Winter Pea Mixtures with Triticale and Oat for Biogas and Methane Production in Semiarid Conditions of the South Pannonian Basin

Abstract

1. Introduction

2. Materials and Methods

2.1. Field Experiment

2.2. Chemical Analysis and Calculation of Methane Yield

2.3. Data Analysis and Statistical Methods

3. Results

3.1. Influence on Yield Traits, Biogas and Methane Yield

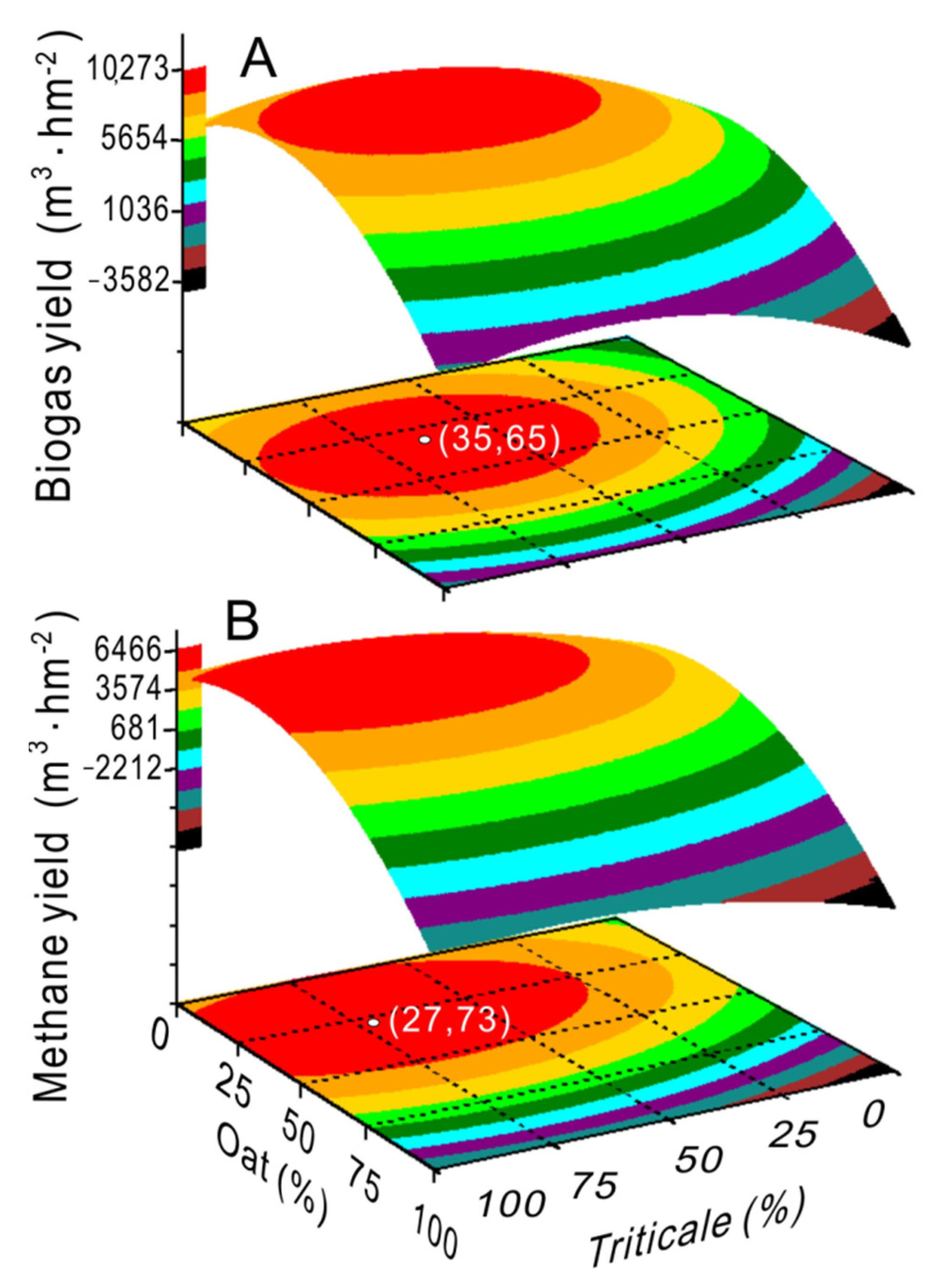

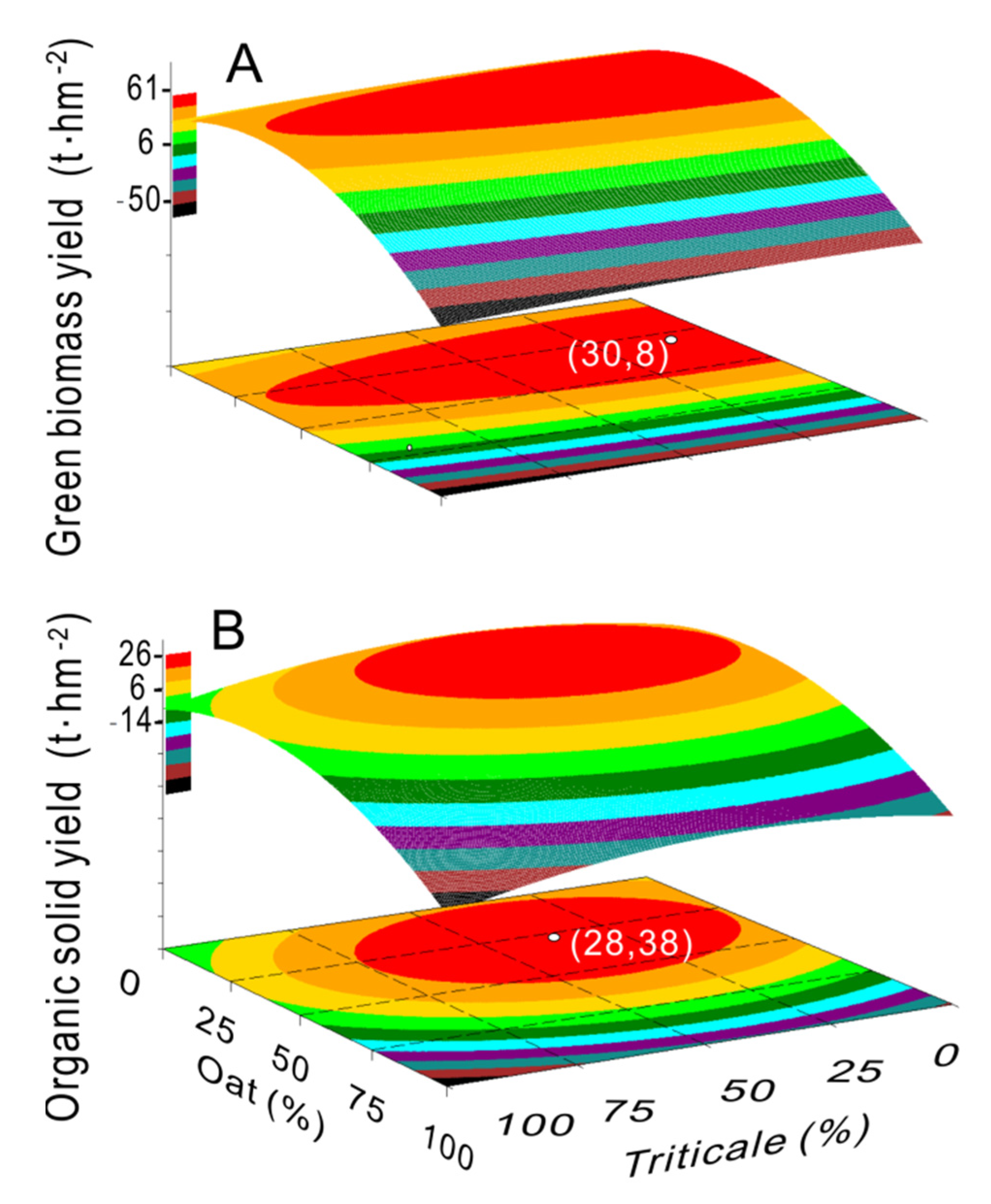

3.2. Surface Plots to Determine Optimal Mixtures for Biogas and Methane Yields

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IPCC. Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Edenhofer, O.R., Pichs-Madruga, Y., Sokona, E., Farahani, S., Kadner, K., Seyboth, A., Adler, I., Baum, S., Brunner, P., Eds.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Bhattarai, K.; Stalick, W.M.; McKay, S.; Geme, G.; Bhattarai, N. Biofuel: An alternative to fossil fuel for alleviating world energy and economic crises. J. Environ. Sci. Health Part A Toxic Hazard. Subst. Environ. Eng. 2011, 46, 1424–1442. [Google Scholar] [CrossRef]

- Martínez-Gutiérrez, E. Biogas production from different lignocellulosic biomass sources: Advances and perspectives. Biotech 2018, 8, 233. [Google Scholar] [CrossRef]

