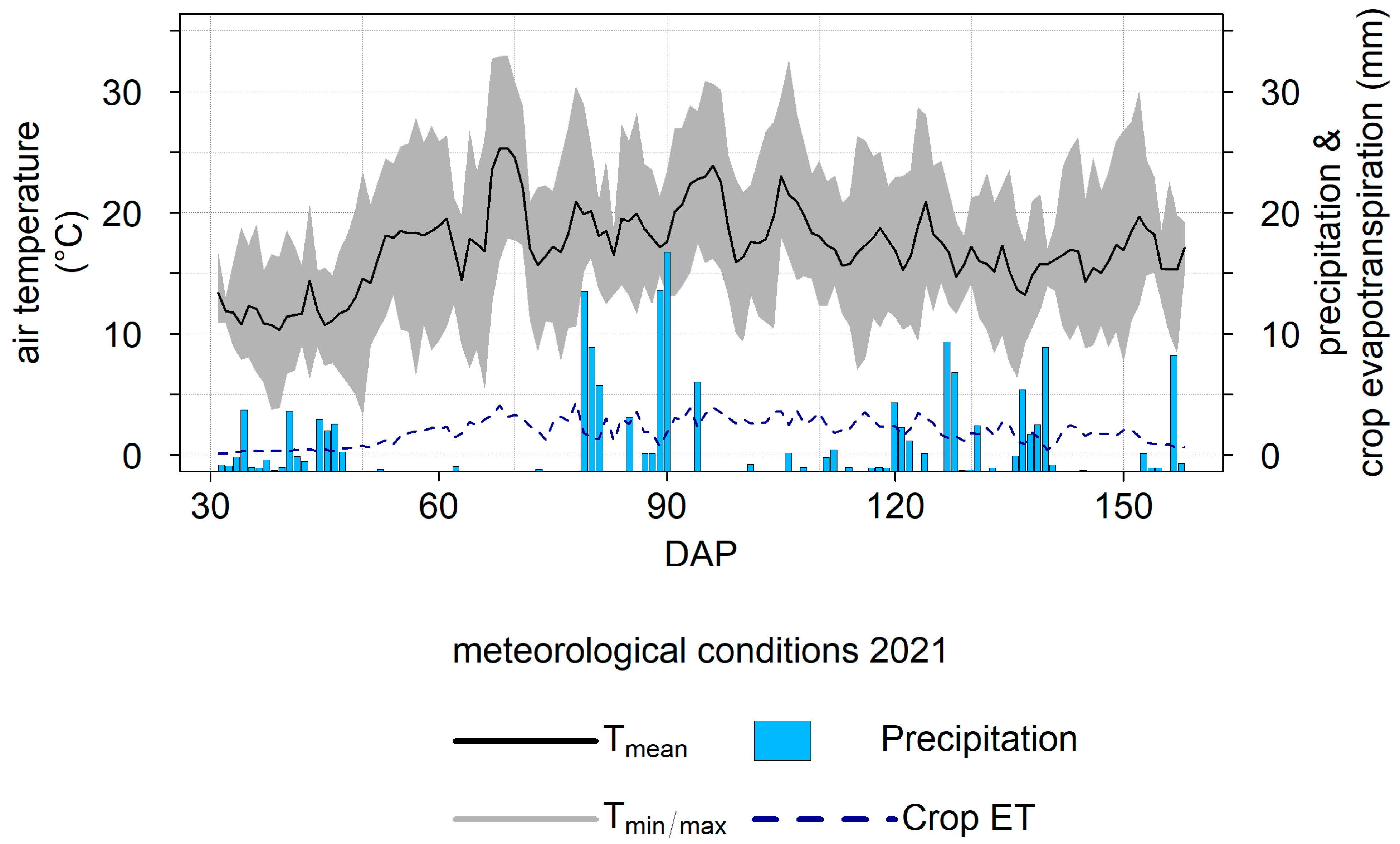

3.1. Weather Conditions

3.2. Water Supply

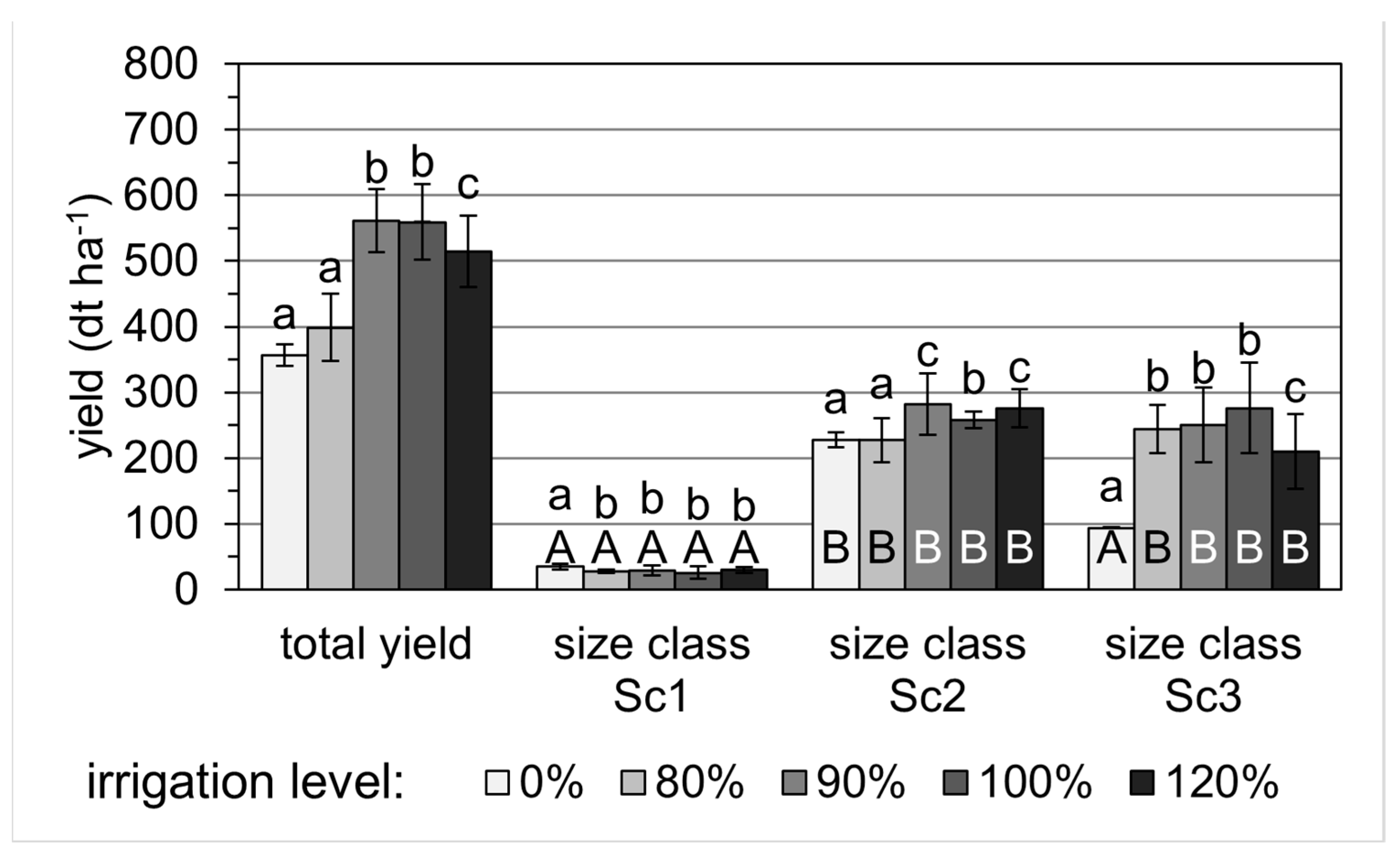

3.3. Total Yield and Tuber Size Distribution

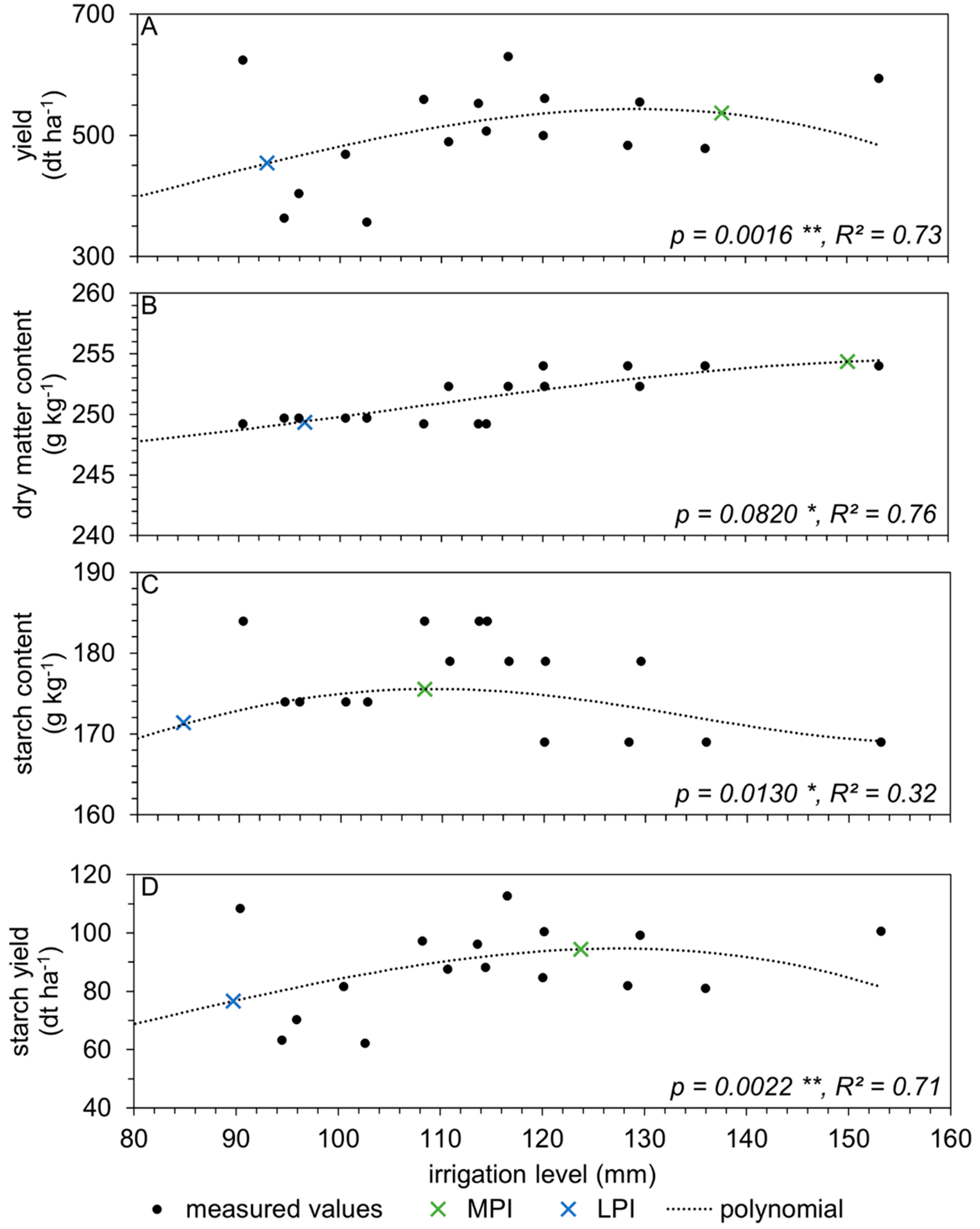

3.4. Tuber Quality

3.5. Economic Indices and Responses

3.6. Maximum and Lowest Profitable Irrigation Levels

4. Discussion

4.1. Weather Conditions

4.2. Water Supply

4.3. Total Yield and Tuber Size Distribution

4.4. Tuber Quality

4.5. Economic Indices and Responses

4.6. Maximum and Lowest Profitable Irrigation Levels

4.7. Experimental Limitations

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- German Federal Statistical Office. Agriculturally Irrigated Area in 2019; Statistisches Bundesamt: Wiesbaden, Germany, 2021. [Google Scholar]

- Federal Association of German Starch Potato Producers. Daten und Fakten 2022. Digital Report. 2022. Available online: http://www.bvs-kartoffel.de/index.php/publikationen (accessed on 28 August 2022).

