Biodegradable Raffia as a Sustainable and Cost-Effective Alternative to Improve the Management of Agricultural Waste Biomass

Abstract

1. Introduction

1.1. Transition from the Conventional Intensive Agricultural Production Model to a Circular and Sustainable One

1.2. Protected Horticulture and Its Role in Food Security and the Fight against Climate Change

1.3. The Importance of Protected Horticulture in the Economic and Social Development of the Regions and the Challenges of Moving towards a More Circular and Sustainable Model

1.4. Background, Current State of the Research Field and Theoretical References

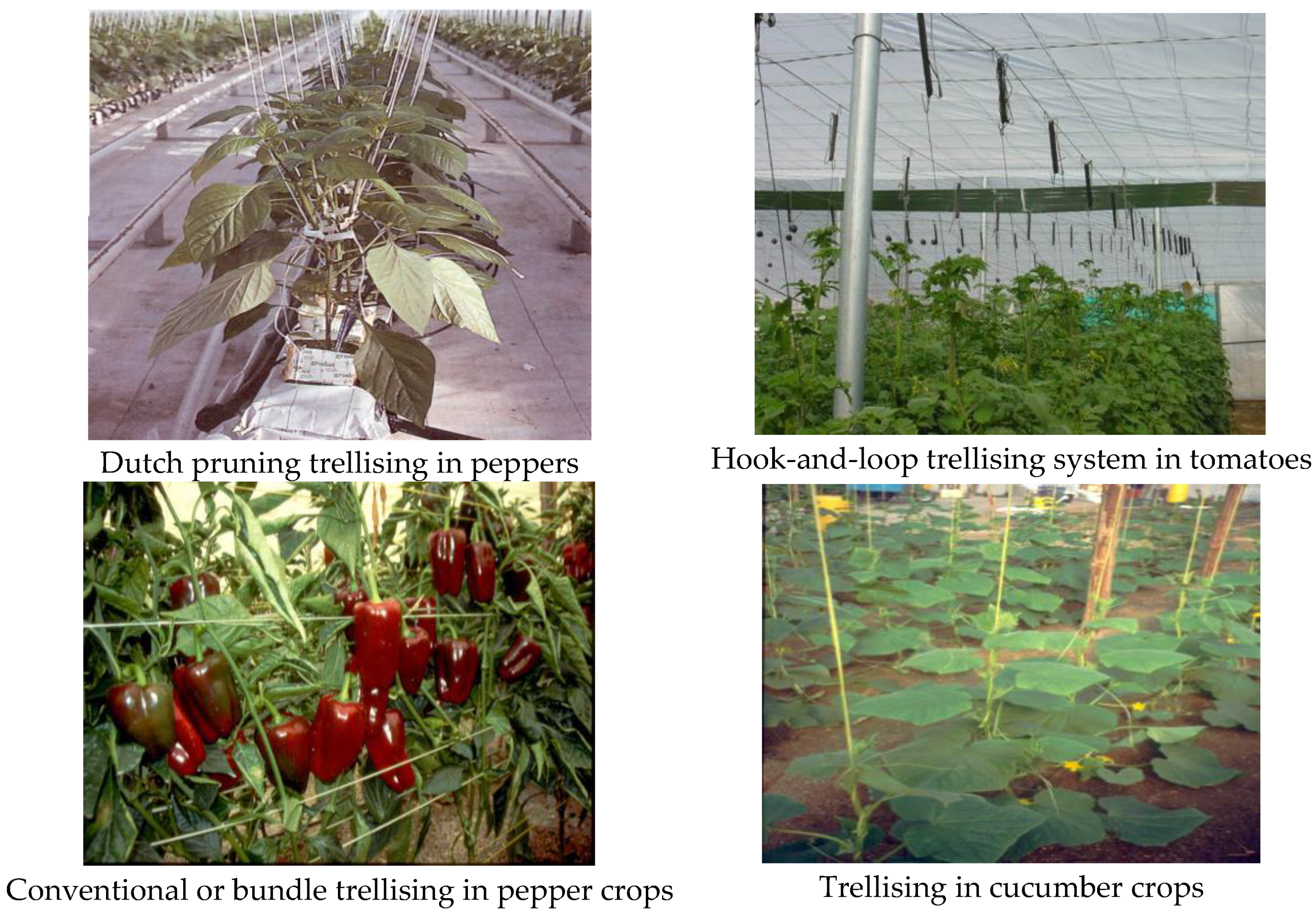

1.5. Characterization and Description of the Trellising Techniques in the Horticulture Crops in the Province of Almería

1.5.1. Importance of the Trellising Work in Horticulture Crops

- To improve the plant airing and to support the use of solar radiation.

- To prevent the contact of fruits and leaves with the ground.

- To reduce and control the incidence of plant illnesses.

- To improve the efficacy of phytosanitary products.

- To ease the processes of pruning, stem removal, fruit harvesting, and any crop maintenance work on the farms.

- To enlarge the density of the plantation in order to increase the productivity of the fields.

- To improve the quality of the fruits (greater homogeneity in visual aspects).

1.5.2. Crop Trellising Techniques in the Province of Almería and Characterization of the Main Elements Used

2. Materials and Methods

2.1. General Description of the Process

2.2. Key Process Steps

3. Results and Discussion

3.1. Main Crops in the Province of Almería that Are Grown Using Trellising Techniques and Estimation of the Amount of Raffia Used According to Type of Crop

