Abstract

An important factor along with the availability of food is its quality. It depends, among other things, on the type of plant protection products used and the method of their application. This manuscript presents research on the possibility of using a shielded band sprayer in field onion cultivation. The shielded band spraying technology presented in this article is the subject of a patent application (application number P.428494-The prototype of the machine was produced in Poland in cooperation with the University of Life Sciences in Poznań). The research consisted in comparing the quantity and quality of the obtained crop, based on various methods of reducing the weed population. The research results indicate that the proposed shielded band spraying technology may affect the food quality (the active substance is not sprayed on onion plants) and profitability of farms (less use of plant protection products).

1. Introduction

Food is the basis of human existence [1]. The increase in the population has caused a need to increase the scale of food production. Agriculture has been intensified to achieve higher productivity [2,3,4]. On the other hand, consumer awareness is increasing, which results in the search for high-quality healthy food [5,6,7]. Growing vegetables is an extremely important element of plant production. Vegetables provide people with vitamins, fiber, and mineral substances. Vegetables should be eaten every day in both fresh and processed form (juices, mousses) and as an addition to other dishes [8,9,10]. Root and alliaceous vegetables are important from a dietary point of view [11,12]. Onion (Allium) is a biennial vegetable plant belonging to the garlic family (Alliaceae Her.). In the process of growing onions, protection against harmful organisms, which primarily include weeds, is an extremely important element. Due to the spread and specificity of onion plants, weeds have very good conditions for development. Mechanical treatment and manual weeding often do not give satisfactory results. In addition, due to the limited availability of the labor force, these results are often unachievable [13]. Currently, the most popular methods of reducing weed infestation are chemical methods, which can significantly reduce yield. The use of herbicides is the most effective method of reducing weed infestation in onion cultivation. Herbicides are defined in the literature as various chemical and non-chemical agents used to inhibit the development of weeds or cause their destruction [13,14]. All herbicides, after reaching the sensitive plant, cause disturbances in its various physiological processes. On-leaf herbicides, after penetrating the plant, through various mechanisms, lead to damage of its cells, tissues, and organs. In the case of soil herbicides, their uptake occurs through the roots, and their action depends on soil and meteorological factors. Herbicides, also known as weed killing agents, constitute the largest group in the sales structure of plant protection products [15,16]. The negative effect of the herbicide on crop is the occurrence of temporary or long-lasting damage called phytotoxicity [13,17]. The effects of phytotoxicity on crops can be observed in all developmental stages and they can affect both parts and whole plants. All the negative effects on crops can affect both the quality and amount of yield. A reduction of the adverse impact on the crop and the natural environment has taken place thanks to the introduction of integrated plant protection, among others. Its purpose is to reduce the consumption of chemical plant protection products [18,19]. Chemical protection treatments should be carried out taking into account three basic principles: Spraying only the object that is necessary, using the amount that is necessary to achieve the intended purpose, and minimizing the amount of plant protection products released into the environment [20].

Systematic reduction of the range of available plant protection products and the occurrence of phytotoxicity in onion plants in the case of using certain herbicides makes it necessary to search for new solutions of weed control. An important aspect is also the improvement of food quality and environmental protection; therefore, integrated production is introduced, and integrated protection is an element of it [21,22,23,24]. The solution that can improve the precision of using plant protection products, and in particular herbicides in in-row cultivation, is the use of band sprayers with a herbicide shield instead of a conventional spraying boom. An additional element improving the precision of the procedure is the use of terrain copying by the support element that the sprayer is mounted on. This solution largely eliminates the horizontal and vertical atomizer movements that occur in the classic spray boom [13]. Movements in the vertical plane are clearly noticeable for the operator, whereas movements in the horizontal plane are often overlooked, and they also contribute to uneven distribution of the spray liquid [25]. It is necessary to conduct research in the field of distribution of spray liquid and coverage of sprayed objects during changes in the position of the field boom during its operation [26]. A very important advantage of inter-row-shielded band spraying is the negligible or complete lack of contact of the spray liquid with the crop. In addition to inter-row spraying, the band method gives the possibility of spraying the crop cultivated in rows with the reduced dose of herbicide (the use of a nozzle with a lower efficiency). The use of a band nozzle allows for an even coverage of the sprayed area over the entire width of the band and the herbicide shield limits the influence of external factors, e.g., wind, on the liquid stream [13].

