Performance Analysis and Optimization for Steering Motion Mode Switching of an Agricultural Four-Wheel-Steering Mobile Robot

Abstract

1. Introduction

2. Problem Formulation and System Modeling

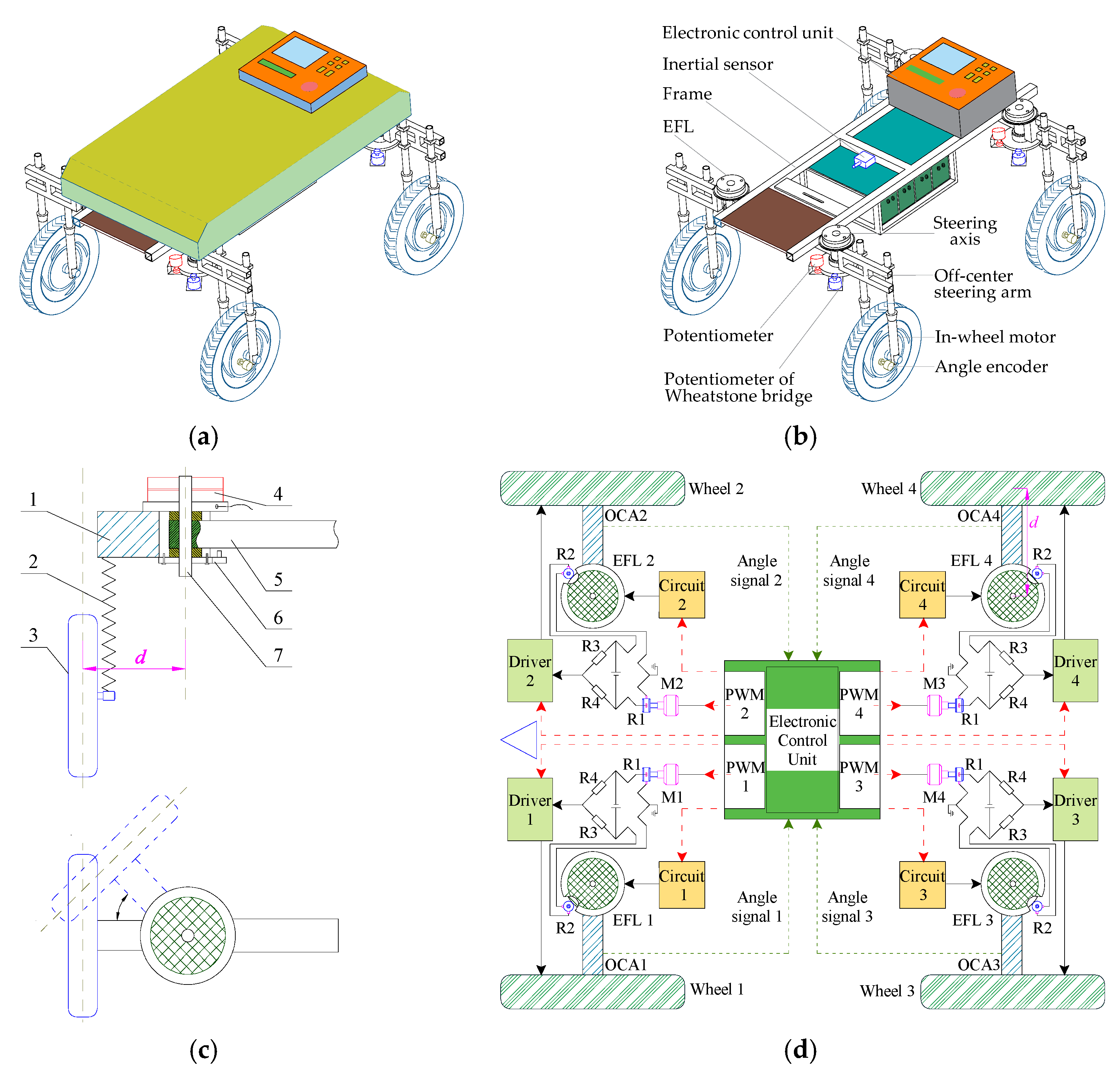

2.1. Overall Structure

2.2. Motion Mode Switching Model

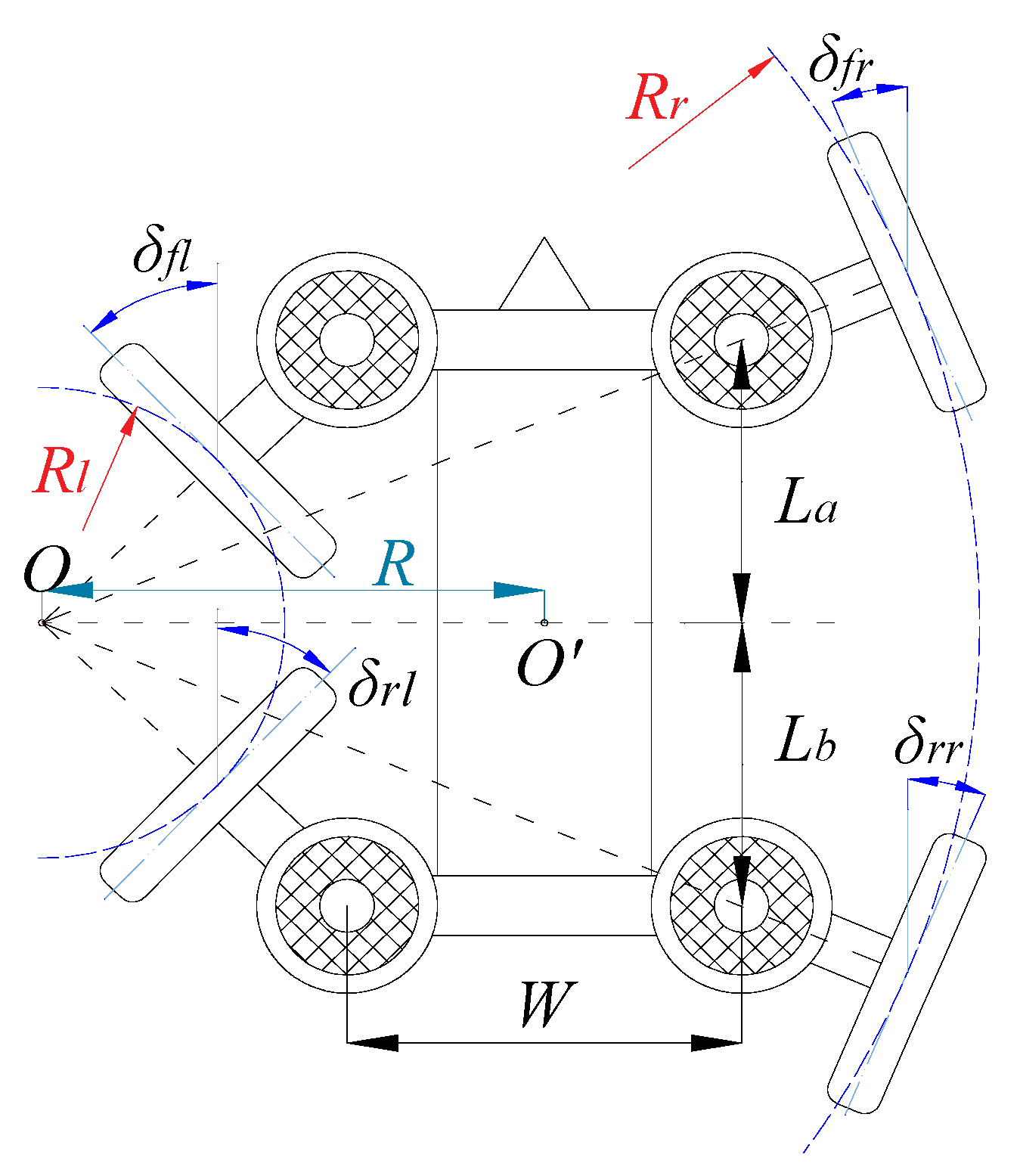

