Integrated Building Energy Simulation–Life Cycle Assessment (BES–LCA) Approach for Environmental Assessment of Agricultural Building: A Review and Application to Greenhouse Heating Systems

Abstract

1. Introduction

2. Review of Literatures

Past BES and LCA Studies

3. Materials and Methods

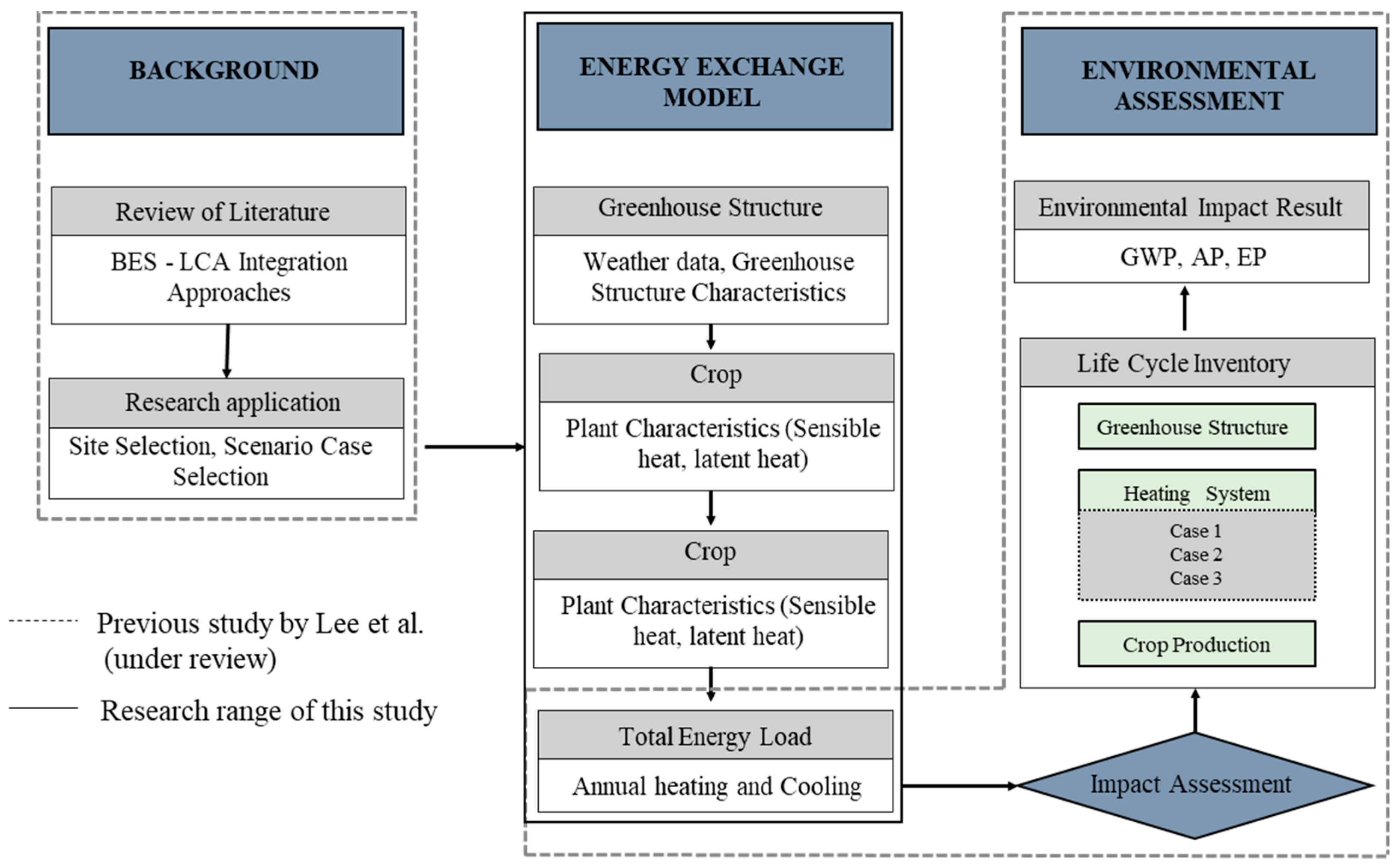

3.1. Research Flow

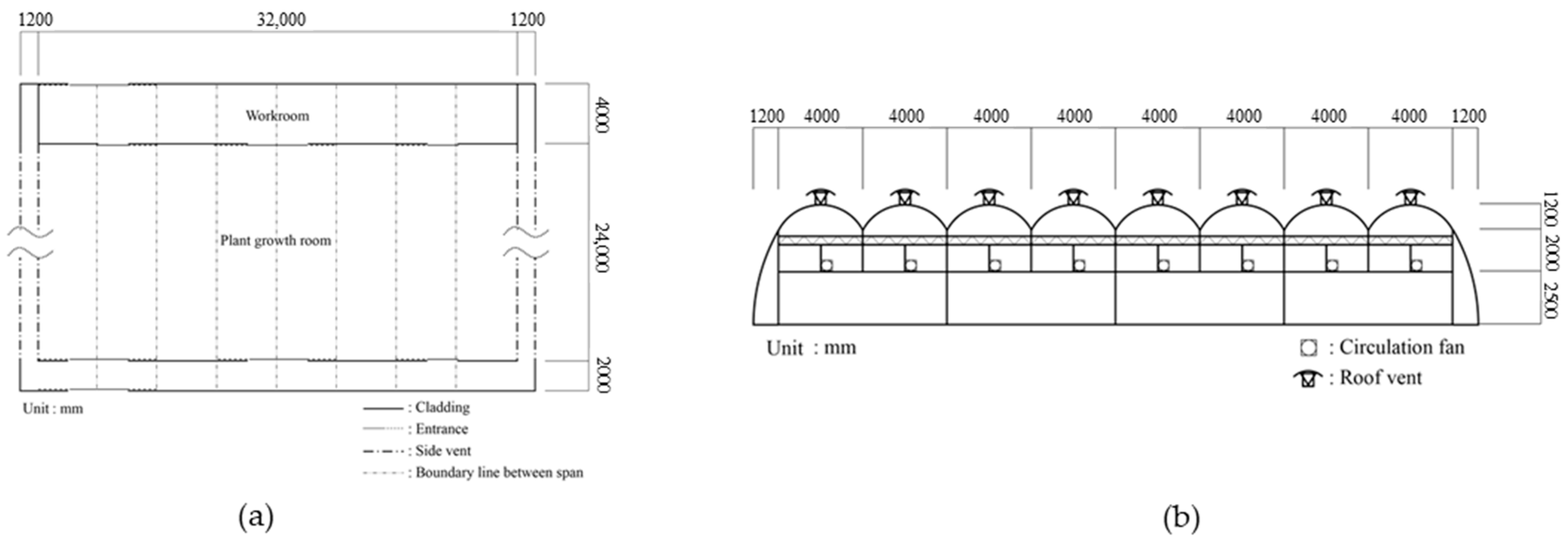

3.2. Target Experimental Greenhouse

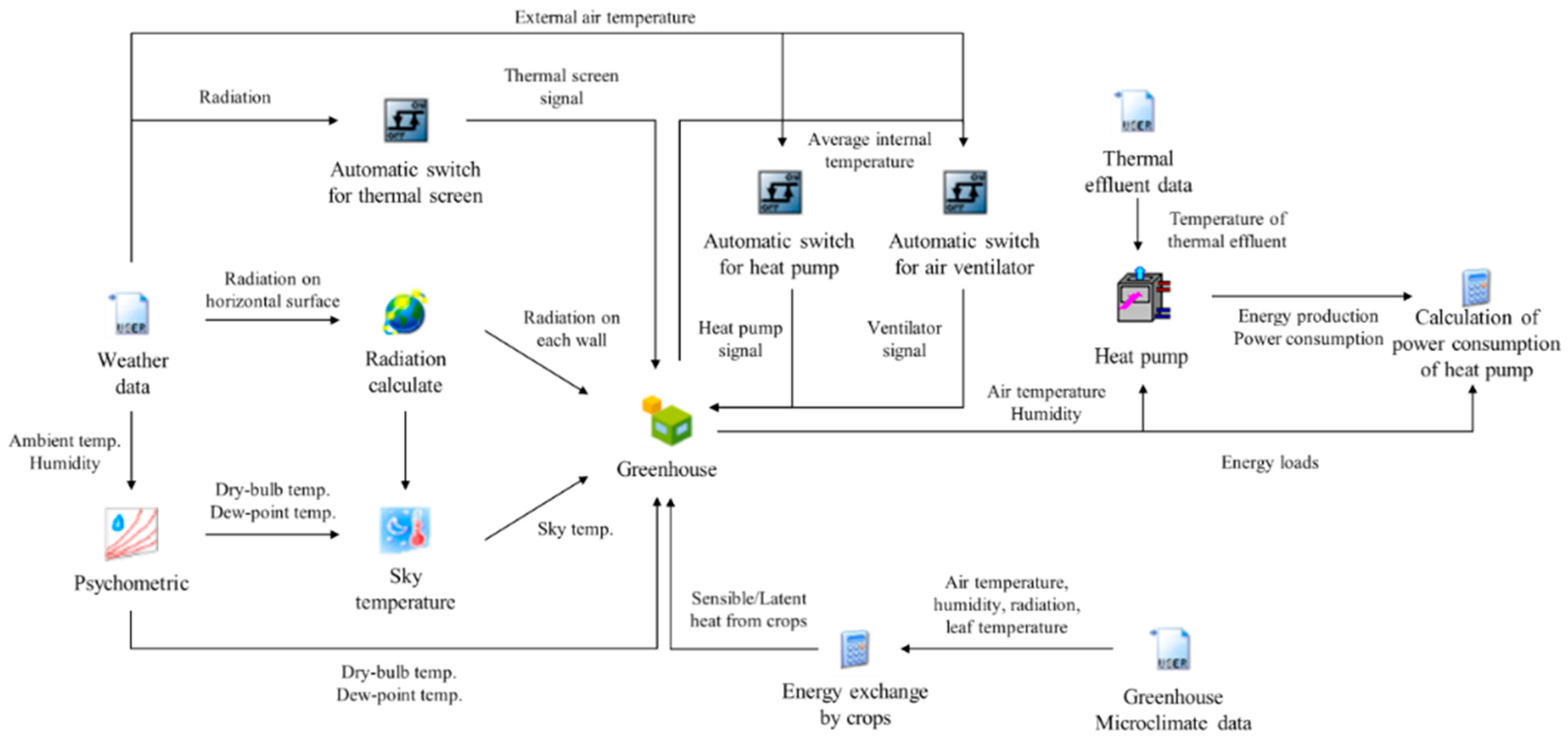

3.3. Softwares and Tools

3.3.1. Building Total Energy Demand

3.3.2. Greenhouse Facility Environmental Impact Assessment

3.4. Introduction to Scenario Cases

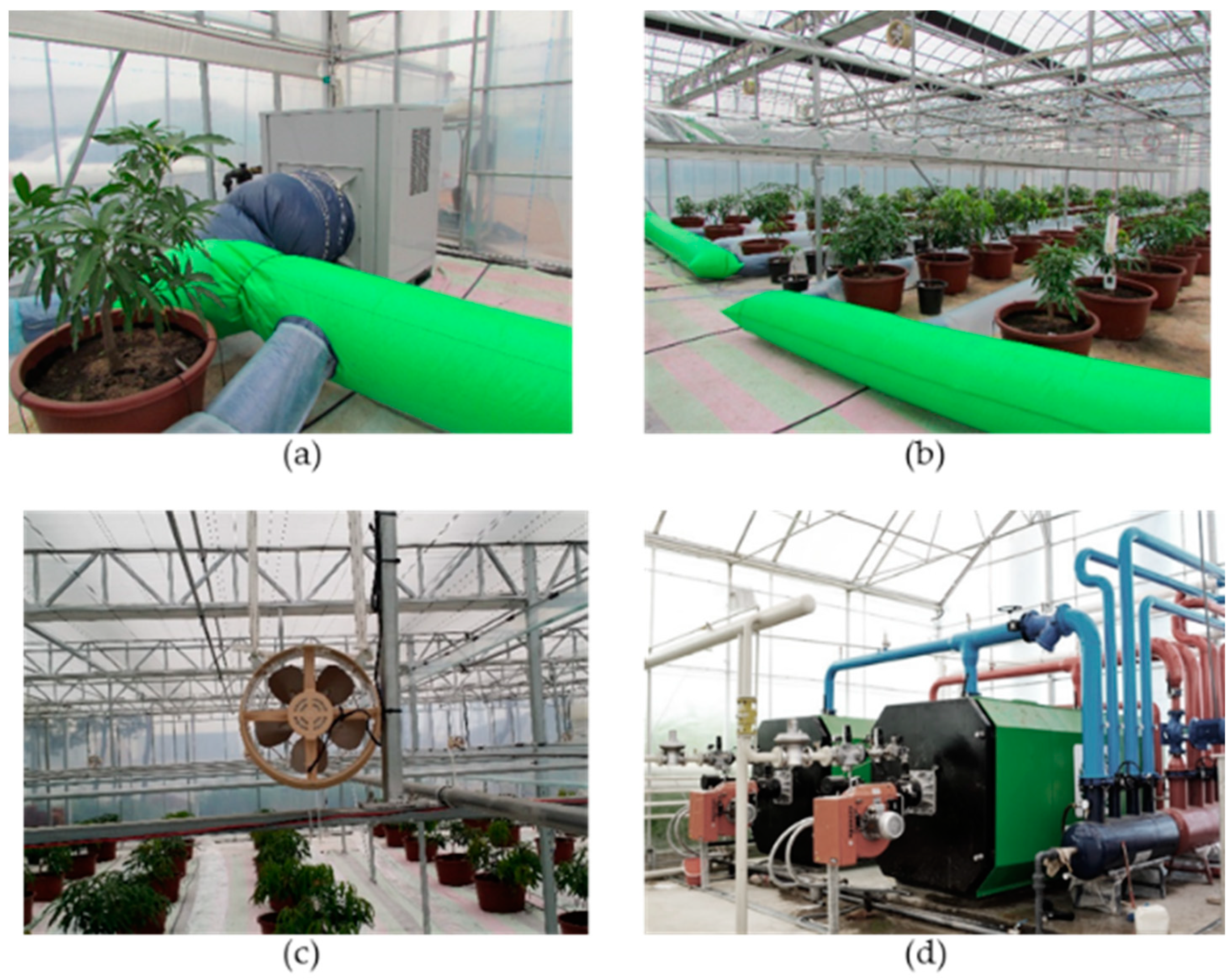

- Case 1: Thermal effluent heat-powered absorption heat pump (AHP). When using an AHP as a heating system inside the experimental greenhouse, additional equipment must be installed. This includes but is not limited to the availability of water storage tanks, heat storage tanks and fan coil units.The thermal effluent from the power plant flows into the heat pump inside the greenhouse. From the manufacturers’ data, the heat pump has a 43,276 W in maximum cooling capacity and 36,786 W in maximum heating capacity. The energy efficiency (COP) for cooling and heating were 4.68 and 4.61, respectively. Storage tanks of 40 m3 (cold) and 80 m3 (hot) were also constructed to store the water flowing into the system. The fan coil has a power unit of 18,000 (kcal h−1) for cooling and 30,000 (kcal h−1) for heating. In the environmental assessment, the life span of the heat pump was assumed to be 20 years and was in continuous operation for 24 h a day during the entire winter season. As described in Figure 4, circulation fans and air ducts were installed to maintain the uniformity of heating distribution throughout the whole building.

- Case 2: Electric-powered heat pump. The electric-powered heat pump included in the hypothetical case study with a maximum cooling capacity of 61.6 KW (−5 to 48 °C) and a maximum heating capacity of 69.3 KW (−20 to 24 °C). The unit has COP and power consumption of 3.55 and 17.35 KW for cooling and 4.15 and 16.70 KW for heating. Similar to the AHP (case 1), the electric-powered heat pump (case 2) used air ducts and fans to uniformly distribute heat throughout the building. Unlike case 1, the case 2 scenario does not require additional installation of facility such as storage tanks unlike those of case 1 since the heat source is electricity. The principle of heating involved in this kind of heat pump allows the heat to move from lower temperature to high temperature. Under this case, the heat transferred in the fan coil provides a higher temperature to the surrounding. The electric-powered heat pump was set to have an expected life span of 15 years.

- Case 3: Kerosene-powered boiler. The second hypothetical case includes the utilization of a natural kerosene-powered boiler. Like the heat pump, the boiler heating system also comprised a various component which includes the burner, chamber, heat exchanger, etc. The basic working principle of a boiler is to store water in a closed vessel and heated by burning fuel in a furnace to produce hot gases. The boiler used in the analysis was assumed to be manufactured abroad with a rated heating of 50 KW and fuel consumption of 5 L/hr. The boiler was also assumed to have 63% operational efficiency. The boiler has a stainless heat exchanger and brass gas burner. Given this material component, the boiler was assumed to be operational for the span of 30 years. Moreover, the kerosene used to power the power was set to have a heating value of 46.20 MJ/kg of kerosene fuel.