- Giannakis, E.; Bruggeman, A.; Djuma, H.; Kozyra, J.; Hammer, J. Water Pricing and Irrigation across Europe: Opportunities and Constraints for Adopting Irrigation Scheduling Decision Support Systems. Water Sci. Technol.-Water Supply 2016, 16, 245–252. [Google Scholar] [CrossRef]

- Allen, R.G. Using the FAO-56 Dual Crop Coefficient Method over an Irrigated Region as Part of an Evapotranspiration Intercomparison Study. J. Hydrol. 2000, 229, 27–41. [Google Scholar] [CrossRef]

- Goussard, J. Interaction between water delivery and irrigation scheduling. In Irrigation Scheduling: From Theory to Practice; Smith, M., Pereira, L.S., Berengena, J., Itier, B., Goussard, J., Ragab, R., Tollefson, L., Van Hoffwegen, P., Eds.; FAO Water Report; ICID; FAO: Rome, Italy, 1996. [Google Scholar]

- Pereira, L.S.; Paredes, P.; Jovanovic, N. Soil Water Balance Models for Determining Crop Water and Irrigation Requirements and Irrigation Scheduling Focusing on the FAO56 Method and the Dual K-c Approach. Agric. Water Manag. 2020, 241, 106357. [Google Scholar] [CrossRef]

- Osborn, H.A.; Plath, C.V. Irrigated Farms under Development. Master´s Thesis, Oregon State College, Corvallis, OR, USA, 1952. [Google Scholar]

- Blanco-Gutierrez, I.; Varela-Ortega, C.; Purkey, D.R. Integrated Assessment of Policy Interventions for Promoting Sustainable Irrigation in Semi-Arid Environments: A Hydro-Economic Modeling Approach. J. Environ. Manag. 2013, 128, 144–160. [Google Scholar] [CrossRef]

- McKinney, D.C.; Maidment, D.R.; Tanriverdi, M. Expert Geographic Information System for Texas Water Planning. J. Water Resour. Plan. Manag. 1993, 119, 170–183. [Google Scholar] [CrossRef]

- Haie, N.; Keller, A.A. Effective Efficiency as a Tool for Sustainable Water Resources Management1. JAWRA J. Am. Water Resour. Assoc. 2008, 44, 961–968. [Google Scholar] [CrossRef]

- Mateos, L. Identifying a New Paradigm for Assessing Irrigation System Performance. Irrig. Sci. 2008, 27, 25–34. [Google Scholar] [CrossRef]

- Mandryk, M.; Reidsma, P.; Ittersum, M.K. van Crop and Farm Level Adaptation under Future Climate Challenges: An Exploratory Study Considering Multiple Objectives for Flevoland, the Netherlands. Agric. Syst. 2017, 152, 154–164. [Google Scholar] [CrossRef]

- Masseroni, D.; Ricart, S.; De Cartagena, F.R.; Monserrat, J.; Gonçalves, J.M.; De Lima, I.; Facchi, A.; Sali, G.; Gandolfi, C. Prospects for Improving Gravity-Fed Surface Irrigation Systems in Mediterranean European Contexts. Water 2017, 9, 20. [Google Scholar] [CrossRef]

- Coppola, A.; Dragonetti, G.; Sengouga, A.; Lamaddalena, N.; Comegna, A.; Basile, A.; Noviello, N.; Nardella, L. Identifying Optimal Irrigation Water Needs at District Scale by Using a Physically Based Agro-Hydrological Model. Water 2019, 11, 841. [Google Scholar] [CrossRef]

- FAO-Food and Agriculture Organization of the United Nations. World Food and Agriculture-Statistical Yearbook 2021; FAO: Rome, Italy, 2021. [Google Scholar]

- Shock, C.C.; Feibert, E.B.G.; Saunders, L.D. Potato Yield and Quality Response to Deficit Irrigation. HortScience 1998, 33, 655–659. [Google Scholar] [CrossRef]

- King, B.A.; Stark, J.C.; Neibling, H. Potato irrigation management. In Potato Production Systems; Stark, J., Thornton, M., Nolte, P., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 417–446. ISBN 978-3-030-39156-0. [Google Scholar]

- Gregory, P.J.; Simmonds, L.P. Water Relations and Growth of Potatoes. In The Potato Crop: The Scientific Basis for Improvement; Harris, P.M., Ed.; Springer: Berlin/Heidelberg, Germany, 1992; pp. 214–246. ISBN 978-94-011-2340-2. [Google Scholar]

- Deblonde, P.M.K.; Ledent, J.F. Effects of Moderate Drought Conditions on Green Leaf Number, Stem Height, Leaf Length and Tuber Yield of Potato Cultivars. Eur. J. Agron. 2001, 14, 31–41. [Google Scholar] [CrossRef]

- Walworth, J.L.; Carling, D.E. Tuber Initiation and Development in Irrigated and Non-Irrigated Potatoes. Am. J. Potato Res. 2002, 79, 387–395. [Google Scholar] [CrossRef]

- Shahnazari, A.; Liu, F.L.; Andersen, M.N.; Jacobsen, S.-E.; Jensen, C.R. Effects of Partial Root-Zone Drying on Yield, Tuber Size and Water Use Efficiency in Potato under Field Conditions. Field Crops Res. 2007, 100, 117–124. [Google Scholar] [CrossRef]

- Ojala, J.C.; Stark, J.C.; Kleinkopf, G.E. Influence of Irrigation and Nitrogen Management on Potato Yield and Quality. Am. Potato J. 1990, 67, 29–43. [Google Scholar] [CrossRef]

- Nasir, M.W.; Toth, Z. Response of Different Potato Genotypes to Drought Stress. Agriculture 2021, 11, 763. [Google Scholar] [CrossRef]

- Islam, J.; Choi, S.P.; Azad, O.K.; Kim, J.W.; Lim, Y.-S. Evaluation of Tuber Yield and Marketable Quality of Newly Developed Thirty-Two Potato Varieties Grown in Three Different Ecological Zones in South Korea. Agriculture 2020, 10, 327. [Google Scholar] [CrossRef]

- Olanya, O.M.; Porter, G.A.; Lambert, D.H. Supplemental Irrigation and Cultivar Effects on Potato Tuber Diseases. Aust. J. Crop Sci. 2010, 4, 29–36. [Google Scholar]

- Starr, G.C.; Rowland, D.; Griffin, T.S.; Olanya, O.M. Soil Water in Relation to Irrigation, Water Uptake and Potato Yield in a Humid Climate. Agric. Water Manag. 2008, 95, 292–300. [Google Scholar] [CrossRef]

- Shock, C.C.; Pereira, A.B.; Eldredge, E.P. Irrigation Best Management Practices for Potato. Am. J. Potato Res. 2007, 84, 29–37. [Google Scholar] [CrossRef]

- Onder, S.; Caliskan, M.E.; Onder, D.; Caliskan, S. Different Irrigation Methods and Water Stress Effects on Potato Yield and Yield Components. Agric. Water Manag. 2005, 73, 73–86. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; Bi, L.; Wang, Y.; Fan, J.; Zhang, F.; Hou, X.; Cheng, M.; Hu, W.; Wu, L.; et al. Multi-Objective Optimization of Water and Fertilizer Management for Potato Production in Sandy Areas of Northern China Based on TOPSIS. Field Crops Res. 2019, 240, 55–68. [Google Scholar] [CrossRef]

- Porter, G.A.; Bradbury, W.B.; Sisson, J.A.; Opena, G.B.; McBurnie, J.C. Soil Management and Supplemental Irrigation Effects on Potato: I. Soil Properties, Tuber Yield, and Quality. Agron. J. 1999, 91, 416–425. [Google Scholar] [CrossRef]

