Abstract

Table grape is a non-climacteric fruit, very sensitive to water loss and gray mold during postharvest handling and storage. The aim of this work was to evaluate the effects of modified atmosphere packaging and chitosan treatment on quality and sensorial parameters of minimally processed cv. ‘Italia’ table grape during cold storage (14 days at 5 °C) and shelf-life (7 and 14 days of cold storage plus 5 days at 20 °C), reproducing a retail sales condition. Our data showed a significant effect of high CO2-modified atmosphere in combination with chitosan and alone on preserving quality, sensorial parameters, and delaying decay of minimally processed table grape. The most effective treatment in terms of preservation of quality, sensory, and nutritional quality was high-CO2 modified atmosphere packaging plus chitosan treatment. The overall results showed that when a proper modified atmosphere packaging is combined with a postharvest chitosan treatment, gray mold growth can effectively be controlled in ready-to-eat cv. ‘Italia’ table grape and that modified atmosphere packaging (MAP) with high levels of CO2 and reduced concentration of O2 in combination with chitosan treatment could prevent the negative effect of high-CO2 in-packages level, like berry browning and rachis browning and dehydration.

1. Introduction

In the last decade, consumer and market demand for ready-to-eat fruits and vegetables considerably increased due to product added value and fast consumption. One of the major challenges facing this agro-industrial sector is maintaining and preserving the quality of minimally processed produce. Indeed, peeling and cutting cause physiological aging due to an overall increase in cellular metabolism [1,2].

Table grape (Vitis vinifera L.) is a non-climacteric fruit with a low rate of physiological activity, very sensitive to water loss and decay during postharvest handling, cold storage, and marketing [3,4]. Grapes are not susceptible to injury at low temperatures, indeed, storage around 0 °C is recommended for mature table grapes during postharvest storage [5]. Nevertheless, the storage life of grapes at low temperatures is affected by their high susceptibility to fungal decay and water loss after harvest, which may result in rachis and pedicel drying and browning, and even shriveling of berries [5]. For that reason, table grapes’ postharvest life is limited and depends on several internal factors such as the structure and consistency of the skin and pulp and the ripening stage, as well as external factors, with temperature and relative humidity being the most important [6].

Gray mold (Botrytis cinerea) is the most aggressive postharvest disease because of its ability to develop at low temperatures. Fungal spores are generally present on fruits surface, and, during post-harvest handling, the berries can supply a suitable environment for spore germination (primarily the damaged ones); moreover, the infection can occur during storage, marketing, and even after customer purchase [7]. To reduce the damage, it is standard practice to fumigate with sulfur dioxide (SO2) immediately after packaging but at the same time the necessary concentration could induce berry and rachis decay and sulfite residue is an important consumer problem, as well as a warning to the consumer about the chemical issue [3,4].

Quality losses that affect consumer acceptance [8] are principally due to weight loss, color changes, berry softening and cracking, rachis browning, insect damage, and berry decay, mainly due to gray mold disease [3].

To maintain table grape postharvest quality, many strategies and technologies have been developed, such as controlled atmosphere (CA), cold storage with high CO2 percentage (15–25%), hot water and ethanol treatments [9,10,11,12], and hypobaric treatments [13], although these treatments may cause injuries like rachis browning and off-flavors. An important aspect to be taken into great account for maintaining the quality of table grape during cold storage and marketing is the choice of the appropriate internal atmosphere and packaging system [8].

Modified atmosphere packaging (MAP) is one of the most effective technologies that control the internal atmosphere, taking into account the natural process of respiration of fruit and the gas permeability of the package [14], used for water loss prevention, reducing metabolic activity, delaying of browning, color retention, reducing respiration rate, lowering microbial populations, and reduced chilling injury symptoms of the horticultural commodities [15]. The effects of the use of MAP in several fruits are reported for strawberries [16,17] and melons [18]. Moreover, the use of MAP has proved useful to maintain fruit firmness by reducing or inhibiting the activities of enzymes responsible for degrading pectic polysaccharides [19]. MAP technology is based on the conjunction of an increase of CO2 and a reduction of O2 percentage; the steady-state maintains the desired atmosphere until the retail display, but low temperature is needed to avoid undesirable high CO2 and low O2 levels [14]. The principal limitation for using a low concentration of O2 (<2%) is the induction of fermentation with the diversion of carbon in glycolysis to acetaldehyde, ethanol, and lactate and the possibility of off-flavor generation [20].

Several authors report that the use of MAP and high CO2-MAP maintained table grape berry quality [2,4,8,14,21], but the CO2 concentration inside packages is usually not high enough to prevent a fungal attack and the problem of the use of SO2 still remains.

New strategies, such as the use of ethanol [22], natural antimicrobial compounds [3], pulsated ultraviolet, ozone, and chitosan [23,24] could avoid the use of SO2 fumigation to prevent a fungal attack during postharvest [2].

Chitosan is a natural biopolymer with antifungal and eliciting properties and is considered an ideal coating to control fresh-fruit decay due to its biocompatibility, biodegradability, and bioactivity properties [25]. Reglinski et al. [26], reported that chitosan enhances resistance against many fungal diseases (in pre- or postharvest treatment); furthermore, has been shown that chitosan affects the germination and growth of several phytopathogenic fungi, including B. cinerea [27]. Moreover, several researchers reported that a pre- or postharvest chitosan treatment or coating has the potential to inhibit decay, prolong the storage life of a variety of products such as citrus fruit, and decrease gray mold incidence in cv. ‘Italia’ table grape [28,29]). Inhibitory effects of chitosan treatments on fungus growth and decay have been reported in litchi fruit, banana, papaya, strawberry, raspberry, peach, Japanese pear, and kiwi fruit [30,31,32,33,34]. Shiri et al. [24] reported that chitosan treatment (0.5 or 1%) decreased weight loss, decay, shattering, and cracking of cv. ‘Shahroudi’ grape during cold storage (60 days); this treatment also delayed total phenols and antioxidant capacity decrease of berry extract [25].

The aim of this work was to select the proper modified atmosphere composition and to evaluate the effects of modified atmosphere packaging and chitosan treatment on quality and sensorial parameters of minimally processed cv. ‘Italia’ table grape during cold storage and shelf-life. Minimally processed table grape quality traits were evaluated after a cold storage period (14 days at 5 °C 90% Relative Humidity) followed by a period at ambient temperature in air (shelf-life), reproducing a retail sales condition.

