Fine-Crush Straw Returning Enhances Dry Matter Accumulation Rate of Maize Seedlings in Northeast China

Abstract

1. Introduction

2. Materials and Methods

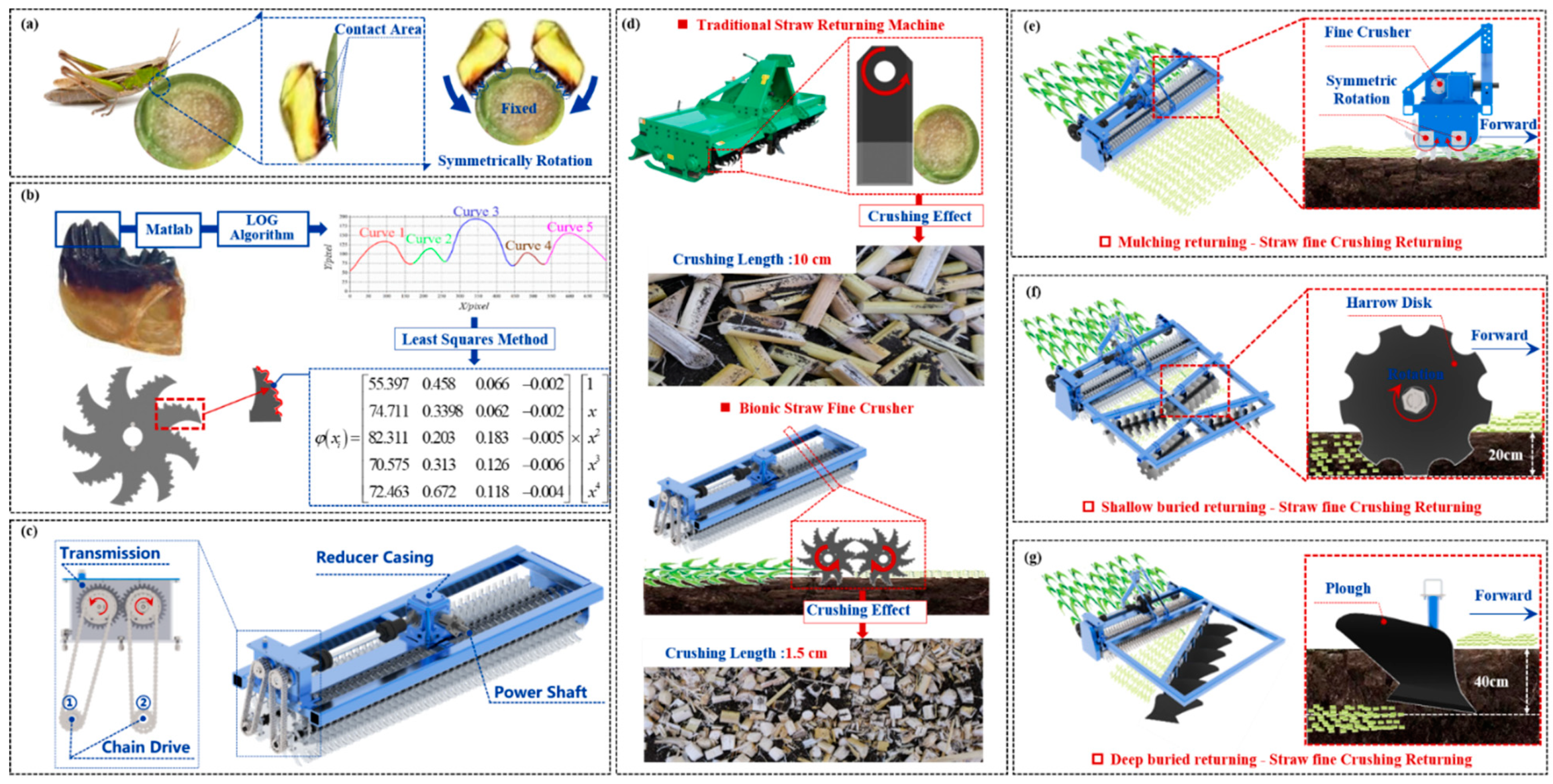

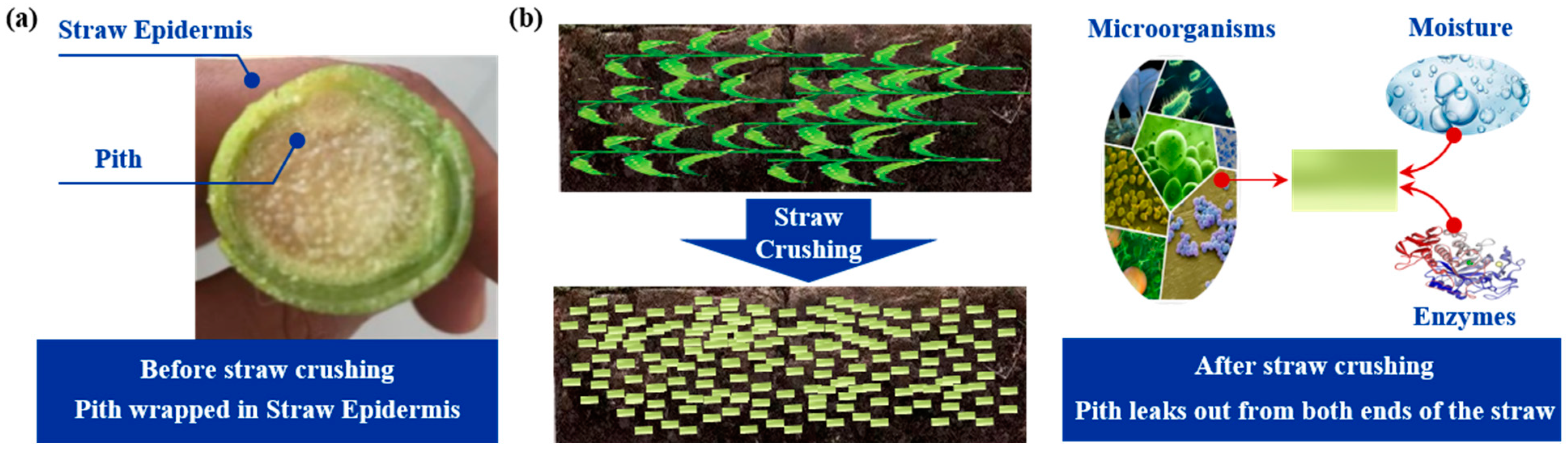

2.1. Fine-Crush Straw Returning and Bionic Straw Fine Crusher

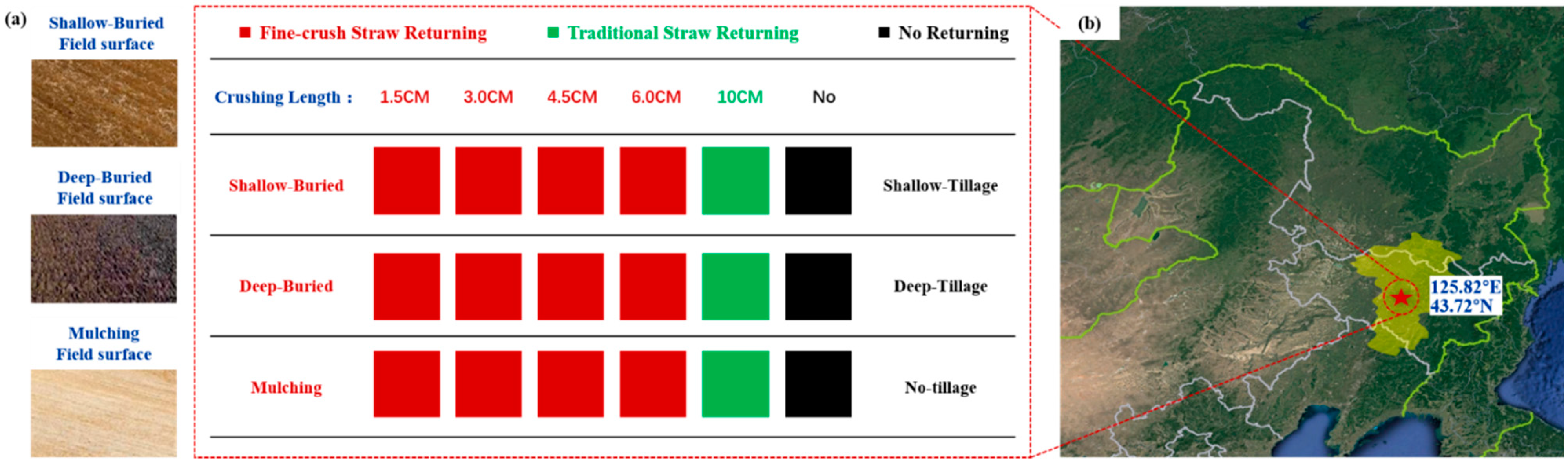

2.2. Field Experiment Design

2.2.1. Experimental Site

2.2.2. Experimental Method

2.3. Experimental Index, Experimental Methods, and Main Experimental Instruments

2.3.1. Straw Decomposition Rate (SDR) before Sowing (0–20 cm)

2.3.2. Soil Organic Matter (SOM) Content before Sowing (0–20 cm)

2.3.3. Soil Accumulated Temperature (SAT) at the Maize Seedling Stage (0–20 cm)

2.3.4. Dry Matter Accumulation (DMM) of Maize at the Seedling Stage