Attempts to control weeds in field crop cultivation has been presented by many authors [26,27,28,29,30,31]; however, due to the high availability of cheap plant protection products and their high efficiency, some of the results described were abandoned.

The aim of the study was to compare the effectiveness of weed control in onion cultivation using band spraying technology and weed control during conventional spraying. The comparative studies were carried out by spraying the selected experimental plots with herbicides using conventional technology and the selected plots using band spraying technology. During the season, herbicidal treatments were performed, and their effectiveness was assessed. For comparative purposes, plots with manual weeding were formed and so-called control plots without weeding.

2. Materials and Methods

The research material was the onion plantation of the Hyduro F1 variety (The seed of the Dutch producer Bejo Zaden was purchased from a local agent of the means of production) in row-band cultivation (Figure 1). All field operations were performed using the parallel steering system.

Figure 1.

Row-band system of onion cultivation using the parallel steering system.

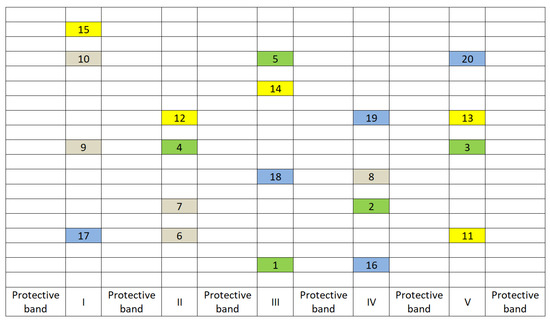

The plantation was located in Poland in the Kuyavian-Pomeranian Voivodeship, in Inowroclaw district, on soil with botanical class IVa and V, pH 6.3, vegetation season 2016. As part of the experiment, 20 experimental plots were formed, with an area of 1.5 m2 each, and placed on the field at random. The plot distribution is shown in Figure 2. The experiment was carried out with 5 repetitions for each experimental combination, i.e.:

Figure 2.

Diagram of the experimental plots’ placement in the field (plots 1–5 control-without weeding, plots 6–10-band spraying, plots 11–15-conventional spraying, plots 16–20-manual weeding. The transverse distance between plots was a minimum of 1.5 m (field patch width). The longitudinal distance within the band (field patch) was a minimum of 10 m. The protective band was 1.5 m (field patch width).

- Control—without weeding,

- Manual weeding,

- Conventional spraying and

- Band spraying.

Table 1 Presents all herbicidal treatments performed, along with the active substance dose.

Table 1.

Table of the used herbicides.

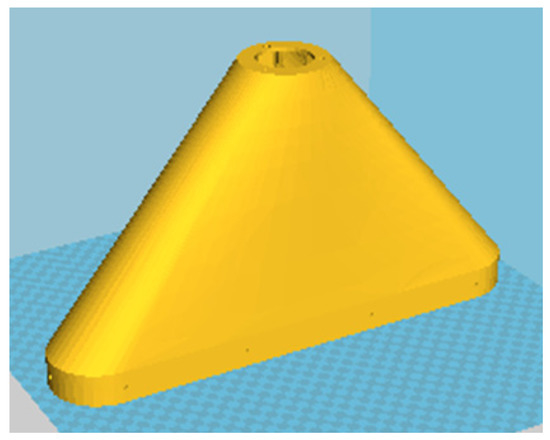

For band spraying, a prototype machine was used, which was built specially for the purpose of the study (the solution is subject to a patent application). The assumption was to apply the spray liquid to the largest area of the field possible, without contact with the crop. As a base for the construction of the machine, a conventional field-mounted sprayer was used with full equipment except for the spray boom. It was placed on a specially designed frame. Each of the spraying sections were placed on a parallelogram construction with a support wheel, enabling ground copying. The essence of this solution was the possibility to apply herbicides to the inter-row surface of the field with full reduction of the contact with the cultivated plant. The spray heads were covered with individually designed herbicide shields (shields were made in 3D printing technology). The shield is presented in Figure 3.

Figure 3.

Herbicide shield.

