Recent Updates on the Conversion of Pineapple Waste (Ananas comosus) to Value-Added Products, Future Perspectives and Challenges

Abstract

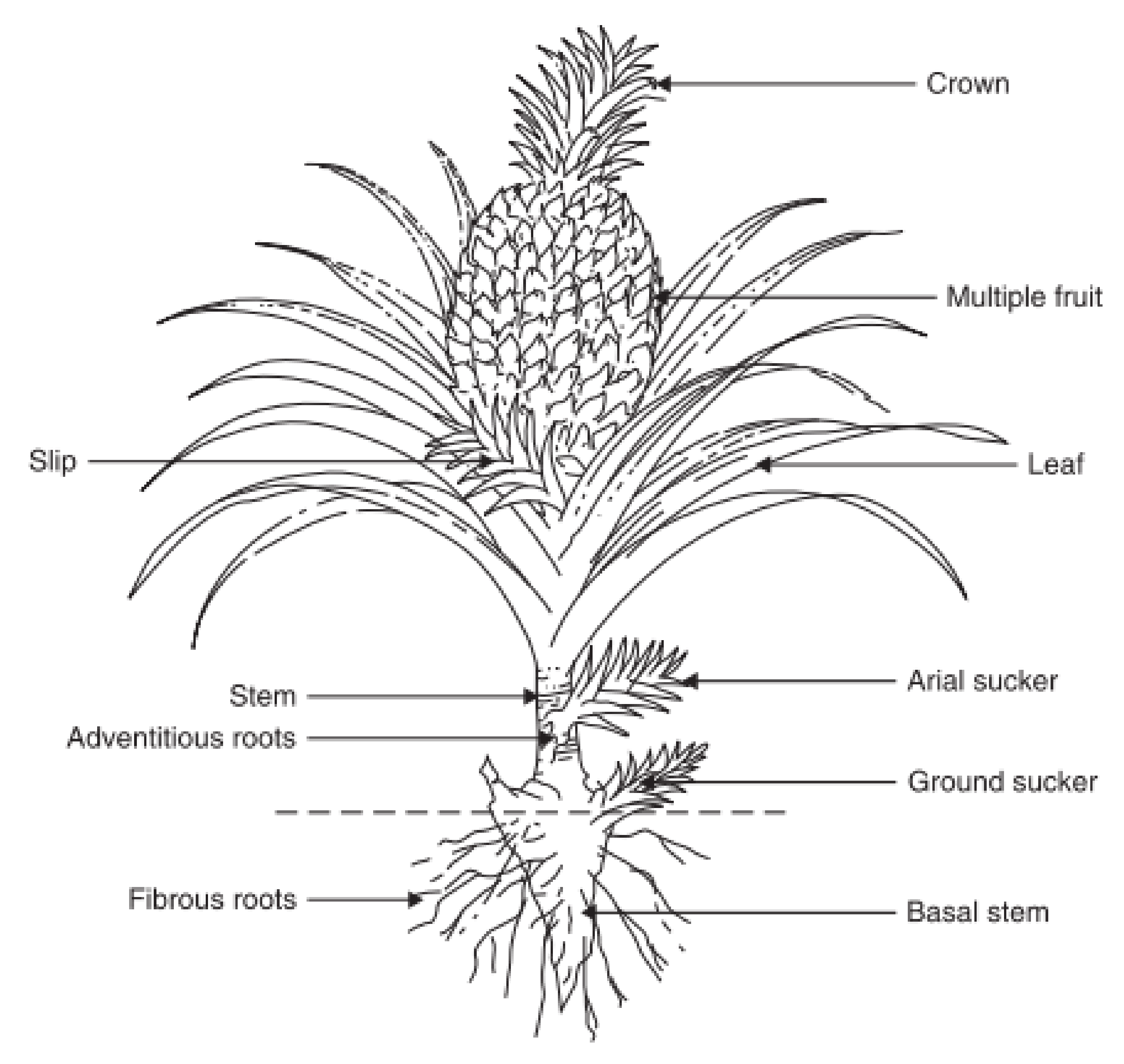

1. Introduction

2. Global Production

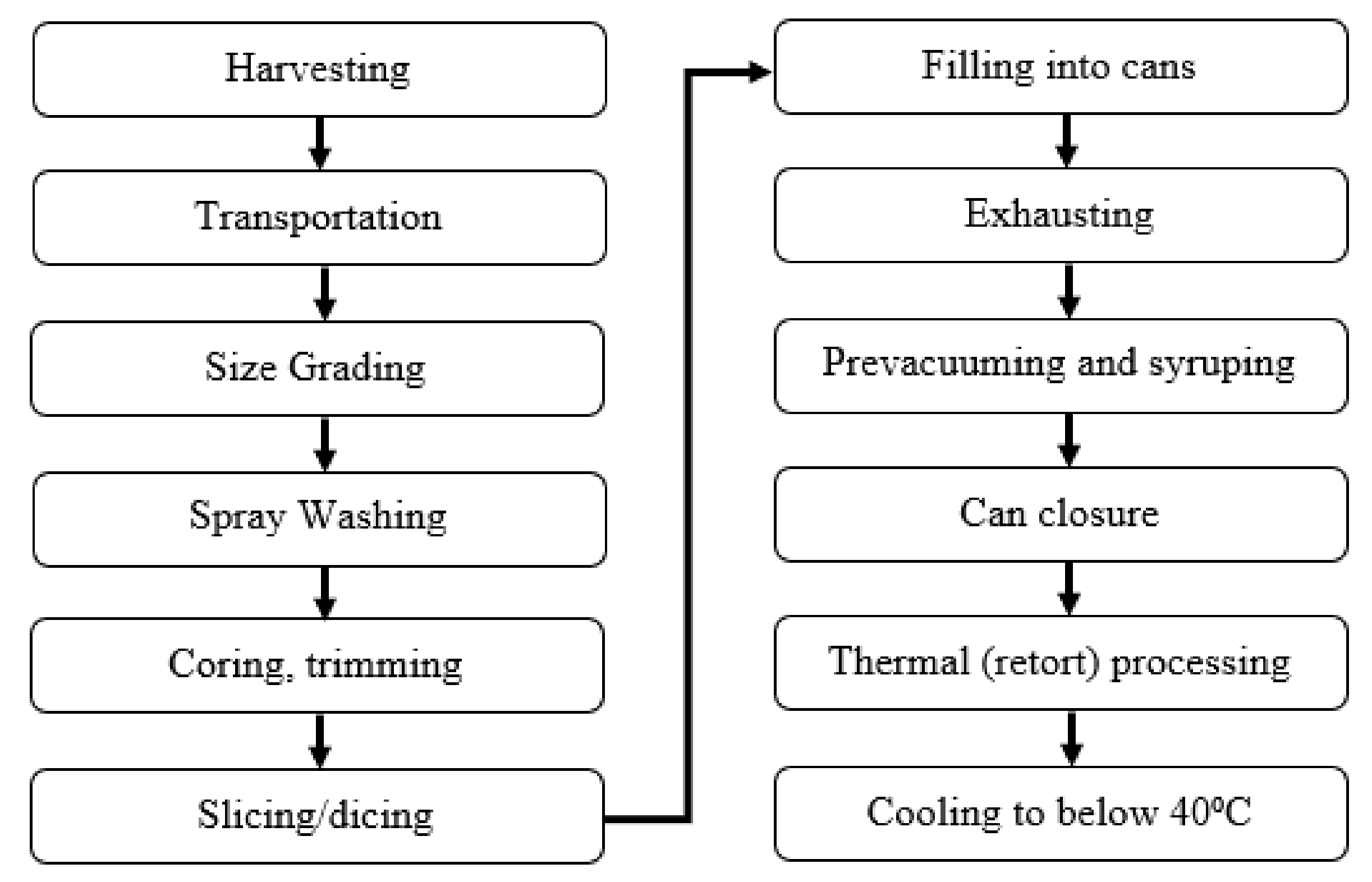

3. Commercial Use of Pineapple

4. Waste Production from Pineapple Waste

5. Characteristics and Composition of Pineapple Waste

6. Conversion of Pineapple Waste to Value-Added Products

6.1. Bio-Based Byproduct and Final Product

6.1.1. Cellulose Nanocrystals

6.1.2. Bromelain Enzyme

6.1.3. Bioactive Compound

6.1.4. Wine and Vinegar

6.1.5. Organic Acid

6.2. Bio-Packaging

6.3. Bio-Adsorbent

6.4. Bioenergy

6.4.1. Biofuel

6.4.1.1. Bioethanol

6.4.1.2. Biobutanol

6.4.1.3. Biodiesel

6.4.2. Biogas

6.4.2.1. Biomethane

6.4.2.2. Biohydrogen

7. Future Perspectives and Challenges

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABE | Acetone–Butanol–Ethanol |

| BT-PP | Bleaching treatment pineapple peel |

| CCD | Central composite design |

| CDU | Casein Digestion Units |

| CNC | Cellulose nanocrystal |

| COD | Chemical oxygen demand |

| FAME | Fatty Acid Methyl Ester |

| FAO | Food and Agricultural Organization |

| FTIR | Fourier Transform Infra-Red |

| GHG | Greenhouse Gases |

| PHA | Polyhydroxyalkanoates |

| PHB | Polyhydroxybutyrate |

| PLA | Polylactic Acid |

| PPC | Pineapple peel cellulose |

| PSSF | Pre-hydrolysis simultaneous saccharification and fermentation |

| SHF | separate hydrolysis and fermentation |

| SSF | Simultaneous saccharification fermentation |

| SSCF | Simultaneous saccharification and co-fermentation |

| TS | Total solid |

| VS | Volatile solid |

| 2LFD | Two-level factorial design |

References

- Lemaire, A.; Limbourg, S. How can food loss and waste management achieve sustainable development goals? J. Clean. Prod. 2019, 234, 1221–1234. [Google Scholar] [CrossRef]