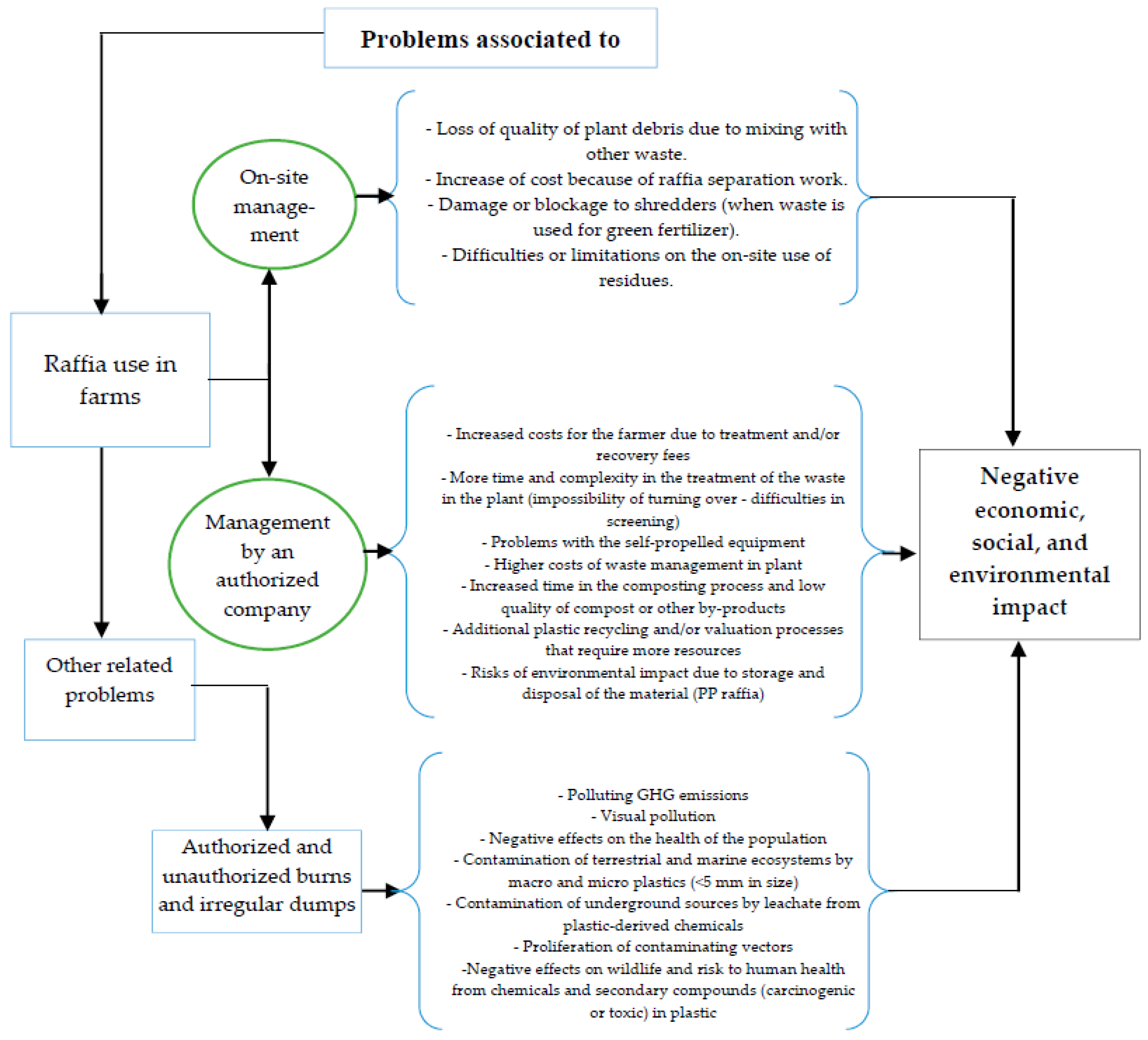

3.2. Characterization of the Use of Non-Biodegradable Raffia in Greenhouses and Main Problems Associated with Its Use

3.3. Estimation of the Residual Non-Biodegradable Raffia Generated in Almería Horticultural Greenhouses

3.4. Current Management of Non-Biodegradable Raffia Used in Almería Horticultural Greenhouses

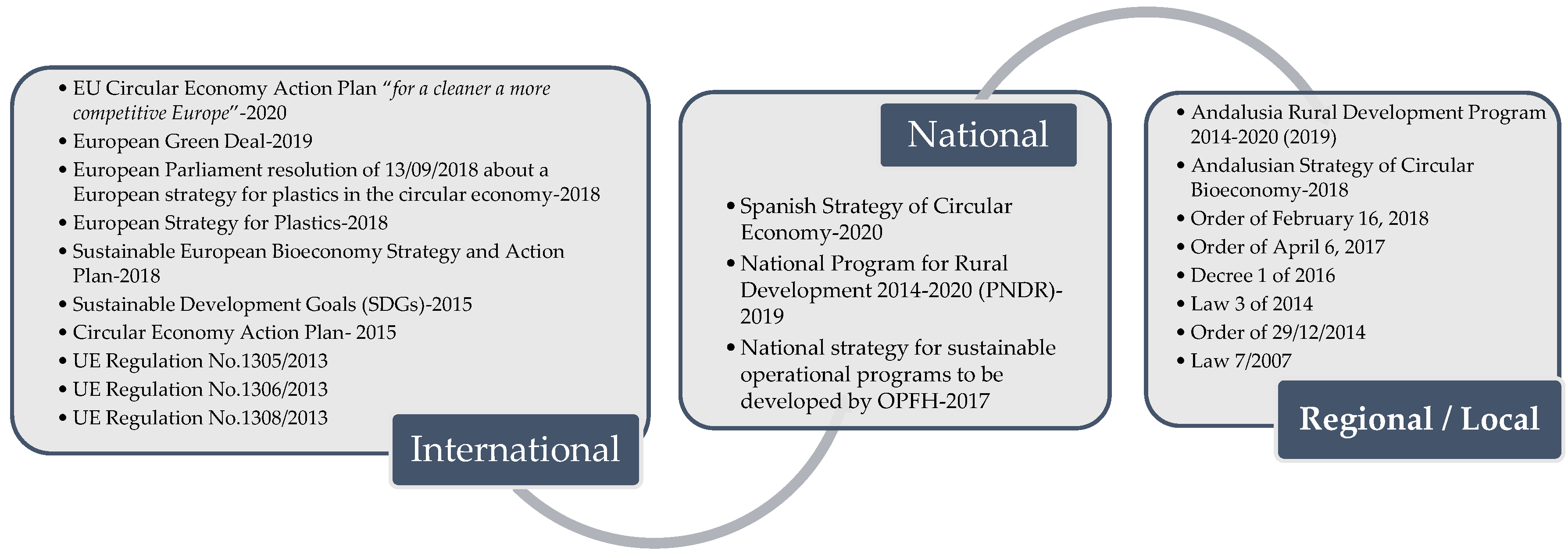

3.5. Policies, Strategies and Regulations Promoting the Use of Biodegradable Raffia

3.6. Analysis of Alternatives and Main Types of Biodegradable Raffia Marketed

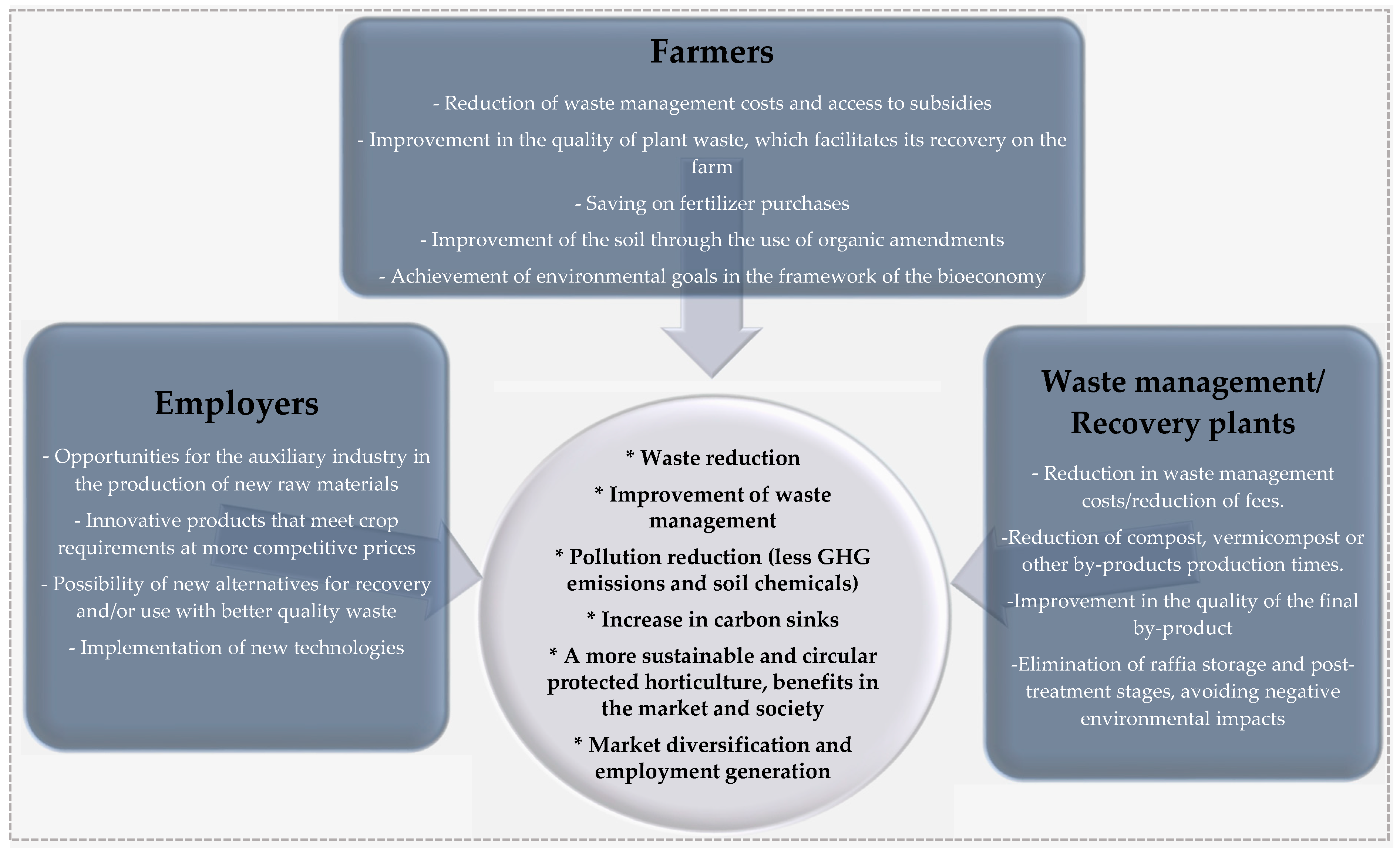

3.7. Main Causes that Reduce the Use of Biodegradable Raffia and Advantages for Farmers

- Factors related to product manufacturing and marketing:

- -

- Low availability of raw materials (bioproducts) for the elaboration of biodegradable raffia (BR).

- -

- High cost of raw materials (bioproducts) for the elaboration of BR.

- -

- Limitations due to field tests.

- -

- Materials (biomaterials) with long decomposition times.

- -

- Low market demand, which in turn reduces the supply of BR.

- Aspects related to the farmer:

- -

- Higher cost of biodegradable raffia (BR) than polypropylene raffia (PR).

- -

- Possible problems due to lesser resistance in BR.

- -

- Possible problems due to BR humidity absorption.

- -

- Reduction of BR breaking strength.

- -

- Low reliability in product quality and mechanical properties because it is relatively new to the market.

- -

- Limitations in compost production because of the degradation times of the BR.

- -

- Insufficient awareness/Ignorance of the product and/or the advantages or benefits of its use and existing subsidies.

Main Advantages and Opportunities Linked to the Use of Biodegradable Raffia

3.8. Economic Evaluation of the Use of Biodegradable Raffia Versus Polypropylene Raffia

- -

- Farm size. All the calculations were adjusted to an area of a 1 ha greenhouse, with a typical Almería greenhouse sloping-roof design (“raspa y amagado”) [10]. The different varieties of raffia available are grouped into two classes: non-biodegradable (BN) and biodegradable (B). The average prices obtained are 1.7 €/kg for non-biodegradable and 2.6 €/kg for biodegradable raffia.

- -

- An average consumption estimate (kg/ha) was used for each crop based on its weight, planting cycle duration and type of trellising technique (see Table 2). According to our calculations, the highest consumption of raffia per hectare is for the pepper crop. This is followed by cucumbers, eggplants, tomatoes, green beans, and zucchini.