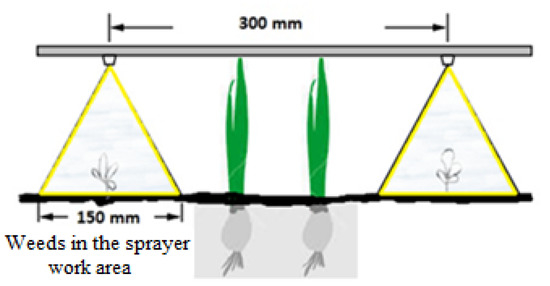

The proposed solution required the use of nozzles with a non-standard spray liquid distribution. On the entire working width of the nozzle, an even distribution of liquid is necessary, because unlike in traditional applications, the spray liquid does not overlap with adjacent nozzles. The area where the spray goes is in the range of just one nozzle. The used nozzles are characterized by an even flat jet, which results in an even flow of liquid over the entire working width. Figure 4 and Figure 5 show the liquid distribution diagram between two adjacent nozzles and the arrangement of nozzles and the working width of the band sprayer. The ejector atomizer manufactured by Agrotop-Germany was the factory equipment of the Amazone sprayer) AirMix 110-03 nozzles were used for conventional spraying. The working speed during spraying was 7.0 km∙h−1 and the working pressure was 3.5 bar. TeeJet TP9501EVS and TeeJet TP9502EVS fine droplet belt sprayers were used for belt spraying with herbicide cover. During the spraying, the band of onions, due to the need to spray bands of varying widths in order to balance the amount applied sprayers of varying capacity, were used on the surface of the liquid. A vascular test of the nozzles output was carried out. The amount of liquid obtained was converted into a unit of area sprayed by a given sprayer. TP9501EVS nozzles were used between the rows in the lane. In contrast, between the rows of adjacent sections, TP9502EVS nozzles were used. The working speed was 6 km h−1 and the working pressure was 2.5 bar.

Figure 4.

Diagram of the liquid distribution between two neighboring nozzles.

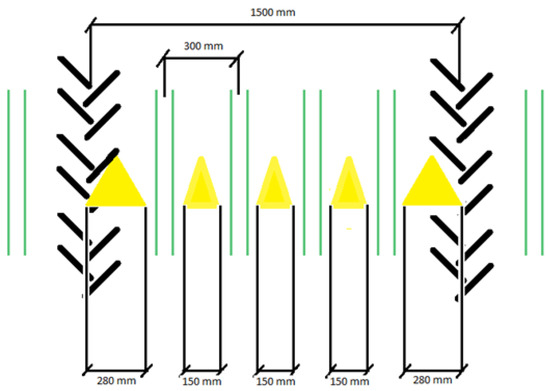

Figure 5.

Arrangement of the nozzles and working width.

The working width of the machine was equal to the working width of the sowing drill and it was 1500 mm. The yellow color in Figure 5 is used to mark the nozzles’ coverage area. The sprayers located above the tractor’s ruts operated at a different angle in the vertical axis from those located in the rows of the crop (Figure 6). Such a nozzle placement forced the use of sprayers with two different orifice sizes to even out the distribution of liquid per area unit. For the sprayers above the ruts, the orifice size was accordingly larger.

Figure 6.

Shielded band sprayer.

Both conventional and band spraying was carried out using a tractor equipped with an automatic steering system based on GPS signal with RTK/NET correction (The real-time correction data from the private base station was sent to the receiver via a mobile network transmission). This allowed the treatments to be performed with high precision and avoided mistakes when using the herbicides. The experimental plots located on the plantation were marked and transferred to the application map of the conventional sprayer, which made the experiment easier, and, above all, ensured the repeatability and accuracy of the journeys. It also eliminated possible human error, which could occur when using herbicides on the rest of the plantation and, e.g., the plot/plots could be sprayed in an uncontrolled manner.

3. Results

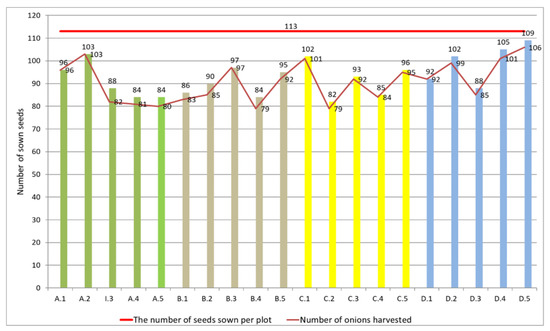

The chart below (Figure 7) shows the average number of onion plants in the seedling phase on the date of 11 May 2016 and the total number of harvested onions for each plot on 2 September 2016 in relation to the average number of seedlings at the level of 113 pieces.

