Bio-Based Value Chains Potential in the Management of Cacao Pod Waste in Colombia, a Case Study

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

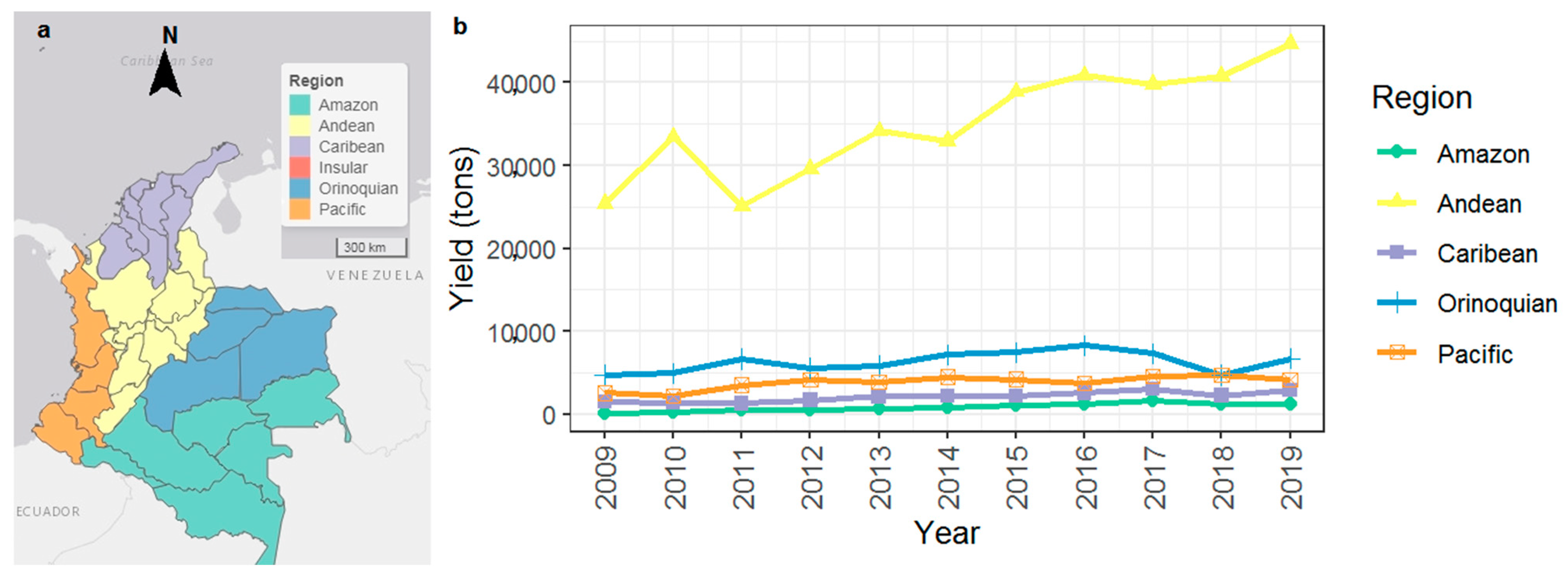

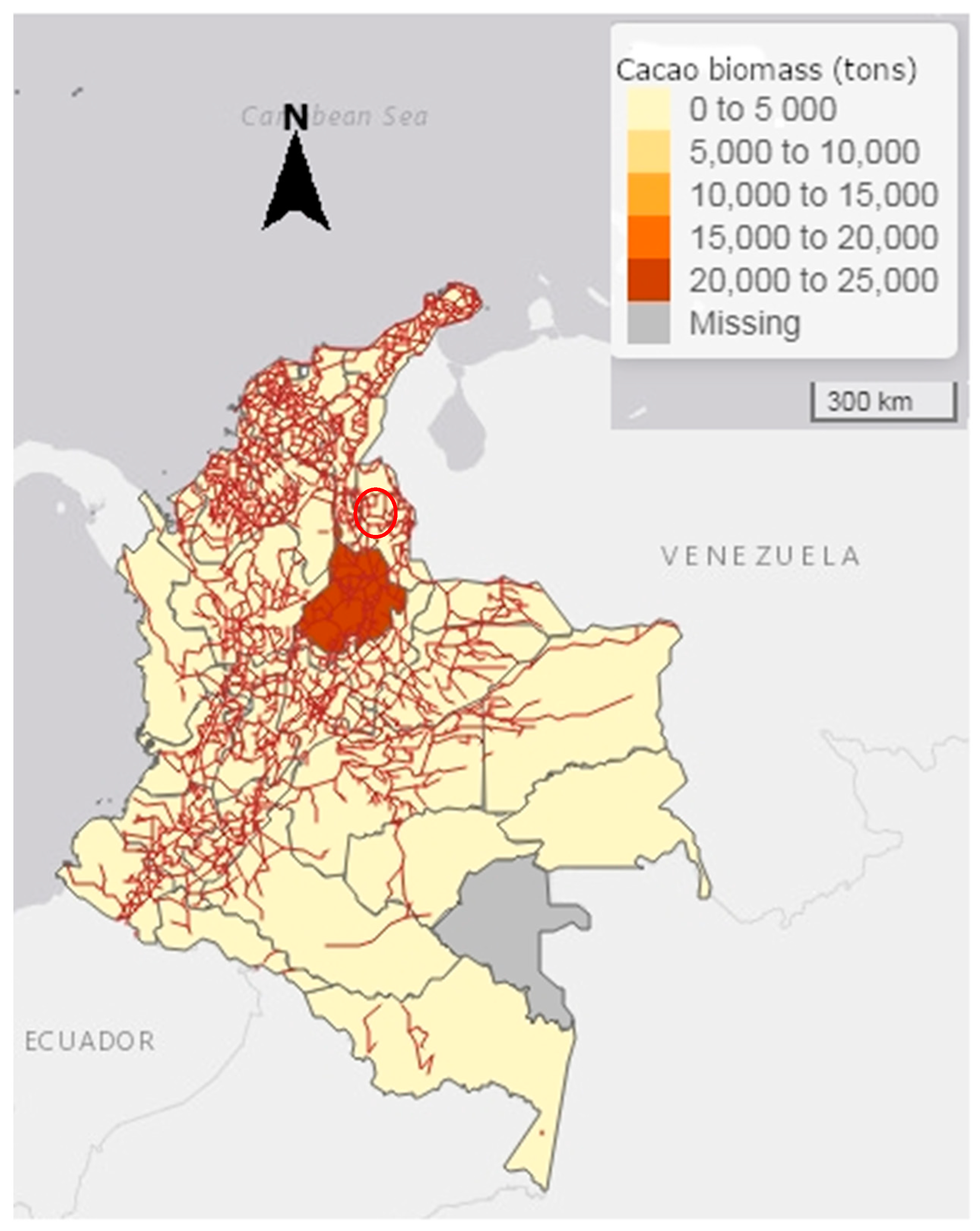

3.1. Cacao Production and Residual Biomass in Colombia

3.2. Cycle and Characterization of Cacao Pod Husk

3.3. Uses of Cacao Pod Waste

- -

- Food for animals: The fresh fruit is cut and then dried and minced until obtaining granules that are used as animal food [51];

- -

- Mild soap making: The ash from the cacao pod shell is mainly used for making mild soap. The fresh husks are spread out in the open air to dry for one or two weeks to prepare the ash. The dried shells are then incinerated in an incineration oven [51];

- -

- Fertilizer for cacao, vegetables, and food crops [51].