3.5. Environmental Assessment Process

3.5.1. Goal and Scope

3.5.2. Data Input Inventory

3.5.3. Life Cycle Impact Assessment (LCIA)

4. Results and Discussion

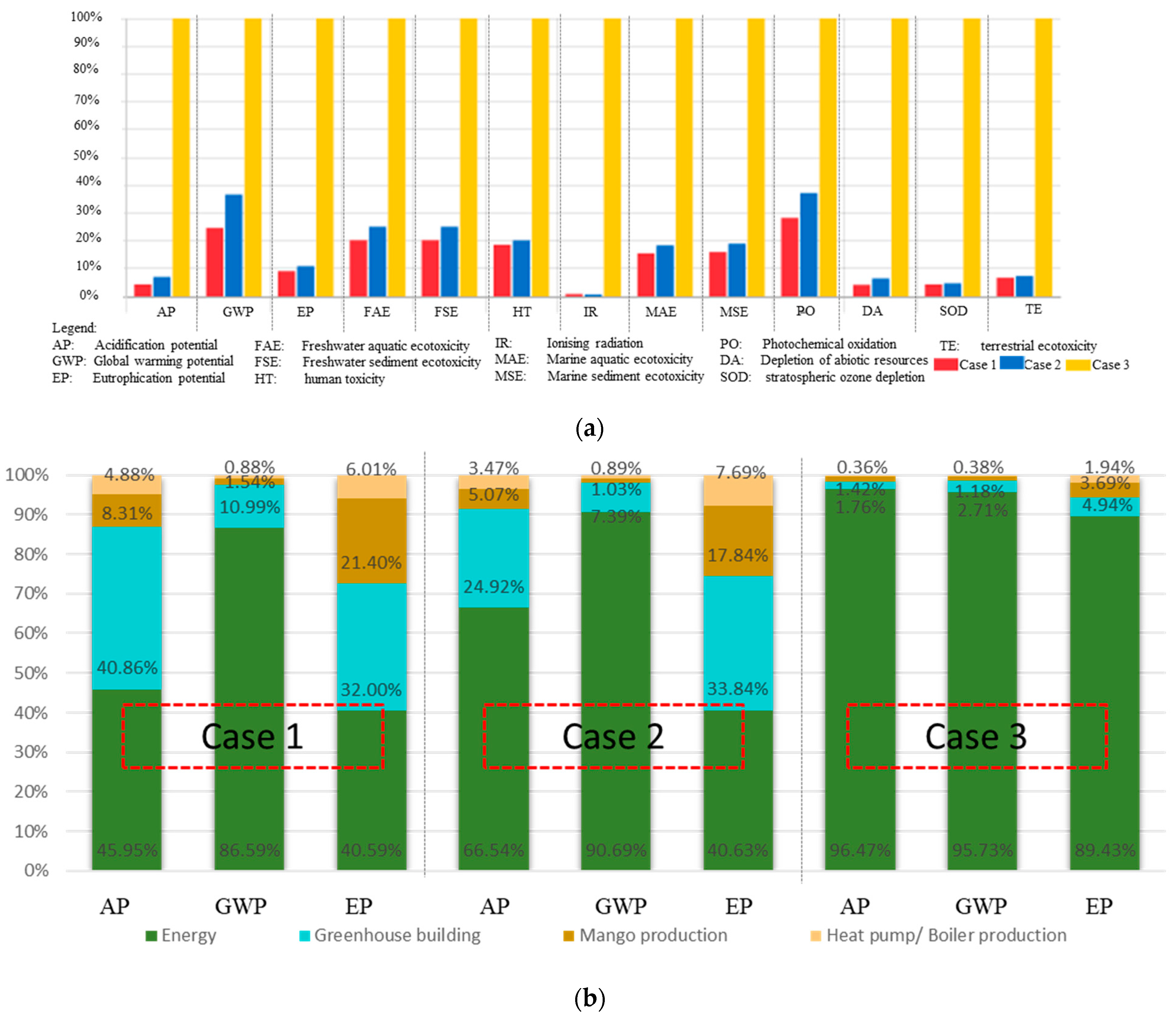

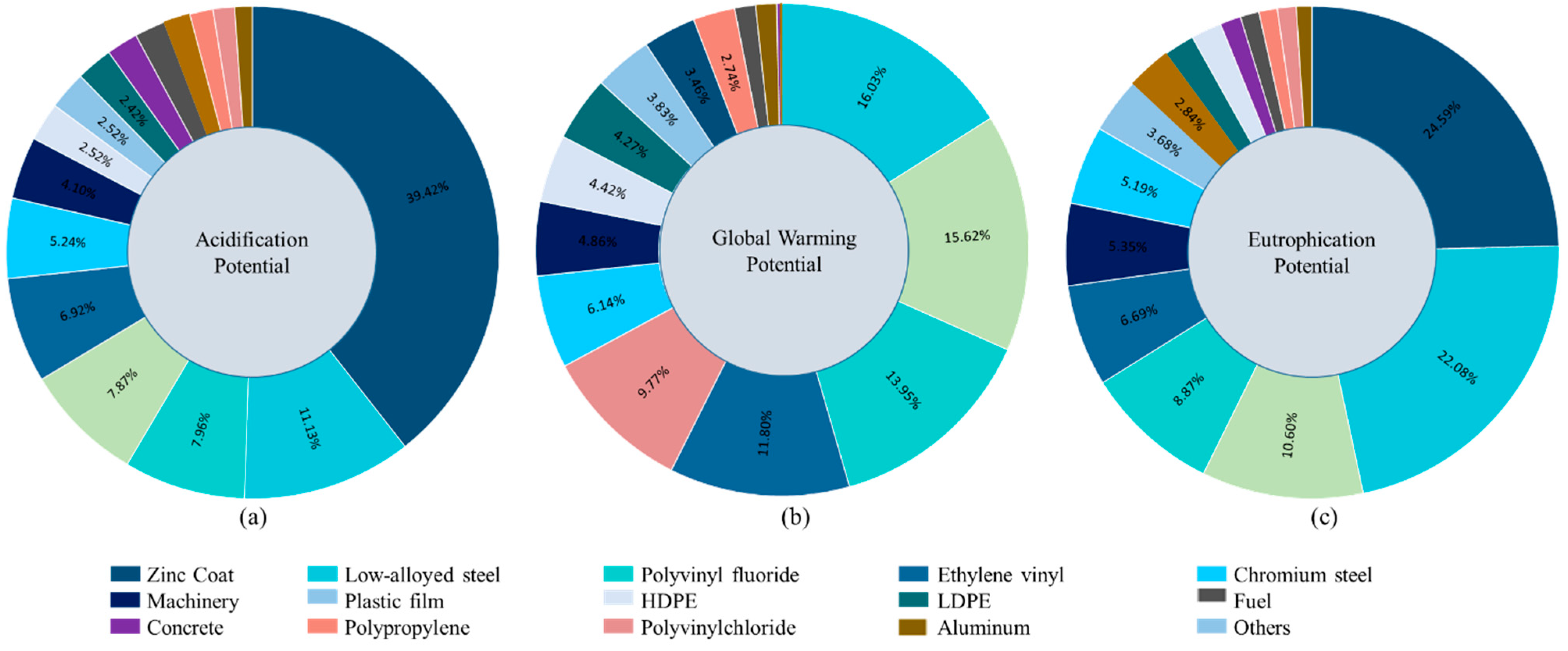

4.1. Case Scenario Environmental Analysis and Life Cycle Interpretation

4.2. Economic Analysis

4.3. Discussion on the Comparison of Different Heating Systems

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Flow | Amount | Unit |

|---|---|---|

| Input | ||

| acrylic varnish, without water, in 87.5% solution state | 1.39 × 10−3 | kg |

| agricultural machinery, unspecified | 9.50 × 10−3 | kg |

| aluminum scrap, post-consumer | −8.00 × 10−3 | kg |

| aluminum, cast alloy | 8.00 × 10−3 | kg |

| bitumen seal | 1.25 × 10−4 | kg |

| blow molding | 3.96 × 10−3 | kg |

| calendering, rigid sheets | 1.25 × 10−3 | kg |

| concrete block | 4.17 × 10−2 | kg |

| concrete block | 9.20 × 10−2 | kg |

| copper | 8.10 × 10−4 | kg |

| diesel, burned in building machine | 4.67 × 10−1 | MJ |

| electricity, low voltage | 2.35 × 10−3 | kWh |

| electronics, for control units | 2.00 × 10−5 | kg |

| ethylene vinyl acetate copolymer | 1.53 × 10−1 | kg |

| extrusion, plastic film | 2.12 × 10−1 | kg |

| extrusion, plastic pipes | 9.28 × 10−2 | kg |

| glass-fiber-reinforced plastic, polyamide, injection molded | 1.02 × 10−4 | kg |