2.4. Statistical Analysis Methods for Experimental Data

3. Results

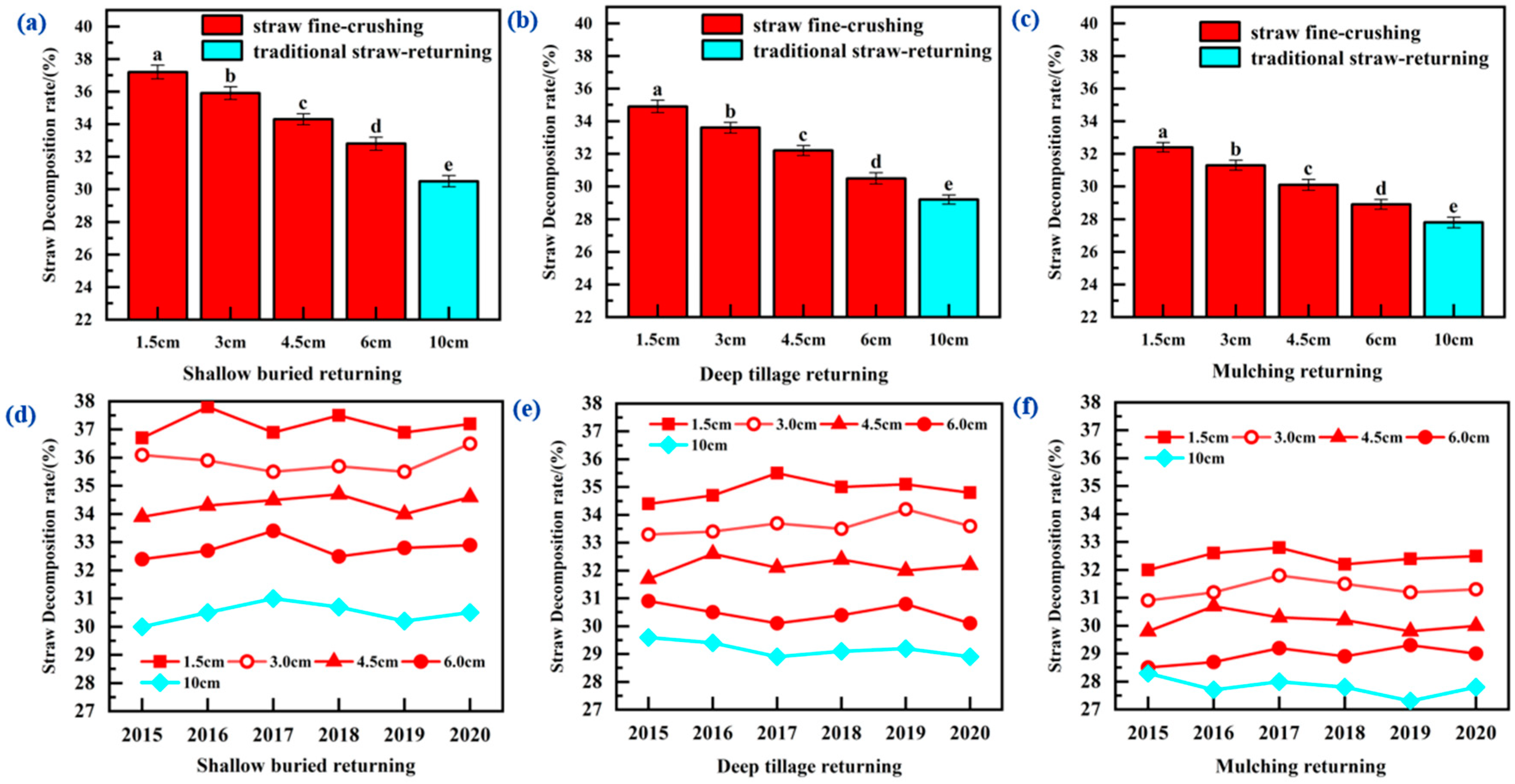

3.1. Straw Decomposition Rate (SDR) before Sowing (0–20 cm)

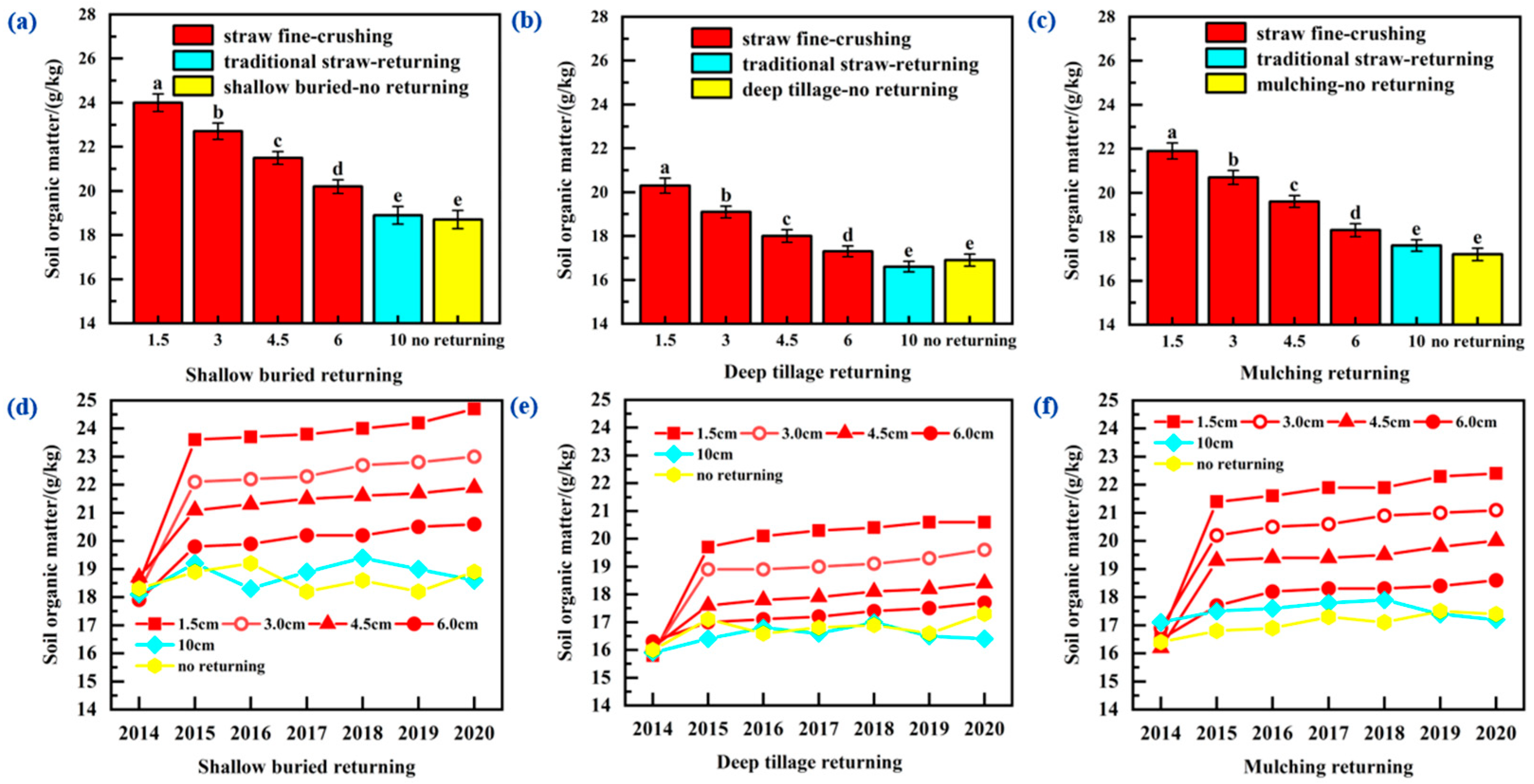

3.2. Soil Organic Matter Content (SOM) before Sowing (0–20 cm)

3.3. Soil Accumulated Temperature (SAT) at the Maize Seedling Stage (0–20 cm)

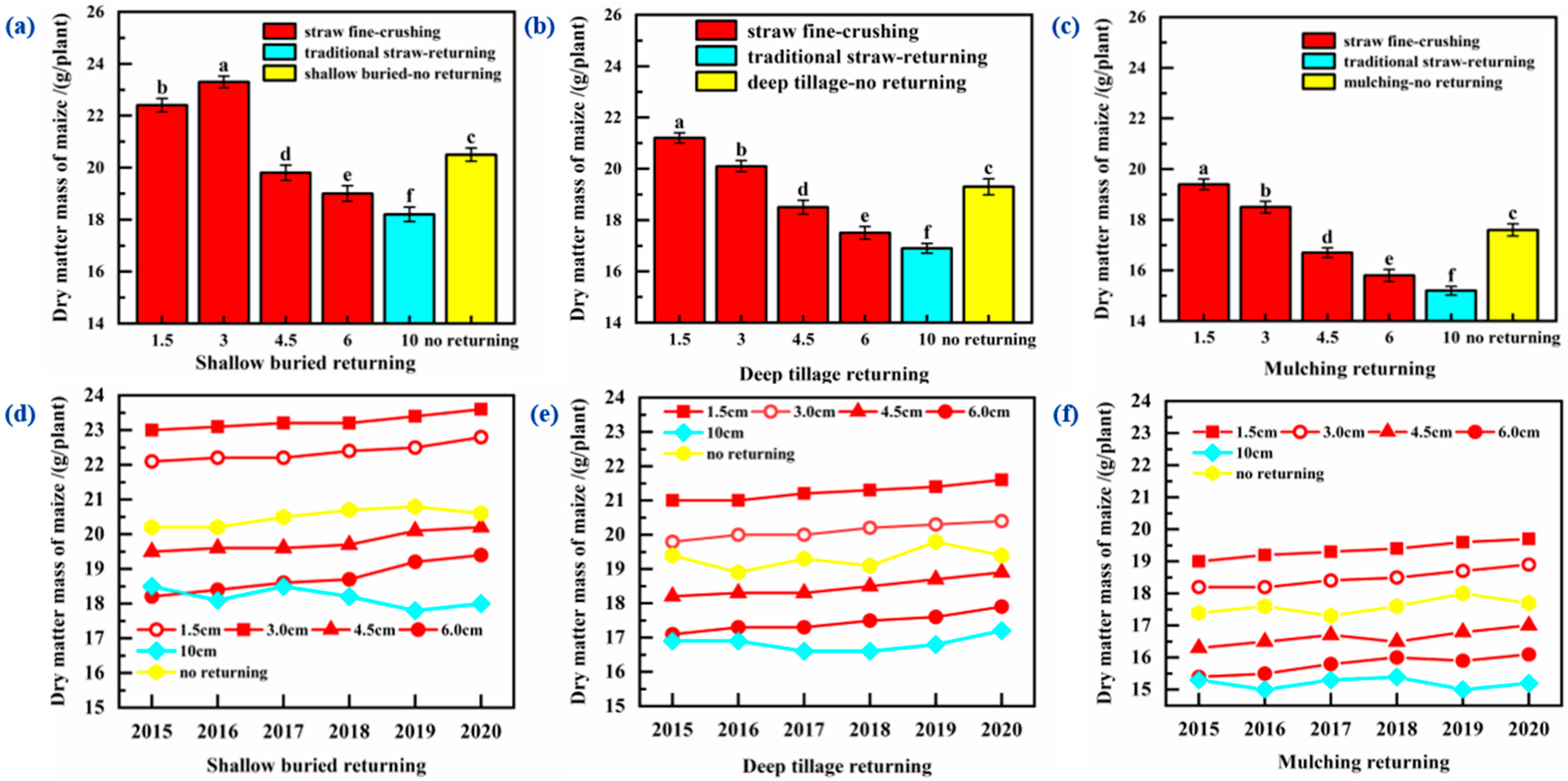

3.4. Dry Matter Accumulation (DMM) of Maize at the Seedling Stage

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lal, R. Tillage and agricultural sustainability. Soil Tillage Res. 1991, 20, 133–146. [Google Scholar] [CrossRef]

