Interfacial Properties of Bamboo Fiber-Reinforced High-Density Polyethylene Composites by Different Methods for Adding Nano Calcium Carbonate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Nano CaCO3 Modification Process

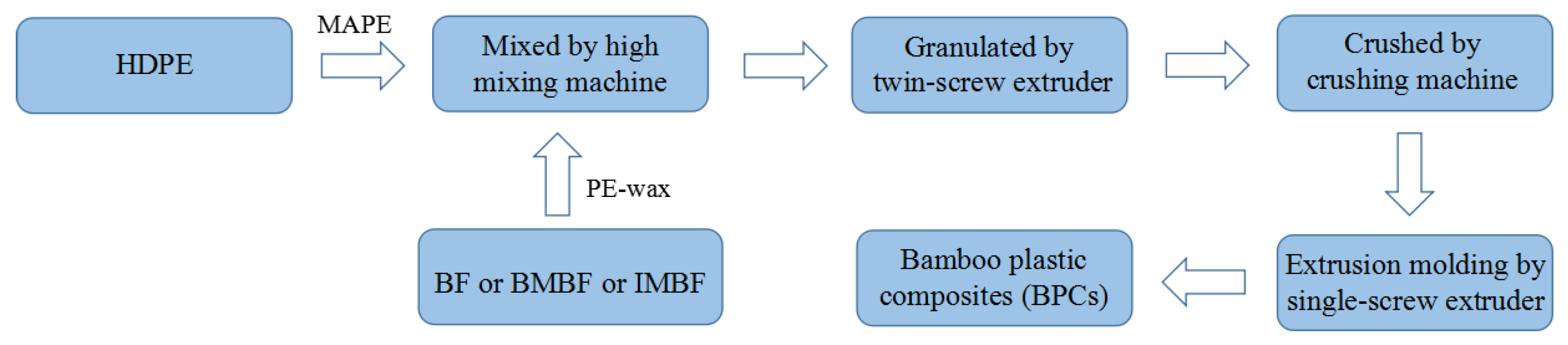

2.3. Composite Manufacture through Extrusion Molding Process

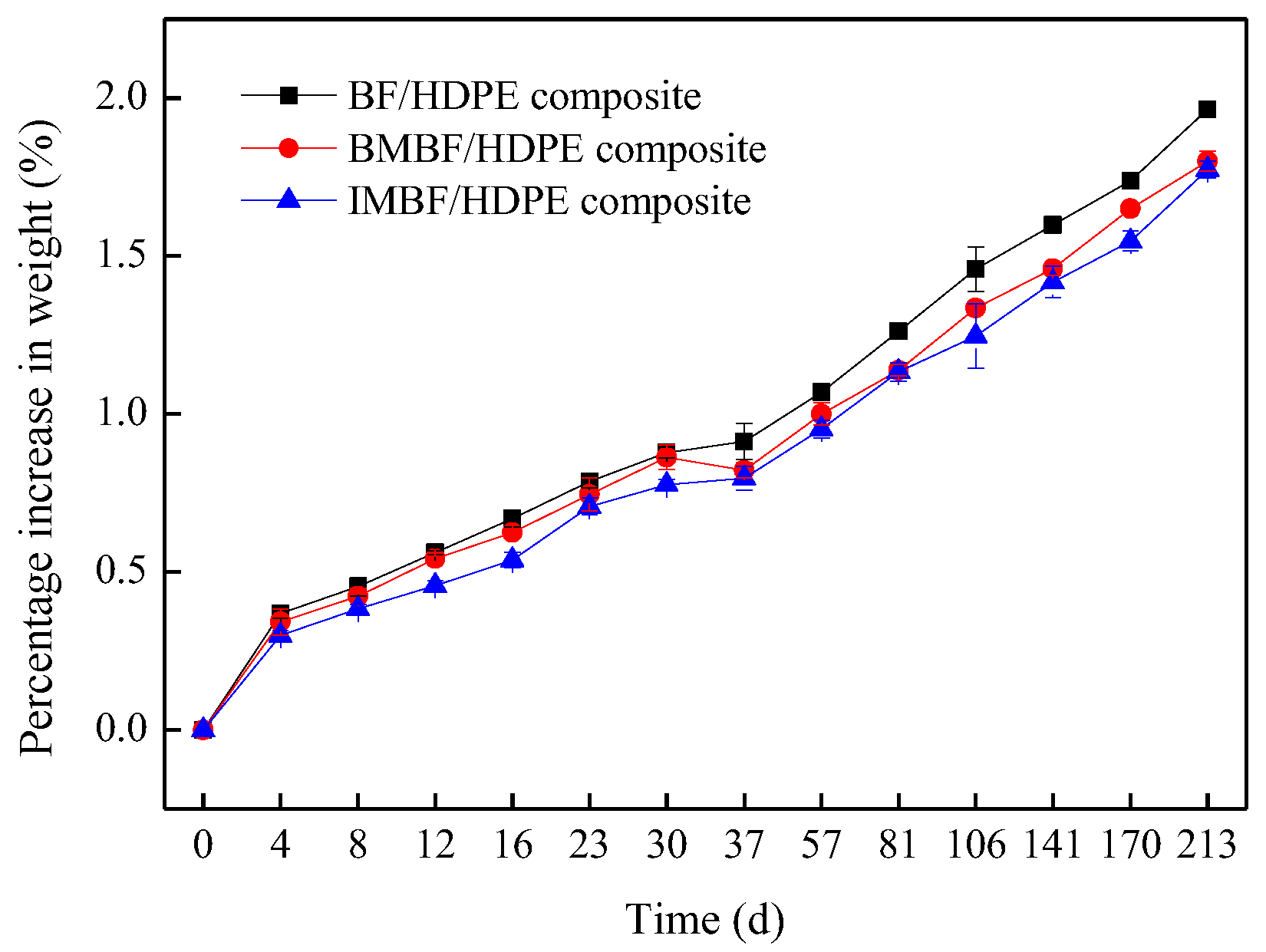

2.4. Water Absorption Tests

2.5. Contact Angle Tests

2.6. The Calculation of Surface Free Energy

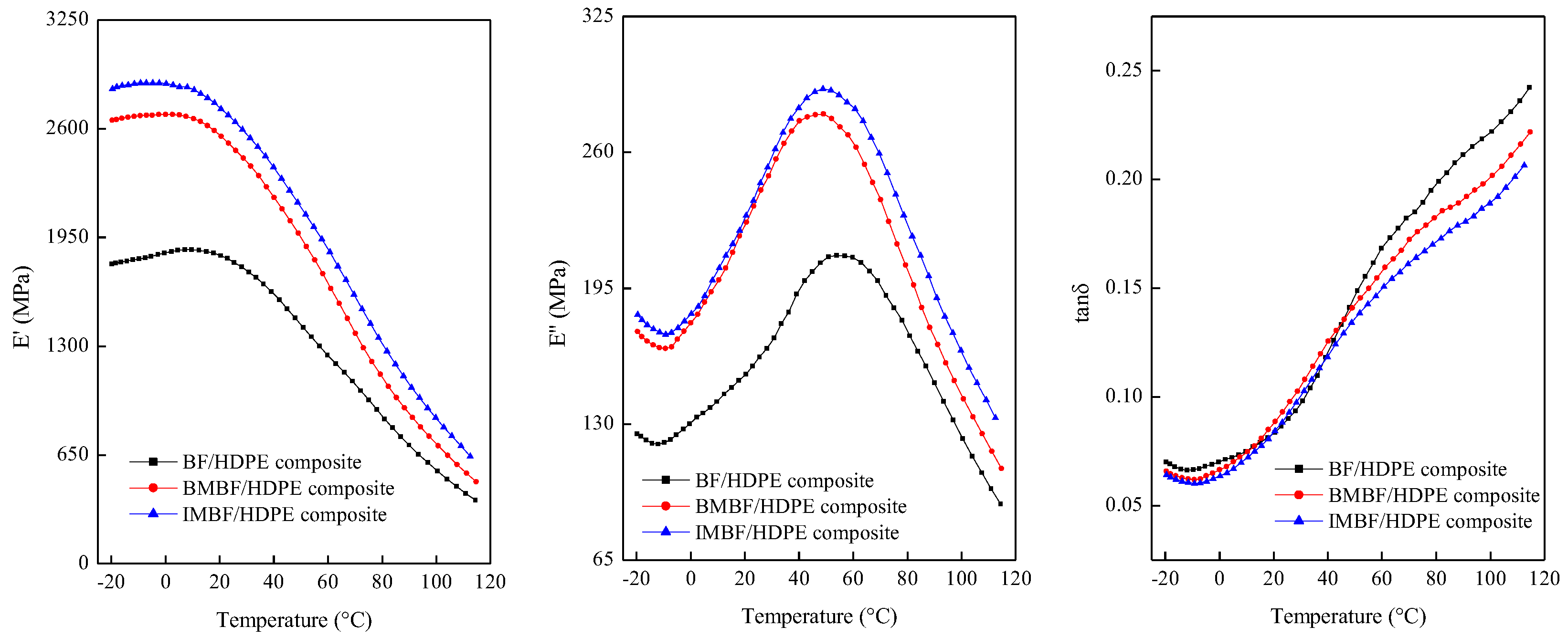

2.7. Dynamic Mechanical Property Tests

3. Results and Discussion

3.1. Water Resistance

3.2. Surface Free Energy of Composites

3.3. The Dynamic Thermo-Mechanical Properties (Single-Frequency)

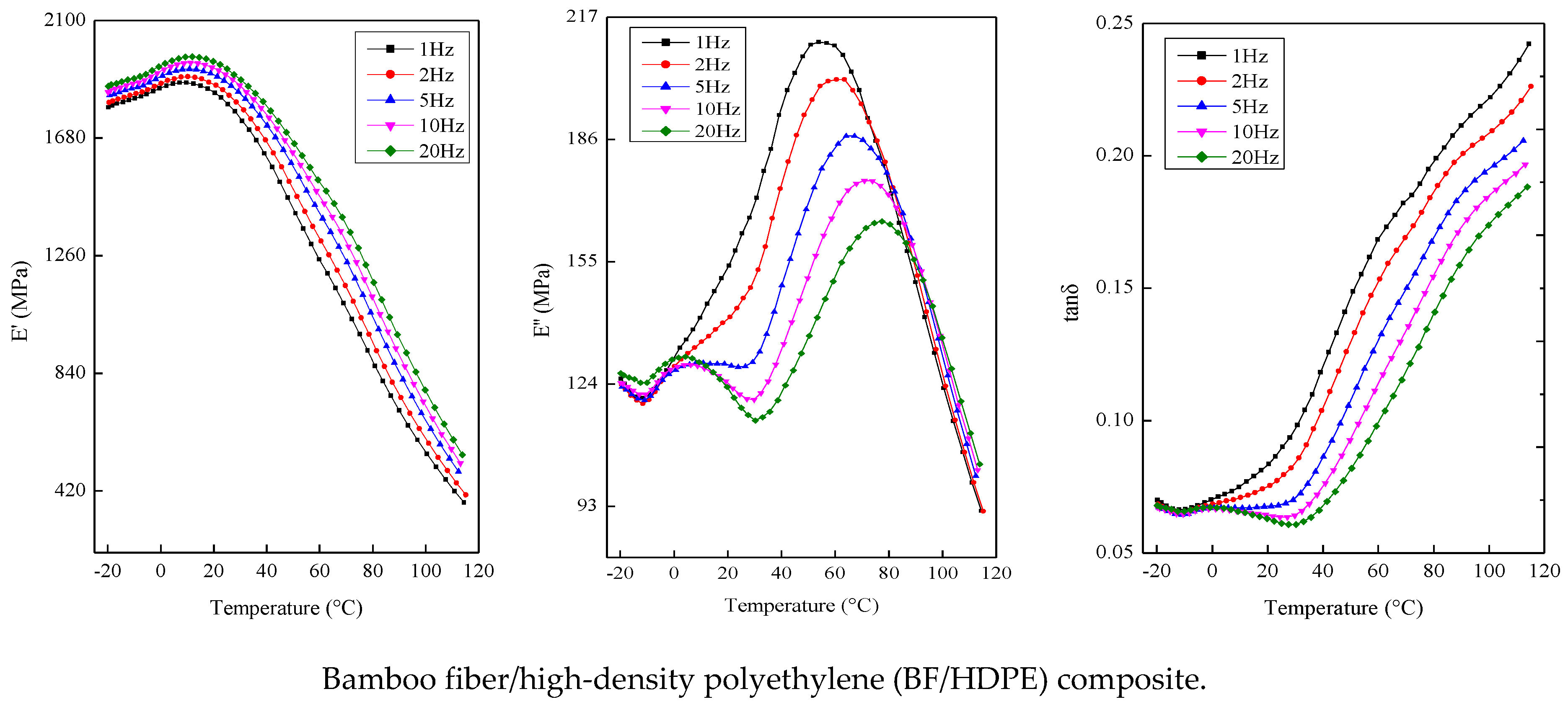

