Development and Use of a Planter for Simultaneous Application of Seed, Fertilizer and Compost in Pearl Millet Production in Niger—Effects on Labor Use, Yield and Economic Return

Abstract

1. Introduction

2. Materials and Methods

2.1. On-Station Experiments

2.2. On-Farm Experiments

2.3. Economic Evaluation

2.4. Statistical Analysis

3. Results

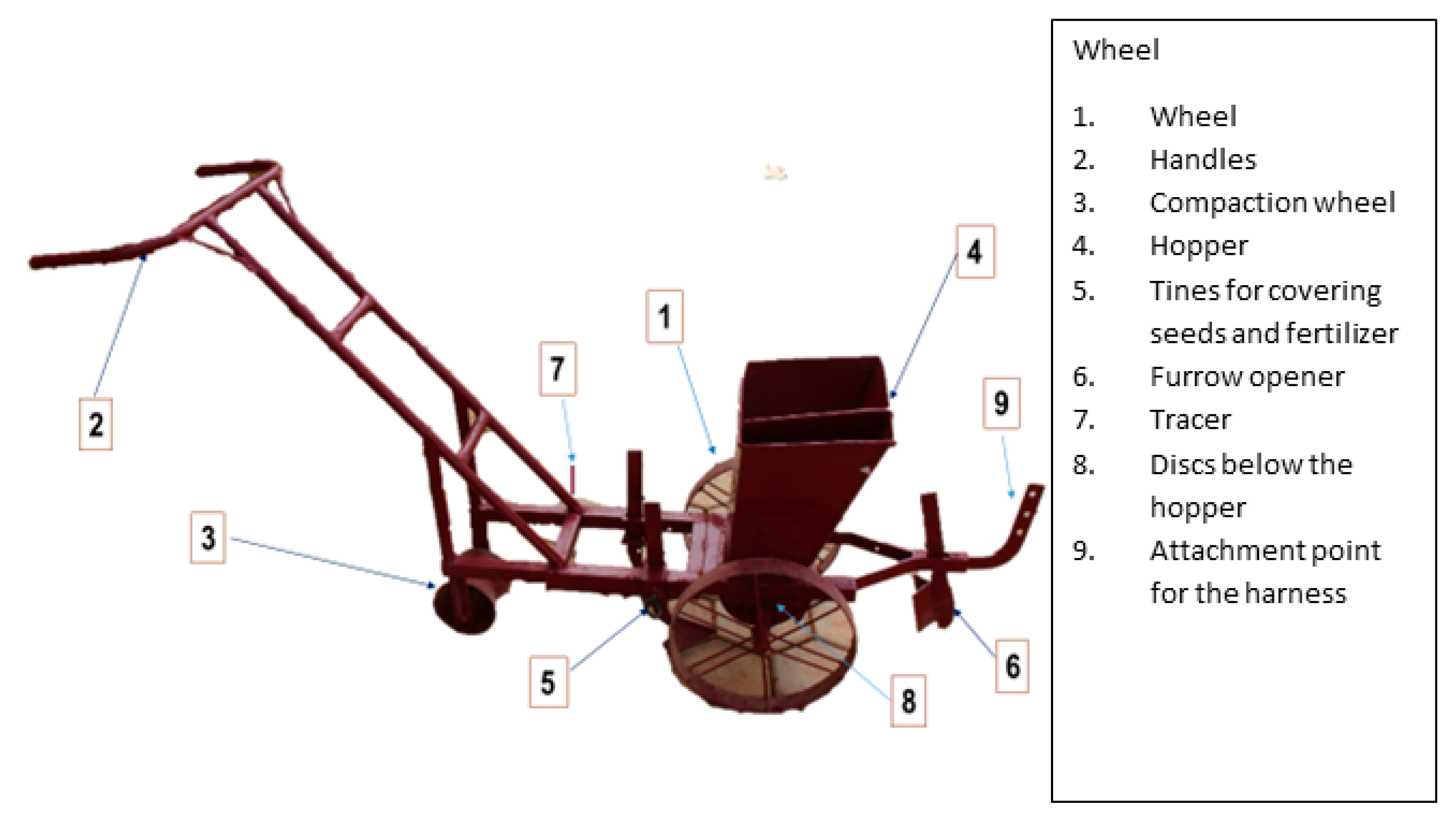

