Fiber Reinforced Polymer Strengthening of Structures by Near-Surface Mounting Method

Abstract

:1. Introduction

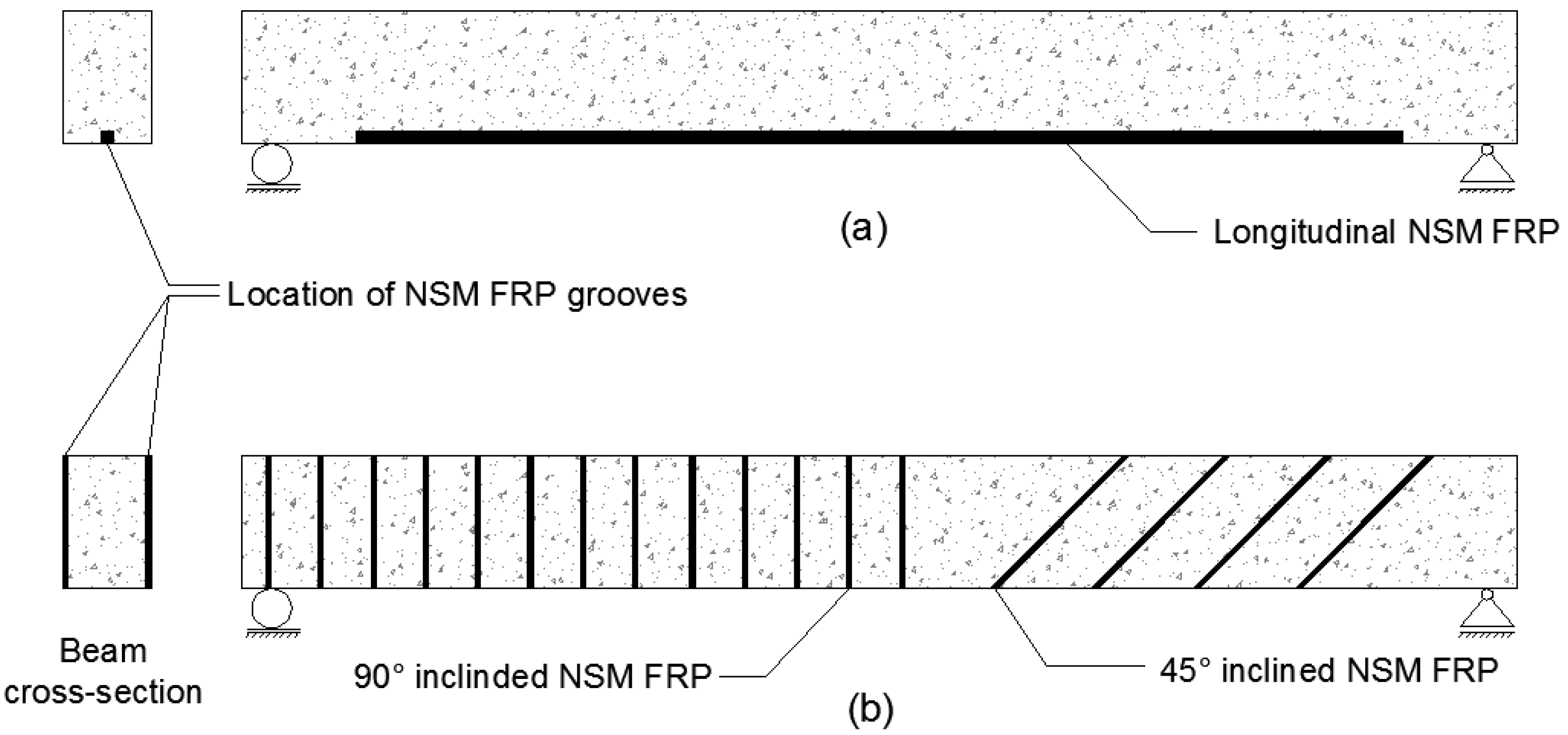

2. Flexural Applications of NSM-FRP for Concrete Members

3. Shear Applications of NSM-FRP for Concrete Members

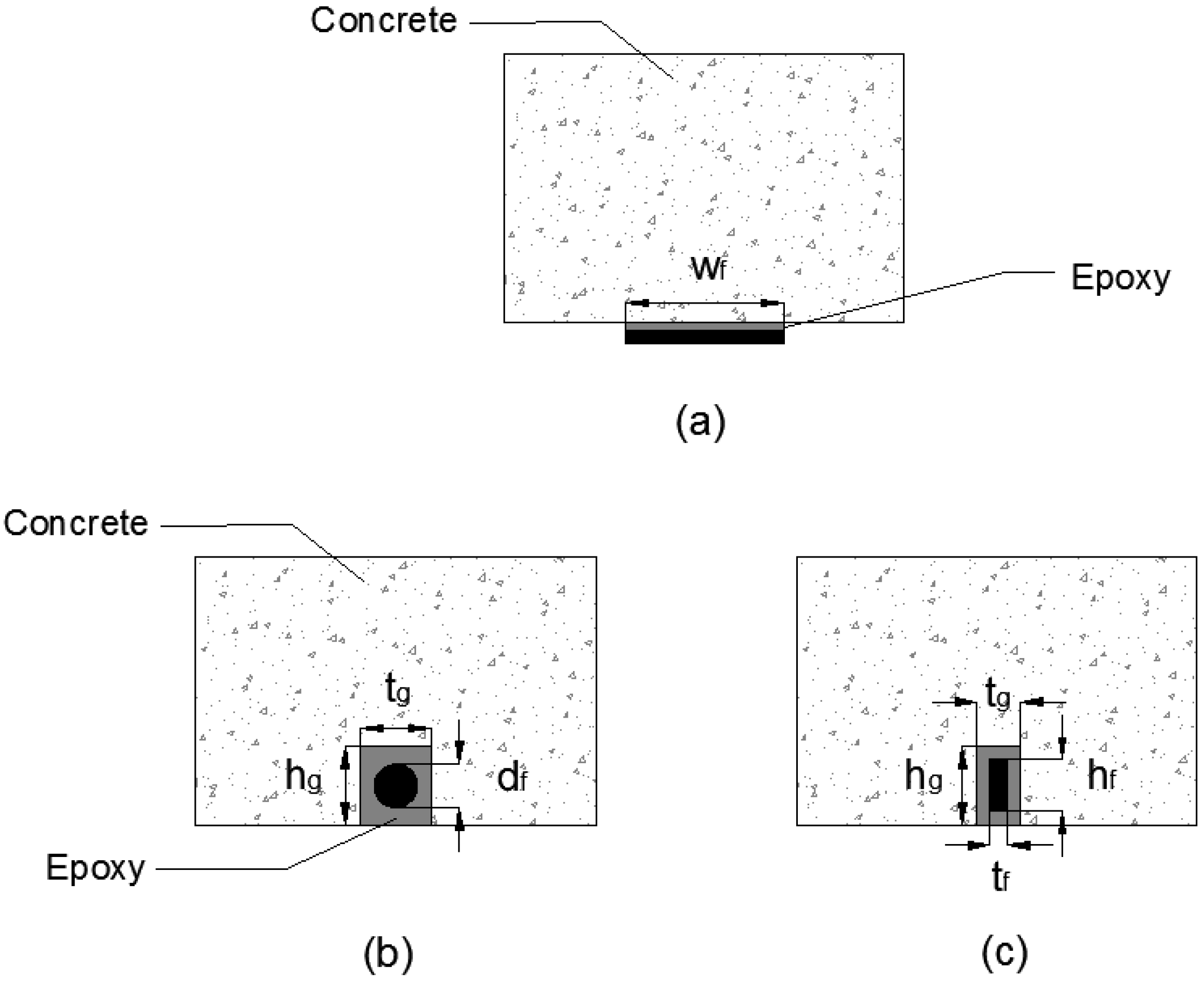

4. Prestressed NSM-FRP Applications for Concrete Members

5. NSM-FRP to Concrete Bond Performance

5.1. Surface Treatment of FRP Bars or Rods

5.2. Adhesive Types

5.3. NSM Groove and Bar Dimensions

5.4. Bonded Length

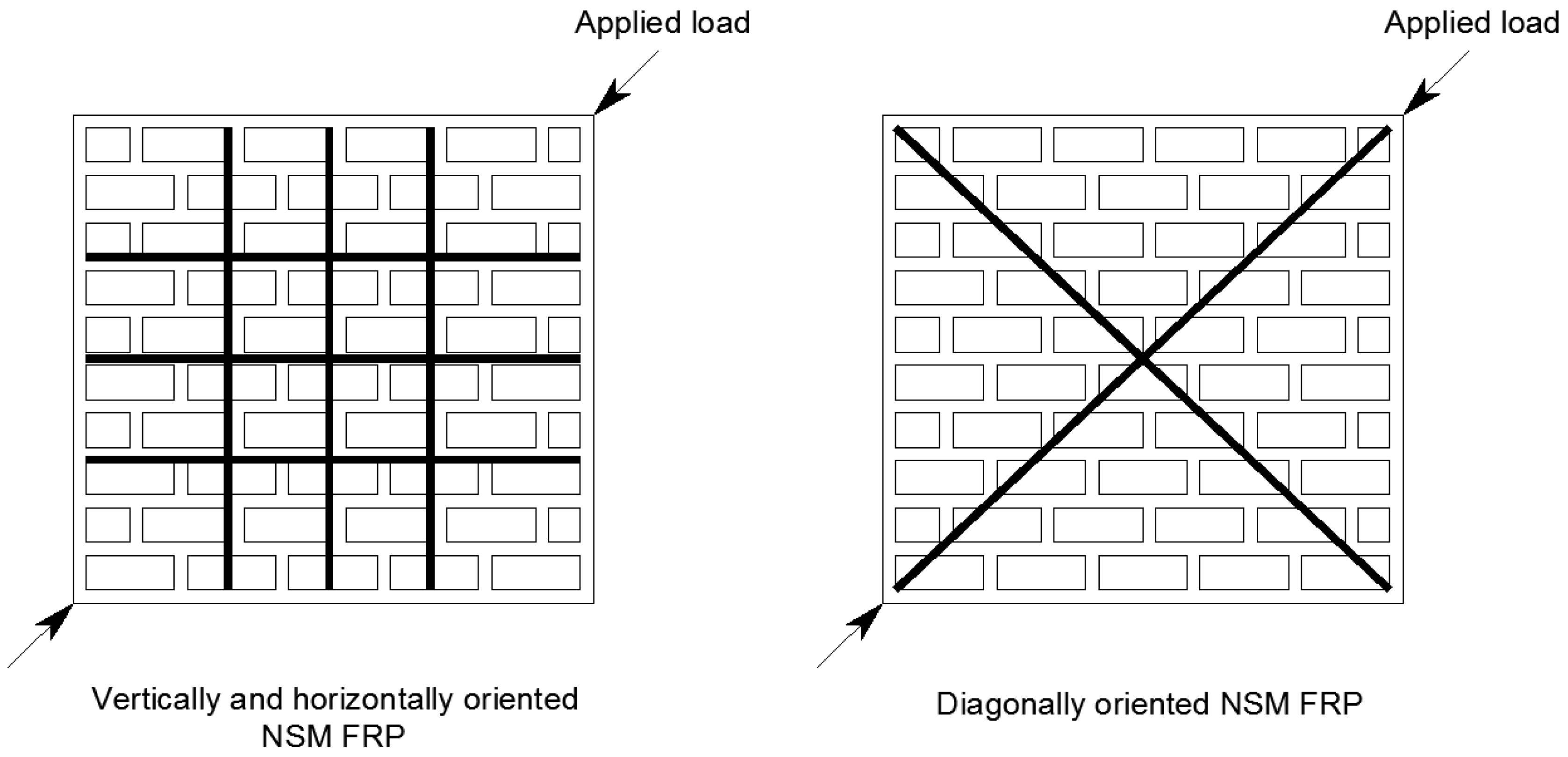

6. NSM-FRP Applications for Masonry Walls

6.1. NSM-FRP Masonry Bond Studies

6.2. In Plane Shear