2.2.1. Ackermann Steering Model

2.2.2. Steering Lock Model

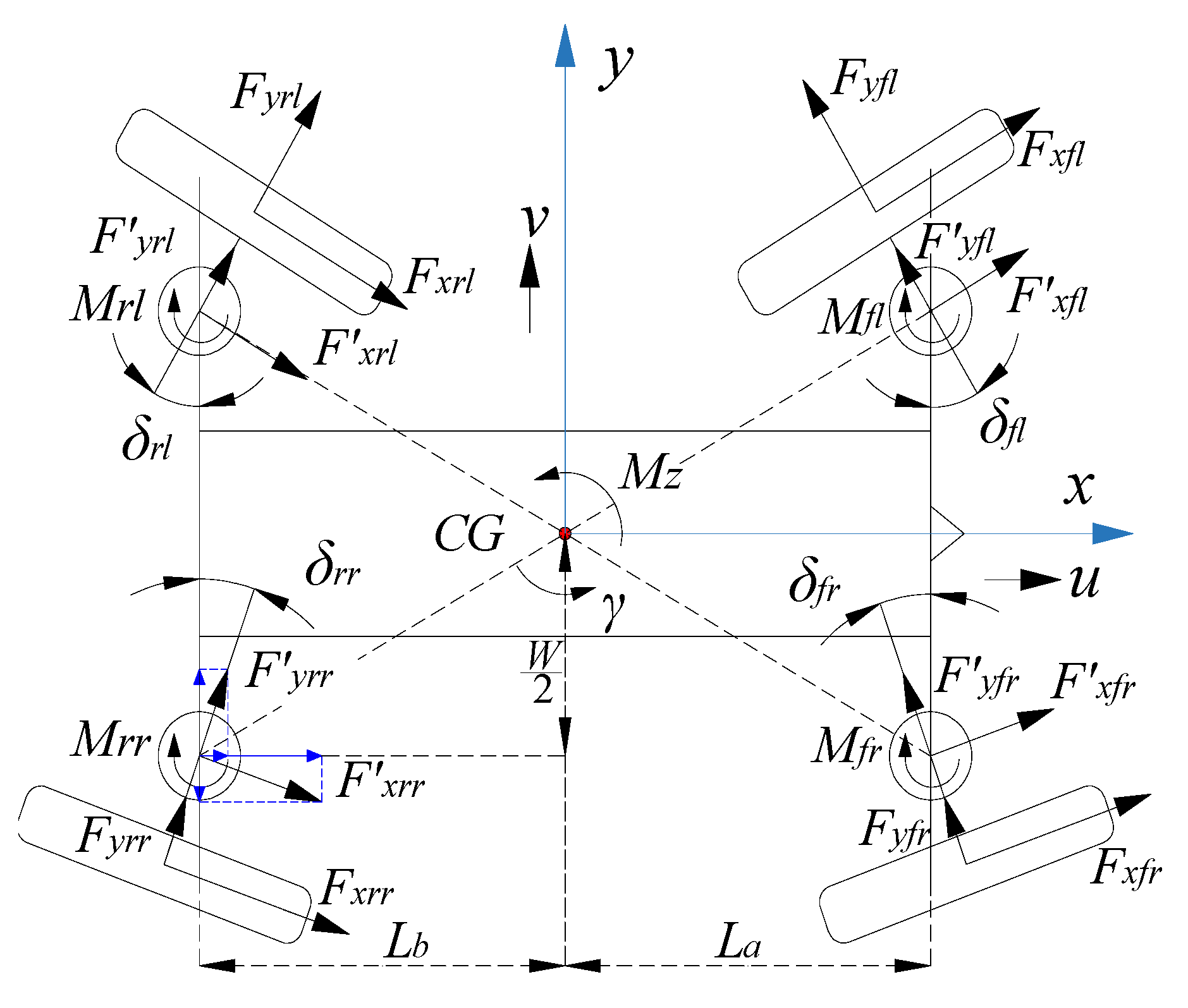

2.2.3. Mechanical Model of the Chassis

3. Materials and Methods

3.1. Test Design

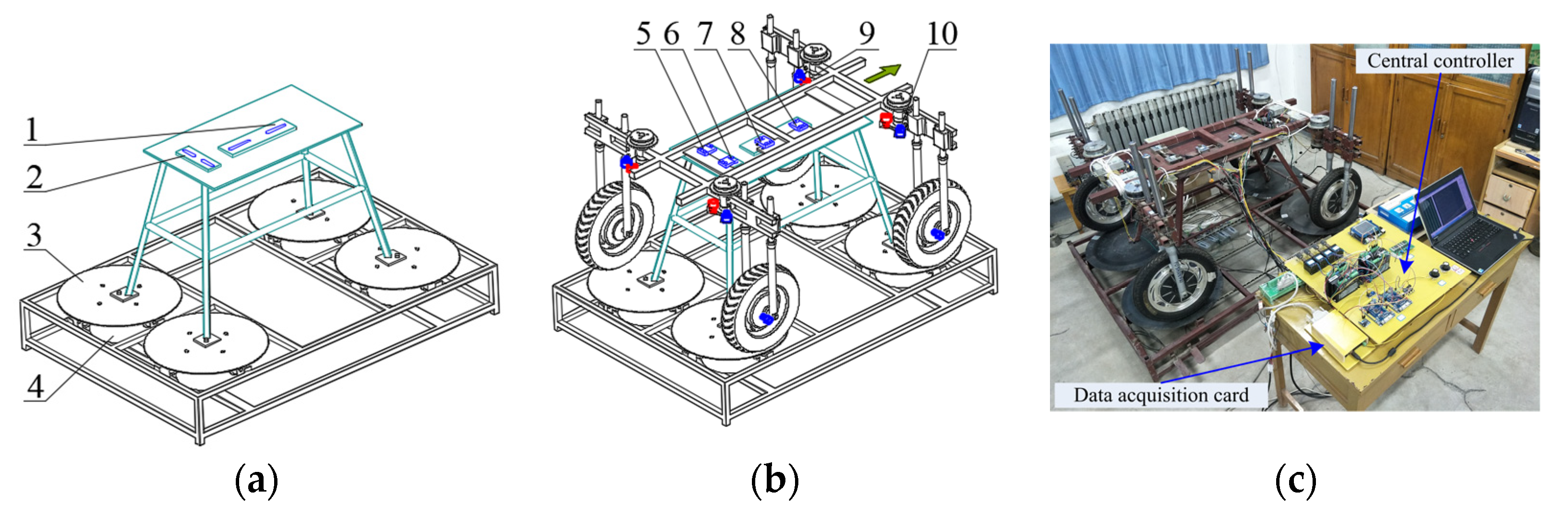

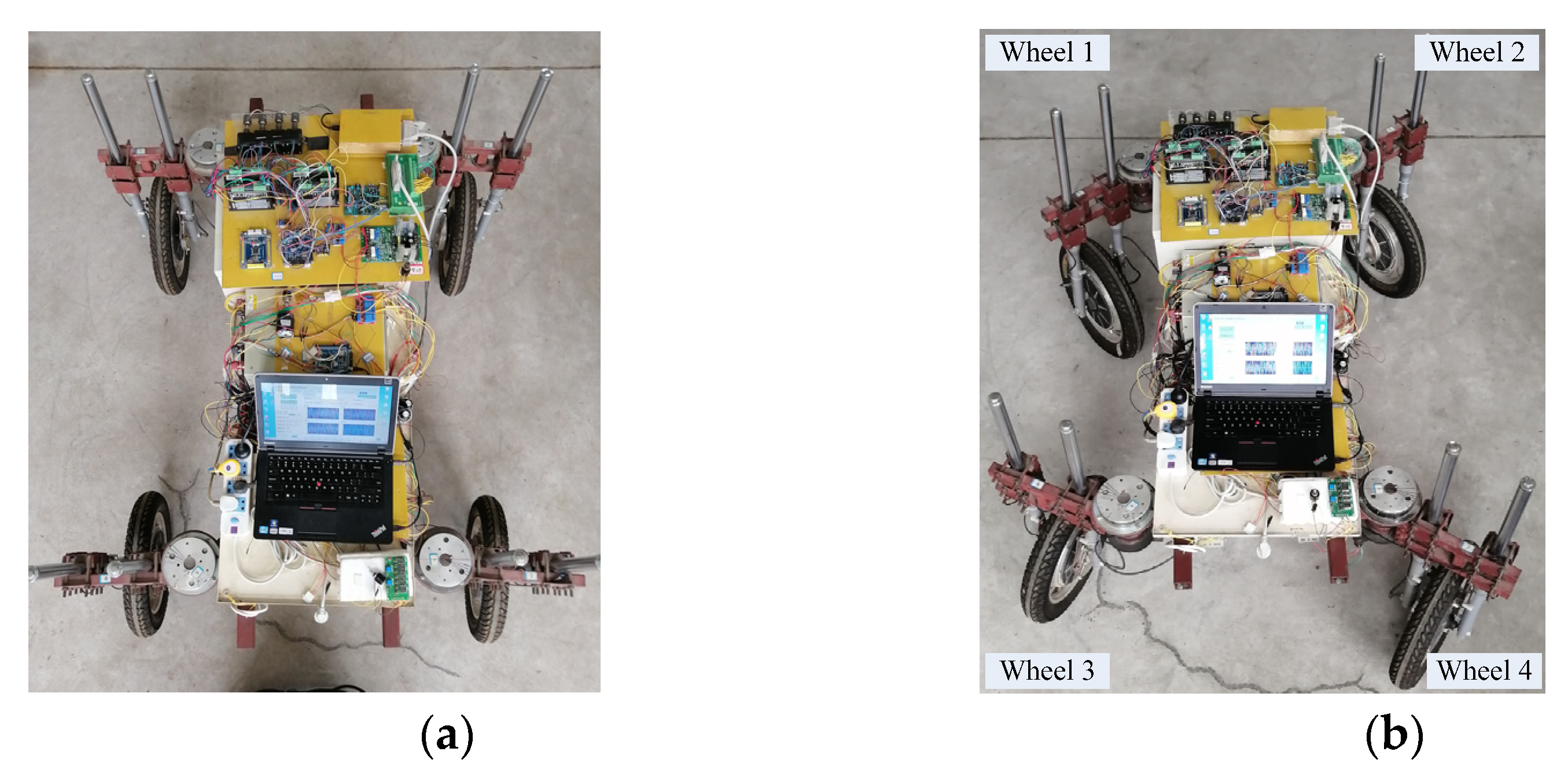

3.2. Experiment Device and Instrument

3.3. Test Method

3.4. Multi-Index Comprehensive Evaluation

- (1)

- Standardization of the index

- (2)

- The weight of each index was computed as:

- (3)

- The entropy value of the j index was given by:

- (4)

- The information entropy redundancy of the j index was expressed as:

- (5)

- The weight of the j index was computed as:

- (6)

- The comprehensive evaluation index was expressed as:

4. Results Analysis

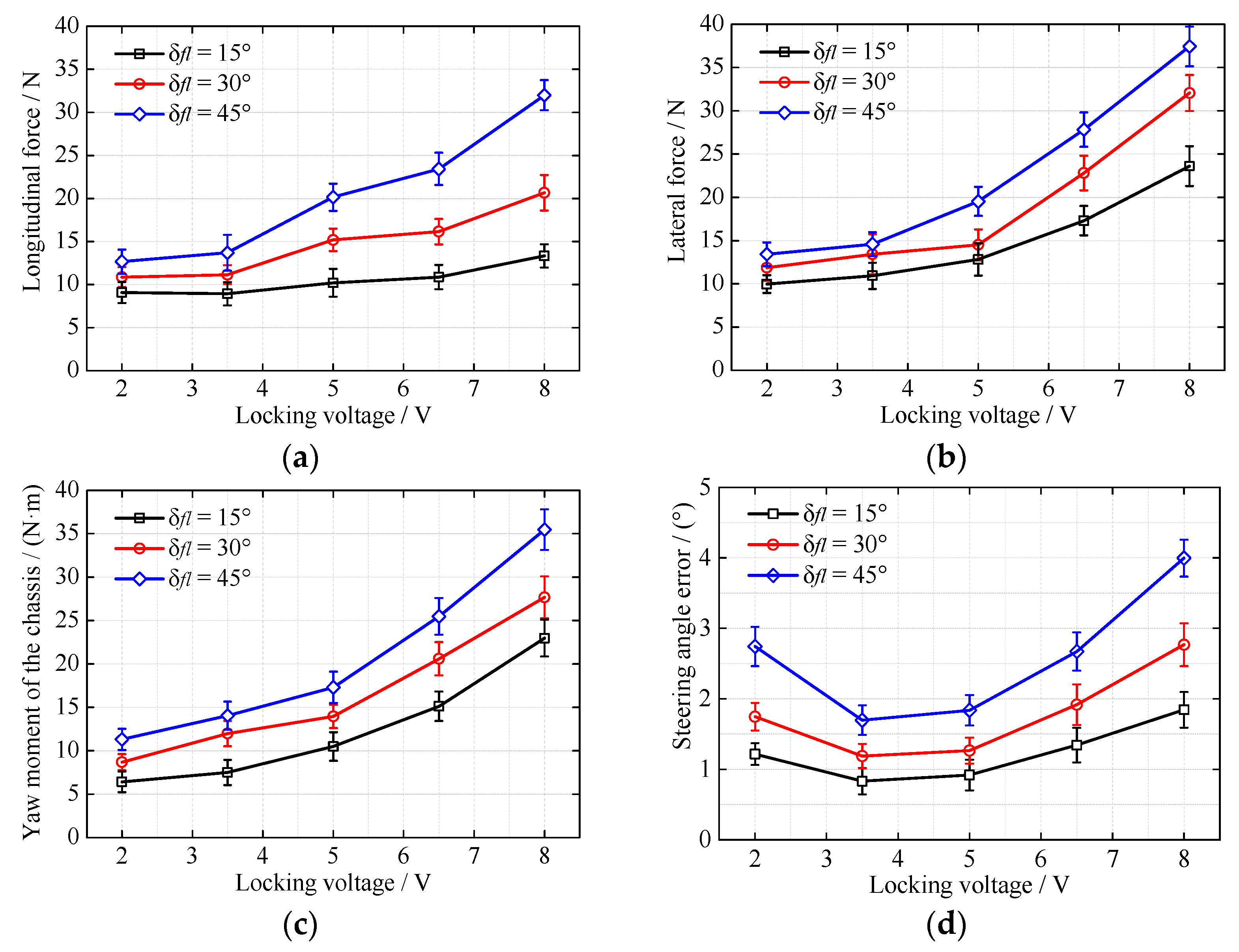

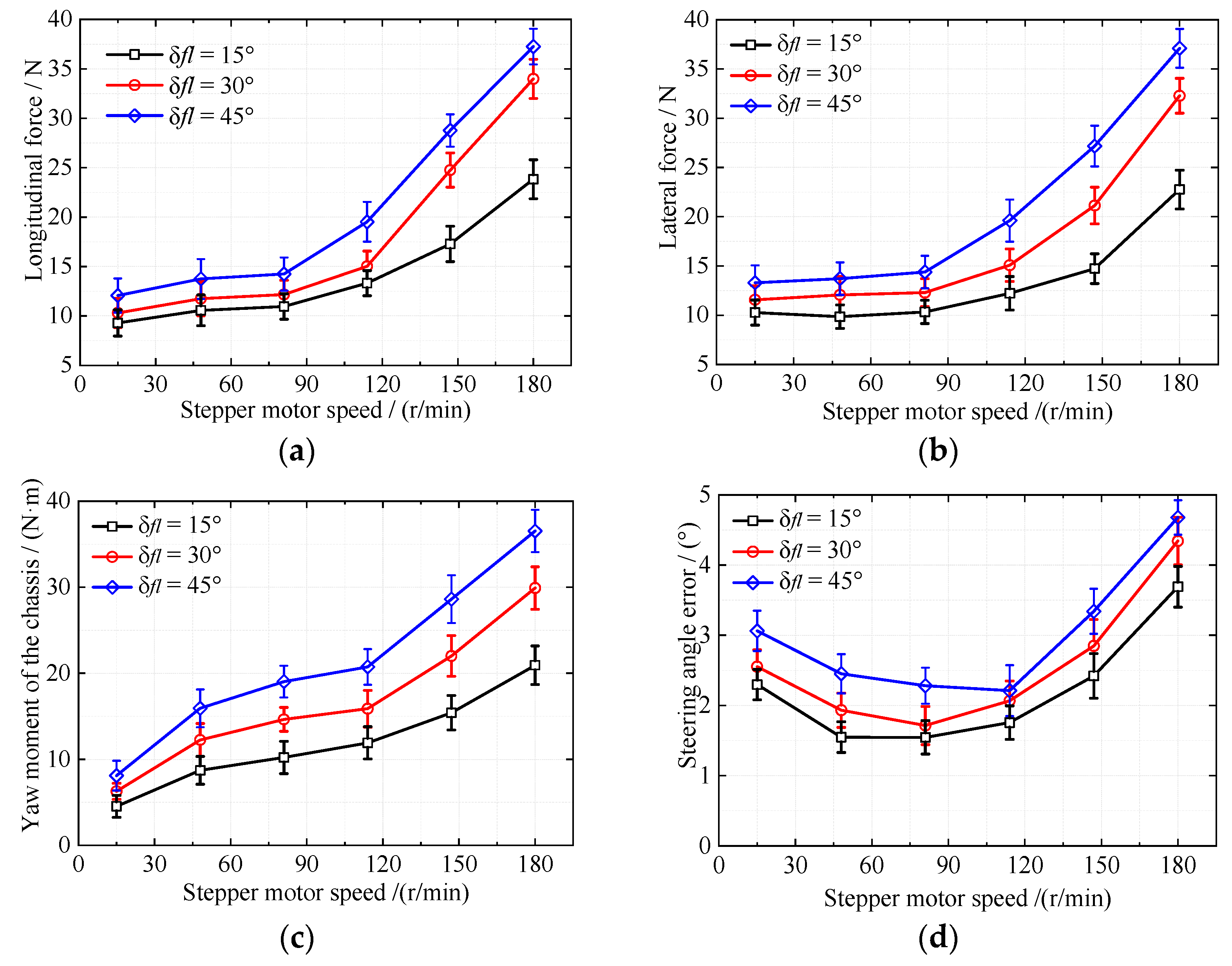

4.1. Single Factor Test Results

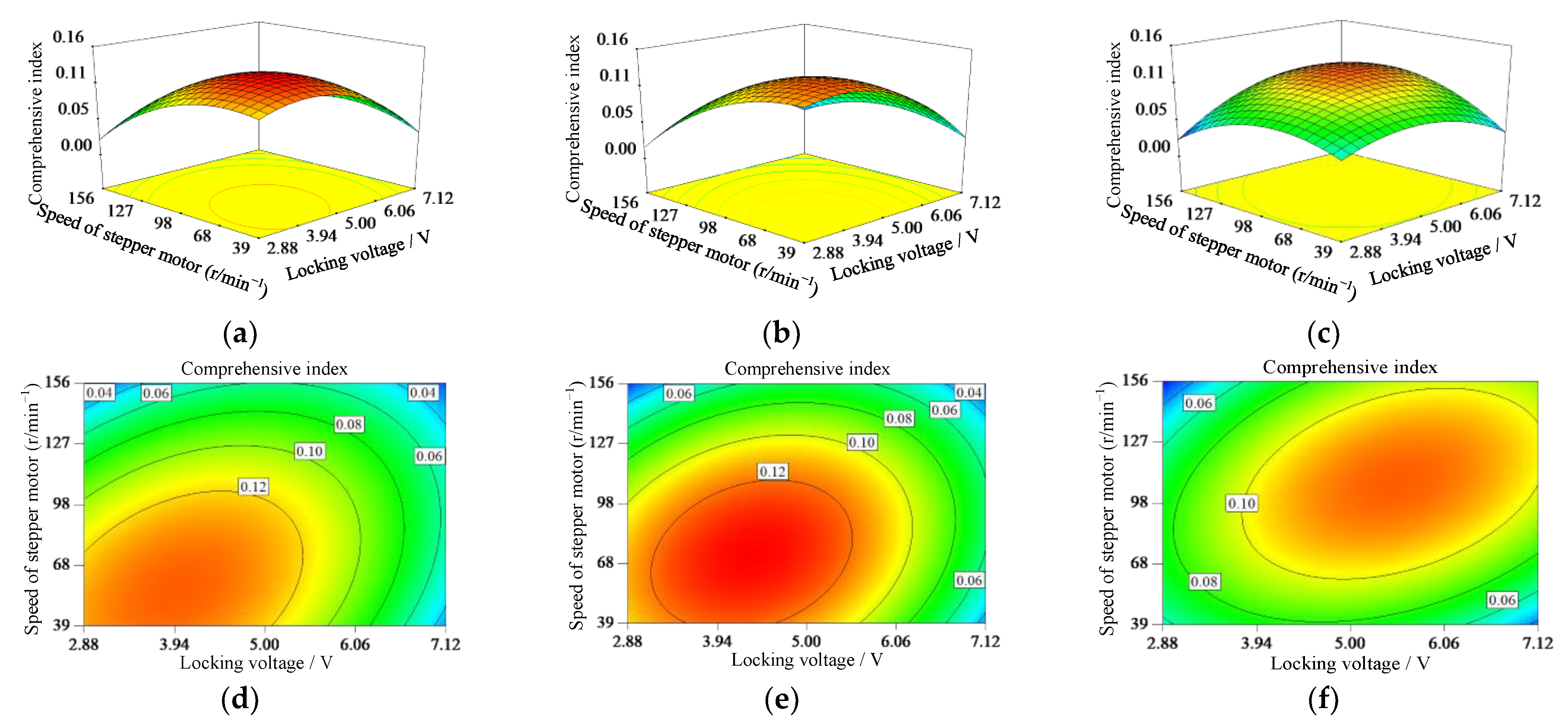

4.2. Combination Test Results

4.2.1. Analysis of Comprehensive Evaluation Index

4.2.2. Response Surface Analysis

4.3. Verification Test Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, J.; Liu, L.; Zhao, Y.; Li, H.; Lian, Y.; Zhang, Z.; Huang, C.; Du, X. Development of a high-resolution emission inventory of agricultural machinery with a novel methodology: A case study for Yangtze River Delta region. Environ. Pollut. 2020, 266, 115075. [Google Scholar] [CrossRef] [PubMed]

- Balafoutis, A.; Beck, B.; Fountas, S.; Vangeyte, J.; van der Wal, T.; Soto, I.; Gomez-Barbero, M.; Barnes, A.; Eory, V. Precision agriculture technologies positively contributing to GHG emissions mitigation, farm productivity and economics. Sustainability 2017, 9, 1339. [Google Scholar] [CrossRef]