- Zhao, J.L.; Lu, Y.; Tian, H.L.; Jia, H.L.; Guo, M.Z. Effects of Straw Returning and Residue Cleaner on the Soil Moisture Content, Soil Temperature, and Maize Emergence Rate in China’s Three Major Maize Producing Areas. Sustainability 2019, 11, 5796. [Google Scholar] [CrossRef]

- Wu, P.N.; Wang, Y.L.; Li, P.F.; Wang, X.N.; Hou, X.Q. Effects of straw returning combined with nitrogen fertilizer on spring maize yield and soil physicochemical properties under drip irrigation condition in Yellow River pumping irrigation area, Ningxia, China. Chin. J. Appl. Ecol. 2019, 30, 4177–4185. [Google Scholar] [CrossRef]

- Zhu, X.; Hu, Y.; Wang, W.; Wu, D. Earthworms promote the accumulation of maize root-derived carbon in a black soil of Northeast China, especially in soil from long-term no-till. Geoderma 2019, 340, 124–132. [Google Scholar] [CrossRef]

- Liang, A.Z.; Yang, X.M.; Zhang, X.P.; Chen, X.W.; McLaughlin, N.B.; Wei, S.C.; Zhang, Y.; Jia, S.X.; Zhang, S.X. Changes in soil organic carbon stocks under 10-year conservation tillage on a Black soil in Northeast China. J. Agric. Sci. 2016, 154, 1425–1436. [Google Scholar] [CrossRef]

- Fang, H.; Li, Q.; Sun, L.; Cai, Q. Using Cs-137 to study spatial patterns of soil erosion and soil organic carbon (SOC) in an agricultural catchment of the typical black soil region, Northeast China. J. Environ. Radioact. 2012, 112, 125–132. [Google Scholar] [CrossRef]

- Cheng, S.; Fang, H.; Zhu, T.; Zheng, J.; Yang, X.; Zhang, X.; Yu, G. Effects of soil erosion and deposition on soil organic carbon dynamics at a sloping field in Black Soil region, North-east China. Soil Sci. Plant Nutr. 2012, 56, 521–529. [Google Scholar] [CrossRef]

- Fan, W.; Wu, J.; Li, J.; Hu, J. Comparative effects of different maize straw returning modes on soil humus composition and humic acid structural characteristics in Northeast China. Chem. Ecol. 2018, 34, 355–370. [Google Scholar] [CrossRef]

- Lu, X.; Wang, J.; Wang, Y.; Wen, W.; Zhang, Y.; Du, J.; Zhao, Y.; Guo, X. Genome-Wide Association Study of Maize Aboveground Dry Matter Accumulation at Seedling Stage. Front. Genet. 2021, 11, 1679–1686. [Google Scholar] [CrossRef]

- Shen, Y.; Zhang, T.; Cui, J.; Chen, S.; Han, H.; Ning, T. Subsoiling increases aggregate-associated organic carbon, dry matter, and maize yield on the North China Plain. PeerJ 2021, 9, e11099. [Google Scholar] [CrossRef]

