Utilization of Olive Oil Processing Waste Composts in Organic Tomato Seedling Production

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Physical and Chemical Properties of Substrates

3.2. Germination Period and Rate

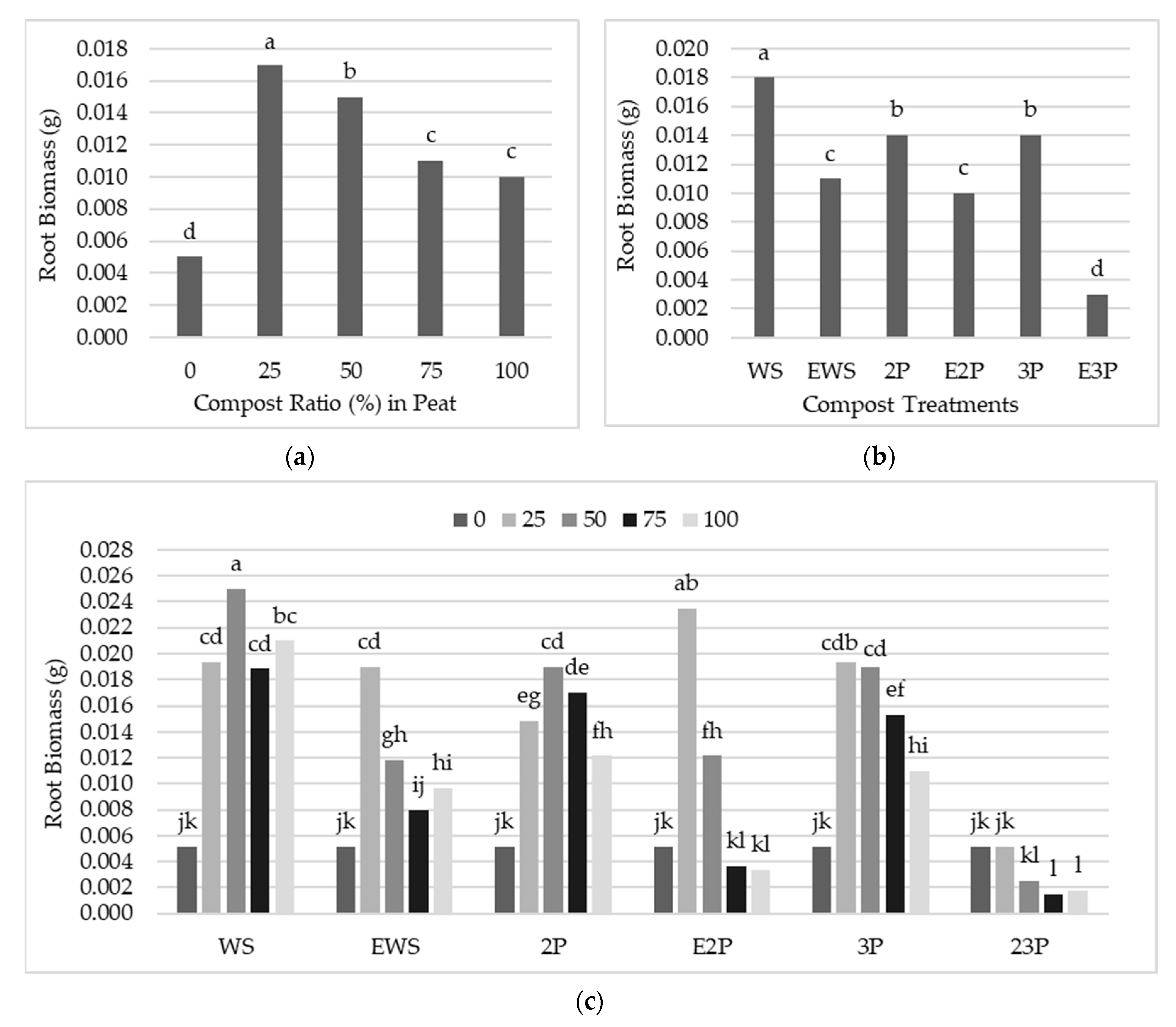

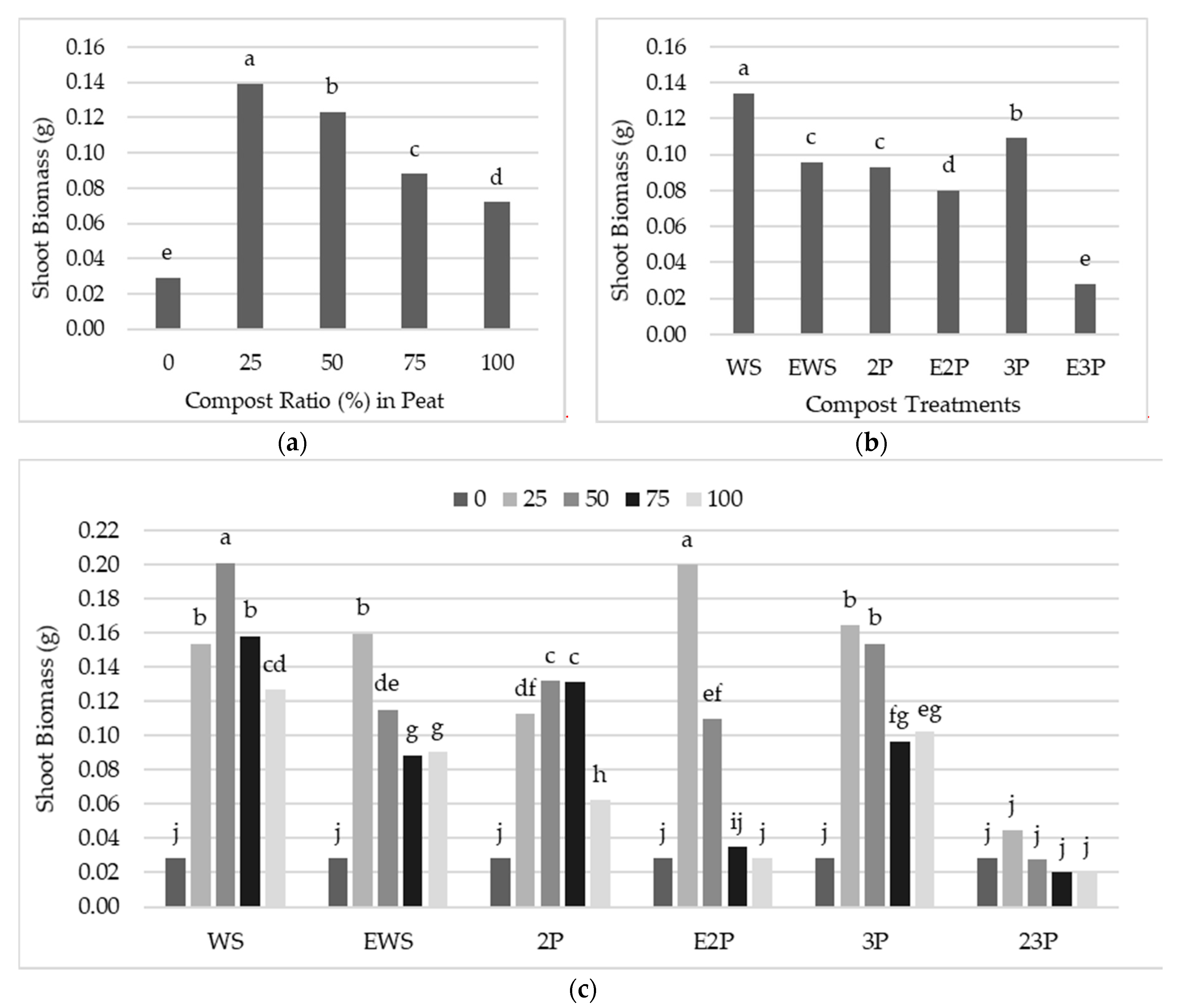

3.3. Seedling Growth

3.4. Chlorophyll Index

3.5. Leaf Color

3.6. Nutrient Concentration

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- TurkStat. Turkish Statistical Institute Data Basis. 2020. Available online: http://www.tuik.gov.tr (accessed on 31 January 2020).

- Republic of Turkey Ministry of Agriculture and Forestry. Organic Agricultural Production Data. 2020. Available online: http://www.tarim.gov.tr/Konular/Bitkisel-Uretim/Organik-Tarim/Istatistikler (accessed on 31 January 2020).

- Roig, A.; Cayuela, M.L.; Sánchez-Monedero, M.A. An overview on olive mill wastes and their valorisation methods. Waste Manag. 2006, 26, 960–969. [Google Scholar] [CrossRef]

- Hocaoglu, S.M.; Haksevenler, B.H.G.; Basturk, I.; Talazan, P.; Aydoner, C. Assessment of technology modification for olive oil sector through mass balance: A case study for Turkey. J. Clean. Prod. 2018, 188, 786–795. [Google Scholar] [CrossRef]

- Tunalıoglu, R.; Bektas, T. The problem of olive mill waste water in the Turkish olive industry. Zeytin Bilimi 2010, 1, 65–71. [Google Scholar]

- Ramos-Cormenzana, A.; Monteoliva-Sanchez, M.; Lopez, M.J. Bioremediation alpechin. Int. Biodeterior. Biodegrad. 1995, 35, 249–268. [Google Scholar] [CrossRef] [Green Version]

- Galiatsatou, P.; Metaxas, M.; Arapoglou, D.; Kasselouri-Rigopoulou, V. Treatment of olive waste water with activated carbons from agricultural byproducts. Waste Manag. 2002, 22, 803–812. [Google Scholar] [CrossRef]

- Ammar, E.; Nasri, M.; Medhioub, K. Isolation of Enterobacteria able to degrade simple aromatic compounds from the wastewater from olive oil extraction. World J. Microbiol. Biotechnol. 2005, 21, 253–259. [Google Scholar] [CrossRef]

