The Influence of Biochemical Modification on the Properties of Adhesive Compounds

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characteristics of Basic Adhesives

2.1.1. Epoxy Resin

2.1.2. Curing Agent

2.2. Characteristics of Biochemically Modified Adhesive

2.3. Shape and Dimensions of the Cured Adhesive Specimens

2.4. Preparation of the Cured Adhesive

2.5. Strength Tests

2.6. Microscopic Examination

3. Results

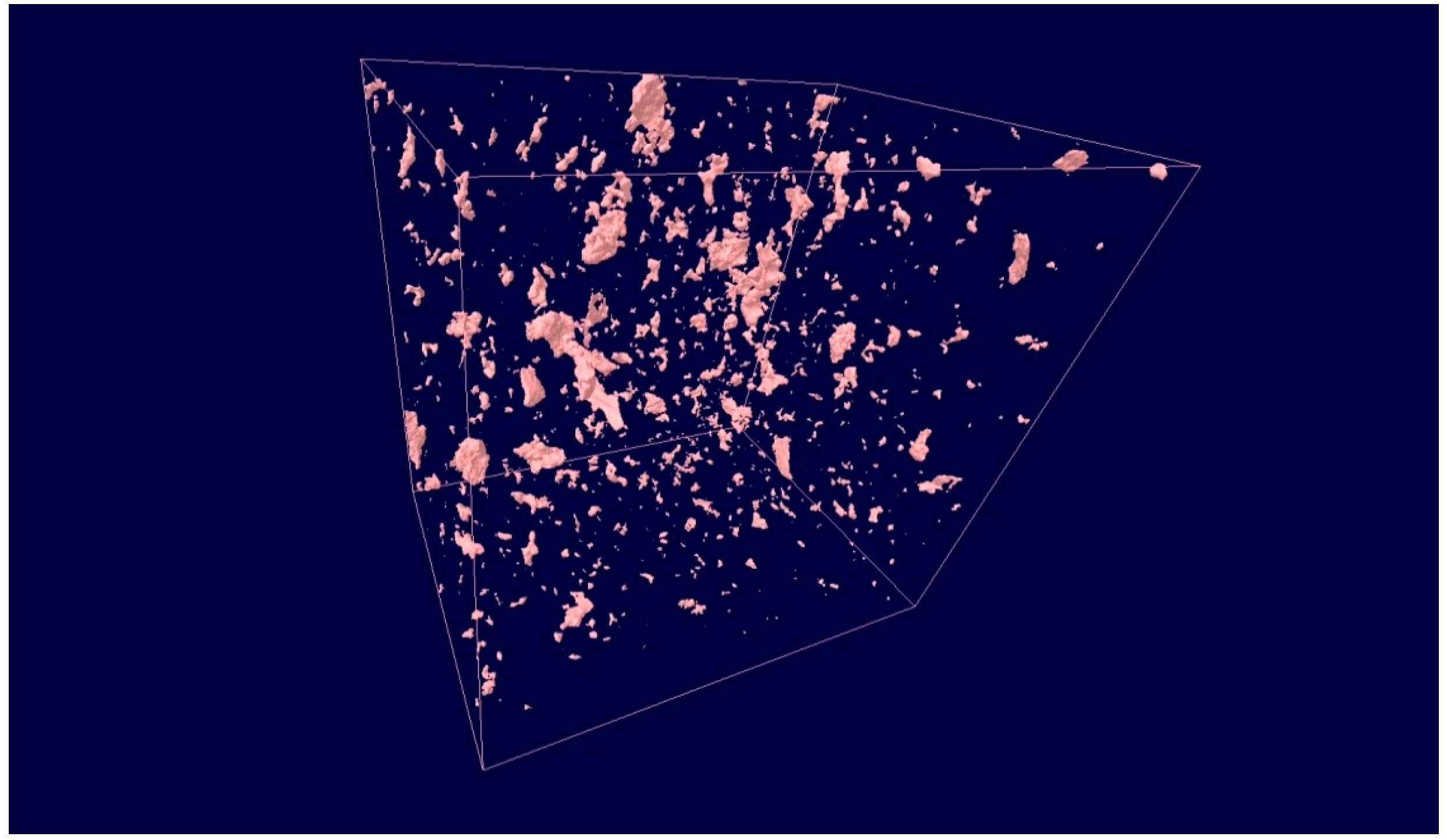

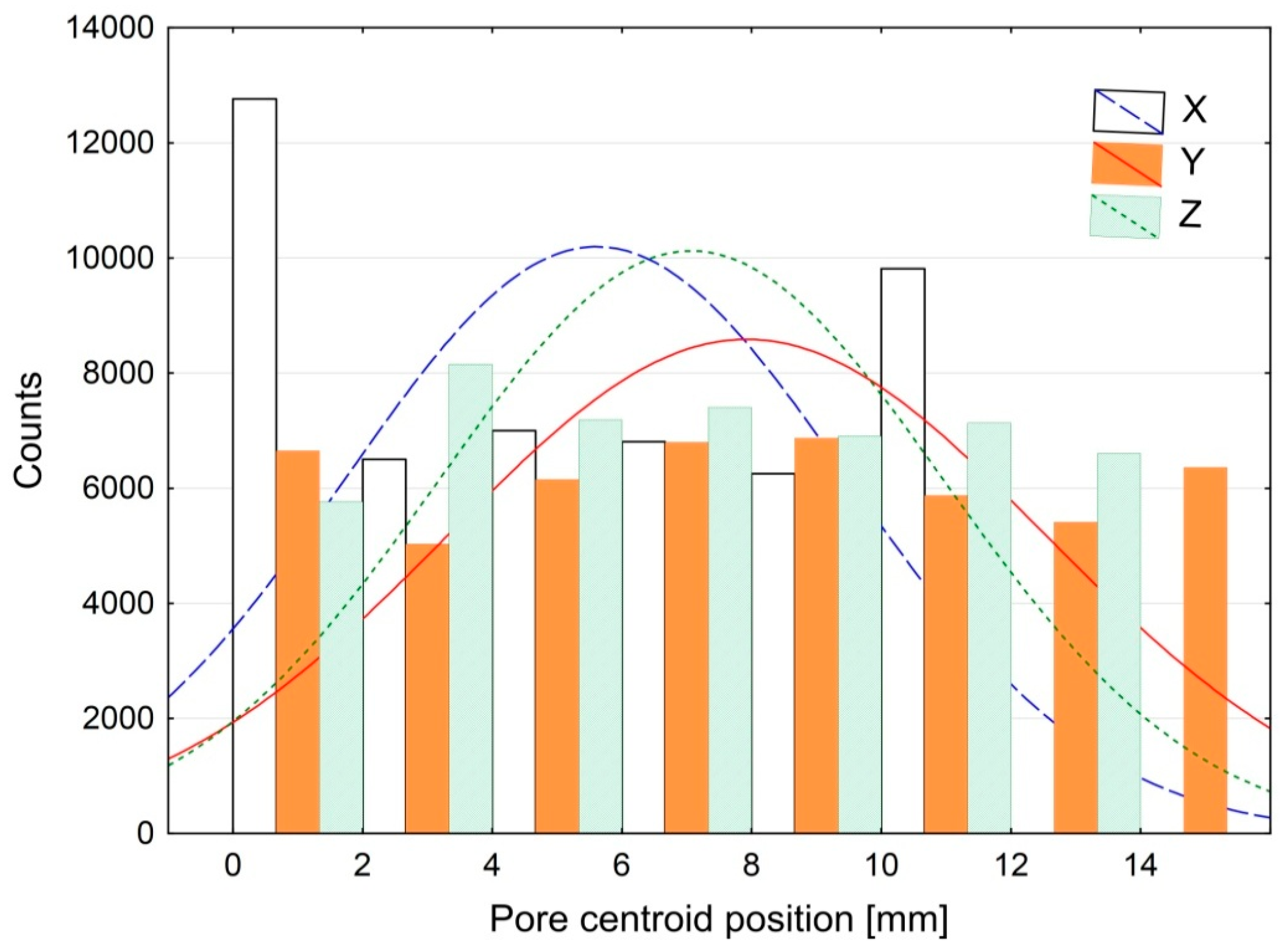

3.1. CT Examination of the Structure of the Modified Adhesive