3.3.1. Energy Uses for Cacao Residues

3.3.2. Food Uses for Cacao Residues

3.3.3. Miscellaneous Uses for Cacao Residues

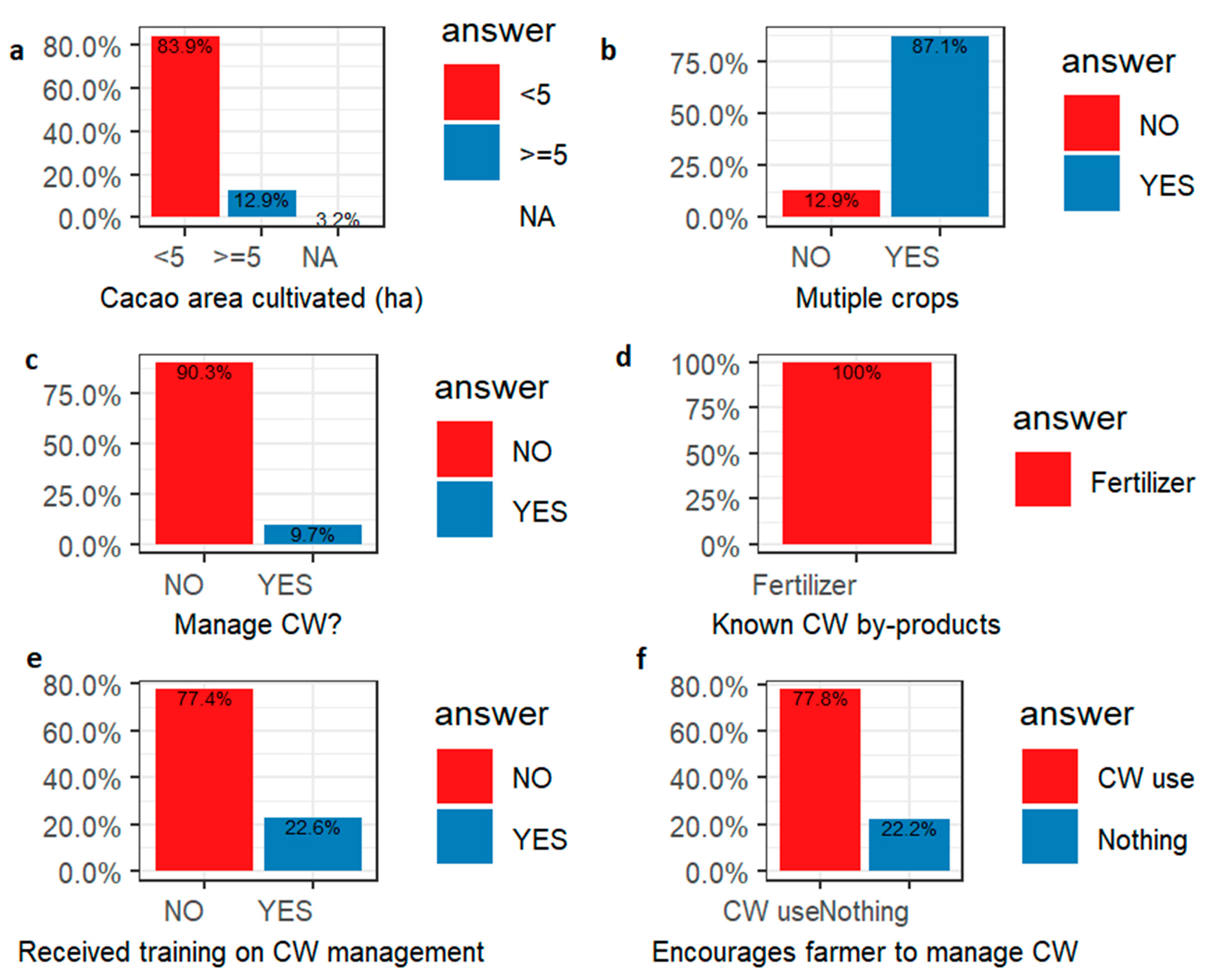

3.4. Farmers Socioeconomics and Waste Management from Caldas Region in Colombia

3.5. Farmers’ Attitude towards the Management of Agricultural Waste

3.6. Strategy to Implement a BBVC from the Cacao Production in Colombia

4. Challenges and Perspectives

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Zorb, C.; Lewandowski, I. Biobased resources and value chains. In Bioeconomy: Shaping the Transition to a Sustainable, Biobased Economy; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 9783319681511. [Google Scholar]

- Inyinbor, A.A.; Oluyori, A.P.; Adelani-Akande, T.A. Biomass Valorization: Agricultural Waste in Environmental Protection, Phytomedicine and Biofuel Production. In Biomass Volume Estimation and Valorization for Energy; InTech: London, UK, 2017; pp. 99–121. [Google Scholar]

- FAO El Desarrollo Sostenible. Available online: http://www.fao.org/3/x5600s/x5600s05.htm (accessed on 17 September 2020).

- Smil, V. Crop Residues: Agriculture’s Largest Harvest. Alzheimer’s Dement. 1999, 49, 299–308. [Google Scholar] [CrossRef]

- Escalante Hernández, H.; Orduz Prada, J.; Zapata Lesmes, H.J.; Cardona Ruiz, M.C.; Ortega, M.D. Atlas del Potencial Energético de la Biomasa Residual en Colombia; Universidad Industrial de Santander: Bucaramanga, Colombia, 2013; Volume 1. [Google Scholar]

- Scarlat, N.; Martinov, M.; Dallemand, J.F. Assessment of the availability of agricultural crop residues in the European Union: Potential and limitations for bioenergy use. Waste Manag. 2010, 30, 1889–1897. [Google Scholar] [CrossRef]