| injection molding | 2.95 × 10−2 | kg |

| iron scrap, unsorted | −3.51 × 10−1 | kg |

| polycarbonate | 1.25 × 10−3 | kg |

| polyester resin, unsaturated | 1.71 × 10−3 | kg |

| polyethylene, high-density, granulate | 5.99 × 10−2 | kg |

| polyethylene, linear low density, granulate | 5.95 × 10−2 | kg |

| polymer foaming | 6.13 × 10−3 | kg |

| polypropylene, granulate | 3.77 × 10−2 | kg |

| polystyrene, expandable | 6.13 × 10−3 | kg |

| polyvinylfluoride | 2.99 × 10−2 | kg |

| section bar extrusion, aluminium | 8.00 × 10−3 | kg |

| section bar rolling, steel | 2.82 × 10−1 | kg |

| sheet rolling, steel | 4.44 × 10−2 | kg |

| silicone product | 1.50 × 10−4 | kg |

| steel, chromium steel 18/8 | 4.30 × 10−2 | kg |

| steel, low-alloyed | 3.07 × 10−1 | kg |

| synthetic rubber | 3.75 × 10−4 | kg |

| tractor, 4-wheel, agricultural | 1.90 × 10−2 | kg |

| wire drawing, copper | 2.25 × 10−3 | kg |

| zinc coat, coils | 2.93 × 10−2 | m2 |

| Output | ||

| waste concrete | 1.19 × 10−0 | kg |

| waste electric and electronic equipment | 8.30 × 10−4 | kg |

| waste plastic, mixture | 1.41 × 10−3 | kg |

| waste polyvinylchloride | 1.07 × 10−4 | kg |

| waste rubber, unspecified | 3.60 × 10−4 | kg |

| Flow | Amount | Unit |

|---|---|---|

| Input | ||

| application of plant protection product, by field sprayer | 4.51 × 10−3 | ha |

| carbon dioxide, in air | 4.01 × 100 | kg |

| chlorine dioxide | 3.45 × 10−7 | kg |

| cobalt | 1.09 × 10−4 | kg |

| dolomite | 5.23 × 10−3 | kg |

| energy, gross calorific value, in biomass | 3.26 × 101 | MJ |

| ethoxylated alcohol (AE > 20) | 6.33 × 10−5 | kg |

| gypsum, mineral | 1.66 × 10−1 | kg |

| harvesting, forestry harvester | 1.25 × 10−4 | h |

| irrigation | 1.07 × 10−2 | m3 |

| lime | 2.62 × 10−4 | kg |

| magnesium oxide | 2.96 × 10−2 | kg |

| mancozeb | 1.73 × 10−4 | kg |

| manganese concentrate | 1.39 × 10−3 | kg |

| mango seedling, for planting | 4.71 × 10−3 | Item(s) |

| molybdenum trioxide | 6.35 × 10−5 | kg |

| nitrogen fertilizer, as N | 3.70 × 10−2 | kg |

| occupation, permanent crop, irrigated | 3.76 × 100 | m2 * a |

| packaging, for fertilizers | 7.91 × 10−1 | kg |

| packaging, for pesticides | 5.49 × 10−2 | kg |

| pesticide, unspecified | 2.71 × 10−3 | kg |

| phenol | 1.98 × 10−5 | kg |

| phosphate fertiliser, as P2O5 | 2.64 × 10−2 | kg |

| planting with starter fertilizer, by no-till planter | 1.25 × 10−5 | ha |

| polydimethylsiloxane | 1.15 × 10−5 | kg |

| potassium fertiliser, as K2O | 7.71 × 10−2 | kg |

| sulfur | 1.93 × 10−2 | kg |

| tap water | 4.26 × 10−5 | kg |

| tillage, harrowing, by offset leveling disc harrow | 2.50 × 10−5 | ha |

| tillage, subsoiling, by subsoiler plow | 1.25 × 10−5 | ha |

| transformation, from permanent crop, irrigated | 1.88 × 10−1 | m2 |

| weed control, by brush cutter, pasture | 2.25 × 10−3 | ha |

| zinc oxide | 3.66 × 10−3 | kg |

| Output | ||

| Abamectin | 1.58 × 10−6 | kg |

| Ammonia | 3.68 × 10−3 | kg |

| Azoxystrobin | 7.32 × 10−5 | kg |

| Cadmium | 1.13 × 10−6 | kg |

| Cadmium, ion | 1.58 × 10−8 | kg |

| Cadmium, ion | 3.53 × 10−9 | kg |

| Carbon dioxide, fossil | 2.55 × 10−2 | kg |

| Chloride | 3.45 × 10−7 | kg |

| Chromium | 9.36 × 10−6 | kg |

| Chromium, ion | 7.40 × 10−6 | kg |

| Chromium, ion | 3.92 × 10−7 | kg |

| Copper | 2.40 × 10−12 | kg |

| Copper, ion | 1.12 × 10−6 | kg |

| Copper, ion | 2.92 × 10−7 | kg |

| Difenoconazole | 6.61 × 10−5 | kg |

| Dinitrogen monoxide | 8.95 × 10−4 | kg |

| Ethephon | 9.65 × 10−5 | kg |

| Indoxacarb | 1.19 × 10−5 | kg |

| Lead | 4.48 × 10−7 | kg |

| Mancozeb | 1.73 × 10−4 | kg |

| Nickel | 1.98 × 10−6 | kg |

| Nitrate | 6.80 × 10−2 | kg |

| Nitrogen oxides | 1.46 × 10−3 | kg |

| Pesticides, unspecified | 1.94 × 10−3 | kg |

| Phosphorus | 1.67 × 10−5 | kg |

| Pyraclostrobin (prop) | 3.67 × 10−5 | kg |

| Spinosad | 5.48 × 10−8 | kg |

| Tebuconazole | 1.06 × 10−4 | kg |

| Thiophanat-methyl | 3.63 × 10−4 | kg |

| Trifloxystrobin | 1.05 × 10−5 | kg |

| waste wood, untreated | 4.58 × 10−1 | kg |

| Water | 3.11 × 100 | m3 |

| Zinc | 1.08 × 10−5 | kg |

| Zinc, ion | 5.76 × 10−6 | kg |

| Flow | Amount | Unit |

|---|---|---|

| Input | ||

| aluminum, wrought alloy | 4.30 × 10−3 | kg |

| ammonia, liquid | 2.93 × 10−4 | kg |

| building, hall, steel construction | 1.74 × 10−6 | m2 |

| building, multi-story | 1.04 × 10−5 | m3 |

| copper | 9.77 × 10−4 | kg |

| electricity, low voltage | 7.81 × 10−3 | kWh |

| electricity, medium voltage | 2.60 × 10−2 | kWh |

| electronics, for control units | 1.95 × 10−5 | kg |

| helium | 7.81 × 10−4 | kg |

| injection moulding | 3.13 × 10−4 | kg |

| Occupation, industrial area, built up | 7.81 × 10−4 | m2 * a |

| polyethylene, high density, granulate | 3.22 × 10−2 | kg |

| reinforcing steel | 6.25 × 10−3 | kg |

| sheet rolling, chromium steel | 3.22 × 10−2 | kg |

| sheet rolling, steel | 6.25 × 10−3 | kg |

| steel, chromium steel 18/8, hot rolled | 1.56 × 10−3 | kg |

| stone wool, packed | 6.25 × 10−6 | kg |

| Transformation, from unknown | 6.25 × 10−6 | m2 |

| Transformation, to industrial area, built up | 3.91 × 10−2 | m2 |

| tube insulation, elastomere | 7.81 × 10−4 | kg |

| water, completely softened | 4.18 × 10−4 | kg |

| water, completely softened | 5.59 × 10−4 | kg |

| Water, unspecified natural origin | 5.96 × 10−5 | m3 |

| zinc coat, coils | 2.93 × 10−3 | m2 |

| Output | ||

| electronics scrap from control units | 7.81 × 10−4 | kg |

| waste mineral wool | 1.11 × 10−3 | kg |

| waste mineral wool | 4.55 × 10−4 | kg |

| waste polyethylene/polypropylene product | 4.41 × 10−4 | kg |

| waste polyethylene/polypropylene product | 1.12 × 10−3 | kg |

| wastewater, from residence | 1.99 × 10−5 | m3 |

| Flow | Amount | Unit |

|---|---|---|

| Input | ||

| copper | 5.73 × 10−3 | kg |

| electricity, medium voltage | 3.65 × 10−2 | kWh |

| lubricating oil | 4.43 × 10−4 | kg |

| polyvinylchloride, bulk polymerized | 2.60 × 10−4 | kg |

| refrigerant R134a | 8.05 × 10−4 | kg |

| reinforcing steel | 1.95 × 10−2 | kg |

| steel, low-alloyed, hot rolled | 5.21 × 10−3 | kg |

| tube insulation, elastomere | 2.60 × 10−3 | kg |

| Water, unspecified natural origin | 1.84 × 10−4 | m3 |

| Output | ||

| ethane, 1,1,1,2-tetrafluoro-, HFC-134a | 9.20 × 10−1 | kWh |

| waste plastic, mixture | 1.59 × 101 | MJ |

| water | 1.42 × 10−1 | m3 |

| water | 8.02 × 10−1 | m3 |

| Flow | Amount | Unit |

|---|---|---|

| Input | ||

| alkyd paint, white, without solvent, in 60% solution state | 2.17 × 10−3 | kg |