2. Materials and Methods

2.1. Plant Material

White table grape cv. ‘Italia’ (Vitis Vinifera L.) clusters were harvested from a 10-year-old commercial vineyard, located in Central Sicily (Naro: 37°18′25.0″ N 13°52′11.0″ E) in the District called “Uva da tavola di Canicattì PGI” (Reg. CE 2325.1997). Vines were grafted onto Ru 140 (V. berlandieri × V. rupestris) spaced 2.5 m × 2.5 m apart (1600 plants/ha) and trained to a “tendone” system, covered with white net and plastic film (LDPE, thickness 170 μm). The orchard received ordinary horticultural care in terms of fertilization, irrigation, and soil management. ‘Italia’ table grape was hand-picked during the third week of September at a commercially ripe stage (≥15.0 °Brix), suitable for the fresh fruit market.

2.2. Sample Preparation and Packaging

After harvest, ‘Italia’ bunches were immediately transported to the laboratory and selected on the basis of uniform size, color, firmness, lack of diseases, and greenish rachises. Each bunch was then cut with sanitized scissors to obtain samples of approximately 200 g of fresh-cut clusters. After selection, 200 g clusters samples were dipped in a sodium hypochlorite solution (150 ppm active chlorine) for 5 min to control microbial spoilage.

At the end of sodium hypochlorite treatment, low molecular weight chitosan (Sigma Chemicals, St. Louis, MO, USA) solution (1%, w/v) was prepared by dissolving chitosan in 0.5% (v/v) concentrated acetic acid under continuous stirring (until the chitosan was dissolved). The pH of the solution was adjusted to 5.2 using 1 N NaOH, and the solution was then autoclaved at 121 °C for 20 min. Samples of 200 g clusters were dipped in the solutions for 1 min and then left for 2 h at room temperature to be dried. Non-treated samples were dipped in the solution at pH 5.2 containing no chitosan [24].

Each 200 g cluster samples (treated with chitosan and non-treated) were then packaged in a 15 × 15 × 8 cm rigid non-perforated polypropylene retail punnets sealed with a non-perforated high-density polyethylene film (permeability at 25 °C for O2: 166 × 106 cm3 μm/m2-h-atm and for CO2: 92 × 106 cm3 μm/m2-h-atm).

The modified atmosphere in packages sealed with the non-perforated high-density polyethylene film was achieved passively (MAP, control), while the initial atmosphere in punnets sealed with the continuous high-density polyethylene films was actively modified using a Supervac GK105/1 packaging machine (Orved, Musile di Piave, Italy): 10 kPa CO2 and 20 kPa O2. The sealed punnets were then stored at 5 °C and 90% RH for 14 days.

Table grapes samples (5 punnets × 3 treatments × 3 storage periods + 30 punnets) were evaluated for quality during storage at 5 °C on days 0, 7, and 14. At the end of the first and the second week of storage at 5 °C, a set of samples (5 punnets × 3 treatments × 3 storage periods + 90 punnets for each shelf-life) was moved to 20 °C for 5 days to simulate shelf-life conditions (retail condition), samples were then evaluated for quality after 0, 3, and 5 days.

At the end of each shelf-life, a set of samples (3 punnets × 3 treatments × 10 judges) was evaluated by sensory analysis judges.

Treatments legend:

- -

- MPA: modified passive atmosphere (air), used as control.

- -

- MAP10 C: modified active atmosphere (10 kPa CO2 and 20 kPa O2) plus Chitosan.

- -

- MAP10: modified active atmosphere (10 kPa CO2 and 20 kPa O2).

2.3. Headspace Gas Composition

In-packages, O2 and CO2 partial pressure were measured immediately before quality evaluation, using an O2 and CO2 portable analyzer (Dansensor Checkpoint, Mocon, Minneapolis, MN, USA) after 0, 7, and 14 days at 5 °C and at 0, 3, and 5 days during the shelf-life at 20 °C using 15 packages for each treatment.

2.4. Quality Parameters: Weight Loss, Total Soluble Solids, Titratable Acidity, Decay, Browning, and Berry Abscission

For each treatment, a sample of randomly chosen packages was used. Berry analysis included: weight loss, total soluble solids content (TSS), juice pH and titratable acidity (TA), berry decay incidence, and browning severity. Total soluble solids content (TSS) was determined by a digital refractometer (Palette PR-32, Atago Co., Ltd, Tokyo, Japan); titratable acidity (TA) was measured by titration of 10 mL homogenized berry flesh juice with 0.1 N NaOH to an endpoint of pH 8.1 and expressed as the percentage of tartaric acid (mod. S compact titrator, Crison Instruments, Barcelona, Spain). Berry weight loss was calculated on 10 sealed packages for each treatment (10 punnets × 3 treatments) and expressed as the percentage reduction with respect to the initial time. Percentages of decay and browning were calculated separately after 7 and 14 days of storage at 5 °C and after 5 days of each shelf-life at 20 °C, by counting the number of rot berries then decay incidence was calculated as the percentage of rotten berries. Flesh browning was assessed by measuring the extent of browned area on each fruit on the following scale: 0 = no browning; 1 = less than 1/4 browning; 2 = 1/4–1/2 browning; 3 = 1/2–3/4 browning; 4 = more than 3/4 browning. The browning index (BI) was calculated using the following formula: [(1·N1 +2·N2 +3·N3 +4·N4) × 100/(4 × N)], where N = total number of fruits measured and N1, N2, N3, and N4 were the number of fruits showing the different degrees of browning [4]. Berry abscission was calculated after 7 and 14 days of storage at 5 °C and after 5 days of each shelf-life at 20 °C, by counting the number of abscissed berries on 250 g cluster and then expressed as a percentage of abscissed berries [24].

2.5. Sensory Evaluation and Rachis Score

After 7 and 14 days of cold storage plus 5 days at 20 °C (shelf-life), for each treatment, 3 sealed packages for each treatment (5 berries for punnets) were evaluated by each judge. The sensory profile was constructed by 10 judges trained panel in a few preliminary meetings: by using commercial grape, the judges generated a list of descriptors. Sensory analysis was focused on firmness, crunchiness, juiciness, sweetness, sourness, off-flavor, off-odor, and visual appearance of the berries [3,4]. The different descriptors were quantified using a ten-point intensity scale where the digit 1 indicates the descriptor absence while the digit 10 the full intensity [4]. The order of presentation was randomized between judges. Water was provided for rinsing between samples.