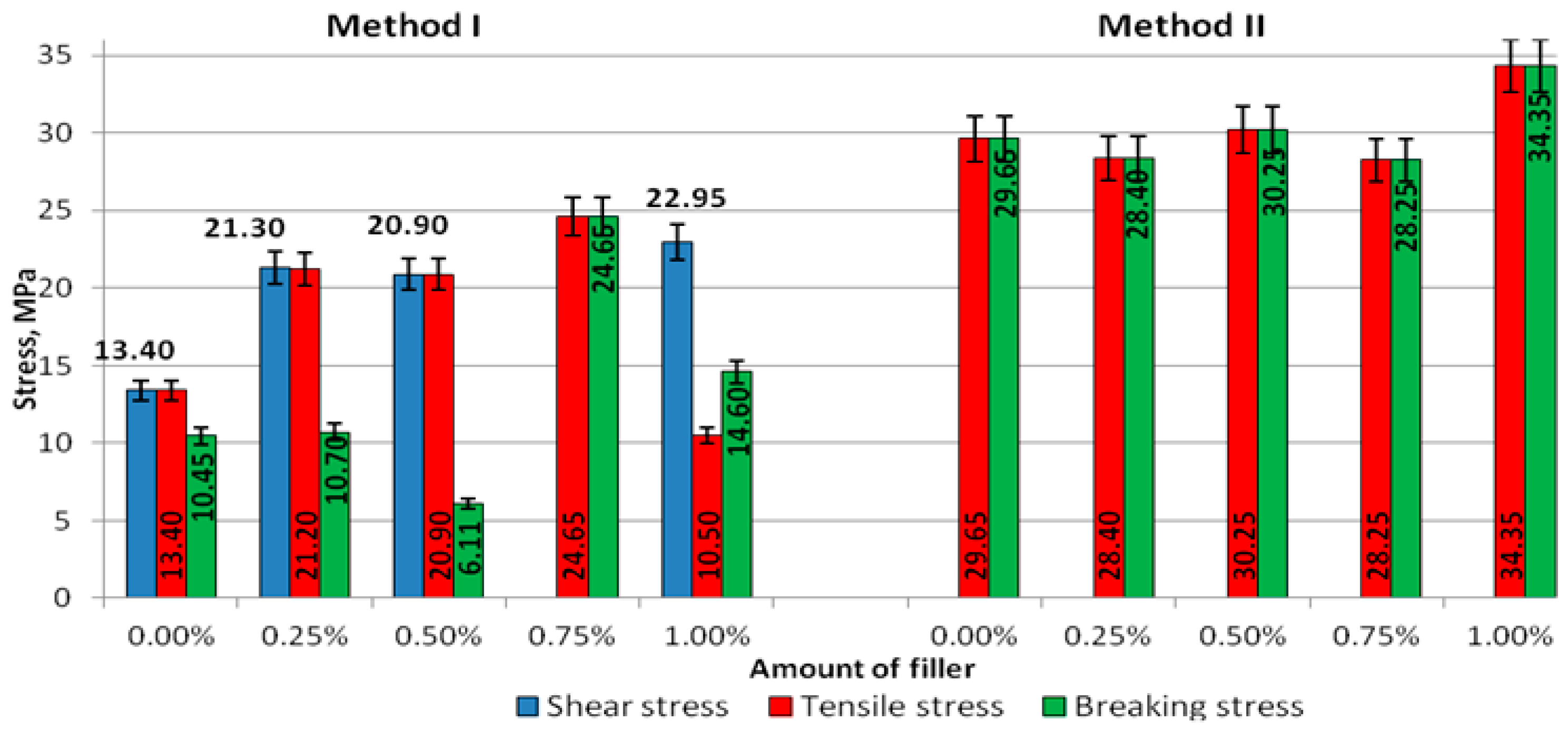

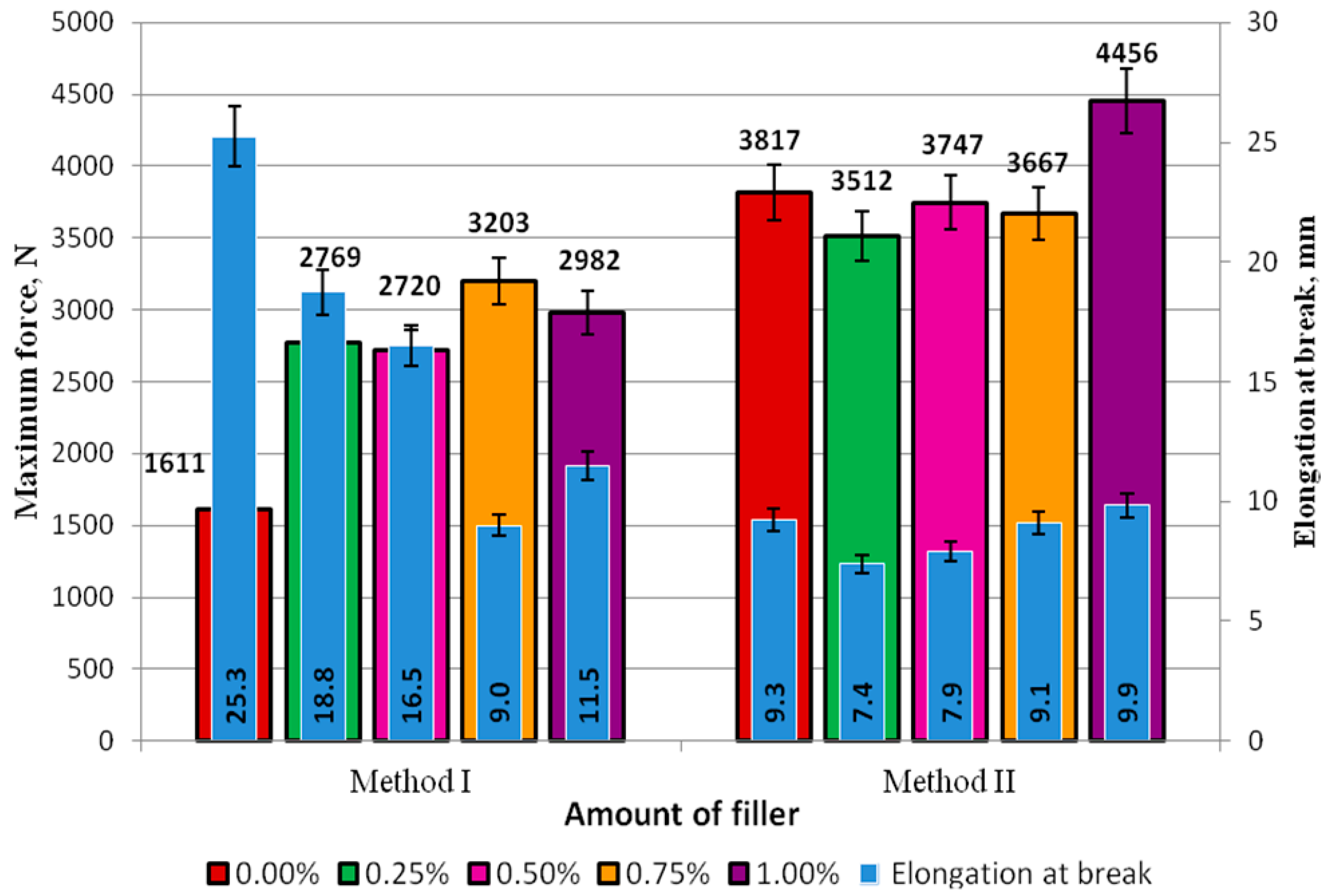

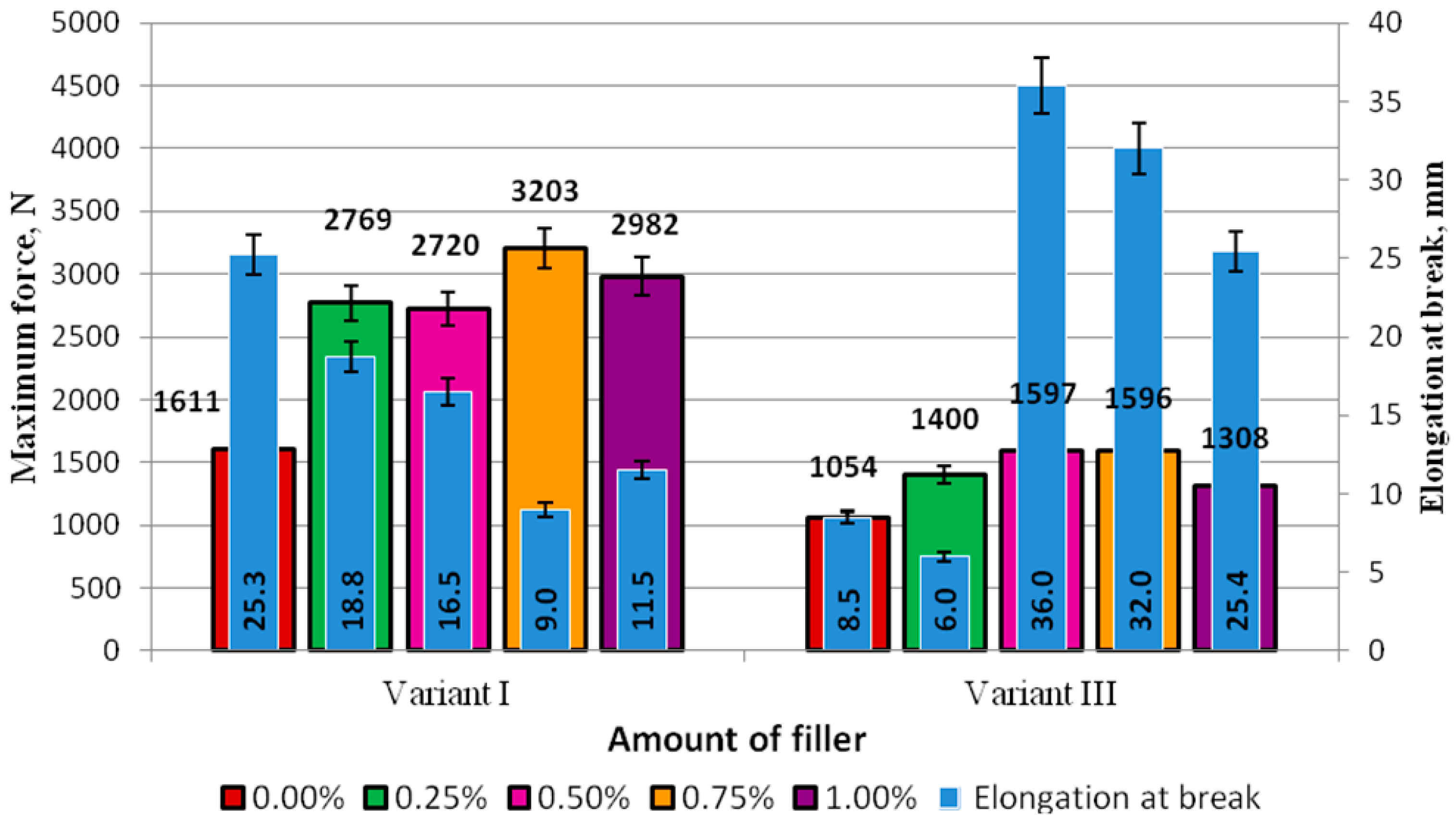

3.2. Strength Test Results—Analysis of the Effect of the Adhesive Compound Preparation Methods on the Mechanical Properties of the Adhesive

3.3. Strength Test Results—The Effect of Seasoning of the Adhesive Compounds on the Mechanical Properties of the Adhesive

3.4. Microscopic Results

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Czaderski, C.; Martinelli, E.; Michels, J.; Motavalli, M. Effect of curing conditions on strength development in an epoxy resin for structural strengthening. Compos. Part B 2012, 43, 398–410. [Google Scholar] [CrossRef]