- DNP. Política de Crecimiento Verde (Documentos CONPES 3934); DNP: Bogotá, Colombia, 2018. [Google Scholar]

- Tonini, D.; Albizzati, P.F.; Fruergaard Astrup, T. Environmental impacts of food waste: Learnings and challenges from a case study on UK. Waste Manag. 2018, 76, 744–766. [Google Scholar] [CrossRef] [PubMed]

- Andini, A.; Bonnet, S.; Rousset, P.; Hasanudin, U. Impact of open burning of crop residues on air pollution and climate change in Indonesia. Curr. Sci. 2018, 115, 2259–2266. [Google Scholar] [CrossRef]

- Devi, S.; Gupta, C.; Jat, S.L.; Parmar, M.S. Crop residue recycling for economic and environmental sustainability: The case of India. Open Agric. 2017, 2, 486–494. [Google Scholar] [CrossRef]

- Kumar, H.; Remote, P.; Centre, S. Crop Residue Burning: Impacts on Air Quality, Health and Climate Change Modelling using Geospatial Technology: A Review. Int. J. Creat. Res. Thoughts 2018, 6, 524–534. [Google Scholar] [CrossRef]

- Ramya, R.; Devi, S.; Manikandan, A.; Kannan, V.R. Standardization of biopolymer production from seaweed associative bacteria. Int. J. Biol. Macromol. 2017, 102, 550–564. [Google Scholar] [CrossRef]

- Martínez-Ángel, J.D.; Villamizar-Gallardo, A.; Ortiz-Rodríguez, O.O. Characterization and evaluation of cacao (Theobroma cacao L.) pod husk as a renewable energy source. Agrociencia 2015, 49, 329–345. [Google Scholar]

- Fedecacao. Federación Nacional de Cacaoteros El Cacaocultor es lo Primero Economía Internacional. Available online: https://www.fedecacao.com.co/portal/index.php/es/2015-02-12-17-20-59/nacionales (accessed on 6 October 2020).

- ICCO International Cacao Organization. Available online: https://www.icco.org/about-cacao/chocolate-industry.html (accessed on 22 September 2020).

