Genetic Variation in Grain Yield and Quality Traits of Spring Malting Barley

Abstract

1. Introduction

2. Materials and Methods

2.1. Field Experiments

2.2. Measurements and Analysis

2.3. Statistical Analysis

3. Results

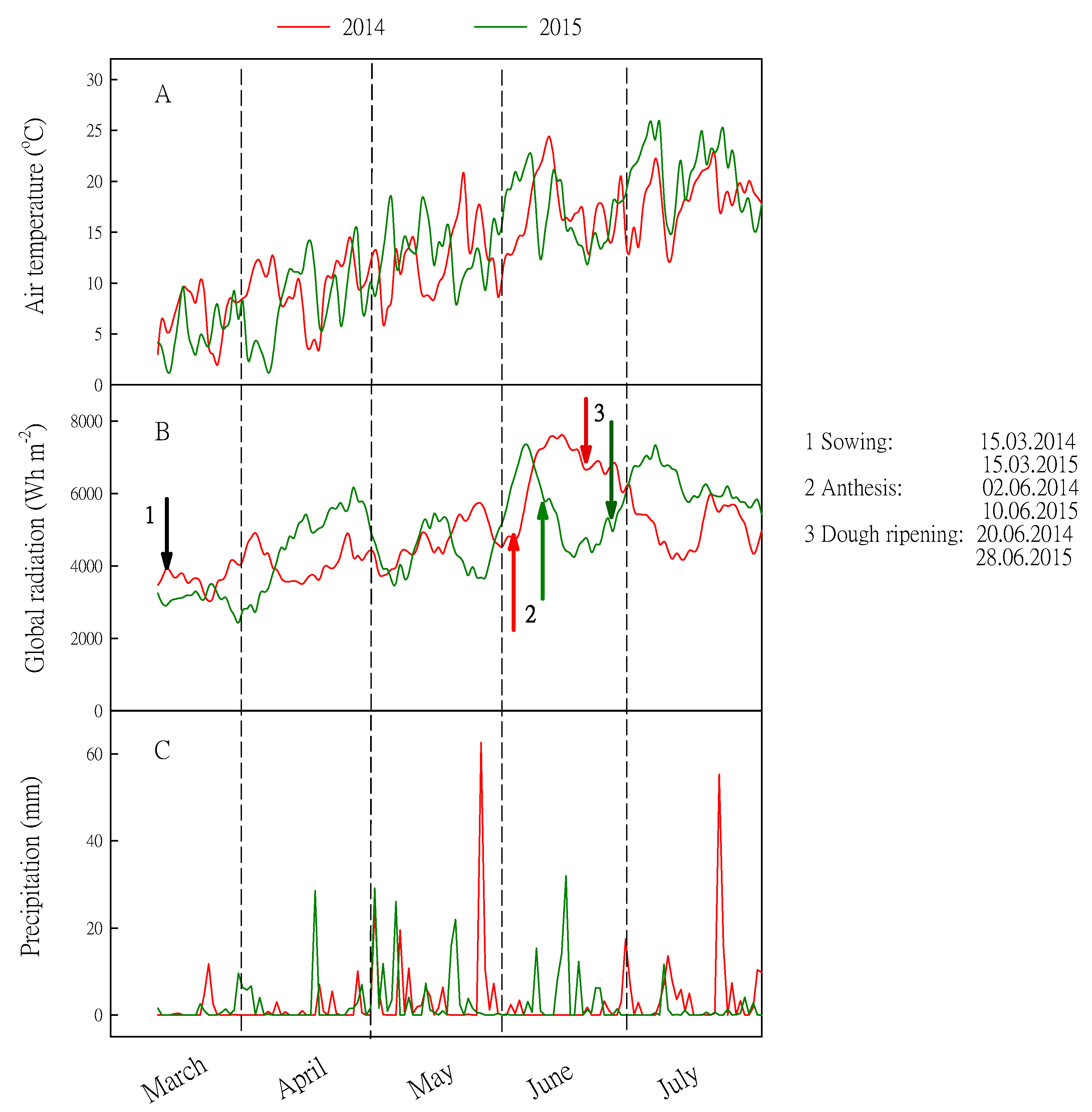

3.1. Weather Conditions

3.2. Grain Yield and Quality and Yield Components

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Newton, A.C.; Flavell, A.J.; George, T.S.; Leat, P.; Mullholland, B.; Ramsay, L.; Revoredo-Giha, C.; Russell, J.; Steffenson, B.J.; Swanston, J.S.; et al. Crops that feed the world 4. Barley: A resilient crop? Strengths and weaknesses in the context of food security. Food Secur. 2011, 3, 141–178. [Google Scholar] [CrossRef]

- Lovarelli, D.; Garcia, L.R.; Sanchez-Giron, V.; Bacenetti, J. Barley production in Spain and Italy: Environmental comparison between different cultivation practices. Sci. Total Environ. 2020, 707, 135982. [Google Scholar] [CrossRef]

- Bundessortenamt Beschreibende Sortenliste 2016: Getreide, Mais, Öl- und Faserpflanzen, Leguminosen, Rüben, Zwischenfrüchte. Bundessortenamt, Hannover. Available online: https://www.bundessortenamt.de/bsa/sorten/beschreibende-sortenlisten/download-bsl-im-pdf-format (accessed on 23 October 2020).

- Braugersten-Germeinschafter Harvest Report Malting Barley Oct. 2020. Available online: https://www.braugerstengemeinschaft.de/en/category/uncategorized/ (accessed on 3 November 2020).