- Patra, A.; Park, T.; Kim, M.; Yu, Z. Rumen methanogens and mitigation of methane emission by anti-methanogenic compounds and substances. J. Anim. Sci. Biotechnol. 2017, 8, 13. [Google Scholar] [CrossRef]

- Breden, C.R.; Buswell, A.M. The Use of Shredded Asbestos in Methane Fermentations. J. Bacteriol. 1933, 26, 379–383. [Google Scholar] [CrossRef]

- Feng, C.; Stewart, W.E. Practical Models for Isothermal Diffusion and Flow of Gases in Porous Solids. Ind. Eng. Chem. 1973, 12, 143–147. [Google Scholar] [CrossRef]

- Sangiorgio, F.; Pinna, M.; Basset, A. Inter– and intra-habitat variability of plant detritus decomposition in a transitional environment (Lake Alimini, Adriatic Sea). Chem. Biol. 2002, 20 (Suppl. 1), 353–366. [Google Scholar] [CrossRef]

- Carlsson, A.S.; van Beilen, J.B.; Möller, R.; Clayton, D.; Bowles, D. (Eds.) Micro- and Macro-Algae: Utility for Industrial Applications, Outputs from the EPOBIO Project; CPL Press: Newbury, UK, 2007; p. 86. [Google Scholar]

- Stewart, D.J.; Bogue, M.J.; Badger, D.M. Biogas production from crops and organic wastes. 2. Results of continuous digestion tests. N. Z. J. Sci. 1984, 27, 285–294. [Google Scholar]

- Datta, A.; Dutta, S.; Rao, K.S.; Santra, S.C.; Adhya, T.K. Methane and nitrous oxide emission from rice-based cropping systems. BVAAP 2010, 18, 154–157. Available online: http://hdl.handle.net/123456789/11490 (accessed on 5 August 2021).

- Lindorfer, H.; Braun, R.; Kirchmayr, R. Self-heating of anaerobic digesters using energy crops. Water Sci. Technol. A J. Int. Assoc. Water Pollut. Res. 2006, 53, 159–166. [Google Scholar] [CrossRef]

- Gao, Y. China’s response to climate change issues after Paris Climate Change Conference. Adv. Clim. Chang. Res. 2016, 7, 235–240. [Google Scholar] [CrossRef]

- Elghandour, M.Y.M.; Salem, M.Z.; Greiner, R.; Salem, A.Z. Effects of natural blends of garlic and eucalypt essential oils on biogas production of four fibrous feeds at short-term of incubation in the ruminal anaerobic biosystem. J. Sci. Food Agric. 2018, 98, 5313–5321. [Google Scholar] [CrossRef]

- Zhang, H.; Tian, Y.; Wang, L.; Zhang, L.; Dai, L. Ecophysiological characteristics and biogas production of cadmium-contaminated crops. Bioresour. Technol. 2013, 146, 628–636. [Google Scholar] [CrossRef]

- Graß, G.; Burger, N.; Lücke, A. Projekt GASQUAL—Pilot-Studie Deutschland. Gaswärme Int. 2013, 154, 240–248. [Google Scholar]

- Halmemies-Beauchet-Filleau, A.; Rinne, M.; Lamminen, M.; Mapato, C.; Ampapon, T.; Wanapat, M.; Vanhatalo, A. Review: Alternative and novel feeds for ruminants: Nutritive value, product quality and environmental aspects. Animal 2018, 12, s295–s309. [Google Scholar] [CrossRef] [PubMed]

- Ranck, E.J.; Holden, L.A.; Dillon, J.A.; Rotz, C.A.; Soder, K.J. Economic and environmental effects of double cropping winter annuals and corn using the Integrated Farm System Model. J. Dairy Sci. 2020, 103, 3804–3815. [Google Scholar] [CrossRef]

- Ceglar, A.; Toreti, A.; Prodhomme, C.; Zampieri, M.; Turco, M.; Doblas-Reyes, F.J. Land-surface initialisation improves seasonal climate prediction skill for maize yield forecast. Sci. Rep. 2018, 8, 1322. [Google Scholar] [CrossRef] [PubMed]

- Crocetti, L.; Forkel, M.; Fischer, M.; Jurečka, F.; Grlj, A.; Salentinig, A.; Trnka, M.; Anderson, M.; Ng, W.T.; Kokalj, Ž.; et al. Earth Observation for agricultural drought monitoring in the Pannonian Basin (southeastern Europe): Current state and future directions. Reg. Env. Chang. 2020, 20, 123. [Google Scholar] [CrossRef]

