1. Introduction

Due to its nutrient density, potato (

Solanum tuberosum L.) is an essential dietary staple crop grown throughout the world and is particularly important in the temperate climates. Potato production contributes highly to the global food security. According to the estimates of the Food and Agriculture Organization (FAO), in 2019, over 370 million tons of potatoes were produced worldwide, a substantial increase from 334 million tons in 2010 [

1].

Potatoes, originating from the high-altitude regions of the South America, developed hardiness that makes it easy grow them in areas with relatively harsh conditions, where wheat and maize cannot be grown. Nevertheless, potato yield and quality are sensitive to both excess and deficit soil water [

2]. Schafleitner et al. predicted that, due to the climatic changes, the most significant losses in suitability of land for potato production will occur in southern Africa and tropical highlands [

3]. Moreover, in India, the second largest producer of potato globally, yield losses of 11% are expected by 2080 [

4].

Therefore, it is urgent to explore alternative production systems that allow an increase in global food security under the future climatic scenarios, by expanding areas for potato production, utilizing land with unsuitable or degraded soils. Hydroponics is a soilless cultivation method in which plants are grown using a nutrient solution. This production system removes the dependency on agricultural land and soil, reduces the presence of diseases and can mitigate the negative effects of extreme weather events utilizing precisely dosed nutrient solution (fertigation). Lakhiar et al. reviewed and described aeroponics, a type of hydroponic production, as a useful system for production of different plant cultures, including potatoes [

5]. The hydroponic production of potatoes has been also investigated in a NASA-funded research as a part of life support systems for extraterrestrial bases [

6].

Growing potatoes completely without growing media requires advanced production setup, which may be a limiting factor for widespread adoption of this technology. Substrate-based hydroponic production of potato minitubers, a less technologically complex growing system, has been studied. Testing of perlite, soil, combinations of perlite and vermiculite, perlite and peat moss, perlite and soil, perlite, soil and composted cattle manure, as well as perlite, soil and vermicompost, showed that minituber yield was greater in growing media without any soil [

7]. Rolot and Seutine concluded that minitubers from soilless culture have larger size and higher average weight when compared with minitubers grown in soil culture [

8]. Hydroponic systems have also been considered for production of table potatoes [

9].

Regarding the choice of growing medium, not only its properties and performance, but also economic and environmental factors are important and should be taken into consideration in the light of ongoing climatic changes [

10]. Wood-based products are obtained from a renewable resource and are therefore interesting in the context of circular economy. Chiota et al. provided evidence that hydroponic potato production is possible in growing media based on different woody fractions (coir, pine bark and sawdust) [

11]. To date, wood fiber has not received enough attention as a candidate substrate for potato production. Therefore, the aim of this case-study was to test the feasibility of hydroponically grown table potatoes in a stand-alone wood fiber growing medium.

2. Materials and Methods

A preliminary small-scale case-study was conducted in 2020 at the NIBIO Apelsvoll research station located in southeast Norway (60°42′ N, 10°51′ E, ca. 250 m a.s.l.) to investigate the applicability of wood fiber as a growing medium in alternative potato production. The potato cv. “Folva”, which is a medium-early fresh market consumption variety, was grown hydroponically in wood fiber (for 105 days, from 25.06 to 07.10) under high polytunnel and in field conditions to obtain a reference crop. There was a considerable temperature difference between the two growing systems. On average the temperature was 0.9 °C higher under the polytunnel than in the field, with 1.3 °C and 0.3 °C difference in the first and the second part of the growing period, respectively.

Two separate feasibility tests were performed to study various aspects of hydroponic production: (I) a substrate test aimed at understanding the influence of various types of wood fiber and the challenges of cropping system architecture and (II) a fertigation test to study the influence of various irrigation strategies.