| aluminum, cast alloy | 1.30 × 10−2 | kg |

| brass | 4.34 × 10−5 | kg |

| brazing solder, cadmium free | 5.21 × 10−3 | kg |

| copper | 2.17 × 10−2 | kg |

| corrugated board box | 1.01 × 10−1 | kg |

| corrugated board box | 8.58 × 10−3 | kg |

| polyethylene, high density, granulate | 1.22 × 10−3 | kg |

| steel, chromium steel 18/8, hot rolled | 2.17 × 10−2 | kg |

| steel, low-alloyed, hot rolled | 4.21 × 10−1 | kg |

| stone wool, packed | 1.65 × 10−2 | kg |

| tap water | 6.43 × 10−1 | kg |

| waste paperboard, unsorted | −8.68 × 10−3 | kg |

| Output | ||

| hazardous waste, for incineration | 1.69 × 10−3 | kg |

| hazardous waste, for incineration | 3.52 × 10−3 | kg |

| waste mineral wool, for final disposal | 9.39 × 10−3 | kg |

| waste mineral wool, for final disposal | 7.10 × 10−3 | kg |

| waste plastic, mixture | 1.35 × 10−4 | kg |

| waste plastic, mixture | 9.46 × 10−4 | kg |

| waste plastic, mixture | 1.15 × 10−4 | kg |

| waste plastic, mixture | 3.73 × 10−6 | kg |

| waste plastic, mixture | 6.83 × 10−7 | kg |

| waste plastic, mixture | 9.03 × 10−6 | kg |

| waste plastic, mixture | 3.54 × 10−6 | kg |

| waste plastic, mixture | 1.51 × 10−6 | kg |

| wastewater from pig iron production | 6.22 × 10−5 | m3 |

| wastewater from pig iron production | 4.72 × 10−4 | m3 |

| Water | 9.65 × 10−5 | m3 |

| Water | 1.29 × 10−5 | m3 |

| Flow | Amount | Unit |

|---|---|---|

| Input | ||

| heat, district or industrial, natural gas | 4.34 × 102 | MJ |

| heat, district or industrial, natural gas | 1.06 × 103 | MJ |

| kerosene | 2.29 × 101 | kg |

References

- Lee, S. Design of a Greenhouse Energy Model Including Energy Exchange of Internal Plants and Its Application for Energy Loads Estimation. Master’s Thesis, Seoul National University, Seoul, Korea, 2017. [Google Scholar]

- Greenhouse Horticulture in Korea. 2016. Available online: https://www.agroberichtenbuitenland.nl/binaries/agroberichtenbuitenland/documenten/rapporten/2016/06/22/greenhouse-horticulture-in-korea/Greenhouse-Horticulture-in-South-KoreaJune-2016.pdf (accessed on 28 January 2021).

- KEEI. Korea Energy Review Monthly; Energy Statistics Analysis Div.: Ulsan, Korea, 2020. [Google Scholar]

- Institute, K.R.E. Feasibility for Commercial Use of Nuclear Hot Water; Korea Rural Economic Research Institute: Seoul, Korea, 2005. [Google Scholar]

- KEPCO. Available online: Home.kepco.co.kr (accessed on 28 January 2021).

- D’Arpa, S.; Colangelo, G.; Starace, G.; Petrosillo, I.; Bruno, D.E.; Uricchio, V.; Zurlini, G. Heating requirements in greenhouse farming in southern Italy: Evaluation of ground-source heat pump utilization compared to traditional heating systems. Energy Effic. 2015, 9, 1065–1085. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, P.; Mao, J.; Tang, X.; Li, Z.; Shi, J. A low cost seasonal solar soil heat storage system for greenhouse heating: Design and pilot study. Appl. Energy 2015, 156, 213–222. [Google Scholar] [CrossRef]

- Shen, Y.; Wei, R.; Xu, L. Energy Consumption Prediction of a Greenhouse and Optimization of Daily Average Temperature. Energies 2018, 11, 65. [Google Scholar] [CrossRef]

- Koroneos, C.; Tsarouhis, M. Exergy analysis and life cycle assessment of solar heating and cooling systems in the building environment. J. Clean. Prod. 2012, 32, 52–60. [Google Scholar] [CrossRef]

- Beccali, M.; Cellura, M.; Longo, S.; Nocke, B.; Finocchiaro, P. LCA of a solar heating and cooling system equipped with a small water–ammonia absorption chiller. Sol. Energy 2012, 86, 1491–1503. [Google Scholar] [CrossRef]

- Beccali, M.; Cellura, M.; Longo, S.; Guarino, F. Solar heating and cooling systems versus conventional systems assisted by photovoltaic: Application of a simplified LCA tool. Sol. Energy Mater. Sol. Cells 2016, 156, 92–100. [Google Scholar] [CrossRef]

- Hosseini-Fashami, F.; Motevali, A.; Nabavi-Pelesaraei, A.; Hashemi, S.J.; Chau, K.W. Energy-Life cycle assessment on applying solar technologies for greenhouse strawberry production. Renew. Sustain. Energy Rev. 2019, 116. [Google Scholar] [CrossRef]

- Bird, N.; Cowie, A.; Cherubini, F.; Jugmeier, G. Using A Life Cycle Assessment Approach to Estimate the Net Greenhouse Gas Emissions of Bioenergy; IEA Bioenergy: Rotorua, New Zealand, 2011. [Google Scholar]

- Hendricks, P. Life Cycle Assessment of Greenhouse Tomato (Solanum lycopersicum L.) Production in Southwestern Ontario. Master’s Thesis, University of Guelph, Guelph, ON, Canada, 2012. [Google Scholar]

- Singh, A.; Berghorn, G.; Joshi, S.; Syal, M. Review of Life-Cycle Assessment Applications in Building Construction. J. Archit. Eng. 2011, 17, 15–23. [Google Scholar] [CrossRef]

- Röck, M.; Hollberg, A.; Habert, G.; Passer, A. LCA and BIM: Visualization of environmental potentials in building construction at early design stages. Build. Environ. 2018, 140, 153–161. [Google Scholar] [CrossRef]

- Rodrigues, V.; Martins, A.A.; Nunes, M.I.; Quintas, A.; Mata, T.M.; Caetano, N.S. LCA of constructing an industrial building: Focus on embodied carbon and energy. Energy Procedia 2018, 153, 420–425. [Google Scholar] [CrossRef]

- Nguyen, T.T.H. Life Cycle Assessment of Cattle Production: Exploring Practices and System Changes to Reduce Environmental Impacts. Ph.D. Thesis, Université Blaise Pascal, Aubière, France, 2013. [Google Scholar]

- Liao, W.; van der Werf, H.M.; Salmon-Monviola, J. Improved Environmental Life Cycle Assessment of Crop Production at the Catchment Scale via a Process-Based Nitrogen Simulation Model. Environ. Sci. Technol. 2015, 49, 10790–10796. [Google Scholar] [CrossRef]

- Niero, M.; Ingvordsen, C.H.; Jørgensen, R.B.; Hauschild, M.Z. How to manage uncertainty in future Life Cycle Assessment (LCA) scenarios addressing the effect of climate change in crop production. J. Clean. Prod. 2015, 107, 693–706. [Google Scholar] [CrossRef]

- Zhang, H.; Burr, J.; Zhao, F. A comparative life cycle assessment (LCA) of lighting technologies for greenhouse crop production. J. Clean. Prod. 2017, 140, 705–713. [Google Scholar] [CrossRef]

- Asem-Hiablie, S.; Battagliese, T.; Stackhouse-Lawson, K.R.; Alan Rotz, C. A life cycle assessment of the environmental impacts of a beef system in the USA. Int. J. Life Cycle Assess. 2018, 24, 441–455. [Google Scholar] [CrossRef]

- Ha, T.; Lee, I.B.; Kwon, K.S.; Hong, S.W. Computation and field experiment validation of greenhouse energy load using building energy simulation model. Int. J. Agric. Biol. Eng. 2015. [Google Scholar] [CrossRef]