- Saharinen, J.; Hyytiäinen, M.; Taipale, J.; Keskioja, J. Latent transforming growth factor-beta binding proteins (LTBPs)—Structural extracellular matrix proteins for targeting TGF-beta action. Cytokine Growth Factor Rev. 1999, 10, 99. [Google Scholar] [CrossRef]

- Amendolia, S.R.; Binder, M.; Blum, W.; Cherney, M.; Farilla, A.; Fidecaro, F.; Izen, J.M.; Jared, R.C.; Lehraus, I.; Marrocchesi, P.S. Dependence of the transverse diffusion of drifting electrons on magnetic field. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 1986, 244, 516–520. [Google Scholar] [CrossRef][Green Version]

- Gunaseelan, V.N. Anaerobic digestion of biomass for methane production: A review. Biomass Bioenergy 1997, 13, 83–114. [Google Scholar] [CrossRef]

- Viola, L.C. Protection and Nutritional Nervosa. Trans. Anal. J. 1985, 15, 168–172. [Google Scholar] [CrossRef]

- Vasiljević, S.; Karagić, D.; Martinov, M.; Đatkov, Đ.; Pržulj, N.; Denčić, S.; Živanov, D.; Milošević, B. Potential of Biogas Production by Using Winter Pea Mixtures with Triticale and Oat; ePosters: Sudbury, UK, 2014. [Google Scholar]

- Vasiljević, S.; Milić, D.; Karagić, D.; Mihailović, V.; Mikić, A.; Živanov, D.; Milošević, B.; Katanski, S. Yield of Forage Pea-Cereal Intercropping Using Three Seed Ratios at Two Maturity Stages. In Breeding in a World of Scarcity; Roldán-Ruiz, I., Baert, J., Reheul, D., Eds.; Springer: Cham, Switzerland, 2016. [Google Scholar] [CrossRef]

- Liebetrau, J.; Pfeiffer, D.; Thrän, D. (Eds.) Collection of Measurement Methods for Biogas—Methods to Determine Parameters for Analysis Purposes and Parameters that Describe Processes in the Biogas Sector; Series of the Funding Programme “Biomass Energy Use”; DBFZ: Leipzig, Germany, 2015. [Google Scholar]

- Hansen, T.L.; Schmidt, J.E.; Angelidaki, I.; Marca, E.; La Cour Jansen, J.; Mosbæk, H.; Christensen, T.H. Method for determination of methane potentials of solid organic waste. Waste Manag. 2004, 24, 393–400. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association: Washington DC, USA, 1998. [Google Scholar]

- Gregory, S. Statistical Methods and Geographer; Longman Inc.: London, UK; New York, NY, USA, 1978. [Google Scholar]

- Lattin, J.; Carroll, J.; Green, P. Analyzing Multivariate Data; Brooks/Cole: New York, NY, USA, 2003. [Google Scholar]

- SAS Institute Inc. SAS/STAT User’s Guide; SAS Institute Inc.: Cary, NC, USA, 2008. [Google Scholar]

- Dandikas, V.; Heuwinkel, H.; Lichti, F.; Drewes, J.E.; Koch, K. Correlation between biogas yield and chemical composition of energy crops. Bioresour. Technol. 2014, 174, 316–320. [Google Scholar] [CrossRef]

- Gissén, T.; Prade, E.; Kreuger, I.A.; Nges, H.; Rosenqvist, S.E.; Svensson, M.; Lantz, J.E.; Mattsson, P.; Börjesson, L. Comparing energy crops for biogas production—Yields, energy input and costs in cultivation using digestate and mineral fertilization. Biomass Bioenergy 2014, 64, 199–210. [Google Scholar] [CrossRef]

- Wu, J.Z.; Huang, M.; Wang, Z.M.; Li, Y.J.; Fu, G.Z.; Chen, M.C. Effects of extremely-late sowing on the grain yield, nitrogen uptake and utilization, and grain protein content in winter wheat. Ying Yong Sheng Tai Xue Bao 2018, 29, 185–192. [Google Scholar] [CrossRef] [PubMed]

- Huebner, M.; Oechsner, H.; Koch, S.; Seggl, A.; Hrenn, H.; Schmiedchen, B.; Wilde, P.; Miedaner, T. Impact of genotype, harvest time and chemical composition on the methane yield of winter rye for biogas production. Biomass Bioenergy 2011, 35, 4316–4323. [Google Scholar] [CrossRef]

- Hosseini–Koupaie, E.; Dahadha, S.; Bazyar Lakeh, A.A.; Azizi, A.; Elbeshbishy, E. Enzymatic pretreatment of lignocellulosic biomass for enhanced biomethane production—A review. J. Environ. Manag. 2019, 233, 774–784. [Google Scholar] [CrossRef]