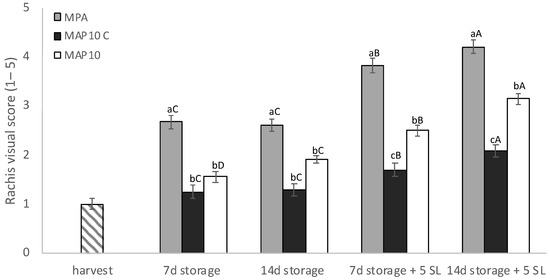

After 7 and 14 days of storage at 5 °C and after 5 days of each shelf-life at 20 °C, 3 sealed packages for each treatment were evaluated by each judge. Rachis visual quality was evaluated to quantify symptoms of dehydration and browning for primary and secondary branches on a ranked scale of 1 to 5, where 1 = absence of these symptoms, 2 = slight occurrence, 3 = moderate, 4 = severe, and 5 = extremely severe browning and dehydration [35]. A score of 3 was considered to be the limit of marketability. The order of presentation was randomized between judges.

2.6. Microbiological Analysis

After 7 and 14 days of cold storage plus 5 days of shelf-life, microbiological analyses were carried out. Samples of 25 g (5 berries) from each sealed box and for each treatment (3 punnets × 3 treatments) were obtained under sterilized conditions (laminar fume cupboard and gloves), which were homogenized in 225 mL of sterile distilled water and shaken for 30 min at 200 rpm on a rotary shaker. Serial dilutions were carried out, and 1 mL was added to plate count agar for mesophilic aerobic and for mold and yeast counts (Petrifilm Aerobic Count Plate, Laboratories 3M Santé, Cergy-Pontoise, France) [4]. Samples were prepared in triplicate, and only counts of 30–300 colony forming units (CFU) were considered. All plates were incubated for 3 days at 30 °C and 5 days at 25 °C for mesophilic aerobic and yeast and mold, respectively [35].

2.7. Statistical Analysis

Data were submitted to one-way analysis of variance (ANOVA) and means were separated with Tukey’s test at p ≤ 0.05. The statistical analysis was carried out using Systat 10 (Systat, Chicago, IL, USA).

3. Results

3.1. Headspace Gas Composition

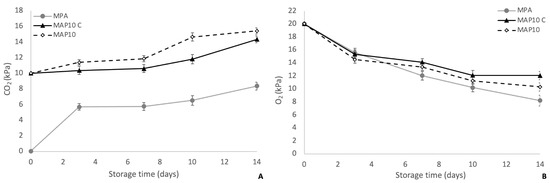

During cold storage, a decrease in O2 and an increase in CO2 in-packages levels were observed for all the modified atmosphere packaging (MPA, MAP10, and MAP10 C), MPA table grape samples showed a significantly higher level of CO2 than MAP10 and MAP10 C (Figure 1A,B), reaching a steady-state after 2 days of cold storage at 5 °C (Figure 1A). MAP10 and MAP10 C did not show any significant differences in terms of O2 and CO2 in-packages levels during cold storage (Figure 1A,B). After 14 days of cold storage, the O2/CO2 in-packages concentration (kPa) in MPA, MAP10, and MAP10 C was about 8/8, 10/15, and 12/14, respectively (Figure 1A,B).

Figure 1.

Concentrations of CO2 (A) and O2 (B) in packages of ready-to-eat table grape (cv. ‘Italia’) sealed in continuous polyethylene film under passive (modified passive atmosphere (MPA)) and active modified atmosphere treated with chitosan (MAP10 C) and non-treated (MAP10) during cold storage (14 days at 5 °C). Data are the mean ± SE (bars represent standard error of the means - SE, n = 15).

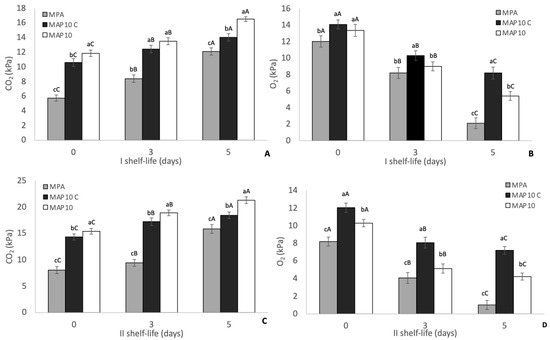

Furthermore, during the first and the second shelf-life, a decrease in O2 and an increase in CO2 in-packages levels were detected for all the modified atmosphere packaging (MPA, MAP10, and MAP10 C) (Figure 2A–D).

Figure 2.

Concentrations of CO2 (A,C) and O2 (B,D) in packages of ready-to-eat table grape (cv. ‘Italia’) sealed in continuous polyethylene film under passive (MPA) and active modified atmosphere treated with chitosan (MAP10 C) and non-treated (MAP10) during the first (A,B: 7 days at 5 °C plus 5 days at 20 °C) and second shelf-life (C,D: 14 days at 5 °C plus 5 days at 20 °C). Different capital letters indicate significant differences (Tukey’s test at p ≤ 0.05) of the same treatment within the sampling dates. Different lowercase letters indicate differences (Tukey’s test at p ≤ 0.05) between the treatments in each sampling date. Vertical bars represent standard error (n = 15).

CO2 in-packages levels almost doubled in MPA table grape samples at end of the first and second shelf-life (Figure 2A,C), while O2 in-packages levels were six and eight times lower, respectively, from the beginning to the end of the first and second shelf-life (Figure 2B,D). MPA10 CO2 in-packages levels were 1.4 times higher at the end of the first and second shelf-life (Figure 2A,C), while O2 in-packages levels decreased 2.4 times from the beginning to the end of the first and second shelf-life (Figure 2B,D). MAP10 C CO2 in-packages levels showed a similar behavior compared to MAP10 ones (1.3 times higher at the end of the first and second shelf-life) (Figure 2A,C), while O2 in-packages levels decreased, respectively, 1.7 and 1.6 times at the end of the first and second shelf-life, showing significantly lower values compared to MAP10 ones (Figure 2B,D).

After the first shelf-life, the O2/CO2 in-packages concentration (kPa) in MPA, MAP10, and MAP10 C was about 2/12, 5/16, and 8/14, respectively, and after the second shelf-life the O2/CO2 in-packages concentration (kPa) in MPA, MAP10, and MAP10 C was about 1/16, 4/21, and 7/18, respectively (Figure 2A–D).