In the substrate test, three seed tubers were planted in plastic bags filled with 90 L of wood fibers (forming a cylindrical growing space of 45 cm in height and diameter). Two wood fiber variants were tested: Hunton fiber (HUN) produced from Norway spruce (Picea abies), using the defibrator method (Hunton Agri, Hunton, Norway), and Pindstrup fiber (PIN) from Scots pine (Pinus sylvestris), using the high pressure steam method (Forest Gold, Pindstrup, Denmark). The nutrient solutions with EC 1.5 mS/cm were prepared by mixing 50:50 Kristalon Scarlet and Calcinit (Yara, Norway). Fertigation was applied for 20 min (one 1.2 L/h drip per seed tuber) and triggered from 2 to 5 times per day (based on the temperature and irradiation conditions in the tunnel).

For testing various irrigation strategies, one seed tuber was placed on the top of vertically placed growbag filled with Florentaise fiber (FLO) from Scots pine (Florentaise Hortipain, France, 85 cm × 20 cm × 7 cm). Three fertigation regimes were tested following the previous setup, however differing in duration of watering event (3, 6 and 20 min).

Potatoes were also grown in the field for reference. The tubers were harvested from three plants in each of the two field trials located 250 m away from one another. Field A featured conventional potato production, including modern cultivation practices such as split fertilization and supplementary irrigations at periods of low rainfall. Field B was a legacy growing system, used in the study region in the 1970s and 1980s, including basal fertilization only and no additional irrigation during the growing season. Field A and Field B were located 250 m and 400 m away from the polytunel, respectively. The plants were grown for 121 days (from 24.04 to 25.08) and 124 days (from 27.04 to 25.08) in field A and B, respectively. The tubers were planted at 12 cm depth with a distance of 30 cm within rows and 80 cm between rows. Both fields were fertilized with a total of 100 kg N ha−1 (=84 kg NPK 12-4-18). Field A was split-fertilized, receiving 70% of the total dose at planting and the remaining 30% 30 days after planting, whereas Field B was fertilized with a single dose at planting. Pesticide applications were performed at the study locations according to standard local procedures.

At harvest, the number of shoots was counted per plant and shoot length was measured using a ruler. Unexpectedly, due to the fact that the yield in the substrate test was extraordinarily high, it was not possible to separate the yield of a single plant. Potato tuber yield was therefore measured per three plants. The tubers were separated in four size fractions, <40 mm, 40–50 mm, 50–60 mm and >60 mm, and tubers in each fraction were counted and weighed (g). The results were then recalculated per single plant. The dry matter content was determined by over- and under-water weight to determine potato density. The following equation was used to calculate the dry matter content [

12]: Dry matter = 215.73 (x − 0.9825), where x is the specific weight calculated as weight in air/(weight in air − weight in water). Because of the preliminary character of the trial, there were not enough plants to perform statistical tests on the results.

3. Results

The plants grown in the field for 121–124 days were subjected to 845–846 growing degree days. Plants harvested from the two locations (A and B) were quite similar, with ca. 85 cm shoot length and ca. 6 shoots per plant (

Table 1). Field A (conventional production system) produced slightly more yield and dry matter than field B (legacy production system).

Compared to the field reference, the plants grown hydroponically were approximately two times larger (

Figure 1). The difference in biomass between the two tested substrates was minimal, with 150 cm long shoots and 9 and 8 shoots for HUN and PIN, respectively. Higher yield was observed when growing in PIN fiber (1877 g plant

−1) than when growing in HUN (1537 g plant

−1) (

Table 1). Compared to the field-grown potatoes, the yields of the hydroponic production were larger by more than 200% (

Table 1). Dry matter in the hydroponic-grown tubers was considerably lower than in the field-grown tubers, yet DM production on a per plant basis was still higher in the hydroponic system.