- Bruni, E.; Jensen, A.P.; Pedersen, E.S.; Angelidaki, I. Anaerobic digestion of maize focusing on variety, harvest time and pretreatment. Appl. Energy 2010, 87, 2212–2217. [Google Scholar] [CrossRef]

- Massé, D.; Gilbert, Y.; Savoie, P.; Bélanger, G.; Parent, G.; Babineau, D. Methane yield from switchgrass harvested at different stages of development in Eastern Canada. Bioresour. Technol. 2010, 101, 9536–9541. [Google Scholar] [CrossRef]

- Herrmann, C.; Prochnow, A.; Heiermann, M.; Idler, C. Biomass from landscape management of grassland used for biogas production: Effects of harvest date and silage additives on feedstock quality and methane yield. Grass Forage Sci. 2013, 69, 549–566. [Google Scholar] [CrossRef]

- Abraham, A.; Mathew, A.K.; Park, H.; Choi, O.; Sindhu, R.; Parameswaran, B.; Pandey, A.; Park, J.H.; Sang, B.I. Pretreatment strategies for enhanced biogas production from lignocellulosic biomass. Bioresour. Technol. 2020, 301, 122725. [Google Scholar] [CrossRef] [PubMed]

- Strassberger, Z.; Tanase, S.; Rothenberg, G. The pros and cons of lignin valorisation in an integrated biorefinery. RSC Adv. 2014, 4, 25310–25318. [Google Scholar] [CrossRef]

- Paul, S.; Dutta, A. Challenges and opportunities of lignocellulosic biomass for anaerobic digestion. Resour. Conserv. Recycl. 2018, 130, 164–174. [Google Scholar] [CrossRef]

- Casaretto, R.; Agdal, E.B.L.; Cayenne, A.; Chaturvedi, T.; Holm-Nielsen, J.B. Low-Temperature Pretreatment of Lignocellulosic Biomass for Enhanced Biogas Production. Chem. Eng. Technol. 2019, 42, 2565–2573. [Google Scholar] [CrossRef]

- Kandel, T.P.; Sutaryo, S.; Moller, H.B.; Jorgensen, U.; Laerke, P.E. Chemical composition and methane yield of reed canary grass as influenced by harvesting time and harvest frequency. Bioresour. Technol. 2013, 130, 659–666. [Google Scholar] [CrossRef]

- Cattani, M.; Sartori, A.; Bondesan, V.; Bailoni, L. In vitro degradability, gas production, and energy value of different hybrids of sorghum after storage in mini-silos. Ann. Anim. Sci. 2016, 16, 769–777. [Google Scholar] [CrossRef]

- Holmes, D.E.; Smith, J.A. Biologically Produced Methane as a Renewable Energy Source. Adv. Appl. Microbiol. 2016, 97, 1–61. [Google Scholar] [CrossRef]

- Schippers, J.H. Transcriptional networks in leaf senescence. Curr. Opin. Plant Biol. 2015, 27, 77–83. [Google Scholar] [CrossRef]

- Coblentz, W.K.; Akins, M.S.; Kalscheur, K.F.; Brink, G.E.; Cavadini, J.S. Effects of growth stage and growing degree day accumulations on triticale forages: 1. Dry matter yield, nutritive value, and in vitro dry matter disappearance. J. Dairy Sci. 2018, 101, 8965–8985. [Google Scholar] [CrossRef]

- Ayalew, H.; Kumssa, T.T.; Butler, T.J.; Ma, X.F. Triticale Improvement for Forage and Cover Crop Uses in the Southern Great Plains of the United States. Front. Plant Sci. 2018, 9, 1130. [Google Scholar] [CrossRef]

- Tayeh, N.; Aubert, G.; Pilet-Nayel, M.L.; Lejeune-Hénaut, I.; Warkentin, T.D.; Burstin, J. Genomic Tools in Pea Breeding Programs: Status and Perspectives. Front. Plant Sci. 2015, 6, 1037. [Google Scholar] [CrossRef]

- Grass, R.; Heuser, F.; Stuelpnagel, R.; Piepho, H.P.; Wachendorf, M. Energy crop production in double-cropping systems: Results from an experiment at seven sites. Eur. J. Agron. 2013, 51, 120–129. [Google Scholar] [CrossRef]

- Fahlbusch, W.; Hey, K.; Sauer, B.; Ruppert, H. Trace element delivery for biogas production enhanced by alternative energy crops: Results from two-year field trials. Energy Sustain. Soc. 2018, 8, 38. [Google Scholar] [CrossRef]