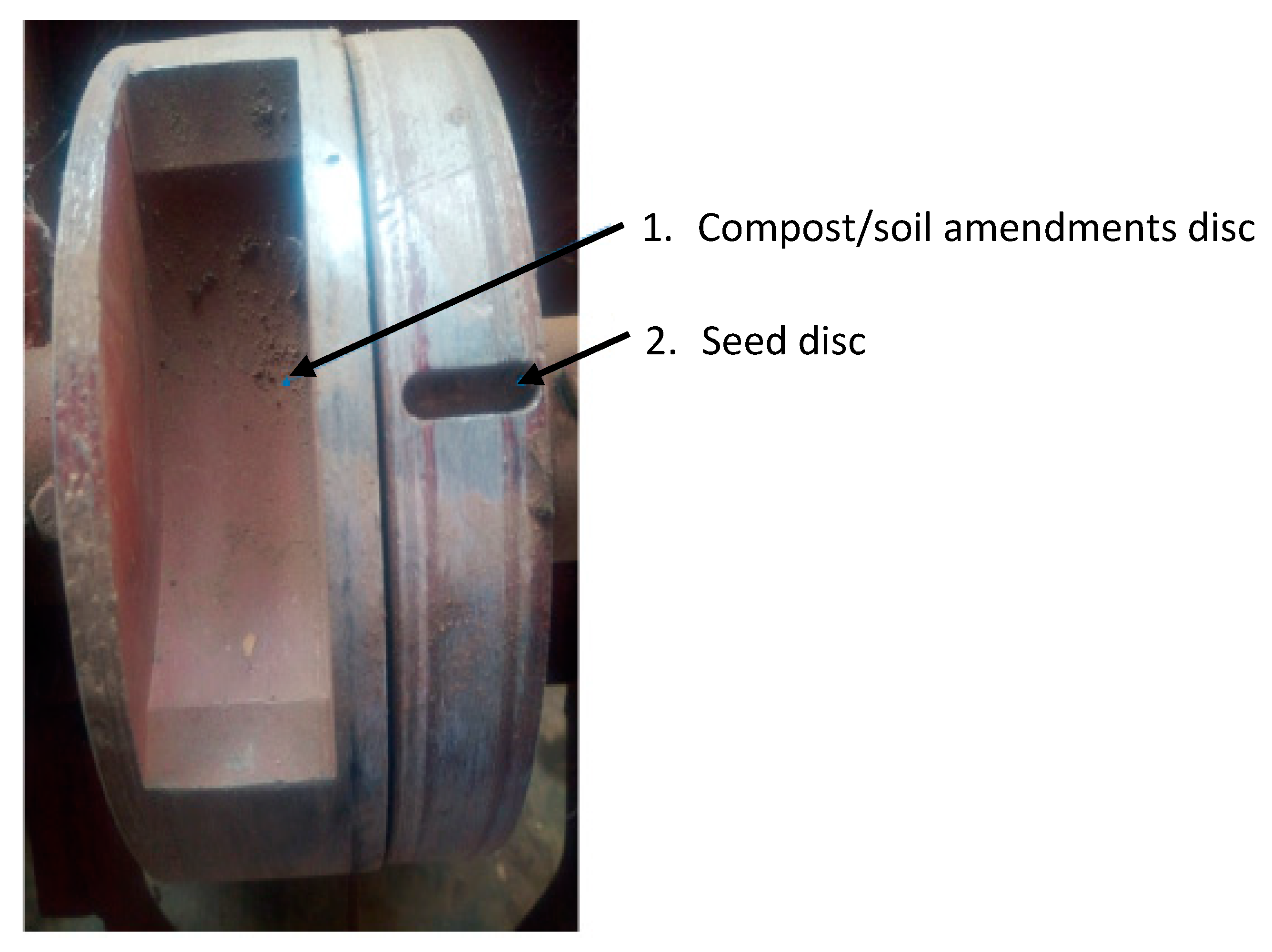

3.1. Development and Use of the Gangaria Planter

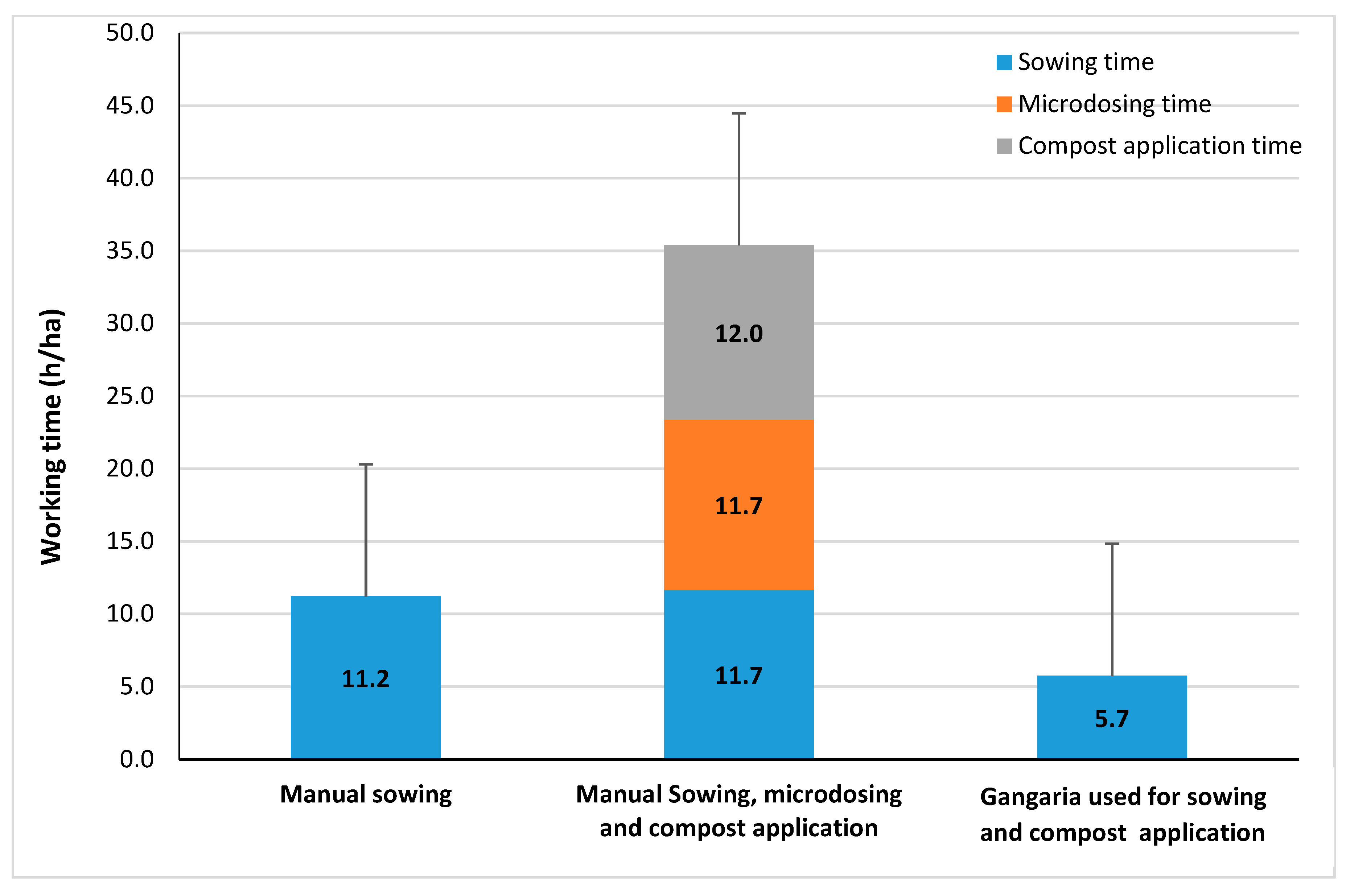

3.2. Labor Use in Manual and Mechanized Sowing

3.3. Agronomic Experiments on Mechanization Combined with Seed Priming, Seed Treatment and Microdosing of Organic and Mineral Fertilizer

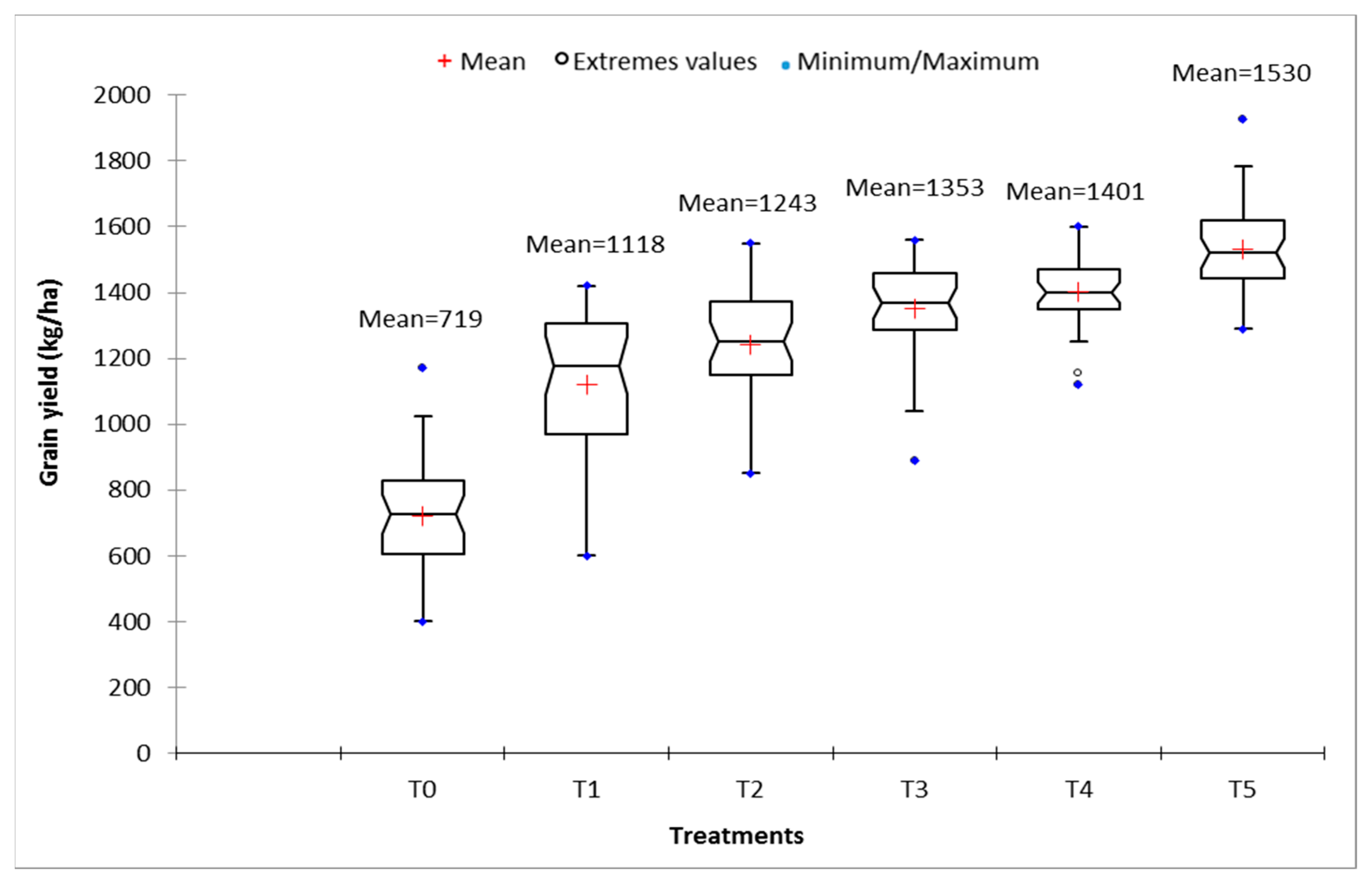

3.3.1. On-Station Experiments

3.3.2. On-Farm Experiments

3.4. Economic Analysis of On-Station Experiments

4. Discussion

4.1. The Effects of the Planter

4.2. Agronomic Effects

4.3. Economic Effects

4.4. Overall Sustainability of the Approach

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- IRD. Le mil, aliment du futur au Sahel; Actualité Scientifique; Fiche No. 325; IRD: Marseille, France, 2009; 2p.