- Rodić, L.; Wilson, D. Resolving Governance Issues to Achieve Priority Sustainable Development Goals Related to Solid Waste Management in Developing Countries. Sustainability 2017, 9, 404. [Google Scholar] [CrossRef]

- Pujara, Y.; Pathak, P.; Sharma, A.; Govani, J. Review on Indian Municipal Solid Waste Management practices for reduction of environmental impacts to achieve sustainable development goals. J. Environ. Manag. 2019, 248, 109238. [Google Scholar] [CrossRef]

- Cheok, C.Y.; Mohd Adzahan, N.; Abdul Rahman, R.; Zainal Abedin, N.H.; Hussain, N.; Sulaiman, R.; Chong, G.H. Current trends of tropical fruit waste utilization. Crit. Rev. Food Sci. Nutr. 2016, 58, 1–27. [Google Scholar] [CrossRef] [PubMed]

- Ong, K.L.; Kaur, G.; Pensupa, N.; Uisan, K.; Lin, C.S.K. Trends in food waste valorization for the production of chemicals, materials and fuels: Case study South and Southeast Asia. Bioresour. Technol. 2018, 248, 100–112. [Google Scholar] [CrossRef] [PubMed]

- Rico, X.; Gullón, B.; Alonso, J.L.; Yáñez, R. Recovery of high value-added compounds from pineapple, melon, watermelon and pumpkin processing by-products: An overview. Food Res. Int. 2020, 132, 109086. [Google Scholar] [CrossRef]

- Sindhu, R.; Gnansounou, E.; Rebello, S.; Binod, P.; Varjani, S.; Thakur, I.S.; Nair, R.B.; Pandey, A. Conversion of food and kitchen waste to value-added products. J. Environ. Manag. 2019, 241, 619–630. [Google Scholar] [CrossRef]

- Mohd Ali, M.; Hashim, N.; Abd Aziz, S.; Lasekan, O. Pineapple (Ananas comosus): A comprehensive review of nutritional values, volatile compounds, health benefits, and potential food products. Food Res. Int. 2020, 137, 109675. [Google Scholar] [CrossRef] [PubMed]

- Wali, N. Pineapple (Ananas comosus). In Nonvitamin and Nonmineral Nutritional Supplements; Elsevier: Amsterdam, The Netherlands, 2019; pp. 367–373. ISBN 9780128124918. [Google Scholar]

- Roda, A.; Lambri, M. Food uses of pineapple waste and by-products: A review. Int. J. Food Sci. Technol. 2019, 54, 1009–1017. [Google Scholar] [CrossRef]

- Campos, D.A.; Coscueta, E.R.; Valetti, N.W.; Pastrana-Castro, L.M.; Teixeira, J.A.; Picó, G.A.; Pintado, M.M. Optimization of bromelain isolation from pineapple byproducts by polysaccharide complex formation. Food Hydrocoll. 2019, 87, 792–804. [Google Scholar] [CrossRef]

- Van Dyk, J.S.; Gama, R.; Morrison, D.; Swart, S.; Pletschke, B.I. Food processing waste: Problems, current management and prospects for utilisation of the lignocellulose component through enzyme synergistic degradation. Renew. Sustain. Energy Rev. 2013, 26, 521–531. [Google Scholar] [CrossRef]

- Prado, K.S.; Spinacé, M.A.S. Isolation and characterization of cellulose nanocrystals from pineapple crown waste and their potential uses. Int. J. Biol. Macromol. 2019, 122, 410–416. [Google Scholar] [CrossRef]

- Singh, P.; Baisthakur, P.; Yemul, O.S. Synthesis, characterization and application of crosslinked alginate as green packaging material. Heliyon 2020, 6, e03026. [Google Scholar] [CrossRef] [PubMed]

- Suwannasing, W.; Imai, T.; Kaewkannetra, P. Potential Utilization of Pineapple Waste Streams for Polyhydroxyalkanoates (PHAs) Production via Batch Fermentation. J. Water Environ. Technol. 2015, 13, 335–347. [Google Scholar] [CrossRef]

- Zain, N.A.M.; Aziman, S.N.; Suhaimi, M.S.; Idris, A. Optimization of L(+) Lactic Acid Production from Solid Pineapple Waste (SPW) by Rhizopus oryzae NRRL 395. J. Polym. Environ. 2021, 29, 230–249. [Google Scholar] [CrossRef]

- Roda, A.; De Faveri, D.M.; Dordoni, R.; Cases, E.V.; Jáuregui, N.N.; Carbonell Barrachina, Â.A.; Frutos Fernandez, M.J.; Lambri, M. Pineapple Wines Obtained from Saccharification of Its Waste with Three Strains of Saccharomyces cerevisiae. J. Food Process. Preserv. 2017, 41, e13111. [Google Scholar] [CrossRef]

- Umaru, F.F.; Esedafe, W.K.; Obidah, J.S.; Akinwotu, O.; Danba, E. Production of Vinegar from Pineapple Peel Wine Using Acetobacter Species. In Proceedings of the 3rd International Conference on Biological, Chemical & Environmental Sciences (BCES-2015), Kuala Lumpur, Malaysia, 21–22 September 2015. [Google Scholar]

- Dai, H.; Huang, H. Modified pineapple peel cellulose hydrogels embedded with sepia ink for effective removal of methylene blue. Carbohydr. Polym. 2016, 148, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Casabar, J.T.; Ramaraj, R.; Tipnee, S.; Unpaprom, Y. Enhancement of hydrolysis with Trichoderma harzianum for bioethanol production of sonicated pineapple fruit peel. Fuel 2020, 279, 118437. [Google Scholar] [CrossRef]

- Kanakdande, A.; Agrwal, D.; Khobragade, C. Pineapple Waste and Wastewater: Route for Biodiesel Production from Candida tropicalis (MF510172). Brazilian Arch. Biol. Technol. 2019, 62, 19180499. [Google Scholar] [CrossRef]

- Khedkar, M.A.; Nimbalkar, P.R.; Gaikwad, S.G.; Chavan, P.V.; Bankar, S.B. Sustainable biobutanol production from pineapple waste by using Clostridium acetobutylicum B 527: Drying kinetics study. Bioresour. Technol. 2017, 225, 359–366. [Google Scholar] [CrossRef]

- Dahunsi, S.O. Liquefaction of pineapple peel: Pretreatment and process optimization. Energy 2019, 185, 1017–1031. [Google Scholar] [CrossRef]

- Cahyari, K.; Putri, A.M.; Oktaviani, E.D.; Hidayat, M.A.; Norajsha, J.D. Biohydrogen Production from Pineapple Waste: Effect of Substrate Concentration and Acid Pretreatment. IOP Conf. Ser. Mater. Sci. Eng. 2018, 358, 012001. [Google Scholar] [CrossRef]

- Chu, C.-Y.; Vo, T.-P.; Chen, T.-H. A novel of biohythane gaseous fuel production from pineapple peel waste juice in two-stage of continuously stirred anaerobic bioreactors. Fuel 2020, 279, 118526. [Google Scholar] [CrossRef]

- Azevedo, A.; Gominho, J.; Duarte, E. Performance of Anaerobic Co-digestion of Pig Slurry with Pineapple (Ananas comosus) Bio-waste Residues. Waste and Biomass Valorization 2021, 12, 303–311. [Google Scholar] [CrossRef]

- Hossain, M.F. World pineapple production: An overview. African J. Food, Agric. Nutr. Dev. 2016, 16, 11443–11456. [Google Scholar] [CrossRef]

- Pandit, P.; Pandey, R.; Singha, K.; Shrivastava, S.; Gupta, V.; Jose, S. Pineapple Leaf Fibre: Cultivation and Production. In Green Energy and Technology; Springer: Berlin, Germany, 2020; pp. 1–20. [Google Scholar]

- Campos, D.A.; Ribeiro, T.B.; Teixeira, J.A.; Pastrana, L.; Pintado, M.M. Integral Valorization of Pineapple (Ananas comosus L.) By-Products through a Green Chemistry Approach towards Added Value Ingredients. Foods 2020, 9, 60. [Google Scholar] [CrossRef] [PubMed]

- Lasekan, O.; Khalifa Hussein, F. Classification of different pineapple varieties grown in Malaysia based on volatile fingerprinting and sensory analysis. Chem. Cent. J. 2018, 12, 140. [Google Scholar] [CrossRef]

- MPIB Publication | Malaysian Pineapple Industry Board. Available online: http://www.mpib.gov.my/en/publication/ (accessed on 31 March 2021).