- Zhang, C. Study on the Dynamic of Soil Organic Carbon Accumulation and Maize Production in Long Term Straw Returning. Master’s Thesis, Gansu Agricultural University, Lanzhou, China, 2017. [Google Scholar]

- Liu, S.-B.; Chai, Q.; Huang, G.-B. Relationships among soil respiration, soil temperature and dry matter accumulation for wheat-maize intercropping in an arid environment. Can. J. Plant Sci. 2013, 93, 715–724. [Google Scholar] [CrossRef]

- Tian, P.; Sui, P.; Lian, H.; Wang, Z.; Meng, G.; Sun, Y.; Wang, Y.; Su, Y.; Ma, Z.; Qi, H.; et al. Maize Straw Returning Approaches Affected Straw Decomposition and Soil Carbon and Nitrogen Storage in Northeast China. Agronomy 2019, 9, 818. [Google Scholar] [CrossRef]

- Yan, Q.; Dong, F.; Li, J.; Duan, Z.; Yang, F.; Li, X.; Lu, J.; Li, F. Effects of maize straw-derived biochar application on soil temperature, water conditions and growth of winter wheat. Eur. J. Soil Sci. 2019, 70, 1280–1289. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, F.; Hu, G.; Shao, S.; He, H.; Zhang, W.; Zhang, X.; Li, L. Dynamic contribution of microbial residues to soil organic matter accumulation influenced by maize straw mulching. Geoderma 2019, 333, 35–42. [Google Scholar] [CrossRef]

- Maraldi, M.; Molari, L.; Regazzi, N.; Molari, G. Analysis of the parameters affecting the mechanical behaviour of straw bales under compression. Biosyst. Eng. 2017, 160, 179–193. [Google Scholar] [CrossRef]

- Zhao, J.; Guo, M.; Lu, Y.; Huang, D.; Zhuang, J. Design of bionic locust mouthparts stubble cutting device. Int. J. Agric. Biol. Eng. 2020, 13, 20–28. [Google Scholar] [CrossRef]

- Tong, J.; Ji, W.; Jia, H.; Chen, D.; Yang, X. Design and tests of biomimetic blades for soil-rototilling and stubble-breaking. J. Bionic Eng. 2015, 12, 495–503. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Y.-H.; Qu, Y.-S.; Wei, Q.-Y.; Li, H.-Q. Effect of the organizational difference of corn stalk on hemicellulose extraction and enzymatic hydrolysis. Ind. Crop. Prod. 2018, 112, 698–704. [Google Scholar] [CrossRef]

- Stemmer, M.; Gerzabek, M.; Kandeler, E. Invertase and xylanase activity of bulk soil and particle-size fractions during maize straw decomposition. Soil Biol. Biochem. 1998, 31, 9–18. [Google Scholar] [CrossRef]

- Wiedermann, A.; Harms, H.H. Straw-cutting machine Investigations on combine harvester straw-cutting machine with exact reaping. In Proceedings of the Conference on Agricultural Engineering, Limenas Hersonissou, Greece, 23–25 June 2008; Volume 2045, pp. 257–262. [Google Scholar]

- Ren, L.Q.; Liang, Y.H. Biological couplings: Classification and characteristic rules. Sci. China Ser. E Technol. Sci. 2009, 52, 2791–2800. [Google Scholar] [CrossRef]

- Jia, H.; Li, C.; Zhang, Z.; Wang, G. Design of Bionic Saw Blade for Corn Stalk Cutting. J. Bionic Eng. 2013, 10, 497–505. [Google Scholar] [CrossRef]

- Tian, K.; Li, X.; Zhang, B.; Chen, Q.; Shen, C.; Huang, J. Design and test research on cutting blade of corn harvester based on bionic principle. Appl. Bionics Biomech. 2017, 2017, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.H.; Liang, Z.H.; Guo, J.D. Experimental comparison of litchi fruit stalk cutting force. Appl. Eng. Agric. 2012, 28, 297–302. [Google Scholar] [CrossRef]

- Guo, M.Z. Design and Key Technology Research of Stubble Breaking and Subsoiling Combined Machine Based on Dynamic Bionics. Ph.D. Thesis, Jilin University, Changchun, China, 2019. [Google Scholar]

- Lin, Y.; Feng, Z.; Wu, W.; Yang, Y.; Zhou, Y.; Xu, C. Potential impacts of climate change and adaptation on maize in northeast China. Agron. J. 2017, 109, 1476–1490. [Google Scholar] [CrossRef]

- Inner Mongolia Province National Bureau of Statistics. China Statistical Yearbook; China Statistical Publishing House: Beijing, China, 2020.

- Heilongjiang Province National Bureau of Statistics. China Statistical Yearbook; China Statistical Publishing House: Beijing, China, 2020.

- Jilin Province National Bureau of Statistics. China Statistical Yearbook; China Statistical Publishing House: Beijing, China, 2020.