3.2. Quality Parameters: Weight Loss, Total Soluble Solids, Titratable Acidity, Decay, Browning, and Berry Abscission

High-CO2 modified atmosphere packaging in combination with chitosan treatment (MAP10 C) and high-CO2 modified atmosphere packaging (MPA10) significantly decreased weight loss percentage during cold storage (7 and 14 days at 5 °C) and during the first (7 days at 5 °C plus 5 days at 20 °C) and the second shelf-life (14 days at 5 °C plus 5 days at 20 °C) compared to the modified passive atmosphere (air), used as control (MPA) (Table 1). High-CO2 modified atmosphere packaging in combination with chitosan treatment (MAP10 C) was the most effective treatment during cold storage and shelf-life, indeed, minimally process table grape sealed in the modified passive atmosphere (air) showed a weight loss almost 6, 3.5, 4, and 3 times higher after the two cold storage periods (7 and 14 days at 5 °C) and after the two shelf-life (7 and 14 days at 5 °C plus 5 days at 20 °C), respectively, than MAP10 C (Table 1). MPA weight loss was significantly higher than MAP10 in all the cold storage and shelf-life periods; the higher weight loss was measured in MPA samples at end of the second shelf-life, with values 3 and 2 times higher than MAP10 C and MAP10, respectively (Table 1). Total solid soluble (TSS) content was not affected by the modified atmosphere packaging after 7 days of cold storage at 5 °C, indeed, no significant differences were found (Table 1). After 14 days of cold storage at 5 °C and after the second shelf-life, MAP10 C was the most effective treatment in terms of TSS retention (Table 1). MPA table grape samples showed the lowest TSS content in all the cold storage and shelf-life periods, showing significantly lower values compared to MAP10, and MAP10C after 14 days of cold storage and after the first and the second shelf-life (Table 1). Particularly, MPA table grape samples showed TSS values of 11%, 10%, and 19% lower than harvest, respectively, after 14 days of cold storage and after the first and second shelf-life (Table 1). Instead, MAP10 and MAP10C table grape samples showed TSS values of 6%, 2%, 8%, and 2%, 1%, and 4%, respectively, lower than harvest after 14 days of cold storage and after the first and the second shelf-life (Table 1).

Table 1.

Changes in weight loss, total soluble solids (TSS), titratable acidity (TA), decay, browning, and berry abscission in ready-to-eat table grape (cv. ‘Italia’) sealed in continuous polyethylene film under passive (MPA) and active modified atmosphere treated with chitosan (MAP10 C) and non-treated (MAP10) during cold storage (7 and 14 days at 5 °C) and at the end of the first (7 days at 5 °C plus 5 days at 20 °C) and the second shelf-life (14 days at 5 °C plus 5 days at 20 °C). Different lowercase letters indicate differences, ns = not significant (Tukey’s test at p ≤ 0.05) between the treatments in each sampling date. Data are the mean ± SE (n = 15).

Titratable acidity (TA) was not affected by the modified atmosphere packaging during cold storage (7 and 14 days at 5 °C) and shelf-life (7 and 14 days at 5 °C plus 5 days at 20 °C); as a matter of fact, no significant differences were found between the treatments (Table 1). Anyway, MAP10 and MAP10C table grape samples showed higher values than MPA after the first and the second shelf-life (Table 1). In terms of TA retention, no significant differences were found between MAP10 and MAP10 C after the cold storage and the two shelf-life (Table 1).

Decay, browning, and berry abscission were affected by MAP10 and MAP10 C, which showed significantly lower values after cold storage and shelf-life (Table 1). In MPA table grape samples, decay and browning incidence were more than two times higher than MAP10 and MAP10C ones during cold storage; in MPA samples, decay incidence increased when table grape samples were moved to 20 °C, becoming almost four and five times higher than MAP10 and MAP10 C, respectively, after the first and the second shelf-life (Table 1). Browning incidence showed a similar trend also in MPA table grape samples during the two shelf-life (Table 1). MPA berry abscission incidence showed values almost two, four, six, and eight times higher, respectively, after 7 and 14 days of cold storage and the two shelf-life than MAP10 and MAP10 C (Table 1).

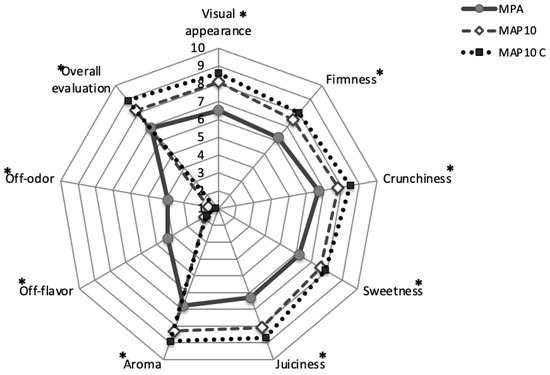

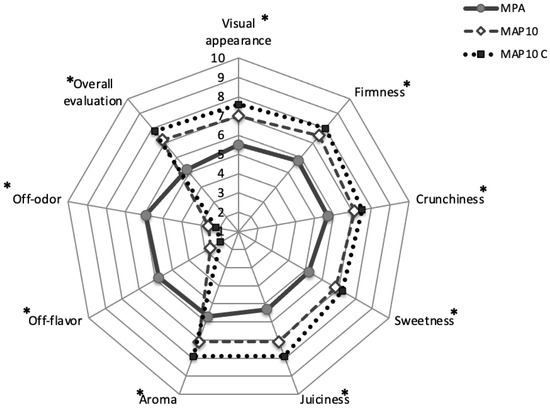

3.3. Sensory Evaluation and Rachis Score

Minimally processed table grape sensory profiles were affected positively by the High-CO2 MAP and by the chitosan treatment in combination with high-CO2 MAP. Indeed, panelists gave the highest scores to all the descriptors of MAP10 and MAP10C samples than MPA ones in both shelf-life (Figure 3 and Figure 4).

Figure 3.

Sensorial analysis of ready-to-eat table grape (cv. ‘Italia’) sealed in continuous polyethylene film under passive (MPA) and active modified atmosphere treated with chitosan (MAP10 C) and non-treated (MAP10) evaluated at end of the first shelf-life (7 days at 5 °C plus 5 days at 20 °C). * indicate differences (Tukey’s test at p ≤ 0.05) between the MPA and MAP treatments (n = 30).

Figure 4.

Sensorial analysis of ready-to-eat table grape (cv. ‘Italia’) sealed in continuous polyethylene film under passive (MPA) and active modified atmosphere treated with chitosan (MAP10 C) and non-treated (MAP10) evaluated at end of the second shelf-life (14 days at 5 °C plus 5 days at 20 °C). * indicate differences (Tukey’s test at p ≤ 0.05) between the MPA and MAP treatments (n = 30).