- Fox, G.P. Chemical Composition in Barley Grains and Malt Quality. In Genetics and Improvement of Barley Malt Quality; Zhang, G., Li, C., Eds.; Zhejiang University Press, Springer: Hangzhou, China, 2010; pp. 63–98. [Google Scholar]

- Molina-Cano, J.L.; Francesch, M.; Perez-Vendrell, A.M.; Ramo, T.; Voltas, J.; Brufau, J. Genetic and environmental variation in malting and feed quality of barley. J. Cereal Sci. 1997, 25, 37–47. [Google Scholar] [CrossRef]

- Cochrane, M.P.; Duffus, C.M. Endosperm cell number in cultivars of barley differing in grain weight. Ann. Appl. Biol. 1983, 102, 177–181. [Google Scholar] [CrossRef]

- Voltas, J.; Romagosa, I.; Araus, J.L. Grain size and nitrogen accumulation in sink-reduced barley under Mediterranean conditions. Field Crop. Res. 1997, 52, 117–126. [Google Scholar] [CrossRef]

- Voltas, J.; Romagosa, I.; Araus, J.L. Growth and final weight of central and lateral barley grains under Mediterranean conditions as influenced by sink strength. Crop Sci. 1998, 38, 84–89. [Google Scholar] [CrossRef]

- Abeledo, L.G.; Calderini, D.F.; Slafer, G.A. Genetic improvement of barley yield potential and its physiological determinants in Argentina (1944–1998). Euphytica 2003, 130, 325–334. [Google Scholar] [CrossRef]

- Abeledo, L.G.; Calderini, D.F.; Slafer, G.A. Nitrogen economy in old and modem malting barleys. Field Crop. Res. 2008, 106, 171–178. [Google Scholar] [CrossRef]

- Sadras, V.O.; Slafer, G.A. Environmental modulation of yield components in cereals: Heritabilities reveal a hierarchy of phenotypic plasticities. Field Crop. Res. 2012, 127, 215–224. [Google Scholar] [CrossRef]

- Gallagher, J.N.; Biscoe, P.V.; Scott, R.K. Barley and its environment 5. Stability of grain weight. J. Appl. Eco. 1975, 12, 319–336. [Google Scholar] [CrossRef]

- Baethgen, W.E.; Christianson, C.B.; Lamothe, A.G. Nitrogen-fertilizer effects on growth, grain-yield, and yield components of malting barley. Field Crop. Res. 1995, 43, 87–99. [Google Scholar] [CrossRef]

- Del Moral, L.F.G.; Del Moral, M.B.G.; Molina-Cano, J.L.; Slafer, G.A. Yield stability and development in two- and six-rowed winter barleys under Mediterranean conditions. Field Crop. Res. 2003, 81, 109–119. [Google Scholar] [CrossRef]

- Bingham, I.J.; Blake, J.; Foulkes, M.J.; Spink, J. Is barley yield in the UK sink limited? I. Post-anthesis radiation interception, radiation-use efficiency and source-sink balance. Field Crop. Res. 2007, 101, 198–211. [Google Scholar] [CrossRef]

- Bingham, I.J.; Blake, J.; Foulkes, M.J.; Spink, J. Is barley yield in the UK sink limited? II. Factors affecting potential grain size. Field Crop. Res. 2007, 101, 212–220. [Google Scholar] [CrossRef]

- Serrago, R.A.; Alzueta, I.; Savin, R.; Slafer, G.A. Understanding grain yield responses to source-sink ratios during grain filling in wheat and barley under contrasting environments. Field Crop. Res. 2013, 150, 42–51. [Google Scholar] [CrossRef]

- Kennedy, S.P.; Bingham, I.J.; Spink, J.H. Determinants of spring barley yield in a high-yield potential environment. J. Agric. Sci. 2017, 155, 60–80. [Google Scholar] [CrossRef]

- Bulman, P.; Mather, D.E.; Smith, D.L. Genetic-improvement of spring barley cultivars grown in eastern Canada from 1910 to 1988. Euphytica 1993, 71, 35–48. [Google Scholar] [CrossRef]

- Del Moral, M.B.G.; Del Moral, L.F.G. Tiller production and survival in relation to grain yield in winter and spring barley. Field Crop. Res. 1995, 44, 85–93. [Google Scholar] [CrossRef]

- Arisnabarreta, S.; Miralles, D.J. Radiation effects on potential number of grains per spike and biomass partitioning in two- and six-rowed near isogenic barley lines. Field Crop. Res. 2008, 107, 203–210. [Google Scholar] [CrossRef]

- Paynter, B.H.; Juskiw, P.E.; Helm, J.H. Leaf development in two-row spring barley under long-day and short-day field conditions. Can. J. Plant Sci. 2004, 84, 477–486. [Google Scholar] [CrossRef]

- Ugarte, C.; Calderini, D.F.; Slafer, G.A. Grain weight and grain number responsiveness to pre-anthesis temperature in wheat, barley and triticale. Field Crop. Res. 2007, 100, 240–248. [Google Scholar] [CrossRef]

- Abbate, P.E.; Andrade, F.H.; Culot, J.P.; Bindraban, P.S. Grain yield in wheat: Effects of radiation during spike growth period. Field Crop. Res. 1997, 54, 245–257. [Google Scholar] [CrossRef]

- Kennedy, S.P.; Lynch, J.P.; Spink, J.; Bingham, I.J. Grain number and grain filling of two-row malting barley in response to variation in post-anthesis radiation: Analysis by grain position on the ear and its implications for yield improvement and quality. Field Crop. Res. 2018, 225, 74–82. [Google Scholar] [CrossRef]

- Passarella, V.S.; Savin, R.; Slafer, G.A. Grain weight and malting quality in barley as affected by brief periods of increased spike temperature under field conditions. Austr. J. Agric. Res. 2002, 53, 1219–1227. [Google Scholar] [CrossRef]

- Andersson, A.; Holm, L. Effects of mild temperature stress on grain quality and root and straw nitrogen concentration in malting barley cultivars. J. Agron. Crop Sci. 2011, 197, 466–476. [Google Scholar] [CrossRef]

- Rischbeck, P.; Cardellach, P.; Mistele, B.; Schmidhalter, U. Thermal phenotyping of stomatal sensitivity in spring barley. J. Agron. Crop Sci. 2017, 203, 483–493. [Google Scholar] [CrossRef]

- Savin, R.; Nicolas, M.E. Effects of timing of heat stress and drought on growth and quality of barley grains. Austr. J. Agric. Res. 1999, 50, 357–364. [Google Scholar] [CrossRef]