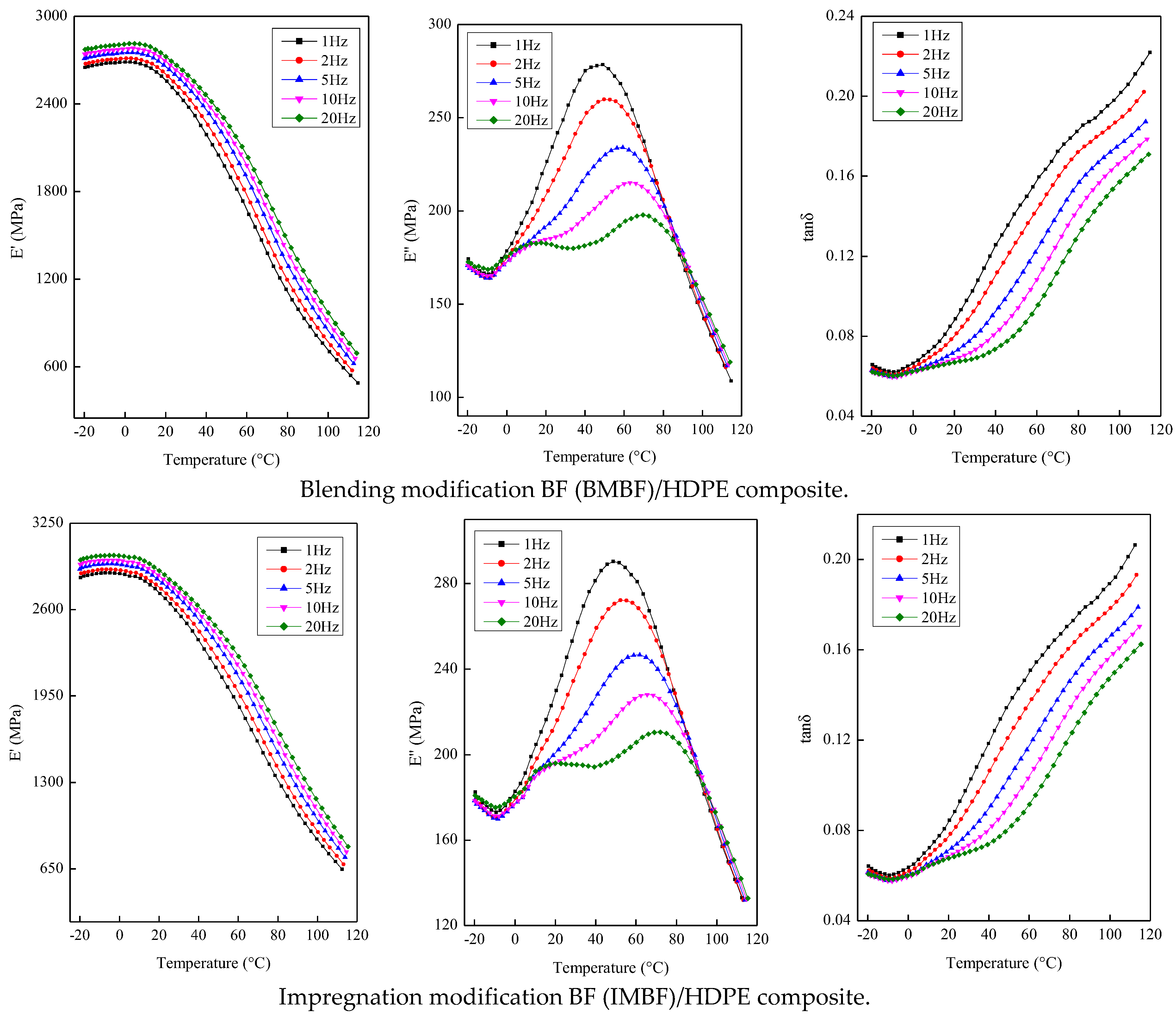

3.4. The Dynamic Thermo-Mechanical Properties (Multiple-Frequency)

3.4.1. The Effect on Storage Modulus E′ of Composite by the Test Frequency f

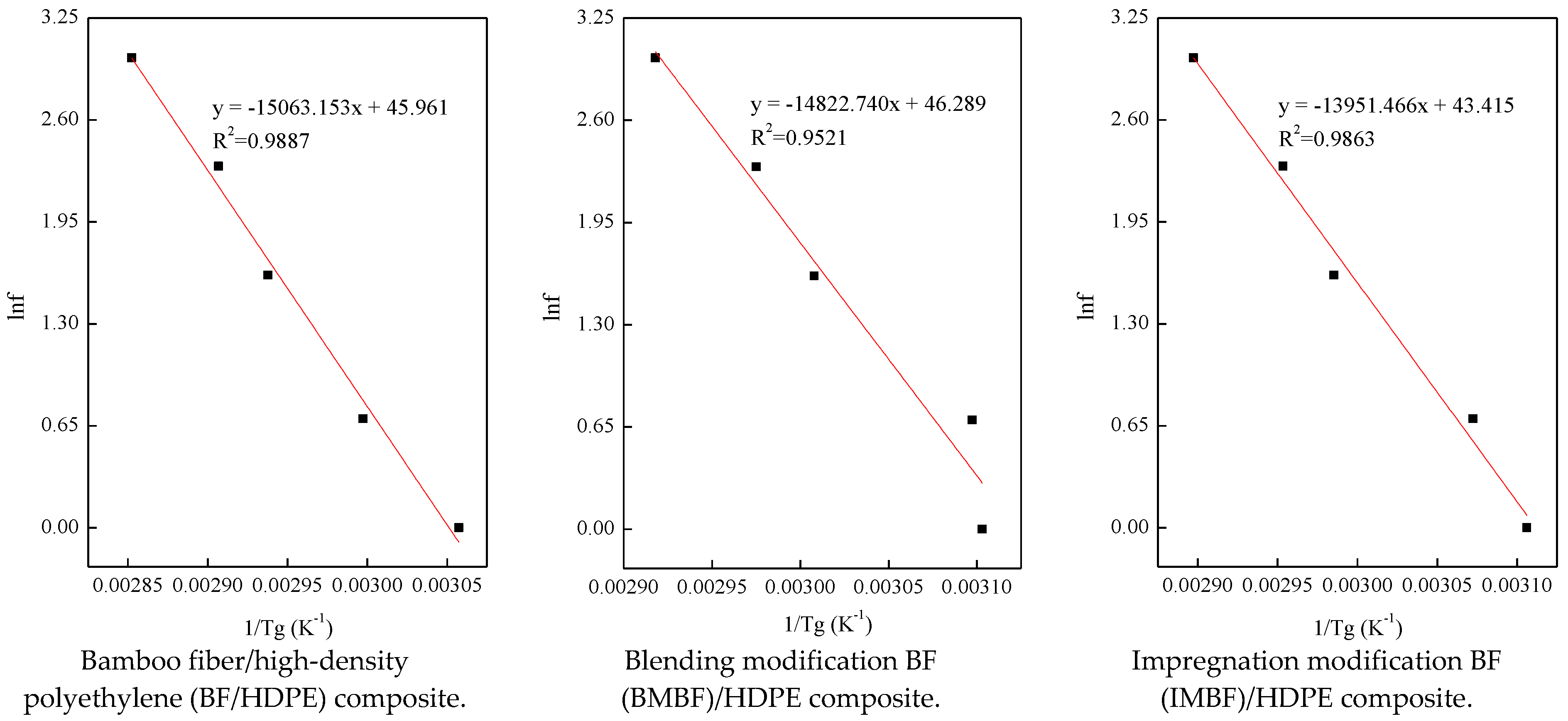

3.4.2. The Apparent Activation Energy

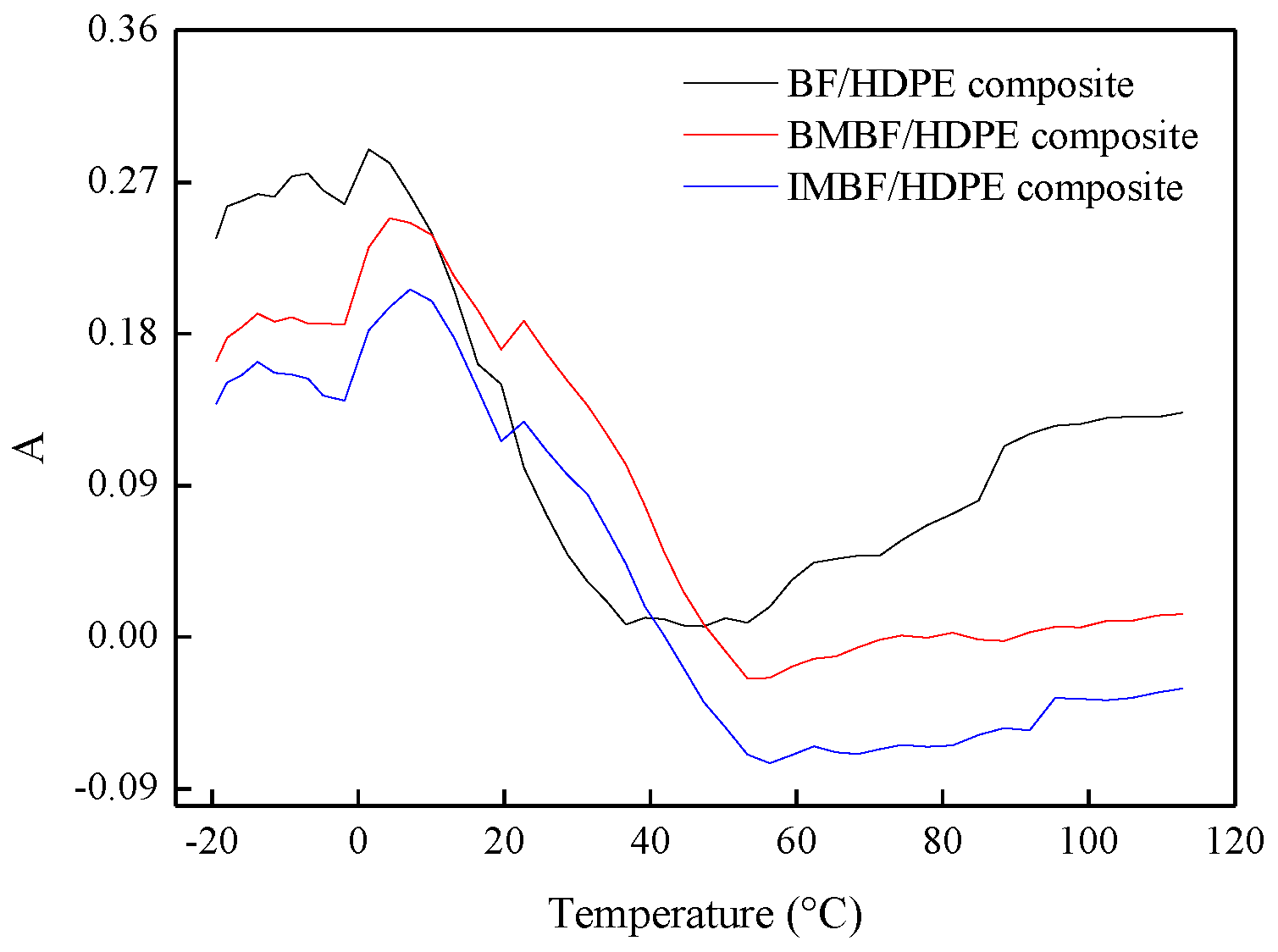

3.5. The Interfacial Properties of Composites

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ochi, S. Mechanical properties of uni-directional long bamboo fiber/bamboo powder composite materials. Mater. Sci. Appl. 2014, 5, 1011–1019. [Google Scholar] [CrossRef]

- Manalo, A.C.; Wani, E.; Zukarnain, N.A.; Karunasena, W.; Lau, K. Effects of alkali treatment and elevated temperature on the mechanical properties of bamboo fibre-polyester composites. Compos. Part B 2015, 80, 73–83. [Google Scholar] [CrossRef]