- Chowdhury, A.K.M.M.B.; Akratos, C.S.; Vayenas, D.V.; Pavlou, S. Olive mill waste composting: A review. Int. Biodeter. Biodegrad. 2013, 85, 108–119. [Google Scholar] [CrossRef]

- Madejón, E.; Galli, E.; Tomati, U. Composting of wastes produced by low water consuming olive mill technology. Agrochimica 1998, 42, 135–146. [Google Scholar]

- Cegarra, J.; Amor, J.B.; Gonzálvez, J.; Bernal, M.P.; Roig, A. Characteristics of a new solid olive-mill-byproduct (“alperujo”) and its suitability for composting. In Proceedings of the International Composting Symposium, Halifax/Dartmouth, NS, Canada, 19–23 September 1999; Volume 1, pp. 124–140. [Google Scholar]

- Gruda, N.S. Increasing sustainability of growing media constituents and stand-alone substrates in soilless culture systems. Agronomy 2019, 9, 298. [Google Scholar] [CrossRef] [Green Version]

- Raviv, M.; Aviani, I.; Laor, Y.; Medina, S.H.; Krassnov, A. Co-composting of solid and liquid olive mill wastes: Management aspects and the horticultural value of the resulting composts. Bioresour. Technol. 2010, 101, 6699–6706. [Google Scholar]

- Michailides, M.; Christou, G.; Akratos, C.S.; Tekerlekopoulou, A.G.; Vayenas, D.V. Composting of olive leaves and pomace from a three-phase olive mil plant. Int. Biodeterior. Biodegrad. 2011, 65, 560–564. [Google Scholar] [CrossRef]

- Killi, D.; Kavdır, Y. Effects of olive solid waste and olive solid waste compost application on soil properties and growth of Solanum lycopersicum. Int. Biodeterior. Biodegrad. 2013, 82, 157–165. [Google Scholar] [CrossRef]

- Diacono, M.; Montemurro, F. Olive pomace compost in organic emmer crop: Yield, soil properties, and heavy metals’ fate in plant and soil. J. Soil Sci. Plant. Nutr. 2019, 19, 63–70. [Google Scholar] [CrossRef]

- Beşirli, G.; Tüzel, Y.; Türemiş, N.; Ekinci, K.; Varol, N. Final Report. Developing of Input Production Methods for Utilization in Organic Plant Production; TUBITAK Project No. 111G055, Final Report; Tübitak: Ankara, Turkey, 2018; 80p. [Google Scholar]