- Sanchez-Diaz, M.; Garcia, J.L.; Antolin, M.C.; Araus, J.L. Effects of soil drought and atmospheric humidity on yield, gas exchange, and stable carbon isotope composition of barley. Photosynthetica 2002, 40, 415–421. [Google Scholar] [CrossRef]

- González, A.; Martín, I.; Ayerbe, L. Response of barley genotypes to terminal soil moisture stress: Phenology, growth, and yield. Austr. J. Agric. Res. 2007, 58, 29–37. [Google Scholar] [CrossRef]

- Samarah, N.H.; Alqudah, A.M.; Amayreh, J.A.; McAndrews, G.M. The effect of late-terminal drought stress on yield components of four barley cultivars. J. Agron. Crop Sci. 2009, 195, 427–441. [Google Scholar] [CrossRef]

- González, A.; Martín, I.; Ayerbe, L. Yield and osmotic adjustment capacity of barley under terminal water-stress conditions. J. Agron. Crop Sci. 2008, 194, 81–90. [Google Scholar] [CrossRef]

- Rischbeck, P.; Baresel, P.; Elsayed, S.; Mistele, B.; Schmidhalter, U. Development of a diurnal dehydration index for spring barley phenotyping. Func. Plant Biol. 2014, 41, 1249–1260. [Google Scholar] [CrossRef] [PubMed]

- Spiertz, J.H.J.; de Vos, N.M. Agronomical and physiological-aspects of the role of nitrogen in yield formation of cereals. Plant Soil 1983, 75, 379–391. [Google Scholar] [CrossRef]

- Grashoff, C.; d´Antuono, L.F. Effect of shading and nitrogen application on yield, grain size distribution and concentrations of nitrogen and water soluble carbohydrates in malting spring barley (Hordeum vulgare L.). Eur. J. Agron. 1997, 6, 275–293. [Google Scholar] [CrossRef]

- McTaggart, I.P.; Smith, K.A. The effect of rate, form and timing of fertilizer N on nitrogen uptake and grain N content in spring malting barley. J. Agric. Sci. 1995, 125, 341–353. [Google Scholar] [CrossRef]

- Schelling, K.; Born, K.; Weissteiner, C.; Kuhbauch, W. Relationships between yield and quality parameters of malting barley (Hordeum vulgare L.) and phenological and meteorological data. J. Agron. Crop Sci. 2003, 189, 113–122. [Google Scholar] [CrossRef]

- Emebiri, L.C.; Moody, D.B. Potential of low-protein genotypes for nitrogen management in malting barley production. J. Agric. Sci. 2004, 142, 319–325. [Google Scholar] [CrossRef]

- O’Donovan, J.T.; Turkington, T.K.; Edney, M.J.; Clayton, G.W.; McKenzie, R.H.; Juskiw, P.E.; Lafond, G.P.; Grant, C.A.; Brandt, S.; Harker, K.N.; et al. Seeding rate, nitrogen rate, and cultivar effects on malting barley production. Agron. J. 2011, 103, 709–716. [Google Scholar] [CrossRef]

- Barmeier, G.; Mistele, B.; Schmidhalter, U. Referencing laser and ultrasonic height measurements of barley cultivars by using a herbometre as standard. Crop Pasture Sci. 2016, 67, 1215–1222. [Google Scholar] [CrossRef]

- LfL Versuchsergebnisse aus Bayern 2014: Faktorieller Sortenversuch Sommergerste. Available online: http://www.hortigate.de/Apps/WebObjects/ISIP.woa/vb/bericht?nr=63084. (accessed on 23 October 2020).

- LfL Versuchsergebnisse aus Bayern 2015: Faktorieller Sortenversuch Sommergerste. Available online: http://www.hortigate.de/Apps/WebObjects/ISIP.woa/vb/bericht?nr=66624. (accessed on 23 October 2020).

- Peltonen-Sainio, P.; Kangas, A.; Salo, Y.; Jauhiainen, L. Grain number dominates grain weight in temperate cereal yield determination: Evidence based on 30 years of multi-location trials. Field Crop. Res. 2007, 100, 179–188. [Google Scholar] [CrossRef]

- Borras, L.; Slafer, G.A.; Otegui, M.E. Seed dry weight response to source-sink manipulations in wheat, maize and soybean: A quantitative reappraisal. Field Crop. Res. 2004, 86, 131–146. [Google Scholar] [CrossRef]

- Cox, M.C.; Qualset, C.O.; Rains, D.W. Genetic-variation for nitrogen assimilation and translocation in wheat. 2. Nitrogen assimilation in relation to grain-yield and protein. Crop Sci. 1985, 25, 435–440. [Google Scholar] [CrossRef]

- Löffler, C.M.; Rauch, T.L.; Busch, R.H. Grain and plant protein relationships in hard red spring wheat. Crop Sci. 1985, 25, 521–524. [Google Scholar] [CrossRef]

- Bulman, P.; Smith, D.L. Post-heading nitrogen uptake, retranslocation, and partitioning in spring barley. Crop Sci. 1994, 34, 977–984. [Google Scholar] [CrossRef]

- Elsayed, S.; Barmeier, G.; Schmidhalter, U. Passive reflectance sensing and digital image analysis allows for the assessing the biomass and nitrogen status of wheat in early and late tillering stages. Front. Plant Sci. 2018, 10, 1478. [Google Scholar] [CrossRef] [PubMed]

- Barmeier, G.; Hofer, K.; Schmidhalter, U. Mid-season prediction of grain yield and protein content of spring barley cultivars using high-throughput spectral sensing. Eur. J. Agron. 2017, 90, 108–116. [Google Scholar] [CrossRef]

- Barmeier, G.; Schmidhalter, U. High-throughput field phenotyping of leaves, leaf sheaths, culms and ears of spring barley cultivars at anthesis and dough ripeness. Front. Plant Sci. 2017, 8, 1920. [Google Scholar] [CrossRef]

- Schmidhalter, U.; Bredemeier, C.; Geesing, D.; Mistele, B.; Selige, T.; Jungert, S. Precision Agriculture: Spatial and temporal variability of soil water, soil nitrogen and plant crop response. Bibl. Fragm. Agron. 2006, 11, 97–105. [Google Scholar]