Figure 7.

Number of onion seedlings (11 May 2016) and the number of harvested onions (02 September 2016) on individual plots for all weeding methods.

The average values obtained for each of the plot groups were adopted for the general assessment. The groups were divided in terms of weeding methods (Table 2).

Table 2.

Average values for all plot groups.

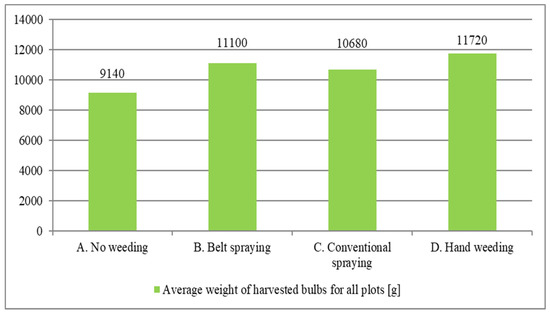

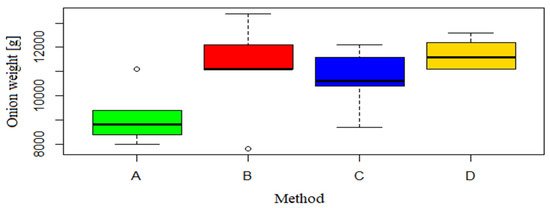

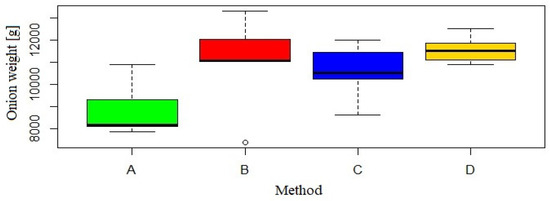

The average yield for each weeding method was calculated based on the results in individual plots. The average total yield (without division into fractions) for one plot was between 9140 and 11,720 g (Figure 8).

Figure 8.

Average onion yield per plot for individual weeding methods.

The results obtained in the experiment were subjected to statistical analysis. The following plot designations were adopted in the analysis:

A—without weeding,

B—band spraying,

C—conventional spraying and

D—manual weeding.

The data presented in the table below were obtained after manual harvesting of individual plots, and then each batch was weighted and measured and counted in accordance with the adopted division assumptions. Detailed data for each individual plot were taken into account for the sake of statistical analysis (Table 3) and compiled as described below.

Table 3.

Detailed data obtained in the experiment.

Normal distribution was tested by the Shapiro–Wilk method. In the case of normal distribution, Bartlett’s test was performed to verify the homogeneity of variance. Then, Tukey’s test allowed comparison of statistically significant differences.

If the Shapiro-Wilk test showed that the variable distribution was not close to normal, i.e., the probability value (p-value) is was than 0.05, a Kruskal-Wallis test was performed in order to determine the differences between groups of plots.

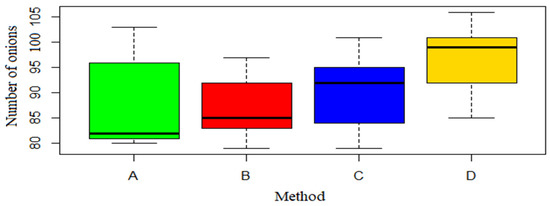

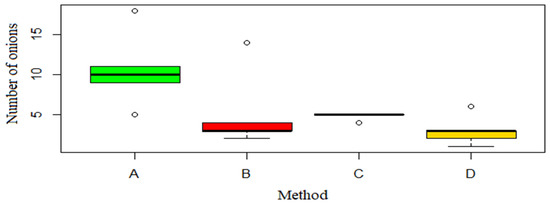

The analysis showed that the weeding method did not statistically significantly affect the average number of harvested onions (Figure 9). The average number for the trail without weeding was slightly more than 88 pieces and for band spraying was 87 pieces. The highest probability of occurrence of the number of harvested onions was determined at 82 pieces for plots without weeding and 85 pieces for band weeding.

Figure 9.

The number of all onions harvested from the plots.