- -

- The average annual generation of biomass for each crop-type in Almería [10] is based on 2019 data. The cost of off-site processing of the residual biomass is based on the average of the rates applied by companies operating in Almería. In all cases, the management of the vegetal residue with raffia is at least 15-percent more expensive than those residues not containing raffia or those containing a compostable one. The results show that the highest quantity of residual biomass is generated in tomato crops (49 t/ha), followed by pepper crops (28 t/ha), eggplants (27 t/ha), cucumbers (24 t/ha), green beans (23 t/ha), and zucchini (20 t/ha). Average prices for the off-site treatment of the waste are 8 €/t when vegetable remains are mixed with non-biodegradable raffia and 6.8 €/t when the remains are either without raffia or only a compostable one.

- -

- The regional government of the Andalusia Council introduced a maximum subsidy of 600 €/ha per year for those farms that commit to use a minimum of 40,000 m (80 kg on average) of biodegradable raffia during a period of five years. Each applicant farmer must provide the corresponding purchase invoice each year and will be reimbursed up to the aforementioned limit of 600 €/ha. The goal of this subsidy was to encourage the use of biodegradable raffia in years when there was little commercial supply and therefore average prices were much higher than those of conventional plastic raffia. This is a transitional rule, with positive results for the use of biodegradable raffia.

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- United Nations—Intergovernmental Panel on Climate Change. Climate Change and Land: Summary for Policymakers. An IPCC Special Report on Climate Change, Desertification, Land Degradation, Sustainable Land Management, Food Security, and Greenhouse Gas Fluxes in Terrestrial Ecosystems. Summary for Policymakers; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019; ISBN 9781784710644. [Google Scholar]

- Food and Agriculture Organization (FAO). FAO’S Work on Climate change. In Proceedings of the United Nations Climate Change Conference 2019, Madrid, Spain, 2–13 December 2019. [Google Scholar]

- Tubiello, F.N.; Salvatore, M.; Golec, R.D.C.; Ferrara, A.; Rossi, S.; Biancalani, R.; Federici, S.; Jacobs, H.; Flammini, A. Agriculture, Forestry and Other Land Use Emissions by Sources and Removals by Sinks; Statistics Division, Food and Agriculture Organization: Rome, Italy, 2014; Volume 2. [Google Scholar]

- Braimoh, A.K.; Hou, X.; Heumesser, C.; Zhao, Y. Greenhouse Gas Mitigation Opportunities in Agricultural Landscapes: A Practitioner’s Guide to Agricultural and Land Resources Management; Group, W.B., Ed.; Office of the Publisher, The World Bank: Washington, DC, USA, 2016. [Google Scholar]

- Fahad, S.; Wang, J. Farmers’ risk perception, vulnerability, and adaptation to climate change in rural Pakistan. Land Use Policy 2018, 79, 301–309. [Google Scholar] [CrossRef]

- Nelson, G.C.; Rosegrant, M.W.; Koo, J.; Robertson, R.; Sulser, T.; Zhu, T.; Ringler, C.; Msangi, S.; Palazzo, A.; Batka, M.; et al. CLIMATE CHANGE. Impact on Agriculture and Costs of Adaptation; International Food Policy Research Institute (IFPRI), Ed.; International Food Policy Research Institute: Washington, DC, USA, 2009. [Google Scholar]

- Working Group II to the Fourth Assessment Report of the IPCC. Climate Change 2007: Impacts, Adaptation and Vulnerability; Parry, M., Canziani, O., Palutikof, J., van der Linden, P., Hanson, C., Eds.; Intergovernmental Panel on Climate Change (IPCC): New York, NY, USA, 2007. [Google Scholar]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Cortés-García, F.J.; Camacho-Ferre, F. Agricultural waste: Review of the evolution, approaches and perspectives on alternative uses. Glob. Ecol. Conserv. 2020, 22, e00902. [Google Scholar] [CrossRef]

- Food and Agriculture Organization (FAO). Indicator 2.4.1: Proportion of Agricultural Area Under Productive and Sustainable Agriculture; FAO: Rome, Italy, 2019. [Google Scholar]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Plaza-Úbeda, J.A.; Camacho-Ferre, F. The Management of Agricultural Waste Biomass in the Framework of Circular Economy and Bioeconomy: An Opportunity for Greenhouse Agriculture in Southeast Spain. Agronomy 2020, 10, 489. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Sustainable Agriculture. A Tool to Strengthen Food Security and Nutrition in Latin America and the Caribbean; FAO: Rome, Italy, 2016. [Google Scholar]

- European Commission. A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment. COM(2018) 673 Final; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Hetemäki, L.; Hanewinkel, M.; Muys, B.; Ollikainen, M.; Palahí, M.; Trasobares, A. Leading the Way to a European Circular Bioeconomy Strategy; European Forest Institute: Joensuu, Finland, 2017. [Google Scholar]

- De Schoenmakere, M.; Hoogeveen, Y.; Gillabel, J.; Manshoven, S. EEA Report No 8/2018. The Circular Economy and the Bioeconomy Partners in Sustainability; European Environmental Agency, Ed.; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-9213-974-2. [Google Scholar]

- Antikainen, R.; Dalhammar, C.; Hildén, M.; Judl, J.; Jääskeläinen, T.; Kautto, P.; Koskela, S.; Kuisma, M.; Lazarevic, D.; Mäenpää, I.; et al. Renewal of Forest Based Manufacturing towards a Sustainable Circular Bioeconomy; Finnish Environment Institute, Ed.; Finnish Environment Institute (SYKE): Helsinki, Finland, 2017; ISBN 9789521146831. [Google Scholar]

- Molina-Sánchez, E.; Leyva-Díaz, J.; Cortés-García, F.; Molina-Moreno, V. Proposal of Sustainability Indicators for the Waste Management from the Paper Industry within the Circular Economy Model. Water 2018, 10, 1014. [Google Scholar] [CrossRef]

- Organisation for Economic Co-operation and Development (OECD). Meeting Policy Challenges for a Sustainable Bioeconomy; OECD: Paris, France, 2018; ISBN 9789264292338. [Google Scholar]

- Sommer, S.G.; Hamelin, L.; Olesen, J.E.; Montes, F.; Jia, W.; Chen, Q.; Triolo, J.M. Agricultural Waste Biomass. In Supply Chain Management for Sustainable Food Networks; John Wiley & Sons, Ltd: Chichester, UK, 2016; pp. 67–106. ISBN 9781118937495. [Google Scholar]

- Smil, V. Crop Residues: Agriculture’s Largest Harvest. Bioscience 1999, 49, 299–308. [Google Scholar] [CrossRef]

- Stegmann, P.; Londo, M.; Junginger, M. The circular bioeconomy: Its elements and role in European bioeconomy clusters. Resour. Conserv. Recycl. X 2020, 6, 100029. [Google Scholar] [CrossRef]

- Philp, J.C.; Winickoff, D.E. Innovation Ecosystems in the Bioeconomy; OECD Science, Technology and Industry Policy Papers: Paris, France, 2019. [Google Scholar]

- Carus, M.; Dammer, L. The Circular Bioeconomy—Concepts, Opportunities, and Limitations. Ind. Biotechnol. 2018, 14, 83–91. [Google Scholar] [CrossRef]

- Jimenez-Lopez, C.; Fraga-Corral, M.; Carpena, M.; Garcia-Oliveira, P.; Echave, J.; Pereira, A.; Lourenço-Lopes, C.; Prieto, M.; Simal-Gandara, J. Agriculture wastes valorisation as a source of antioxidant phenolic compounds within a circular and sustainable bio-economy. Food Funct. 2020, 11, 4853–4877. [Google Scholar] [CrossRef]

- Kretschmer, B.; Smith, C.; Watkins, E.; Allen, B.; Buckwell, A.; Desbarats, J.; Kieve, D. Technology Options for Feeding 10 Billion People. Recycling Agricultural, Forestry & Food Wastes and Residues for Sustainable Bioenergy and Biomaterials. Study IP/A/STOA/FWC/2008-096/Lot3/C1/SC6—SC8 September 2013; European Parliament: Brussels, Belgium, 2013; ISBN 978-92-823-4734-8. [Google Scholar]

- Iqbal, Y.; Lewandowski, I.; Weinreich, A.; Wippel, B.; Pforte, B.; Hadai, O.; Tryboi, O.; Spottle, M.; Peters, D. Maximising the Yield of Biomass from Residues of Agricultural Crops and Biomass from Forestry; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- Bhuvaneshwari, S.; Hettiarachchi, H.; Meegoda, J. Crop Residue Burning in India: Policy Challenges and Potential Solutions. Int. J. Environ. Res. Public Health 2019, 16, 832. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations and World Health Organization. Fruit and Vegetables for Health. Report of a Joint FAO/WHO Workshop, 1–3 September 2004, Kobe, Japan; FAO, WHO, Eds.; Food and Agriculture Organization of the United Nations—World Health Organization: Kope, Japan, 2004; ISBN 978-92-5-105268-6. [Google Scholar]

- Gruda, N.; Bisbis, M.; Tanny, J. Influence of climate change on protected cultivation: Impacts and sustainable adaptation strategies—A review. J. Clean. Prod. 2019, 225, 481–495. [Google Scholar] [CrossRef]

- Guodaar, L.; Asante, F.; Eshun, G.; Abass, K.; Afriyie, K.; Appiah, D.O.; Gyasi, R.; Atampugre, G.; Addai, P.; Kpenekuu, F. How do climate change adaptation strategies result in unintended maladaptive outcomes? Perspectives of tomato farmers. Int. J. Veg. Sci. 2020, 26, 15–31. [Google Scholar] [CrossRef]