- Finstein, M.S.; Miller, F.C. Principles of Composting Leading to Maximization of Decomposition Rate, Odor Control and Cost Effectiveness. In Composting of Agricultural and Other Wastes; Gasser, J.K.R., Ed.; Elsevier Applied Science Publications: Barking/Essex, UK, 1985; pp. 13–26. [Google Scholar]

- OG. Regulation on the Principles of Organic Farming and Their Implementation; The Official Gazette of Republic of Turkey; No: 27676; Republic of Turkey, Official Gazette: Turkey, 2010. (In Turkish) [Google Scholar]

- Roig, A.; Cayuela, M.L.; Sanchez-Monedero, M.A. The use of elemental sulphur as organic alternative to control pH during composting of olive mill wastes. Chemosphere 2004, 57, 1099–1105. [Google Scholar] [CrossRef] [PubMed]

- Tuzel, Y.; Oztekin, G.B.; Tan, E. Use of different growing media and nutrition on organic seedling production. Acta Hort. 2015, 1107, 165–175. [Google Scholar] [CrossRef]

- McGuire, R.G. Reporting of objective color measurements. HortScience 1992, 27, 1254–1255. [Google Scholar] [CrossRef] [Green Version]

- Jones, J.B., Jr.; Wolf, B.; Mills, H.A. Plant Analysis Handbook. A Practical Sampling, Preparation, Analysis, And Interpretation Guide; Micro-Macro Publishing Inc.: Athens, Greece, 1991. [Google Scholar]

- USCC. Test Methods for the Examination of Composting and Composts; US Government Printing Office, The US Composting Council, 2002. Available online: http://tmecc.org/tmecc/index.html (accessed on 15 April 2020).

- Şevik, F.; Tosun, İ.; Ekinci, K. The effect of FAS and C/N ratios on co-composting of sewage sludge, dairy manure and tomato stalks. Waste Manag. 2018, 80, 450–456. [Google Scholar] [CrossRef]

- Reis, M.; Coelho, L. Compost mixes as substrates for seedlıng productıon. Acta Hort. 2007, 747, 283–292. [Google Scholar] [CrossRef]

- Landis, T.D.; Douglass, F.J.; Wilkinson, K.M.; Luna, T. Tropical Nursery Manual: A guide to starting and operating a nursery for native and traditional plants. In Growing Media; Wilkinson, K.M., Landis, T.D., Haase, D.L., Daley, B.F., Dumroese, R.K., Eds.; Agriculture Handbook 732; U.S. Department of Agriculture, Forest Service: Washington, DC, USA, 2014; 376p. [Google Scholar]

- Altieri, R.; Esposito, A. Evaluation of the fertilizing effect of olive mill waste compost in short-term crops. Int. Biodeterior. Biodegrad. 2010, 64, 124–128. [Google Scholar] [CrossRef]

- Ceglie, F.G.; Elshafie, H.; Verrastro, V.; Tittarelli, F. Evaluation of olive pomace and green waste composts as peat substitutes for organic tomato seedling production. Compost Sci. Util. 2011, 9, 293–300. [Google Scholar] [CrossRef]

- Cabrera, M.L.; Kissel, D.E.; Vigil, M.F. Nitrogen mineralization from organic residues: Research opportunities. J. Environ. Qual. 2005, 34, 75–79. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sanchez-Monedero, M.A.; Roig, A.; Cegarra, J.; Pilar Bernal, M.; Noguera, P.; Abad, M.; Antón, A. Composts as media constituents for vegetable transplant production. Compost Sci. Util. 2004, 12, 161–168. [Google Scholar] [CrossRef]

- Tuzel, Y.; Oztekin, G.B.; Aktan, H.; Yolageldi, L. Improvement of Organic Seedling Production Methods; TUBITAK Project No 111G151, Final Report; Tübitak: Ankara, Turkey, 2017; 119p. [Google Scholar]

- Perez-Murcia, M.D.; Moreno-Caselles, J.; Moral, R.; Perez-Espinosa, A.; Paredes, C.; Rufete, B. Utilization of composted sewage sludge as horticultural growth media: Effects on germination and trace element extraction. Commun. Soil Sci. Plant Anal. 2005, 36, 571. [Google Scholar] [CrossRef]

- Oztekin, G.B.; Ekinci, K.; Tuzel, Y.; Merken, O. Effects of Composts obtained from two different composting methods on organic tomato seedling production. Acta Hort. 2017, 1164, 209–216. [Google Scholar] [CrossRef]

- Tuzel, Y.; Varol, N.; Öztekin, G.B.; Ekinci, K.; Merken, O. Effects of composts obtained from olive oil production wastes on organic tomato seedling production. Acta Hort. 2017, 1164, 217–224. [Google Scholar] [CrossRef]

- Atif, M.J.; Jellani, G.; Malik, M.H.A.; Saleem, N.; Ullah, H.; Khan, M.Z.; İkram, S. Different growth media effect the germination and growth of tomato seedlings. Sci. Tech. Dev. 2016, 35, 123–127. [Google Scholar]

- Tanji, K.K.; Kielen, N.C.; Food and Agriculture Organization of The United Nations. Agricultural Drainage Water Management in Arid and Semi-Arid Areas; FAO Irrigation and Drainage Paper; FAO: Rome, Italy, 2003; ISBN 92-5-104839-8. [Google Scholar]

- Zhang, P.; Senge, M.; Dai, Y. Effects of salinity stress on growth, yield, fruıt quality and water use effıciency of tomato under hydroponics system. Rev. Agric. Sci. 2016, 4, 46–55. [Google Scholar] [CrossRef]

- Maggio, A.; Raimondi, G.; Martino, A.; De Pascale, S. Salt stress response in tomato beyond the salinity tolerance threshold. Environ. Exp. Bot. 2007, 59, 276–282. [Google Scholar] [CrossRef]

- Aktas, H.; Daler, S.; Ozen, O.; Gencer, K.; Bayindur, D.; Erdal, I. The effect of some growing substrate media on yield and fruit quality of eggplant (Solanum melongena L.) grown and irrigated by drip irrigation system in green house. Infrastruktura i Ekologia Terenów Wiejskich 2013, 1, 5–11. [Google Scholar]