- Jane, J.; Chen, Y.Y.; Lee, L.F.; McPherson, A.E.; Wong, K.S.; Radosavljevic, M.; Kasemsuwan, T. Effects of Amylopectin Branch Chain Length and Amylose Content on the Gelatinization and Pasting Properties of Starch. Cereal Chem. 1999, 76, 629–637. [Google Scholar] [CrossRef]

- Yan, H.; Yayuan, Z.; Ling, Z.; Zhengbiao, G. Study on Physicochemical Characteristics of Waxy Potato Starch in Comparison with Other Waxy Starches. Starch-Stärke 2011, 63, 754–759. [Google Scholar] [CrossRef]

- Blennow, A.; Hansen, M.; Schulz, A.; Jørgensen, K.; Donald, A.M.; Sanderson, J. The Molecular Deposition of Transgenically Modified Starch in the Starch Granule as Imaged by Functional Microscopy. J. Struct. Biol. 2003, 143, 229–241. [Google Scholar] [CrossRef] [PubMed]

- McPherson, A.E.; Jane, J. Comparison of Waxy Potato with Other Root and Tuber Starches. Carbohydr. Polym. 1999, 40, 57–70. [Google Scholar] [CrossRef]

- Visser, R.G.F.; Suurs, L.C.J.M.; Bruinenberg, P.M.; Bleeker, I.; Jacobsen, E. Comparison between Amylose-Free and Amylose Containing Potato Starches. Starch-Stärke 1997, 49, 438–443. [Google Scholar] [CrossRef]

- Spengler, D.; Förster, M.; Borg, E. Editorial. PFG Journal of Photogrammetry, Remote Sensing and Geoinformation Science. Remote Sens. Geoinf. Sci. 2018, 86, 49–51. [Google Scholar] [CrossRef]

- IUSS Working Group WRB. World Reference Base for Soil Resources 2014, Update 2015; World Soil Resources Report No. 106; FAO: Rome, Italy, 2015. [Google Scholar]

- Soil Science Division Staff. Soil Survey Manual, USDA Handbook 18; Ditzler, C., Scheffe, K., Monger, H.C., Eds.; United States Department of Agriculture, Government Printing Office: Washington, DC, USA, 2017. [Google Scholar]

- German Meteorological Service 2021. Open Climate Data Portal. Database. Available online: https://opendata.dwd.de/ (accessed on 25 September 2021).

- Allen, R.G.; Pereira, L.S.; Raes, D.; Smith, M. Crop Evapotranspiration. Guidelines for Computing Crop Water Requirements; FAO Irrigation and Drainage Paper; Food and agriculture organization of the United Nations FAO: Rome, Italy, 1998; p. 300. [Google Scholar]

- Michel, R.; Dannowski, R. Using Soil–Water–Plant Models to Improve the Efficiency of Irrigation. In Novel Measurement and Assessment Tools for Monitoring and Management of Land and Water Resources in Agricultural Landscapes of Central Asia; Müller, L., Saparov, A., Lischeid, G., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 379–388. [Google Scholar]

- Brouwer, C.; Prins, K.; Heibloem, M. Irrigation Water Management: Irrigation Scheduling; FAO Training Manual; Food and Agriculture Organization of the United Nations FAO: Rome, Italy, 1989. [Google Scholar]

- Fischer, G.; Tubiello, F.N.; van Velthuizen, H.; Wiberg, D.A. Climate Change Impacts on Irrigation Water Requirements: Effects of Mitigation, 1990–2080. Technol. Forecast. Soc. Change 2007, 74, 1083–1107. [Google Scholar] [CrossRef]

- Nissen, M. The Weight of Potatoes in Water. Am. Potato J. 1955, 32, 332–339. [Google Scholar] [CrossRef]

- Eckert, K. Kartoffelstärke-Waage Mit Einem Korb. Kartoffelbau 1975, 26, 232–233. [Google Scholar]

- Talburt, W.F.; Smith, O. Potato Processing, 3rd ed.; The AVI; Publishing Company: Westport, CT, USA, 1959. [Google Scholar]

- Simmonds, N.W. Relations between Specific Gravity, Dry Matter Content and Starch Content of Potatoes. Potato Res. 1977, 20, 137–140. [Google Scholar] [CrossRef]

- Wang, F.-X.; Wu, X.-X.; Shock, C.C.; Chu, L.-Y.; Gu, X.-X.; Xue, X. Effects of Drip Irrigation Regimes on Potato Tuber Yield and Quality under Plastic Mulch in Arid Northwestern China. Field Crops Res. 2011, 122, 78–84. [Google Scholar] [CrossRef]

- Gondwe, R.L.; Kinoshita, R.; Suminoe, T.; Aiuchi, D.; Palta, J.P.; Tani, M. Yield and Quality Characteristics of Popular Processing Potato (Solanum Tuberosum L.) Cultivars in Two Contrasting Soil Types under Grower Management in Hokkaido, Japan. Potato Res. 2020, 63, 385–402. [Google Scholar] [CrossRef]

- Islam, M.M.; Naznin, S.; Naznin, A.; Uddin, M.N.; Amin, M.N.; Rahman, M.M.; Tipu, M.M.H.; Alsuhaibani, A.M.; Gaber, A.; Ahmed, S. Dry Matter, Starch Content, Reducing Sugar, Color and Crispiness Are Key Parameters of Potatoes Required for Chip Processing. Horticulturae 2022, 8, 362. [Google Scholar] [CrossRef]

- United States Department of Agriculture (USDA). United States Standards for Grades of Potatoes for Processing; USDA: Washington, DC, USA, 1997. [Google Scholar]

- Malcolmson, J.F. Assessment of Field Resistance to Blight (Phytophthora Infestans) in Potatoes. Trans. Br. Mycol. Soc. 1976, 67, 321–325. [Google Scholar] [CrossRef]

- Lambert, D.H.; Loria, R. Streptomyces Scabies Sp. Nov., Nom. Rev. Int. J. Syst. Evol. Microbiol. 1989, 39, 387–392. [Google Scholar] [CrossRef]

- Hughes, J.C. Role of Tuber Properties in Determining Susceptibility of Potatoes to Damage. Ann. Appl. Biol. 1980, 96, 344–345. [Google Scholar]

- Buck, R.W.; Akeley, R.V. Effect of Maturity Storage Temperature and Storage Time on Greening of Potato Tubers. Am. Potato J. 1967, 44, 56. [Google Scholar] [CrossRef]

- Leromancer, M.; Kerlan, C. Superficial ringspot necrosis of potato tubers: A recent disease caused by potato virus-Y. Agronomie 1991, 11, 889–900. [Google Scholar]

- Kuratorium für Technik und Bauwesen in der Landwirtschaft (KTBL). Kartoffelproduktion-Betriebs- Und Arbeitswirtschaftliche Kalkulationen, 1st ed.; Böhm, H., Fröba, N., Funk, M., Grube, J., Sauer, N., Kloepfer, F., Küppers, P.-H., Lange, W., Mohr, M., Peters, R., et al., Eds.; Hrsg.: Darmstadt, Germany, 2010. [Google Scholar]

- European Energy Exchange AG EEX 2021. European Processing Potato Futures. Database. Available online: https://www.eex.com/de/marktdaten/agrarprodukte/kartoffeln (accessed on 30 September 2021).