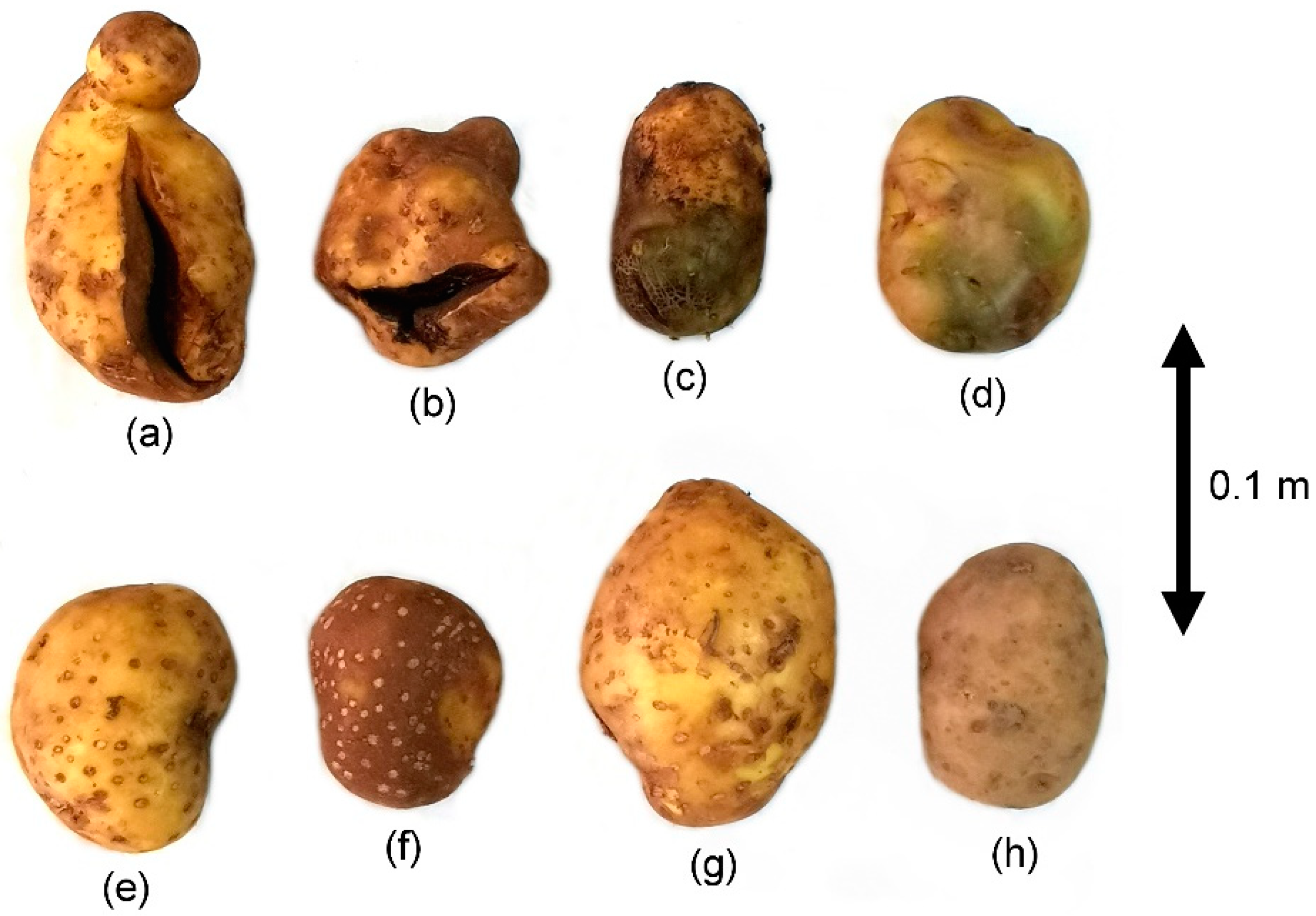

The substrate test showed that tuber production did not utilize the entire space of the container but only 20–25 cm around the seed potato, but the roots grew everywhere in the container and mostly at the bottom. The harvested tubers displayed certain challenges of the hydroponic production in wood-fiber based substrates (

Figure 2). Some tubers grew next to the walls of the container and they were still slightly green during harvest (

Figure 2c). Several tubers were found deformed (

Figure 2a,b) or oversized (

Figure 2g), others with overgrown lenticels (

Figure 2d,e) or with peel degradation (

Figure 2e), indicating wet growing conditions.