- Bond, T.; Brouckaert, C.J.; Foxon, K.M.; Buckley, C.A. A critical review of experimental and predicted methane generation from anaerobic codigestion. Water Sci. Technol. 2012, 65, 183–189. [Google Scholar] [CrossRef] [PubMed]

- Negri, M.; Bacenetti, J.; Fiala, M.; Bocchi, S. Evaluation of anaerobic degradation, biogas and digestate production of cereal silages using nylon-bags. Bioresour. Technol. 2016, 209, 40–49. [Google Scholar] [CrossRef] [PubMed]

- Aboagye, I.A.; Rosser, C.L.; Baron, V.S.; Beauchemin, K.A. In Vitro Assessment of Enteric Methane Emission Potential of Whole-Plant Barley, Oat, Triticale and Wheat. Animals 2021, 11, 450. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Sun, F.; Yu, J.; Cai, Y.; Luo, X.; Cui, Z.; Hu, Y.; Wang, X. Co-digestion of oat straw and cow manure during anaerobic digestion: Stimulative and inhibitory effects on fermentation. Bioresour. Technol. 2018, 269, 143–152. Available online: https://10.1016/j.biortech.2018.08.040 (accessed on 5 August 2021).

- Zhong, B.; An, X.; Shen, F.; An, W.; Zhang, Q. Anaerobic co-digestion of rice straw and pig manure pretreated with a cellulolytic microflora: Methane yield evaluation and kinetics analysis. Front. Bioeng. Biotechnol. 2021, 4, 579405. [Google Scholar] [CrossRef]

- Mehmood, K.; Berns, A.E.; Pütz, T.; Burauel, P.; Vereecken, H.; Opitz, T.; Zoriy, M.; Hofmann, D. No effect of digestate amendment on Cs-137 and Sr-90 translocation in lysimeter experiments. Chemosphere 2017, 172, 310–315. [Google Scholar] [CrossRef]

- Andersen, M.R.; Giese, M.R.; de Vries, P.; Nielsen, J. Mapping the polysaccharide degradation potential of Aspergillus niger. BMC Genom. 2012, 13, 313. [Google Scholar] [CrossRef] [PubMed]

- Frommhagen, M.; Koetsier, M.J.; Westphal, A.H.; Visser, J.; Hinz, S.W.; Vincken, J.P.; van Berkel, W.J.; Kabel, M.A.; Gruppen, H. Lytic polysaccharide monooxygenases from Myceliophthora thermophila C1 differ in substrate preference and reducing agent specificity. Biotechnol. Biofuels 2016, 9, 186. [Google Scholar] [CrossRef]

- Huang, D.; Liu, J.; Qi, Y.; Yang, K.; Xu, Y.; Feng, L. Synergistic hydrolysis of xylan using novel xylanases, β-xylosidases, and an α-L-arabinofuranosidase from Geobacillus thermodenitrificans NG80-2. Appl. Microbiol. Biotechnol. 2017, 101, 6023–6037. [Google Scholar] [CrossRef]

- Jia, X.; Han, Y. The extracellular endo-β-1,4-xylanase with multidomain from the extreme thermophile Caldicellulosiruptor lactoaceticus is specific for insoluble xylan degradation. Biotechnol. Biofuels 2019, 12, 143. [Google Scholar] [CrossRef]

- de Almeida, M.; Guimarães, N.V.M.; Bischoff, K.M.; Falkoski, D.L.; Pereira, O.L.; Gonçalves, D.S.; de Rezende, S.T. Cellulases and hemicellulases from endophytic Acremonium species and its application on sugarcane bagasse hydrolysis. Appl. Biochem. Biotechnol. 2011, 165, 594–610. [Google Scholar] [CrossRef]

- Bhalla, A.; Bischoff, K.M.; Uppugundla, N.; Balan, V.; Sani, R.K. Novel thermostable endo-xylanase cloned and expressed from bacterium Geobacillus sp. WSUCF1. Bioresour. Technol. 2014, 165, 314–318. [Google Scholar] [CrossRef] [PubMed]

- Maroušek, J. Prospects in straw disintegration for biogas production. Environ. Sci. Pollut. Res. 2013, 20, 7268–7274. [Google Scholar] [CrossRef]

- Sapci, Z. The effect of microwave pretreatment on biogas production from agricultural straws. Bioresour. Technol. 2013, 128, 487–494. [Google Scholar] [CrossRef] [PubMed]