- Thalip, A.A.; Tong, P.S.; Ng, C. The MD2 “Super Sweet” Pineapple (Ananas comosus). UTAR Agric. Sci. J. 2015, 1, 14–17. [Google Scholar]

- Hassan, A.; Othman, Z.; Siriphanich, J. Pineapple ( Ananas comosus L. Merr.). In Postharvest Biology and Technology of Tropical and Subtropical Fruits; Elsevier: Berlin, Germany, 2011; Volume 4, pp. 194–218e. ISBN 9780857090904. [Google Scholar]

- FAO. Faostat Database. Available online: http://www.fao.org/faostat (accessed on 12 March 2021).

- Siow, L.-F.; Lee, K.-H. Canned, frozen and dried pineapple. In Handbook of Pineapple Technology; John Wiley & Sons, Ltd.: Chichester, UK, 2016; pp. 126–139. ISBN 9781118967355. [Google Scholar]

- Chaudhary, V.; Kumar, V.; Singh, K.; Kumar, R.; Kumar, V.; Vipul Chaudhary, C. Pineapple (Ananas cosmosus) product processing: A review. J. Pharmacogn. Phytochem. 2019, 8, 4642–4652. [Google Scholar]

- Couto, D.S.; Cabral, L.M.C.; Matta, V.M.D.; Deliza, R.; Freitas, D.D.G.C. Concentration of pineapple juice by reverse osmosis: Physicochemical characteristics and consumer acceptance. Food Sci. Technol. 2011, 31, 905–910. [Google Scholar] [CrossRef]

- Hounhouigan, M.H.; Linnemann, A.R.; Soumanou, M.M.; Van Boekel, M.A.J.S. Effect of Processing on the Quality of Pineapple Juice. Food Rev. Int. 2014, 30, 112–133. [Google Scholar] [CrossRef]

- Jori, D.; Ladole, M.; Gore, A.; Bhand, V. Study on Effect of Carbonation on Storage and Stability of Pineapple Fruit Juice. Int. J. Eng. Res. Technol. 2013, 2, 1841–1847. [Google Scholar]

- Aina, V.O.; Ibrahim, M.B.; Waziri, P.M.; Adewumi, A.A.J. Abdulsalam Nutrient and Anti-Nutritional Composition of Jam Prepared from Pineapple Ananas Comosus. J. Nat. Sci. Res. 2015, 5, 2224–3186. [Google Scholar]

- Aisyah, N.; Ismail, M.; Abdullah, N.; Muhammad, N. Effect of Microwave-Assisted Processing on Quality Characteristics of Pineapple Jam. J. Adv. Res. Fluid Mech. Therm. Sci. J. 2018, 42, 24–30. [Google Scholar]

- Doke, A.; Arya, A.; Bhaleraq, J.G.; Shinde, R.S. Development of value added papaya and pineapple jams. Food Sci. Res. J. 2017, 8, 76–82. [Google Scholar] [CrossRef]

- Nduko, J.M.; Maina, R.W.; Muchina, R.K.; Kibitok, S.K. Application of chia (Salvia hispanica) seeds as a functional component in the fortification of pineapple jam. Food Sci. Nutr. 2018, 6, 2344–2349. [Google Scholar] [CrossRef] [PubMed]

- Jothi, J.S.; Islam, M.; Islam, M.S.; Rahman, M.R.T.; Akther, S. Development and Shelf-Life Prediction of Pineapple (Ananas comosus) Preserve and Candy. Int. J. Innov. Sci. Res. 2014, 10, 77–82. [Google Scholar]

- Khanom, S.A.A.; Rahman, M.M.; Uddin, M.B. Preparation of Pineapple (Ananas comosus) Candy Using Osmotic Dehydration Combined With Solar Drying. Agric. 2016, 13, 87–93. [Google Scholar] [CrossRef][Green Version]

- Kumar, R.; Kirad, K.S. Effect of Different Levels Of Sugar In The Preparation Of Pineapple (Ananas comosus L.) Candy. World Res. J. Biotechnol. 2013, 1, 1–3. [Google Scholar]

- Domingo, C.J.A.; De Vera, W.M.; Pambid, R.C. Exploring Oven-drying Technique in Producing Pineapple Powder. Asia Pacific J. Multidiscip. Res. 2017, 5, 90–96. [Google Scholar]

- Hashib, S.A.; Rahman, N.A.; Suzihaque, M.U.; Ibrahim, U.K.; Hanif, N.E. Effect of Slurry Concentration and Inlet Temperature Towards Glass Temperature of Spray Dried Pineapple Powder. Procedia Soc. Behav. Sci. 2015, 195, 2660–2667. [Google Scholar] [CrossRef]

- Wong, C.W.; Pui, L.P.; Ng, J.M.L. Production of spray-dried Sarawak pineapple (Ananas comosus) powder from enzyme liquefied puree. Int. Food Res. J. 2015, 22, 1631–1636. [Google Scholar]

- Shaari, N.A.; Sulaiman, R.; Rahman, R.A.; Bakar, J. Production of pineapple fruit (Ananas comosus) powder using foam mat drying: Effect of whipping time and egg albumen concentration. J. Food Process. Preserv. 2018, 42, e13467. [Google Scholar] [CrossRef]

- Sah, B.N.P.; Vasiljevic, T.; McKechnie, S.; Donkor, O.N. Effect of pineapple waste powder on probiotic growth, antioxidant and antimutagenic activities of yogurt. J. Food Sci. Technol. 2016, 53, 1698–1708. [Google Scholar] [CrossRef]

- Thivani, M.; Mahendran, T.; Kanimoly, M. Study on the physico-chemical properties, sensory attributes and shelf life of pineapple powder incorporated biscuits. Ruhuna J. Sci. 2016, 7, 32. [Google Scholar] [CrossRef]

- Sudharshan Reddy, R.; Kumar Malik, G.; Madhava, M.; Golla, S. Sensory evaluation of flavoured milk: Effect of incorporation of dried pineapple powder and drying temperature. Pharma Innov. J. 2018, 7, 246–248. [Google Scholar]

- Downing, D.L. Canning of Fruits. In A Complete Course in Canning and Related Processes; Elsevier: Amsterdam, The Netherlands, 1996; pp. 129–192. ISBN 978-1-84569-606-1. [Google Scholar]

- Zainal Alam, M.N.H.; Adrus, N.; Abdul Wahab, M.F.; Kamaruddin, M.J.; Sani, M.H. Utilization of Agro-Waste as Carbon Source for Biohydrogen Production: Prospect and Challenges in Malaysia. In Valorisation of Agro-industrial Residues—Volume I: Biological Approaches; Springer: Cham, Switzerland, 2020; pp. 131–147. [Google Scholar]

- Ozturk, M.; Saba, N.; Altay, V.; Iqbal, R.; Hakeem, K.R.; Jawaid, M.; Ibrahim, F.H. Biomass and bioenergy: An overview of the development potential in Turkey and Malaysia. Renew. Sustain. Energy Rev. 2017, 79, 1285–1302. [Google Scholar] [CrossRef]

- Ahmad Zamri, M.F.M.; Akhiar, A.; Mohd Roslan, M.E.; Mohd Marzuki, M.H.; Saad, J.M.; Shamsuddin, A.H. Valorisation of organic fraction municipal solid waste via anaerobic co-digestion of Malaysia tropical fruit for biogas production. IOP Conf. Ser. Earth Environ. Sci. 2020, 476, 012077. [Google Scholar] [CrossRef]

- Nga, N.T.; Trang, N.T. Influence of the fermentation of pineapple wastes with the use of Methanobacterium strains separated in Vietnam on the production of biogas from them. J. Eng. Phys. Thermophys. 2015, 88, 392–397. [Google Scholar] [CrossRef]

- Jehan, O.S.; Sanusi, S.N.A.; Sukor, M.Z.; Noraini, M.; Buddin, M.M.H.S.; Hamid, K.H.K. Biogas production from pineapple core-A preliminary study. AIP Proc. Conf. 2017, 1885, 1–6. [Google Scholar]

- Md Zaki, N.A.; Abd Rahman, N.; Ahmad Zamanhuri, N.; Abd Hashib, S. Ascorbic Acid Content and Proteolytic Enzyme Activity of Microwave-Dried Pineapple Stem and Core. Chem. Eng. Trans. 2017, 56, 1369–1374. [Google Scholar]

- Yahayu, M.; Mahmud, K.N.; Mahamad, M.N.; Ngadiran, S.; Lipeh, S.; Ujang, S.; Zakaria, Z.A. Efficacy of Pyroligneous Acid From Pineapple Waste Biomass As Wood Preserving Agent. J. Teknol. 2017, 79, 1–8. [Google Scholar] [CrossRef]

- Rabiu, Z.; Maigari, F.U.; Lawan, U.; Mukhtar, Z.G. Pineapple Waste Utilization as a Sustainable Means of Waste Management. In Sustainable Technologies for the Management of Agricultural Wastes; Springer Singapore: Singapore, 2018; pp. 143–154. [Google Scholar]

- Banerjee, S.; Ranganathan, V.; Patti, A.; Arora, A. Valorisation of pineapple wastes for food and therapeutic applications. Trends Food Sci. Technol. 2018, 82, 60–70. [Google Scholar] [CrossRef]