- Lapique, F.; Redford, K. Curing effects on viscosity and mechanical properties of a commercial epoxy resin adhesive. Int. J. Adhes. Adhes. 2002, 22, 337–346. [Google Scholar] [CrossRef]

- Brockmann, H.; Haufe, M.; Schulenburg, J.O. Mechanism of the curing reaction of model epoxy compounds with monuron. Int. J. Adhes. Adhes. 2000, 20, 333–340. [Google Scholar] [CrossRef]

- Mimura, K.; Ito, H. Characteristics of epoxy resin cured with in situ polymerized curing agent. Polymers 2002, 43, 7559–7566. [Google Scholar] [CrossRef]

- Adams, R.D. Adhesive Bonding Science, Technology and Applications, 1st ed.; Woodhead Publishing: Cambridge, UK, 2010; pp. 221–222. [Google Scholar]

- Morancho, J.M.; Cadenato, A.; Ramis, X.; Fernández-Francos, X.; Salla, J.M. Thermal curing and photocuring of an epoxy resin modified with a hyperbranched polymer. Thermochim. Acta 2010, 510, 1–8. [Google Scholar] [CrossRef]

- Prolongo, S.G.; del Rosario, G.; Ureña, A. Comparative study on the adhesive properties of different epoxy resins. Int. J. Adhes. Adhes. 2006, 26, 125–132. [Google Scholar] [CrossRef]

- Ferreira, I.C.F.R.; Vaz, J.A.; Vasconcelos, M.H.; Martins, A. Compounds from wild mushrooms with antitumor potential. Anti-Cancer Agents Med. Chem. 2010, 10, 424–436. [Google Scholar] [CrossRef]

- Pizzi, A. From Reinvigorating Tannin Adhesives to Wood Welding. In Proceedings of the International Conference of Wood Adhesives, Toronto, ON, Canada, 9–11 October 2013.

- Grigsby, W.; Thumm, A. Visualising the Wood Fibre-Adhesive Interface: Implications for Adhesive Behaviour, Performance and Design. In Proceedings of the International Conference of Wood Adhesives, Toronto, ON, Canada, 9–11 October 2013.