Comparing the two different wood fiber variants, the tubers grown in PIN were more uniform than in HUN, with relatively smaller lenticels. They were also more compressed with the substrate and it was more difficult to separate the tubers from the substrate. In HUN, the tubers featured substantial growth cracks (

Figure 2a,b) and some of them showed symptoms of pest infestation (occurrence of click beetle larvae) (

Figure 2a).

The fertigation test showed a strict relationship between the amount of water and the duration of its application on plant growth in wood fiber (

Figure 3,

Table 1). Plants fertigated for 3 min showed a limited tuber and biomass production, they yielded 64% of the field reference with relatively small tubers and the mother tuber was still hard at harvest. Plants fertigated for 6 min grew similarly as the plants grown in the field, with a rotten mother tuber at harvest. The plants fertigated for 20 min, on the other hand, produced the same biomass as the plant grown in larger containers with the same fertigation regime in the growing system test. In the limited rooting space provided in this test, there was not enough space for the tuber growth and the tubers were squeezed towards the walls and exposed to heat. Therefore, they were partly green at harvest. The 20-min fertigation treatment led to an overirrigated rootzone and tubers with many large lenticels.

4. Discussion

This study showed that the yield of hydroponically grown potatoes in wood fiber may exceed the yields obtained in a conventional potato production system. However, the tuber quality should be taken as a main challenge when producing tubers in this growing system. Sufficient rootzone aeration is a central factor affecting plant growth. Lack of oxygen may lead to decrease in nutrient absorption and, additionally, it may lead to severe damage and quality defects of the potato tubers [

7]. This was confirmed in this study, where the excess moisture present in the wood fiber based growing system led to a range of tuber-defects (

Figure 2). However, variation in severity of degradation and deformation among treatments and types of wood fibers suggest that adaptation of fertigation strategy may lead to improved tuber quality. Optimizing the watering periods and intervals will limit the peel degradation and will be an important research aim in future investigations on wood fiber-based potato production.

Challenges with green tubers in the fiber-based production was presumably related to limited space for tuber growth in the current study. Green tubers were mostly found next to the container walls, areas mostly exposed to solar radiation. This challenge should be addressed in future investigations of the fiber based hydroponic growing system.

When compared to the field reference, dry matter content (

Table 1) in hydroponically grown tubers was lower, which indicates less mature tubers at harvest. It may also suggest that the fertigation regime was inadequate. In addition, a relatively higher temperature under polytunnel may have contributed to lower tuber dry matter content. Therefore, in future investigations, the balance between moisture of the root zone, composition of the nutrient solution and access to oxygen should be addressed. Moreover, Folva was the only cultivar tested. It would be interesting to investigate other cultivars and include varieties with a higher market value or varieties that are challenging when grown in soil.

The proposed hydroponic system for table potato production may have several applications:

as a main production in areas where the soils are degraded or where soils are not present;

as an additional production combined with main crop grown in the tunnel system (i.e., berry crops);

wood fiber may become an important hydroponic growing medium for potato minitubers production;

the wood fiber based growing system is potentially applicable for the future food production on space stations or in extraterrestrial bases.

5. Conclusions

This study shows the yield potential of potatoes produced in the proposed wood fiber based hydroponic growing system. It also identifies the challenges related to this type of production leading to reduced quality of the tubers in relation to the crop produced in conventional systems. Hydroponic production of potato in a stand-alone wood fiber resulted in over 200% higher yield compared to the conventional potato production in soil. The sub-optimal fertigation strategy and water distribution in the substrate, as well as slightly shorter production time and higher temperature under polytunnel, were the factors that probably led to a decreased dry matter content. Optimization of these factors will be a topic of a following full-scale research study on the fiber based hydroponic growing system.