- Haameem, J.A.M.; Abdul Majid, M.S.; Afendi, M.; Marzuki, H.F.A.; Fahmi, I.; Gibson, A.G. Mechanical properties of Napier grass fibre/polyester composites. Compos. Struct. 2016, 136, 1–10. [Google Scholar] [CrossRef]

- Liu, W.D.; Xie, T.S.; Qiu, R.H. Bamboo fibers grafted with a soybean-oil-based monomer for its unsaturated polyester composites. Cellulose 2016. [Google Scholar] [CrossRef]

- Kushwaha, P.K.; Kumar, R. Studies on water absorption of bamboo-polyester composites: Effect of silane treatment of mercerized bamboo. Polym. Plast. Technol. Eng. 2009, 49, 45–52. [Google Scholar] [CrossRef]

- Kushwaha, P.K.; Kumar, R. Studies on performance of acrylonitrile pretreated bamboo reinforced thermosetting resin composites. J. Reinf. Plast. Compos. 2010, 29, 1347–1352. [Google Scholar] [CrossRef]

- Kushwaha, P.K.; Kumar, R. Influence of chemical treatments on the mechanical and water absorption properties of bamboo fiber composites. J. Reinf. Plast. Compos. 2011, 30, 73–85. [Google Scholar] [CrossRef]

- Kim, H.; Okubo, K.; Fujii, T.; Takemura, K. Influence of fiber extraction and surface modification on mechanical properties of green composites with bamboo fiber. J. Adhes. Sci. Technol. 2013, 27, 1348–1358. [Google Scholar] [CrossRef]