- Bisbis, M.B.; Gruda, N.S.; Blanke, M.M. Securing Horticulture in a Changing Climate—A Mini Review. Horticulturae 2019, 5, 56. [Google Scholar] [CrossRef]

- De la Peña, R.; Hughes, J. Improving Vegetable Productivity in a Variable and Changing Climate. SAT eJ. 2007, 4, 1–22. [Google Scholar]

- Horticulture Australia Council & Horticulture Australia Ltd (HAC/HAL). Submission to the House of Representative’s Standing Committee on Primary Industries and Resources Inquiry—The Role of Government in Assisting Australian Farmers Adapt to the Impacts of Climate Change; HAC/HAL: Sydney, Australia, 2009. [Google Scholar]

- European Comission. EIP-AGRI Focus Group Circular Horticulture. Final Report. February 2019; European Comission: Brussels, Belgium, 2019. [Google Scholar]

- Chang, J.; Wu, X.; Wang, Y.; Meyerson, L.A.; Gu, B.; Min, Y.; Xue, H.; Peng, C.; Ge, Y. Does growing vegetables in plastic greenhouses enhance regional ecosystem services beyond the food supply? Front. Ecol. Environ. 2013, 11, 43–49. [Google Scholar] [CrossRef]

- Baudoin, W.; Nono-Womdim, R.; Lutaladio, N.; Hodder, A.; Castilla, N.; Leonardi, C.; De Pascale, S.; Qaryouti, M. Good Agricultural Practices for Greenhouse Vegetable Crops. Principles for Meditterranean Climate Areas; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013; ISBN 978-92-5-107650-7. [Google Scholar]

- European Commission. EIP-AGRI Focus Group. Circular Horticulture. Starting Paper: FG27; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Baudoin, W.; Nersisyan, A.; Shamilov, A.; Hodder, A.; Gutierrez, D.; De Pascale, S.; Nicola, S.; Chairperson, V.; Gruda, N.; Urban, L.; et al. Good Agricultural Practices for Greenhouse Vegetable Production in the South East European Countries. Principles for Sustainable Intensification of Smallholder Farms; Food and Agriculture Organization of the United Nations: Rome, Italy, 2017; ISBN 978-92-5-109622-2. [Google Scholar]

- Tüzel, Y.; Leonardi, C. Protected cultivation in Mediterranean region: Trends and needs. J. Ege Univ. Fac. Agric. 2009, 46, 215–223. [Google Scholar]

- Ferre, F.C.; Salmerón, V.A.; Carrillo, A.B.; Castillo, F.B.; Tortosa, F.C.; Ferre, Á.J.C.; Martínez, F.C.; Ramos, J.M.C. Técnicas de Producción en Cultivos Protegidos. Tomo I.; Caja Rural Intermediterránea Cajamar, Ed.; Instituto de Estudios de Cajamar: Almeria, Spain, 2003; ISBN 8495531178. [Google Scholar]

- Carrido, J.C.G.; Romero, J.L.R.L. Gestión Integrada de Invernaderos en el Área Mediterranea; Cajamar Caja Rural, Ed.; Cajamar Caja Rural: Almeria, Spain, 2016. [Google Scholar]

- Siwek, P.; Domagala-Swiatkiewicz, I.; Bucki, P.; Puchalski, M. Biodegradable agroplastics in 21st century horticulture. Polimery 2019, 64, 480–486. [Google Scholar] [CrossRef]

- Velandia, M.; Rejesus, R.; Clark, C.; DeLong, K.L.; Wszelaki, A.; Schexnayder, S.; Jensen, K. Evaluating the Relationship between Fruit and Vegetable Growers Use of Plastic Biodegradable Mulches, and Environmental Stewardship and Labor Savings: The Case of Tennessee Fruit and Vegetable Farmers. Sustainability 2020, 12, 2075. [Google Scholar] [CrossRef]

- Scarascia-Mugnozza, G.; Sica, C.; Russo, G. Plastic Materials in European Agriculture: Actual Use and Perspectives. J. Agric. Eng. 2012, 42, 15–28. [Google Scholar] [CrossRef]

- Crippa, M.; De Wilde, B.; Koopmans, R.; Leyssens, J.; Linder, M.; Muncke, J.; Ritschkof, A.-C.; Van Doorsselaer, K.; Velis, C.; Wagner, M. A Circular Economy for Plastics—Insights from Research and Innovation to Inform Policy and Funding Decisions; Smet, M., De Linder, M., Eds.; European Commission: Brussels, Belgium, 2019; ISBN 9789279984297. [Google Scholar]

- Mostafa, N.A.; Farag, A.A.; Abo-dief, H.M.; Tayeb, A.M. Production of biodegradable plastic from agricultural wastes. Arab. J. Chem. 2018, 11, 546–553. [Google Scholar] [CrossRef]

- Torrellas, M.; Antón, A.; López, J.C.; Baeza, E.J.; Parra, J.P.; Muñoz, P.; Montero, J.I. LCA of a tomato crop in a multi-tunnel greenhouse in Almeria. Int. J. Life Cycle Assess. 2012, 17, 863–875. [Google Scholar] [CrossRef]

- Junta de Andalucía—Consejería de Agricultura, Ganadería, Pesca y Desarrollo Sostenible. Síntesis de la Campaña de Hortícolas Protegidos de Almería. Campaña 2018/2019; Junta de Andalucía—Consejería de Agricultura, Ganadería, Pesca y Desarrollo Sostenible: Seville, Spain, 2019. [Google Scholar]

- Ministerio de Agricultura, Pesca y Alimentación. Cifras del Sector de Frutas y Hortalizas. Información Sectorial; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2019. [Google Scholar]

- Camacho-ferre, F.; Belmonte-Ureña, L.J. Análisis del beneficio en el modelo hortícola de Almería de alto rendimiento. Agric. Andal. 2019 2019, 1, 152–153. [Google Scholar]

- Junta de Andalucía—Consejería de Agricultura, Pesca y Desarrollo Rural. Caracterización de los Invernaderos de Andalucía; Junta de Andalucía—Consejería de Agricultura, Pesca y Desarrollo Rural: Seville, Spain, 2015. [Google Scholar]

- López, A.J.C.; García, M.C.G.; Parra, J.J.P.; Gómez, I.M.C. Caracterización de la Explotación Hortícola Protegida de Almería; Gómez, I.M.C., Ed.; Fundación; Fundación para la Investigación Agraria en la Provincia de Almería (FIAPA)—Fundación Cajamar: Almería, Spain, 2009; ISBN 84-88246-32-5. [Google Scholar]

- Junta de Andalucía—Consejería de Agricultura y Pesca. Plan del Sector Hortícola de Almería; Junta de Andalucía—Consejería de Agricultura y Pesca: Seville, Spain, 2002; Volume 2. [Google Scholar]

- Instituto de Estudios de Cajamar. La Economía de la Provincia de Almería; Caja Rural Intermediterránea Cajamar, Ed.; Instituto de Estudios de Cajamar: Almería, Spain, 2005; ISBN 84-95531-27-5. [Google Scholar]

- Cajamar Caja Rural. Proyecto Economía Circular en Agricultura; Cajamar Caja Rural: Almería, Spain, 2020. [Google Scholar]

- Parra, S.; Pérez, J.J.; Calatrava, J. Vegetal waste from protected horticulture in southeastern Spain: Characterisation of environmental externalities. Acta Hortic. 2001, 559, 787–792. [Google Scholar] [CrossRef]

- Castro, A.J.; López-Rodríguez, M.D.; Giagnocavo, C.; Gimenez, M.; Céspedes, L.; La Calle, A.; Gallardo, M.; Pumares, P.; Cabello, J.; Rodríguez, E.; et al. Six Collective Challenges for Sustainability of Almería Greenhouse Horticulture. Int. J. Environ. Res. Public Health 2019, 16, 4097. [Google Scholar] [CrossRef] [PubMed]

- Junta de Andalucía—Consejería de Agricultura, Ganadería, Pesca y Desarrollo Sostenible. Caracterización del Sector Agrario y Pesquero de Andalucía; Junta de Andalucía—Consejería de Agricultura, Ganadería, Pesca y Desarrollo Sostenible: Seville, Spain, 2019. [Google Scholar]

- Junta de Andalucía—Consejería de Agricultura y Pesca. Plan del Sector Hortícola de Almería. Volumen I; Junta de Andalucía—Consejería de Agricultura y Pesca: Seville, Spain, 2002; Volume 1. [Google Scholar]

- Junta de Andalucía. Estrategia Andaluza Bioeconomía Circular; Junta de Andalucía: Sevilla, Spain, 2018. [Google Scholar]

- Ministerio de Medio Ambiente y Medio Rural y Marino. Labores Específicas del Cultivo del Tomate; Ministerio de Medio Ambiente y Medio Rural y Marino: Madrid, Spain, 2008. [Google Scholar]

- García, M.C.G.; López, A.J.C.; Parra, J.J.P.; Mínguez, P.L. El Sistema de Producción Hortícola Protegido de la Provincia de Almería; Instituto de investigación y Formación Agraria y Pesquera (IFAPA), Ed.; Instituto de Investigación y Formación Agraria y Pesquera (IFAPA): Almería, Spain, 2016. [Google Scholar]