6.3. Out of Plane Flexure

7. NSM-FRP Applications under Temperature

8. Emerging and Innovative Methods to Improve the Performance of NSM-FRP Strengthening

9. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| NSM | near surface mounting |

| EBR | externally bonding reinforcement |

| FRP | fiber reinforced polymers |

| CFRP | carbon fiber reinforced polymers |

| RC | reinforced concrete |

| ACI | American Concrete Institute |

| FIB | Fédération Internationale du Béton |

| CSA | Canadian Standards Association |

| HCP | hybrid composite plate |

| SHCC | strain hardening cementitious composite |

| URM | unreinforced masonry |

| ASTM | American Society of the International Association for Testing and Materials |

| ISO | International Organization for Standardization |

| IC | intermediate crack |

| BFRP | basalt fiber reinforced polymers |

| Tg | glass transition temperature |

| Td | decomposition temperature |

| CS | calcium silicate |

| VP | vermiculite/perlite |

| MG | cement and epoxy binder mixed grout |

| DMA | dynamic mechanical analysis |

| TGA | thermogravimetric analysis |

| ETS | embedded through section |

References

- Soudki, K.; Alkhrdaji, T. Guide for the design and construction of externally bonded FRP systems for strengthening concrete structures (ACI 440.2R-02). Str. Congr. 2005. [Google Scholar] [CrossRef]