- Hill, J.; Lazarovits, G. A Mail Survey of Growers to Estimate Potato Common Scab Prevalence and Economic Loss in Canada. Can. J. Plant Pathol. 2005, 27, 46–52. [Google Scholar] [CrossRef]

- Kirkman, M.A. Global Markets for Processed Potato Products. In Potato Biology and Biotechnology-Advances and Perspectives; Vreugdenhil, D., Bradshaw, J., Gebhardt, C., Govers, F., MacKerron, D.K.L., Taylor, M.A., Ross, H.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2007; pp. 27–44. [Google Scholar]

- Zangeneh, M.; Omid, M.; Akram, A. A Comparative Study on Energy Use and Cost Analysis of Potato Production under Different Farming Technologies in Hamadan Province of Iran. Energy 2010, 35, 2927–2933. [Google Scholar] [CrossRef]

- Ginter, A.; Zarzecka, K.; Gugała, M. Effect of Herbicide and Biostimulants on Production and Economic Results of Edible Potato. Agronomy 2022, 12, 1409. [Google Scholar] [CrossRef]

- Brar, A.S.; Buttar, G.S.; Thind, H.S.; Singh, K.B. Improvement of Water Productivity, Economics and Energetics of Potato through Straw Mulching and Irrigation Scheduling in Indian Punjab. Potato Res. 2019, 62, 465–484. [Google Scholar] [CrossRef]

- Ozkan, B.; Akcaoz, H.; Karadeniz, F. Energy Requirement and Economic Analysis of Citrus Production in Turkey. Energy Convers. Manag. 2004, 45, 1821–1830. [Google Scholar] [CrossRef]

- Molden, D. Accounting for Water Use and Productivity; International Irrigation Management Institute: Colombo, Sri Lanka, 1997. [Google Scholar]

- Playan, E.; Salvador, R.; Faci, J.; Zapata, N.; Martinez-Cob, A.; Sanchez, I. Day and Night Wind Drift and Evaporation Losses in Sprinkler Solid-Sets and Moving Laterals. Agric. Water Manag. 2005, 76, 139–159. [Google Scholar] [CrossRef]

- Ierna, A.; Mauromicale, G. Tuber Yield and Irrigation Water Productivity in Early Potatoes as Affected by Irrigation Regime. Agric. Water Manag. 2012, 115, 276–284. [Google Scholar] [CrossRef]

- Ahmadi, S.H.; Anderson, M.N.; Plauborg, F.; Poulsen, R.T.; Jensen, C.R.; Sepaskhah, A.R.; Hansen, S. Effects of Irrigation Strategies and Soils on Field Grown Potatoes: Yield and Water Productivity. Agric. Water Manag. 2010, 97, 1923–1930. [Google Scholar] [CrossRef]

- Ahmadi, S.H.; Agharezaee, M.; Kamgar-Haghighi, A.A.; Sepaskhah, A.R. Effects of Dynamic and Static Deficit and Partial Root Zone Drying Irrigation Strategies on Yield, Tuber Sizes Distribution, and Water Productivity of Two Field Grown Potato Cultivars. Agric. Water Manag. 2014, 134, 126–136. [Google Scholar] [CrossRef]

- Görz, G.; Hock, A. Reichsbodenschätzung Und Bodenkunde. Z. Dtsch. Geol. Ges. 1939, 91, 612–616. [Google Scholar]

- Hancock, R.D.; Morris, W.L.; Ducreaux, L.J.M.; Morris, J.A.; Usman, M.; Verrall, S.R.; Fuller, J.; Simpson, C.G.; Zhang, R.; Hadley, P.E.; et al. Physiological, Biochemical and Molecular Responses of the Potato (Solanum Tuberosum L.) Plant to Moderately Elevated Temperature. Plant Cell Environ. 2014, 37, 439–450. [Google Scholar] [CrossRef] [PubMed]

- Hou, X.-Y.; Wang, F.-X.; Han, J.-J.; Kang, S.-Z.; Feng, S.-Y. Duration of Plastic Mulch for Potato Growth under Drip Irrigation in an Arid Region of Northwest China. Agric. For. Meteorol. 2010, 150, 115–121. [Google Scholar] [CrossRef]

- Kleinwächter, U.; Gastelo, M.; Ritchie, J.T.; Nelson, G.; Asseng, S. Simulating Cultivar Variations in Potato Yields for Contrasting Environments. Agric. Syst. 2016, 145, 51–63. [Google Scholar] [CrossRef]

- Jensen, C.R.; Battilani, A.; Plauborg, F.; Psarras, G.; Chartzoulakis, K.; Janowiak, F.; Stikic, R.; Jovanovic, Z.; Li, G.T.; Qi, X.B.; et al. Deficit Irrigation Based on Drought Tolerance and Root Signalling in Potatoes and Tomatoes. Agric. Water Manag. 2010, 98, 403–413. [Google Scholar] [CrossRef]

- Sepaskhah, A.R.; Ahmadi, S.H. A Review on Partial Root-Zone Drying Irrigation. Int. J. Plant Prod. 2010, 4, 241–258. [Google Scholar]

- Fabeiro, C.; Olalla, F.M.D.; de Juan, J.A. Yield and Size of Deficit Irrigated Potatoes. Agric. Water Manag. 2001, 48, 255–266. [Google Scholar] [CrossRef]

- Gervais, T.; Creelman, A.; Li, X.Q.; Bizimungu, B.; de Koeyer, D.; Dahal, K. Potato Response to Drought Stress Physiological and Growth Basis. Front. Plant Sci. 2021, 2, 698060. [Google Scholar] [CrossRef]

- Badr, M.A.; El-Tohamy, W.A.; Zaghloul, A.M. Yield and Water Use Efficiency of Potato Grown under Different Irrigation and Nitrogen Levels in an Arid Region. Agric. Water Manag. 2012, 110, 9–15. [Google Scholar] [CrossRef]