- Bernal, Ó.R.; Pérez, M.D.; Sánchez, F.T.; Ferre, F.C. Utilización de rafias biodegradables para el entutorado del cultivo de tomate en ciclo largo bajo invernadero. Terralia 2008, 65, 32–34. [Google Scholar]

- Junta de Andalucía—Consejería de Agricultura, Pesca y Desarrollo Rural de M.Am. y O. del T. Líneas de Actuación de las Consejerías de Agricultura, Pesca y Desarrollo Rural y de Medio Ambiente y Ordenación del Territorio en Materia de Gestión de Restos Vegetales en la Horticultura de Andalucía; Junta de Andalucía: Sevilla, Spain, 2016. [Google Scholar]

- Ferre, F.C.; Salmerón, V.A.; Carrillo, A.B.; Castillo, F.B.; Tortosa, F.C.; Ferre, Á.J.C.; Martínez, F.C.; Ramos, J.M.C. Técnicas de Producción de Cultivos Protegidos. Tomo II.; Caja Rural Intermediterránea Cajamar, Ed.; Instituto de Estudios de Cajamar: Almería, Spain, 2003; ISBN 84-95531-17-8. [Google Scholar]

- Ferre, F.C. Estudio Técnico de Plan de Higiene Rural. Término Municipal de Níjar; Mónsul Ingeniería SL: Almería, Spain, 2000; ISBN 84-607-1090-4. [Google Scholar]

- Antón, M.A.; Muñoz, P.; Castells, F.; Montero, J.I.; Soliva, M. Improving waste management in protected horticulture. Agron. Sustain. Dev. 2005, 25, 447–453. [Google Scholar] [CrossRef]

- Díaz-Pérez, M.; González, F.; Moreno, O.; Camacho, F. Use of composts from municipal wastes as substrates to produce tomato and melon seedlings in nurseries. Acta Hortic. 2011, 898, 159–163. [Google Scholar] [CrossRef]

- Instituto de Investigación y Formación Agraria y Pesquera (IFAPA). Jornada Técnica: Gestión de Restos Vegetales en Cultivos Hortícolas Protegidos; IFAPA: Almería, Spain, 2012. [Google Scholar]

- Cuesta, V.N.; Fernández, M.M.F.; Cano, F.C.P. La Gestión de los Residuos en Cultivos Hortícolas Protegidos: Requisitos en Producción Integrada; IFAPA, Centro La Mojonera. Consejería de Agricultura, Pesca y Desarrollo Rural: Almería, Spain, 2015. [Google Scholar]

- Sayadi-Gmada, S.; Gómez, S.P.; García-García, M.C.; Parra-López, C. Sustainable Management of Inorganic Waste in Horticultural Sector: New Approach for Implementing a Bioeconomy Farming System in Almeria (S. Spain); IFAPA (Institute of Agricultural Research and Training), CAPDER: Andalusia, Spain, 2019. [Google Scholar]

- Sayadi-Gmada, S.; Rodríguez-Pleguezuelo, C.R.; Rojas-Serrano, F.; Parra-López, C.; Parra-Gómez, S.; del Carmen García-García, M.; García-Collado, R.; Lorbach-Kelle, M.B.; Manrique-Gordillo, T. Inorganic Waste Management in Greenhouse Agriculture in Almeria (SE Spain): Towards a Circular System in Intensive Horticultural Production. Sustainability 2019, 11, 3782. [Google Scholar] [CrossRef]

- Junta de Andalucía—Consejería de Agricultura, Ganadería, Pesca y Desarrollo Sostenible. Texto consolidado M10—Agroambiente y clima (Versión 3- 7/05/2020); Junta de Andalucía—Consejería de Agricultura, Ganadería, Pesca y Desarrollo Sostenible: Seville, Spain, 2020. [Google Scholar]

- Úbeda, J.A.P.; de Burgos Jiménez, J.; Ureña, L.J.B. Grupos de interés, gestión ambiental y resultado empresarial: Una propuesta integradora. Cuad. Econ. y Dir. la Empres. 2011, 14, 151–161. [Google Scholar]

- Consejería de Agricultura, Pesca y Desarrollo Rural; Territorio, C.; de M.A. y O. del. Líneas de Actuación de las Consejerías de Agrícultura, Pesca y Desarrollo Rural y de Medio Ambiente y Ordenación del Territorio en Materia de Gestión de Restos Vegetales en la Hortícultura de Andalucía. Hacia una Economía Circular; Consejería de Agricultura, Pesca y Desarrollo Rural-Consejería de Medio Ambiente y Ordenación del Territorio: Seville, Spain, 2016. [Google Scholar]

- Sayadi, S.; Rodríguez, C.R.; García, M.C.; Parra, S.; Parra, C.; Lorbach, M.; García, R.; Manrique, T. Economía Circular y Sostenibilidad de la Horticultura Almeriense. Perspectivas Desde un Nuevo Marco Conceptual; Instituto de Investigación y Formación Agraria y Pesquera (IFAPA): Andalusia, Spain, 2019. [Google Scholar]

- Parlamento Europeo. P8_TA(2018)0352 Estrategia Europea Para el Plástico en una Economía Circular. Resolución del Parlamento Europeo, de 13 de Septiembre de 2018, Sobre una Estrategia Europea para el Plástico en una Economía Circular (2018/2035(INI)). (2019/C 433/18); Parlamento Europeo: Brussels, Belgium, 2018. [Google Scholar]

- Kaya-Celiker, H.; Mallikarjunan, P.K. Agricultural Applications of Biodegradable Films. In Edible Films and Coatings Fundamentals and Applications; Garcia, M.P.M., Gómez-Guillén, M.C., López-Caballero, M.E., Barbosa-Cánovas, G.V., Eds.; Taylor & Francis Group: Oxford, UK, 2016; p. 616. ISBN 9781315373713. [Google Scholar]

- Krochta, J.M.; De Mulder-Johnston, C.L.C. Biodegradable Polymers from Agricultural Products. Agric. Mater. Renew. Resour. 1996, 647, 120–140. [Google Scholar]

- Ignatyev, I.A.; Thielemans, W.; Beke, B.V. Recycling of Polymers: A Review. ChemSusChem 2014, 7, 1579–1593. [Google Scholar] [CrossRef]

- Malinconico, M. Different applications of biodegradable and compostable materials in agriculture. Acta Hortic. 2019, 1252, 39–46. [Google Scholar] [CrossRef]

- Malinconico, M. Biodegradable Materials in Agriculture: Case Histories and Perspectives. In Soil Degradable Bioplastics for a Sustainable Modern Agriculture; Guerrini, S., Borreani, G., Voojis, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 35–66. ISBN 9783662541289. [Google Scholar]

- Miles, C.; DeVetter, L.; Ghimire, S.; Hayes, D.G. Suitability of Biodegradable Plastic Mulches for Organic and Sustainable Agricultural Production Systems. HortScience 2017, 52, 10–15. [Google Scholar] [CrossRef]

- Sintim, H.Y.; Flury, M. Is Biodegradable Plastic Mulch the Solution to Agriculture’s Plastic Problem? Environ. Sci. Technol. 2017, 51, 1068–1069. [Google Scholar] [CrossRef] [PubMed]

- Narayan, R. Biodegradable and Biobased Plastics: An Overview. In Soil Degradable Bioplastics for a Sustainable Modern Agriculture; Malinconico, M., Ed.; Springer: Michigan, MI, USA, 2017; pp. 23–34. [Google Scholar]

- Kapanen, A.; Schettini, E.; Vox, G.; Itävaara, M. Performance and Environmental Impact of Biodegradable Films in Agriculture: A Field Study on Protected Cultivation. J. Polym. Environ. 2008, 16, 109–122. [Google Scholar] [CrossRef]

- Yan, C.; He, W.; Xue, Y.; Liu, E.; Liu, Q. Application of biodegradable plastic film to reduce plastic film residual pollution in Chinese agriculture. Chin. J. Biotechnol. 2016, 32, 748–760. [Google Scholar]

- Scott, G. Biodegradable plastics in agriculture. In Biodegradable Polymers for Industrial Applications, 1st ed.; Smith, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2005; pp. 451–473. [Google Scholar]

- Scaringelli, M.A.; Giannoccaro, G.; Prosperi, M.; Lopolito, A. Adoption of biodegradable mulching films in agriculture: Is there a negative prejudice towards materials derived from organic wastes? Ital. J. Agron. 2016, 11, 92–99. [Google Scholar] [CrossRef]

- Kasirajan, S.; Ngouajio, M. Polyethylene and biodegradable mulches for agricultural applications: A review. Agron. Sustain. Dev. 2012, 32, 501–529. [Google Scholar] [CrossRef]

- Chapman, S. Biodegradable Plastics for Agriculture; Welsh Government: Gales, UK, 2018. [Google Scholar]

- Agugliaro, F.M. Gasificacion de residuos de invernadero para la obtención de energía eléctrica en el sur de España: Ubicación mediante SIG. Interciencia 2007, 32, 131–136. [Google Scholar]