- Comite Euro-International du Beton-Federation International de la Precontrainte (CEB-FIP); CEB-FIP Model Code 1990; Thomas Telford: London, UK, 1993.

- Seo, S.Y.; Feo, L.; Hui, D. Bond strength of near surface-mounted FRP plate for retrofit of concrete structures. Compos. Struct. 2013, 95, 719–727. [Google Scholar] [CrossRef]

- Burke, P.J.; Bisby, L.A.; Green, M.F. Effects of elevated temperature on near surface mounted and externally bonded FRP strengthening systems for concrete. Cem. Conc. Compos. 2013, 35, 190–199. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Teng, J. Near-surface mounted FRP reinforcement: An emerging technique for strengthening structures. Compos. Part B 2007, 38, 119–143. [Google Scholar] [CrossRef]

- Baghi, H.; Barros, J. Shear strengthening of reinforced concrete T-beams with hybrid composite plate. J. Compos. Constr. 2016. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Nanni, A.; La Tegola, A. Strengthening of reinforced concrete structures with near surface mounted FRP rods. In Proceedings of the International Meeting on Composite Materials, Milan, Italy, 9–11 May 2000.

- Astorga, A.; Santa Maria, H.; Lopez, M. Behavior of a concrete bridge cantilevered slab reinforced using NSM CFRP strips. Constr. Building Mat. 2013, 40, 461–472. [Google Scholar] [CrossRef]

- Barros, J.; Dias, S.; Lima, J. Efficacy of CFRP-based techniques for the flexural and shear strengthening of concrete beams. Cem. Conc. Compos. 2007, 29, 203–217. [Google Scholar] [CrossRef]

- Al-Mahmoud, F.; Castel, A.; François, R.; Tourneur, C. Strengthening of RC members with near-surface mounted CFRP rods. Compos. Struct. 2009, 91, 138–147. [Google Scholar] [CrossRef]

- Soliman, S.; El-Salakawy, M.; Benmokrane, B. Flexural behaviour of concrete beams strengthened with near surface mounted fibre reinforced polymer bars. Can. J. Civil Eng. 2010, 21, 1371–1382. [Google Scholar] [CrossRef]

- El-Hacha, R.; Rizkalla, S. Near-surface-mounted fiber-reinforced polymer reinforcements for flexural strengthening of concrete structures. Struct. J. 2004, 101, 717–726. [Google Scholar]

- Barros, J.; Dias, S. Near surface mounted CFRP laminates for shear strengthening of concrete beams. Cem. Conc. Compos. 2006, 28, 276–292. [Google Scholar] [CrossRef]

- Rizzo, A.; De Lorenzis, L. Behavior and capacity of RC beams strengthened in shear with NSM FRP reinforcement. Constr. Building Mat. 2009, 23, 1555–1567. [Google Scholar] [CrossRef]

- Barros, J.; Dias, S. Assessment of the effectiveness of the NSM shear strengthening technique for deep T cross section RC beams. In Proceedings of the 11th International Symposium on Fiber Reinforced Polymers for Reinforced Concrete Structures, Guimarães, Portugal, 26–28 June 2013; pp. 1–10.

- Jalali, M.; Sharbatdar, M.; Chen, J.F.; Alaee, F. Shear strengthening of RC beams using innovative manually made NSM FRP bars. Constr. Building Mat. 2012, 36, 990–1000. [Google Scholar] [CrossRef]

- Hajihashemi, A.; Mostofinejad, D.; Azhari, M. Investigation of RC beams strengthened with prestressed NSM CFRP laminates. J. Compos. Constr. 2011, 15, 887–895. [Google Scholar] [CrossRef]

- Hong, S.; Park, S.K. Effect of prestress and transverse grooves on reinforced concrete beams prestressed with near-surface-mounted carbon fiber-reinforced polymer plates. Compos. Part B 2016, 91, 640–650. [Google Scholar] [CrossRef]