- Espinal, C.F.; Martínez, H.J.; Ortíz, L. La cadena del cacao en Colombia una mirada global de su estructura y dinámica 1991–2005 Documento de Trabajo No. 58. Minist. Agric. y Desarro. Rural. Obs. Agrocadenas Colomb. 2005, 51, 1. [Google Scholar]

- Ortiz, K.; Álvarez, R. Efecto del Vertimiento de (Theobroma cacao L.) sobre algunas propiedades quimicas y biológicas en los suelos de una finca cacaotera, Municipio de Yaguara (Huila, Colombia). Boletín Científico Cent. Mus. Mus. Hist. Nat. 2015, 19, 65–84. [Google Scholar] [CrossRef]

- Ministerio de Agricultura y Desarrollo Rural. Área Sembrada, Área Cosechada, Producción y Rendimiento del Cultivo 2014; Ministerio de Agricultura y Desarrollo Rural: Bogotá, Colombia, 2014. [Google Scholar]

- Ministerio de Agricultura y Desarrollo Rural. Informe de Rendición de Cuentas 2016-2017 El Renacer del Campo; Ministerio de Agricultura y Desarrollo Rural: Bogotá, Colombia, 2017. [Google Scholar]

- Perez, M.I.; Peñaranda, L.F.; Herazo, M.M. Impacto, Manejo y Control de Enfermedades Causadas por Phytophthora Palmivora en Diferentes Cultivos; Universidad de Pamplona: Norte de Santander, Colombia, 2010. [Google Scholar]

- Rojas, F.; Sacristán, E.J. Guía Ambiental Para el Cultivo del Cacao; Peinado, J.E., Ed.; FEDECACAO: Bogotá, Colombia, 2013. [Google Scholar]

- Barraza, F.; Schreck, E.; Lévêque, T.; Uzu, G.; López, F.; Ruales, J.; Prunier, J.; Marquet, A.; Maurice, L. Cadmium bioaccumulation and gastric bioaccessibility in cacao: A field study in areas impacted by oil activities in Ecuador. Environ. Pollut. 2017, 229, 950–963. [Google Scholar] [CrossRef]

- Superintendencia de industria y comecio. Cadena Productiva del Cacao: Diagnostico de Libre Competencia; Superintendencia Industria y Comercio: Bogota, Colombia, 2011; pp. 1–6. [Google Scholar]

- Fedecacao. Federación Nacional de Cacaoteros Boletín de prensa—Así quedó el ranking de producción de cacao en Colombia. Available online: http://www.fedecacao.com.co/portal/index.php/es/2015-04-23-20-00-33/1193-boletin-de-prensa-asi-quedo-el-ranking-de-produccion-de-cacao-en-colombia%0Ahttps://www.fedecacao.com.co/portal/index.php/es/2015-04-23-20-00-33/1193-boletin-de-prensa-asi-quedo-el-ran (accessed on 10 September 2020).

- Perea, A.; Martínez Guerrero, N.; Aranzazu Hernández, F.; Cadena, T. Caracteristicas de Calidad del Cacao de Colombia; Universidad Industrial de Santander: Bucaramanga, Colombia, 2013; ISBN 9789588915227. [Google Scholar]

- Mejía, L.A.; Argüello, O. Tecnología Para el Sistema de Producción de Cacao; Corporación Colombiana de Investigación Agropecuaria, CORPOICA: Bucaramanga, Colombia, 2000. [Google Scholar]

- Torres Cabezas, M.A. Obtención de Celulosa a Partir de la Cáscara de Cacao Ecuatoriano (Theobroma cacao L.) Mediante Hidrólisis Térmica Para la Elaboración de Pulpa de Papel; Universidad Central del Ecuador: Quito, Ecuador, 2019; Volume 6. [Google Scholar]

- Orjuela, W.A.; Cardona, E.A.; Murillo, W.; Méndez, J.J. Aprovechamiento de la Biomasa Lignocelulósica de la Cadena del Cacao, UN Camino a la Bioeconomia Circular; Universidad del Tolima: Ibague, Colombia, 2019; pp. 1–20. [Google Scholar]

- Encalada, J.; Jácome, T. Determinación de Parámetros Cinéticos en la Devolatilización de Biomasa Residual de Cacao Ecuatoriano; Universidad Central de Ecuador: Quito, Ecuador, 2018; Volume 10. [Google Scholar]

- Ten Hoopen, G.M.; Deberdt, P.; Mbenoun, M.; Cilas, C. Modelling cacao pod growth: Implications for disease control. Ann. Appl. Biol. 2012, 160, 260–272. [Google Scholar] [CrossRef]

- Daymond, A.J.; Hadley, P. Differential effects of temperature on fruit development and bean quality of contrasting genotypes of cacao (Theobroma cacao). Ann. Appl. Biol. 2008, 153, 175–185. [Google Scholar] [CrossRef]

- Oliveira, L.S.; Franca, A.S. An Overview of the Potential Uses for Coffee Husks; Elsevier Inc.: Amsterdam, The Netherlands, 2015; ISBN 9780124167162. [Google Scholar]

- Franco, M.; Ramírez, M.; García, R.; Bernal, M.; Espinosa, B.; Solís, J.; Durán, C. Reaprovechamiento Integral de Residuos Agroindustriales: Cáscara y Pulpa de Cacao para la Producción de Pectinas. Rev. Lat. Ambiente Cienc. 2010, 1, 45–66. [Google Scholar]

- Guevara, J. The Chocolate Fruit: Looking Inside a Cacao Pod. Available online: https://perfectdailygrind.com/2018/02/chocolate-fruit-looking-inside-cacao-pod/ (accessed on 10 September 2020).

