Non-Destructive Estimation of Fruit Weight of Strawberry Using Machine Learning Models

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Collection of Strawberries

2.2. Measurement of Biometrical Characteristics

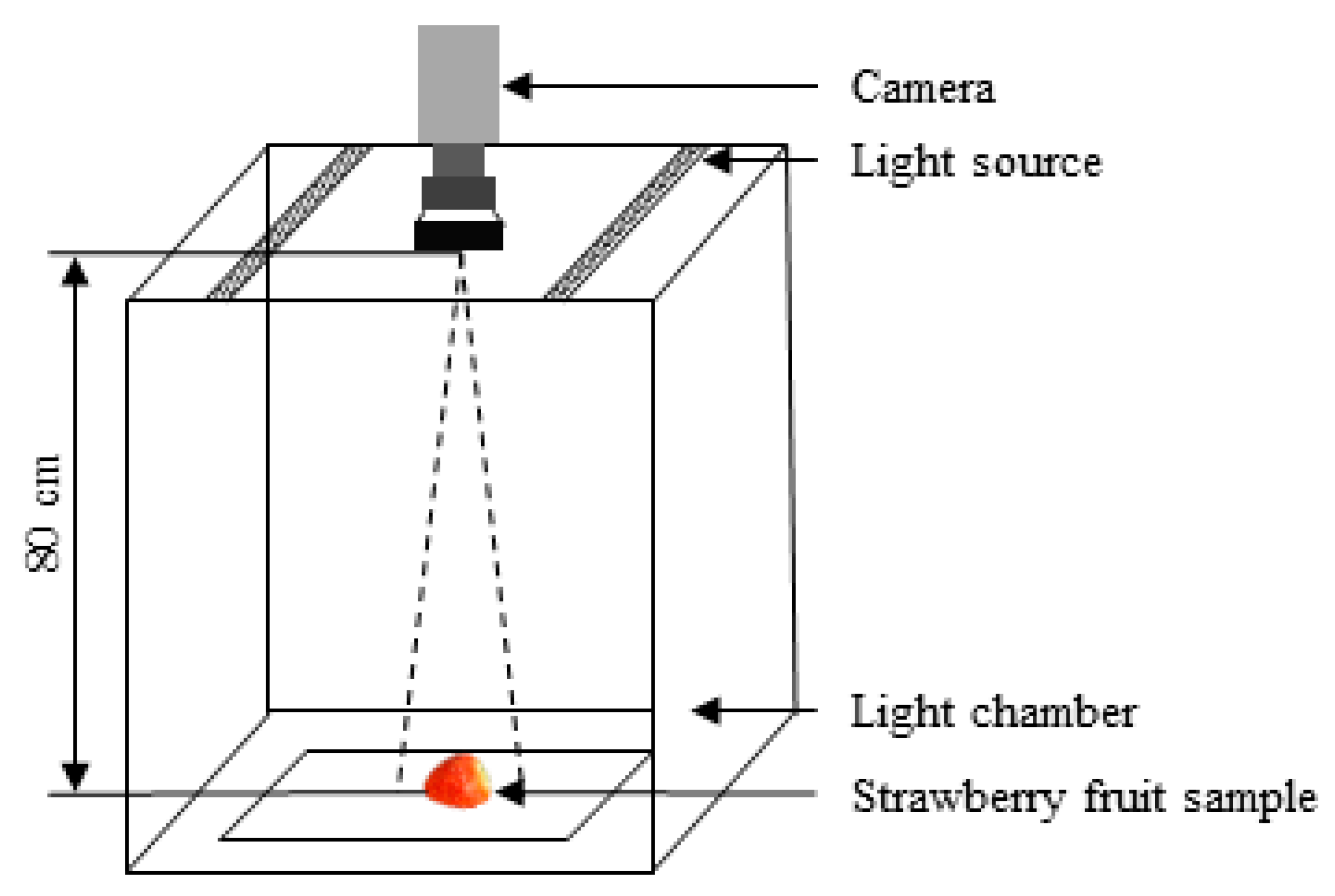

2.3. Image Acquisition of Strawberry Fruits

2.4. Pixel Numbers Calculation from Strawberry Image

2.5. Data Pre-Processing for Prediction Models Development

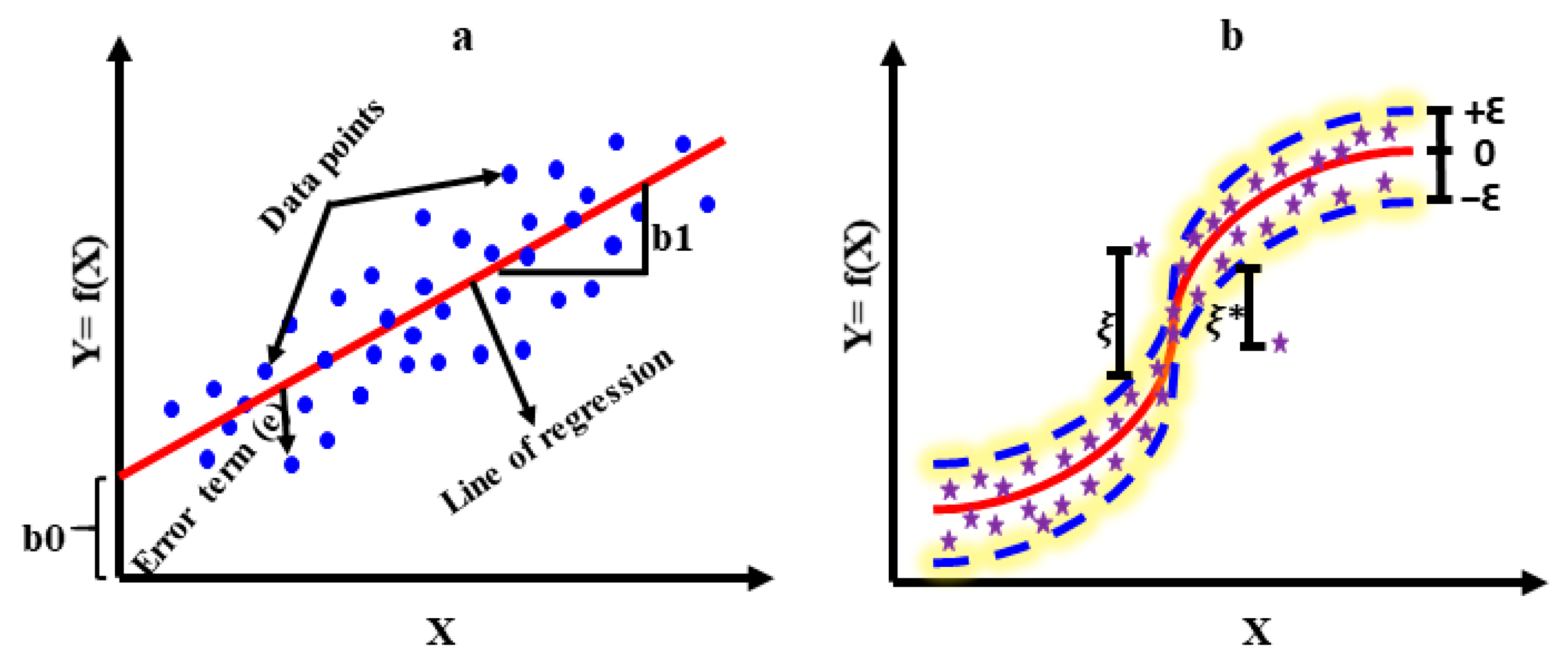

2.6. Development of Linear Regression (LR) Model