- Przulj, N.; Momcilovic, V. Genetic variation for dry matter and nitrogen accumulation and translocation in two-rowed spring barley II. Nitrogen translocation. Eur. J. Agron. 2001, 15, 255–265. [Google Scholar] [CrossRef]

- Dordas, C. Variation in dry matter and nitrogen accumulation and remobilization in barley as affected by fertilization, cultivar, and source-sink relations. Eur. J. Agron. 2012, 37, 31–42. [Google Scholar] [CrossRef]

| No. | Variety Name | Listed | Country |

|---|---|---|---|

| 1 | Aspen | 1999 | G |

| 2 | Barke | 1996 | G |

| 3 | Baronesse | 1989 | G |

| 4 | Braemar | 2002 | G |

| 5 | Carina | 1973 | G |

| 6 | Grace | 2008 | G |

| 7 | IPZ 24727 | - | G |

| 8 | Irina | 2012 | G |

| 9 | Mackay | 2003 | AUS |

| 10 | Marthe | 2005 | G |

| 11 | Melius | 2012 | G |

| 12 | Power | 1998 | G |

| 13 | Quench | 2006 | G |

| 14 | Salome | 2011 | G |

| 15 | Scarlett | 1995 | G |

| 16 | Shakira | 2004 | G |

| 17 | Sissy | 1990 | G |

| 18 | Solist | 2012 | G |

| 19 | Trumpf | 2003 | G |

| 20 | Union | 1950 | G |

| 21 | Ursa | 2002 | G |

| 22 | Volla | 1957 | G |

| 23 | Wiebke | 1998 | G |

| Source of Variance | df | Grain Yield and Quality | Yield Components | Plant Height | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Yield | Protein Content | Grain Retention (>2.5 mm) | Grain Number m–2 | Spike Number m–2 | Grain Number Spike–1 | Grain Weight Spike–1 | TGW | HI | |||||||||||||

| Year (Y) | 1 | 2.2 | NS | 201 | *** | 2153 | *** | 196,405,741 | *** | 32,309 | NS | 227 | *** | 0.01 | NS | 865 | *** | 0.004 | NS | 1.9 | *** |

| Variety (V) | 22 | 1.2 | NS | 2.5 | *** | 10 | *** | 6,530,199 | NS | 17,764 | * | 5.2 | NS | 0.03 | *** | 33 | *** | 0.010 | *** | 0.041 | *** |

| Y × V | 22 | 1.4 | NS | 0.43 | NS | 7.1 | *** | 7,762,290 | NS | 15,986 | NS | 3.3 | NS | 0.01 | NS | 3.5 | NS | 0.001 | NS | 0.006 | NS |

| Block (B) | 3 | 0.22 | NS | 0.26 | NS | 8.1 | NS | 1,666,474 | NS | 6078 | NS | 1.6 | NS | 0.004 | NS | 5.9 | NS | 0.002 | NS | 0.012 | NS |

| B × V | 66 | 0.72 | NS | 0.24 | NS | 1.9 | NS | 4,180,474 | NS | 7405 | NS | 3.7 | NS | 0.005 | NS | 5.0 | NS | 0.001 | NS | 0.006 | NS |

| Variety Name | Grain Yield and Quanlity | Yield Components | Plant Height | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Yield | Protein Content | Grain Retention (>2.5 mm) | Grains | Spikes | Grains | Grain Weight | TGW | HI | ||||||||||||||||||||||||||||||||

| t ha–1 | % | Number m–2 | Number Spike–1 | g Spike–1 | g | m | ||||||||||||||||||||||||||||||||||

| Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | |||||||||||||||||||||||||||||||

| Aspen | 5.7 | ± | 0.4 | a | 8.7 | ± | 0.4 | a–d | 97.7 | ± | 0.4 | ab | 12,614 | ± | 921 | ab | 643 | ± | 27.1 | ab | 19.6 | ± | 0.6 | a | 0.90 | ± | 0.04 | ab | 45.2 | ± | 0.14 | a–c | 0.55 | ± | 0.03 | abc | 0.80 | ± | 0.04 | a–c |

| Barke | 6.1 | ± | 0.7 | a | 8.4 | ± | 0.3 | a–d | 98.2 | ± | 0.1 | b | 13,197 | ± | 1562 | ab | 622 | ± | 61.6 | ab | 21.1 | ± | 0.6 | a | 0.98 | ± | 0.05 | a–c | 46.2 | ± | 0.62 | a–c | 0.60 | ± | 0.00 | bc | 0.73 | ± | 0.03 | ab |

| Baronesse | 5.8 | ± | 0.2 | a | 8.7 | ± | 0.3 | a–d | 97.2 | ± | 0.3 | ab | 12,430 | ± | 494 | ab | 592 | ± | 36.5 | ab | 22.0 | ± | 1.0 | a | 1.00 | ± | 0.04 | a–c | 45.7 | ± | 0.37 | a–c | 0.60 | ± | 0.00 | bc | 0.77 | ± | 0.04 | a–c |

| Braemar | 6.7 | ± | 0.5 | a | 7.9 | ± | 0.1 | ab | 98.2 | ± | 0.3 | b | 13,658 | ± | 917 | ab | 659 | ± | 30.4 | ab | 20.7 | ± | 0.8 | a | 1.00 | ± | 0.04 | a–c | 48.9 | ± | 0.87 | bc | 0.60 | ± | 0.00 | bc | 0.71 | ± | 0.03 | ab |

| Carina | 5.7 | ± | 0.5 | a | 8.4 | ± | 0.2 | a–d | 97.7 | ± | 0.2 | ab | 13,087 | ± | 992 | ab | 632 | ± | 47.9 | ab | 20.7 | ± | 0.4 | a | 0.93 | ± | 0.03 | a–c | 43.5 | ± | 0.48 | ab | 0.53 | ± | 0.03 | ab | 0.88 | ± | 0.05 | cd |

| Grace | 6.6 | ± | 0.5 | a | 8.5 | ± | 0.4 | a–d | 97.8 | ± | 0.6 | ab | 13,247 | ± | 746 | ab | 602 | ± | 53.9 | ab | 22.2 | ± | 0.8 | a | 1.10 | ± | 0.00 | c | 49.6 | ± | 0.97 | c | 0.60 | ± | 0.00 | bc | 0.65 | ± | 0.08 | a |