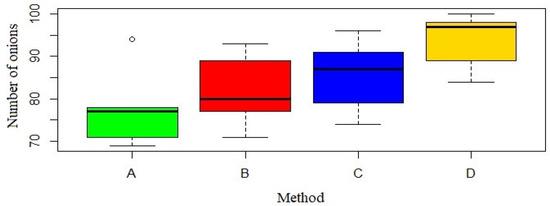

In terms of the number of harvested onions, the cultivation method without weeding was significantly statistically different from the manual weeding (Figure 10). The dominant value for group A was 20 pieces lower than in group D. The analysis showed no significant differences in the number of onions for the B and C methods.

Figure 10.

The number of onions harvested from the plots, which is the productive yield.

The varieties differed statistically significantly in the number of onions harvested from the plot that were not a productive yield, depending on the weeding method (Figure 11). In addition, there were significant differences in the numbers among plot groups. For the weed control by band spraying, it can be expected that onions with a diameter below 40 mm will occur in a quantity of 3 pieces, whereas for plots without weeding, this value is 10 pieces. On one of the plots without weeding, the onions that were not the main yield occurred most numerously, i.e., 17 pieces. Crop growing in the company of other plants competes for water and nutrients. The high density of plants caused the division of available nutrients between them, which resulted in lower growth and lower final yield of the crop. In addition, for a large part of the onions, there was not enough water and nutrients, so they could not grow up to the size required by the market and consumers, a result of which was onions with a diameter below 40 mm, thus constituting a loss.

Figure 11.

The number of onions harvested from plots that are not a productive yield.

The A method differed significantly from the D method in terms of the total weight of onions harvested from the plot (Figure 12). The value for the method without weeding was 8800 g and for manual weeding it was 11,600 g. For individual plots, the highest weight was 13,400 g on the plot with band weeding. Comparing the band spraying method and the conventional one, the probability of obtaining a higher yield was higher in the B plot, with 5000 g.

Figure 12.

Weight of all onions harvested from the plots.

The weeding methods showed significant differences taking into account the weight of onions in the productive yield (Figure 13). The lowest average yield was obtained on the plots without weeding. On plots weeded with the band spraying method, there was the highest probability of obtaining a weight of 11,050 g, whereas in the case of the conventional spraying method, there was the probability of obtaining a weight of 10,500 g. The highest dominant occurred in the group of manually weeded plots and it amounted to 11,500 g. The highest productive yield among the individual plots was obtained from the B group plot and it was 13,290 g.

Figure 13.

Weight of onions harvested form the plots, which is the productive yield (fractions 40−80).

4. Discussion

Roten et al. [32] and Foster et al. [33] showed that the use of low-drift nozzles resulted in a reduction of drift in the range from 81% to 94% compared to control nozzles (standard ones). As it is clear from the analyses carried out by these researchers, the precise application of herbicides is possible using a shield, ensuring cooperation with the appropriate type of sprayer. One of the main purposes of this paper was the design and implementation of a herbicide shield with the desired parameters. The shields were made using 3D printing technology. The comparative studies of traditional technologies with newly developed solutions allow an assessment of their effectiveness and set development directions.

The need to fight weeds to increase crop yield is undisputed in the literature. Many researchers around the world see the need to search for new methods and their combinations, which are useful in the weeding of crops, including onions. An example of this approach is a study conducted by Rahman et al. [34], where the effectiveness of various weeding methods in onion cultivation was compared. The experiment was conducted in three repetitions during two growing seasons. Six methods were compared in the experiment, two of which consisted only of manual weeding. In both the experiment conducted by our research team and in the experiment conducted by Rahman et al. [34], the highest weight of onions was recorded on plots with manual weeding, and the worst result was on control objects without weeding. Similar results in the research on methods of controlling weed infestation in onion cultivation were obtained by Sahoo et al. [35]. Additionally, the experiment conducted in Polish conditions confirmed that the best yield of onions was from the plots that were systematically manually weeded [36].

Researchers also emphasize the importance of using precise positioning systems when performing herbicide treatments [37,38].

Achieving yields at high levels with an appropriate weed control and reducing herbicide consumption is the subject of many studies [17,39,40,41].