2.7. Development of Support Vector Regression (SVR)

2.8. Application Methodology and Model Performance Metrics

3. Results and Discussion

3.1. Changes in Biometrical Characteristics and Pixel Numbers

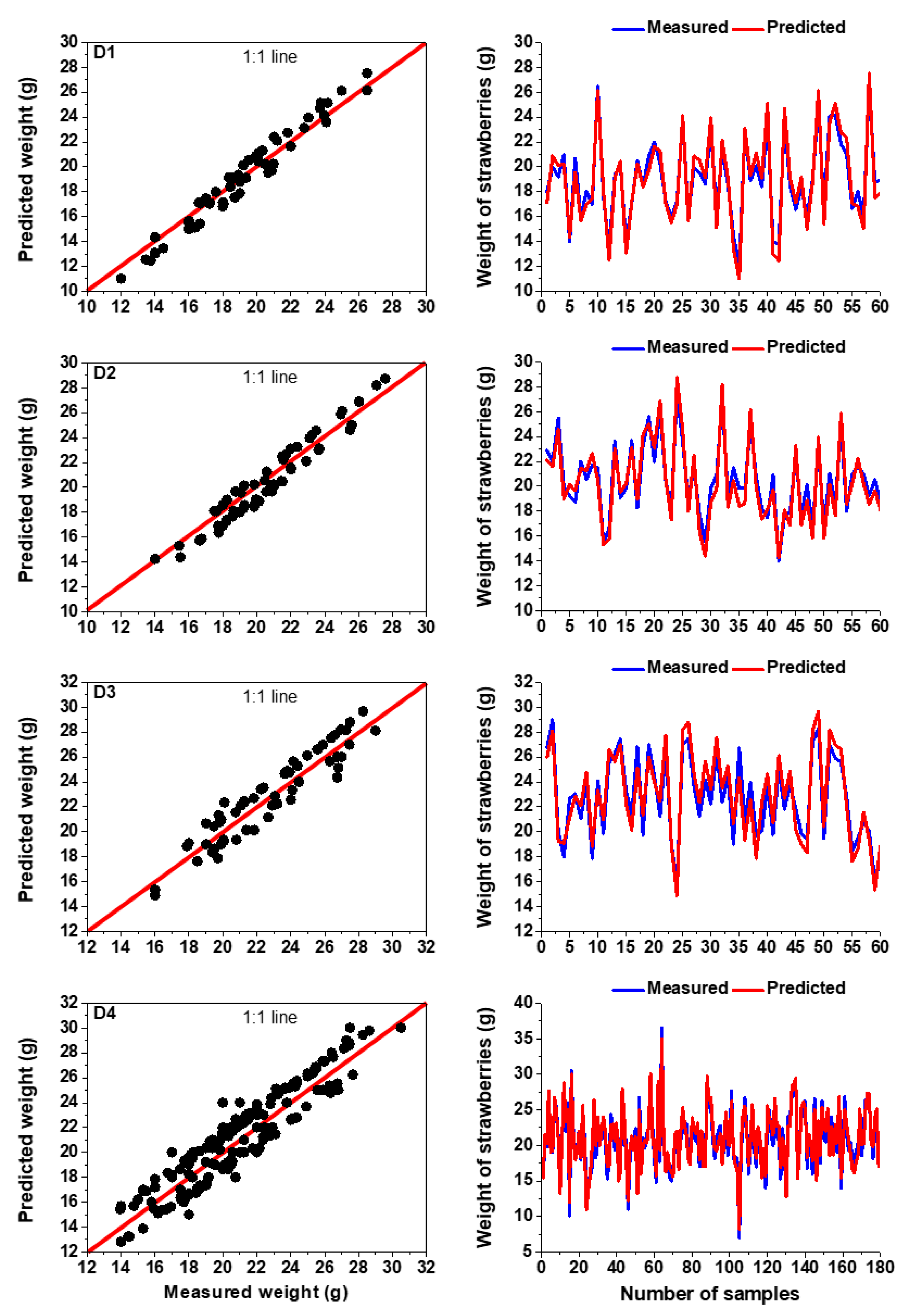

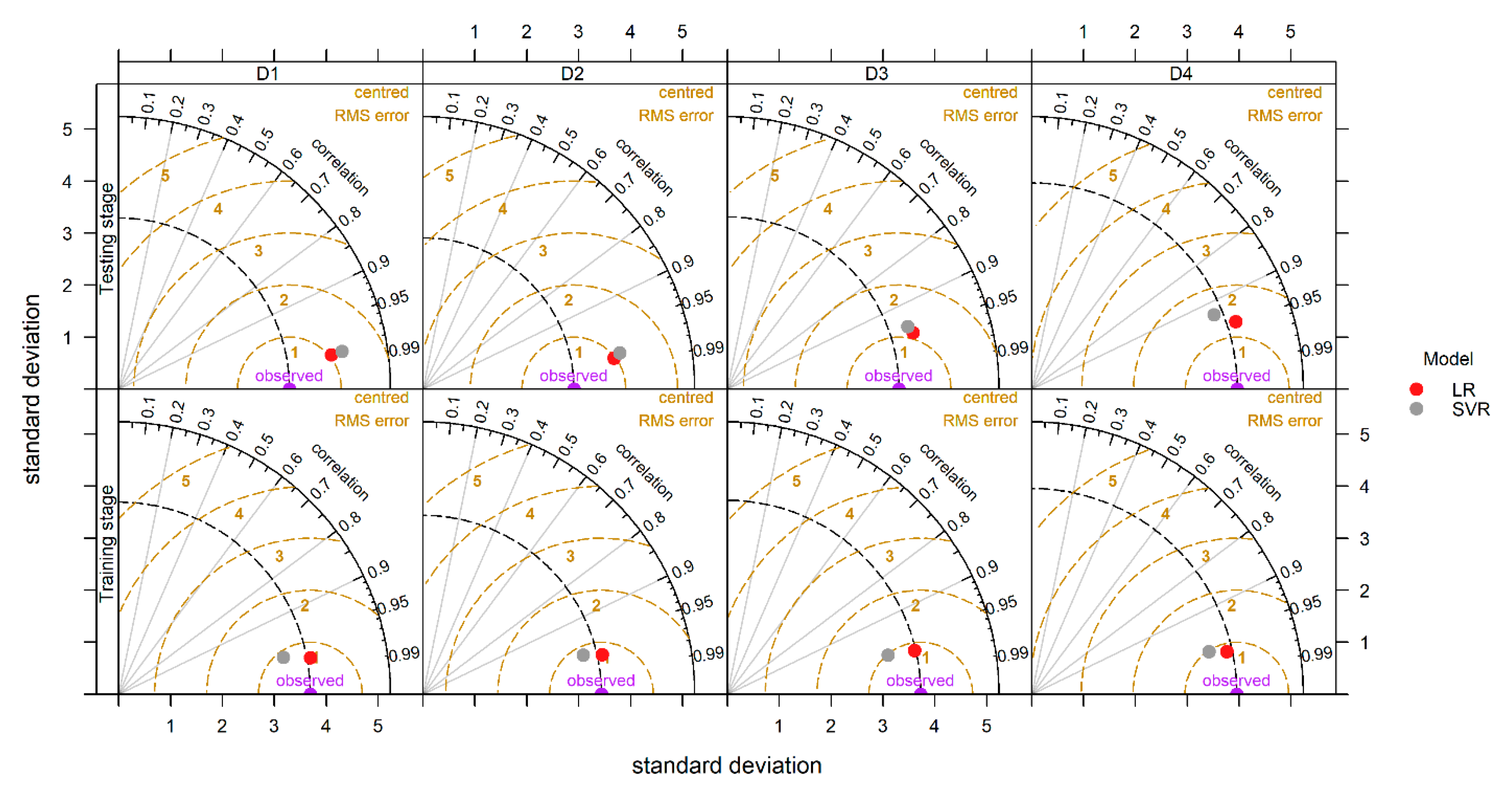

3.2. LR Model Performance for Fruit Weight Prediction

3.3. SVR Model Performance for Fruit Weight Prediction

3.4. Comparison LR and SVR Model’s Performance and Proposed Model

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Simpson, D. The Economic Importance of Strawberry Crops. In The Genomes of Rosaceous Berries and Their Wild Relatives; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1–7. [Google Scholar]

- Giampieri, F.; Forbes-Hernandez, T.Y.; Gasparrini, M.; Alvarez-Suarez, J.M.; Afrin, S.; Bompadre, S.; Quiles, J.L.; Mezzetti, B.; Battino, M. Strawberry as a Health Promoter: An Evidence Based Review. Food Funct. 2015, 6, 1386–1398. [Google Scholar] [CrossRef] [PubMed]