- Darwish, T.M.; Atallah, T.W.; Hajhasan, S.; Haidar, A. Nitrogen and Water Use Efficiency of Fertigated Processing Potato. Agric. Water Manag. 2006, 85, 95–104. [Google Scholar] [CrossRef]

- Yactayo, W.; Ramirez, D.A.; Guiterrez, R.; Mares, V.; Posadas, A.; Quiroz, R. Effect of Partial Root-Zone Drying Irrigation Timing on Potato Tuber Yield and Water Use Efficiency. Agric. Water Manag. 2013, 123, 65–70. [Google Scholar] [CrossRef]

- Hawkes, J.G.; Harris, P.M. The Potato Crop: The Scientific Basis for Improvement, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 1971. [Google Scholar]

- Rudack, K.; Seddig, S.; Sprenger, H.; Kohl, K.; Uptmoor, R.; Ordon, F. Drought Stress-Induced Changes in Starch Yield and Physiological Traits in Potato. J. Agron. Crop Sci. 2017, 203, 494–505. [Google Scholar] [CrossRef]

- Meise, P.; Seddig, S.; Uptmoor, R.; Ordon, F.; Schum, A. Assessment of Yield and Yield Components of Starch Potato Cultivars (Solanum Tuberosum L.) Under Nitrogen Deficiency and Drought Stress Conditions. Potato Res. 2019, 62, 193–220. [Google Scholar] [CrossRef]

- Xing, Y.; Zhang, T.; Jiang, W.; Li, P.; Shi, P.; Xu, G.; Cheng, S.; Cheng, Y.; Fan, Z.; Wang, X. Effects of Irrigation and Fertilization on Different Potato Varieties Growth, Yield and Resources Use Efficiency in the Northwest China. Agric. Water Manag. 2022, 261, 107351. [Google Scholar] [CrossRef]

- Bombik, A.; Rymuza, K.; Olszewski, T. Variation and Correlation of Starch Potato Utility Features and Tuber Quality Traits. Acta Agroph. 2019, 26, 29–42. [Google Scholar] [CrossRef]

- Lapwood, D.H.; Wellings, L.W.; Hawkins, J.H. Irrigation as a Practical Means to Control Potato Common Scab (Streptomyces Scabies)-Final Experiment and Conclusions. Plant Pathol. 1973, 22, 35–41. [Google Scholar] [CrossRef]

- Larkin, R.P.; Honeycutt, C.W.; Griffin, T.S.; Olanya, O.M.; Halloran, J.M.; He, Z. Effects of Different Potato Cropping System Approaches and Water Management on Soilborne Diseases and Soil Microbial Communities. Phytopathology 2011, 101, 58–67. [Google Scholar] [CrossRef]

- Bohmig, H.J.; Friessleben, G.; Gerdes, K.; Truckenbrodt, M.; Janke, C.; Lucke, W.; Schnieder, E. The Effects of Heavy Mineral N Fertilization and Sprinkling Irrigation on the Yield and Quality of Potatoes. Part 2. Tuber Quality Characters Occurrence of Fungal and Bacterial Diseases, Crop Storate Quality and Erosion of Potato Ridges. Archiv. für Acker-Und Pflanzenbau Und Bodenkunde 1975, 19, 793–809. [Google Scholar]

- Orum, J.E.; Boesen, M.V.; Jovanovic, Z.; Pedersen, S.M. Farmers’ Incentives to Save Water with New Irrigation Systems and Water Taxation-A Case Study of Serbian Potato Production. Agric. Water Manag. 2010, 98, 465–471. [Google Scholar] [CrossRef]

- Li, X.; Zhang, X.; Niu, J.; Tong, L.; Kang, S.; Du, T.; Li, S.; Ding, R. Irrigation Water Productivity Is More Influenced by Agronomic Practice Factors than by Climatic Factors in Hexi Corridor, Northwest China. Sci. Rep. 2016, 6, 37971. [Google Scholar] [CrossRef]

- Saibene, D.; Seetharaman, K. Amylose Involvement in the Amylopectin Clusters of Potato Starch Granules. Carbohydr. Polym. 2010, 82, 376–383. [Google Scholar] [CrossRef]

- Stading, M.; Rindlav-Westling, A.; Gatenholm, P. Humidity-Induced Structural Transitions in Amylose and Amylopectin Films. Carbohydr. Polym. 2001, 45, 209–217. [Google Scholar] [CrossRef]

- Zebarth, B.J.; Bélanger, G.; Cambouris, A.N.; Ziadi, N. Nitrogen Fertilization Strategies in Relation to Potato Tuber Yield, Quality, and Crop N Recovery. In Sustainable Potato Production: Global Case Studies; He, Z., Larkin, R., Honeycutt, W., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 165–186. ISBN 978-94-007-4104-1. [Google Scholar]

- Sarker, K.K.; Hossain, A.; Timsina, J.; Biswas, S.K.; Kundu, B.C.; Barman, A.; Ibn Murad, K.F.; Akter, F. Yield and Quality of Potato Tuber and Its Water Productivity Are Influenced by Alternate Furrow Irrigation in a Raised Bed System. Agric. Water Manag. 2019, 224, 105750. [Google Scholar] [CrossRef]

- Wigboldus, S.; Klerkx, L.; Leeuwis, C.; Schut, M.; Muilerman, S.; Jochemsen, H. Systemic Perspectives on Scaling Agricultural Innovations. A Review. Agron. Sustain. Dev. 2016, 36, 46. [Google Scholar] [CrossRef]

- Cumming, G.S.; Olsson, P.; Chapin, F.S.; Holling, C.S. Resilience, Experimentation, and Scale Mismatches in Social-Ecological Landscapes. Landsc. Ecol. 2013, 28, 1139–1150. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, C.; Jones, G.; Yang, H.; Li, Z.; Yang, G.; Chen, L.; Wu, Y. Effect and Economic Benefit of Precision Seeding and Laser Land Leveling for Winter Wheat in the Middle of China. Artif. Intell. Agric. 2022, 6, 1–9. [Google Scholar] [CrossRef]

- Lima, J.R.; Goes, M.D.; Hammecker, C.; Antonino, A.C.; Medeiros, É.V.; Sampaio, E.V.; Leite, M.C.; Silva, V.P.; de Souza, E.S.; Souza, R. Effects of Poultry Manure and Biochar on Acrisol Soil Properties and Yield of Common Bean. A Short-Term Field Experiment. Agriculture 2021, 11, 290. [Google Scholar] [CrossRef]

- Rodriguez, D.; Sadras, V.O.; Christensen, L.K.; Belford, R. Spatial Assessment of the Physiological Status of Wheat Crops as Affected by Water and Nitrogen Supply Using Infrared Thermal Imagery. Aust. J. Agric. Res. 2005, 56, 983–993. [Google Scholar] [CrossRef]