- Wen, H.J. A Study on Maize Planting Density and Nitrogen Application Rates of Maize Xianyu335 Based on Experiments of Single Factor and Two-Factor Interaction Effect. Master’s Thesis, Jilin University, Changchun, China, 2011. [Google Scholar]

- Han, Y.; Ma, W.; Zhou, B.; Salah, A.; Geng, M.; Cao, C.; Zhan, M.; Zhao, M. Straw return increases crop grain yields and K-use efficiency under a maize-rice cropping system. Crop. J. 2021, 9, 168–180. [Google Scholar] [CrossRef]

- Liu, J.; Geng, Y.; Li, J.; Cao, G.; Zhang, Z. Effect of Straw Substituting Partial Mineral N Fertilizer on N Distribution of Maize Plants and Soil in Northeast China. Appl. Ecol. Environ. Res. 2021, 19, 625–639. [Google Scholar] [CrossRef]

- He, T.C. Effect of Straw Returning Mode on Soil Water Retention and Fertilizer Supply Capacity and Maize Growth and Development. Master’s Thesis, Shenyang Agricultural University, Shenyang, China, 2020. [Google Scholar]

- Lv, Y.; Wang, Y.; Wang, L.; Zhu, P. Straw Return with Reduced Nitrogen Fertilizer Maintained Maize High Yield in Northeast China. Agronomy 2019, 9, 229. [Google Scholar] [CrossRef]

- Pang, L.D. Decomposition Rate of Corn Straw Returning and Its Effects on Soil Nutrients. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2017. [Google Scholar]

- Zou, W.X.; Han, X.Z.; Lu, X.C.; Chen, X.; Yan, J.; Song, B.H.; Yang, N.; Lin, Q.H.; He, Y. Effects of the construction of fertile and cultivated upland soil layer on soil fertility and maize yield in black soil region in North-east China. J. Appl. Ecol. 2020, 31, 4134–4146. [Google Scholar] [CrossRef]

- Zhao, R.D.; Wu, J.P.; Jiang, C.L.; Liu, F. Effects of biochar particle size and concomi-tant nitrogen fertilization on soil microbial community structure during the maize seed-ling stage. Environ. Sci. Pollut. Res. 2020, 27, 13095–13104. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.P. Effect of Straw Returning and Plastic Film Mulching Coupling on Maize Yield and the Balance of Organic Matter in the LOESS Plateau. Ph.D. Thesis, Lanzhou University, Lanzhou, China, 2014. [Google Scholar]

- Jia, T.Y. Effects of Corn Straw Mulching on Soil Water and Heat and Weeds Occurrence. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2020. [Google Scholar]

- Zhang, L.L.; Sun, S.J.; Chen, Z.J.; Jiang, H.; Zhang, X.D.; Chi, D.C. Effects of different colored plastic film mulching and planting density on dry matter accumulation and yield of spring maize. J. Appl. Ecol. 2018, 29, 113–124. [Google Scholar] [CrossRef]

- Zheng, L.; Wu, W.; Wei, Y.; Hu, K. Effects of straw return and regional factors on spatio-temporal variability of soil organic matter in a high-yielding area of northern China. Soil Tillage Res. 2015, 145, 78–86. [Google Scholar] [CrossRef]

- Farooq, N.; Sarwar, G.; Abbas, T.; Bessely, L.; Nadeem, M.A.; Javaid, M.M.; Matloob, A.; Naseem, M.; Ikram, N.A. Effect of drying-rewetting durations in combination with synthetic fertilizers and crop residues on soil fertility and maize production. Pak. J. Bot. 2020, 52, 2051–2058. [Google Scholar] [CrossRef]

- Pegoraro, E.F.; Mauritz, M.E.; Ogle, K.; Ebert, C.H.; Schuur, E.A.G. Lower soil moisture and deep soil temperatures in thermokarst features increase old soil carbon loss after 10 years of experimental permafrost warming. Glob. Chang. Biol. 2021, 27, 1293–1308. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Zhang, X.; Pei, D.; Sun, H.; Chen, S. Effects of straw mulching on soil temperature, evaporation and yield of winter wheat: Field experiments on the North China Plain. Ann. Appl. Biol. 2007, 150, 261–268. [Google Scholar] [CrossRef]

- Stemmer, M.; Von Lützow, M.; Kandeler, E.; Pichlmayer, F.; Gerzabek, M.H. The effect of maize straw placement on mineralization of C and N in soil particle size fractions. Eur. J. Soil Sci. 1999, 50, 73–85. [Google Scholar] [CrossRef]

- Kayaci, N.; Demir, H. Numerical modelling of transient soil temperature distribution for horizontal ground heat exchanger of ground source heat pump. Geothermics 2018, 73, 33–47. [Google Scholar] [CrossRef]

- Jin, L.; Wei, D.; Yin, D.; Zhou, B.; Ding, J.; Wang, W.; Zhang, J.; Qiu, S.; Zhang, C.; Li, Y.; et al. Investigations of the effect of the amount of biochar on soil porosity and aggregation and crop yields on fertilized black soil in northern China. PLoS ONE 2020, 15, e0238883. [Google Scholar] [CrossRef] [PubMed]