- Erdal, I.; Kaya, M.; Kucukyumuk, Z. Effects of zinc and nitrogen fertilizations on grain yield and some parameters affecting zinc bioavailability in lentil seeds. Legume Res. 2014, 37, 55–61. [Google Scholar] [CrossRef]

- Erdal, I.; Aktas, H.; Daler, S.; Gencer, K. Effects of Different Growing Mediums on Nutrient Concentration of Eggplant in Soilless Culture (Chapter: 38). In Technological Advancement for Vibrant Agriculture, 2nd ed.; Amitava, R., Ed.; Athens Institute for Education and Research: Athens, Greece, 2014; pp. 417–424. [Google Scholar]

- Çelik, C.; Yüksek, L.T.; Kimya, A.B.D. Zeytin Karasuyundan Humik (HA) ve Fulvik (FA) Asitlerin Eldesi ve Karakterizasyonu; Fen Bilimleri Enstitüsü, Çukurova Üniversitesi: Adana, Turkey, 2010; 50p. [Google Scholar]

- Niaounakis, M.; Halvadakis, C.P. Olive-Mill Waste Management: Literature Review and Patent Survey; Typothito-George Dardanos: Athens, Grecee, 2004; ISBN 960-402-123-0. [Google Scholar]

- Piotrowska, A.; Iamarino, G.; Rao, M.A.; Gianfreda, L. Short-term effects of olive mill waste water (OMW) on chemical and biochemical properties of a semiarid Mediterranean soil. Soil Biol. Biochem. 2006, 38, 600–610. [Google Scholar] [CrossRef]

- Zenjari, B.; El Hajjouji, H.; Ait Baddi, G.; Bailly, J.R.; Revel, J.C.; Nejmeddine, A.; Hafidi, M. Eliminating toxic compounds by composting olive mill wastewater–straw mixtures. J. Hazard. Mater. 2006, 13, 433–437. [Google Scholar] [CrossRef] [PubMed]

- Herrera, F.; Castillo, J.E.; Chica, A.F.; López Bellido, L. Use of municipal solid waste compost (MSWC) as a growing medium in the nursery production of tomato plants. Bioresour. Technol. 2008, 99, 287–296. [Google Scholar] [CrossRef] [PubMed]

- Singh, C.P.; Amberger, A. Solubilization and availability of P during decomposition of rock phosphate enriched straw and urine. Biol. Agric. Hortic. 1991, 7, 261–269. [Google Scholar] [CrossRef]

- Singh, C.P.; Amberger, A. The effect of rock phosphate enriched compost on the yield and phosphorus nutrition of rye grass. Am. J. Altern. Agric. 1995, 10, 82–87. [Google Scholar] [CrossRef]

- Biswas, D.R.; Narayanasamy, G. Mobilization of phosphorus from rock phosphate through composting using crop residue. Fert. News 2002, 47, 53–56. [Google Scholar]

- Vassilev, N.; Vassileva, M. Biotechnological solubilization of rock phosphate on media containing agro-industrial wastes. Appl. Microbiol. Biotechnol. 2003, 61, 435–440. [Google Scholar] [CrossRef]

- Erdal, I.; Bozkurt, M.A.; Mesut, K.M.; Karaca, S.; Saglam, M. Effects of humic acid and phosphorus applications on growth and phosphorus uptake of corn plant (Zea mays L.) grown in a calcareous soil. Turk. J. Agric. For. 2000, 24, 663–668. [Google Scholar]

- Papafotiou, M.; Phsyhalou, M.; Kargas, G.; Chatzipavlidis, I.; Chronopoulos, J. Olive-mill wastes compost as growing medium component for the production of poinsettia. Sci. Hort. 2004, 102, 167–175. [Google Scholar] [CrossRef]

- Bustamente, M.A.; Paredes, C.; Moral, R.; Agullo, E.; Perez-Murcia, M.D.; Abad, M. Composts from distillery wastes as peat substitutes for transplant production. Resour. Conserv. Recycl. 2008, 52, 792–799. [Google Scholar] [CrossRef]

- Zandstra, J.W.; Liptay, A. Nutritional effects on transplant root and shoot growth—A review. Acta Hort. 1999, 504, 23–32. [Google Scholar] [CrossRef]

- Clark, S.; Cavigelli, M. Suitability of composts as potting media for production of organic vegetable transplants. Compost Sci. Util. 2005, 13, 150–156. [Google Scholar] [CrossRef]

- EGTOP. Final Report on Greenhouse Production (Protected Cropping). 7th plenary meeting of 19–20 June 2013. Available online: https://ec.europa.eu/agriculture/organic/sites/orgfarming/files/docs/body/final_report_egtop_on_greenhouse_production_en.pdf (accessed on 7 January 2013).

| 2P | 3P | WS | |

|---|---|---|---|

| Mixing Ratios (%) | |||

| Two-phase olive mill solid wastes | 60 | - | - |

| Three-phase olive mill solid wastes | - | 46 | - |

| Olive oil waste water | 1 | - | |

| Olive oil waste water sludge | - | - | 20 |

| Separated dairy manure | 23 | 27 | 53 |

| Poultry manure | 10 | 21 | 21 |

| Wheat straws | 7 | 5 | 6 |

| C/N ratio | 30.17 | 25.26 | 20.16 |

| Composts | Compost Ratios in Peat (%) | Organic Matter (%) | EC (dS m−1) | pH |