- FAO-Stat FAO Stat Crops. 2020. Available online: http://www.fao.org/faostat/en/#data/QC (accessed on 27 November 2020).

- Christiansson, C.B.; Bationo, A.; Baethegen, W.E. The effect of soil tillage and fertilizer use on pearl millet yields in Niger. Plant Soil 1990, 123, 51–58. [Google Scholar] [CrossRef]

- Zeinabou, H. Contribution du niébé et des fumures organiques et minérales à la nutrition azotée et aux rendements du mil dans les systèmes de cultures en zone sahélo-soudanienne au Niger. Ph.D. Thesis, Université de Bobo-Dioulasso, Bobo-Dioulasso, Burkina Faso, 2017; 126p. Available online: http://www.beep.ird.fr/collect/upb/index/assoc/IDR-2017-HAL-CON/IDR-2017-HAL-CON.pdf (accessed on 27 November 2020).

- ICRISAT. Fertilizer Micro-Dosing. Boosting Production in Unproductive Lands. 2019. Available online: http://oar.icrisat.org/5666/1/Microdosing_Flyer_2009.pdf (accessed on 27 November 2020).

- Bielders, C.; Gerard, B. Millet response to microdose fertilization in south–western Niger: Effect of antecedent fertility management and environmental factors. Field Crops Res. 2015, 171, 165–175. [Google Scholar] [CrossRef]

- Coulibaly, A.; Woumou, K.; Aune, J.B. Sustainable intensification of sorghum and pearl millet production by seed priming, seed treatment and fertilizer microdosing under different rainfall regimes in Mali. Agronomy 2019, 9, 664. [Google Scholar] [CrossRef]

- Aune, J.B.; Ousman, A. Effect of seed priming and micro-dosing of fertilizers on sorghum and pearl millet in Western Sudan. Exp. Agric. 2011, 47, 419–435. [Google Scholar] [CrossRef]

- Quinn, D.J.; Lee, C.D.; Poffenbarger, H.J. Corn yield response to sub-surface banded starter fertilizer in U.S.: A meta-analysis. Field Crops Res. 2020, 243, 107834. [Google Scholar] [CrossRef]

- Buerkert, A.; Bationo, A.; Dossa, K. Mechanism of residue mulch-induced cereal growth increase in West Africa. Soil Sci. Soc. Am. J. 2000, 64, 346–358. [Google Scholar] [CrossRef]

- Bationo, A.; Waswa, B.S. New Challenges and Opportunities for Integrated Soil Fertility Management ISFM in Africa. In Innovations as Key to the Green Revolution in Africa; Springer: New York, NY, USA; London, UK, 2011; Volume 1, pp. 3–17. [Google Scholar]

- Bationo, A.; Mokwunye, A.U. Role of manures and crop residue in alleviating soil fertility constraints to crop production: With special reference to the Sahelian and Sudanian zones of West Africa. Fertil. Res. 1991, 29, 117–125. [Google Scholar] [CrossRef]

- Aune, J.B.; Coulibaly, A.; Giller, K.E. Precision farming for increased land and labour productivity in semi-arid West Africa. A review. Agron. Sustain. Dev. 2017, 37, 16. [Google Scholar] [CrossRef]

- Aune, J.B.; Coulibaly, A.; Woumou, K. Intensification of dryland farming in Mali through mechanisation of sowing, fertiliser application and weeding. Arch. Agron. Soil Sci. 2019, 65, 400–410. [Google Scholar] [CrossRef]

- Sims, B.; Kienzle, J. Mechanization of Conservation Agriculture for Smallholders: Issues and Options for Sustainable Intensification. Environments 2015, 2, 139–166. [Google Scholar] [CrossRef]

- Harris, D. Development and testing of “on-farm” seed priming. Adv. Agron. 2006, 90, 129–178. [Google Scholar] [CrossRef]

- Aune, J.B.; Traoré, C.O.; Mamadou, S. Low-cost technologies for improved productivity of dryland farming in Mali. Outlook Agric. 2012, 41, 103–108. [Google Scholar] [CrossRef]

- Bayala, J.; Ky-Dembele, C.; Kalinganire, A.; Olivier, A.; Nantoumé, H. A Review of Pasture and Fodder Production and Productivity for Small Ruminants in the Sahel; ICRAF Occational Paper No. 21; Word Agroforestry Center: Nairobi, Kenya, 2014; 87p, Available online: https://www.researchgate.net/publication/262943657 (accessed on 27 November 2020).

- Yamoah, C.; Bationo, A.; Shapiro, B.; Koala, S. Trend and stability analysis of millet yields with treated with fertilizer and crop residues in the Sahel. Field Crops Res. 2002, 75, 53–62. [Google Scholar] [CrossRef]

- Ibrahim, A.; Abaidoo, R.C.; Fatondji, D.; Opoku, A. Hill placement of manure and fertilizer micro-dosing improves yield and water use efficiency in the Sahelian low input millet-based cropping system. Field Crops Res. 2015, 180, 29–36. [Google Scholar] [CrossRef]

| Treatments | Sowing Method | Seed Priming | Seed Treatment | Fertilizer Application | Weeding Method |

|---|---|---|---|---|---|

| T0 | Manual sowing | No seed priming | No seed coating | No mineral fertilizer | Manual weeding |

| T1 | Mechanical sowing | Seed priming | Seed coated with fungicide | Microdosing 0.3 g NPK hill−1 | Mechanical weeding |

| T2 | Mechanical sowing | Seed priming | Seed coated with fungicide | Microdosing 25 g compost hill−1 | Mechanical weeding |