- Tran, D.T.; Nguyen, D.M.; HaThuc, C.N.; Dang, T.T. Effect of coupling agents on the properties of bamboo fiber-reinforced unsaturated polyester resin composites. Compos. Interface 2013, 20, 343–353. [Google Scholar] [CrossRef]

- Qiu, R.; Liu, W.; Li, K. Investigation of bamboo pulp fiber-reinforced unsaturated polyester composites. Holzforschung 2015, 69, 967–974. [Google Scholar] [CrossRef]

- Shi, J.; Shi, S.Q.; Barnes, H.M.; Horstemeyer, M.F.; Wang, G. Kenaf bast fibers. Part II: Inorganic nanoparticle impregnation for polymer composites. Int. J. Polym. Sci. 2011, 7, 736474. [Google Scholar] [CrossRef]

- Cheng, H.T.; Gao, J.; Wang, G.; Shi, S.Q.; Zhang, S.B.; Cai, L.P. Enhancement of mechanical properties of composites made of calcium carbonate modified bamboo fibers and polypropylene. Holzforschung 2015, 69, 215–221. [Google Scholar] [CrossRef]

- Cheng, H.T.; Gao, J.; Wang, G.; Shi, S.Q.; Zhang, S.B.; Cai, L.P. Effect of temperature on calcium carbonate deposition in situ on bamboo fiber and polymer interfaces. Wood Fiber Sci. 2014, 46, 247–258. [Google Scholar]

- Wang, C.C.; Xian, Y.; Cheng, H.T.; Li, W.Y.; Zhang, S.B. Tensile properties of bamboo fiber-reinforced polypropylene composites modified by impregnation with calcium carbonate nanoparticles. Bioresources 2015, 10, 6783–6796. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Li, N.N.; Li, G.L.; Wang, H.D.; Kang, J.J. Research progress of surface free energy’s computing methods and the influence on the properties of material surface. Mater. Rev. A. 2015, 29, 30–40. [Google Scholar]