|---|---|---|---|---|

| WS | 0 | 38.45 h | 1.11 n | 7.38 a |

| 25 | 42.11 fgh | 1.77 lmn | 7.13 a | |

| 50 | 47.01 d–h | 2.26 k–n | 6.69 abc | |

| 75 | 45.93 d–h | 3.26 f–k | 6.28 bcd | |

| 100 | 53.25 b–e | 4.49 ef | 5.60 d | |

| EWS | 0 | 38.45 h | 1.11 n | 7.38 a |

| 25 | 38.58 h | 2.75 h–m | 6.77 abc | |

| 50 | 44.08 e–h | 3.69 f–i | 7.13 a | |

| 75 | 42.63 fgh | 4.30 efg | 7.01 ab | |

| 100 | 49.34 d–g | 6.23 cd | 6.64 a | |

| 2P | 0 | 38.45 h | 1.11 n | 7.38 a |

| 25 | 38.30 h | 1.65 mn | 7.28 a | |

| 50 | 44.29 e–h | 2.35 j–n | 7.33 a | |

| 75 | 49.34 d–g | 2.19 k–n | 6.92 abc | |

| 100 | 54.37 bcd | 3.59 f–j | 6.16 cd | |

| E2P | 0 | 38.45 h | 1.11 n | 7.38 a |

| 25 | 38.30 h | 2.00 k–n | 6.96 ab | |

| 50 | 42.53 fgh | 2.98 g–l | 7.02 ab | |

| 75 | 48.90 d–g | 4.30 efg | 6.95 ab | |

| 100 | 45.85 d–h | 7.39 c | 7.06 a | |

| 3P | 0 | 38.45 h | 1.11 n | 7.38 a |

| 25 | 40.48 gh | 2.06 k–n | 7.13 a | |

| 50 | 47.57 d–h | 2.99 g–l | 7.06 a | |

| 75 | 48.89 d–g | 2.45 i–m | 7.35 a | |

| 100 | 62.37 ab | 3.79 e–h | 6.78 abc | |

| E3P | 0 | 38.45 h | 1.11 n | 7.38 a |

| 25 | 43.71 e–h | 3.67 f–j | 7.19 a | |

| 50 | 50.95 c–f | 5.04 de | 7.33 a | |

| 75 | 59.80 abc | 9.08 b | 7.25 a | |

| 100 | 64.48 a | 11.14 a | 7.04 ab | |

| * | *** | *** |

| Composts | Compost Ratios in Peat (%) | N (%) | P (%) | K (%) | Ca (%) | Mg (%) |

|---|---|---|---|---|---|---|

| WS | 0 | 0.81 i | 0.12 f | 0.62 e | 2.33 | 0.80 a |

| 25 | 0.88 hi | 0.22 ef | 0.63 e | 1.92 | 0.82 a | |

| 50 | 0.94 ghi | 0.28 de | 0.63 e | 3.52 | 0.82 a | |

| 75 | 1.07 e–i | 0.36 cd | 0.71 de | 2.85 | 0.81 a | |

| 100 | 1.09 e–i | 0.41 bc | 0.95 b–e | 2.02 | 0.80 a | |

| EWS | 0 | 0.81 i | 0.12 f | 0.62 e | 2.33 | 0.80 a |

| 25 | 1.03 f–i | 0.67 a | 0.77 cde | 1.97 | 0.69 a–d | |

| 50 | 1.10 e–i | 0.69 a | 0.76 cde | 1.84 | 0.76 ab | |

| 75 | 1.42 a–d | 0.72 a | 1.04 bcd | 2.09 | 0.75 abc | |

| 100 | 1.38 b–e | 0.74 a | 1.12 b | 2.17 | 0.66 a–d | |

| 2P | 0 | 0.81 i | 0.12 f | 0.62 e | 2.33 | 0.80 a |

| 25 | 0.80 i | 0.15 f | 0.68 e | 2.73 | 0.82 a | |

| 50 | 0.95 ghi | 0.22 ef | 0.75 cde | 2.32 | 0.78 ab | |

| 75 | 0.95 ghi | 0.24 ef | 0.69 e | 2.66 | 0.77 ab | |

| 100 | 0.94 ghi | 0.37 cd | 0.90 b–e | 2.18 | 0.77 ab | |

| E2P | 0 | 0.81 i | 0.12 f | 0.62 e | 2.33 | 0.80 a |

| 25 | 0.99 f–i | 0.67 a | 0.72 de | 2.08 | 0.68 a–d | |

| 50 | 1.23 d–g | 0.73 a | 0.89 b–e | 1.97 | 0.68 a–d | |

| 75 | 1.28 d–g | 0.76 a | 1.08 bc | 3.31 | 0.72 a–d | |

| 100 | 1.24 c–g | 0.75 a | 1.51 b | 2.32 | 0.77 a–b | |

| 3P | 0 | 0.81 i | 0.12 f | 0.62 e | 2.33 | 0.80 a |

| 25 | 0.94 ghi | 0.31 cde | 0.84 b–e | 3.05 | 0.81 a | |

| 50 | 1.00f–i | 0.43 bc | 0.89 b–e | 2.66 | 0.79 ab | |

| 75 | 1.08 e–i | 0.39 bcd | 0.89 b–e | 2.52 | 0.79 ab | |

| 100 | 1.31 b–f | 0.50 b | 1.11 b | 3.87 | 0.72 a–d | |

| E3P | 0 | 0.81 i | 0.12 f | 0.62 e | 2.33 | 0.80 a |

| 25 | 1.19 d–h | 0.74 a | 0.81 b–e | 2.46 | 0.45 de | |

| 50 | 1.59 ab | 0.74 a | 0.75 cde | 2.71 | 0.52 b–e | |

| 75 | 1.56 abc | 0.75 a | 1.77 a | 2.57 | 0.49 cde | |

| 100 | 1.71 a | 0.74 a | 1.80 a | 2.69 | 0.64 a–d | |

| *** | * | ** | ns | *** |

| Composts | Compost Ratios in Peat (%) | Zn (mg kg−1) | Mn (mg kg−1) | Cu (mg kg−1) |