- Basak, J.K.; Gamage, B.; Madhavi, K.; Paudel, B.; Kim, N.E.; Kim, H.T. Prediction of Total Soluble Solids and pH of Strawberry Fruits Using RGB, HSV and HSL Colour Spaces and Machine Learning Models. Foods 2022, 11, 2086. [Google Scholar] [CrossRef] [PubMed]

- Amoriello, T.; Ciccoritti, R.; Ferrante, P. Prediction of Strawberries’ Quality Parameters Using Artificial Neural Networks. Agronomy 2022, 12, 963. [Google Scholar] [CrossRef]

- Zhou, C.; Hu, J.; Xu, Z.; Yue, J.; Ye, H.; Yang, G. A Novel Greenhouse-Based System for the Detection and Plumpness Assessment of Strawberry Using an Improved Deep Learning Technique. Front. Plant Sci. 2020, 11, 559. [Google Scholar] [CrossRef]

- de Jesús Ornelas-Paz, J.; Yahia, E.M.; Ramírez-Bustamante, N.; Pérez-Martínez, J.D.; del Pilar Escalante-Minakata, M.; Ibarra-Junquera, V.; Acosta-Muñiz, C.; Guerrero-Prieto, V.; Ochoa-Reyes, E. Physical Attributes and Chemical Composition of Organic Strawberry Fruit (Fragaria x ananassa Duch, Cv. Albion) at Six Stages of Ripening. Food Chem. 2013, 138, 372–381. [Google Scholar] [CrossRef]

- Suárez, J.C.; Casanoves, F.; Di Rienzo, J. Non-Destructive Estimation of the Leaf Weight and Leaf Area in Common Bean. Agronomy 2022, 12, 711. [Google Scholar] [CrossRef]

- Tagawa, A.; Ehara, M.; Ito, Y.; Araki, T.; Ozaki, Y.; Shishido, Y. Effects of CO2 Enrichment on Yield, Photosynthetic Rate, Translocation and Distribution of Photoassimilates in Strawberry ‘Sagahonoka’. Agronomy 2022, 12, 473. [Google Scholar] [CrossRef]

- Zhang, B.; Gu, B.; Tian, G.; Zhou, J.; Huang, J.; Xiong, Y. Challenges and Solutions of Optical-Based Nondestructive Quality Inspection for Robotic Fruit and Vegetable Grading Systems: A Technical Review. Trends Food Sci. Technol. 2018, 81, 213–231. [Google Scholar] [CrossRef]

- Kohyama, K.; Masuda, T.; Shimada, H.; Tanaka, T.; Wada, Y. A Simple Mechanical Index of Storage Quality of Strawberry Fruits. Rep. Natl. Food Res. Inst. 2013, 77, 1–11. [Google Scholar]

- Ruan, J.; Lee, Y.H.; Hong, S.J.; Yeoung, Y.R. Sugar and Organic Acid Contents of Day-Neutral and Ever-Bearing Strawberry Cultivars in High-Elevation for Summer and Autumn Fruit Production in Korea. Hortic. Environ. Biotechnol. 2013, 54, 214–222. [Google Scholar] [CrossRef]

- Diago, M.P.; Tardaguila, J.; Aleixos, N.; Millan, B.; Prats-Montalban, J.M.; Cubero, S.; Blasco, J. Assessment of Cluster Yield Components by Image Analysis. J. Sci. Food Agric. 2015, 95, 1274–1282. [Google Scholar] [CrossRef]

- Linares Torres, R.; Baeza Trujillo, P.; Miranda, C.; Lissarrague Garcia-Gutierrez, J.R. Comparison of Different Methods of Grapevine Yield Prediction in the Time Window between Fruitset and Veraison. J. Int. Sci. Vigne Vin 2015, 49, 27–35. [Google Scholar]

- Demirsoy, H.; Demirsoy, L. Prediction Model for Estimating Peach Fruit Weight and Volume on the Basis of Fruit Linear Measurements during Growth. J. Fruit Ornam. Plant Res. 2007, 15, 65–69. [Google Scholar]

- van Dijk, A.D.J.; Kootstra, G.; Kruijer, W.; de Ridder, D. Machine Learning in Plant Science and Plant Breeding. iScience 2021, 24, 101890. [Google Scholar] [CrossRef]

- Lu, X.; Ma, F.; Xu, J.; Zhang, Z. Oil Futures Volatility Predictability: New Evidence Based on Machine Learning Models1. Int. Rev. Financ. Anal. 2022, 83, 102299. [Google Scholar] [CrossRef]

- Hesami, M.; Naderi, R.; Tohidfar, M. Introducing a Hybrid Artificial Intelligence Method for High-Throughput Modeling and Optimizing Plant Tissue Culture Processes: The Establishment of a New Embryogenesis Medium for Chrysanthemum, as a Case Study. Appl. Microbiol. Biotechnol. 2020, 104, 10249–10263. [Google Scholar] [CrossRef]

- Singh, A.; Ganapathysubramanian, B.; Singh, A.K.; Sarkar, S. Machine Learning for High-Throughput Stress Phenotyping in Plants. Trends Plant Sci. 2016, 21, 110–124. [Google Scholar] [CrossRef]

- Hesami, M.; Alizadeh, M.; Jones, A.M.P.; Torkamaneh, D. Machine Learning: Its Challenges and Opportunities in Plant System Biology. Appl. Microbiol. Biotechnol. 2022, 106, 3507–3530. [Google Scholar] [CrossRef]