- Chandra, A.; Jain, R.; Solomon, S.; Shrivastava, S.; Roy, A.K. Exploiting EST databases for the development and characterisation of 3425 gene-tagged CISP markers in biofuel crop sugarcane and their transferability in cereals and orphan tropical grasses. BMC Res. Notes 2013, 6, 47. [Google Scholar] [CrossRef]

- Cuervo-Soto, L.I.; Valdés-García, G.; Batista-García, R.; del Rayo Sánchez-Carbente, M.; Balcázar-López, E.; Lira-Ruan, V.; Pastor, N.; Folch-Mallol, J.L. Identification of a novel carbohydrate esterase from Bjerkandera adusta: Structural and function predictions through bioinformatics analysis and molecular modeling. Proteins 2015, 83, 533–546. [Google Scholar] [CrossRef]

- Hayden, D.M.; Rolletschek, H.; Borisjuk, L.; Corwin, J.; Kliebenstein, D.J.; Grimberg, A.; Stymne, S.; Dehesh, K. Cofactome analyses reveal enhanced flux of carbon into oil for potential biofuel production. Plant J. 2011, 67, 1018–1028. [Google Scholar] [CrossRef]

- Kolbusz, M.A.; Di Falco, M.; Ishmael, N.; Marqueteau, S.; Moisan, M.C.; Baptista, C.D.S.; Powlowski, J.; Tsang, A. Transcriptome and exoproteome analysis of utilization of plant-derived biomass by Myceliophthora thermophila. Fungal Genet. Biol. 2014, 72, 10–20. [Google Scholar] [CrossRef] [PubMed]

- Nges, I.A.; Escobar, F.; Fu, X.; Björnsson, L. Benefits of supplementing an industrial waste anaerobic digester with energy crops for increased biogas production. Waste Manag. 2012, 32, 53–59. [Google Scholar] [CrossRef] [PubMed]

- Croce, S.; D’Imporzano, Q.; Wei, G.; Dong, R.; Adani, F. Anaerobic digestion of straw and corn stover: The effect of biological process optimization and pre-treatment on total bio-methane yield and energy performance. Biotechnol. Adv. 2016, 34, 1289–1304. [Google Scholar] [CrossRef] [PubMed]

| Year | pH | Humus (%) | Total Nitrogen (%) | mg 100 g Soil | ||

|---|---|---|---|---|---|---|

| in H2O | in KCl | P2O5 | K2O | |||

| 2012 | 8.10 | 7.18 | 3.52 | 0.241 | 61.90 | 40.0 |

| 2013 | 8.25 | 7.28 | 2.58 | 0.19 | 32.4 | 30.6 |

| Month | Precipitation (mm) | Temperature (°C) | ||||

|---|---|---|---|---|---|---|

| 2012–2013 | 2013–2014 | 1963–2013 | 2012–2013 | 2013–2014 | 1963–2013 | |

| October | 49 | 67 | 45 | 13.7 | 14.7 | 11.7 |

| November | 36 | 41 | 52 | 10.0 | 9.03 | 6.0 |

| December | 55 | 2 | 46 | 1.0 | 2.0 | 1.7 |

| January | 60 | 24 | 37 | 3.0 | 4.3 | ·0.3 |

| February | 49 | 10 | 33 | 4.3 | 7.0 | 1.7 |

| March | 68 | 50 | 39 | 6.0 | 10.4 | 6.3 |

| April | 30 | 49 | 47 | 13.7 | 13.4 | 11.7 |

| May | 118 | 203 | 60 | 18.4 | 16.4 | 17.0 |

| Total | 465 | 446 | 359 | |||

| Average | 8.7 | 9.6 | 7.0 | |||

| Treatment | Composition of Crops | Seed Weight Ratios |

|---|---|---|

| 1. | Pure crops of oat | 100% (150 kg ha−1) |

| 2. | Winter pea: oat mixture | 50%:50% (70 + 75 kg ha−1) |

| 3. | Winter pea: oat mixture | 75%:25% (105 + 37.5 kg ha−1) |

| 4. | Pure crops of pea | 100% (140 kg ha−1) |

| 5. | Pure crops of triticale | 100% (250 kg ha−1) |

| 6. | Winter pea: triticale mixture | 50%:50% (70 + 125 kg ha−1) |

| 7. | Winter pea: triticale mixture | 75%:25% (105 + 62.5 kg ha−1) |

| Source (Factors) | Green Mass Yield | Dry Matter Yield | Yield of Organic Solids | ||||

|---|---|---|---|---|---|---|---|

| DF | F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | |

| Treatment (T) | 6 | 5.24 | 0.0004 | 40.64 | <0.0001 | 43.62 | <0.0001 |

| Harvested stage (S) | 1 | 39.03 | <0.0001 | 86.66 | <0.0001 | 60.01 | <0.0001 |