- Xian, Y.; Wang, C.C.; Wang, G.; Ren, W.H.; Cheng, H.T. Understanding the mechanical and interfacial properties of core-shell structured bamboo-plastic composites. J. Appl. Polym. Sci. 2016, 133, 1–8. [Google Scholar] [CrossRef]

- Hong, C.K.; Kim, N.; Kang, S.L.; Nah, C.; Lee, Y.S.; Cho, B.H.; Ahn, J.H. Mechanical properties of maleic anhydride treated jute fibre/polypropylene composites. Plast. Rubber Compos. 2008, 37, 325–330. [Google Scholar] [CrossRef]

- Ibarra, L.; Panos, D. Dynamic properties of thermoplastic butadiene-Styrene (SBS) and oxidized short carbon fiber composite materials. J. Appl. Polym. Sci. 1998, 67, 1819–1826. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Yang, J.; Wang, Y.L.; Li, B.S.; Li, Y. Calculation and comparison on the surface free energy of methyl-modified silica films. Mater. Rev. B. 2013, 27, 134–146. [Google Scholar]

- Girifalco, L.A.; Good, R.J. A Theory for the estimation of surface and interfacial energies. I. Derivation and application to interfacial tension. J. Phys. Chem. 1957, 61, 904–909. [Google Scholar] [CrossRef]

- Park, S.J.; Jin, J.S. Effect of silane coupling agent on interphase and performance of glass fibers/ unsaturated polyester composites. J. Colloid Interface Sci. 2001, 242, 174–179. [Google Scholar] [CrossRef]

- Van oss, C.J.; Chaudhury, M.K.; Good, R.J. Interfacial Lifshitz-van der Waals and polar interaction in macroscopic system. Chem. Rev. 1988, 88, 927–941. [Google Scholar] [CrossRef]

- Van oss, C.J.; Good, R.J.; Chaudhury, M.K. Additive and nonaditive surface tension components and the interpretation of contact angles. Langmuir 1987, 4, 884–891. [Google Scholar] [CrossRef]

- Van oss, C.J. Use of the combined Lifshitz-van der Waals and Lewis acid-base approaches in determining the apolar and polar contributions to surface and interfacial tensions and free energies. J. Adhes. Sci. Technol. 2002, 16, 669–677. [Google Scholar] [CrossRef]

- Wang, H.; Gu, G.H.; Qiu, G.Z. Evaluation of surface free energy of polymers by contact angle goniometry. J. Cent. South Univ. (Sci. Technol.) 2006, 37, 942–947. [Google Scholar]

- Hu, Z.; Zen, X.; Gong, J.; Deng, Y. Water resistance improvement of paper by super hydrophobic modification with microsized CaCO3 and fatty acid coating. Colloids Surf. A. Physicochem. Eng. Asp. 2009, 351, 65–70. [Google Scholar] [CrossRef]

- Ren, W.H.; Zhang, D.; Wang, G.; Cheng, H.T. Mechanical and thermal properties of bamboo pulp fiber reinforced polyethylene composites. BioResources 2014, 9, 4117–4127. [Google Scholar] [CrossRef]

- Guo, M.L. Dynamic Mechanical Thermal Analysis of Polymer and Composite; Chemical Industry Press: Beijing, China, 2002; pp. 21–75. [Google Scholar]

- Wang, C.C.; Wang, S.; Cheng, H.T.; Xian, Y.; Zhang, S.B. Mechanical properties and prediction for nano calcium carbonate-treated bamboo fiber/high-density polyethylene composites. J. Mater. Sci. 2017, 52, 11482–11495. [Google Scholar] [CrossRef]

- Chen, Y.L.; Lin, C.Y.; Wu, T.L.; Chung, M.J.; Chen, T.Y.; Yang, T.H. Evaluation and application of the invasive weed Mikania micrantha as an alternative reinforcement in recycled high density polyethylene. Bioresources 2012, 7, 2403–2417. [Google Scholar] [CrossRef]

- Chen, X.H.; Li, W.Q.; Sheng, J. Estimation of dynamic mechanical properties of polymer binary system. Polym. Bull. 2008, 10–15. [Google Scholar]

- Ziegel, K.D.; Romanov, A. Modulus reinforcement in elastomer composites. I. inorganic fillers. J. Appl. Polym. Sci. 1973, 17, 1119–1131. [Google Scholar] [CrossRef]

- Ziegel, K.D.; Romanov, A. Modulus reinforcement in elastomer composites. II. Polymeric fillers. J. Appl. Polym. Sci. 1973, 17, 1133–1142. [Google Scholar] [CrossRef]