| IPZ 24727 | 5.7 | ± | 0.7 | a | 9.6 | ± | 0.4 | cd | 97.1 | ± | 0.4 | ab | 11,838 | ± | 1454 | ab | 602 | ± | 101 | ab | 20.0 | ± | 0.8 | a | 0.98 | ± | 0.03 | a–c | 47.6 | ± | 0.56 | bc | 0.58 | ± | 0.03 | abc | 0.74 | ± | 0.08 | a–c |

| Irina | 6.9 | ± | 0.3 | a | 7.7 | ± | 0.2 | ab | 96.9 | ± | 0.3 | ab | 14,485 | ± | 766 | ab | 633 | ± | 20 | ab | 22.8 | ± | 0.6 | a | 1.10 | ± | 0.04 | bc | 48.0 | ± | 0.43 | bc | 0.60 | ± | 0.00 | bc | 0.67 | ± | 0.01 | ab |

| Mackay | 6.2 | ± | 0.5 | a | 8.0 | ± | 0.2 | ab | 97.6 | ± | 0.7 | ab | 12,778 | ± | 871 | ab | 583 | ± | 30.8 | ab | 21.9 | ± | 0.7 | a | 1.08 | ± | 0.03 | c | 48.8 | ± | 0.89 | bc | 0.60 | ± | 0.00 | bc | 0.77 | ± | 0.04 | a–c |

| Marthe | 7.4 | ± | 0.6 | a | 8.7 | ± | 0.4 | a–d | 97.6 | ± | 0.5 | ab | 16,612 | ± | 1310 | b | 793 | ± | 52.9 | b | 20.9 | ± | 0.4 | a | 0.95 | ± | 0.03 | a–c | 44.5 | ± | 0.42 | a–c | 0.60 | ± | 0.00 | bc | 0.70 | ± | 0.04 | ab |

| Melius | 6.6 | ± | 0.6 | a | 7.5 | ± | 0.2 | ab | 97.2 | ± | 0.5 | ab | 13,291 | ± | 938 | ab | 616 | ± | 49.9 | ab | 21.7 | ± | 0.7 | a | 1.08 | ± | 0.05 | bc | 49.5 | ± | 0.84 | c | 0.60 | ± | 0.00 | bc | 0.70 | ± | 0.02 | ab |

| Power | 7.0 | ± | 0.6 | a | 7.7 | ± | 0.2 | ab | 95.5 | ± | 0.4 | a | 14,945 | ± | 1228 | ab | 661 | ± | 54.1 | ab | 22.6 | ± | 0.3 | a | 1.05 | ± | 0.03 | a–c | 46.6 | ± | 0.44 | a–c | 0.60 | ± | 0.00 | bc | 0.66 | ± | 0.01 | ab |

| Quench | 6.7 | ± | 0.8 | a | 7.8 | ± | 0.3 | ab | 97.1 | ± | 0.5 | ab | 14,537 | ± | 1579 | ab | 665 | ± | 64.1 | ab | 21.8 | ± | 0.5 | a | 0.98 | ± | 0.03 | a–c | 45.8 | ± | 0.57 | a–c | 0.60 | ± | 0.00 | bc | 0.68 | ± | 0.03 | ab |

| Salome | 7.2 | ± | 0.6 | a | 7.3 | ± | 0.1 | a | 97.1 | ± | 0.4 | ab | 14,771 | ± | 1075 | ab | 713 | ± | 36.7 | ab | 20.7 | ± | 0.6 | a | 1.00 | ± | 0.04 | a–c | 48.4 | ± | 0.59 | bc | 0.63 | ± | 0.03 | c | 0.63 | ± | 0.04 | a |

| Scarlett | 6.4 | ± | 0.4 | a | 8.4 | ± | 0.4 | a–d | 97.8 | ± | 0.2 | ab | 14,538 | ± | 1004 | ab | 718 | ± | 80.6 | ab | 20.6 | ± | 1.0 | a | 0.93 | ± | 0.05 | a–c | 44.2 | ± | 0.78 | a–c | 0.58 | ± | 0.03 | abc | 0.64 | ± | 0.04 | a |

| Shakira | 5.1 | ± | 0.3 | a | 7.7 | ± | 0.2 | ab | 97.9 | ± | 0.4 | ab | 10,373 | ± | 507 | a | 492 | ± | 25.8 | a | 21.2 | ± | 0.9 | a | 1.05 | ± | 0.03 | a–c | 49.6 | ± | 0.41 | c | 0.60 | ± | 0.00 | bc | 0.73 | ± | 0.02 | ab |

| Sissy | 5.5 | ± | 0.1 | a | 8.7 | ± | 0.2 | a–d | 97.3 | ± | 0.2 | ab | 12,477 | ± | 220 | ab | 617 | ± | 19.1 | ab | 20.3 | ± | 0.6 | a | 0.90 | ± | 0.00 | ab | 43.2 | ± | 0.92 | a | 0.57 | ± | 0.03 | abc | 0.83 | ± | 0.07 | a–c |

| Solist | 7.4 | ± | 0.7 | a | 7.6 | ± | 0.4 | ab | 98.3 | ± | 0.5 | b | 16,057 | ± | 1380 | b | 704 | ± | 55.7 | ab | 22.8 | ± | 0.8 | a | 1.05 | ± | 0.03 | a–c | 46.1 | ± | 0.84 | a–c | 0.60 | ± | 0.00 | bc | 0.70 | ± | 0.04 | ab |

| Trumpf | 6.4 | ± | 0.5 | a | 8.1 | ± | 0.1 | a–c | 98.1 | ± | 0.5 | b | 13,873 | ± | 1151 | ab | 650 | ± | 44.6 | ab | 21.3 | ± | 0.4 | a | 1.00 | ± | 0.00 | a–c | 46.5 | ± | 0.84 | a–c | 0.60 | ± | 0.00 | bc | 0.75 | ± | 0.02 | a–c |