|---|---|---|---|---|

| WS | 0 | 68.2 d | 136.0 def | 49.7 |

| 25 | 108.3 bcd | 184.1 b–f | 37.3 | |

| 50 | 199.1 bcd | 205.0 a–d | 39.1 | |

| 75 | 179.6 bcd | 206.4 a–d | 39.4 | |

| 100 | 240.6 bcd | 230.9 abc | 45.9 | |

| EWS | 0 | 68.2 d | 136.0 def | 49.7 |

| 25 | 123.9 bcd | 108.5 ef | 50.5 | |

| 50 | 150.8 bcd | 123.4 def | 50.8 | |

| 75 | 263.8 abc | 135.8 def | 52.1 | |

| 100 | 228.9 bcd | 152.3 c–f | 49.7 | |

| 2P | 0 | 68.2 d | 136.0 def | 49.7 |

| 25 | 86.7 cd | 149.5 c–f | 37.3 | |

| 50 | 88.9 cd | 110.1 ef | 40.0 | |

| 75 | 88.4 cd | 116.5 ef | 41.3 | |

| 100 | 108.9 bcd | 107.8 f | 40.2 | |

| E2P | 0 | 68.2 d | 136.0 def | 49.7 |

| 25 | 140.7 bcd | 154.5 c–f | 41.9 | |

| 50 | 171.0 bcd | 186.2 b–f | 52.7 | |

| 75 | 247.5 a–d | 241.0 ab | 52.1 | |

| 100 | 432.4 a | 287.8 a | 46.8 | |

| 3P | 0 | 68.2 d | 136.0 def | 49.7 |

| 25 | 137.3 bcd | 194.6 b–e | 36.6 | |

| 50 | 162.6 bcd | 185.9 b–f | 38.6 | |

| 75 | 97.7 bcd | 164.9 b–f | 38.5 | |

| 100 | 147.1 bcd | 160.2 b–f | 39.9 | |

| E3P | 0 | 68.2 d | 136.0 def | 49.7 |

| 25 | 132.9 bcd | 120.5 def | 55.0 | |

| 50 | 215.8 bcd | 131.6 def | 46.7 | |

| 75 | 134.8 bcd | 167.7 b–f | 45.2 | |

| 100 | 282.2 ab | 168.3 b–f | 45.4 | |

| * | ** | ns | ||

| Compost Ratios in Peat (%) | Composts | ||||||

|---|---|---|---|---|---|---|---|

| WS | EWS | 2P | E2P | 3P | E3P | Meanratio | |

| Germination Period (day) | |||||||

| 0 | 4.25 j | 4.25 j | 4.25 j | 4.25 j | 4.25 j | 4.25 j | 4.25 E |

| 25 | 4.75 ij | 5.00 ij | 4.50 j | 5.00 ij | 4.50 j | 9.00 fg | 5.46 D |

| 50 | 6.00 hi | 9.00 fg | 5.25 hj | 9.00 fg | 6.50 h | 12.75 b | 8.08 C |

| 75 | 8.00 g | 11.25 cd | 8.00 g | 11.75 bd | 9.50 ef | 15.50 a | 10.67 A |

| 100 | 6.00 hi | 15.00 a | 9.25 fg | 12.50 bc | 10.75 de | 0.00 k* | 8.92 B |

| Meancompost | 5.80 D | 8.90 A | 6.25 D | 8.50 AB | 7.10 C | 8.30 B | |

| Germination Rate (%) | |||||||

| 0 | 94.92 ab | 94.92 ab | 94.92 ab | 94.92 ab | 94.92 ab | 94.92 ab | 94.92 A |

| 25 | 94.14 ab | 90.23 bc | 91.41 ac | 95.31 ab | 92.58 ab | 92.97 ab | 92.77 AB |

| 50 | 91.18 ac | 94.92 ab | 91.02 ac | 93.36 ab | 94.92 ab | 79.30 e | 90.78 B |

| 75 | 96.88 a | 85.94 cd | 92.58 ab | 81.64 de | 91.02 ac | 70.70 f | 86.46 C |

| 100 | 94.53 ab | 54.02 g | 94.53 ab | 71.88 f | 76.95 ef | 14.45 h | 67.73 D |

| Meancompost | 94.33 A | 84.01 D | 92.89 AB | 87.42 C | 90.08 BC | 70.47 E | |

| Compost Ratios in Peat (%) | Composts | ||||||

|---|---|---|---|---|---|---|---|

| WS | EWS | 2P | E2P | 3P | E3P | Meanratio | |

| Shoot Length (cm) | |||||||

| 0 | 4.95 mn | 4.95 mn | 4.95 mn | 4.95 mn | 4.95 mn | 4.95 mn | 4.95 D |

| 25 | 13.03 d | 15.66 ab | 11.10 eg | 15.13 bc | 14.48 c | 6.43 kl | 12.63 A |

| 50 | 14.38 c | 16.33 a | 10.40 gi | 12.23 de | 14.73 bc | 5.25 mn | 12.22 A |

| 75 | 15.65 ab | 11.19 eg | 9.93 hi | 7.00 jk | 11.83 ef | 4.65 n | 10.04 B |

| 100 | 11.15 eg | 10.89 fh | 7.83 j | 5.85 lm | 9.48 i | 4.74 mn | 8.32 C |

| Meancompost | 11.83 A | 11.80 A | 8.84 C | 9.03C | 11.09 B | 5.20 D | |

| Root Length (cm) | |||||||

| 0 | 7.03 de | 7.03 de | 7.03 de | 7.03 de | 7.03 de | 7.03 de | 7.03 |

| 25 | 7.70 ad | 7.21 ce | 7.78 ad | 7.28 be | 8.00 ac | 6.63 e | 7.43 |

| 50 | 7.28 be | 7.95 ac | 7.83 ad | 7.33 be | 8.03 ac | 4.48 f | 7.15 |

| 75 | 7.25 be | 8.33 a | 8.28 a | 7.38 be | 8.33 a | 3.73 fg | 7.21 |

| 100 | 8.08 ab | 8.40 a | 7.95 ac | 7.38 be | 8.00 ac | 2.93 g | 7.12 |

| Meancompost | 7.47 BC | 7.78 AB | 7.77 AB | 7.28 C | 7.88 A | 4.96 D | |

| Stem Diameter (mm) | |||||||

| 0 | 1.17 jk | 1.17 jk | 1.17 jk | 1.17 jk | 1.17 jk | 1.17 jk | 1.17 E |

| 25 | 2.14 ce | 2.46 a | 1.83 h | 2.46 a | 2.37 ab | 1.33 ij | 2.10 A |

| 50 | 2.41 ab | 2.23 bd | 1.88 fh | 2.05 dg | 2.46 a | 1.01 k | 2.00 B |

| 75 | 2.31 ac | 1.94 eh | 1.84 gh | 1.38 ij | 2.06 dg | 0.77 l | 1.72 C |

| 100 | 2.20 bd | 1.86 fh | 1.52 i | 1.09 k | 2.08 df | 0.79 l | 1.59 D |

| Meancompost | 2.04 A | 1.93 B | 1.65 C | 1.63 C | 2.02 AB | 1.01 D | |

| Compost Ratios in Peat (%) | Composts | ||||||

|---|---|---|---|---|---|---|---|

| WS | EWS | 2P | E2P | 3P | E3P | Meanratio | |

| 0 | 30.58 d–h | 30.58 d–h | 30.58 d–h | 30.58 d–h | 30.58 d–h | 30.58 d–h | 30.58 BC |