- Márquez, M.A.; Diánez, F.; Camacho, F. The use of vegetable subproducts from greenhouses (VSG) for animal feed in the Poniente region of Almería. Renew. Agric. Food Syst. 2011, 26, 4–12. [Google Scholar] [CrossRef]

- Becerra, A.T.; Bravo, X.L. La agricultura intensiva del poniente almeriense. Diagnóstico e instrumentos de gestión ambiental. M+A Rev. Electrónica Medioambiente 2010, 8, 18–40. [Google Scholar]

- Callejón, A.J.; Carreño, A.; Sánchez-Hermosilla, J.; Pérez, J. Evaluación de impacto ambiental de centro de transformación y gestión de residuos sólidos agrícolas en la provincia de Almería (España). Inf. Constr. 2010, 62, 79–93. [Google Scholar] [CrossRef]

- Mármol, J.R. Cultivo del Pimiento Dulce en Invernadero; Junta de Andalucía, Consejería de Agricultura y Pesca., Ed.; Signatura; Secretaría General Técnica, Servicio de Publicaciones y Divulgación: Sevilla, Spain, 2010; ISBN 978-84-8474-288-3. [Google Scholar]

- Callejón-Ferre, A.J.; López-Martínez, J.A.; López-Martínez, J.A. Briquettes of plant remains from the greenhouses of Almería (Spain). Span. J. Agric. Res. 2009, 7, 525–534. [Google Scholar] [CrossRef]

- Callejón-Ferre, A.J.; Velázquez-Martí, B.; López-Martínez, J.A.; Manzano-Agugliaro, F. Greenhouse crop residues: Energy potential and models for the prediction of their higher heating value. Renew. Sustain. Energy Rev. 2011, 15, 948–955. [Google Scholar] [CrossRef]

- Grupo Ecologista Mediterráneo. Residuos Agrícolas. Propuestas para la Reducción y Gestión de los Residuos Agrícolas en el Poniente Almeriense; Grupo Ecologista Mediterráneo: Almería, Spain, 1999. [Google Scholar]

- Elorrieta, M.A. Gestión de los Restos Vegetales: Cuestión de Espacio y Prevención. Available online: https://www.cajamar.es/es/agroalimentario/innovacion/formacion/actividades-de-transferencia/ano-2016/gestion-de-restos-vegetales-de-invernadero/ (accessed on 25 May 2020).

- Pérez, J.B.E. Transporte y Gestión de Restos Vegetales de Invernadero en Planta. Available online: https://www.cajamar.es/es/agroalimentario/innovacion/formacion/actividades-de-transferencia/ano-2016/gestion-de-restos-vegetales-de-invernadero/ (accessed on 25 May 2020).

- Nieto, J.M.T. Documentos Técnicos No. 10. Cajamar Caja Rural. Uso Agronómico de Restos de Cosecha en los Invernaderos Enarenados de la Cuenta Mediterránea; Cajamar Caja Rural: Almería, Spain, 2016. [Google Scholar]

- Luque-Romero, J.L.R. Manejo de Restos Vegetales con Rafias. Available online: https://www.cajamar.es/es/agroalimentario/innovacion/formacion/actividades-de-transferencia/ano-2016/gestion-de-restos-vegetales-de-invernadero/ (accessed on 25 May 2020).

- Instituto de Investigación y Formación Agraria y Pesquera (IFAPA). Hacia una Economía Circular en la Horticultura Almeriense; IFAPA: Almería, Spain, 2020. [Google Scholar]

- Ministerio de Agricultura, Pesca y Alimentación. Estrategia Nacional de los Programas Operativos Sostenibles a Desarrollar por las Organizaciones de Productores de Frutas y Hortalizas; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2017. [Google Scholar]

- Lau, A.K.; Cheuk, W.W.; Lo, K.V. Degradation of greenhouse twines derived from natural fibers and biodegradable polymer during composting. J. Environ. Manage. 2009, 90, 668–671. [Google Scholar] [CrossRef]

- Adelana, B.O. Effect of Staking on Growth and Yield of Tomatoes. East Afr. Agric. For. J. 1976, 41, 243–249. [Google Scholar] [CrossRef]

- Cajamar Caja Rural. Entutorado de Pimiento y Berenjena; El huerto de CRM; Cajamar Caja Rural: Almeria, Spain, 2012. [Google Scholar]

- Del Carmen Salas, M. Informe sobre la industria Hortícola. Densidades de plantación, poda y entutorado en cultivo de tomate protegido. Hortic. Int. 2002, 1, 98–109. [Google Scholar]

- Guil, A.M.; Garcia, I.M. Manual Práctico para el Cultivo del Pimiento en Agricultura Protegida; Guil, A.M., Garcia, I.M., Eds.; Ediciones: Madrid, Spain, 2018; ISBN 978-84-8476-670-4. [Google Scholar]

- Valera, D.L.; Belmonte, L.J.; Molina-Aiz, F.D.; López, A.; Camacho, F. The greenhouses of Almería, Spain: Technological analysis and profitability. Acta Hortic. 2017, 1170, 219–226. [Google Scholar] [CrossRef]

- Ferre, F.C.; Zapata, J.G.; Ferre, A.J.C.; Martínez, J.A.L.; Domínguez, J.V.S. Construcción de invernaderos “tipo Almería”. Hortic. Glob. 1998, 130, 66–69. [Google Scholar]

- Gázquez, J.C.; Meca, D.E.; Baeza, E.; Pérez, C.; García, R.; López, J.C. Evaluación de Tres Sistemas de Guiado para Tomate en Invernadero en Clima Cálido: Descuelgue Tradicional; Tradicional Intensivo y Perchas (Tipo Holandés); Centro de Innovación Agroalimentaria y Sostenibilidad (E.E. ‘Las Palmerillas’)-Fundación Cajamar: Almería, Spain, 2016. [Google Scholar]

- Goodship, V. Plastic Recycling. Sci. Prog. 2007, 90, 245–268. [Google Scholar] [CrossRef]

- Cajamar Caja Rural V Seminario Técnico Agronómico—Gestión de Restos Vegetales de Invernadero. Available online: https://www.cajamar.es/es/agroalimentario/innovacion/formacion/actividades-de-transferencia/ano-2016/gestion-de-restos-vegetales-de-invernadero/ (accessed on 26 May 2020).

- Servicio de Estudios Agroalimentarios de Cajamar. Análisis de la Campaña Hortofrutícola 2018/2019; Servicio de Estudios Agroalimentarios de Cajamar: Almeria, Spain, 2019. [Google Scholar]

- Consejería de Agricultura, Ganadería, Pesca y Desarrollo Sostenible. Estadísticas Provisionales de la Producción Ecológica 2019; Consejería de Agricultura, Ganadería, Pesca y Desarrollo Sostenible: Seville, Spain, 2019. [Google Scholar]

- Cajamar Caja Rural. Tutorado y Poda de Tomate en Invierno; El huerto de CRM; Cajamar Caja Rural: Almeria, Spain, 2012. [Google Scholar]

- Cajamar Caja Rural. Sistemas de Entutorado en Pimiento y Berenjena; Cajamar Caja Rural: Almeria, Spain, 2012. [Google Scholar]

- Vizcaino, A.G. Introduccion al Cultivo de tomate en invernadero; Instituto de Investigación y Formación Agraria y Pesquera-Consejería de Agricultura, Pesca y Desarrollo Rural: Almería, España, 2013. [Google Scholar]

- Cajamar Caja Rural. Entutorado de Pimiento; Cajamar Caja Rural: Almeria, Spain, 2015. [Google Scholar]

- World Economic Forum. Ellen MacArthur Foundation and McKinsey & Company, The New Plastics Economy. Rethinking the Future of Plastics; World Economic Forum: Colony, Switzerland, 2016. [Google Scholar]

- European Commission. Report from the Commission to the European Parliament and the Council. On the Impact of the Use of Oxo-Degradable Plastic, Including Oxo-Degradable Plastic Carrier Bags, on the Environment. Brussels, 16.1.2018 COM(2018) 35 Final; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Hernández, J.C.L.; Martínez, C.P.; Fernández, G.A. Ficha de Transferencia Nro. 017. Residuos Vegetales Procedentes de los Invernaderos de Almería; Cajamar Caja Rural: Almería, Spain, 2016. [Google Scholar]

- Touchaleaume, F.; Martin-Closas, L.; Angellier-Coussy, H.; Chevillard, A.; Cesar, G.; Gontard, N.; Gastaldi, E. Performance and environmental impact of biodegradable polymers as agricultural mulching films. Chemosphere 2016, 144, 433–439. [Google Scholar] [CrossRef]

- de Polanía, I.Z.; Baracaldo, F.P. Plastic products in Agriculture: Benefice and ambient cost: A review. Rev. UDCA Actual. Divulg. Científica 2013, 16, 139–150. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A European Strategy for Plastics in a Circular Economy. {SWD(2018) 16 Final}; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Junta de Andalucía—Consejería de Agricultura, Pesca y Desarrollo Rural. Caracterización de las Explotaciones de Invernadero de Andalucía: Campo de Dalías (Almería); Junta de Andalucía—Consejería de Agricultura, Pesca y Desarrollo Rural: Seville, Spain, 2015. [Google Scholar]

- Europapress Ayuntamiento de El Ejido Insta a la Junta a dar una “Respuesta” al “Colapso” de la Planta de Residuos Agrícolas. Available online: https://www.europapress.es/andalucia/Almería-00350/noticia-ayuntamiento-ejido-insta-junta-dar-respuesta-colapso-planta-residuos-agricolas-20150225185948.html (accessed on 18 May 2020).