| Union | 7.0 | ± | 0.4 | a | 9.8 | ± | 0.4 | d | 96.9 | ± | 0.6 | ab | 15,306 | ± | 792 | ab | 686 | ± | 34.8 | ab | 22.4 | ± | 1.1 | a | 1.03 | ± | 0.05 | a–c | 45.9 | ± | 0.76 | a–c | 0.50 | ± | 0.00 | a | 0.96 | ± | 0.08 | c |

| Ursa | 6.1 | ± | 0.2 | a | 9.1 | ± | 0.5 | b–d | 97.3 | ± | 0.7 | ab | 13,387 | ± | 359 | ab | 633 | ± | 20.7 | ab | 21.2 | ± | 0.9 | a | 0.98 | ± | 0.05 | a–c | 45.8 | ± | 0.9 | a–c | 0.60 | ± | 0.00 | bc | 0.76 | ± | 0.02 | a–c |

| Volla | 6.1 | ± | 0.4 | a | 8.9 | ± | 0.4 | a–d | 97.4 | ± | 0.3 | ab | 14,139 | ± | 766 | ab | 710 | ± | 72.4 | ab | 20.3 | ± | 1.4 | a | 0.88 | ± | 0.05 | a | 43.2 | ± | 0.45 | ab | 0.50 | ± | 0.04 | a | 0.88 | ± | 0.02 | cd |

| Wiebke | 7.0 | ± | 0.3 | a | 8.5 | ± | 0.2 | a–d | 97.7 | ± | 0.1 | ab | 14,711 | ± | 653 | ab | 675 | ± | 35.4 | ab | 21.9 | ± | 0.2 | a | 1.03 | ± | 0.03 | a | 44.8 | ± | 0.5 | a–c | 0.60 | ± | 0.00 | bc | 0.78 | ± | 0.02 | a–c |

| Mean | 6.4 | 8.3 | 97.5 | 13,754 | 648 | 21.3 | 1.00 | 46.4 | 0.58 | 0.74 | ||||||||||||||||||||||||||||||

| Min | 5.1 | 7.3 | 95.5 | 10,373 | 492 | 19.6 | 0.88 | 43.2 | 0.50 | 0.63 | ||||||||||||||||||||||||||||||

| Max | 7.4 | 9.8 | 98.3 | 16,612 | 793 | 22.8 | 1.10 | 49.6 | 0.63 | 0.96 | ||||||||||||||||||||||||||||||

| Variety Name | Grain Yield and Quanlity | Yield Components | Plant Height | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Yield | Protein Content | Grain Retention (>2.5 mm) | Grains | Spikes | Grains | Grain Weight | TGW | HI | ||||||||||||||||||||||||||||||||

| t ha–1 | % | Number m–2 | Number Spike–1 | g Spike–1 | g | m | ||||||||||||||||||||||||||||||||||

| Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | Mean ± SE | |||||||||||||||||||||||||||||||

| Aspen | 6.2 | ± | 0.6 | a | 11.2 | ± | 0.0 | ef | 88.8 | ± | 0.7 | a–d | 15,452 | ± | 1,075 | a | 657 | ± | 49 | a | 23.6 | ± | 0.7 | a | 0.93 | ± | 0.05 | ab | 39.9 | ± | 0.9 | a–c | 0.58 | ± | 0.03 | ab | 0.58 | ± | 0.03 | a–f |

| Barke | 6.0 | ± | 0.5 | a | 10.3 | ± | 0.1 | a–f | 93.1 | ± | 0.8 | cd | 13,858 | ± | 981 | a | 561 | ± | 57 | a | 25.1 | ± | 1.3 | a | 1.08 | ± | 0.03 | a–c | 43.3 | ± | 1.3 | b–e | 0.60 | ± | 0.00 | ab | 0.53 | ± | 0.01 | a–f |

| Baronesse | 7.6 | ± | 0.9 | a | 10.2 | ± | 0.2 | a–f | 91.0 | ± | 0.4 | a–d | 18,078 | ± | 2,335 | a | 762 | ± | 76 | a | 23.7 | ± | 1.4 | a | 1.00 | ± | 0.04 | a–c | 42.0 | ± | 0.5 | a–e | 0.60 | ± | 0.00 | ab | 0.55 | ± | 0.03 | a–f |

| Braemar | 6.9 | ± | 0.3 | a | 10.7 | ± | 0.6 | b–f | 91.5 | ± | 0.7 | a–d | 16,334 | ± | 666 | a | 685 | ± | 37 | a | 23.9 | ± | 0.4 | a | 1.03 | ± | 0.03 | a–c | 42.5 | ± | 0.2 | a–e | 0.60 | ± | 0.00 | ab | 0.50 | ± | 0.01 | a–c |

| Carina | 7.4 | ± | 0.9 | a | 10.6 | ± | 0.2 | a–f | 88.1 | ± | 0.7 | ab | 18,632 | ± | 2,319 | a | 827 | ± | 88 | a | 22.5 | ± | 0.9 | a | 0.90 | ± | 0.04 | ab | 40.0 | ± | 0.5 | a–c | 0.53 | ± | 0.03 | a | 0.67 | ± | 0.02 | f |

| Grace | 7.0 | ± | 0.3 | a | 10.7 | ± | 0.2 | b–f | 93.7 | ± | 0.4 | d | 14,974 | ± | 468 | a | 587 | ± | 36 | a | 25.7 | ± | 0.8 | a | 1.18 | ± | 0.05 | c | 46.6 | ± | 0.7 | e | 0.63 | ± | 0.03 | b | 0.54 | ± | 0.02 | a–f |

| IPZ 24727 | 6.9 | ± | 0.5 | a | 11.4 | ± | 0.4 | f | 90.9 | ± | 1.1 | a–d | 16,446 | ± | 897 | a | 699 | ± | 46 | a | 23.7 | ± | 1.1 | a | 0.98 | ± | 0.05 | a–c | 42.0 | ± | 0.7 | a–e | 0.58 | ± | 0.03 | ab | 0.64 | ± | 0.02 | d–f |