- Sisbudi Harsono, S. Coffee Husk Biopellet Characteristics as Solid Fuel for Combustion Stove. Environ. Sci. Curr. Res. 2019, 2, 1–6. [Google Scholar] [CrossRef]

- Syamsiro, M.; Saptoadi, H.; Tambunan, B.H. Experimental investigation on combustion of bio-pellets from Indonesian Cacao Pod Husk. Asian J. Appl. Sci. 2011, 4, 712–719. [Google Scholar] [CrossRef]

- Titiloye, J.O.; Abu Bakar, M.S.; Odetoye, T.E. Thermochemical characterisation of agricultural wastes from West Africa. Ind. Crops Prod. 2013, 47, 199–203. [Google Scholar] [CrossRef]

- Forero-Nuñez, C.A.; Jochum, J.; Vargas, F.E.S. Effect of particle size and addition of cacao pod husk on the properties of sawdust and coal pellets. Ing. Investig. 2015, 35, 17–23. [Google Scholar] [CrossRef]

- Villamizar, Y.L.; Rodriguez, J.S.; León, L.C. Caracterización fisicoquímica, microbiológica y funcional de harina de cáscara de cacao (Theobroma cacao L.) variedad CCN-51. Cuad. Act. 2017, 9, 65–75. [Google Scholar]

- Nguyen, V.T.; Nguyen, N.H. Proximate Composition, Extraction, and Purification of Theobromine from Cacao Pod Husk (Theobroma cacao L.). Technologies 2017, 5, 14. [Google Scholar] [CrossRef]

- Castillo, E.; Alvarez, C.; Contreras, Y. Caracterización fisicoquímica de la cáscara del fruto de un clon de cacao (Theobroma cacao L.) Cosechados en Caucagua, estado Miranda. Venezuela. Rev. Invest. 2018, 42, 154–176. [Google Scholar]

- Njoku, V.O.; Ayuk, A.A.; Ejike, E.E.; Oguzie, E.E.; Duru, C.E.; Bello, O.S. Cacao pod husk as a low cost biosorbent for the removal of Pb(II) and Cu(II) from aqueous solutions. Aust. J. Basic Appl. Sci. 2011, 5, 101–110. [Google Scholar]

- Daud, Z.; Awang, H.; Mohd Kassim, A.S.; Mohd Hatta, M.Z.; Mohd Aripin, A. Cacao Pod Husk and Corn Stalk: Alternative Paper Fibres Study on Chemical Characterization and Morphological Structures. Adv. Mater. Res. 2014, 911, 331–335. [Google Scholar] [CrossRef]

- Vásquez, Z.S.; de Carvalho Neto, D.P.; Pereira, G.V.M.; Vandenberghe, L.P.S.; de Oliveira, P.Z.; Tiburcio, P.B.; Rogez, H.L.G.; Góes Neto, A.; Soccol, C.R. Biotechnological approaches for cacao waste management: A review. Waste Manag. 2019, 90, 72–83. [Google Scholar] [CrossRef] [PubMed]

- Alemawor, F.; Dzogbefia, V.P.; Oddoye, E.O.K.; Oldham, J.H. Enzyme cocktail for enhancing poultry utilisation of cacao pod husk. Sci. Res. Essay 2009, 4, 555–559. [Google Scholar]

- Daniyan, I.A.; Adeodu, A.O.; Adewumi, D.F. Design of a Processor for the Production of 30,000 Tons of Caustic Potash per Anum from Cacao Pod. Int. J. Sci. Res. 2014, 3, 691–700. [Google Scholar]

- Adeyeye, S.A.; Ayodele, S.O.; Oloruntola, O.D.; Agbede, J.O. Processed cacao pod husk dietary inclusion: Effects on the performance, carcass, haematogram, biochemical indices, antioxidant enzyme and histology of the liver and kidney in broiler chicken. Bull. Natl. Res. Cent. 2019, 8. [Google Scholar] [CrossRef]

- García Torres, A.M.; Torres Sáe, R.G. Producción de enzimas lignolíticas por Basidiomycetes mediante la técnica de fermentación en sustrato sólido. Rev. Colomb. Biotecnol. 2003, 1, 56–64. [Google Scholar]

- Diep, N.Q.; Sakanishi, K.; Nakagoshi, N.; Fujimoto, S.; Minowa, T.; Xuan, T.D. Biorefinery: Concepts, Current Status, and Development Trends. Int. J. Ofbiomass Renew. 2012, 1, 1–8. [Google Scholar]

- Wang, M.; Cao, W.; Sun, C.; Sun, Z.; Miao, Y.; Liu, M.; Zhang, Z.; Xie, Y.; Wang, X.; Hu, S.; et al. To distinguish the primary characteristics of agro-waste biomass by the principal component analysis: An investigation in East China. Waste Manag. 2019, 90, 100–120. [Google Scholar] [CrossRef] [PubMed]

- ICCO International Cacao Organization (ICCO). Available online: http://www.icco.org/about-us/international-cacao-agreements/cat_view/30-related-documents/46-statistics-production.html (accessed on 6 October 2020).