- Mantoam, E.J.; Angnes, G.; Mekonnen, M.M.; Romanelli, T.L. Energy, carbon and water footprints on agricultural machinery. Biosyst. Eng. 2020, 198, 304–322. [Google Scholar] [CrossRef]

- Lovarelli, D.; Bacenetti, J. Exhaust gases emissions from agricultural tractors: State of the art and future perspectives for machinery operators. Biosyst. Eng. 2019, 186, 204–213. [Google Scholar] [CrossRef]

- Gonzalez-de-Soto, M.; Emmi, L.; Benavides, C.; Garcia, I.; Gonzalez-de-Santos, P. Reducing air pollution with hybrid-powered robotic tractors for precision agriculture. Biosyst. Eng. 2016, 143, 79–94. [Google Scholar] [CrossRef]

- Bechar, A.; Vigneault, C. Agricultural robots for field operations: Concepts and components. Biosyst. Eng. 2016, 149, 94–111. [Google Scholar] [CrossRef]

- Chang, C.L.; Song, G.B.; Lin, K.M. Two-stage guidance control scheme for high- precision straight-line navigation of a four-wheeled planting robot in a greenhouse. Trans. ASABE 2016, 59, 1193–1204. [Google Scholar] [CrossRef]

- Reina, G.; Milella, A.; Rouveure, R.; Nielsen, M.; Worst, R.; Blas, M.R. Ambient awareness for agricultural robotic vehicles. Biosyst. Eng. 2016, 146, 114–132. [Google Scholar] [CrossRef]

- Lombardi, G.V.; Berni, R. Renewable energy in agriculture: Farmers willingness-to-pay for a photovoltaic electric farm tractor. J. Clean. Prod. 2021, 313, 127520. [Google Scholar] [CrossRef]

- Jones, M.H.; Bell, J.; Dredge, D.; Seabright, M.; Scarfe, A.; Duke, M.; MacDonald, B. Design and testing of a heavy-duty platform for autonomous navigation in kiwifruit orchards. Biosyst. Eng. 2019, 187, 129–146. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, Y.; Zou, T.; Zhao, L.; Lou, P.; Yin, Z. Coordinated path tracking of two vision-guided tractors for heavy-duty robotic vehicles. Robot Cim.-Int. Manuf. 2018, 53, 93–107. [Google Scholar] [CrossRef]

- Mahmud, M.S.A.; Abidin, M.S.Z.; Mohamed, Z.; Rahman, M.K.I.A.; Iida, M. Multi- objective path planner for an agricultural mobile robot in a virtual greenhouse environment. Comput. Electron. Agric. 2019, 157, 488–499. [Google Scholar] [CrossRef]