- Morone, P.; Koutinas, A.; Gathergood, N.; Arshadi, M.; Matharu, A. Food waste: Challenges and opportunities for enhancing the emerging bio-economy. J. Clean. Prod. 2019, 221, 10–16. [Google Scholar] [CrossRef]

- Font-Palma, C. Methods for the Treatment of Cattle Manure—A Review. C J. Carbon Res. 2019, 5, 27. [Google Scholar] [CrossRef]

- Yaashikaa, P.R.; Kumar, P.S.; Saravanan, A.; Varjani, S.; Ramamurthy, R. Bioconversion of municipal solid waste into bio-based products: A review on valorisation and sustainable approach for circular bioeconomy. Sci. Total Environ. 2020, 748, 141312. [Google Scholar] [CrossRef] [PubMed]

- Cigolotti, V. Biomass and Waste as Sustainable Resources. In Fuel Cells in the Waste-to-Energy Chain; Springer: London, UK, 2012; pp. 23–44. [Google Scholar]

- McPhail, S.J.; Cigolotti, V.; Moreno, A. Fuel cells in the waste-to-energy Chain. Green Energy Technol. 2012, 45, 3–21. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Lu, C. Development perspectives of promising lignocellulose feedstocks for production of advanced generation biofuels: A review. Renew. Sustain. Energy Rev. 2021, 136, 110445. [Google Scholar] [CrossRef]

- Pardo, M.E.S.; Cassellis, M.E.R.; Escobedo, R.M.; García, E.J. Chemical Characterisation of the Industrial Residues of the Pineapple (Ananas comosus). J. Agric. Chem. Environ. 2014, 3, 53–56. [Google Scholar] [CrossRef]

- Mohamad, N.; Ramli, N.; Abd-Aziz, S.; Ibrahim, M.F. Comparison of hydro-distillation, hydro-distillation with enzyme-assisted and supercritical fluid for the extraction of essential oil from pineapple peels. 3 Biotech. 2019, 9, 234. [Google Scholar] [CrossRef]

- Li, T.; Shen, P.; Liu, W.; Liu, C.; Liang, R.; Yan, N.; Chen, J. Major Polyphenolics in Pineapple Peels and their Antioxidant Interactions. Int. J. Food Prop. 2014, 17, 1805–1817. [Google Scholar] [CrossRef]

- Banerjee, R.; Chintagunta, A.D.; Ray, S. A cleaner and eco-friendly bioprocess for enhancing reducing sugar production from pineapple leaf waste. J. Clean. Prod. 2017, 149, 387–395. [Google Scholar] [CrossRef]

- Astuti, W.; Sulistyaningsih, T.; Kusumastuti, E.; Thomas, G.Y.R.S.; Kusnadi, R.Y. Thermal conversion of pineapple crown leaf waste to magnetized activated carbon for dye removal. Bioresour. Technol. 2019, 287, 121426. [Google Scholar] [CrossRef]

- Mansor, A.M.; Lim, J.S.; Ani, F.N.; Hashim, H.; Ho, W.S. Ultimate and Proximate Analysis of Malaysia Pineapple Biomass from MD2 Cultivar for Biofuel Application. Chem. Eng. Trans. 2018, 63, 127–132. [Google Scholar]

- Nor, M.Z.M.; Ramchandran, L.; Duke, M.; Vasiljevic, T. Characteristic properties of crude pineapple waste extract for bromelain purification by membrane processing. J. Food Sci. Technol. 2015, 52, 7103–7112. [Google Scholar] [CrossRef]

- Sepúlveda, L.; Romaní, A.; Aguilar, C.N.; Teixeira, J. Valorization of pineapple waste for the extraction of bioactive compounds and glycosides using autohydrolysis. Innov. Food Sci. Emerg. Technol. 2018, 47, 38–45. [Google Scholar] [CrossRef]

- Upadhyay, A.; Lama, J.P.; Tawata, S. Utilization of Pineapple Waste: A Review. J. Food Sci. Technol. Nepal 2013, 6, 10–18. [Google Scholar] [CrossRef]

- Raquel Madureira, A.; Atatoprak, G.; Sousa, F.; Pullar, R.C.; Pintado, M. Extraction and characterisation of cellulose nanocrystals from pineapple peel. Int. J. Food Stud. 2018, 7, 24–33. [Google Scholar] [CrossRef]

- Dos Santos, R.M.; Flauzino Neto, W.P.; Silvério, H.A.; Martins, D.F.; Dantas, N.O.; Pasquini, D. Cellulose nanocrystals from pineapple leaf, a new approach for the reuse of this agro-waste. Ind. Crops Prod. 2013, 50, 707–714. [Google Scholar] [CrossRef]

- Brinchi, L.; Cotana, F.; Fortunati, E.; Kenny, J.M. Production of nanocrystalline cellulose from lignocellulosic biomass: Technology and applications. Carbohydr. Polym. 2013, 94, 154–169. [Google Scholar] [CrossRef] [PubMed]

- Chawalitsakunchai, W.; Dittanet, P.; Loykulnant, S.; Sae-oui, P.; Tanpichai, S.; Seubsai, A.; Prapainainar, P. Properties of natural rubber reinforced with nano cellulose from pineapple leaf agricultural waste. Mater. Today Commun. 2021, 28, 102594. [Google Scholar] [CrossRef]

- Anwar, B.; Bundjali, B.; Sunarya, Y.; Arcana, I.M. Properties of Bacterial Cellulose and Its Nanocrystalline Obtained from Pineapple Peel Waste Juice. Fibers Polym. 2021, 22, 1228–1236. [Google Scholar] [CrossRef]

- Vivian Abiaziem, C.; Bassey Williams, A.; Ibijoke Inegbenebor, A.; Theresa Onwordi, C.; Osereme Ehi-Eromosele, C.; Felicia Petrik, L. Preparation and Characterisation of Cellulose Nanocrystal from Sugarcane Peels by XRD, SEM and CP/MAS 13 C NMR. J. Phys. Conf. Ser. 2019, 1299, 012123. [Google Scholar] [CrossRef]

- Pereira, P.H.F.; Ornaghi, H.L., Jr.; Coutinho, L.V.; Duchemin, B.; Cioffi, M.O.H. Obtaining cellulose nanocrystals from pineapple crown fibers by free-chlorite hydrolysis with sulfuric acid: Physical, chemical and structural characterization. Cellulose 2020, 27, 5745–5756. [Google Scholar] [CrossRef]

- Naduparambath, S.; Jinitha, T.V.; Shaniba, V.; Sreejith, M.P.; Balan, A.K.; Purushothaman, E. Isolation and characterisation of cellulose nanocrystals from sago seed shells. Carbohydr. Polym. 2018, 180, 13–20. [Google Scholar] [CrossRef] [PubMed]

- Wijaya, C.J.; Saputra, S.N.; Soetaredjo, F.E.; Putro, J.N.; Lin, C.X.; Kurniawan, A.; Ju, Y.-H.; Ismadji, S. Cellulose nanocrystals from passion fruit peels waste as antibiotic drug carrier. Carbohydr. Polym. 2017, 175, 370–376. [Google Scholar] [CrossRef] [PubMed]

- Sai Prasanna, N.; Mitra, J. Isolation and characterization of cellulose nanocrystals from Cucumis sativus peels. Carbohydr. Polym. 2020, 247, 116706. [Google Scholar] [CrossRef]

- Gnanasekaran, S.; Nordin, N.I.A.A.; Jamari, S.S.; Shariffuddin, J.H. Effect of Steam-Alkaline coupled treatment on N36 cultivar pineapple leave fibre for isolation of cellulose. Mater. Today: Proc 2021, (in press).

- Balakrishnan, P.; Gopi, S.; Geethamma, V.G.; Kalarikkal, N.; Thomas, S. Cellulose Nanofiber vs Nanocrystals From Pineapple Leaf Fiber: A Comparative Studies on Reinforcing Efficiency on Starch Nanocomposites. Macromol. Symp. 2018, 380, 1800102. [Google Scholar] [CrossRef]

- Camacho, M.; Ureña, Y.R.C.; Lopretti, M.; Carballo, L.B.; Moreno, G.; Alfaro, B.; Baudrit, J.R.V. Synthesis and Characterization of Nanocrystalline Cellulose Derived from Pineapple Peel Residues. J. Renew. Mater. 2017, 5, 271–279. [Google Scholar] [CrossRef]

- Huang, C.W.; Lin, I.J.; Liu, Y.; Mau, J.L. Composition, enzyme and antioxidant activities of pineapple. Int. J. Food Prop. 2021, 24, 1244–1251. [Google Scholar] [CrossRef]

- Nor, M.Z.M.; Ramchandran, L.; Duke, M.; Vasiljevic, T. Integrated ultrafiltration process for the recovery of bromelain from pineapple waste mixture. J. Food Process. Eng. 2017, 40, e12492. [Google Scholar] [CrossRef]

- Li, R.; Ding, L.; Wu, Z.; Wang, Y.; Liu, W.; Wang, Y. β-cyclodextrin assisted two-stage foam fractionation of bromelain from the crude extract of pineapple peels. Ind. Crops Prod. 2016, 94, 233–239. [Google Scholar] [CrossRef]

- Vicente, F.A.; Lario, L.D.; Pessoa, A.; Ventura, S.P.M. Recovery of bromelain from pineapple stem residues using aqueous micellar two-phase systems with ionic liquids as co-surfactants. Process. Biochem. 2016, 51, 528–534. [Google Scholar] [CrossRef]