- Pizzi, A. Recent developments in eco-efficient bio-based adhesives for wood bonding: Opportunities and issues. J. Adhes. Sci. Technol. 2006, 20, 829–846. [Google Scholar] [CrossRef]

- Rudawska, A.; Czarnota, M. Selected aspects of epoxy adhesive compositions curing process. J. Adhes. Sci. Technol. 2013, 27, 1933–1950. [Google Scholar] [CrossRef]

- Yoon, I.-N.; Lee, Y.; Kang, D.; Min, J.; Won, J.; Kim, M.; Kang, Y.S.; Kim, S.-H.; Kim, J.-J. Modification of hydrogenated Bisphenol A epoxy adhesives using nanomaterials. Int. J. Adhes. Adhes. 2011, 31, 119–125. [Google Scholar] [CrossRef]

- Guan, Y.; Chen, X.; Li, F.; Gao, H. Study on the curing process and shearing tests of die attachment by Ag-epoxy electrically conductive adhesive. Int. J. Adhes. Adhes. 2010, 30, 80–88. [Google Scholar] [CrossRef]

- Gladkikh, S.; Kolobova, V.; Kuznetsova, L. Fast-curing adhesive compositions based on modified epoxy resins. Polym. Sci. Ser. C 2007, 49, 193–194. [Google Scholar] [CrossRef]

- Zhang, Y.; Lee, S.; Yoonessi, M.; Liang, K.; Pittman, C.U. The toughening effect and mechanism of styrene-butadiene rubber nanoparticles for novolac resin. Polymer 2006, 47, 2984–2996. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Fan, M. Lignin in straw and its applications as an adhesive. Int. J. Ahes. Adhes. 2014, 48, 92–101. [Google Scholar] [CrossRef]

- El Mansouri, N.-E.; Pizzi, A.; Salvado, J. Lignin-based polycondensation resin for wood adhesives. J. Appl. Polym. Sci. 2007, 103, 1690–1699. [Google Scholar] [CrossRef]

- Leonowicz, A.; Grzywnowicz, K. Quantitative estimation of laccase forms in some white-rot fungi using syringaldazine as a substrate. Enzym. Microb. Technol. 1981, 3, 55–58. [Google Scholar] [CrossRef]

- El Mansouri, N.-E.; Pizzi, A.; Salvado, J. Lignin-based wood panel adhesives without formaldehyde. Holz. Roh. Werkst. 2007, 65, 65–70. [Google Scholar] [CrossRef]

- Amiri, A.; Cholodowski, D.; Bompeix, G. Adhesion and germination of waterbone and airbone conidia of Pencillium expansum to apple and inert surfaces. Physiol. Mol. Plant Pathol. 2005, 67, 40–48. [Google Scholar] [CrossRef]

- Yang, D.-Q.; Zhang, Y.; Wang, X.-M.; Feng, M. Fungal Modifications of Chitosan Adhesives for Manufacturing Wood Composites. In Proceedings of the International Conference of Wood Adhesives, Toronto, ON, Canada, 9–11 October 2013.

- Ibrahim, V.; Mamo, G.; Gustafsson, P.-J.; Hatti-Kaul, R. Production and properties of adhesive formulated from laccase modified Kraft lignin. Ind. Crop. Prod. 2013, 45, 343–348. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, D.-Q.; Wang, X.-M.; Feng, M.; He, G. Fungus-Modified Lignin Sands Its Use in Wood Adhesives for Wood Composites. In Proceedings of the International Conference of Wood Adhesives, Toronto, ON, Canada, 9–11 October 2013.

- Nimz, H. Lignin-Based Wood Adhesives. In Wood Adhesive: Chemistry and Technology; Pizzi, A., Ed.; Marcel Dekker: New York, NY, USA, 1983; pp. 247–288. [Google Scholar]

- Nieh, W.; Glasser, W.G. Lignin Derivatives with Epoxy Functionality. In Lignin: Properties and Materials; Glasser, W., Sarkanen, S., Eds.; ASC: Washington, DC, USA, 1989; pp. 506–514. [Google Scholar]

- Hofmann, K.; Glasser, W. Engineering plastics from lignin, 22. Cure of lignin-based epoxy resins. J. Adhes. 1993, 40, 229–241. [Google Scholar] [CrossRef]

- Hofmann, K.; Glasser, W. Engineering plastics from lignin, 23. Network formation of lignin-based epoxy resins. Macromol. Chem. Phys. 1994, 195, 65–80. [Google Scholar] [CrossRef]

- Widsten, P.; Kandelbauer, A. Laccase applications in the forest products industry: A review. Enzym. Microb. Technol. 2008, 42, 293–307. [Google Scholar] [CrossRef]