- Abbott, P.C.; Benjamin, T.J.; Burniske, G.R.; Croft, M.M.; Fenton, M.; Kelly, C.R.; Lundy, M.; Rodriguez Camayo, F.; Wilcox, M., Jr. An Analysis of the Supply Chain of Cacao in Colombia; United States Agency for International Development: Washington, DC, USA, 2019. [Google Scholar]

- Ofori-Boateng, C.; Lee, K.T. The potential of using cacao pod husks as green solid base catalysts for the transesterification of soybean oil into biodiesel: Effects of biodiesel on engine performance. Chem. Eng. J. 2013, 220, 395–401. [Google Scholar] [CrossRef]

- Khanahmadi, S.; Yusof, F.; Chyuan Ong, H.; Amid, A.; Shah, H. Cacao pod husk: A new source of CLEA-lipase for preparation of low-cost biodiesel: An optimized process. J. Biotechnol. 2016, 231, 95–105. [Google Scholar] [CrossRef]

- Dahunsi, S.O.; Osueke, C.O.; Olayanju, T.M.A.; Lawal, A.I. Co-digestion of Theobroma cacao (Cacao) pod husk and poultry manure for energy generation: Effects of pretreatment methods. Bioresour. Technol. 2019, 283, 229–241. [Google Scholar] [CrossRef] [PubMed]

- Dahunsi, S.O.; Adesulu-Dahunsi, A.T.; Izebere, J.O. Cleaner energy through liquefaction of Cacao (Theobroma cacao) pod husk: Pretreatment and process optimization. J. Clean. Prod. 2019, 226, 578–588. [Google Scholar] [CrossRef]

- Hermansyah, H.; Fedrizal, F.F.; Wijanarko, A.; Sahlan, M.; Utami, T.S.; Arbianti, R. Biogas production from co-digestion of cacao pod husk and cow manure with cow rumen fluid as inoculum. In Proceedings of the International Conference On Trends In Material Science And Inventive Materials, Coimbatore, India, 9–10 April 2020. [Google Scholar]

- Adepoju, T.F.; Olatunji, O.M.; Ibeh, M.A.; Kamoru, A.S.; Olatunbosun, B.E.; Asuquo, A.J. Heavea brasiliensis (Rubber seed): An alternative source of renewable energy. Sci. Afr. 2020, 8, e00339. [Google Scholar] [CrossRef]

- Ofori, P.; Akoto, O. Production and Characterisation of Briquettes from Carbonised Cacao Pod Husk and Sawdust. Open Access Libr. J. 2020, 7, 1–20. [Google Scholar] [CrossRef]

- Velazquez-Araque, L.; Cárdenas, J. Study of influence of starch as binder material for Ecuadorian cacao pod husk pellets. In Proceedings of the WMSCI 2017-21st World Multi-Conference on Systemics, Cybernetics and Informatics, Orlando, FL, USA, 8–11 July 2017; Volume 1, pp. 373–377. [Google Scholar]

- Campoverde, J.F. Elaboración de Biocarbón Obtenido a Partir de la Cáscara del Cacao y Raquis del Banano; Universidad de Machala: Machala, Ecuador, 2019. [Google Scholar]

- Valencia, A. Obtención de Carbón Activado a Partir de la Cáscara de Mazorca de Theobroma cacao L. de la Granja Gilberto Peláez Ángel del Corregimiento de Combia Risaralda; Universidad tecnológica de Pereira: Pereira, Colombia, 2018. [Google Scholar]

- Sakagami, H.; Satoh, K.; Fukamachi, H.; Ikarashi, T.; Shimizu, A.; Yano, K.; Kanamoto, T.; Terakubo, S.; Nakashima, H.; Hasegawa, H.; et al. Anti-HIV and vitamin C-synergized radical scavenging activity of cacao husk lignin fraction. Vivo (Brooklyn) 2008, 22, 327–332. [Google Scholar]

- Yapo, B.M.; Besson, V.; Koubala, B.B.; Koffi, K.L. Adding Value to Cacao Pod Husks as a Potential Antioxidant-Dietary Fiber Source. Am. J. Food Nutr. 2013, 1, 38–46. [Google Scholar] [CrossRef]

- Oduro-Mensah, D.; Ocloo, A.; Lowor, S.T.; Bonney, E.Y.; Okine, L.K.N.A.; Adamafio, N.A. Isolation and characterisation of theobromine-degrading filamentous fungi. Microbiol. Res. 2018, 206, 16–24. [Google Scholar] [CrossRef]