MAP10 C was the most effective treatment in terms of sensorial parameters in both the sampling date, showing mean scores of 0.5 higher than MAP10 samples in each descriptor after the first and the second shelf-life (Figure 3 and Figure 4). MPA samples showed the lowest scores in all the descriptors in each sampling date (Figure 3 and Figure 4). Panelists perceived off-flavor (fermented) and off-odor in MPA samples after the first and the second shelf-life, while the perception of those descriptors was almost absent in MPA10 and MAP10 C samples in each sampling date (Figure 3 and Figure 4).

Panelists gave the best evaluation scores also to the rachis of MAP10 and MAP10 C samples scores in each sampling date compared to the MPA ones (Figure 5). MPA rachis samples showed moderate and severe browning and dehydration, respectively, after the first and second shelf-life, while MAP10 samples showed moderate browning and dehydration only after the second shelf-life and MAP10 C rachis samples showed only a slight occurrence of browning and dehydration until the end of the second shelf-life (Figure 5).

Figure 5.

Effect of packaging treatments on rachis visual quality of ready-to-eat table grape (cv. ‘Italia’) sealed in continuous polyethylene film under passive (MPA) and active modified atmosphere treated with chitosan (MAP10 C) and non-treated (MAP10) evaluated during cold storage (14 days at 5 °C) and after the first (7 days at 5 °C plus 5 days at 20 °C) and the second shelf-life (14 days at 5 °C plus 5 days at 20 °C) (SL). Visual rachis score: 1 = absence of these symptoms, 2 = slight occurrence, 3 = moderate, 4 = severe, and 5 = extremely severe browning and dehydration. Different capital letters indicate significant differences (Tukey’s test at p ≤ 0.05) of the same treatment within the sampling dates. Different lowercase letters indicate differences (Tukey’s test at p ≤ 0.05) between the treatments in each sampling date. Vertical bars represent standard error (n = 15).

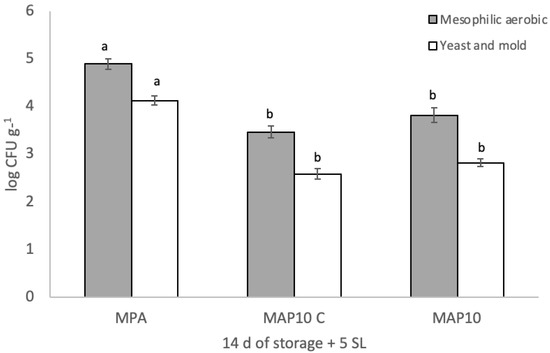

3.4. Microbiological Analysis

Mesophilic aerobic and yeast and mold counts in MAP10 and MAP10 C minimally processed table grape were significantly lower than MPA ones after the first (data not shown) and second shelf-life (Figure 6). No significant differences were found between the treatments, which were both effective in terms of control of mesophilic aerobic and yeast and mold development (Figure 6).

Figure 6.

Mesophilic aerobic and yeast and mold counts in ready-to-eat table grape (cv. ‘Italia’) sealed in continuous polyethylene film under passive (MPA) and active modified atmosphere treated with chitosan (MAP10 C) and non-treated (MAP10) evaluated after the second shelf-life (14 days at 5 °C plus 5 days at 20 °C) (SL). Different lowercase letters indicate differences (Tukey’s test at p ≤ 0.05) between the treatments. Vertical bars represent standard error (n = 15).

4. Discussion

Table grape is a non-climacteric fruit with a very low respiration rate but is characterized by several physicochemical, biochemical, and microbiological changes during storage that affect its shelf-life. Weight loss, stem browning, and, above all, gray mold are the main causes that reduce table grape marketability. Sulfur dioxide is still the most popular treatment used to control gray mold [36], but its application is not recommended on minimally processed table grape that will be consumed within a few days from packaging [4]. For that reason, several efforts are being made worldwide to find alternative technologies to replace sulfur dioxide in ready-to-eat table grape, as well as, passive and active modified atmosphere, avoiding the use of chemicals [25,35,37]. In cv. ‘Italia’, no remarkable differences were found in terms of appearance and marketable quality due to film packaging, while a significant reduction of decay after 7 days at 0 °C followed by 4 days at 8 °C plus 2 days at 20 °C was found in cv. ‘Superior seedless’ table grape sealed in a micro-perforated polypropylene [38].

In the last decade, there is a growing worldwide interest in the use of natural compounds instead of synthetic chemicals for controlling decay and improving grape quality during cold storage and shelf-life [25], but there is still a lack of data regarding the natural product application in combination with active and passive modified atmosphere on ready-to-eat table grape products [39]. For that reason, the aim of our study was to evaluate the effect of High-CO2 modified atmosphere alone and in combination with chitosan on quality and sensorial parameters of minimally processed cv. ‘Italia’ table grape during cold storage and shelf-life to understand which technology is the most effective for ready-to-eat table grape quality and consumer acceptance.

Our study showed that high-CO2 modified atmosphere in combination with chitosan postharvest treatment (MAP10 C) was the most effective treatment on quality of minimally processed table grape after storage and shelf-life compared to the other treatments (modified passive atmosphere-MPA and High-CO2 modified atmosphere-MAP10).

During the first 3 days of cold storage, O2 and CO2 in-packages concentration changed significantly in all the treatments, probably due to the table grape aerobic metabolism; later, values remained almost stable until the 7th day of cold storage, after that, an increase in CO2 and a decrease in O2 was measured due to the enhancement of respiration activity. In any case, during cold storage, MPA table grape samples showed the highest CO2 in-packages concentration increase (from 0 to 8%) compared to MAP10 and MAP10 C (Figure 1) due to the well-known inhibitory effect of High-CO2 on table grape respiration rate, as reported by several studies [18,36]. Even during the first and the second shelf-life, in-packages gas composition significantly changed. Indeed, a decrease in O2 and an increase in CO2 in-packages levels were detected in all the treatments. MPA samples showed the same behavior of cold storage, showing the highest CO2 in-packages concentration increase during the first (from 5 to 12 kPa) and second shelf-life (from 8 to 16 kPa) compared with MAP10 (first shelf-life from 12 to 16 kPa; second shelf-life from 15 to 21 kPa) and MAP10 C (first shelf-life from 11 to 16 kPa; second shelf-life from 14 to 18 kPa) (Figure 2). MPA samples showed the same behavior of cold storage, showing the highest CO2 in-packages concentration increase during the first (from 5 to 12 kPa) and second shelf-life (from 8 to 16 kPa) compared with MAP10 (first shelf-life from 12 to 16 kPa; second shelf-life from 15 to 21 kPa) and MAP10 C (first shelf-life from 11 to 16 kPa; second shelf-life from 14 to 18 kPa) (Figure 2). MPA samples showed even the lowest O2 in-packages concentration for the first (4 kPa) and second shelf-life (2 kPa) compared with MAP10 (first shelf-life: 5 kPa; second shelf-life: 3 kPa) and MAP10 C (first shelf-life: 8 kPa; second shelf-life: 7 kPa) (Figure 2). During shelf-life, the high-CO2 modified atmosphere in combination with chitosan was the most effective treatment in terms of respiration rate control, showing that chitosan is more efficient at air temperature conditions (20 °C).