- Ha, T.; Kwon, K.-S.; Hong, S.-W.; Choi, H.-C.; Lee, J.-Y.; Lee, D.-H.; Woo, S.; Yang, K.-Y.; Kim, R.-W.; Yeo, U.-H.; et al. Estimation of THI index to evaluate thermal stress of animal occupied zone in a broiler house using BES method. In Proceedings of the 10th International Livestock Environment Symposium (ILES X), Omaha, Nebraska, 25–27 September 2018. [Google Scholar]

- Rasheed, A.; Lee, J.; Lee, H. Development and Optimization of a Building Energy Simulation Model to Study the Effect of Greenhouse Design Parameters. Energies 2018, 11, 2001. [Google Scholar] [CrossRef]

- Rasheed, A.; Na, W.H.; Lee, J.W.; Kim, H.T.; Lee, H.W. Optimization of Greenhouse Thermal Screens for Maximized Energy Conservation. Energies 2019, 12, 3592. [Google Scholar] [CrossRef]

- Kumar, P.; Martani, C.; Morawska, L.; Norford, L.; Choudhary, R.; Bell, M.; Leach, M. Indoor air quality and energy management through real-time sensing in commercial buildings. Energy Build. 2016, 111, 145–153. [Google Scholar] [CrossRef]

- Ramírez-Villegas, R.; Eriksson, O.; Olofsson, T. Assessment of renovation measures for a dwelling area–Impacts on energy efficiency and building certification. Build. Environ. 2016, 97, 26–33. [Google Scholar] [CrossRef]

- Wei, W.; Wargocki, P.; Zirngibl, J.; Bendžalová, J.; Mandin, C. Review of parameters used to assess the quality of the indoor environment in Green Building certification schemes for offices and hotels. Energy Build. 2020, 209. [Google Scholar] [CrossRef]

- Maile, T.; Fischer, M.; Barjanaz, V. Building energy performance simulation tools—A life-cycle and interoperable perspective. Cent. Integr. Facil. Eng. Work. Pap. 2007, 107, 1–49. [Google Scholar]

- Stadler, M.; Firestone, R.; Curtil, D.; Marnay, C. On-Site Generation Simulation with EnergyPlus for Commercial Buildings. In Proceedings of the 2006 ACEEE Summer Study on Energy Efficiency in Buildings, Asilomar, CA, USA, 13–18 August 2006. [Google Scholar]

- Fabrizio, E. Energy reduction measures in agricultural greenhouses heating: Envelope, systems and solar energy collection. Energy Build. 2012, 53, 57–63. [Google Scholar] [CrossRef]

- Boyano, A.; Hernandez, P.; Wolf, O. Energy demands and potential savings in European office buildings: Case studies based on EnergyPlus simulations. Energy Build. 2013, 65, 19–28. [Google Scholar] [CrossRef]

- Al-ajmi, F.F.; Hanby, V.I. Simulation of energy consumption for Kuwaiti domestic buildings. Energy Build. 2007, 40, 1101–1109. [Google Scholar] [CrossRef]

- Hong, S.W.; Lee, I.B.; Hong, H.K.; Seo, I.H.; Hwang, H.S.; Bitog, J.P.; Yoo, J.I.; Kwon, K.S.; Ha, T.H.; Kim, K.S. Analysis of Heating Load of a Naturally Ventilated Broiler House using BES Simulation. J. Korean Soc. Agric. Eng. 2008, 50, 39–47. [Google Scholar] [CrossRef]

- Vadiee, A.; Martin, V. Energy analysis and thermoeconomic assessment of the closed greenhouse–The largest commercial solar building. Appl. Energy 2013, 102, 1256–1266. [Google Scholar] [CrossRef]

- Shah, V.P.; Debella, D.C.; Ries, R.J. Life cycle assessment of residential heating and cooling systems in four regions in the United States. Energy Build. 2008, 40, 503–513. [Google Scholar] [CrossRef]

- Blumsack, S.; Brownson, J.; Witmer, L. Efficiency, Economic and Environmental Assessment of Ground-Source Heat Pumps in Central Pennsylvania. In Proceedings of the 42nd Hawaii International Conference on System Sciences, Waikoloa, HI, USA, 5–8 January 2009. [Google Scholar]

- Rodriguez Droguett, B. Embodied Carbon of Heating, Ventilation, Air Conditioning and Refrigerants (HVAC+R) Systems. Ph.D. Thesis, University of Washington, Seattle, WA, USA, 2019. [Google Scholar]

- Ylmén, P.; Peñaloza, D.; Mjörnell, K. Life Cycle Assessment of an Office Building Based on Site-Specific Data. Energies 2019, 12, 2588. [Google Scholar] [CrossRef]

- Santos, R.; Costa, A. BIM in LCA/LCEA Analysis: Comparative analysis of Multi-family House and Single-family. In Proceedings of the CIB World Building Congress 2016, Tampere, Finland, 30 May–3 June 2016. [Google Scholar]

- Sanyé-Mengual, E.; Oliver-Solà, J.; Montero, J.I.; Rieradevall, J. An environmental and economic life cycle assessment of rooftop greenhouse (RTG) implementation in Barcelona, Spain. Assessing new forms of urban agriculture from the greenhouse structure to the final product level. Int. J. Life Cycle Assess. 2015, 20, 350–366. [Google Scholar] [CrossRef]

- Bartzas, G.; Zaharaki, D.; Komnitsas, K. Life cycle assessment of open field and greenhouse cultivation of lettuce and barley. Inf. Process. Agric. 2015, 2, 191–207. [Google Scholar] [CrossRef]

- Benis, L.; Vicente, R.; Ferrão, P.; Fernández, J.E. Rooftop Greenhouses: LCA and Energy Simulation. In Proceedings of the CISBAT 2015 International Conference “Future Buildings and Districts—Sustainability from Nano to Urban Scale”, Lausanne, Switzerland, 9–11 September 2015. [Google Scholar]

- Perez Neira, D.; Soler Montiel, M.; Delgado Cabeza, M.; Reigada, A. Energy use and carbon footprint of the tomato production in heated multi-tunnel greenhouses in Almeria within an exporting agri-food system context. Sci. Total Environ. 2018, 628, 1627–1636. [Google Scholar] [CrossRef]

- Koroneos, C.J.; Nanaki, E.A. Environmental impact assessment of a ground source heat pump system in Greece. Geothermics 2017, 65, 1–9. [Google Scholar] [CrossRef]

- Saner, D.; Juraske, R.; Kübert, M.; Blum, P.; Hellweg, S.; Bayer, P. Is it only CO2 that matters? A life cycle perspective on shallow geothermal systems. Renew. Sustain. Energy Rev. 2010, 14, 1798–1813. [Google Scholar] [CrossRef]

- Carvalho, A. High Efficiency Ground Source Heat Pump Systems for Sustainable Building Space Conditioning. Ph.D. Thesis, Combria University, Coimbra, Portugal, 2015. [Google Scholar]

- Blum, P.; Campillo, G.; Münch, W.; Kölbel, T. CO2 savings of ground source heat pump systems—A regional analysis. Renew. Energy 2010, 35, 122–127. [Google Scholar] [CrossRef]

- Bayer, P.; Saner, D.; Bolay, S.; Rybach, L.; Blum, P. Greenhouse gas emission savings of ground source heat pump systems in Europe: A review. Renew. Sustain. Energy Rev. 2012, 16, 1256–1267. [Google Scholar] [CrossRef]