- Lu, F.; Rodriguez-Garcia, J.; Van Damme, I.; Westwood, N.J.; Shaw, L.; Robinson, J.S.; Warren, G.; Chatzifragkou, A.; McQueen Mason, S.; Gomez, L.; et al. Valorisation strategies for cacao pod husk and its fractions. Curr. Opin. Green Sustain. Chem. 2018, 14, 80–88. [Google Scholar] [CrossRef]

- Valero-Valdivieso, M.F.; Ortegón, Y.; Uscategui, Y. Biopolímeros: Avances y perspectivas. DYNA 2013, 80, 171–180. [Google Scholar]

- Anyaoha, K.E.; Sakrabani, R.; Patchigolla, K.; Mouazen, A.M. Critical evaluation of oil palm fresh fruit bunch solid wastes as soil amendments: Prospects and challenges. Resour. Conserv. Recycl. 2018, 136, 399–409. [Google Scholar] [CrossRef]

- Praveena, C.; Suresh, J.; Jegadeeswari, V.; Kannan, J.; Karthikeyan, S. Studies on composting of cacoa (Theobroma cacao L.) Pod husk. Int. J. Adv. Res. 2018, 6, 1081–1085. [Google Scholar] [CrossRef]

- Kone, K.; Akueson, K.; Norval, G. On the Production of Potassium Carbonate from Cacao Pod Husks. Recycling 2020, 5, 23. [Google Scholar] [CrossRef]

- SoDRé, G.A.; Venturini, M.T.; Ribeiro, D.O.; Marrocos, P.C.L. Extract from the bark of cacao fruit as potassium fertilizer on growth of cacao seedlings. Rev. Bras. Frutic. 2012, 34, 881–887. [Google Scholar] [CrossRef]

- Aggrey, W.N.; Asiedu, N.Y.; Tackie-Otoo, B.N.; Stephen Adjei, E.M.-B. Performance of Carboxymethyl Cellulose Produced from Cacao Pod Husk as Fluid Loss Control Agent at High Temperatures and Variable (Low and High) Differential Pressure Conditions-Part 1. J. Pet. Sci. Technol. 2019, 9, 22–38. [Google Scholar]

- Sarmiento Hernandez, J. Evaluación del Uso de la Cáscara de Cacao Como Sustituto Parcial de la Matriz Polimérica en la Obtención de Espumas de Poliuretano; Universidad de América: Bogotá, Colombia, 2019; Volume 6, pp. 5–10. [Google Scholar]

- González, L.M.R. Aprovechamiento de la Cáscara de Cacao Para la Elaboración de un Biocomposito con Aplicación en la Construcción Sostenible; Universidad Del Bosque: Bogotá, Colombia, 2019; Volume 53. [Google Scholar]

- Campos-Vega, R.; Nieto-Figueroa, K.H.; Oomah, B.D. Cacao (Theobroma cacao L.) pod husk: Renewable source of bioactive compounds. Trends Food Sci. Technol. 2018, 81, 172–184. [Google Scholar] [CrossRef]

- Muñoz-Almagro, N.; Valadez-Carmona, L.; Mendiola, J.A.; Ibáñez, E.; Villamiel, M. Structural characterisation of pectin obtained from cacao pod husk. Comparison of conventional and subcritical water extraction. Carbohydr. Polym. 2019, 217, 69–78. [Google Scholar] [CrossRef]

- Valadez-Carmona, L.; Plazola-Jacinto, C.P.; Hernández-Ortega, M.; Hernández-Navarro, M.D.; Villarreal, F.; Necoechea-Mondragón, H.; Ortiz-Moreno, A.; Ceballos-Reyes, G. Effects of microwaves, hot air and freeze-drying on the phenolic compounds, antioxidant capacity, enzyme activity and microstructure of cacao pod husks (Theobroma cacao L.). Innov. Food Sci. Emerg. Technol. 2017, 41, 378–386. [Google Scholar] [CrossRef]

- Vriesmann, L.C.; de Mello Castanho Amboni, R.D.; De Oliveira Petkowicz, C.L. Cacao pod husks (Theobroma cacao L.): Composition and hot-water-soluble pectins. Ind. Crops Prod. 2011, 34, 1173–1181. [Google Scholar] [CrossRef]

- Vriesmann, L.C.; Teófilo, R.F.; Lúcia de Oliveira Petkowicz, C. Extraction and characterization of pectin from cacao pod husks (Theobroma cacao L.) with citric acid. LWT Food Sci. Technol. 2012, 49, 108–116. [Google Scholar] [CrossRef]

- Vriesmann, L.C.; de Oliveira Petkowicz, C.L. Cacao pod husks as a source of low-methoxyl, highly acetylated pectins able to gel in acidic media. Int. J. Biol. Macromol. 2017, 101, 146–152. [Google Scholar] [CrossRef] [PubMed]

- Diniz, D.M.; Druzian, J.I.; Audibert, S. Produção de goma xantana por cepas nativas de Xanthomonas campestris a partir de casca de cacau ou soro de leite. Polimeros 2012, 22, 278–281. [Google Scholar] [CrossRef]