MAP10 C significantly reduced weight loss during cold storage and shelf-life as its chitosan coating enabled epidermal tissues to control water loss and reduce respiratory exchange, indeed, fruit weight loss is strictly related to respiration and transpiration, our data are in line with those reported by Shiri et al. (2013) [24] on cv. Shahrudi table grape during storage. MPA table grape samples showed weight loss values 3 and 2 times, respectively, higher than MAP10 C and MAP10 at end of the second shelf-life, confirming the positive effect of High-CO2 modified atmosphere alone and in combination with chitosan on table grape quality (Table 1).

Total soluble solids content decreased over time during cold storage and shelf-life in all the table grape samples and no significant differences were found between the treatments until 7 days of cold storage. The high-CO2 modified atmosphere alone and in combination with chitosan became effective only after 14 days of cold storage and after the two shelf-life compared to the control MPA, probably due to a fermentative metabolism that replaced aerobic respiration in MPA table grape samples after 14 days of cold storage and after the two shelf-life (Table 1), as reported in a previous study [4]. Titratable acidity was not affected by the treatments or the storage time (Table 1), most likely the principal available substrates were sugars and not organic acids, according to previous research work [21].

MAP10 and MAP10 C showed the lowest percentage of decay, browning, and berry abscission and the highest rachis visual score, compared to MPA during all the sampling dates (cold storage and shelf-life), no differences between the two high-CO2 treatment (with and without chitosan) were measured in terms of berry decay and berry abscission during cold storage and the two shelf-life (Table 1); those results confirm the positive effect of high-CO2 MAP in decay control as previously reported by several authors [3,21]. Instead, MAP10 C was more effective in terms of browning control in berry, dehydration, and browning control of rachis than MAP10, such effect suggests that chitosan solution could be an antioxidant and anti-browning agent (Table 1), as reported by Romanazzi et al. [40] in strawberry, and it is useful to prevent the negative effects caused by high-CO2 in-package concentration, like rachis browning.

The positive effect of chitosan treatment on minimally processed table grape is due also to its fungicidal and/or fungistatic and eliciting properties as reported in previous studies [25,33,41].

MAP10 and MAP10 C table grape samples were preferred by the panelist in all the descriptors that gave scores much higher than 8 and 7 to overall quality and visual appearance, respectively, after the first and the second shelf-life, while MPA table grape samples get scores higher than 6 in overall quality and visual appearance, respectively, after the first and the second shelf-life (Figure 3 and Figure 4), accordingly with the previous study based on high-CO2 MAP and coating application on table grape [18,32]. It is important to point out that none of the panelists could discern any “off-odor” or “off-flavor” in MAP10 and MAP10 C table grape samples, contrary to what was reported on MPA table grape samples, where panelists found “off flavor” and “off-odor” in both shelf-life, probably due to the low O2 in-packages level (Figure 3 and Figure 4).

Mesophilic microorganisms represent one of the most important indicators of food quality and their level is extensively used to assess microbiological quality and safety of ready-to-eat produce. It expresses the adequacy of temperature and sanitation control during processing, transport, and storage, and reveals potential sources of contamination during the production chain [41]. Our results showed an overall lower population both of mesophilic aerobic microorganisms and of yeast and mold in MAP10 and MAP10C packages. In this case, chitosan treatment did not improve the antimicrobial effect of high-CO2 MAP, but even in MPA table grape samples, the overall microorganism population never exceeded 105 CFU g−1 during the two shelf-life (Figure 6) and was similar to the load detected in other studies [3,4], with values below the safe quality limits established in Europe, which suggest the range of 105–108 CFU g−1 [41].

5. Conclusions

The aim of our study was to assess the effects of modified atmosphere packaging and chitosan treatment on quality and sensorial parameters of minimally processed cv. ‘Italia’ table grape during cold storage and shelf-life.

Our data showed a significant effect of a high CO2-modified atmosphere in combination with chitosan and alone on preserving quality, sensorial parameters, and delaying decay of minimally processed table grape. The most effective treatment in terms of preservation of quality, sensory, and nutritional quality was high-CO2 MAP plus chitosan treatment. MAP10 C was able to ensure a suitable atmosphere composition during the whole cold storage period and shelf-life; the CO2 and O2 in-package levels after 14 days of cold storage plus 5 days of shelf-life were found to be about 18 kPa and 7 kPa, respectively. The CO2 in-package concentrations were enough to decay control and the O2 in-package concentration was sufficiently far from the anaerobic condition. The MPA low O2 in-package levels (2 kPa) after 14 days of cold storage plus 5 days of shelf-life may induce fermentative processes on berries that probably influenced the panelists that found “off-odor” and “off-flavor” on those table grape samples.

The overall results showed that when a proper modified atmosphere packaging is combined with a postharvest chitosan treatment, gray mold growth can effectively be controlled in ready-to-eat cv. ‘Italia’ table grape and that MAP with high levels of CO2 and reduced concentration of O2 in combination with chitosan treatment could prevent the negative effect of high-CO2 in-packages level, like berry browning and rachis browning and dehydration. Furthermore, the addition of postharvest chitosan treatment to high-CO2 MAP creates a natural film on rachis and berries surface, protecting the fruit against pathogen infection, reducing respiration rate, and decreasing decay.

Further research should be aimed to find the most popular table grape cultivar and the proper high-CO2 MAP concentration in combination with chitosan able to guarantee sensory and nutritional quality during cold and shelf-life of ready-to-eat products. Furthermore, future studies should be focused on the development of spraying technology to apply commercially chitosan during postharvest storage, because its molecular weight, structure, application concentration, and solvent may affect its antifungal ability on pathogenicity of pathogens and its exogenous elicitor activity on fruits.