- Lagakos, N.; Jarzynski, J.; Cole, J.H.; Bucaro, J.A. Frequency and temperature dependence of elastic moduli of polymers. J. Appl. Phys. 1986, 59, 4017–4031. [Google Scholar] [CrossRef]

- Lv, M.F.; Zhang, S.J.; Yu, D.S. Effect of POE-g-GMA on active energy of glass transition temperature of PP/APP composite. China Plast. Ind. 2007, 35, 269–271. [Google Scholar]

- Kubát, J.; Rigdahl, M.; Welander, M. Characterization of interfacial interactions in high density polyethylene filled with glass spheres using dynamic-mechanical analysis. J. Appl. Polym. Sci. 1990, 39, 1527–1539. [Google Scholar] [CrossRef]

| Types of liquid | |||||||

|---|---|---|---|---|---|---|---|

| Deionized water | 72.80 | 21.80 | 51.00 | 21.80 | 51.00 | 25.50 | 25.50 |

| Diiodomethane | 50.80 | 50.80 | 0.00 | 50.80 | 0.00 | 0.00 | 0.00 |

| Formamide | 58.00 | 39.00 | 19.00 | 39.00 | 19.00 | 2.28 | 39.60 |

| Glycerol | 64.00 | 34.00 | 30.00 | 34.00 | 30.00 | 3.90 | 57.40 |

| Sample | Deionized Water | Diiodomethane | Formamide | Glycerol |

|---|---|---|---|---|

| Nano CaCO3 | 12.1 (1.70) | 24.1 (0.26) | 12.6 (1.86) | — |

| BF/HDPE composite | 81.53 (1.34) | 39.53 (0.55) | 67.60 (0.52) | 80.23 (2.84) |

| BMBF/HDPE composite | 80.06 (2.15) | 39.50 (3.58) | 68.85 (3.89) | 83.60 (1.42) |

| IMBF/HDPE composite | 81.03 (0.95) | 37.85 (3.75) | 70.30 (2.84) | 59.95 (2.59) |

| Sample | (mJ/m2) | ||||

|---|---|---|---|---|---|

| BF/HDPE composite | 43.75 | 39.84 | 3.91 | 0.41 | 9.43 |

| BMBF/HDPE composite | 45.48 | 39.86 | 5.62 | 0.67 | 11.79 |

| IMBF/HDPE composite | 47.45 | 40.67 | 6.77 | 0.98 | 11.72 |

| Sample | (mJ/m2) | ||

|---|---|---|---|

| BF/HDPE composite | 42.80 | 39.84 | 2.96 |

| BMBF/HDPE composites | 43.28 | 39.86 | 3.42 |

| IMBF/HDPE composites | 43.63 | 40.67 | 2.96 |

| Sample | Tg (°C) | tanδ | B |

|---|---|---|---|

| BF/HDPE composite | 53.93 | 0.1553 | 0.2138 |

| BMBF/HDPE composite | 49.11 | 0.1410 | 0.9348 |

| IMBF/HDPE composite | 48.78 | 0.1343 | 1.1020 |

| Sample | k | ||

|---|---|---|---|

| −20 °C | 45 °C | 110 °C | |

| BF/HDPE composite | 57.658 | 173.348 | 149.704 |

| BMBF/HDPE composite | 94.708 | 231.033 | 160.773 |

| IMBF/HDPE composite | 102.404 | 243.562 | 189.129 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Yu, X.; Smith, L.M.; Wang, G.; Cheng, H.; Zhang, S. Interfacial Properties of Bamboo Fiber-Reinforced High-Density Polyethylene Composites by Different Methods for Adding Nano Calcium Carbonate. Polymers 2017, 9, 587. https://doi.org/10.3390/polym9110587

Wang C, Yu X, Smith LM, Wang G, Cheng H, Zhang S. Interfacial Properties of Bamboo Fiber-Reinforced High-Density Polyethylene Composites by Different Methods for Adding Nano Calcium Carbonate. Polymers. 2017; 9(11):587. https://doi.org/10.3390/polym9110587

Chicago/Turabian StyleWang, Cuicui, Xian Yu, Lee M. Smith, Ge Wang, Haitao Cheng, and Shuangbao Zhang. 2017. "Interfacial Properties of Bamboo Fiber-Reinforced High-Density Polyethylene Composites by Different Methods for Adding Nano Calcium Carbonate" Polymers 9, no. 11: 587. https://doi.org/10.3390/polym9110587

APA StyleWang, C., Yu, X., Smith, L. M., Wang, G., Cheng, H., & Zhang, S. (2017). Interfacial Properties of Bamboo Fiber-Reinforced High-Density Polyethylene Composites by Different Methods for Adding Nano Calcium Carbonate. Polymers, 9(11), 587. https://doi.org/10.3390/polym9110587