- Grinblat, G.L.; Uzal, L.C.; Larese, M.G.; Granitto, P.M. Deep Learning for Plant Identification Using Vein Morphological Patterns. Comput. Electron. Agric. 2016, 127, 418–424. [Google Scholar] [CrossRef]

- Mishra, B.; Kumar, N.; Mukhtar, M.S. Systems Biology and Machine Learning in Plant–Pathogen Interactions. Mol. Plant-Microbe Interact. 2019, 32, 45–55. [Google Scholar] [CrossRef]

- Li, B.; Lecourt, J.; Bishop, G. Advances in Non-Destructive Early Assessment of Fruit Ripeness towards Defining Optimal Time of Harvest and Yield Prediction—A Review. Plants 2018, 7, 3. [Google Scholar] [CrossRef]

- Lu, W.; Du, R.; Niu, P.; Xing, G.; Luo, H.; Deng, Y.; Shu, L. Soybean Yield Preharvest Prediction Based on Bean Pods and Leaves Image Recognition Using Deep Learning Neural Network Combined With GRNN. Front. Plant Sci. 2022, 12, 791256. [Google Scholar] [CrossRef]

- Zhao, S.; Zheng, H.; Chi, M.; Chai, X.; Liu, Y. Rapid Yield Prediction in Paddy Fields Based on 2D Image Modelling of Rice Panicles. Comput. Electron. Agric. 2019, 162, 759–766. [Google Scholar] [CrossRef]

- Yang, W.; Nigon, T.; Hao, Z.; Paiao, G.D.; Fernández, F.G.; Mulla, D.; Yang, C. Estimation of Corn Yield Based on Hyperspectral Imagery and Convolutional Neural Network. Comput. Electron. Agric. 2021, 184, 106092. [Google Scholar] [CrossRef]

- Zhang, B.; Guo, N.; Huang, J.; Gu, B.; Zhou, J. Computer Vision Estimation of the Volume and Weight of Apples by Using 3D Reconstruction and Noncontact Measuring Methods. J. Sens. 2020, 2020, 5053407. [Google Scholar] [CrossRef]

- Teoh, C.C.; Syaifudin, A.R.M. Image Processing and Analysis Techniques for Estimating Weight of Chokanan Mangoes. J. Trop. Agric. Food Sci. 2007, 35, 183–190. [Google Scholar]

- ElMasry, G.; Wang, N.; ElSayed, A.; Ngadi, M. Hyperspectral Imaging for Nondestructive Determination of Some Quality Attributes for Strawberry. J. Food Eng. 2007, 81, 98–107. [Google Scholar] [CrossRef]

- Peng, Y.; Lu, R. Analysis of Spatially Resolved Hyperspectral Scattering Images for Assessing Apple Fruit Firmness and Soluble Solids Content. Postharvest Biol. Technol. 2008, 48, 52–62. [Google Scholar] [CrossRef]

- Indrabayu, I.; Arifin, N.; Areni, I.S. Strawberry Ripeness Classification System Based on Skin Tone Color Using Multi-Class Support Vector Machine. In Proceedings of the 2019 International Conference on Information and Communications Technology (ICOIACT), Yogyakarta, Indonesia, 24–25 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 191–195. [Google Scholar]

- Pardede, J.; Husada, M.G.; Hermana, A.N.; Rumapea, S.A. Fruit Ripeness Based on RGB, HSV, HSL, L* A* B* Color Feature Using SVM. In Proceedings of the 2019 International Conference of Computer Science and Information Technology (ICoSNIKOM), Medan, Indonesia, 28–29 November 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–5. [Google Scholar]

- Li, X.; Li, J.; Tang, J. A Deep Learning Method for Recognizing Elevated Mature Strawberries. In Proceedings of the 2018 33rd Youth Academic Annual Conference of Chinese Association of Automation (YAC), Nanjing, China, 18–20 May 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1072–1077. [Google Scholar]

- Elhariri, E.; El-Bendary, N.; Hussein, A.M.M.; Hassanien, A.E.; Badr, A. Bell Pepper Ripeness Classification Based on Support Vector Machine. In Proceedings of the 2014 International Conference on Engineering and Technology (ICET), Cairo, Egypt, 19–20 April 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1–6. [Google Scholar]

- Omid, M.; Khojastehnazhand, M.; Tabatabaeefar, A. Estimating Volume and Mass of Citrus Fruits by Image Processing Technique. J. Food Eng. 2010, 100, 315–321. [Google Scholar] [CrossRef]

- Jung, D.-H.; Park, S.H.; Han, X.Z.; Kim, H.-J. Image Processing Methods for Measurement of Lettuce Fresh Weight. J. Biosyst. Eng. 2015, 40, 89–93. [Google Scholar] [CrossRef]

- Bozkurt, Y.; Aktan, S.; Ozkaya, S. Body Weight Prediction Using Digital Image Analysis for Slaughtered Beef Cattle. J. Appl. Anim. Res. 2007, 32, 195–198. [Google Scholar] [CrossRef]

- Lee, J.W.; Son, J.E. Nondestructive and Continuous Freshweight Measurements of Bell Peppers Grown in Soilless Culture Systems. Agronomy 2019, 9, 652. [Google Scholar] [CrossRef]

- Sayinci, B.; Ercisli, S.; Ozturk, I.; Eryilmaz, Z.; Demir, B. Determination of Size and Shape in the’Moro’blood Orange and’Valencia’sweet Orange Cultivar and Its Mutants Using Image Processing. Not. Bot. Horti Agrobot. Cluj-Napoca 2012, 40, 234–242. [Google Scholar] [CrossRef][Green Version]