- Oudah, F.; El-Hacha, R. Performance of RC beams strengthened using prestressed NSM-CFRP strips subjected to fatigue loading. J. Compos. Constr. 2011, 16, 300–307. [Google Scholar] [CrossRef]

- Hosseini, M.; Dias, S.; Barros, J. Effectiveness of prestressed NSM CFRP laminates for the flexural strengthening of RC slabs. Compos. Struct. 2014, 111, 249–258. [Google Scholar] [CrossRef]

- Hosseini, M.; Dias, S.; Barros, J. Flexural strengthening of reinforced low strength concrete slabs using prestressed NSM CFRP laminates. Compos. Part B 2016, 90, 14–29. [Google Scholar] [CrossRef]

- Rezazadeh, M.; Costa, I.; Barros, J. Influence of prestress level on NSM CFRP laminates for the flexural strengthening of RC beams. Compos. Struct. 2014, 116, 489–500. [Google Scholar] [CrossRef]

- Ye, Y.; Guo, Z.; Chai, Z. Flexural behavior of stone slabs reinforced with prestressed NSM CFRP Bars. J. Compos. Constr. 2014. [Google Scholar] [CrossRef]

- Wu, G.; Dong, Z.; Wu, Z.; Zhang, L. Performance and parametric analysis of flexural strengthening for RC beams with NSM-CFRP bars. J. Compos. Constr. 2013. [Google Scholar] [CrossRef]

- Seracino, R.; Jones, N.; Ali, M.; Page, M.; Oehlers, D. Bond strength of near-surface mounted FRP strip-to-concrete joints. J. Compos. Constr. 2007, 11, 401–409. [Google Scholar] [CrossRef]

- Bianco, V.; Barros, J.; Monti, G. Bond model of NSM-FRP strips in the context of the shear strengthening of RC beams. J. Struct. Eng. 2009, 135, 619–631. [Google Scholar] [CrossRef]

- Lee, D.; Cheng, L.; Hui, J. Bond characteristics of various NSM FRP reinforcements in concrete. J. Compos. Constr. 2012, 17, 117–129. [Google Scholar] [CrossRef]

- Sharaky, I.A.; Torres, L.; Baena, M.; Miàs, C. An experimental study of different factors affecting the bond of NSM FRP bars in concrete. Compos. Struct. 2013, 99, 350–365. [Google Scholar] [CrossRef]

- Soliman, S.; El-Salakawy, E.; Benmokrane, B. Bond performance of near-surface-mounted FRP bars. J. Compos. Constr. 2010, 15, 103–111. [Google Scholar] [CrossRef]

- Petersen, R.; Masia, M.; Seracino, R. Bond behavior of near-surface mounted FRP strips bonded to modern clay brick masonry prisms: Influence of strip orientation and compression perpendicular to the strip. J. Compos. Constr. 2009, 13, 169–178. [Google Scholar] [CrossRef]

- Willis, C.; Yang, Q.; Seracino, R.; Griffith, M. Bond behaviour of FRP-to-clay brick masonry joints. Eng. Struct. 2009, 31, 2580–2587. [Google Scholar] [CrossRef]

- Kashyap, J.; Willis, C.; Griffith, M.; Ingham, J.; Masia, M. Debonding resistance of FRP-to-clay brick masonry joints. Eng. Struct. 2012, 41, 186–198. [Google Scholar] [CrossRef]

- Dizhur, D.; Griffith, M.; Ingham, J. In-plane shear improvement of unreinforced masonry wall panels using NSM CFRP strips. J. Compos. Constr. 2013. [Google Scholar] [CrossRef]

- Petersen, R.; Masia, M.; Seracino, R. In-plane shear behavior of masonry panels strengthened with NSM CFRP strips. I: Experimental investigation. J. Compos. Constr. 2010, 14, 754–763. [Google Scholar]

- Mahmood, H.; Ingham, J. Diagonal compression testing of FRP-retrofitted unreinforced clay brick masonry wallettes. J. Compos. Constr. 2011, 15, 810–820. [Google Scholar] [CrossRef]

- Konthesingha, K.; Masia, M.; Petersen, R.; Mojsilovic, N.; Simundic, G.; Page, A. Static cyclic in-plane shear response of damaged masonry walls retrofitted with NSM FRP strips–An experimental evaluation. Eng. Struct. 2013, 50, 126–136. [Google Scholar] [CrossRef]