Author Contributions

Conceptualization, G.L.; methodology, G.L.; software, G.L. and G.S.; validation, G.L., G.S. and G.G.; formal analysis, G.L. and G.S.; investigation, G.L. and G.S.; resources, P.I.; data curation, G.L., G.S. and G.G.; writing—original draft preparation, G.L. and P.I.; writing—review and editing, G.L., G.S. and P.I.; supervision, P.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rolle, R.S.; Chism, G.W. Physiological consequences of minimally processed fruits and vegetables. J. Food Qual. 1987, 10, 157–177. [Google Scholar] [CrossRef]

- Sabir, A.; Sabir, F.K.; Kara, Z. Effects of modified atmosphere packing and honey dip treatments on quality maintenance of minimally processed grape cv. Razaki (V. vinifera L.) during cold storage. J. Food Sci. Technol. 2011, 48, 312–318. [Google Scholar] [PubMed]

- Valero, D.; Valverde, J.M.; Martínez-Romero, D.; Guillén, F.; Castillo, S.; Serrano, M. The combination of modified atmosphere packaging with eugenol or thymol to maintain quality, safety and functional properties of table grapes. Postharvest Biol. Technol. 2006, 41, 317–327. [Google Scholar] [CrossRef]

- Liguori, G.; D’Aquino, S.; Sortino, G.; De Pasquale, C.; Inglese, P. Effects of passive and active modified atmosphere packaging conditions on quality parameters of minimally processed table grapes during cold storage. J. Berry Res. 2015, 5, 131–143. [Google Scholar] [CrossRef]

- Rosales, R.; Romero, I.; Fernandez-Caballero, C.; Escribano, M.I.; Merodio, C.; Sanchez-Ballesta, M.T. Low Temperature and Short-Term High-CO2 Treatment in Postharvest Storage of Table Grapes at Two Maturity Stages: Effects on Transcriptome Profiling. Front. Plant Sci. 2016, 7, 1020. [Google Scholar] [CrossRef]

- Romero, I.; Vazquez-Hernandez, M.; Maestro-Gaitan, I.; Escribano, M.I.; Merodio, C.; Sanchez-Ballesta, M.T. Table Grapes during Postharvest Storage: A Review of the Mechanisms Implicated in the Beneficial Effects of Treatments Applied for Quality Retention. Int. J. Mol. Sci. 2020, 21, 9320. [Google Scholar] [CrossRef]

- De Simone, N.; Pace, B.; Grieco, F.; Chimienti, M.; Tyibilika, V.; Santoro, V.; Capozzi, V.; Colelli, G.; Spano, G.; Russo, P. Botrytis cinerea and Table Grapes: A Review of the Main Physical, Chemical, and Bio-Based Control Treatments in Post-Harvest. Foods 2020, 9, 1138. [Google Scholar] [CrossRef]

- Costa, C.; Lucera, A.; Conte, A.; Mastromatteo, M.; Speranza, B.; Antonacci, A.; Del Nobile, M.A. Effects of passive and active modified atmosphere packaging conditions on ready-to-eat table grape. J. Food Eng. 2011, 102, 115–121. [Google Scholar] [CrossRef]

- Crisosto, C.H.; Mitchell, F.G. Postharvest handling systems: Table grapes. In Postharvest Technology of Horticultural Crops; Kader, A.A., Ed.; University of California: Berkeley, CA, USA, 2002; pp. 357–363. [Google Scholar]

- Crisosto, C.H.; Garner, D.; Crisosto, G. High carbon dioxide atmospheres affect stored ‘Thompson seedless’ table grapes. HortScience 2002, 37, 1074–1078. [Google Scholar] [CrossRef]

- Karabulut, O.A.; Gabler, F.M.; Mansour, M.; Smilanick, J.L. Postharvest ethanol and hot water treatments of table grapes to control gray mold. Postharvest Biol. Technol. 2004, 34, 169–177. [Google Scholar] [CrossRef]

- Schena, L.; Nigro, F.; Pentimone, I.; Ligorio, A.; Ippolito, A. Control of postharvest rots of sweet cherries and table grapes with endophytic isolates of Aureobasidium pullulans. Postharvest Biol. Technol. 2002, 30, 209–220. [Google Scholar] [CrossRef]

- Romanazzi, G.; Nigro, F.; Ippolito, A.; Salerno, M. Effect of short hypobaric treatments on postharvest rots of sweet cherries, strawberries and table grapes. Postharvest Biol. Technol. 2001, 22, 1–6. [Google Scholar] [CrossRef]

- Martinez-Romero, D.; Guillen, F.; Castillo, S.; Valero, D.; Serrano, M. Modified atmosphere packaging maintains quality of table grapes. J. Food Sci. 2003, 68, 1838–1843. [Google Scholar] [CrossRef]

- Kader, A.A.; Zagory, D.; Kerbel, E.L. Modified atmosphere packaging of fruits and vegetables. Crit. Rev. Food Sci. Nutr. 1983, 28, 1–30. [Google Scholar] [CrossRef]

- Sanz, C.; Pérez, A.G.; Olías, R.; Olías, J.M. Quality of strawberries packed with perforated polypropylene. J. Food Sci. 1999, 64, 748–752. [Google Scholar] [CrossRef]

- Chamara, D.; Illeperuma, K.; Galappatty, P.T.; Saranda, K.H. Modified atmosphere packaging of ‘Kolikuttu’ bananas at low temperature. J. Hortic. Sci. Biotechnol. 2000, 75, 92–96. [Google Scholar] [CrossRef]

- Bai, J.H.; Saftner, R.A.; Watada, A.E.; Lee, Y.S. Modified atmosphere maintains quality of fresh-cut cantaloupe (Cucumis melo L.). J. Food Sci. 2001, 66, 1207–1211. [Google Scholar] [CrossRef]

- Femenia, A.; Sánchez, E.S.; Simal, S.; Roselló, C. Modification of cell wall composition of apricot (Prunus armeniaca) during drying and storage under modified atmospheres. J. Agric. Food Chem. 1998, 46, 5228–5253. [Google Scholar] [CrossRef]

- Beaudry, R.M. Effect of O2 and CO2 partial pressure on selected phenomena affecting fruit and vegetable quality. Postharvest Biol. Technol. 1999, 15, 293–303. [Google Scholar] [CrossRef]