The control of weeds in agricultural crops should be carried out by an integrated method, including the use of herbicides, while simultaneously maximizing their reduction. In some row cultivations, researchers recommend band spraying with herbicides only in the rows of plants (sprayers with shields) and mechanical weed control in the inter-rows [42]. In some cultivations, such as root vegetable cultivations on ridges, the use of mechanical methods is limited due to the possibility of damaging the ridge structure and lowering the quality of the yield.

5. Conclusions

The conducted research, discussion, and analysis of the results allowed the following conclusions to be formulated:

- The use of band spraying with a shield may lead to less absorption of herbicides by the crop and its faster growth, which should be confirmed in further studies.

- Similar yield levels in the conventional and band method allow for further testing for spraying during adverse weather conditions (including strong wind).

- Further research should be carried out, which may indicate the occurrence of statistical differences in the production yield between weed control methods in onion cultivation.

- It is recommended to continue crop tests based on the band spraying method in terms of the effectiveness of weed control and to extend the scope of tests with the quantitative analysis of the used herbicides and their possible residues in crop yield.

Author Contributions

Conceptualization, A.O. and P.P.; Data curation, P.P., P.R., E.O. and A.P.; Formal analysis, A.O. and E.O. Methodology, P.P.; Project administration, P.P. and P.R.; Supervision, E.O.; Visualization, E.O.; Writing—original draft, A.O. and A.P.; Writing—review and editing, P.R., M.H., I.K. and L.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Acknowledgments

In this section you can acknowledge any support given which is not covered by the author contribution or funding sections. This may include administrative and technical support, or donations in kind (e.g., materials used for experiments).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Jablonski, B.B.R.; Carolan, M.; Hale, J.; Thilmany McFadden, D.; Love, E.; Christensen, L.; Covey, T.; Bellows, L.; Cleary, R.; David, O.; et al. Connecting Urban Food Plans to the Countryside: Leveraging Denver’s Food Vision to Explore Meaningful Rural–Urban Linkages. Sustainability 2019, 11, 2022. [Google Scholar] [CrossRef]

- Wichelns, D. Achieving Water and Food Security in 2050: Outlook, Policies, and Investments. Agriculture 2015, 5, 188–220. [Google Scholar] [CrossRef]

- Steiner, G.; Geissler, B.; Schernhammer, E.S. Hunger and Obesity as Symptoms of Non-Sustainable Food Systems and Malnutrition. Appl. Sci. 2019, 9, 1062. [Google Scholar] [CrossRef]

- Cambareri, G.; Grant-Young, J. Addressing the Conceptual Controversy of Sustainable Intensification of Agriculture: A Combined Perspective from Environmental Philosophy and Agri-Environmental Sciences. Philosophies 2018, 3, 37. [Google Scholar] [CrossRef]

- Simon, X.; Montero, M.; Bermudez, Ó. Advancing Food Security through Agroecological Technologies: The Implementation of the Biointensive Method in the Dry Corridor of Nicaragua. Sustainability 2020, 12, 844. [Google Scholar] [CrossRef]

- Story, M.; Kaphingst, K.M.; Robinson-O’Brien, R.; Glanz, K. Creating healthy food and eating environments: Policy and environmental approaches. Annu. Rev. Public Health 2008, 29, 253–272. [Google Scholar] [CrossRef] [PubMed]

- Pawlewicz, A. Change of Price Premiums Trend for Organic Food Products: The Example of the Polish Egg Market. Agriculture 2020, 10, 35. [Google Scholar] [CrossRef]

- Głąbska, D.; Guzek, D.; Groele, B.; Gutkowska, K. Fruit and Vegetable Intake and Mental Health in Adults: A Systematic Review. Nutrients 2020, 12, 115. [Google Scholar] [CrossRef] [PubMed]

- Miceli, C.; Moncada, A.; Vetrano, F.; Iapichino, G.; D’Anna, F.; Miceli, A. Effect of Agronomic Practices on Yield and Quality of Borage at Harvest and During Storage as Minimally-Processed Produce. Agronomy 2020, 10, 242. [Google Scholar] [CrossRef]

- Rop, O.; Mlcek, J.; Jurikova, T.; Neugebauerova, J.; Vabkova, J. Edible Flowers—A New Promising Source of Mineral Elements in Human Nutrition. Molecules 2012, 17, 6672–6683. [Google Scholar] [CrossRef]