- Peng, W.; Riedl, B. The chemorheology of phenol-formaldehyde thermoset resin and mixtures of the resin with lignin fillers. Polymer 1994, 35, 1280–1286. [Google Scholar] [CrossRef]

- Aracri, E.; Diaz Blanco, C.; Tzanov, T. An enzymatic approach to develop a lignin-based adhesive for wool floor coverings. Green Chem. 2014, 16, 2597–2603. [Google Scholar] [CrossRef]

- Wesenberg, D.; Kyriakides, I.; Agathos, S.N. White-rot fungi and their enzymes for the treatment of industrial dye effluents. See comment in PubMed Commons below. Biotechnol. Adv. 2003, 22, 161–187. [Google Scholar] [CrossRef] [PubMed]

- Bürgers, R.; Hahnel, S.; Reichert, T.E.; Rosentritt, M.; Behr, M.; Gerlach, T.; Handel, G.; Gosau, M. Adhesion of Candida albicans to various dental implant surfaces and the influence of salivary pellicle proteins. Acta Biomater. 2010, 6, 2307–2313. [Google Scholar] [CrossRef] [PubMed]

- Jaszek, M.; Osińska-Jaroszuk, M.; Janusz, G.; Matuszewska, A.; Stefaniuk, D.; Sulej, J.; Polak, J.; Ruminowicz, M.; Grzywnowicz, K.; Jarosz-Wilkolazka, A. New bioactive fungal molecules with high antioxidant and antimicrobial capacity isolated from Cerrena unicolor idiophasic cultures. BioMed Res. Int. 2013, 2013, 497492. [Google Scholar] [CrossRef] [PubMed]

- Jaszek, M.; Kos, K.; Matuszewska, A.; Grąz, M.; Stefaniuk, D.; Osińska-Jaroszuk, M.; Prendecka, M.; Jóźwik, E.; Grzywnowicz, K. Effective stimulation of the biotechnological potential of the medicinal white rot fungus: Phellinus pini by menadione-mediated oxidative stress. Appl. Biochem. Biotechnol. 2014, 174, 644–656. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.A.; Ashraft, S.M.; Malhorta, V.P. Development and characterization of wood adhesive using bagasse lignin. Int. J. Adhes. Adhes. 2004, 24, 485–493. [Google Scholar] [CrossRef]

- Li, M.; Zhang, G.; Wang, H.; Ng, T. Purification and characterization of a laccase from the edible wild mushroom Tricholoma mongolicum. J. Microbiol. Biotechnol. 2010, 20, 1069–1076. [Google Scholar] [PubMed]

- Xu, X.; Yan, H.; Chen, J.; Zhang, X. Bioactive proteins from mushrooms. Biotechnol. Adv. 2011, 29, 667–674. [Google Scholar] [CrossRef] [PubMed]

- Vázquez, G.; González, J.; Freire, S.; Antorrena, G. Effect of chemical modification of lignin on the gluebond performance of lignin-phenolic resins. Bioresour. Technol. 1997, 60, 191–198. [Google Scholar] [CrossRef]

- Jin, Y.; Cheng, X.; Zheng, Z. Preparation and characterization of phenol-formaldehyde adhesives modified with enzymatic hydrolysis lignin. Bioresour. Technol. 2010, 101, 2046–2048. [Google Scholar] [CrossRef] [PubMed]

- Jaszek, M.; Osińska-Jaroszuk, M.; Sulej, J.; Matuszewska, A.; Stefaniuk, D.; Maciąg, K.; Polak, J.; Matuszewski, Ł.; Grzywnowicz, K. Stimulation of the antioxidative and antimicrobial potential of the blood red bracket mushroom Pycnoporus sanguineus (higher Basidiomycetes). Int. J. Med. Mushrooms 2015, 17, 701–712. [Google Scholar] [CrossRef] [PubMed]

- May, C.A. Epoxy Resins, Chemistry and Technology, 2nd ed.; Marcel Dekker: New York, NY, USA, 1988; pp. 9–20. [Google Scholar]

- Czub, P.; Bończa-Tomaszewski, Z.; Pęczek, P.; Pielichowski, J. Chemistry and Technology of Epoxy Resins; Scientific and Technical Publishers: Warsaw, Poland, 2002; pp. 17–60. [Google Scholar]

- Resins. Available online: http://ciechgroup.com/produkty/chemia-organiczna/zywice/ (accessed on 9 May 2016).

- Hardeners. Available online: http://ciechgroup.com/produkty/chemia-organiczna/zywice/utwardzacze/ (accessed on 9 May 2016).