- Gorjian, S.; Ebadi, H.; Trommsdorff, M.; Sharon, H.; Demant, M.; Schindele, S. The advent of modern solar-powered electric agricultural machinery: A solution for sustainable farm operations. J. Clean. Prod. 2021, 292, 126030. [Google Scholar] [CrossRef]

- Zhang, Y.; Ni, J.; Tian, H.; Wu, W.; Hu, J. Integrated robust dynamics control of all-wheel-independently-actuated unmanned ground vehicle in diagonal steering. Mech. Syst. Signal Process. 2022, 164, 108263. [Google Scholar] [CrossRef]

- Liu, X.; Wang, W.; Li, X.; Liu, F.; He, Z.; Yao, Y.; Ruan, H.; Zhang, T. MPC-based high-speed trajectory tracking for 4WIS robot. ISA Transact. 2022, 123, 413–424. [Google Scholar] [CrossRef] [PubMed]

- Raikwar, S.; Fehrmann, J.; Herlitzius, T. Navigation and control development for a four-wheel-steered mobile orchard robot using model-based design. Comput. Electron. Agric. 2022, 202, 107410. [Google Scholar] [CrossRef]

- Qiu, Q.; Fan, Z.; Meng, Z.; Zhang, Q.; Cong, Y.; Li, B.; Wang, N.; Zhao, C. Extended Ackerman Steering Principle for the coordinated movement control of a four wheel drive agricultural mobile robot. Comput. Electron. Agric. 2018, 152, 40–50. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, Z.; Zhang, L.; Dorrell, D.G. Braking/steering coordination control for in-wheel motor drive electric vehicles based on nonlinear model predictive control. Mech. Mach. Theory 2019, 142, 103586. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, D.; Zhu, S.; Feng, J.-E. Distributed active disturbance rejection control for Ackermann steering of a four-in-wheel motor drive vehicle with deception attacks on controller area networks. Inf. Sci. 2020, 540, 370–389. [Google Scholar] [CrossRef]

- Ghobadpour, A.; Boulon, L.; Mousazadeh, H.; Malvajerdi, A.S.; Rafiee, S. Asm and A. Sr. State of the art of autonomous agricultural off-road vehicles driven by renewable energy systems. Energy Procedia 2019, 162, 4–13. [Google Scholar] [CrossRef]

- Song, S.; Qu, J.; Li, Y.; Zhou, W.; Guo, K. Fuzzy control method for a steering system consisting of a four-wheel individual steering and four-wheel individual drive electric chassis. J. Int. Fuzzy Syst. 2016, 31, 2941–2948. [Google Scholar] [CrossRef]

- Qu, J.; Guo, K.; Zhang, Z.; Song, S.; Li, Y. Coupling control strategy and experiments for motion mode switching of a novel electric chassis. Appl. Sci. 2020, 10, 701. [Google Scholar] [CrossRef]

- Song, S.; Guo, K. Automatic tracking steering system for off-centered flexible chassis steering axis based on fuzzy-PI composite control. J. Int. Fuzzy Syst. 2018, 35, 187–195. [Google Scholar] [CrossRef]

- Song, S.; Li, Y.; Qu, J.; Zhou, W.; Guo, K. Design and test of flexible chassis automatic tracking steering system. Int. J. Agric. Biol. Eng. 2017, 10, 45–54. [Google Scholar] [CrossRef][Green Version]

- Lotfi, H.F.; Fallahnejad, R. Imprecise Shannon’s Entropy and Multi Attribute Decision Making. Entropy 2010, 12, 53–62. [Google Scholar] [CrossRef]

- Shannon, C.E. A mathematical theory of communication. Bell Syst. Tech. J. 1948, 27, 379–423. [Google Scholar] [CrossRef]

- Tu, X.; Gai, J.; Tang, L. Robust navigation control of a 4WD/4WS agricultural robotic vehicle. Comput. Electron. Agric. 2019, 164, 104892. [Google Scholar] [CrossRef]

- Grimstad, L.; From, P. The Thorvald II agricultural robotic system. Robotics 2017, 6, 24. [Google Scholar] [CrossRef]

- Utstumo, T.; Urdal, F.; Brevik, A.; Dorum, J.; Netland, J.; Overskeid, O.; Berge, T.W.; Gravdahl, J.T. Robotic in-row weed control in vegetables. Comput. Electron. Agric. 2018, 154, 36–45. [Google Scholar] [CrossRef]

- Wen, C.; Xie, B.; Song, Z.; Yang, Z.; Dong, N.; Han, J.; Yang, Q.; Liu, J. Methodology for designing tractor accelerated structure tests for an indoor drum-type test bench. Biosyst. Eng. 2021, 205, 1–26. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, H.; Shi, H. Study on energy flow test of electric vehicle based on four-wheel drive powertrain bench. In Proceedings of the 2020 6th International Conference on Energy, Environment and Materials Science, EEMS 2020, Hulun Buir, China, 28–30 August 2020; IOP Publishing Ltd.: Bristol, UK, 2020. [Google Scholar] [CrossRef]

- Parczewski, K.; Wnek, H. Influence of clearance on the rocker arm pin on the steerability and stability of the vehicle motion. Energies 2021, 14, 7827. [Google Scholar] [CrossRef]