| T3 | Mechanical sowing | Seed priming | Seed coated with fungicide | Microdosing 0.3 g NPK and 25 g compost hill−1 | Mechanical weeding |

| T4 | Mechanical sowing | Seed priming | Seed coated with fungicide | Microdosing 50 g compost hill−1 | Mechanical weeding |

| T5 | Mechanical sowing | Seed priming | Seed coated with fungicide | Microdosing 0.3 g NPK and 50 g compost hill−1 | Mechanical weeding |

| Treatments | Sowing Method | Seed Priming | Seed Treatment | Fertilizer Application | Weeding Method |

|---|---|---|---|---|---|

| T0 | Manual sowing | No seed priming | No seed coating | No mineral fertilizer | Manual weeding |

| T1 | Manual sowing | No seed priming | No seed coating with fungicide/insecticide | 2 g NPK hill−1 and 150 g compost hill−1 | Manual weeding |

| T2 | Mechanical sowing | Seed priming | Seed coated with fungicide/insecticide | Microdosing 25 g compost hill−1 | Mechanical weeding |

| Village | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Trait. | Aguié | Arewa | Danja | Kandoussa | Karosofoua | Lossa | N’Dounga | Sabon Gida | Average |

| T0 | 11.1 ± 0.2 | 11.9 ± 0.3 | 11.3 ± 0.3 | 12 ± 0.4 | 11.5 ± 0.6 | 11.5 ± 0.2 | 12.1 ± 0.1 | 12.1 ± 0.1 | 11.7 ± 0.4 |

| T1 | 34.7 ± 0.6 | 35.9 ± 0.8 | 34.2 ± 1.4 | 35.7 ± 0.3 | 34.9 ± 0.1 | 34.9 ± 0.9 | 35.9 ± 0.3 | 36.8 ± 0.6 | 35.4 ± 1 |

| T2 | 5.5 ± 0.3 | 6.1 ± 0.3 | 5.4 ± 0.3 | 5.7 ± 0.2 | 5.6 ± 0.1 | 5.7 ± 0.4 | 5.8 ± 0.4 | 6 ± 0.4 | 5.7 ± 0.3 |

| Df. | Significance | ||||||||

| Treatment (T) | 2 | <0.001 | |||||||

| Villages (V) | 7 | <0.001 | |||||||

| T × V | 14 | 0.113 | |||||||

| CV% | 2.7 | ||||||||

| Location | Year | Average Percent Germination 2.5 Days after Sowing | |||||

|---|---|---|---|---|---|---|---|

| T0 | T1 | T2 | T3 | T4 | T5 | ||

| Konni | 2018 | 20.0 ± 7.1 | 93.3 ± 6.1 | 94.2 ± 8.0 | 99.2 ± 2.0 | 95.0 ± 4.5 | 97.5 ± 4.2 |

| 2019 | 32.3 ± 17.1 | 100 | 97.5 ± 4.2 | 96.7 ± 5.2 | 95.8 ± 3.8 | 95.0 ± 6.3 | |

| N’Dounga | 2018 | 26.7 ± 12.9 | 91.7 ± 4.1 | 92.5 ± 7.6 | 92.5 ± 8.8 | 93.3 ± 7.5 | 93.3 ± 5.2 |

| 2019 | 25.0 ± 10.5 | 91.7 ± 7.5 | 90.8 ± 3.8 | 86.7 ± 4.1 | 87.5 ± 5.2 | 87.5 ± 7.6 | |

| Lossa | 2018 | 30.0 ± 6.3 | 90.0 ± 0.0 | 87.5 ± 6.1 | 97.5 ± 4.2 | 90.8 ± 2.0 | 97.5 ± 4.2 |

| 2019 | 34.2 ± 10.1 | 92.5 ± 7.6 | 92.5 ± 5.2 | 90.8 ± 5.8 | 95.0 ± 4.5 | 96.7 ± 4.1 | |

| Average | 2018 | 25.6 ± 9.7 | 91.7 ± 4.2 | 91.4 ± 7.4 | 96.4 ± 6.1 | 93.1 ± 5.2 | 96.1 ± 4.7 |

| 2019 | 30.5 ± 13.0 | 94.7 ± 7.0 | 93.6 ± 5.1 | 91.4 ± 6.4 | 92.8 ± 5.7 | 93.1 ± 7.1 | |

| Average 2018–2019 | 28 ± 11.6 | 93.2 ± 5.9 | 92.5 ± 6.4 | 93.9 ± 6.7 | 92.9 ± 5.4 | 94.6 ± 6.1 | |

| Fpr | Df. | Significance | |||||

| Treatment (T) | 5 | <0.001 | |||||

| Location (L) | 2 | <0.001 | |||||

| Year (Y) | 1 | 0.728 | |||||

| T × L | 10 | 0.071 | |||||

| T × Y | 5 | 0.014 | |||||

| L × Y | 2 | 0.011 | |||||

| T × L × Y | 10 | 0.56 | |||||

| CV% | 8.1 | ||||||

| Location | Year | Average Grain Yield (±SD) | |||||

|---|---|---|---|---|---|---|---|

| T0 | T1 | T2 | T3 | T4 | T5 | ||

| Konni | 2018 | 724 ± 82.1 | 1123 ± 107.1 | 1269 ± 53.9 | 1344 ± 36.1 | 1398 ± 60.4 | 1475 ± 65.7 |

| 2019 | 926 ± 145.4 | 1290 ± 83.5 | 1262 ± 127.9 | 1476 ± 48.6 | 1387 ± 76.2 | 1647 ± 156.5 | |