- Canaj, K.; Mehmeti, A.; Cantore, V.; Todorovic, M. LCA of tomato greenhouse production using spatially differentiated life cycle impact assessment indicators: An Albanian case study. Environ. Sci. Pollut. Res. Int. 2020, 27, 6960–6970. [Google Scholar] [CrossRef]

- Salehpour, T.; Khanali, M.; Rajabipour, A. Environmental impact assessment for ornamental plant greenhouse: Life cycle assessment approach for primrose production. Environ. Pollut. 2020, 266, 115258. [Google Scholar] [CrossRef]

- Zarei, M.J.; Kazemi, N.; Marzban, A. Life cycle environmental impacts of cucumber and tomato production in open-field and greenhouse. J. Saudi Soc. Agric. Sci. 2019, 18, 249–255. [Google Scholar] [CrossRef]

- Lee, S.Y.; Lee, I.B.; Lee, S.N.; Kim, R.W.; Yeo, U.K.; Kim, J.G.; Decano-Valentin, C.V. Dynamic energy exchange modelling for a plastic-coverded multi-span greenhouse utilizing a thermal effluent from power plant. Agrononomy. on review.

- Pombo, O.; Allacker, K.; Rivela, B.; Neila, J. Sustainability assessment of energy saving measures: A multi-criteria approach for residential buildings retrofitting—A case study of the Spanish housing stock. Energy Build. 2016, 116, 384–394. [Google Scholar] [CrossRef]

- Cecconet, D.; Raček, J.; Callegari, A.; Hlavínek, P. Energy Recovery from Wastewater: A Study on Heating and Cooling of a Multipurpose Building with Sewage-Reclaimed Heat Energy. Sustainability 2019, 12, 116. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, M.P.; Yang, T. Estimation of carbon stock for greenhouse gas emissions from hydropower reservoirs. Stoch. Environ. Res. Risk Assess. 2018, 32, 3183–3193. [Google Scholar] [CrossRef]

- Jan, P.; Dux, D.; Lips, M.; Alig, M.; Dumondel, M. On the link between economic and environmental performance of Swiss dairy farms of the alpine area. Int. J. Life Cycle Assess. 2012, 17, 706–719. [Google Scholar] [CrossRef]

- Greening, B.; Azapagic, A. Domestic heat pumps: Life cycle environmental impacts and potential implications for the UK. Energy 2012, 39, 205–217. [Google Scholar] [CrossRef]

| Year | Annual | Total Load |

|---|---|---|

| Heating (MJ) | (kWh) | |

| 2009~2010 | 838,243.37 | 315,960.47 |

| 2010~2011 | 825,247.94 | 312,197.47 |

| 2011~2012 | 802,653.62 | 297,472.02 |

| 2012~2013 | 901,318.95 | 332,306.58 |

| 2013~2014 | 786,186.39 | 306,118.99 |

| 2014~2015 | 813,409.80 | 297,472.27 |

| 2015~2016 | 782,307.87 | 290,323.42 |

| 2016~2017 | 793,454.47 | 300,480.89 |

| 2017~2018 | 813,209.88 | 300,179.06 |

| 2018~2019 | 755,980.29 | 322,996.59 |

| Average | 811,201.26 | 307,550.78 |

| AP (kg SO2-eq) | GWP (kg CO2-eq) | EP (kg PO4-eq) | |

|---|---|---|---|

| Case 1 | 4.96 × 10−2 | 2.79 × 101 | 1.47 × 10−2 |

| Case 2 | 8.12 × 10−2 | 4.15 × 101 | 1.77 × 10−2 |

| Case 3 | 1.16 × 100 | 1.14 × 102 | 1.63 × 10−1 |

| Impact | Description | Case 1 | Case 2 | Case 3 |

|---|---|---|---|---|

| Acidification Potential (kg SO2-eq) | Energy | 2.28 × 10−2 | 5.40 × 10−2 | 1.11 × 10−0 |

| Greenhouse building | 2.03 × 10−2 | 2.02 × 10−2 | 2.02 × 10−2 | |

| Mango production | 4.12 × 10−3 | 4.11 × 10−3 | 1.63 × 10−2 | |

| Heat pump/Boiler production | 2.43 × 10−3 | 2.81 × 10−3 | 4.11 × 10−3 | |

| Global Warming Potential (kg CO2-eq) | Energy | 2.42 × 101 | 3.75 × 101 | 1.08 × 102 |

| Greenhouse building | 3.07 × 100 | 3.06 × 100 | 3.06 × 100 | |

| Mango production | 4.29 × 10−1 | 4.28 × 10−1 | 1.33 × 100 | |

| Heat pump/Boiler production | 2.46 × 10−1 | 3.68 × 10−1 | 4.28 × 10−1 | |

| Eutrophication Potential (kg PO4-eq) | Energy | 5.97 × 10−3 | 7.16 × 10−3 | 1.45 × 10−1 |

| Greenhouse building | 4.71 × 10−3 | 5.96 × 10−3 | 7.99 × 10−3 | |

| Mango production | 3.15 × 10−3 | 3.14 × 10−3 | 5.96 × 10−3 | |

| Heat pump/Boiler production | 8.81 × 10−4 | 1.35 × 10−3 | 3.14 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Decano-Valentin, C.; Lee, I.-B.; Yeo, U.-H.; Lee, S.-Y.; Kim, J.-G.; Park, S.-J.; Choi, Y.-B.; Cho, J.-H.; Jeong, H.-H. Integrated Building Energy Simulation–Life Cycle Assessment (BES–LCA) Approach for Environmental Assessment of Agricultural Building: A Review and Application to Greenhouse Heating Systems. Agronomy 2021, 11, 1230. https://doi.org/10.3390/agronomy11061230

Decano-Valentin C, Lee I-B, Yeo U-H, Lee S-Y, Kim J-G, Park S-J, Choi Y-B, Cho J-H, Jeong H-H. Integrated Building Energy Simulation–Life Cycle Assessment (BES–LCA) Approach for Environmental Assessment of Agricultural Building: A Review and Application to Greenhouse Heating Systems. Agronomy. 2021; 11(6):1230. https://doi.org/10.3390/agronomy11061230

Chicago/Turabian StyleDecano-Valentin, Cristina, In-Bok Lee, Uk-Hyeon Yeo, Sang-Yeon Lee, Jun-Gyu Kim, Se-Jun Park, Young-Bae Choi, Jeong-Hwa Cho, and Hyo-Hyeog Jeong. 2021. "Integrated Building Energy Simulation–Life Cycle Assessment (BES–LCA) Approach for Environmental Assessment of Agricultural Building: A Review and Application to Greenhouse Heating Systems" Agronomy 11, no. 6: 1230. https://doi.org/10.3390/agronomy11061230

APA StyleDecano-Valentin, C., Lee, I.-B., Yeo, U.-H., Lee, S.-Y., Kim, J.-G., Park, S.-J., Choi, Y.-B., Cho, J.-H., & Jeong, H.-H. (2021). Integrated Building Energy Simulation–Life Cycle Assessment (BES–LCA) Approach for Environmental Assessment of Agricultural Building: A Review and Application to Greenhouse Heating Systems. Agronomy, 11(6), 1230. https://doi.org/10.3390/agronomy11061230