- Wu, W.-C.; Ng, H.S.; Sun, I.-M.; Lan, J.C.-W. Single step purification of bromelain from Ananas comosus pulp using a polymer/salt aqueous biphasic system. J. Taiwan Inst. Chem. Eng. 2017, 79, 158–162. [Google Scholar] [CrossRef]

- Gil, L.S.; Maupoey, P.F. An integrated approach for pineapple waste valorisation. Bioethanol production and bromelain extraction from pineapple residues. J. Clean. Prod. 2018, 172, 1224–1231. [Google Scholar] [CrossRef]

- Misran, E.; Idris, A.; Mat Sarip, S.H.; Ya’akob, H. Properties of bromelain extract from different parts of the pineapple variety Morris. Biocatal. Agric. Biotechnol. 2019, 18, 101095. [Google Scholar] [CrossRef]

- Nwagu, T.N.; Ugwuodo, C.J. Stabilizing bromelain for therapeutic applications by adsorption immobilization on spores of probiotic Bacillus. Int. J. Biol. Macromol. 2019, 127, 406–414. [Google Scholar] [CrossRef]

- Banerjee, S.; Arora, A.; Vijayaraghavan, R.; Patti, A.F. Extraction and crosslinking of bromelain aggregates for improved stability and reusability from pineapple processing waste. Int. J. Biol. Macromol. 2020, 158, 318–326. [Google Scholar] [CrossRef]

- Abbas, S.; Shanbhag, T.; Kothare, A. Applications of bromelain from pineapple waste towards acne. Saudi J. Biol. Sci. 2021, 28, 1001–1009. [Google Scholar] [CrossRef]

- Jebur, A.B.; El-Demerdash, F.M.; Kang, W. Bromelain from Ananas comosus stem attenuates oxidative toxicity and testicular dysfunction caused by aluminum in rats. J. Trace Elem. Med. Biol. 2020, 62, 126631. [Google Scholar] [CrossRef]

- Rashad, M.M.; Mahmoud, A.E.; Ali, M.M.; Nooman, M.U.; Al-Kashef, A.S. Antioxidant and Anticancer Agents Produced from Pineapple Waste by Solid State Fermentation. Int. J. Toxicol. Pharmacol. Res. 2015, 7, 287–296. [Google Scholar]

- Othman, N.; Peng Teoh, Y.; Ooi, Z.X.; Sam, S.T. Comparative Study on the Extraction of Bioactive Compound from Banana and Pineapple Peel Extract. In Proceedings of the 7th International Conference on Chemical, Agricultural, Biological and Environmental Sciences (CABES-2017), Pattaya, Thailand, 10–11 July 2017; pp. 12–17. [Google Scholar]

- Mathew, S.; Zakaria, Z.A.; Musa, N.F. Antioxidant property and chemical profile of pyroligneous acid from pineapple plant waste biomass. Process. Biochem. 2015, 50, 1985–1992. [Google Scholar] [CrossRef]

- Tang, G.-Y.; Zhao, C.-N.; Liu, Q.; Feng, X.-L.; Xu, X.-Y.; Cao, S.-Y.; Meng, X.; Li, S.; Gan, R.-Y.; Li, H.-B. Potential of Grape Wastes as a Natural Source of Bioactive Compounds. Molecules 2018, 23, 2598. [Google Scholar] [CrossRef] [PubMed]

- Marcillo-Parra, V.; Anaguano, M.; Molina, M.; Tupuna-Yerovi, D.S.; Ruales, J. Characterization and quantification of bioactive compounds and antioxidant activity in three different varieties of mango (Mangifera indica L.) peel from the Ecuadorian region using HPLC-UV/VIS and UPLC-PDA. NFS J. 2021, 23, 1–7. [Google Scholar] [CrossRef]

- Segovia Gómez, F.; Almajano Pablos, M.P. Pineapple Waste Extract for Preventing Oxidation in Model Food Systems. J. Food Sci. 2016, 81, C1622–C1628. [Google Scholar] [CrossRef] [PubMed]

- Roda, A.; Lucini, L.; Torchio, F.; Dordoni, R.; De Faveri, D.M.; Lambri, M. Metabolite profiling and volatiles of pineapple wine and vinegar obtained from pineapple waste. Food Chem. 2017, 229, 734–742. [Google Scholar] [CrossRef] [PubMed]

- Ekechukwu, C.C.; Ikele, C.C.; Okafor, C.A.; Igwebuike, I.C. Comparative assessment of three yeast samples for wine production from pineapple. Multidiscip. Sci. J. 2021, 3, e2021003. [Google Scholar] [CrossRef]

- Tortoe, C.; Johnson, P.-N.T.; Slaghek, T.; Miedema, M.; Timmermans, T. Physicochemical, Proximate and Sensory Properties of Pineapple (Ananas sp.) Syrup Developed from Its Organic Side-Stream. Food Nutr. Sci. 2013, 4, 163–168. [Google Scholar] [CrossRef]

- Vandenberghe, L.P.S.; Karp, S.G.; de Oliveira, P.Z.; de Carvalho, J.C.; Rodrigues, C.; Soccol, C.R. Solid-State Fermentation for the Production of Organic Acids. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2018; pp. 415–434. [Google Scholar]

- Soccol, C.R.; Vandenberghe, L.P.S.; Rodrigues, C.; Medeiros, A.B.P.; Larroche, C.; Pandey, A. Production of Organic Acids by Solid-state Fermentation. In Current Developments in Solid-State Fermentation; Springer New York: New York, NY, USA, 2008; pp. 205–229. ISBN 9780387752129. [Google Scholar]

- Aziman, S.N.; Tumari, H.H.; Mohd Zain, N.A. Determination of Lactic Acid Production by Rhizopus Oryzae in Solid State Fermentation of Pineapple Waste. J. Teknol. 2015, 77, 95–102. [Google Scholar] [CrossRef]

- Bustamante, D.; Tortajada, M.; Ramón, D.; Rojas, A. Production of D-Lactic Acid by the Fermentation of Orange Peel Waste Hydrolysate by Lactic Acid Bacteria. Fermentation 2019, 6, 1. [Google Scholar] [CrossRef]

- Arekemase, M.O.; Adetitun, D.O.; Ahmed, M.I. Biochemical analysis of some fruit peels and comparison of Lactic acid production by authochthonous Lactic acid bacteria using fruit peels. Sri Lankan J. Biol. 2020, 5, 15. [Google Scholar] [CrossRef]

- Jusoh, N.; Othman, N.; Idris, A.; Nasruddin, A. Characterization of Liquid Pineapple Waste as Carbon Source for Production of Succinic Acid. J. Teknol. 2014, 69, 11–13. [Google Scholar] [CrossRef][Green Version]

- Ayeni, A.O.; Daramola, M.O.; Taiwo, O.; Olanrewaju, O.I.; Oyekunle, D.T.; Sekoai, P.T.; Elehinafe, F.B. Production of Citric Acid from the Fermentation of Pineapple Waste by Aspergillus niger. Open Chem. Eng. J. 2019, 13, 88–96. [Google Scholar] [CrossRef]

- Kareem, S.O.; Akpan, I.; Alebiowu, O.O. Production of citric acid by Aspergillus niger using pineapple waste. Malays. J. Microbiol. 2010, 6, 161–165. [Google Scholar] [CrossRef]

- Imandi, S.B.; Bandaru, V.V.R.; Somalanka, S.R.; Bandaru, S.R.; Garapati, H.R. Application of statistical experimental designs for the optimization of medium constituents for the production of citric acid from pineapple waste. Bioresour. Technol. 2008, 99, 4445–4450. [Google Scholar] [CrossRef]

- Abdullah, A.; Winaningsih, I. Effect of some parameter on lactic acid fermentation from pineapple waste by Lactobacillus delbrueckii. Proc. AIP Conf. Proc. N. Y. 2020, 2197, 1–9. [Google Scholar]

- Rodsamran, P.; Sothornvit, R. Preparation and characterization of pectin fraction from pineapple peel as a natural plasticizer and material for biopolymer film. Food Bioprod. Process. 2019, 118, 198–206. [Google Scholar] [CrossRef]

- Kumar, P.; Tanwar, R.; Gupta, V.; Upadhyay, A.; Kumar, A.; Gaikwad, K.K. Pineapple peel extract incorporated poly(vinyl alcohol)-corn starch film for active food packaging: Preparation, characterization and antioxidant activity. Int. J. Biol. Macromol. 2021, 187, 223–231. [Google Scholar] [CrossRef]

- Pornbencha, K.; Boonmalert, T.; Seubsai, A.; Dittanet, P. Synthesis of Polylactic Acid/Cellulose Composite Extracted from Pineapple Leaves. Key Eng. Mater. 2021, 891, 131–136. [Google Scholar] [CrossRef]

- Marzuki, M.N.A.; Tawakkal, I.S.M.A.; Basri, M.S.M.; Othman, S.H.; Kamarudin, S.H.; Lee, C.H.; Khalina, A. The Effect of Jackfruit Skin Powder and Fiber Bleaching Treatment in PLA Composites with Incorporation of Thymol. Polymers. 2020, 12, 2622. [Google Scholar] [CrossRef]