| 25 | 27.45 f–i | 32.69 c–g | 30.94 d–h | 34.81 b–e | 30.03 e–i | 41.63 a | 32.92 A |

| 50 | 26.21 hi | 36.16 ad | 29.18 e–i | 33.23 c–f | 25.43 hi | 39.97 ab | 31.70 ABC |

| 75 | 26.06 hi | 34.33 b–e | 25.84 hi | 34.12 b–e | 25.86 hi | 34.48 b–e | 30.11 C |

| 100 | 24.18 i | 38.69 abc | 26.86 ghi | 34.9 b–e | 29.75 e–i | 37.31 abc | 31.96 AB |

| Meancompost | 26.90 C | 34.49 B | 28.68 C | 33.55 B | 28.33 C | 36.79 A | |

| Compost Ratios in Peat (%) | Composts | ||||||

|---|---|---|---|---|---|---|---|

| WS | EWS | 2P | E2P | 3P | E3P | Meanratio | |

| L* | |||||||

| 0 | 28.91 | 28.91 | 28.91 | 28.91 | 28.91 | 28.91 | 28.91 B |

| 25 | 47.92 | 39.63 | 48.18 | 40.61 | 48.30 | 39.59 | 44.04 A |

| 50 | 49.75 | 37.79 | 47.57 | 40.28 | 49.41 | 39.66 | 44.07 A |

| 75 | 49.34 | 38.85 | 48.97 | 43.19 | 51.35 | 40.52 | 45.37 A |

| 100 | 49.04 | 39.14 | 48.39 | 40.14 | 42.91 | 42.29 | 43.65 A |

| Meancompost | 44.99 A | 36.86 B | 44.40 A | 38.63 B | 44.17 A | 38.19 B | |

| a* | |||||||

| 0 | −0.56 | −0.56 | −0.56 | −0.56 | −0.56 | −0.56 | −0.56 A |

| 25 | −14.51 | −15.96 | −12.61 | −15.60 | −17.43 | −15.33 | −15.24 B |

| 50 | −17.15 | −16.73 | −16.17 | −16.52 | −17.69 | −15.09 | −16.56 B |

| 75 | −18.24 | −15.31 | −15.78 | −17.12 | −18.03 | −16.34 | −16.80 B |

| 100 | −16.89 | −15.41 | −15.38 | −15.86 | −15.47 | −14.07 | −15.51 B |

| Meancompost | −13.47 | −12.79 | −12.10 | −13.13 | −13.84 | −12.28 | |

| b* | |||||||

| 0 | 8.38 h | 8.38 h | 8.38 h | 8.38 h | 8.38 h | 8.38 h | 8.38 D |

| 25 | 28.86 a–f | 23.47 efg | 24.60 c–g | 21.52 g | 29.82 a–e | 21.05 g | 24.89 BC |

| 50 | 31.00 abc | 20.64 g | 32.38 ab | 22.22 fg | 33.76 a | 20.56 g | 26.76 AB |

| 75 | 31.13 abc | 20.20 g | 33.37 a | 25.42 b–g | 34.22 a | 21.84 fg | 27.70 A |

| 100 | 32.26 ab | 20.14 g | 30.80 a–d | 21.44 g | 23.83 d–g | 19.09 g | 24.59 C |

| Meancompost | 26.32 A | 18.57 B | 25.90 A | 19.80 B | 26.00 A | 18.18 B | |

| h° | |||||||

| 0 | 173.75 | 173.75 | 173.75 | 173.75 | 173.75 | 173.75 | 173.75 A |

| 25 | 116.71 | 124.30 | 117.08 | 125.99 | 120.31 | 126.07 | 121.74 B |

| 50 | 119.04 | 129.08 | 116.53 | 126.62 | 117.68 | 126.41 | 122.56 B |

| 75 | 120.36 | 127.19 | 115.41 | 123.99 | 117.77 | 126.79 | 121.92 B |

| 100 | 117.71 | 127.45 | 116.44 | 126.51 | 123.18 | 126.44 | 122.96 B |

| Meancompost | 129.52 | 136.54 | 127.84 | 135.37 | 130.54 | 135.89 | |

| C* | |||||||

| 0 | 9.45 h | 9.45 h | 9.45 h | 9.45 h | 9.45 h | 9.45 h | 9.45 C |

| 25 | 32.30 a–e | 28.39 c–g | 27.64 d–g | 26.58 efg | 34.54 abc | 26.04 efg | 29.25 B |

| 50 | 35.43 ab | 26.59 efg | 36.19 ab | 27.69 d–g | 38.13 a | 25.53 efg | 31.59 A |

| 75 | 36.08 ab | 25.35 fg | 36.94 ab | 30.65 b–f | 38.69 a | 27.27 efg | 32.50 A |

| 100 | 36.45 ab | 25.36 fg | 34.44 a–d | 26.67 efg | 28.43 c–g | 23.76 g | 29.18 B |

| Meancompost | 29.94 A | 23.03 B | 28.93A | 24.21 B | 29.85 A | 22.41 B | |

| Compost Ratios in Peat (%) | Composts | ||||||

|---|---|---|---|---|---|---|---|

| WS | EWS | 2P | E2P | 3P | E3P | Meanratio | |

| N (%) | |||||||

| 0 | 3.05 c–f | 3.05 c–f | 3.05 c–f | 3.05 c–f | 3.05 c–f | 3.05 c–f | 3.05 AB |