| T × S interaction | 6 | 2.54 | 0.0344 | 3.70 | 0.0048 | 3.04 | 0.0146 |

| Model | 13 | 6.60 | <0.0001 | 27.19 | <0.0001 | 26.21 | <0.0001 |

| R-Square | 0.6712 | 0.8936 | 0.8903 | ||||

| Source (Factors) | Biogas Yield | Methane Yield | |||

|---|---|---|---|---|---|

| DF | F-Value | p-Value | F-Value | p-Value | |

| Treatment (T) | 6 | 126.20 | <0.0001 | 141.29 | <0.0001 |

| Harvested stage (S) | 1 | 5.47 | 0.0213 | 29.44 | <0.0001 |

| T × S interaction | 6 | 7.90 | <0.0001 | 8.43 | <0.0001 |

| Model | 13 | 62.31 | <0.0001 | 71.34 | <0.0001 |

| R-Square | 0.8921 | 0.9455 | |||

| Factors | Statistic | Wilks’ Lambda | Pillai’s Trace | Hotelling–Lawley Trace | Roy’s Greatest Root |

|---|---|---|---|---|---|

| Treatment (T) | F-value | 12.37 | 5.70 | 22.50 | 108.02 |

| p-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 | |

| Harvested stage (S) | F-value | 144.57 | 144.57 | 144.57 | 144.57 |

| p-value | <0.0001 | <0.0001 | <0.0001 | <0.0001 |

| Source (Factors) | Biogas Yield | Methane Yield | Green Mass Yield | Organic Solids | |||||

|---|---|---|---|---|---|---|---|---|---|

| DF | F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | |

| Oat | 2 | 37.02 | <0.0001 | 31.56 | <0.0001 | 11.69 | <0.0001 | 33.11 | <0.0001 |

| Triticale | 2 | 115.14 | <0.0001 | 118.02 | <0.0001 | 0.17 | 0.8458 | 29.43 | <0.0001 |

| Model | 4 | 58.95 | <0.0001 | 60.06 | <0.0001 | 12.74 | <0.0001 | 20.51 | <0.0001 |

| R-Square | 0.6879 | 0.6919 | 0.3226 | 0.4340 | |||||

| Maximum | 13218 | 8595 | 61.48 | 25.64 | |||||

| DM | OS | BDM | BOS | MDM | MOS | |

|---|---|---|---|---|---|---|

| GM | 0.223 | 0.248 | 0.448 ** | 0.446 ** | 0.372 ** | 0.368 ** |

| DM | 1.000 | 0.988 *** | 0.899 *** | 0.899 *** | 0.932 *** | 0.929 *** |

| OS | 1.000 | 0.929 *** | 0.929 *** | 0.957 *** | 0.956 *** | |

| BDM | 1.000 | 0.999 *** | 0.992 *** | 0.991 *** | ||

| BOS | 1.000 | 0.992 *** | 0.990 *** | |||

| MDM | 1.000 | 0.998 *** |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasiljevic, S.; Djalovic, I.; Miladinovic, J.; Xu, N.; Sui, X.; Wang, Q.; Prasad, P.V.V. Winter Pea Mixtures with Triticale and Oat for Biogas and Methane Production in Semiarid Conditions of the South Pannonian Basin. Agronomy 2021, 11, 1800. https://doi.org/10.3390/agronomy11091800

Vasiljevic S, Djalovic I, Miladinovic J, Xu N, Sui X, Wang Q, Prasad PVV. Winter Pea Mixtures with Triticale and Oat for Biogas and Methane Production in Semiarid Conditions of the South Pannonian Basin. Agronomy. 2021; 11(9):1800. https://doi.org/10.3390/agronomy11091800

Chicago/Turabian StyleVasiljevic, Sanja, Ivica Djalovic, Jegor Miladinovic, Nan Xu, Xin Sui, Quanzhen Wang, and P. V. Vara Prasad. 2021. "Winter Pea Mixtures with Triticale and Oat for Biogas and Methane Production in Semiarid Conditions of the South Pannonian Basin" Agronomy 11, no. 9: 1800. https://doi.org/10.3390/agronomy11091800

APA StyleVasiljevic, S., Djalovic, I., Miladinovic, J., Xu, N., Sui, X., Wang, Q., & Prasad, P. V. V. (2021). Winter Pea Mixtures with Triticale and Oat for Biogas and Methane Production in Semiarid Conditions of the South Pannonian Basin. Agronomy, 11(9), 1800. https://doi.org/10.3390/agronomy11091800