- Vega-Castro, O.; Contreras-Calderon, J.; León, E.; Segura, A.; Arias, M.; Pérez, L.; Sobral, P.J.A. Characterization of a polyhydroxyalkanoate obtained from pineapple peel waste using Ralsthonia eutropha. J. Biotechnol. 2016, 231, 232–238. [Google Scholar] [CrossRef]

- Sukruansuwan, V.; Napathorn, S.C. Use of agro-industrial residue from the canned pineapple industry for polyhydroxybutyrate production by Cupriavidus necator strain A-04. Biotechnol. Biofuels 2018, 11, 202. [Google Scholar] [CrossRef] [PubMed]

- Yuliusman; Nasruddin; Naf’an, H.I.; Sinto, J.; Nugroho, Y.W. Utilization of crown pineapple waste as raw material preparation of activated carbon as adsorbent in natural gas storage. E3S Web Conf. 2018, 67, 02018. [Google Scholar] [CrossRef]

- Selvanathan, N.; Subki, N.S.; Sulaiman, M.A.; Subki, N.S. Dye Adsorbent by Activated Carbon. J. Trop. Resour. Sustain. Sci 2015, 3, 169–173. [Google Scholar]

- Mahamad, M.N.; Zaini, M.A.A.; Zakaria, Z.A. Preparation and characterization of activated carbon from pineapple waste biomass for dye removal. Int. Biodeterior. Biodegradation 2015, 102, 274–280. [Google Scholar] [CrossRef]

- Jawad, A.H.; Kadhum, A.M.; Ngoh, Y.S. Applicability of dragon fruit (Hylocereus polyrhizus) peels as low-cost biosorbent for adsorption of methylene blue from aqueous solution: Kinetics, equilibrium and thermodynamics studies. Desalin. Water Treat. 2018, 109, 231–240. [Google Scholar] [CrossRef]

- Abd Latif, N.A.F.; Nordin, A.H.; Ngadi, N.; Nabgan, W.; Jusoh, M.; Mohamad, Z.; Mohd Nawawi, M.G. Pineapple leaves based activated carbon for efficient removal of reactive black 5 in aqueous. Mater. Today Proc. 2021, 1–5. [Google Scholar]

- Deebansok, S.; Amornsakchai, T.; Sae-ear, P.; Siriphannon, P.; Smith, S.M. Sphere-like and flake-like ZnO immobilized on pineapple leaf fibers as easy-to-recover photocatalyst for the degradation of congo red. J. Environ. Chem. Eng. 2021, 9, 104746. [Google Scholar] [CrossRef]

- Mahmud, K.N.; Wen, T.H.; Zakaria, Z.A. Activated carbon and biochar from pineapple waste biomass for the removal of methylene blue. Environ. Toxicol. Manag. 2021, 1, 30–36. [Google Scholar] [CrossRef]

- Patel, R.K.; Prasad, R.; Shankar, R.; Khare, P.; Yadav, M. Adsorptive removal of methylene blue dye from soapnut shell & pineapple waste derived activated carbon. Int. J. Eng. Sci. Technol. 2021, 13, 81–87. [Google Scholar] [CrossRef]

- Dai, H.; Huang, H. Synthesis, characterization and properties of pineapple peel cellulose-g-acrylic acid hydrogel loaded with kaolin and sepia ink. Cellulose 2017, 24, 69–84. [Google Scholar] [CrossRef]

- Dai, H.; Huang, Y.; Zhang, Y.; Zhang, H.; Huang, H. Green and facile fabrication of pineapple peel cellulose/magnetic diatomite hydrogels in ionic liquid for methylene blue adsorption. Cellulose 2019, 26, 3825–3844. [Google Scholar] [CrossRef]

- Dai, H.; Huang, Y.; Zhang, H.; Ma, L.; Huang, H.; Wu, J.; Zhang, Y. Direct fabrication of hierarchically processed pineapple peel hydrogels for efficient Congo red adsorption. Carbohydr. Polym. 2020, 230, 115599. [Google Scholar] [CrossRef] [PubMed]

- Agnihotri, S.; Sillu, D.; Sharma, G.; Arya, R.K. Photocatalytic and antibacterial potential of silver nanoparticles derived from pineapple waste: Process optimization and modeling kinetics for dye removal. Appl. Nanosci. 2018, 8, 2077–2092. [Google Scholar] [CrossRef]

- Mohammed, M.A.; Ibrahim, A.; Shitu, A. Batch Removal of Hazardous Safranin-O in Wastewater Using Pineapple Peels as an Agricultural Waste Based Adsorbent. Int. J. Environ. Monit. Anal. 2014, 2, 128. [Google Scholar] [CrossRef]

- Fu, B.; Ge, C.; Yue, L.; Luo, J.; Feng, D.; Deng, H.; Yu, H. Characterization of Biochar Derived from Pineapple Peel Waste and Its Application for Sorption of Oxytetracycline from Aqueous Solution. BioResources 2016, 11, 9017–9035. [Google Scholar] [CrossRef]

- Rosales, E.; Escudero, S.; Pazos, M.; Sanromán, M.A. Sustainable Removal of Cr(VI) by Lime Peel and Pineapple Core Wastes. Appl. Sci. 2019, 9, 1967. [Google Scholar] [CrossRef]

- Tangtubtim, S.; Saikrasun, S. Adsorption behavior of polyethyleneimine-carbamate linked pineapple leaf fiber for Cr(VI) removal. Appl. Surf. Sci. 2019, 467–468, 596–607. [Google Scholar] [CrossRef]

- Rambabu, K.; Bharath, G.; Banat, F.; Show, P.L. Biosorption performance of date palm empty fruit bunch wastes for toxic hexavalent chromium removal. Environ. Res. 2020, 187, 109694. [Google Scholar] [CrossRef]

- Ranasinghe, S.H.; Navaratne, A.N.; Priyantha, N. Enhancement of adsorption characteristics of Cr(III) and Ni(II) by surface modification of jackfruit peel biosorbent. J. Environ. Chem. Eng. 2018, 6, 5670–5682. [Google Scholar] [CrossRef]

- Gogoi, S.; Chakraborty, S.; Saikia, M.D. Surface modified pineapple crown leaf for adsorption of Cr(VI) and Cr(III) ions from aqueous solution. J. Environ. Chem. Eng. 2018, 6, 2492–2501. [Google Scholar] [CrossRef]

- Ahmad, A.; Khatoon, A.; Mohd-Setapar, S.-H.; Kumar, R.; Rafatullah, M. Chemically oxidized pineapple fruit peel for the biosorption of heavy metals from aqueous solutions. Desalin. Water Treat. 2016, 57, 6432–6442. [Google Scholar] [CrossRef]

- Mopoung, R.; Kengkhetkit, N. Lead and Cadmium Removal Efficiency from Aqueous Solution by NaOH Treated Pineapple Waste. Int. J. Appl. Chem. 2016, 12, 23–35. [Google Scholar]

- Ibisi, N.E.; Asoluka, C.A. Use of agro-waste (Musa paradisiaca peels) as a sustainable biosorbent for toxic metal ions removal from contami. Chem. Int. 2018, 4, 52–59. [Google Scholar]

- Voloshin, R.A.; Rodionova, M.V.; Zharmukhamedov, S.K.; Nejat Veziroglu, T.; Allakhverdiev, S.I. Review: Biofuel production from plant and algal biomass. Int. J. Hydrogen Energy 2016, 41, 17257–17273. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Joo, H.-S.S.; Yang, Y.-H.H. Biowaste-to-bioenergy using biological methods—A mini-review. Energy Convers. Manag. 2018, 177, 640–660. [Google Scholar] [CrossRef]

- Ayodele, B.V.; Alsaffar, M.A.; Mustapa, S.I. An overview of integration opportunities for sustainable bioethanol production from first- and second-generation sugar-based feedstocks. J. Clean. Prod. 2020, 245, 118857. [Google Scholar] [CrossRef]

- Huzir, N.M.; Aziz, M.M.A.; Ismail, S.B.; Abdullah, B.; Mahmood, N.A.N.; Umor, N.A.; Syed Muhammad, S.A.F. Agro-industrial waste to biobutanol production: Eco-friendly biofuels for next generation. Renew. Sustain. Energy Rev. 2018, 94, 476–485. [Google Scholar] [CrossRef]

- Athar, M.; Zaidi, S. A review of the feedstocks, catalysts, and intensification techniques for sustainable biodiesel production. J. Environ. Chem. Eng. 2020, 8, 104523. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Kumar Sharma, P.; Jhalani, A. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 2020, 262, 116553. [Google Scholar] [CrossRef]

- Su, T.; Zhao, D.; Khodadadi, M.; Len, C. Lignocellulosic biomass for bioethanol: Recent advances, technology trends, and barriers to industrial development. Curr. Opin. Green Sustain. Chem. 2020, 24, 56–60. [Google Scholar] [CrossRef]

- Chintagunta, A.D.; Ray, S.; Banerjee, R. An integrated bioprocess for bioethanol and biomanure production from pineapple leaf waste. J. Clean. Prod. 2017, 165, 1508–1516. [Google Scholar] [CrossRef]