- Shrestha, H. A Plant Monograph on Onion (Allium cepa L.); The School of Pharmaceutical and Biomedical Sciences Pokhara University: Pokhara, Nepal, 2007. [Google Scholar]

- Cases, A.; Cigarrán-Guldrís, S.; Mas, S.; Gonzalez-Parra, E. Vegetable-Based Diets for Chronic Kidney Disease? It Is Time to Reconsider. Nutrients 2019, 11, 1263. [Google Scholar] [CrossRef] [PubMed]

- Przygodziński, P. Technology for Precision Application of Plant Protection Products in Field Crops. Ph.D. Thesis, Institute of Biosystems Engineering, Poznan University of Life Sciences, Poznan, Poland, 2019. (In Polish). [Google Scholar]

- Praczyk, T.; Skrzypczak, G. Herbicides; Academic Handbook; PWRiL: Warsaw, Poland, 2004. (In Polish) [Google Scholar]

- Urban, S. Changes in the use of plant protection products in Poland and their economic aspects. Sci. Ann. Assoc. Agric. Agribus. Econ. 2014, 16, 505–509. (In Polish) [Google Scholar]

- Ibáñez, M.D.; Blázquez, M.A. Ginger and Turmeric Essential Oils for Weed Control and Food Crop Protection. Plants 2019, 8, 59. [Google Scholar] [CrossRef] [PubMed]

- Anyszka, Z.; Elkner, K. The Influence of some Herbicides on Yield and Chemical Composition of Baby Carrots. Ann. Agric. Univ. Pozn. Gard. 2007, 41, 417–420. (In Polish) [Google Scholar]

- Doruchowski, G. Spraying technique in the context of the requirements of effective and safe plant protection. In Proceedings of the Farmer’s Conference, through Innovation to Success, Skierniewice, Poland, 5 January−15 February 2015; Institute of Horticulture in Skierniewice: Skierniewice, Poland (In Polish). [Google Scholar]

- EPPO. PP1/135 (3) European and Mediterranean Plant Protection Organization; Bulletin OEPP/EPPO Bulletin; EPPO: Paris, France, 2007; Volume 37, pp. 4–10. [Google Scholar]

- Hołownicki, R.; Doruchowski, G. The role of spraying technique in reducing environmental contamination with plant protection products. Agric. Eng. 2006, 5, 239–247. (In Polish) [Google Scholar]

- Foqué, D. Optimization of Spray Application Technology in Ornamental Crops. Ph.D. Thesis, University of Gent, Ghent, Belgium, 2012; 237p. [Google Scholar]

- Laursen, M.S.; Jørgensen, R.N.; Midtiby, H.S.; Jensen, K.; Christiansen, M.P.; Giselsson, T.M.; Mortensen, A.K.; Jensen, P.K. Dicotyledon Weed Quantification Algorithm for Selective Herbicide Application in Maize Crops. Sensors 2016, 16, 1848. [Google Scholar] [CrossRef]

- García-Angulo, P.; Alonso-Simón, A.; Encina, A.; Álvarez, J.M.; Acebes, J.L. Cellulose Biosynthesis Inhibitors: Comparative Effect on Bean Cell Cultures. Int. J. Mol. Sci. 2012, 13, 3685–3702. [Google Scholar] [CrossRef]

- Robak, J.; Anyszka, Z.; Felczyński, K.; Rogowska, M.; Wrzodak, R. Methodology of Integrated Onion Protection (Materials for Consultants); Collective Study of Prof. Dr Hab. Józef Robak, Update 2016; Institute of Horticulture in Skierniewice: Skierniewice, Poland, 2013. (In Polish) [Google Scholar]

- Ramon, H.; Anthonis, J.; Moshou, D.; De Baerdemaeker, J. Evaluation of a Cascade Compensator for Horizontal Vibrations of a Flexible Spray Boom. J. Agric. Eng. Res. 1998, 71, 81–92. [Google Scholar] [CrossRef]

- Szewczyk, A. Expertise. Spraying Technique for Flat Field Crops–Current State of Research and Development Directions. Wroclaw, Poland, 2009. (In Polish). Available online: https://docplayer.pl/24630607-Ekspertyza-dr-ins-antoni-szewczyk-instytut-insynierii-rolniczej-uniwersytet-przyrodniczy-wroclaw-2009.html (accessed on 10 February 2020).