- Campillo, C.; Prieto, M.H.; Daza, C.; Monino, M.J.; Garcia, M.I. Using Digital Images to Characterize Canopy Coverage and Light Interception in a Processing Tomato Crop. Hortscience 2008, 43, 1780–1786. [Google Scholar] [CrossRef]

- Lee, D.H.; Cho, Y.; Choi, J.M. Strawberry Volume Estimation Using Smartphone Image Processing. Hortic. Sci. Technol. 2017, 35, 707–716. [Google Scholar]

- Basak, J.K.; Eun, N.; Shihab, K.; Shahriar, A.; Paudel, B.; Eun, B. Applicability of Statistical and Machine Learning—Based Regression Algorithms in Modeling of Carbon Dioxide Emission in Experimental Pig Barns. Air Qual. Atmos. Health 2022, 15, 1899–1912. [Google Scholar] [CrossRef]

- Basak, J.K.; Okyere, F.G.; Arulmozhi, E.; Park, J.; Khan, F.; Kim, H.T. Artificial Neural Networks and Multiple Linear Regression as Potential Methods for Modelling Body Surface Temperature of Pig. J. Appl. Anim. Res. 2020, 48, 207–219. [Google Scholar] [CrossRef]

- Basak, J.K.; Qasim, W.; Okyere, F.G.; Khan, F.; Lee, Y.J.; Park, J.; Kim, H.T. Regression Analysis to Estimate Morphology Parameters of Pepper Plant in a Controlled Greenhouse System. J. Biosyst. Eng. 2019, 44, 57–68. [Google Scholar] [CrossRef]

- Arulmozhi, E.; Basak, J.K.; Sihalath, T.; Park, J.; Kim, H.T.; Moon, B.E. Machine Learning-Based Microclimate Model for Indoor Air Temperature and Relative Humidity Prediction in a Swine Building. Animals 2021, 11, 222. [Google Scholar] [CrossRef]

- Basak, J.K.; Arulmozhi, E.; Moon, B.E.; Bhujel, A.; Kim, H.T. Modelling Methane Emissions from Pig Manure Using Statistical and Machine Learning Methods. Air Qual. Atmos. Health 2022, 15, 575–589. [Google Scholar] [CrossRef]

- Madhavi, B.G.K.; Basak, J.K.; Paudel, B.; Kim, N.E.; Choi, G.M.; Kim, H.T. Prediction of Strawberry Leaf Color Using RGB Mean Values Based on Soil Physicochemical Parameters Using Machine Learning Models. Agronomy 2022, 12, 981. [Google Scholar] [CrossRef]

- Khan, F.; Kim, N.E.; Bhujel, A.; Jaihuni, M.; Lee, D.H.; Basak, J.K.; Kim, H.T. Assessment of Combined Trichoderma-Enriched Biofertilizer and Nutrients Solutions on the Growth and Yield of Strawberry Plants. J. Biosyst. Eng. 2021, 46, 225–235. [Google Scholar] [CrossRef]

- Cubero, S.; Aleixos, N.; Moltó, E.; Gómez-Sanchis, J.; Blasco, J. Advances in Machine Vision Applications for Automatic Inspection and Quality Evaluation of Fruits and Vegetables. Food Bioprocess Technol. 2011, 4, 487–504. [Google Scholar] [CrossRef]

- Phan, B.T. Bayesian Deep Learning and Uncertainty in Computer Vision. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2019. [Google Scholar]

- Bhujel, A.; Khan, F.; Basak, J.K.; Jaihuni, M.; Sihalath, T.; Moon, B.E.; Park, J.; Kim, H.T. Detection of Gray Mold Disease and Its Severity on Strawberry Using Deep Learning Networks. J. Plant Dis. Prot. 2022, 129, 579–592. [Google Scholar] [CrossRef]

- Basak, J.K.; Arulmozhi, E.; Khan, F.; Okyere, F.G.; Park, J.; Kim, H.T. Modeling of Ambient Environment and Thermal Status Relationship of Pig’s Body in a Pig Barn. Indian J. Anim. Res. 2020, 54, 1049–1054. [Google Scholar] [CrossRef]

- Bhujel, A.; Kim, N.E.; Arulmozhi, E.; Basak, J.K.; Kim, H.T. A Lightweight Attention-Based Convolutional Neural Networks for Tomato Leaf Disease Classification. Agriculture 2022, 12, 228. [Google Scholar] [CrossRef]

- Kumari, K.; Yadav, S. Linear Regression Analysis Study. J. Pract. Cardiovasc. Sci. 2018, 4, 33–36. [Google Scholar] [CrossRef]

- Zhao, T.; Xue, H. Regression Analysis and Indoor Air Temperature Model of Greenhouse in Northern Dry and Cold Regions. In Proceedings of the International Conference on Computer and Computing Technologies in Agriculture, Nanchang, China, 22–25 October 2010; Springer: Berlin/Heidelberg, Germany, 2010; pp. 252–258. [Google Scholar]

- Thissen, U.; Pepers, M.; Üstün, B.; Melssen, W.J.; Buydens, L.M.C. Comparing Support Vector Machines to PLS for Spectral Regression Applications. Chemom. Intell. Lab. Syst. 2004, 73, 169–179. [Google Scholar] [CrossRef]