Author Contributions

Conceptualization, T.W. and K.K.; methodology, T.W., P.J.M., P.H. and K.K.; writing—original draft preparation, T.W., P.J.M., P.H. and K.K.; writing—review and editing, T.W., P.H. and K.K.; visualization, K.K.; funding acquisition, T.W. and K.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was conducted in the SUBTECH project funded by the Norwegian Agricultural Agreement Research Fund/Foundation for Research Levy on Agricultural Products, grant number 302129 and Grofondet, grant number 190024.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

The authors would like to thank Robert Nybråten for his help during the experiment.

Conflicts of Interest

The authors declare no conflict of interest.

References

- FAOSTAT Food and Agriculture Organization of the United Nations. 2015. Available online: http://www.fao.org/faostat/ (accessed on 7 February 2021).

- Saue, T.; Kadaja, J. Water limitations on potato yield in Estonia assessed by crop modelling. Agric. For. Meteorol. 2014, 194, 20–28. [Google Scholar] [CrossRef]

- Schafleitner, R.; Ramirez, J.; Jarvis, A.; Evers, D.; Gutierrez, R.; De Scurrah, M.M. Adaptation of the Potato Crop to Changing Climates. In Crop Adaptation to Climate Change; John Wiley & Sons Ltd.: Chichester, UK, 2011; pp. 287–297. [Google Scholar]

- Naresh Kumar, S.; Govindakrishnan, P.M.; Swarooparani, D.N.; Nitin, C.; Surabhi, J.; Aggarwal, P.K. Assessment of impact of climate change on potato and potential adaptation gains in the Indo-Gangetic Plains of India. Int. J. Plant Prod. 2014, 9, 151–170. [Google Scholar]

- Lakhiar, I.A.; Gao, J.; Syed, T.N.; Chandio, F.A.; Buttar, N.A. Modern plant cultivation technologies in agriculture under controlled environment: A review on aeroponics. J. Plant Interact. 2018, 13, 338–352. [Google Scholar] [CrossRef]

- Tibbits, T.W.; Cao, W.; Wheeler, R.M. Growth of Potatoes for CELSS; NASA Contractor Report 177646; Ames Research Center: Moffett Field, CA, USA, 1994.

- Kamrani, M.H.; Chegeni, A.R.; Hosseinniya, H. Effects of Different Growing Media on Yield and Growth Parameters of Potato Minitubers (Solanum tuberosum L.). Commun. Soil Sci. Plant Anal. 2019, 50, 1838–1853. [Google Scholar] [CrossRef]

- Rolot, J.L.; Seutin, H. Soilless production of potato minitubers using a hydroponic technique. Potato Res. 1999, 42, 457–469. [Google Scholar] [CrossRef]

- Lommen, W.J.M. The Canon of Potato Science: 27. Hydroponics. Potato Res. 2007, 50, 315–318. [Google Scholar] [CrossRef] [Green Version]

- Eigenbrod, C.; Gruda, N. Urban vegetable for food security in cities. A review. Agron. Sustain. Dev. 2015, 35, 483–498. [Google Scholar] [CrossRef] [Green Version]

- Chiota, W.M.; Mabiza, P.; Chaibva, P.; Gama, T. Evaluating the effects of non-soil media on emergence and growth of potato (Solunum tuberosum L.). Int. J. Biosci. 2015, 7, 24–30. [Google Scholar] [CrossRef]

- Lunden, A.P. Undersøkelser over forholdet mellom potetenes spesifikke vekt og deres tørrstoffog stivelsesinnhold. Forsk. Fors. Landbr. 1956, 7, 81–107. [Google Scholar]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).