| 25 | 1.73 ef | 3.46 b–e | 2.01 ef | 2.98 c–f | 1.90 ef | 4.19 a–d | 2.71 B |

| 50 | 1.90 ef | 4.79 abc | 1.27 f | 4.81 abc | 1.87 ef | 4.41 a–d | 3.17 AB |

| 75 | 2.12 ef | 5.02 ab | 1.27 f | 5.21 ab | 2.22 ef | 5.39 a | 3.54 A |

| 100 | 2.21 ef | 4.40 a–d | 2.33 ef | 5.33 a | 2.70 def | 3.48 b–e | 3.41 A |

| Meancompost | 2.20 B | 4.14 A | 1.98 B | 4.28 A | 2.35 B | 4.10 A | |

| P (%) | |||||||

| 0 | 0.15 g | 0.15 g | 0.15 g | 0.15 g | 0.15 g | 0.15 g | 0.15 D |

| 25 | 0.28 fg | 0.71 bc | 0.20 g | 0.69 bc | 0.32 fg | 0.84 ab | 0.50 C |

| 50 | 0.41 d–g | 0.83 ab | 0.37 efg | 0.84 ab | 0.59 b–e | 0.83 ab | 0.64 B |

| 75 | 0.68 bcd | 0.84 ab | 0.51 c–f | 0.78 ab | 0.71 bc | 1.05 a | 0.76 A |

| 100 | 0.61 b–e | 0.81 ab | 0.63 b–e | 0.81 ab | 0.75 bc | 0.69 bc | 0.72 AB |

| Meancompost | 0.42 BC | 0.67 A | 0.37 C | 0.65 A | 0.50 B | 0.71 A | |

| Ca (%) | |||||||

| 0 | 6.70 a | 6.70 a | 6.70 a | 6.70 a | 6.70 a | 6.70 a | 6.70 A |

| 25 | 2.69 b–g | 2.88 b–f | 3.18 bcd | 2.86 b–f | 3.05b–e | 3.36 bc | 3.00 B |

| 50 | 2.49 c–g | 2.36 d–g | 2.68 b–g | 2.25 d–g | 2.49 c–g | 2.84 b–f | 2.52 C |

| 75 | 2.10 efg | 1.87g | 2.28 d–g | 2.39 d–g | 2.32 d–g | 2.81 b–g | 2.30 C |

| 100 | 2.02 fg | 1.96fg | 2.77 b–g | 2.84 b–f | 2.26 d–g | 3.56 b | 2.57 C |

| Meancompost | 3.20 BC | 3.15 C | 3.52 B | 3.41 BC | 3.36 BC | 3.85 A | |

| Mg (%) | |||||||

| 0 | 0.93 b | 0.93 b | 0.93 b | 0.93 b | 0.93 b | 0.93 b | 0.93 A |

| 25 | 0.78 bc | 0.78 bc | 0.7 0 bc | 0.76 bcd | 0.75 bcd | 1.20 a | 0.84 B |

| 50 | 0.73bcd | 0.76 bcd | 0.71 bcd | 0.76 bcd | 0.73 bcd | 0.76 bc | 0.74 C |

| 75 | 0.70 b–e | 0.77 bc | 0.67 cde | 0.78 bc | 0.72 bcd | 0.63 cde | 0.71 C |

| 100 | 0.57 cde | 0.77 bc | 0.45 e | 0.58 cde | 0.72 bcd | 0.51 de | 0.60 D |

| Meancompost | 0.74 AB | 0.80 A | 0.70 B | 0.76 AB | 0.77 AB | 0.81 A | |

| Compost Ratios in Peat (%) | Composts | ||||||

|---|---|---|---|---|---|---|---|

| WS | EWS | 2P | E2P | 3P | E3P | Meanratio | |

| Zn (mg kg−1) | |||||||

| 0 | 44 g | 44 g | 44 g | 44 g | 44 g | 44 g | 44 C |

| 25 | 49 fg | 91 c–g | 76 d–g | 95 c–g | 67 efg | 103 c–g | 80 B |

| 50 | 67 efg | 143 b–g | 67 efg | 160 b–f | 86 c–g | 188 bc | 118 AB |

| 75 | 84 c–g | 170 b–e | 64 efg | 155 b–f | 100 c–g | 325 a | 150 A |

| 100 | 101 c–g | 150 b–g | 100 c–g | 186 bcd | 125 b–g | 226 ab | 148 A |

| Meancompost | 69 D | 120 BC | 70 D | 128 B | 85 CD | 177 A | |

| Mn (mg kg−1) | |||||||

| 0 | 32 | 32 | 32 | 32 | 32 | 32 | 32 C |

| 25 | 12 | 15 | 14 | 18 | 18 | 33 | 18 C |

| 50 | 10 | 50 | 15 | 52 | 26 | 60 | 36 C |

| 75 | 70 | 83 | 40 | 62 | 52 | 89 | 66 B |

| 100 | 114 | 104 | 90 | 102 | 69 | 76 | 93 A |

| Meancompost | 49 AB | 57 A | 38 B | 53 A | 39 B | 58 A | |

| Cu (mg kg−1) | |||||||

| 0 | 28 | 28 | 28 | 28 | 28 | 28 | 28 A |

| 25 | 9 | 14 | 12 | 12 | 8 | 21 | 13 B |

| 50 | 7 | 15 | 11 | 19 | 11 | 24 | 14 B |

| 75 | 7 | 14 | 9 | 16 | 16 | 22 | 14 B |

| 100 | 6 | 14 | 7 | 20 | 14 | 24 | 14 B |

| Meancompost | 11 C | 17 AB | 13 BC | 19 AB | 15 ABC | 24 A | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tüzel, Y.; Ekinci, K.; Öztekin, G.B.; Erdal, İ.; Varol, N.; Merken, Ö. Utilization of Olive Oil Processing Waste Composts in Organic Tomato Seedling Production. Agronomy 2020, 10, 797. https://doi.org/10.3390/agronomy10060797

Tüzel Y, Ekinci K, Öztekin GB, Erdal İ, Varol N, Merken Ö. Utilization of Olive Oil Processing Waste Composts in Organic Tomato Seedling Production. Agronomy. 2020; 10(6):797. https://doi.org/10.3390/agronomy10060797

Chicago/Turabian StyleTüzel, Yüksel, Kamil Ekinci, Gölgen Bahar Öztekin, İbrahim Erdal, Nurhan Varol, and Özen Merken. 2020. "Utilization of Olive Oil Processing Waste Composts in Organic Tomato Seedling Production" Agronomy 10, no. 6: 797. https://doi.org/10.3390/agronomy10060797

APA StyleTüzel, Y., Ekinci, K., Öztekin, G. B., Erdal, İ., Varol, N., & Merken, Ö. (2020). Utilization of Olive Oil Processing Waste Composts in Organic Tomato Seedling Production. Agronomy, 10(6), 797. https://doi.org/10.3390/agronomy10060797