- infoAgro.com Situación Extrema por Rafia en Restos Vegetales. No se Permite Descargar a los Agricultores Restos Vegetales con Rafia Debido a una Prohibición de la Delegación. Available online: https://www.infoagro.com/noticias/2015/situacion_extrema_por_rafia_en_restos_vegetales.asp (accessed on 18 May 2020).

- Ministerio de Agricultura, Pesca y Alimentación. Produccion y Consumo Sostenibles y Residuos Agrarios; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2012. [Google Scholar]

- Albaida Tratamiento de Residuos Albaida Tratamiento de Residuos. Available online: http://albaidaresiduos.es/index.php (accessed on 4 May 2020).

- Joseantonioarcos.es La Rafia Biodegradable se abre Paso. Available online: https://joseantonioarcos.es/2020/01/18/hilobi-rafia-hilo-biodegradable-agrinature/ (accessed on 13 May 2020).

- Reciclados Almerienses 2005 S.L Tarifas de Residuos Vegetales. Available online: https://recicladosalmerienses2005.com/residuos-vegetales/#intro (accessed on 15 May 2020).

- Joseantonioarcos.es La Nueva Planta de Reciclaje Agrícola de El Ejido Logra Separar la Rafia. Available online: https://joseantonioarcos.es/2016/07/23/reciclar-separar-rafia/ (accessed on 18 May 2020).

- Ecotech Valoriza Gestión y Tratamiento de Residuos Agrícolas y Vegetales. Available online: http://www.ecotechvaloriza.com/ (accessed on 18 May 2020).

- European Commission. COM(2019) 640 Final. The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. Circular Economy Action Plan. For a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Union. Reglamento (UE) No. 1305/2013 del Parlamento Europeo y del Consejo de 17 de Diciembre de 2013, Relativo a la Ayuda al Desarrollo Rural a Través del Fondo Europeo Agrícola de Desarrollo Rural (Feader) y por el que se Deroga el Reglamento (CE) No. 1698/2005; European Union: Brussels, Belgium, 2013. [Google Scholar]

- Parlamento Europeo; Consejo de la Unión Europea. Reglamento (UE) No 1306/2013 del Parlamento Europeo y del Consejo de 17 de Diciembre de 2013; Parlamento Europeo; Consejo de la Unión Europea: Brussels, Belgium, 2013. [Google Scholar]

- Parlamento Europeo y Consejo de la Unión Europea. Reglamento (UE) N° 1308/2013 del Parlamento Europeo y del Consejo, de 17 de Diciembre de 2013; Parlamento Europeo; Consejo de la Unión Europea: Brussels, Belgium, 2013; Volume L 347/671. [Google Scholar]

- Ministerio de Agricultura, Pesca y Alimentación. España—Programa Nacional de Desarrollo Rural. Versión 7.1; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2019. [Google Scholar]

- Ministerio de Agricultura, Pesca y Alimentación. Desarrollo de la Normativa Relativa a las Acciones 7.6, 7.19 y 7.28 Incluidas en las Directrices Medioambientales que Forman parte de la Estrategia Nacional de Programas Operativos Sostenibles; Ministerio de Agricultura, Pesca y Alimentación: Madrid, Spain, 2019. [Google Scholar]

- Gobierno de España. España Circular 2030. Estrategia Española de Economía Circular; Gobierno de España: Madrid, Spain, 2020. [Google Scholar]

- Junta de Andalucía. Programa de Desarrollo Rural de Andalucía 2014–2020; Versión 6.1; Junta de Andalucía: Sevilla, Spain, 2019. [Google Scholar]

- Consejería de Agricultura, Pesca y Desarrollo Rural. Orden de 26 de Mayo de 2015, por la que se Aprueban en la Comunidad Autónoma de Andalucía las Bases Reguladoras para la Concesión de Subvenciones a la Medida 10: Agroambiente y Clima, Incluida en el Programa de Desarrollo Rural de Andalucía 2014–2020, y s; Consejería de Agricultura, Pesca y Desarrollo Rural: Seville, Spain, 2015. [Google Scholar]

- Consejería de Agricultura, Pesca y Desarrollo Rural. Orden de 6 de Abril de 2017, por la que se Modifican las Órdenes de 26 de Mayo de 2015, por la que se Aprueban en la Comunidad Autónoma de Andalucía las Bases Reguladoras para la Concesión de Subvenciones a la Medida 10: Agroambiente y Clima, y Medida 11; Consejería de Agricultura, Pesca y Desarrollo Rural: Seville, Spain, 2017. [Google Scholar]

- Junta de Andalucía. Orden de 16 de Febrero de 2018, por la que se Efectúa la Convocatoria para el año 2018 de Subvenciones a la Medida 10: Agroambiente y Clima, a la Medida 11: Agricultura Ecológica y a la Medida 13: Pagos a Zonas con Limitaciones Naturales u otras Limitacio; Junta de Andalucía: Sevilla, Spain, 2018. [Google Scholar]

- Junta de Andalucía. Ley 7/2007, de 9 de Julio de Gestión Integrada de la Calidad Ambiental; Junta de Andalucía: Sevilla, Spain, 2007. [Google Scholar]

- Junta de Andalucía. Ley 3/2014, de 1 de Octubre, de Medidas Normativas para Reducir las Trabas Administrativas para las Empresas; Junta de Andalucía: Sevilla, Spain, 2014. [Google Scholar]

- Junta de Andalucía—Consejería de Economía y Conocimiento. Decreto 1/2016, de 12 de Enero, por el que se Establece un Conjunto de Medidas para la Aplicación de la Declaración Responsable para Determinadas Actividades Económicas Reguladas en la Ley 3/2014, de 1 de Octubre, de Medidas Normativas para Reducir las tr; Junta de Andalucía—Consejería de Economía y Conocimiento: Sevilla, Spain, 2016. [Google Scholar]

- Ayuntamiento de El Ejido. B.O.P de Almería—Número 148 del 03 de Agosto de 2017. Ordenanza de Invernaderos y su Entorno; Ayuntamiento de El Ejido: Almería, Spain, 2017. [Google Scholar]

- Consejería de Agricultura, Pesca y Desarrollo Rural. Orden de 29 de Diciembre de 2014, por la que se Modifica la Orden de 12 de Diciembre de 2001, por la que se Establecen las Medidas de Control Obligatorias, así como las Recomendadas en la Lucha Contra las Enfermedades Víricas en los Cultivos Hortícolas; Consejería de Agricultura, Pesca y Desarrollo Rural: Seville, Spain, 2015. [Google Scholar]

- Control Bío Hilo Biodegradable R35. Available online: https://controlbio.es/es/insumos-agricolas/256-hilo-biodegradable-resistencia-35-kg (accessed on 26 May 2020).

- Agrinature Indálica SA Hilo Biodegradable. Available online: https://www.agri-nature.com/producto/hilo-biodegradable/ (accessed on 25 May 2020).

- Reyenvas Rafia Agrícola para Entutorar (Tutor Agrícola). Available online: https://reyenvas.com/productos/c-9-horticola (accessed on 25 May 2020).

- Royal Brinkman Rafia. Available online: https://royalbrinkman.es/ir-al-catalogo-cambio-de-cultivo/rafia (accessed on 25 May 2020).

- Royal Brinkman ¿Cuál es la Diferencia Entre la Rafia PLA, la Rafia de Polipropileno, la Rafia de Yute y la Rafia de Yute con Cordenka? Available online: https://royalbrinkman.es/centro-de-conocimiento/cambio-de-cultivo/cual-es-la-diferencia-entre-la-rafia-pla-la-rafia-de-polipropileno-la-rafia-de-yute-y-la-rafia-de-yute-con-cordenka (accessed on 27 May 2020).

- Hilos Técnicos, S.M. Rafia. Available online: http://hilostecnicos.com/index.php/productos/rafia (accessed on 26 May 2020).