- Chang, N.; Zhai, Z.; Li, H.; Wang, L.; Deng, J. Impacts of nitrogen management and or-ganic matter application on nitrous oxide emissions and soil organic carbon from spring maize fields in the North China Plain. Soil Tillage Res. 2020, 196, 104441. [Google Scholar] [CrossRef]

- Liu, J.; Hayakawa, N.; Lu, M.; Dong, S.; Yuan, J. Hydrological and geocryological re-sponse of winter streamflow to climate warming in Northeast China. Cold Reg. Sci. Technol. 2003, 37, 15–24. [Google Scholar] [CrossRef]

- Wang, C.; Chang, Z.; Niu, S. Effect of Maize Straw-Derived Biochar on Calcar-eous Arable Soil Organic Carbon Mineralization Under the Condition of with or Without Nitrogen-Fertilizer Addition. J. Soil Sci. Plant Nutr. 2020, 20, 2606–2616. [Google Scholar] [CrossRef]

- Andrade, J.A.; Abreu, F.G. Influence of temperature and soil moisture on leaf area and dry matter accumulation during establishment of pea, maize and sunflower. Rev. Ciênc. Agrár. 2007, 30, 27–37. [Google Scholar]

- Yang, Q.; Zheng, F.; Jia, X.; Liu, P.; Dong, S.; Zhang, J.; Zhao, B. The combined application of organic and inorganic fertilizers increases soil organic matter and improves soil microenvironment in wheat-maize field. J. Soils Sediments 2020, 20, 2395–2404. [Google Scholar] [CrossRef]

- Xu, H.N. Effect of Applying Organic Fertilizer and Reducing Fertilizer on Maize Nutrient Accumulation and Yield. Master’s Thesis, Northeast Agricultural University, Harbin, China, 2019. [Google Scholar]

| Crushing Length (cm) | Adjacent Tool Interval (cm) | Tool Rotation Speed (R/min) | Crushing Length Qualification Rate (%) |

|---|---|---|---|

| 1.5 | 3 | 1550 | 92.4 |

| 3.0 | 4 | 1250 | 93.2 |

| 4.5 | 6 | 1080 | 95.6 |

| 6.0 | 8 | 950 | 97.8 |

| Climate and Soil Parameters | Experiment Site | Maize-Growing Regions of Northeast China |

|---|---|---|

| annual sunshine hours (h) | 2450 ± 74 | 2430 ± 82 |

| annual precipitation (mm) | 591 ± 31 | 602 ± 37 |

| sowing temperature (°C) | 10.1 ± 0.37 | 9.7 ± 0.26 |

| soil type | black clay | black clay |

| pH | 7.08 ± 0.19 | 7.08 ± 0.26 |

| organic matter (%) | 3.75 ± 0.08 | 3.61 ± 0.12 |

| soil compactness (MPa) | 0.99 ± 0.04 | 1.03 ± 0.06 |

| soil moisture content (% d. b.) | 19.6 ± 0.9 | 20.1 ± 1.2 |

| total nitrogen content (%) | 0.13 ± 0.01 | 0.15 ± 0.01 |

| Olsen-K (K2O, mg/kg) | 173.2 ± 8.3 | 165.7 ± 10.7 |

| Olsen-P (P2O5, mg/kg) | 16.5 ± 0.71 | 16.2 ± 0.87 |

| pH | Total C (g/kg) | Total N (g/kg) | Total P (g/kg) | Total K (g/kg) | C/N | Average Pore Size (nm) |

|---|---|---|---|---|---|---|

| 7.8 | 429.3 | 6.4 | 3.43 | 17.6 | 67 | 10.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Wang, X.; Zhuang, J.; Cong, Y.; Lu, Y.; Guo, M. Fine-Crush Straw Returning Enhances Dry Matter Accumulation Rate of Maize Seedlings in Northeast China. Agronomy 2021, 11, 1144. https://doi.org/10.3390/agronomy11061144

Zhao J, Wang X, Zhuang J, Cong Y, Lu Y, Guo M. Fine-Crush Straw Returning Enhances Dry Matter Accumulation Rate of Maize Seedlings in Northeast China. Agronomy. 2021; 11(6):1144. https://doi.org/10.3390/agronomy11061144

Chicago/Turabian StyleZhao, Jiale, Xiaogeng Wang, Jian Zhuang, Yongjian Cong, Yun Lu, and Mingzhuo Guo. 2021. "Fine-Crush Straw Returning Enhances Dry Matter Accumulation Rate of Maize Seedlings in Northeast China" Agronomy 11, no. 6: 1144. https://doi.org/10.3390/agronomy11061144

APA StyleZhao, J., Wang, X., Zhuang, J., Cong, Y., Lu, Y., & Guo, M. (2021). Fine-Crush Straw Returning Enhances Dry Matter Accumulation Rate of Maize Seedlings in Northeast China. Agronomy, 11(6), 1144. https://doi.org/10.3390/agronomy11061144