- Carballido, J.; Rodriguez-Lizana, A.; Aguera, J.; Perez-Ruiz, M. Field sprayer for inter- and intra-row weed control: Performance and labor savings. Span. J. Agric. Res. 2013, 11, 642–651. [Google Scholar] [CrossRef]

- Clayton, J. The Varidome precision band sprayer for row crops. International Advances in Pesticide Application. Asp. Appl. Biol. 2014, 122, 55–62. [Google Scholar]

- Ivany, J.A. Banded herbicides and cultivation for weed control in potatoes (Solanum tuberosum L.). Can. J. Plant Sci. 2002, 82, 617–620. [Google Scholar] [CrossRef]

- Oliver, D.P.; Anderson, J.S.; Davis, A.; Lewis, S.; Brodie, J.; Kookana, R. Banded applications are highly effective in minimising herbicide migration from furrow-irrigated sugar cane. Sci. Total Environ. 2014, 466, 841–848. [Google Scholar] [CrossRef] [PubMed]

- Perez-Ruiz, M.; Carballido, J.; Aguera, J.; Rodriguez-Lizana, A. Development and Evaluation of a Combined Cultivator and Band Sprayer with a Row-Centering RTK-GPS Guidance System. Sensors 2013, 13, 3313–3330. [Google Scholar] [CrossRef]

- Roten, R.L.; Ferguson, J.C.; Hewitt, A.J. Drift reducing potential of low drift nozzles with the use of spray-hoods. N. Z. Plant Prot. 2014, 67, 274–277. [Google Scholar]

- Foster, C.H.; Sperry, B.P.; Reynolds, D.B.; Kruger, G.R.; Clause, S. Reducing Herbicide Particle Drift: Effect of Hooded Sprayer and Spray Quality. Weed Technol. 2018, 32, 714–721. [Google Scholar] [CrossRef]

- Rahman, H.; Ullah, K.; Sadiq, M.; Zubair, M.; Favaria, S.; Khan, M.A.; Khattak, A.M. Relative Efficacy of Different Weed Control Methods in Onion (Allium cepa L.) Crop. Pak. J. Weed Sci. Res. 2011, 17, 343–350. [Google Scholar]

- Sahoo, S.K.; Charkavorty, S.; Soren, L.; Mishra, C.; Sahoo, B.B. Effect of weed management on growth and yield of onion (Allium cepa L.). J. Crop Weed 2017, 13, 208–211. [Google Scholar]

- Kohut, M.; Anyszka, Z.; Golian, J. The effect of combining chemical protection with mechanical treatments on weed infestation, growth and onion yields (Allium cepa L.). Prog. Plant Prot. 2014, 54, 31–37. (In Polish) [Google Scholar]

- Gidea, M. The Differentiated Weed Control Methods in Onion Crops on the Cambic Chernozem in South Romania. J. Proc. Rom. Acad. Ser. B 2014, 16, 49–53. [Google Scholar]

- Peruzzi, A.; Frasconi, C.; Martelloni, L.; Fontanelli, M.; Rafaelli, M. A New Prototype to Perform Precision Treatments of Activated Streaming to Kill weed Seed Before Sowing of Organic Vegetable. In Proceedings of the First International Conference on Robotics and Associated High-Technologies and Equipment for Agriculture. Applications of Automated Systems and Robotics for Crop Protection in Sustainable Precision Agriculture, Pisa, Italy, 19−21 September 2012; Peruzzi, A., Ed.; pp. 49–54. [Google Scholar]

- Main, D.C.; Sanderson, K.R.; Fillmore, S.A.E.; Ivany, J.A. Comparison of synthetic and organic herbicides applied banded for weed control in carrots (Daucus carota L.). Can. J. Plant Sci. 2013, 93, 857–861. [Google Scholar] [CrossRef]

- Dammer, K.H. Real-time variable-rate herbicide application for weed control in carrots. Weed Res. 2016, 56, 237–246. [Google Scholar] [CrossRef]

- Anyszka, Z.; Golian, J. The effect of Flaming and Mechanical Treatments on Weed Control, Growth and Yield of Carrot. J. Res. Appl. Agric. Eng. 2017, 62, 7–12. [Google Scholar]

- Dobrzanski, A. Rules for the use of herbicides. Vegetables 2008, 6, 54–57. (In Polish) [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).