- Drucker, H.; Burges, C.J.; Kaufman, L.; Smola, A.; Vapnik, V. Support Vector Regression Machines. In Advances in Neural Information Processing Systems 9; MIT Press: Cambridge, MA, USA, 1996. [Google Scholar]

- Sarkar, S.; Basak, J.K.; Moon, B.E.; Kim, H.T. A Comparative Study of PLSR and SVM-R with Various Preprocessing Techniques for the Quantitative Determination of Soluble Solids Content of Hardy Kiwi Fruit by a Portable Vis/NIR Spectrometer. Foods 2020, 9, 1078. [Google Scholar] [CrossRef] [PubMed]

- Van Der Walt, S.; Colbert, S.C.; Varoquaux, G. The NumPy Array: A Structure for Efficient Numerical Computation. Comput. Sci. Eng. 2011, 13, 22–30. [Google Scholar] [CrossRef]

- McKinney, W. Data Structures for Statistical Computing in Python. In Proceedings of the 9th Python in Science Conference, Austin, TX, USA, 28 June–3 July 2010; Volume 445, pp. 51–56. [Google Scholar]

- Jeong, H.J.; Choi, H.G.; Moon, B.Y.; Cheong, J.W.; Kang, N.J. Comparative Analysis of the Fruit Characteristics of Four Strawberry Cultivars Commonly Grown in South Korea. Hortic. Sci. Technol. 2016, 34, 396–404. [Google Scholar] [CrossRef]

- Ferreyra, R.M.; Viña, S.Z.; Mugridge, A.; Chaves, A.R. Growth and Ripening Season Effects on Antioxidant Capacity of Strawberry Cultivar Selva. Sci. Hortic. 2007, 112, 27–32. [Google Scholar] [CrossRef]

- Figueroa, C.R.; Pimentel, P.; Gaete-Eastman, C.; Moya, M.; Herrera, R.; Caligari, P.D.S.; Moya-León, M.A. Softening Rate of the Chilean Strawberry (Fragaria Chiloensis) Fruit Reflects the Expression of Polygalacturonase and Pectate Lyase Genes. Postharvest Biol. Technol. 2008, 49, 210–220. [Google Scholar] [CrossRef]

- Doymaz, I. Convective Drying Kinetics of Strawberry. Chem. Eng. Process. Process Intensif. 2008, 47, 914–919. [Google Scholar] [CrossRef]

- Nunes, M.C.N.; Brecht, J.K.; Morais, A.M.M.B.; Sargent, S.A. Physicochemical Changes during Strawberry Development in the Field Compared with Those That Occur in Harvested Fruit during Storage. J. Sci. Food Agric. 2006, 86, 180–190. [Google Scholar] [CrossRef]

- Arulmozhi, E.; Bhujel, A.; Moon, B.-E.; Kim, H.-T. The Application of Cameras in Precision Pig Farming: An Overview for Swine-Keeping Professionals. Animals 2021, 11, 2343. [Google Scholar] [CrossRef] [PubMed]

- Khoshnam, F.; Tabatabaeefar, A.; Varnamkhasti, M.G.; Borghei, A. Mass Modeling of Pomegranate (Punica granatum L.) Fruit with Some Physical Characteristics. Sci. Hortic. 2007, 114, 21–26. [Google Scholar] [CrossRef]

- Mancini, M.; Mazzoni, L.; Gagliardi, F.; Balducci, F.; Duca, D.; Toscano, G.; Mezzetti, B.; Capocasa, F. Application of the Non-Destructive NIR Technique for the Evaluation of Strawberry Fruits Quality Parameters. Foods 2020, 9, 441. [Google Scholar] [CrossRef]

- Nyalala, I.; Okinda, C.; Nyalala, L.; Makange, N.; Chao, Q.; Chao, L.; Yousaf, K.; Chen, K. Tomato Volume and Mass Estimation Using Computer Vision and Machine Learning Algorithms: Cherry Tomato Model. J. Food Eng. 2019, 263, 288–298. [Google Scholar] [CrossRef]

- Khojastehnazhand, M.; Omid, M.; Tabatabaeefar, A. Determination of Tangerine Volume Using Image Processing Methods. Int. J. Food Prop. 2010, 13, 760–770. [Google Scholar] [CrossRef]

- Elhariri, E.; El-Bendary, N.; Fouad, M.M.M.; Platoš, J.; Hassanien, A.E.; Hussein, A.M.M. Multi-Class SVM Based Classification Approach for Tomato Ripeness. In Innovations in Bio-Inspired Computing and Applications; Springer: Berlin/Heidelberg, Germany, 2014; pp. 175–186. [Google Scholar]

- Fellegari, R.; Navid, H. Determining the Orange Volume Using Image Processing. In Proceedings of the Interbational Conference on Food Engineering and Biotechnoly (ICFEB 2011), Bangkok, Thailand, 7–9 May 2011; Citeseer: University Park, PA, USA, 2011; pp. 180–184. [Google Scholar]

- Raj, R.; Cosgun, A.; Kulić, D. Strawberry Water Content Estimation and Ripeness Classification Using Hyperspectral Sensing. Agronomy 2022, 12, 425. [Google Scholar] [CrossRef]

- Weng, S.; Yu, S.; Guo, B.; Tang, P.; Liang, D. Non-Destructive Detection of Strawberry Quality Using Multi-Features of Hyperspectral Imaging and Multivariate Methods. Sensors 2020, 20, 3074. [Google Scholar] [CrossRef]