- Choonut, A.; Saejong, M.; Sangkharak, K. The production of ethanol and hydrogen from pineapple peel by Saccharomyces cerevisiae and Enterobacter aerogenes. In Proceedings of the Energy Procedia; Elsevier Ltd.: Amsterdam, The Netherlands, 2014; Volume 52, pp. 242–249. [Google Scholar]

- Domínguez-Bocanegra, A.R.; Torres-Muñoz, J.A.; López, R.A. Production of Bioethanol from agro-industrial wastes. Fuel 2015, 149, 85–89. [Google Scholar] [CrossRef]

- Sarkar, D.; Prajapati, S.; Poddar, K.; Sarkar, A. Production of ethanol by Enterobacter sp. EtK3 during fruit waste biotransformation. Int. Biodeterior. Biodegradation 2019, 145, 104795. [Google Scholar] [CrossRef]

- Teoh, Y.P.; Hanani, S.Z. Simultaneous Saccharification and Co-Fermentation (SSCF) Using Banana and Pineapple Waste as Substrate. Mater. Sci. Forum 2016, 857, 465–468. [Google Scholar] [CrossRef]

- Soontornchaiboon, W.; Chunhachart, O.; Pawongrat, R. Ethanol Production from Pineapple Waste by Co-culture of Saccharomyces cerevisiae TISTR 5339 and Candida shehatae KCCM 11422. KKU Res. J. 2016, 21, 347–355. [Google Scholar] [CrossRef]

- Oliveira, J.A.R.; Conceição, A.C.; Silva Martins, L.H.; Moreira, D.K.T.; Passos, M.F.; Komesu, A. Evaluation of the technological potential of four wastes from Amazon fruit industry in glucose and ethanol production. J. Food Process. Eng. 2021, 44, e13610. [Google Scholar] [CrossRef]

- Mund, N.K.; Dash, D.; Mishra, P.; Nayak, N.R. Cellulose solvent–based pretreatment and enzymatic hydrolysis of pineapple leaf waste biomass for efficient release of glucose towards biofuel production. Biomass Convers. Biorefinery 2021, 1–10. [Google Scholar] [CrossRef]

- Casabar, J.T.; Unpaprom, Y.; Ramaraj, R. Fermentation of pineapple fruit peel wastes for bioethanol production. Biomass Convers. Biorefinery 2019, 9, 761–765. [Google Scholar] [CrossRef]

- Chen, A.; Guan, Y.J.; Bustamante, M.; Uribe, L.; Uribe-Lorío, L.; Roos, M.M.; Liu, Y. Production of renewable fuel and value-added bioproducts using pineapple leaves in Costa Rica. Biomass and Bioenergy 2020, 141, 105675. [Google Scholar] [CrossRef]

- Khedkar, M.A.; Nimbalkar, P.R.; Kamble, S.P.; Gaikwad, S.G.; Chavan, P.V.; Bankar, S.B. Process intensification strategies for enhanced holocellulose solubilization: Beneficiation of pineapple peel waste for cleaner butanol production. J. Clean. Prod. 2018, 199, 937–947. [Google Scholar] [CrossRef]

- Sanguanchaipaiwong, V.; Leksawasdi, N. Butanol production by Clostridium beijerinckii from pineapple waste juice. Energy Procedia 2018, 153, 231–236. [Google Scholar] [CrossRef]

- Rattanapoltee, P.; Kaewkannetra, P. Utilization of Agricultural Residues of Pineapple Peels and Sugarcane Bagasse as Cost-Saving Raw Materials in Scenedesmus acutus for Lipid Accumulation and Biodiesel Production. Appl. Biochem. Biotechnol. 2014, 173, 1495–1510. [Google Scholar] [CrossRef]

- Barros, S. de S.; Pessoa Junior, W.A.G.; Sá, I.S.C.; Takeno, M.L.; Nobre, F.X.; Pinheiro, W.; Manzato, L.; Iglauer, S.; de Freitas, F.A. Pineapple (Ananás comosus) leaves ash as a solid base catalyst for biodiesel synthesis. Bioresour. Technol. 2020, 312, 123569. [Google Scholar] [CrossRef]

- Aili Hamzah, A.F.; Hamzah, M.H.; Ahmad Mazlan, F.N.; Che Man, H.; Jamali, N.S.; Siajam, S.I. Anaerobic Co-digestion of Pineapple Wastes with Cow Dung: Effect of Different Total Solid Content on Bio-methane Yield. Adv. Agri Food Res. J. 2020, 1, a0000109. [Google Scholar] [CrossRef]

- Mir, M.A.; Hussain, A.; Verma, C. Design considerations and operational performance of anaerobic digester: A review. Cogent Eng. 2016, 3, 1181696. [Google Scholar] [CrossRef]

- Morales-Polo, C.; del Mar Cledera-Castro, M.; Moratilla Soria, B.Y. Reviewing the Anaerobic Digestion of Food Waste: From Waste Generation and Anaerobic Process to Its Perspectives. Appl. Sci. 2018, 8, 1804. [Google Scholar] [CrossRef]

- Reungsang, A.; Sreela-or, C. Bio-hydrogen production from pineapple waste extract by anaerobic mixed cultures. Energies 2013, 6, 2175–2190. [Google Scholar] [CrossRef]

- Usman, T.M.M.; Kavitha, S.; Banu, J.R.; Kaliappan, S. Valorization of food waste for biogas, biohydrogen, and biohythane generation. In Food Waste to Valuable Resources; Elsevier: Amsterdam, The Netherlands, 2020; pp. 15–38. [Google Scholar]

- Nguyen, T.-T.; Chu, C.-Y.; Ou, C.-M. Pre-treatment study on two-stage biohydrogen and biomethane productions in a continuous co-digestion process from a mixture of swine manure and pineapple waste. Int. J. Hydrogen Energy 2021, 46, 11325–11336. [Google Scholar] [CrossRef]

- Neshat, S.A.; Mohammadi, M.; Najafpour, G.D.; Lahijani, P. Anaerobic co-digestion of animal manures and lignocellulosic residues as a potent approach for sustainable biogas production. Renew. Sustain. Energy Rev. 2017, 79, 308–322. [Google Scholar] [CrossRef]

- Muenmee, S.; Prasertboonyai, K. Potential Biogas Production Generated by Mono- and Co-digestion of Food Waste and Fruit Waste (Durian Shell, Dragon Fruit and Pineapple Peel) in Different Mixture Ratio under Anaerobic Condition. Environ. Res. Eng. Manag. 2021, 77, 25–35. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, G.; Peng, L.; Su, H.; Tan, T. The anaerobic co-digestion of food waste and cattle manure. Bioresour. Technol. 2013, 129, 170–176. [Google Scholar] [CrossRef] [PubMed]

- Dos Santos, L.A.; Valença, R.B.; da Silva, L.C.S.; de Holanda, S.H.B.; da Silva, A.F.V.; Jucá, J.F.T.; Santos, A.F.M.S. Methane generation potential through anaerobic digestion of fruit waste. J. Clean. Prod. 2020, 256, 120389. [Google Scholar] [CrossRef]

- Dahunsi, S.O.; Ogunwole, J.O.; Owoseni, A.A.; Olutona, G.O.; Nejo, Y.T.; Atobatele, O.E. Valorization of pineapple peel and poultry manure for clean energy generation. Food Energy Secur. 2021, e228. [Google Scholar] [CrossRef]

- Wichitsathian, B.; Yimrattanabavorn, J.; Wonglertarak, W. Enhancement of biogas production from pineapple waste by acid-alkaline pretreatment. IOP Conf. Ser. Earth Environ. Sci. 2020, 471, 012005. [Google Scholar] [CrossRef]

- Aworanti, O.A.; Agarry, S.E.; Ogunleye, O.O. Biomethanization of the Mixture of Cattle Manure, Pig Manure and Poultry Manure in Co-Digestion with Waste Peels of Pineapple Fruit and Content of Chicken-Gizzard—Part II: Optimization of Process Variables. Open Biotechnol. J. 2017, 11, 54–71. [Google Scholar] [CrossRef][Green Version]

- Aworanti, O.A.; Agarry, S.E.; Ogunleye, O.O. Biomethanization of Cattle Manure, Pig Manure and Poultry Manure Mixture in Co-digestion with Waste of Pineapple Fruit and Content of Chicken-Gizzard- Part I: Kinetic and Thermodynamic Modelling Studies. Open Biotechnol. J. 2017, 11, 37–53. [Google Scholar] [CrossRef]

- Azouma, Y.O.; Reppich, M.; Turek, V.; Weiß, M. Using Agricultural Waste for Biogas Production as a Sustainable Energy Supply for Developing Countries. Chem. Eng. Trans. 2018, 70, 445–450. [Google Scholar] [CrossRef]

- Deng, Y.G.; Wang, J.L.; Jiao, J.; Zhang, J.; Peng, Z.L.; Zheng, Y.; Wang, G.; Qin, S.M. Effects of Temperature on Gas Production Efficiency and Fermentation Time of Anaerobic Fermentation of Pineapple Leaf Residue. Adv. Mater. Res. 2012, 512–515, 392–396. [Google Scholar] [CrossRef]

- Kumar, M.; Jacob, S.; Upadrasta, L.; Banerjee, R. Biomethanation of Pineapple Wastes Using Potent Anaerobic Consortia Substituting Cow Manure. Environ. Eng. Manag. J. 2017, 16, 2647–2655. [Google Scholar] [CrossRef]