- Ko, M.H.; Ryuh, B.S.; Kim, K.C.; Suprem, A.; Mahalik, N.P. Autonomous greenhouse mobile robot driving strategies from system integration perspective: Review and application. IEEE/ASME Trans. Mechatron. 2015, 20, 1705–1716. [Google Scholar] [CrossRef]

| Value Codes | Experimental Factors | |

|---|---|---|

| Locking Voltage Vl (V) | Stepper Motor Speed ns (r·min−1) | |

| 1.414 | 8.00 | 180.00 |

| 1 | 7.12 | 156.00 |

| 0 | 5.00 | 98.00 |

| −1 | 2.88 | 39.00 |

| −1.414 | 2.00 | 15.00 |

| Codes | Factors and Levels | Comprehensive Indexes | |||

|---|---|---|---|---|---|

| Locking Voltage Vl (V) | Speed of Stepper Motor ns (r·min−1) | YH1 (δfl = 15°) | YH2 (δfl = 30°) | YH3 (δfl = 45°) | |

| 1 | −1 | −1 | 0.0494 | 0.0495 | 0.0413 |

| 2 | 1 | −1 | 0.0098 | 0.0172 | 0.0854 |

| 3 | −1 | 1 | 0.0794 | 0.0336 | 0.0252 |

| 4 | 1 | 1 | 0.0359 | 0.0326 | 0.0391 |

| 5 | −1.414 | 0 | 0.1136 | 0.1281 | 0.1244 |

| 6 | 1.414 | 0 | 0.1415 | 0.128 | 0.111 |

| 7 | 0 | −1.414 | 0.0139 | 0.0188 | 0.0711 |

| 8 | 0 | 1.414 | 0.094 | 0.0842 | 0.0471 |

| 9 | 0 | 0 | 0.0912 | 0.1193 | 0.1106 |

| 10 | 0 | 0 | 0.1373 | 0.1216 | 0.0642 |

| 11 | 0 | 0 | 0.0197 | 0.0197 | 0.0566 |

| 12 | 0 | 0 | 0.1233 | 0.1331 | 0.1142 |

| 13 | 0 | 0 | 0.0911 | 0.1143 | 0.1097 |

| Sources | YH1 (δfl = 15°) | YH2 (δfl = 30°) | YH3 (δfl = 45°) | |||

|---|---|---|---|---|---|---|

| F Value | Significant Level p | F Value | Significant Level p | F Value | Significant Level p | |

| Model | 14.44 | 0.0014 | 45.11 | <0.0001 | 96.82 | <0.0001 |

| x1 | 9.92 | 0.0162 | 22.78 | 0.002 | 30.51 | 0.0009 |

| x2 | 17.73 | 0.004 | 38.75 | 0.0004 | 7.56 | 0.0285 |

| x1x2 | 6.01 | 0.044 | 10.85 | 0.0132 | 56.46 | 0.0001 |

| x12 | 28.48 | 0.0011 | 105.89 | <0.0001 | 202.94 | <0.0001 |

| x22 | 15.01 | 0.0061 | 67.22 | <0.0001 | 235.68 | <0.0001 |

| Lack of fit | 0.84 | 0.5379 | 3.66 | 0.1211 | 0.52 | 0.6922 |

| Signal to noise ratio | 8.760 | 14.967 | 23.536 | |||

| R Square | R2 = 0.9116 = 0.8485 | R2 = 0.9699 = 0.9484 | R2 = 0.9857 = 0.9756 | |||

| Comparison Items | YH1 (δfl = 15°) | YH2 (δfl = 30°) | YH3 (δfl = 45°) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Y1 (m·s−2) | Y2 (m·s−2) | Y3 (rad·s−2) | Y4 (°) | Y1 (m·s−2) | Y2 (m·s−2) | Y3 (rad·s−2) | Y4 (°) | Y1 (m·s−2) | Y2 (m·s−2) | Y3 (rad·s−2) | Y4 (°) | |

| Optimized | 0.0112 | 0.0109 | 0.0392 | 0.95 | 0.0153 | 0.0149 | 0.0508 | 1.04 | 0.0214 | 0.0198 | 0.0732 | 1.98 |

| Unoptimized | 0.0187 | 0.0183 | 0.0597 | 1.37 | 0.0282 | 0.0295 | 0.0858 | 1.56 | 0.0374 | 0.0386 | 0.1213 | 2.73 |

| Variation (%) | 40.1% | 40.4% | 34.3% | 30.7% | 45.7% | 49.5% | 40.8% | 33.3% | 42.8% | 48.7% | 39.7% | 27.5% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, J.; Li, H.; Zhang, Z.; Xi, X.; Zhang, R.; Guo, K. Performance Analysis and Optimization for Steering Motion Mode Switching of an Agricultural Four-Wheel-Steering Mobile Robot. Agronomy 2022, 12, 2655. https://doi.org/10.3390/agronomy12112655

Qu J, Li H, Zhang Z, Xi X, Zhang R, Guo K. Performance Analysis and Optimization for Steering Motion Mode Switching of an Agricultural Four-Wheel-Steering Mobile Robot. Agronomy. 2022; 12(11):2655. https://doi.org/10.3390/agronomy12112655

Chicago/Turabian StyleQu, Jiwei, Hongji Li, Zhe Zhang, Xiaobo Xi, Ruihong Zhang, and Kangquan Guo. 2022. "Performance Analysis and Optimization for Steering Motion Mode Switching of an Agricultural Four-Wheel-Steering Mobile Robot" Agronomy 12, no. 11: 2655. https://doi.org/10.3390/agronomy12112655

APA StyleQu, J., Li, H., Zhang, Z., Xi, X., Zhang, R., & Guo, K. (2022). Performance Analysis and Optimization for Steering Motion Mode Switching of an Agricultural Four-Wheel-Steering Mobile Robot. Agronomy, 12(11), 2655. https://doi.org/10.3390/agronomy12112655