- Epoxy. Available online: https://en.wikipedia.org/wiki/Epoxy (accessed on 20 April 2016).

| Components of the epoxy adhesive compound | Control test (g) | Test run 1 (g) | Test run 2 (g) | Test run 3 (g) | Test run 4 (g) |

|---|---|---|---|---|---|

| Epidian 53 | 50 | 50 | 50 | 50 | 50 |

| PAC | 50 | 50 | 50 | 50 | 50 |

| Lyophilized preparation with a low molecular weight secondary metabolite subfraction | 0.00 | 0.25 | 0.50 | 0.75 | 1.00 |

| Denotation | Method description |

|---|---|

| Method I | The epoxy resin and curing agent were mixed with the fungal material in the desired concentration. The whole was mixed and used for production of the specimens of the cured adhesive and adhesive bonding of the sheets. |

| Method II | Resin was mixed with the mortar-grounded lyophilized material containing a low molecular weight secondary metabolite subfraction (LMS) obtained from idiophase fungal cultures of Pycnoporus sanquineus in the required concentration. After thorough mixing, the polyaminoamide curing agent was added, and the whole was mixed again. |

| Variant | Method | Seasoning time | Seasoning conditions |

|---|---|---|---|

| Variant I | Method I | 7 days | Temperature: 23 ± 2 °C |

| Humidity: 23% ± 2% | |||

| Variant II | Method II | 7 days | Temperature: 23 ± 2 °C |

| Humidity: 23% ± 2% | |||

| Variant III | Method I | 2 months | Temperature: 50 ± 1 °C |

| Humidity: 50% ± 1% |

| Amount of filler | Specimens prepared with Method I | Specimens prepared with Method II |

|---|---|---|

| Et, MPa | Et, MPa | |

| 0.00% | 419 ± 23 | 833 ± 24 |

| 0.25% | 395 ± 27 | 743 ± 31 |

| 0.50% | 429 ± 18 | 842 ± 23 |

| 0.75% | 464 ± 16 | 839 ± 12 |

| 1.00% | 379 ± 17 | 1024 ± 26 |

| Amount of filler | Specimens—Variant III | |||||

|---|---|---|---|---|---|---|

| Fmax, N | Et, MPa | σγ, MPa | σM, MPa | εM, % | σB, MPa | |

| 0.00% | 1055 ± 68 | 212 ± 12 | 8.8 ± 0.46 | 8.8 ± 0.18 | 10.0 ± 0.50 | 8.8 ± 0.22 |

| 0.25% | 1400 ± 49 | 374 ± 18 | - | 11.4 ± 0.07 | 7.0 ± 0.18 | 11.4 ± 0.08 |

| 0.50% | 1597 ± 59 | 222 ± 22 | 12.4 ± 0.35 | 12.4 ± 0.11 | 6.8 ± 0.12 | 10.7 ± 0.09 |

| 0.75% | 1596 ± 87 | 251 ± 21 | 13.2 ± 0.18 | 13.2 ± 0.18 | 7.4 ± 0.16 | 10.7 ± 0.13 |

| 1.00% | 1308 ± 12 | 237 ± 13 | 10.9 ± 0.12 | 10.9 ± 0.12 | 7.1 ± 0.08 | 7.4 ± 0.17 |

| Amount of filler | Method I (Variant I) | Method II (Variant I) | Method I (Variant III) |

|---|---|---|---|

| 0.00% |  |  |  |

| 0.25% |  |  |  |

| 0.50% |  |  |  |

| 0.75% |  |  |  |

| 1.00% |  |  |  |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rudawska, A.; Haniecka, I.; Jaszek, M.; Osińska-Jaroszuk, M. The Influence of Biochemical Modification on the Properties of Adhesive Compounds. Polymers 2017, 9, 9. https://doi.org/10.3390/polym9010009

Rudawska A, Haniecka I, Jaszek M, Osińska-Jaroszuk M. The Influence of Biochemical Modification on the Properties of Adhesive Compounds. Polymers. 2017; 9(1):9. https://doi.org/10.3390/polym9010009

Chicago/Turabian StyleRudawska, Anna, Izabela Haniecka, Magdalena Jaszek, and Monika Osińska-Jaroszuk. 2017. "The Influence of Biochemical Modification on the Properties of Adhesive Compounds" Polymers 9, no. 1: 9. https://doi.org/10.3390/polym9010009

APA StyleRudawska, A., Haniecka, I., Jaszek, M., & Osińska-Jaroszuk, M. (2017). The Influence of Biochemical Modification on the Properties of Adhesive Compounds. Polymers, 9(1), 9. https://doi.org/10.3390/polym9010009