- Junta de Andalucía. Anexo 1: Relación de Expedientes Incluidos en Resolución Definitiva De solicitud Anual de pago. Convocatoria 2018. Campaña 2018; Junta de Andalucía: Almería, Spain, 2019. [Google Scholar]

- Junta de Andalucía—Consejería de Agricultura, Ganadería, P. y D.S.-D.G. de A.D. y de M. Resolución DGADM/SGCIA/SAMA 30/05/2019 Dirección General de Ayudas Directas y de Mercados por la que se Resuelve la Solicitud Anual de Pago de Ayudas a la Medida 10: Agroambiente y Clima, Operación 10.1.9 Sistemas Sostenibles de Cultivos hortícolas Intensivos y flor Cortada en Invernadero. Actuación 2: Rafia Biodegradable en Lugar de Convencional, Campaña 2017 y por la que se Modifica, en su Caso, las UnidadesiInicialmente comprometidas; Junta de Andalucía: Sevilla, Spain, 2019. [Google Scholar]

- Junta de Andalucía. Anexo 1: Relación de Expedientes Incluidos en Resolución Definitiva de Solicitud Anual de Pago. Convocatoria 2017. Campaña 2018; Junta de Andalucía: Sevilla, Spain, 2019. [Google Scholar]

- Honoré, M.N.; Belmonte-Ureña, L.J.; Navarro-Velasco, A.; Camacho-Ferre, F. Profit Analysis of Papaya Crops under Greenhouses as an Alternative to Traditional Intensive Horticulture in Southeast Spain. Int. J. Environ. Res. Public Health 2019, 16, 2908. [Google Scholar] [CrossRef] [PubMed]

| Year | Name of the Study | Type of Alternative Materials Analyzed | Type of Parameters Analyzed/Features | Key Findings of the Study | Conclusions | BIBLIOGRAPHICAL REFERENCE |

|---|---|---|---|---|---|---|

| 2008 | Use of biodegradable raffia for tomato crop trellising in long cycle under greenhouse | Jute-Rattan-Potato and corn starch | Maximum force Maximum elasticity Gradient | Raffia made from potato and corn starch + rattan, has less resistance to breakage and less gradient. Jute is more elastic. | Different alternative biodegradable materials can be found on the market, which makes it possible to obtain a completely organic waste. | [62] |

| 2009 | Degradation of greenhouse twines derived from natural fibres and biodegradable polymer during composting | Yarn of cotton, jute and a biodegradable polymer yarn (EcoPLA) | Test of biodegradation (Composting) for 15 weeks. Monitoring of the physical properties of the yarns: linear density, % weight loss and resistance to traction. | Composting tests showed that all three materials could be easily degraded in a composting environment within a reasonable time. | EcoPLA yarn has the advantage of being the most environmentally compatible biodegradable material. | [105] |

| 2016 | Management of vegetable waste with raffia | Cellulose biopolymer (20 kg) Cellulose biopolymer (45 kg) Jute-Rayon P Sisal Biopolymer | Tensile test-Deformation of new and used raffia | The results of the composting test show that after 11 months all materials degrade, even without being shredded, except the Biopolymer. | A high number of material breaks. There is a large availability of materials that meet strength and degradation specifications. | [102] |

| 2016 | Action lines for the management of plant residues in Andalusian horticulture. Annex II. Cost analysis of the use of biodegradable raffia vs. propylene raffia. | Cellulose raffia/biopolymer 100% biodegradable | Economic | The results obtained show that the increase in cost of using biodegradable raffia is 419.29 euros/ha more than conventional raffia. | The number of companies that market or distribute biodegradable raffia is low. Three companies have been identified in the province of Almería. | [63] |

| 2017 | Biodegradable Materials in Agriculture: Case Histories and Perspectives. Case History: The Greenhouse Plastic Materials in Greenhouses | Clips of biodegradable and compostable materials | Basic test of functional properties: resistance of the thread under stress. Laboratory and field composting tests. | The clips were very well decomposed in 4 months and the compost obtained could be certified and commercialised. | The use of compostable clips provides advantages in reducing pollution of the compost and represents less costs for farmers and composting companies. | [81] |

| 2019 | Different applications of biodegradable and compostable materials in agriculture | PLA Polylactic Acid threads | It is a material highly resistant to ultraviolet radiation. It is strong, lightweight and has a low moisture absorption. | PLA threads can be recycled as green waste and composted at the same time with other compostable materials | This alternative is already on the market (Netherlands) and can replace non-biodegradable materials. It contributes to savings for farmers by reducing waste disposal fees. | [80] |

| 2019 | Inorganic Waste Management in Greenhouse Agriculture in Almería (SE Spain): Towards a Circular System in Intensive Horticultural Production | Biodegradable yarn made from recycled cotton and agro-nutrients, jute fibre, and other natural materials, cellulose-rayon. | Compostable materials | The use of these materials prevents the work of separating the ropes from the rest of the organic elements once the crop has been harvested. This allows to reduce costs and to produce compost in the farms. | This practice is part of the list of Best Available Techniques (BAT) for the Management of Inorganic Greenhouse Waste in Almería. | [71] |

| 2020 | REINWASTE Project (MED Cooperation Programme 2014–2020. Institute for Agricultural and Fisheries Research and Training (IFAPA in Spanish) | Alternative 1: use of reusable raffia. Alternative 2: use of natural raffia of vegetable origin (jute), 100% compostable. Alternative 3: use of mixed biodegradable raffia (natural + polymer). |

| Not yet obtained | The project is currently in the pilot testing phase. | [103] |

| Crop | Area(ha) 2019 | Type of Technique | Average of Raffia Used | Observations | |||

|---|---|---|---|---|---|---|---|

| (ST) | (HTb) | (kg/ha) | Total (kg/Year) | Total (t/Year) | |||

| Tomato | 1715 | × | 160 | 274,400 | 274 | LCC and hook | |

| Tomato | 7840 | × | 53 | 415,520 | 416 | SCC | |

| Pepper | 9865 | × | 80 | 789,200 | 789 | ||

| Pepper | 695 | × | 132 | 86,988 | 87 | ||

| Cucumber | 5023 | × | 53 | 266,219 | 266 | ||

| Zucchini | 7349 | × | 33 | 242,517 | 243 | Trellising 10% | |

| Eggplant | 2164 | × | 80 | 173,120 | 173 | ||

| Green beans | 243 | × | 40 | 9720 | 8 | ||

| Total | 2,257,684 | 2256 | |||||

| Type of Commercialized Raffia | Main Characteristics | Reference |

|---|---|---|

| Cellulose/Biopolymer raffia | 100% biodegradable. Special for trellising horticultural crops | [63,153,154] |

| Biopolymer raffia | 100% biocompostable product. Bio trellis thread designed for industrial composting. Suitable for organic composting processes. | [155] |

| 1. PLA Raffia: Polylactic Acid Rope 2. Jute cordenka: Cordenka wire and jute strands | 100% biodegradable threads PLA rope in horticulture is spun and then braided to improve its strength. It is not sensitive to UV rays. | [156,157] |

| PLA raffia | Biodegradable raffia | [158] |

| Tomato | Pepper | Cucumber | Zucchini | Eggplant | Green Bean | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type of Raffia | NB | B | NB | B | NB | B | NB | B | NB | B | NB | B |

| Average Raffia Consumption (kg/ha) | 72.2 | 83.3 | 80.0 | 33.0 | 80.0 | 70.0 | ||||||

| Average Price €/kg) | 1.7 € | 2.6 € | 1.7 € | 2.6 € | 1.7 € | 2.6 € | 1.7 € | 2.6 € | 1.7 € | 2.6 € | 1.7 € | 2.6 € |

| Purchase Annual Cost | 126 € | 188 € | 145 € | 216 € | 139 € | 208 € | 57 € | 86 € | 139 € | 208 € | 122 € | 182 € |

| Amount of Residual Biomass (t/year) per ha | 49 | 28 | 24 | 20 | 27 | 23 | ||||||

| Average Cost of External Processing (€/t) | 8.0 € | 6.8 € | 8.0 € | 6.8 € | 8.0 € | 6.8 € | 8.0 € | 6.8 € | 8.0 € | 6.8 € | 8.0 € | 6.8 € |

| Annual Cost of Waste Treatment | 392 € | 333 € | 224 € | 190 € | 192 € | 163 € | 160 € | 136 € | 216 € | 184 € | 184 € | 156 € |

| Total Cost at the End of the Season before Subsidy | 518 € | 521 € | 369 € | 407 € | 331 € | 371 € | 217 € | 222 € | 355 € | 392 € | 306 € | 338 € |

| Aid/Subsidy from the Regional Government | −€ | −€ | −€ | −144 € | −€ | −139 € | −€ | −€ | −€ | −139 € | −€ | −€ |

| Net Cost after Subsidy | 518 € | 521 € | 369 € | 263 € | 331 € | 233 € | 217 € | 222 € | 355 € | 253 € | 306 € | 338 € |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Toresano-Sánchez, F.; Camacho-Ferre, F. Biodegradable Raffia as a Sustainable and Cost-Effective Alternative to Improve the Management of Agricultural Waste Biomass. Agronomy 2020, 10, 1261. https://doi.org/10.3390/agronomy10091261

Duque-Acevedo M, Belmonte-Ureña LJ, Toresano-Sánchez F, Camacho-Ferre F. Biodegradable Raffia as a Sustainable and Cost-Effective Alternative to Improve the Management of Agricultural Waste Biomass. Agronomy. 2020; 10(9):1261. https://doi.org/10.3390/agronomy10091261

Chicago/Turabian StyleDuque-Acevedo, Mónica, Luis Jesús Belmonte-Ureña, Fernando Toresano-Sánchez, and Francisco Camacho-Ferre. 2020. "Biodegradable Raffia as a Sustainable and Cost-Effective Alternative to Improve the Management of Agricultural Waste Biomass" Agronomy 10, no. 9: 1261. https://doi.org/10.3390/agronomy10091261

APA StyleDuque-Acevedo, M., Belmonte-Ureña, L. J., Toresano-Sánchez, F., & Camacho-Ferre, F. (2020). Biodegradable Raffia as a Sustainable and Cost-Effective Alternative to Improve the Management of Agricultural Waste Biomass. Agronomy, 10(9), 1261. https://doi.org/10.3390/agronomy10091261