| N’Dounga | 2018 | 817 ± 67;7 | 1345 ± 77.1 | 1434 ± 85.2 | 1490 ± 55.5 | 1533 ± 83.3 | 1655 ± 86.0 |

| 2019 | 606 ± 71.1 | 998 ± 121.4 | 1190 ± 52.1 | 1296 ± 43.2 | 1380 ± 29.9 | 1473 ± 35.0 | |

| Lossa | 2018 | 753 ± 60.6 | 1258 ± 63.5 | 1347 ± 69.9 | 1425 ± 85.7 | 1488 ± 92.9 | 1591 ± 96.2 |

| 2019 | 488 ± 60.0 | 698 ± 98.1 | 953 ± 90.2 | 1086 ± 109.7 | 1219 ± 64.8 | 1337 ± 35.0 | |

| Average | 2018 | 765 ± 77.4 | 1242 ± 123.1 | 1350 ± 96.2 | 1420 ± 84.9 | 1473 ± 94.6 | 1574 ± 109.7 |

| 2019 | 673 ± 212.3 | 995 ± 266.3 | 1135 ± 162.5 | 1286 ± 178.1 | 1329 ± 97.7 | 1486 ± 158 | |

| Average 2018–2019 | 719 ± 164.2 | 1118 ± 239.7 | 1243 ± 170.8 | 1353 ± 153.4 | 1401 ± 119.8 | 1530 ± 141.3 | |

| Df. | Significance | ||||||

| Treatment (T) | 5 | <0.001 | |||||

| Location (L) | 2 | <0.001 | |||||

| Year (Y) | 1 | <0.001 | |||||

| T × L | 10 | 0.002 | |||||

| T × Y | 5 | <0.001 | |||||

| L × Y | 2 | <0.001 | |||||

| T × L × Y | 10 | 0.001 | |||||

| CV% | 7.0 | ||||||

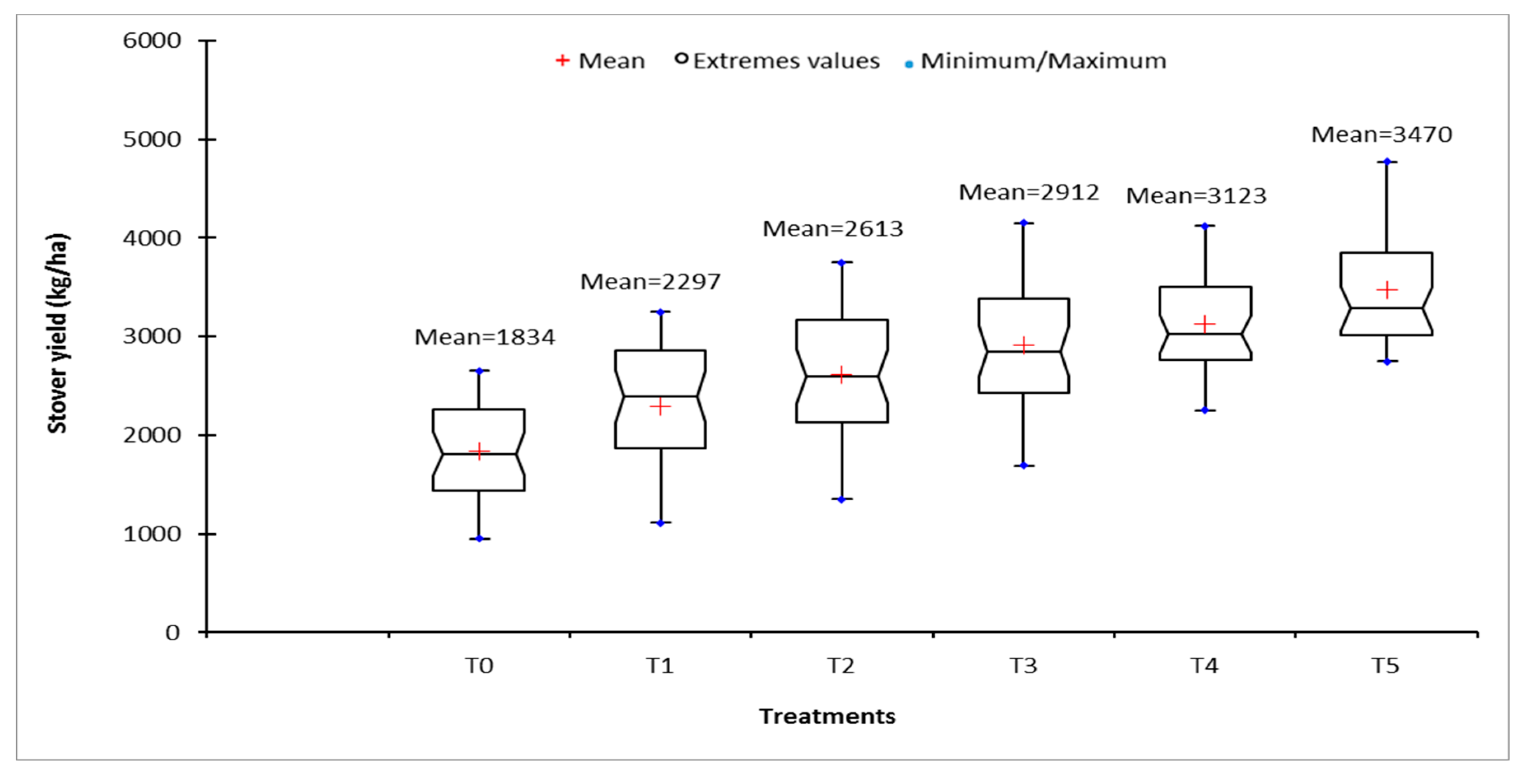

| Location | Year | Average stover yield (±SD) | |||||

|---|---|---|---|---|---|---|---|

| T0 | T1 | T2 | T3 | T4 | T5 | ||

| Konni | 2018 | 1844 ± 272.4 | 2395 ± 274.3 | 2595 ± 181.4 | 2847 ± 273.7 | 3014 ± 189.1 | 3198 ± 184.8 |