- Cefola, M.; Pace, B. High CO2-modified atmosphere to preserve sensory and nutritional quality of organic table grape (cv. ‘Italia’) during storage and shelf-life. Eur. J. Hortic. Sci. 2016, 81, 197–203. [Google Scholar] [CrossRef]

- Lichter, A.; Zutkhy, Y.; Sonego, L.; Dvir, O.; Kaplunov, T.; Sarig, P.; Ben-Arie, R. Ethanol controls postharvest decay of table grapes. Postharvest Biol. Technol. 2001, 24, 301–308. [Google Scholar] [CrossRef]

- Xu, W.T.; Huang, K.L.; Guo, F.; Qu, W.; Yang, J.J.; Liang, Z.H.; Lou, Y.B. Postharvest grapefruit seed extract and chitosan treatments of table grapes to control Botrytis cinerea. Postharvest Biol. Technol. 2007, 46, 86–94. [Google Scholar] [CrossRef]

- Shiri, A.; Bakhshi, D.; Ghasemnezhad, M.; Dadi, M.; Papachatzis, A.; Kalorizou, H. Chitosan coating improved the shelf life and postharvest quality of table grape (Vitis vinifera) cultivar ‘Shahrudi’. Turk. J. Agric. For. 2013, 37, 148–156. [Google Scholar]

- Al-Qurashi, A.D.; Awad, M.A. Postharvest chitosan treatment affects quality, antioxidant capacity, antioxidant compounds and enzymes activities of ‘El-Bayadi’ table grapes after storage. Sci. Hortic. 2015, 197, 392–398. [Google Scholar] [CrossRef]

- Reglinski, T.; Elmer, P.A.G.; Taylor, J.T.; Parry, F.J.; Marsden, R.; Wood, P.N. Suppression of Botrytis bunch rot in Chardonnay grapevines by induction of host resistance and fungal antagonism. Australas. Plant Path. 2005, 34, 481–488. [Google Scholar] [CrossRef]

- Ben-Shalom, N.; Ardi, R.; Pinto, R.; Aki, C.; Fallik, E. Controlling gray mould caused by Botrytis cinerea in cucumber plants by means of chitosan. Crop Prot. 2003, 22, 285–290. [Google Scholar] [CrossRef]

- Chien, P.J.; Sheu, F.; Lin, H.R. Coating citrus (Murcott tangor) fruit with low molecular weight chitosan increases postharvest quality and shelf life. Food Chem. 2007, 100, 1160–1164. [Google Scholar] [CrossRef]

- Romanazzi, G.; Nigro, F.; Ippolito, A.; Di Venere, D.; Salerno, M. Effect of pre and postharvest chitosan treatments to control storage grey mould of table grapes. J. Food Sci. 2002, 67, 1862–1867. [Google Scholar] [CrossRef]

- Zhang, D.; Quantick, P.C. Effect of chitosan coating on enzymatic browning and decay during postharvest storage of litchi (Litchi chinensis Sonn) fruit. Postharvest Biol. Technol. 1997, 12, 195–202. [Google Scholar] [CrossRef]

- Zhang, D.; Quantick, P.C. Antifungal effects of chitosan coating on fresh strawberries and raspberries during storage. J. Hortic. Sci. Biotechnol. 1998, 73, 763–767. [Google Scholar] [CrossRef]

- Du, J.; Gemma, H.; Iwahori, S. Effects of chitosan coating on the storage of peach, Japanese pear and kiwifruit. J. Jpn. Soc. Hortic. Sci. 1997, 66, 15–22. [Google Scholar] [CrossRef]

- Bautista-Banos, S.; Hernandez-Lauzardo, A.N.; Velazquez-del Valle, M.G.; Hernandez-Lopez, M.; Ait Barka, E.; Bosquez-Molina, E.; Wilson, C.L. Chitosan as a potential natural compound to control pre and postharvest diseases of horticultural commodities. Crop Prot. 2006, 25, 108–118. [Google Scholar] [CrossRef]

- Jinasena, D.; Pavithra Pathirathna, P.; Wickramarachchi, S.; Marasinghe, E. Use of chitosan to control anthracnose on Embul banana. In Proceedings of the International Conference on Asia Agriculture and Animal, Bangkok, Thailand, 5–7 June 2011; pp. 56–60. [Google Scholar]

- Valverde, J.M.; Valero, D.; Martínez-Romero, D.; Guillén, F.; Castillo, S.; Serrano, M. Novel edible coating based on aloe vera gel to maintain table grape quality and safety. J. Agric. Food Chem. 2005, 53, 7807–7813. [Google Scholar] [CrossRef] [PubMed]

- Mencarelli, F.; Bellincontro, A.; Di Renzo, G. GRAPE: Post-harvest Operations. In Agricultural and Food Engineering Technologies Service; Mejıa, D., Ed.; Food and Agriculture Organization of the United Nations: Roma, Italy, 2005. [Google Scholar]

- Romanazzi, G.; Lichter, A.; Mlikota Gabler, F.; Smilanick, J. Recent advances on the use of natural and safe alternatives to conventional methods to control postharvest gray mold of table grapes. Postharvest Biol. Technol. 2012, 54, 118–121. [Google Scholar] [CrossRef]

- Del Nobile, M.A.; Conte, A.; Scrocco, C.; Brescia, I.; Speranza, B.; Sinigaglia, M.; Perniola, R.; Antonacci, D. A study on quality loss of minimally processed grapes as affected by film packaging. Postharvest Biol. Technol. 2009, 51, 21–26. [Google Scholar] [CrossRef]

- Kader, A.A. Postharvest biology and technology: An overview. In Postharvest Technology of Horticultural Crops 1; Kader, A.A., Ed.; Publication 331; University of California and Agricultural and Natural Resources: Berkeley, CA, USA, 2002; pp. 39–47. [Google Scholar]

- Romanazzi, G.; Feliziani, E.; Santini, M.; Landi, L. Effectiveness of postharvest treatment with chitosan and other resistance inducers in the control of storage decay of strawberry. Postharvest Biol. Technol. 2013, 75, 24–27. [Google Scholar] [CrossRef]

- Barth, M.; Hankinson, T.R.; Zhuang, H.; Breidt, F. Microbiological spoilage of fruits and vegetables. In Compendium of the Microbiological Spoilage of Foods and Beverages, Food Microbiology and Food Safety; Sperber, W.H., Doyle, M.P., Eds.; Springer Science Business Media: Berlin/Heidelberg, Germany, 2009; pp. 135–183. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).