- Reckling, M.; Ahrends, H.; Chen, T.-W.; Eugster, W.; Hadasch, S.; Knapp, S.; Laidig, F.; Linstädter, A.; Macholdt, J.; Piepho, H.-P.; et al. Methods of Yield Stability Analysis in Long-Term Field Experiments. A Review. Agron. Sustain. Dev. 2021, 41, 27. [Google Scholar] [CrossRef]

- Shull, H.; Dylla, A.S. Traveling Gun Application Uniformity in High Winds. Trans. Am. Soc. Agric. Eng. 1976, 19, 0254–0258. [Google Scholar] [CrossRef]

- Darko, R.O.; Shouqi, Y.; Junping, L.; Haofang, Y.; Xingye, Z. Overview of Advances in Improving Uniformity and Water Use Efficiency of Sprinkler Irrigation. Int. J. Agric. Biol. Eng. 2017, 10, 1–15. [Google Scholar]

| Depth | BD | AC | FC | PAW | Ksat |

|---|---|---|---|---|---|

| (cm) | (g cm−3) | (%) | (%) | (%) | (cm d−1) |

| 10 | 1.28 | 29.84 | 21.75 | 17.99 | 297 |

| 20 | 1.40 | 26.01 | 21.26 | 16.83 | 165 |

| 30 | 1.46 | 24.89 | 21.06 | 16.87 | 148 |

| 50 | 1.55 | 22.68 | 18.85 | 15.78 | 83 |

| Production Segment | Calculation | Costs (USD ha−1) | |

|---|---|---|---|

| water and energy for irrigation | variable (mm) × 1.76 USD mm−1 | 80% 90% 100% 120% | 171.17 185.57 207.46 233.79 |

| labor 1 | 40 h ha−1 × 17.6 USD h−1 | 704.00 | |

| fuel 1 | fixed costs | 872.00 | |

| fertilization 1 | fixed costs | 213.00 | |

| agrochemicals 1 | fixed costs | 330.60 | |

| seed tubers | 35,088 tubers ha−1 × 0.06 kg tuber−1 × 0.35 USD kg−1 | 736.85 | |

| Tuber Quality Criterion | Threshold | Reductions of the TPVtotal |

|---|---|---|

| dry matter content | 195.0 g kg−1 | 10% |

| starch content 1 | 170.0 g kg−1 | 0.77 USD kg−1 reduced starch yield (dt ha−1) 2 |

| deep scab 3 | 20% of all tubers | 10% |

| growth cracks 3 | 20% of all tubers | 10% |

| tuber greening | 10% of all tubers | 10% |

| iron staining | 10% of all tubers | 10% |

| net necrosis | 1% of all tubers | full rejection |

| Tuber Quality Criterion | Irrigation Level | ||||||

|---|---|---|---|---|---|---|---|

| 0% | 80% | 90% | 100% | 120% | |||

| tuber number | (-) | SC1 | 5.1 aA | 5.6 aA | 4.4 bA | 3.6 cA | 4.4 bA |

| SC2 | 9.7 aB | 8.2 bB | 9.1 aB | 9.4 aB | 9.4 aB | ||

| SC3 | 1.8 aC | 3.0 bA | 4.7 cA | 4.6 cA | 3.6 bA | ||

| total | 16.6 a | 16.8 a | 18.2 b | 17.6 c | 17.4 c | ||

| mean tuber weight | (kg) | SC1 | 0.02 aA | 0.01 aA | 0.02 aA | 0.02 aA | 0.02 aA |

| SC2 | 0.06 aA | 0.08 bB | 0.09 bB | 0.08 bB | 0.08 bB | ||

| SC3 | 0.15 aB | 0.13 bC | 0.15 aC | 0.17 cC | 0.17 cC | ||

| total | 0.08 a | 0.08 a | 0.08 a | 0.09 a | 0.09 a | ||

| dry matter content | (g kg−1) | SC1 | 246.9 aA | 236.3 bA | 237.9 bA | 242.8 abA | 250.7 aA |

| SC2 | 256.3 aB | 255.1 aB | 256.1 aB | 259.1 aB | 256.7 aB | ||

| SC3 | 259.5 aB | 257.8 aB | 253.7 aB | 255.1 aB | 254.7 aB | ||

| total | 253.8 a | 249.3 a | 250.9 a | 254.8 a | 254.7 a | ||

| starch content | (g kg−1) | SC1 | 170.0 aA | 168.0 aA | 158.0 bA | 170.0 aA | 160.0 bA |

| SC2 | 174.5 aB | 176.0 aB | 181.0 bB | 180.5 bB | 173.3 aB | ||

| SC3 | 177.5 aC | 178.5 aC | 182.5 bC | 186.5 bC | 175.0 aC | ||

| total | 173.4 a | 173.8 a | 175.6 a | 179.9 b | 170.2 c | ||

| starch yield | (dt ha−1) | SC1 | 6.0 aA | 4.6 bA | 4.6 bA | 4.4 bA | 4.7 bA |

| SC2 | 39.7 aB | 40.0 aB | 51.1 cB | 46.5 bB | 47.7 bB | ||

| SC3 | 16.7 aC | 25.7 aB | 46.3 cB | 51.5 cB | 36.7 bB | ||

| total | 62.3 a | 70.3 a | 102.0 c | 102.3 c | 89.1 b | ||

| common scab | (1–9) | SC1 | 1.5 | 1.5 | 1.5 | 1.8 | 2.0 |

| SC2 | 1.5 | 2.5 | 2.7 | 2.2 | 2.5 | ||

| SC3 | 2.0 | 2.0 | 1.8 | 2.3 | 2.0 | ||

| total | 1.7 | 2.0 | 2.2 | 2.1 | 2.3 | ||

| iron staining | (1–9) | SC1 | 1.0 | 1.0 | 1.0 | 1.0 | 2.0 |

| SC2 | 1.0 | 1.0 | 2.0 | 1.0 | 2.0 | ||

| SC3 | 1.0 | 2.0 | 1.0 | 1.0 | 2.0 | ||

| total | 1.0 | 1.2 | 1.5 | 1.0 | 2.0 | ||

| tuber greening | (%) | SC1 | 8.3 | 10.6 | 15.3 | 10.2 | 10.3 |

| SC2 | 7.4 | 3.6 | 10.5 | 11.2 | 7.1 | ||

| SC3 | 6.2 | 2.0 | 5.3 | 0.0 | 0.0 | ||

| total | 21.9 | 16.2 | 31.1 | 21.4 | 17.4 | ||

| Economic Indices | Irrigation Level | ||||||

|---|---|---|---|---|---|---|---|

| 0% | 80% | 90% | 100% | 120% | |||

| TPVtotal | (USD ha−1) | SC1 | 310.47 aA | 252.90 aA | 332.87 aA | 291.69 aA | 318.39 aA |