| 2019 | 2172 ± 368.0 | 2732 ± 315.5 | 2829 ± 432.7 | 3386 ± 434.1 | 3251 ± 364.5 | 3887 ± 600.4 | |

| N’Dounga | 2018 | 2374 ± 312.1 | 3037 ± 235.6 | 3410 ± 231.9 | 3534 ± 343.8 | 3793 ± 338.7 | 3999 ± 325.6 |

| 2019 | 1417 ± 80.7 | 1699 ± 418.8 | 2137 ± 421.6 | 2408 ± 310.5 | 2818 ± 297.9 | 3203 ± 218.6 | |

| Lossa | 2018 | 1986 ± 164.1 | 2539 ± 331.7 | 2805 ± 467.6 | 3113 ± 576.1 | 3371 ± 545.1 | 3675 ± 614.2 |

| 2019 | 1213 ± 199.8 | 1378 ± 148.5 | 1903 ± 182.1 | 2182 ± 260 | 2495 ± 148.3 | 2863 ± 96.8 | |

| Average | 2018 | 2068 ± 334.0 | 2657 ± 388.4 | 2937 ± 465 | 3165 ± 489.1 | 3393 ± 488.7 | 3624 ± 516.7 |

| 2019 | 1600 ± 483.5 | 2297 ± 663.9 | 2613 ± 329.9 | 2912 ± 626.6 | 3123 ± 416.2 | 3470 ± 561.1 | |

| Average 2018–2019 | 1834 ± 473.2 | 2297 ± 648.8 | 2613 ± 590.8 | 2912 ± 610.6 | 3123 ± 524 | 3470 ± 553.9 | |