- Lateef, A.; Oloke, J.K.; Gueguim Kana, E.B.; Oyeniyi, S.O.; Onifade, O.R.; Oyeleye, A.O.; Oladosu, O.C.; Oyelami, A.O. Improving the quality of agro-wastes by solid-state fermentation: Enhanced antioxidant activities and nutritional qualities. World J. Microbiol. Biotechnol. 2008, 24, 2369–2374. [Google Scholar] [CrossRef]

- Abdul Karim, A.; Azlan, A.; Ismail, A.; Hashim, P.; Abd Gani, S.S.; Zainudin, B.H.; Abdullah, N.A. Efficacy of cacao pod extract as anti-wrinkle gel on human skin surface. J. Cosmet. Dermatol. 2016, 15, 283–295. [Google Scholar] [CrossRef]

- Bean, C.; Chain, V. Customize the Report. Available online: https://www.mordorintelligence.com/industry-reports/cacao-beans-value-chain-analysis (accessed on 17 September 2020).

- Porrini, G. Creative Cacao. Available online: https://www.creativecacao.com/the-cacao-international-value-chain-how-many-actors-are-involved-between-the-cacao-plantation-to-chocolate-shop (accessed on 10 December 2020).

- Biopro Bw BIOPRO Baden-Württemberg. Available online: https://www.biooekonomie-bw.de/en/bw/location# (accessed on 9 October 2020).

| Parameter | Minimum | Maximum | Average | References |

|---|---|---|---|---|

| % Moisture | 6.67 | 16.1 | 10.19 | [28,36,37,38,39,40,41] |

| % Volatile material | 49.9 | 68.49 | 59.39 | [28,36,37,38] |

| % Ash | 6.7 | 13.5 | 10.92 | [28,36,37,38,39,40,41,42,43,44] |

| % Fixed carbon | 10.43 | 20.5 | 16.42 | [28,36,37,38] |

| Crude protein | 4.21 | 14.63 | 8.55 | [39,41,44,45,46] |

| % Fat | 0.12 | 1.5 | 0.48 | [39,40,41,44] |

| % Fiber | 3.1 | 136.6 | 43.65 | [39,40,41,45,46,47] |

| Starch mg/100 g | 2.2 | 2.2 | 2.2 | [45] |

| % Carbohydrates | 74.93 | 74.93 | 74.93 | [39,44] |

| Glucose mg/100 g | 1.16 | 1.16 | 1.16 | [46] |

| Sucrose mg/100 g | 0.18 | 0.18 | 0.18 | [46] |

| Total sugars | 45.42 | 45.42 | 45.42 | [41] |

| Total polyphenols (g/Kg sample) | 21.41 | 21.41 | 21.41 | [41] |

| Caffeine mg/100 g | 0.03 | 0.03 | 0.03 | [47] |

| Tannins mg/100 g | 0.12 | 5.20 | 0.12 | [44,47] |

| Theobromine mg/100 g | 0.2 | 0.679 | 0.41 | [36,40,44,47] |

| Hemicellulose mg/100 g | 37 | 37 | 37 | [43] |

| Cellulose mg/100 g | 26.1 | 35.4 | 33.02 | [43,45,48] |

| Lignin mg/100 g | 14.7 | 21.6 | 23.75 | [43,45,48] |

| Pectin mg/100 g | 3.71 | 3.71 | 3.71 | [46] |

| pH | 6.25 | 6.25 | 6.25 | [41] |

| Titratable acidity | 0.38 | 0.38 | 0.38 | [41] |

| % Calorific value | 331.31 | 331.31 | 331.31 | [39] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meza-Sepúlveda, D.C.; Castro, A.M.; Zamora, A.; Arboleda, J.W.; Gallego, A.M.; Camargo-Rodríguez, A.V. Bio-Based Value Chains Potential in the Management of Cacao Pod Waste in Colombia, a Case Study. Agronomy 2021, 11, 693. https://doi.org/10.3390/agronomy11040693

Meza-Sepúlveda DC, Castro AM, Zamora A, Arboleda JW, Gallego AM, Camargo-Rodríguez AV. Bio-Based Value Chains Potential in the Management of Cacao Pod Waste in Colombia, a Case Study. Agronomy. 2021; 11(4):693. https://doi.org/10.3390/agronomy11040693

Chicago/Turabian StyleMeza-Sepúlveda, Diana C., Ana M. Castro, Annie Zamora, Jorge W. Arboleda, Adriana M. Gallego, and Anyela V. Camargo-Rodríguez. 2021. "Bio-Based Value Chains Potential in the Management of Cacao Pod Waste in Colombia, a Case Study" Agronomy 11, no. 4: 693. https://doi.org/10.3390/agronomy11040693

APA StyleMeza-Sepúlveda, D. C., Castro, A. M., Zamora, A., Arboleda, J. W., Gallego, A. M., & Camargo-Rodríguez, A. V. (2021). Bio-Based Value Chains Potential in the Management of Cacao Pod Waste in Colombia, a Case Study. Agronomy, 11(4), 693. https://doi.org/10.3390/agronomy11040693