- Abd Jalil, N.K.; Asli, U.A.; Hashim, H.; Abd Jalil, A.; Ahmad, A.; Khamis, A.K. Biohydrogen Production from Pineapple Biomass Residue using Immobilized Co-culture of Clostridium sporogenes and Enterobacter aerogenes. J. Energy Saf. Technol. 2018, 1, 51–57. [Google Scholar] [CrossRef]

| Canned | Export Unit (Tonnes) | Juice | Export Unit (Tonnes) | Concentrated Juice | Export Unit (Tonnes) |

|---|---|---|---|---|---|

| Thailand | 477,224 | Costa Rica | 150,596 | Philippines | 111,483 |

| Philippines | 221,287 | Netherlands | 105,742 | Thailand | 109,847 |

| Indonesia | 185,466 | Belgium | 18,456 | Netherlands | 59,391 |

| Kenya | 30,154 | Germany | 12,556 | Indonesia | 29,143 |

| Netherlands | 28,122 | Philippines | 11,201 | Costa Rica | 27,496 |

| Germany | 14,822 | Cyprus | 9195 | Kenya | 14,875 |

| Viet Nam | 14,359 | Mexico | 4683 | South Africa | 10,232 |

| China | 10,954 | Nepal | 4626 | Brazil | 3348 |

| Singapore | 8297 | Austria | 3954 | United States of America | 2155 |

| United Arab Emirates | 7528 | Guatemala | 3825 | Spain | 1900 |

| Eswatini | 6396 | France | 3447 | Eswatini | 1456 |

| United States of America | 4661 | Benin | 2977 | Lebanon | 1403 |

| Malaysia | 3726 | El Salvador | 2919 | France | 1330 |

| France | 3103 | Ireland | 2825 | Ghana | 1269 |

| Spain | 3623 | Honduras | 1955 | Germany | 1260 |

| Type of Organic Acid | Microorganism | Type of Pineapple Waste | Maximum Acid Production | References |

|---|---|---|---|---|

| Lactic Acid | Rhizopus oryzae | Solid | 103.69 mg/g | [16] |

| Lactic Acid | Rhizopus oryzae | Solid | 0.0236 g/g | [113] |

| Succinic Acid | Escherichia coli | Liquid | 6.26 g/L | [116] |

| Citric Acid | Aspergillus niger | Solid (peels) | 15.51 g/L | [117] |

| Citric Acid | Aspergillus niger | Solid (peels) | 60.61 g/kg | [118] |

| Citric Acid | Yarrowia lipolytica | Solid | 202.35 g/kg | [119] |

| Lactic Acid | Lactobacillus delbrueckii | Liquid | 54.97 g/L | [121] |

| Adsorbent | Dye | Removal Efficiency (%) | Adsorption Capacity (mg/g) | Isothermal Model | Kinetic Model | References |

|---|---|---|---|---|---|---|

| Hydrogel from pineapple peel cellulose | Methylene blue | ns | 138.25 | ns | Pseudo- second-order | [19] |

| Activated carbon from pineapple wastes | Methylene blue | 38.6 | ns | ns | ns | [128] |

| Activated carbon from pineapple wastes | Malachite green | 18.7 | ns | ns | ns | [128] |

| Activated carbon from pineapple wastes | Methylene blue | ns | 288.34 | Langmuir | ns | [129] |

| Activated carbon from pineapple leaves | Reactive black 5 | ns | 50 | ns | ns | [131] |

| Pineapple leaf fibre adsorbents | Congo red | >95 | ns | ns | ns | [132] |

| Activated carbon from pineapple waste | Methylene blue | 96 | ns | Langmuir | ns | [134] |

| Hydrogel from pineapple peel cellulose | Methylene blue | ns | 153.85 | ns | Pseudo second-order | [135] |

| Hydrogel from pineapple peel cellulose | Methylene blue | ns | 101.94 | Langmuir | Pseudo second-order | [136] |

| Hydrogel from pineapple peels | Congo red | ns | 138.89 | Langmuir | Pseudo second-order | [137] |

| Silver nanoparticles from pineapple peels waste | Methylene blue | 98.04 | ns | First-order kinetic model | ns | [138] |

| Pineapple peels | Safranin-O | ns | 21.7 | Freundlich | ns | [139] |

| Generation | First | Second | Third |

|---|---|---|---|

| Examples of feedstock | Human food-based feedstock | Lignocellulose materials and other non-edible lipids, oils, solid municipal waste etc. | Microbial organisms |

| Production methods | Transesterification or fermentation reaction | Thermochemical or biochemical conversion processes | Lipid extraction or direct fermentation, transesterification, product purification |

| Product types | Biodiesel, bioethanol | Syngas, biodiesel, jet fuel, bioalcohol, pyrolysis liquid, etc. | Biodiesel, bioethanol, biobutanol, biogasoline, biohydrogen, biomethane, etc. |

| Representative feedstock | Canola, coconut, corn, cottonseed, hazelnut, olive, palm, peanut, rapeseed, rice, bran, soya bean, sunflower, etc. | Lignocellulosic waste, jatropha, rice or wheat straw, wood chips, paper pulp, etc. | Chlorophyceae, Bacilleriophyceae, Rhodophyceae, Bacillus licheniformis, Escherichia coli, Pseudomonas sp., Brevundimonas sp., Pelagibaca bermudenis, etc. |

| Source | Bacteria | Raw Material (w/v) | Yield | Fermentation Method | References |

|---|---|---|---|---|---|

| Sonicated pineapple peels | Trichoderma harzianum | 5% | 197.6 g/L | ns | [20] |

| Pineapple leaves | Cellulase-xylanase concoction and Saccharomyces cerevisiae | 5–40% | 7.12% | SSF | [155] |

| Pineapple peels | Saccharomyces cerevisiae and Enterobacter aerogenes | 20% | 9.69 g/L | SHF | [156] |

| Pineapple peels | Trichoderma harzianum | 5% | 5.98 g/L | SHF | [157] |

| Pineapple waste | Aspergillus terreus and Kluyveromyces marxianus | 50% | 0.27 g/L | SSCF | [158] |

| Pineapple Part | Co-Substrate | Operating Conditions | Pre-Treatment | Methane Content (%) | References |

|---|---|---|---|---|---|

| Pineapple peels | - | T= 37 °C; STD= VDI 4630 | Hydrogen peroxide and sulfuric acid pre-treatment | 70 | [23] |

| Pineapple peels | - | T = 37 °C; pH = 7; Agitation =150 rpm | No pre-treatment | 66.10 | [25] |

| Pineapple waste | - | T= 35–45 °C; pH = 7–7.5; C/N = 30 | No pre-treatment | 57.40 | [58] |

| Pineapple waste | Swine manure | T = 37 °C; pH = 7; Agitation = continuous | Heat shock | 65 | [176] |

| Pineapple waste | Manures | T = 55.2 °C; SIR = 1:2; HRT = 8 days TS = 6.25% (opt) | No pre-treatment | 71.10 | [183] |

| Pineapple waste | Manures | T = 60 °C; SIR = 1:3 and 3:1; Agitation= 30 rpm (opt) | No pre-treatment | 58 | [184] |

| Pineapple waste | Cow dung | T = ambient; SIR = 1:2.4; VS ≤ 8%; HRT = 92, 73 and 67 days | No pre-treatment | 70.50 | [185] |

| Pineapple leaf residue | - | T = 35 °C (opt); pH = 7; TS = 20%; C/N = 25 | No pre-treatment | 63.20 | [186] |

| Pineapple peels and leaves | Cow manure and novel microbial consortia | T = 37 °C; pH = 7 | No pre-treatment | 56.61 | [187] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aili Hamzah, A.F.; Hamzah, M.H.; Che Man, H.; Jamali, N.S.; Siajam, S.I.; Ismail, M.H. Recent Updates on the Conversion of Pineapple Waste (Ananas comosus) to Value-Added Products, Future Perspectives and Challenges. Agronomy 2021, 11, 2221. https://doi.org/10.3390/agronomy11112221

Aili Hamzah AF, Hamzah MH, Che Man H, Jamali NS, Siajam SI, Ismail MH. Recent Updates on the Conversion of Pineapple Waste (Ananas comosus) to Value-Added Products, Future Perspectives and Challenges. Agronomy. 2021; 11(11):2221. https://doi.org/10.3390/agronomy11112221

Chicago/Turabian StyleAili Hamzah, Adila Fazliyana, Muhammad Hazwan Hamzah, Hasfalina Che Man, Nur Syakina Jamali, Shamsul Izhar Siajam, and Muhammad Heikal Ismail. 2021. "Recent Updates on the Conversion of Pineapple Waste (Ananas comosus) to Value-Added Products, Future Perspectives and Challenges" Agronomy 11, no. 11: 2221. https://doi.org/10.3390/agronomy11112221

APA StyleAili Hamzah, A. F., Hamzah, M. H., Che Man, H., Jamali, N. S., Siajam, S. I., & Ismail, M. H. (2021). Recent Updates on the Conversion of Pineapple Waste (Ananas comosus) to Value-Added Products, Future Perspectives and Challenges. Agronomy, 11(11), 2221. https://doi.org/10.3390/agronomy11112221