| Df. | Significance | ||||||

| Treatment (T) | 5 | <0.001 | |||||

| Location (L) | 2 | <0.001 | |||||

| Year (Y) | 1 | <0.001 | |||||

| T × L | 10 | 0.592 | |||||

| T × Y | 5 | 0.118 | |||||

| L × Y | 2 | <0.001 | |||||

| T × L× Y | 10 | 0.918 | |||||

| CV% | 12.4 | ||||||

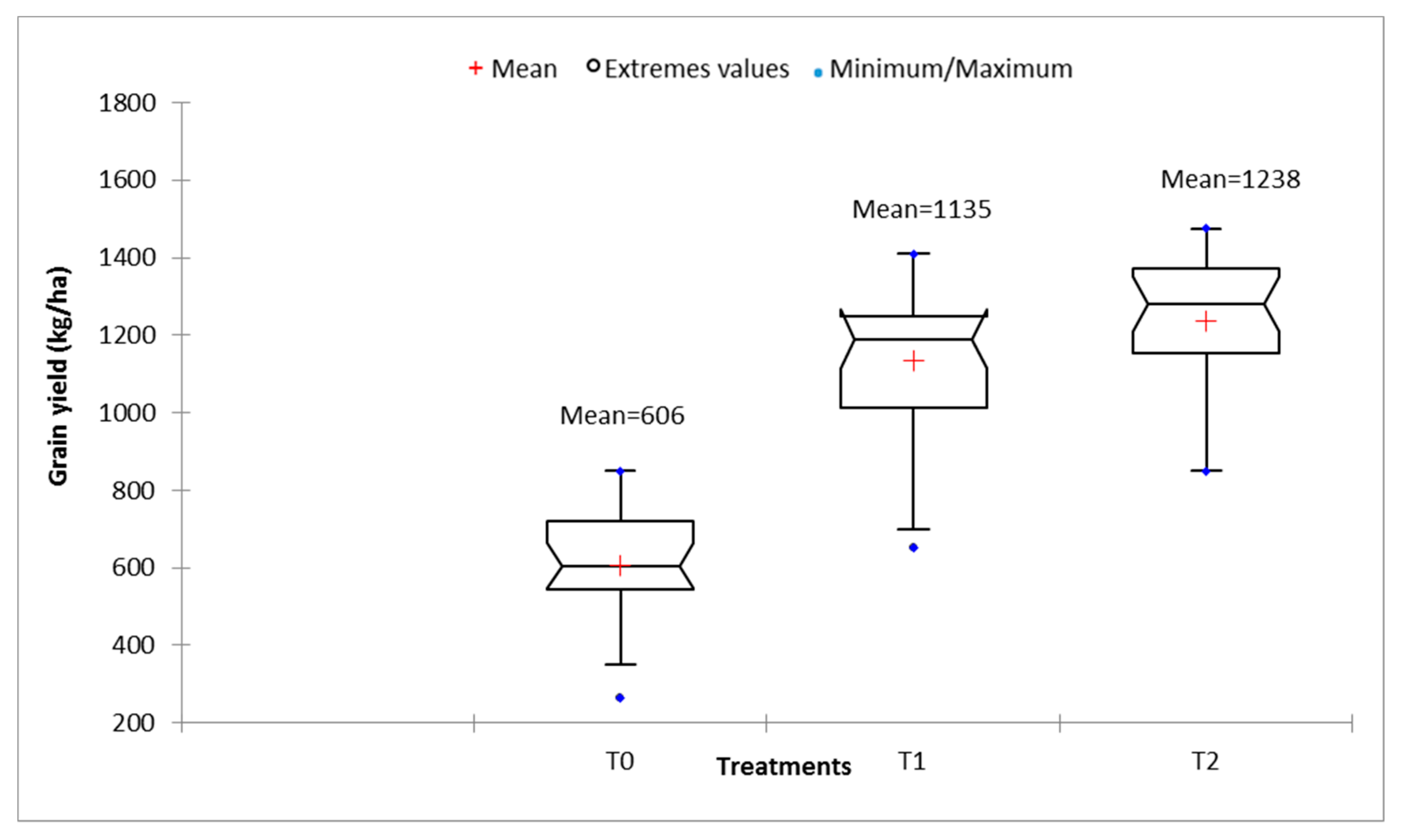

| Village | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Aguié | Arewa | Danja | Kandoussa | Karosofoua | Lossa | N’Dounga | Sabon Gida | Average | |

| T0 | 675 ± 85 | 727 ± 49 | 594 ± 49 | 693 ± 65 | 604 ± 138 | 388 ± 133 | 462 ± 106 | 703 ± 137 | 606 ± 145 |

| T1 | 1191 ± 118 | 1290 ± 87 | 1162 ± 127 | 1202 ± 44 | 1253 ± 138 | 808 ± 151 | 883 ± 161 | 1287 ± 64 | 1135 ± 202 |

| T2 | 1312 ± 65 | 1370 ± 95 | 1392 ± 78 | 1287 ± 81 | 1253 ± 119 | 933 ± 85 | 1043 ± 51 | 1310 ± 60 | 1238 ± 170 |

| Df. | Significance | ||||||||

| Treatment (T) | 2 | <0.001 | |||||||

| Villages (V) | 7 | <0.001 | |||||||

| T × V | 14 | 0.540 | |||||||

| CV% | 8.4 | ||||||||

| Treatments | T0 | T1 | T2 | T3 | T4 | T5 |

|---|---|---|---|---|---|---|

| Income | ||||||

| Grain | 143,000 | 223,600 | 248,600 | 270,600 | 280,200 | 306,000 |

| Stover | 15,039 | 18,835 | 21,427 | 23,878 | 25,609 | 28,454 |

| Total Income | 158,039 | 242,435 | 270,027 | 294,478 | 305,809 | 334,454 |

| Production Costs | ||||||

| Fixed costs per year | ||||||

| Depreciation costs | 0 | 10,800 | 10,800 | 10,800 | 10,800 | 10,800 |

| Interest costs | 0 | 7920 | 7920 | 7920 | 7920 | 7920 |

| Repair costs | 0 | 15,600 | 15,600 | 15,600 | 15,600 | 15,600 |

| Total fixed costs | 0 | 34,320 | 34,320 | 34,320 | 34,320 | 34,320 |

| Variable costs per hectare | ||||||

| Ox rental | ----- | 19,450 | 19,450 | 19,450 | 19,450 | 19,450 |

| Sowing | 5850 | 2850 | 2850 | 2850 | 2850 | 2850 |

| Seeds | 4800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Fungicide | ----- | 300 | 300 | 300 | 300 | 300 |

| Mineral fertilizer | ----- | 1200 | ------ | 1200 | ------ | 1200 |

| Compost | ----- | ------ | 17,500 | 17,500 | 35,000 | 35,000 |

| Thinning | 5000 | ------ | ------ | ------ | ------ | ------ |

| Weeding | 29,100 | 7100 | 7100 | 7100 | 7100 | 7100 |

| Harvesting | 5850 | 8700 | 9750 | 10,650 | 10,800 | 11,700 |

| Transporting harvest | 3900 | 5800 | 6500 | 7100 | 7200 | 7800 |

| Threshing cleaning | 7200 | 11,600 | 13,000 | 14,200 | 14,400 | 15,600 |

| Total variable costs | 61,700 | 57,600 | 77,050 | 80,950 | 97,700 | 101,600 |

| Total costs per hectare | 61,700 | 91,920 | 111,370 | 115,270 | 132,020 | 135,920 |

| Economic return | 96,339 | 150,515 | 158,657 | 179,208 | 173,789 | 198,534 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nourou, A.I.M.; Saidou, A.K.; Aune, J.B. Development and Use of a Planter for Simultaneous Application of Seed, Fertilizer and Compost in Pearl Millet Production in Niger—Effects on Labor Use, Yield and Economic Return. Agronomy 2020, 10, 1886. https://doi.org/10.3390/agronomy10121886

Nourou AIM, Saidou AK, Aune JB. Development and Use of a Planter for Simultaneous Application of Seed, Fertilizer and Compost in Pearl Millet Production in Niger—Effects on Labor Use, Yield and Economic Return. Agronomy. 2020; 10(12):1886. https://doi.org/10.3390/agronomy10121886

Chicago/Turabian StyleNourou, Abdourahamane Issa M., Addam Kiari Saidou, and Jens B. Aune. 2020. "Development and Use of a Planter for Simultaneous Application of Seed, Fertilizer and Compost in Pearl Millet Production in Niger—Effects on Labor Use, Yield and Economic Return" Agronomy 10, no. 12: 1886. https://doi.org/10.3390/agronomy10121886

APA StyleNourou, A. I. M., Saidou, A. K., & Aune, J. B. (2020). Development and Use of a Planter for Simultaneous Application of Seed, Fertilizer and Compost in Pearl Millet Production in Niger—Effects on Labor Use, Yield and Economic Return. Agronomy, 10(12), 1886. https://doi.org/10.3390/agronomy10121886