- Hernandez-Munoz, P.; Almenar, E.; Del Valle, V.; Velez, D.; Gavara, R. Effect of Chitosan Coating Combined with Postharvest Calcium Treatment on Strawberry (Fragaria x ananassa) Quality during Refrigerated Storage. Food Chem. 2008, 110, 428–435. [Google Scholar] [CrossRef]

- Agulheiro-Santos, A.C.; Ricardo-Rodrigues, S.; Laranjo, M.; Melgão, C.; Velázquez, R. Non-destructive Prediction of Total Soluble Solids in Strawberry Using near Infrared Spectroscopy. J. Sci. Food Agric. 2022, 102, 4866–4872. [Google Scholar] [CrossRef]

- Guo, Z.; Huang, W.; Chen, L.; Wang, X.; Peng, Y. Nondestructive Evaluation of Soluble Solid Content in Strawberry by near Infrared Spectroscopy. In Proceedings of the Piageng 2013: Image Processing and Photonics for Agricultural Engineering, Sanya, China, 27 January 2013; SPIE: Bellingham, WA, USA, 2013; Volume 8761, pp. 128–132. [Google Scholar]

- Craninx, M.; Fievez, V.; Vlaeminck, B.; De Baets, B. Artificial Neural Network Models of the Rumen Fermentation Pattern in Dairy Cattle. Comput. Electron. Agric. 2008, 60, 226–238. [Google Scholar] [CrossRef]

- Özesmi, S.L.; Tan, C.O.; Özesmi, U. Methodological Issues in Building, Training, and Testing Artificial Neural Networks in Ecological Applications. Ecol. Modell. 2006, 195, 83–93. [Google Scholar] [CrossRef]

- Abdar, M.; Pourpanah, F.; Hussain, S.; Rezazadegan, D.; Liu, L.; Ghavamzadeh, M.; Fieguth, P.; Cao, X.; Khosravi, A.; Acharya, U.R. A Review of Uncertainty Quantification in Deep Learning: Techniques, Applications and Challenges. Inf. Fusion 2021, 76, 243–297. [Google Scholar] [CrossRef]

- Lee, D.D.; Pham, P.; Largman, Y.; Ng, A. Advances in Neural Information Processing Systems 22; Tech. Rep.; MIT Press: Cambridge, MA, USA, 2009. [Google Scholar]

| Cultivar Name | Dataset | Number of Data |

|---|---|---|

| Maehyang | D1 | 300 |

| Seolhyang | D2 | 300 |

| Santa | D3 | 300 |

| All three cultivars | D4 | 900 |

| Cultivar Name | Length (mm) | Diameter (mm) | Weight (g) | Pixel Numbers |

|---|---|---|---|---|

| Maehyang | 41.78 ± 3.28 a | 31.93 ± 2.41 a | 19.00 ± 3.61 a | 51,460 ± 7425 a |

| Seolhyang | 41.25 ± 3.69 a | 32.51 ± 2.17 ab | 20.41 ± 3.34 ab | 57,579 ± 6776 ab |

| Santa | 45.27 ± 2.95 b | 34.45 ± 2.10 b | 23.28 ± 3.65 b | 59,966 ± 8502 b |

| All three cultivars | 42.77 ± 3.77 | 33.97 ± 2.48 | 20.90 ± 3.96 | 56,335 ± 8396 |

| Model Name | Dataset | Training | Testing | ||

|---|---|---|---|---|---|

| R2 | RMSE | R2 | RMSE | ||

| LR | D1 | 0.963 | 0.712 | 0.896 | 1.054 |

| D2 | 0.950 | 0.785 | 0.871 | 1.136 | |

| D3 | 0.947 | 0.856 | 0.860 | 1.207 | |

| D4 | 0.954 | 0.758 | 0.880 | 1.101 | |

| SVR | D1 | 0.942 | 0.891 | 0.856 | 1.239 |

| D2 | 0.934 | 0.953 | 0.838 | 1.362 | |

| D3 | 0.930 | 0.984 | 0.830 | 1.402 | |

| D4 | 0.936 | 0.946 | 0.840 | 1.280 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basak, J.K.; Paudel, B.; Kim, N.E.; Deb, N.C.; Kaushalya Madhavi, B.G.; Kim, H.T. Non-Destructive Estimation of Fruit Weight of Strawberry Using Machine Learning Models. Agronomy 2022, 12, 2487. https://doi.org/10.3390/agronomy12102487

Basak JK, Paudel B, Kim NE, Deb NC, Kaushalya Madhavi BG, Kim HT. Non-Destructive Estimation of Fruit Weight of Strawberry Using Machine Learning Models. Agronomy. 2022; 12(10):2487. https://doi.org/10.3390/agronomy12102487

Chicago/Turabian StyleBasak, Jayanta Kumar, Bhola Paudel, Na Eun Kim, Nibas Chandra Deb, Bolappa Gamage Kaushalya Madhavi, and Hyeon Tae Kim. 2022. "Non-Destructive Estimation of Fruit Weight of Strawberry Using Machine Learning Models" Agronomy 12, no. 10: 2487. https://doi.org/10.3390/agronomy12102487

APA StyleBasak, J. K., Paudel, B., Kim, N. E., Deb, N. C., Kaushalya Madhavi, B. G., & Kim, H. T. (2022). Non-Destructive Estimation of Fruit Weight of Strawberry Using Machine Learning Models. Agronomy, 12(10), 2487. https://doi.org/10.3390/agronomy12102487