- Konthesingha, K.; Masia, M.; Petersen, R.; Page, A. Experimental evaluation of static cyclic in-plane shear behavior of unreinforced masonry walls strengthened with NSM FRP strips. J. Compos. Constr. 2014. [Google Scholar] [CrossRef]

- Griffith, M.; Kashyap, J.; Mohamed Ali, M. Flexural displacement response of NSM FRP retrofitted masonry walls. Constr. Building Mat. 2013, 49, 1032–1040. [Google Scholar] [CrossRef]

- Dizhur, D.; Griffith, M.; Ingham, J. Out-of-plane strengthening of unreinforced masonry walls using near surface mounted fibre reinforced polymer strips. Eng. Struct. 2014, 59, 330–343. [Google Scholar] [CrossRef]

- Korany, Y.; Drysdale, R. Rehabilitation of masonry walls using unobtrusive FRP techniques for enhanced out-of-plane seismic resistance. J. Compos. Constr. 2006, 10, 213–222. [Google Scholar] [CrossRef]

- Derakhshan, H.; Dizhur, D.; Griffith, M.; Ingham, J. In situ out-of-plane testing of as-built and retrofitted unreinforced masonry walls. J. Struct. Eng. 2014. [Google Scholar] [CrossRef]

- De Sena, C.; Manuel, J.; Barros, J. Bond between near-surface mounted carbon-fiber-reinforced polymer laminate strips and concrete. J. Compos. Constr. 2004, 8, 519–527. [Google Scholar] [CrossRef]

- Yu, B.; Kodur, V. Effect of temperature on strength and stiffness properties of near-surface mounted FRP reinforcement. Compos. Part B 2014, 58, 510–517. [Google Scholar] [CrossRef]

- Palmieri, A.; Matthys, S.; Taerwe, L. Experimental investigation on fire endurance of insulated concrete beams strengthened with near surface mounted FRP bar reinforcement. Compos. Part B 2012, 43, 885–895. [Google Scholar] [CrossRef]

- Palmieri, A.; Matthys, S.; Taerwe, L. Fire endurance and residual strength of insulated concrete beams strengthened with near-surface mounted reinforcement. J. Compos. Constr. 2012, 17, 454–462. [Google Scholar] [CrossRef]

- Zhu, H.; Wu, G.; Zhang, L.; Zhang, J.; Hui, D. Experimental study on the fire resistance of RC beams strengthened with near-surface-mounted high-Tg BFRP bars. Compos. Part B 2014, 60, 680–687. [Google Scholar] [CrossRef]

- López, C.; Firmo, J.; Correia, J.; Tiago, C. Fire protection systems for reinforced concrete slabs strengthened with CFRP laminates. Constr. Building Mat. 2013, 47, 324–333. [Google Scholar] [CrossRef]

- Firmo, J.; Correia, J. Fire behaviour of thermally insulated RC beams strengthened with NSM-CFRP strips: Experimental study. Compos. Part B 2015, 76, 112–121. [Google Scholar] [CrossRef]

- Yu, B.; Kodur, V. Fire behavior of concrete T-beams strengthened with near-surface mounted FRP reinforcement. Eng. Struct. 2014, 80, 350–361. [Google Scholar] [CrossRef]

- Firmo, J.; Correia, J.; Pitta, D.; Tiago, C.; Arruda, M. Bond behavior between near-surface-mounted CFRP Strips and concrete at high temperatures. J. Compos. Constr. 2014, 19, 1943–5614. [Google Scholar] [CrossRef]

- Del Prete, I.; Bilotta, A.; Bisby, L.; Nigro, E. High Tg FRP and cementitious adhesive, potential benefits in fire for NSM FRP strengthened reinforced concrete beams. In Proceedings of the Applications of Structural Fire Engineering, Dubrovnik, Croatia, 19–20 April 2013.