| SC2 | 1960.79 aB | 2033.75 aB | 3146.65 bB | 2843.08 cB | 2896.04 cB | ||

| SC3 | 811.99 aA | 1303.75 bB | 2795.03 cB | 3081.62 cB | 2230.25 cB | ||

| total | 3083.25 a | 3590.40 a | 6274.55 b | 6216.39 b | 5444.68 c | ||

| TPVreduced | (USD ha−1) | SC1 | 301.43 aA | 190.84 aA | 264.50 aA | 254.39 aA | 224.70 aA |

| SC2 | 1756.58 aB | 1822.24 aB | 2823.85 bB | 2550.64 bB | 2598.30 bB | ||

| SC3 | 562.06 aA | 906.30 bA | 2507.39 cB | 3072.58 cB | 1999.09 cB | ||

| total | 2620.07 a | 2919.38 a | 5595.74 b | 5877.61 b | 4822.09 c | ||

| losses | (USD ha−1) | SC1 | 9.04 aA | 62.06 bA | 68.37 bA | 37.30 cA | 93.69 dA |

| SC2 | 204.21 aB | 211.51 aB | 322.80 bB | 292.44 bB | 297.74 bB | ||

| SC3 | 249.93 aB | 397.45 bC | 287.64 aB | 9.04 cA | 231.16 aB | ||

| total | 463.18 a | 671.02 b | 678.81 b | 338.78 c | 622.59 b | ||

| BCR | (-) | SC1 | 1.07 aA | 0.92 aA | 1.67 bA | 1.80 bA | 1.26 cA |

| SC2 | 0.96 aA | 1.05 aA | 1.84 bA | 1.80 bA | 1.56 bB | ||

| SC3 | 0.75 aA | 0.82 aA | 1.84 bB | 2.01 cB | 1.56 bB | ||

| total | 0.92 a | 0.96 a | 1.83 b | 1.90 b | 1.55 c | ||

| IWP | (dt mm−1) | SC1 | - | 0.28 aA | 0.28 aA | 0.22 aA | 0.22 aA |

| SC2 | - | 2.31 aB | 2.69 bB | 2.17 aB | 2.05 aB | ||

| SC3 | - | 1.46 aC | 2.38 bB | 2.31 bB | 1.56 aB | ||

| total | - | 1.89 a | 2.48 b | 2.19 a | 1.78 a | ||

| WP | (dt mm−1) | SC1 | 0.14 aA | 0.08 aA | 0.08 aA | 0.07 aA | 0.08 aA |

| SC2 | 0.89 aB | 0.64 bB | 0.78 aB | 0.69 bB | 0.71 bB | ||

| SC3 | 0.37 aA | 0.41 aB | 0.69 bB | 0.74 bB | 0.54 aB | ||

| total | 0.68 a | 0.52 b | 0.72 a | 0.70 a | 0.61 b | ||

| Yield & Economic Criteria | Irrigation Level | |||

|---|---|---|---|---|

| Δ (80%) | Δ (90%) | |||

| irrigation water | (m3) | SC1 | +9420 | +544 |

| SC2 | +7911 | −9015 | ||

| SC3 | −162,370 | −78,997 | ||

| total | −145,040 | −87,469 | ||

| yield | (t) | SC1 | +139.1 | +245.7 |

| SC2 | −2123.2 | +1710.8 | ||

| SC3 | −9192.4 | −1813.9 | ||

| total | −11,176.6 | +139.5 | ||

| starch yield | (t) | SC1 | +19.5 | +17.4 |

| SC2 | −454.0 | +318.5 | ||

| SC3 | −1794.6 | −360.9 | ||

| total | −2229.1 | −25.0 | ||

| total production value (with regard to tuber quality losses) | (USD) | SC1 | −26,970.70 (−44,181.29) | +28,632.45 (+7063.66) |

| SC2 | −562,727.10 (−506,456.20) | +211,072.23 (+189,966.95) | ||

| SC3 | −1,271,836.89 (−1506,220.38) | −199,266.03 (−412,976.41) | ||

| Total | −1,825,855.65 (−2,056,857.87) | +40,438.65 (−215,945.80) | ||

| Tuber Quality | Irrigation Level | Difference Δ | |||

|---|---|---|---|---|---|

| Maximum Profitable | Lowest Profitable | ||||

| tuber number | SC1 | 7.7 | 7.7 | 0.0 | |

| SC2 | 9.6 | 9.3 | −0.3 | ||

| SC3 | 4.6 | 4.3 | −0.3 | ||

| total | 21.9 | 21.3 | −0.6 | ||

| dry matter content | (g kg−1) | SC1 | 248.9 | 238.3 | −10.6 |

| SC2 | 257.9 | 254.6 | −3.3 | ||

| SC3 | 259.5 | 255.5 | −4.0 | ||

| total | 255.4 | 249.5 | −5.9 | ||

| starch content | (g kg−1) | SC1 | 170.4 | 170.2 | −0.2 |

| SC2 | 179.4 | 175.4 | −4.0 | ||

| SC3 | 182.3 | 180.1 | −2.2 | ||

| total | 175.8 | 173.9 | −1.9 | ||

| starch yield | (dt ha−1) | SC1 | 5.8 | 5.5 | −0.3 |

| SC2 | 49.5 | 44.2 | −5.3 | ||

| SC3 | 36.0 | 30.1 | −5.9 | ||

| total | 91.3 | 79.8 | −11.5 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wenzel, J.L.; Conrad, C.; Piernicke, T.; Spengler, D.; Pöhlitz, J. Assessing the Impact of Different Irrigation Levels on Starch Potato Production. Agronomy 2022, 12, 2685. https://doi.org/10.3390/agronomy12112685

Wenzel JL, Conrad C, Piernicke T, Spengler D, Pöhlitz J. Assessing the Impact of Different Irrigation Levels on Starch Potato Production. Agronomy. 2022; 12(11):2685. https://doi.org/10.3390/agronomy12112685

Chicago/Turabian StyleWenzel, Jan Lukas, Christopher Conrad, Thomas Piernicke, Daniel Spengler, and Julia Pöhlitz. 2022. "Assessing the Impact of Different Irrigation Levels on Starch Potato Production" Agronomy 12, no. 11: 2685. https://doi.org/10.3390/agronomy12112685

APA StyleWenzel, J. L., Conrad, C., Piernicke, T., Spengler, D., & Pöhlitz, J. (2022). Assessing the Impact of Different Irrigation Levels on Starch Potato Production. Agronomy, 12(11), 2685. https://doi.org/10.3390/agronomy12112685