| Irina | 7.1 | ± | 0.4 | a | 9.5 | ± | 0.1 | ab | 88.8 | ± | 1.2 | a–c | 16,253 | ± | 751 | a | 707 | ± | 37 | a | 23.0 | ± | 0.2 | a | 1.00 | ± | 0.00 | a–c | 43.9 | ± | 0.7 | c–e | 0.60 | ± | 0.00 | ab | 0.44 | ± | 0.02 | a |

| Mackay | 6.2 | ± | 1.2 | a | 10.3 | ± | 0.1 | a–f | 89.0 | ± | 1.2 | a–d | 14,559 | ± | 2593 | a | 626 | ± | 90 | a | 22.9 | ± | 0.8 | a | 0.98 | ± | 0.05 | a–c | 42.6 | ± | 0.6 | a–e | 0.60 | ± | 0.00 | ab | 0.51 | ± | 0.05 | a–e |

| Marthe | 7.0 | ± | 0.2 | a | 10.4 | ± | 0.1 | a–f | 92.5 | ± | 0.6 | b–d | 16,823 | ± | 488 | a | 790 | ± | 20 | a | 21.3 | ± | 0.9 | a | 0.90 | ± | 0.04 | ab | 41.8 | ± | 0.4 | a–d | 0.60 | ± | 0.00 | ab | 0.54 | ± | 0.02 | a–f |

| Melius | 6.9 | ± | 0.4 | a | 10.0 | ± | 0.2 | a–d | 88.7 | ± | 1.3 | a–c | 15,411 | ± | 752 | a | 646 | ± | 25 | a | 23.8 | ± | 0.6 | a | 1.08 | ± | 0.03 | a–c | 44.6 | ± | 1.2 | de | 0.60 | ± | 0.00 | ab | 0.55 | ± | 0.02 | a–f |

| Power | 6.1 | ± | 0.4 | a | 10.0 | ± | 0.2 | a–e | 90.5 | ± | 1.3 | a–d | 14,197 | ± | 883 | a | 560 | ± | 46 | a | 25.8 | ± | 2.2 | a | 1.13 | ± | 0.10 | bc | 43.1 | ± | 0.6 | b–e | 0.60 | ± | 0.00 | ab | 0.50 | ± | 0.01 | a–d |

| Quench | 6.6 | ± | 0.7 | a | 10.0 | ± | 0.1 | a–e | 87.5 | ± | 1.3 | a | 16,556 | ± | 1826 | a | 715 | ± | 66 | a | 23.1 | ± | 1.3 | a | 0.90 | ± | 0.04 | ab | 39.9 | ± | 0.9 | a–c | 0.60 | ± | 0.00 | ab | 0.46 | ± | 0.02 | a–f |

| Salome | 5.9 | ± | 0.5 | a | 9.9 | ± | 0.2 | a–c | 93.2 | ± | 1.0 | cd | 13,393 | ± | 1048 | a | 627 | ± | 62 | a | 21.5 | ± | 0.5 | a | 0.93 | ± | 0.03 | ab | 44.2 | ± | 0.7 | c–e | 0.63 | ± | 0.03 | b | 0.43 | ± | 0.02 | a |

| Scarlett | 6.3 | ± | 0.8 | a | 10.7 | ± | 0.2 | b–f | 92.3 | ± | 0.8 | a–d | 15,367 | ± | 2130 | a | 611 | ± | 58 | a | 24.8 | ± | 1.5 | a | 1.00 | ± | 0.04 | a–c | 41.4 | ± | 0.6 | a–d | 0.60 | ± | 0.00 | ab | 0.45 | ± | 0.02 | ab |

| Shakira | 7.0 | ± | 0.9 | a | 10.3 | ± | 0.3 | a–f | 93.2 | ± | 0.5 | d | 16,043 | ± | 2278 | a | 724 | ± | 70 | a | 21.9 | ± | 1.0 | a | 0.95 | ± | 0.03 | a–c | 44.2 | ± | 0.6 | c–e | 0.60 | ± | 0.00 | ab | 0.49 | ± | 0.02 | a–c |

| Sissy | 6.3 | ± | 0.8 | a | 11.3 | ± | 0.2 | ef | 89.3 | ± | 1.3 | a–d | 16,084 | ± | 1513 | a | 690 | ± | 80 | a | 23.6 | ± | 1.2 | a | 0.90 | ± | 0.04 | ab | 39.0 | ± | 1.7 | ab | 0.58 | ± | 0.03 | ab | 0.63 | ± | 0.04 | d–f |

| Solist | 7.3 | ± | 0.5 | a | 9.3 | ± | 0.6 | a | 92.5 | ± | 0.1 | b–d | 17,029 | ± | 1483 | a | 725 | ± | 31 | a | 23.4 | ± | 1.3 | a | 1.03 | ± | 0.05 | a–c | 43.1 | ± | 0.9 | b–e | 0.60 | ± | 0.00 | ab | 0.54 | ± | 0.02 | a–f |

| Trumpf | 6.0 | ± | 0.2 | a | 10.5 | ± | 0.1 | a–f | 90.1 | ± | 0.7 | a–d | 14,664 | ± | 731 | a | 610 | ± | 39 | a | 24.2 | ± | 0.9 | a | 1.00 | ± | 0.04 | a–c | 41.0 | ± | 0.6 | a–d | 0.60 | ± | 0.00 | ab | 0.51 | ± | 0.01 | a–e |

| Union | 6.4 | ± | 0.5 | a | 10.7 | ± | 0.1 | b–f | 91.3 | ± | 0.8 | a–d | 15,502 | ± | 1617 | a | 662 | ± | 27 | a | 23.2 | ± | 1.6 | a | 0.95 | ± | 0.05 | a–c | 41.7 | ± | 1.1 | a–d | 0.60 | ± | 0.00 | ab | 0.62 | ± | 0.05 | c–f |

| Ursa | 6.6 | ± | 0.5 | a | 10.3 | ± | 0.2 | a–f | 88.8 | ± | 0.3 | a–c | 16,567 | ± | 1087 | a | 711 | ± | 26 | a | 23.3 | ± | 0.8 | a | 0.93 | ± | 0.05 | ab | 39.6 | ± | 0.7 | a–c | 0.58 | ± | 0.03 | ab | 0.56 | ± | 0.02 | a–f |

| Volla | 6.3 | ± | 0.2 | a | 11.1 | ± | 0.3 | d–f | 87.6 | ± | 0.5 | ab | 16,593 | ± | 574 | a | 710 | ± | 21 | a | 23.4 | ± | 0.6 | a | 0.88 | ± | 0.03 | a | 38.0 | ± | 0.6 | a | 0.55 | ± | 0.03 | ab | 0.64 | ± | 0.02 | ef |

| Wiebke | 6.3 | ± | 0.5 | a | 10.6 | ± | 0.2 | b–f | 92.0 | ± | 1.7 | a–d | 15,062 | ± | 1492 | a | 618 | ± | 55 | a | 24.4 | ± | 1.0 | a | 1.05 | ± | 0.03 | a–c | 42.0 | ± | 1.5 | a–d | 0.60 | ± | 0.00 | ab | 0.55 | ± | 0.03 | a–f |

| Mean | 6.6 | 10.4 | 90.6 | 15,821 | 674 | 23.5 | 0.98 | 42.0 | 0.59 | 0.54 | ||||||||||||||||||||||||||||||

| Min | 5.9 | 9.3 | 87.5 | 13,393 | 560 | 21.3 | 0.88 | 38.0 | 0.53 | 0.43 | ||||||||||||||||||||||||||||||

| Max | 7.6 | 11.4 | 93.7 | 18,632 | 827 | 25.8 | 1.18 | 46.6 | 0.63 | 0.67 | ||||||||||||||||||||||||||||||

| Grain Yield and Quality | Yield Components | Plant Height | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Yield | Protein Content | Grain Retention (>2.5 mm) | Grain Number per m2 | Spike Number per m2 | Grain Number per Spike | Grain Weight per Spike | TGW | HI | |||||||||||

| Grain yield | 1.00 | ||||||||||||||||||

| Grain protein content | −0.31 | ns | 1.00 | ||||||||||||||||

| Grain retention (>2.5 mm) | −0.16 | ns | −0.02 | ns | 1.00 | ||||||||||||||

| Grain number per m2 | 0.91 | ** | −0.14 | ns | −0.15 | ns | 1.00 | ||||||||||||

| Spike number per m2 | 0.71 | ** | 0.03 | ns | −0.05 | ns | 0.90 | ** | 1.00 | ||||||||||

| Grain number per spike | 0.55 | ** | −0.31 | ns | −0.29 | ns | 0.38 | ns | −0.06 | ns | 1.00 | ||||||||

| Grain weight per spike | 0.39 | ns | −0.42 | * | −0.15 | ns | 0.04 | ns | −0.35 | ns | 0.80 | ** | 1.00 | ||||||

| TGW | 0.15 | ns | −0.44 | * | 0.01 | ns | −0.23 | ns | −0.43 | * | 0.35 | ns | 0.79 | ** | 1.00 | ||||

| HI | 0.23 | ns | −0.60 | ** | 0.05 | ns | −0.01 | ns | −0.15 | ns | 0.26 | ns | 0.48 | * | 0.49 | * | 1.00 | ||

| Plant height | −0.18 | ns | 0.35 | ** | −0.09 | ns | −0.09 | ns | −0.01 | ns | −0.16 | ns | −0.28 | ** | −0.25 | * | −0.47 | ** | 1.00 |

| Grain Yield and Quality | Yield Components | Plant Height | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Yield | Protein Content | Grain Retention (>2.5 mm) | Grain Number per m2 | Spike Number per m2 | Grain Number per Spike | Grain Weight per Spike | TGW | HI | |||||||||||

| Grain yield | 1.00 | ||||||||||||||||||

| Grain protein content | −0.22 | ns | 1.00 | ||||||||||||||||

| Grain retention (>2.5 mm) | 0.01 | ns | −0.11 | ns | 1.00 | ||||||||||||||

| Grain number per m2 | 0.81 | ** | 0.07 | ns | −0.36 | ns | 1.00 | ||||||||||||

| Spike number per m2 | 0.73 | ** | −0.01 | ns | −0.31 | ns | 0.91 | ** | 1.00 | ||||||||||

| Grain number per spike | −0.24 | ns | 0.16 | ns | 0.12 | ns | −0.34 | ns | −0.69 | ** | 1.00 | ||||||||

| Grain weight per spike | 0.01 | ns | −0.25 | ns | 0.45 | * | −0.43 | * | −0.65 | ** | 0.77 | ** | 1.00 | ||||||

| TGW | 0.20 | ns | −0.48 | * | 0.63 | ** | −0.41 | ns | −0.39 | ns | 0.18 | ns | 0.74 | ** | 1.00 | ||||

| HI | −0.17 | ns | −0.41 | ns | 0.64 | ** | −0.61 | ** | −0.55 | ** | 0.17 | ns | 0.53 | ** | 0.73 | ** | 1.00 | ||

| Plant height | 0.59 | ** | 0.44 | ** | −0.12 | ns | 0.53 | ** | 0.51 | ** | 0.09 | ns | −0.02 | ns | −0.24 | * | −0.35 | ** | 1.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Barmeier, G.; Schmidhalter, U. Genetic Variation in Grain Yield and Quality Traits of Spring Malting Barley. Agronomy 2021, 11, 1177. https://doi.org/10.3390/agronomy11061177

Hu Y, Barmeier G, Schmidhalter U. Genetic Variation in Grain Yield and Quality Traits of Spring Malting Barley. Agronomy. 2021; 11(6):1177. https://doi.org/10.3390/agronomy11061177

Chicago/Turabian StyleHu, Yuncai, Gero Barmeier, and Urs Schmidhalter. 2021. "Genetic Variation in Grain Yield and Quality Traits of Spring Malting Barley" Agronomy 11, no. 6: 1177. https://doi.org/10.3390/agronomy11061177

APA StyleHu, Y., Barmeier, G., & Schmidhalter, U. (2021). Genetic Variation in Grain Yield and Quality Traits of Spring Malting Barley. Agronomy, 11(6), 1177. https://doi.org/10.3390/agronomy11061177