- Kotynia, R.; Cholostiakow, S. New proposal for flexural strengthening of reinforced concrete beams using cfrp T-shaped profiles. Polymers 2015, 7, 2461–2477. [Google Scholar] [CrossRef]

- Rahman, M.; Jumaat, M.; Rahman, M.; Qeshta, I. Innovative hybrid bonding method for strengthening reinforced concrete beam in flexure. Constr. Build. Mats. 2015, 79, 370–378. [Google Scholar] [CrossRef]

- Rezazadeh, M.; Baghi, H.; Barros, J.; Laranjeira, J. Exploring the potentialities of a new type of CFRP laminate for the simultaneous flexural and shear strengthening of RC beams: Numerical research. In Proceedings of the 12th International Symposium on Fiber Reinforced Polymers for Reinforced Concrete Structures & the 5th Asia-Pacific Conference on Fiber Reinforced Polymers in Structures, Nanjing, China, 14–16 December 2015; pp. 1–6.

- Kaya, E.; Kütan, C.; Sheikh, S.; İlki, A. Flexural retrofit of support regions of reinforced concrete beams with anchored frp ropes using nsm and ets methods under reversed cyclic loading. J. Compos. Constr. 2016. [Google Scholar] [CrossRef]

| Reference | [7] | [8] | [9] | [10] | [11] |

| Test type | Flexure | ||||

| Specimen | Simply supported RC T-beams | Cantilevered RC bridge slab and RC beam | Simply supported RC beams | Simply supported RC beams | Simply supported RC beams |

| Cross-section dimensions, l × w × d (mm) | Span = 4,572, flange = 381 × 102, web = 152 × 305 | Bridge spans = 61.1, 64.1, and 80.0, beam = 900 × 170 × 200 | 1,000 × 120 × 170 | 3010 × 200 × 300 | 2800 × 150 × 280 |

| f'c (MPa) | 36.17 | 31.4 | 37.6–49.5 | 35 | 36.5–67.2 |

| Test method | 4 point bending | Cantilever, and three-point bending | Four-point bending | Four-point bending | Four-point bending |

| FRP material type and configuration | GFRP (deformed), and CFRP (sand blasted) rods | CFRP strips | CFRP sheet and laminate | CFRP, and GFRP rods | CFRP rods |

| FRP diameter df or FRP sheet width wf (mm) a | 9.5 and 12.7 | - | 0.111–0.167 | 9.5, 12.7, 11.3 and 15.9 | 6 and 12 |

| FRP cross-section hf × tf (mm) a | - | 16 × 2 | 10 × 1.4 | - | - |

| Groove dimensions hg × tg (mm) a | 16 × 16, 19 × 19, and 25.4 × 25.4 | 20 × 4 | N/Ab | 1.5–2 times df a | 12 × 12, and 24 × 24 |

| Test variables | Bonded length, FRP rod diameter, material, and groove | Variable loading conditions, and long term durabilty test | Distance between FRP rods, and FRP reinforcement ratio | Steel reinforcement ratio, FRP rod diameters and bonded lengths, material | Concrete strength, and epoxy |

| Observed failure mode | Concrete crushing, FRP debonding | N/A b | Delamination of concrete cover, FRP debonding and rupture | Steel yielding, and concrete cover splitting | Concrete cover peel-off, FRP pull-out and concrete crushing |

| Increase in ultimate load | 25.7%–44.3% | 41% | 83% (averaged) | up to 104% | 59.2–73.2 kN |

| Reference | [13] | [14] | [15] | [16] |

| Test type | Shear | |||

| Specimen | Simply-supported concrete and RC beams | Simply-supported RC beams | Simply-supported deep RC T-beams | Simply-supported RC beams |

| Cross-section dimensions, l × w × d (mm) | 1500 × 150 × 300, and 900 × 150 × 150 | 2000 × 200 × 210 | Span = 4200, flange = 450 × 100, web = 180 × 500 | 1650 × 200 × 250 |

| f'c (MPa) | 37.6–49.5 | 29.3 | 40.1 | 36.4 |

| Test method | Four-point bending | Four-point bending | Three-point bending | Three-point bending |

| FRP material type and configuration | CFRP strip | CFRP rods, and strips | CFRP rods | CFRP sheets wrapped around wooden rods |

| FRP Diameter df (mm) a | - | 7.5 and 8 | - | - |

| FRP Cross-Section hf × tf (mm) a | 10 × 1.4 | 16 × 2 | 10 × 1.4, and 20 × 1.4 | 0.11 |

| Groove dimensions hg × tg (mm) a | 12 × 5 | 15 × 15, and 18 × 5 | N/A b | 15 × 15 |

| Test variables | FRP spacing and inclination | FRP forms, epoxy, spacing and inclination of FRP | FRP dimensions, spacings and orientations | FRP end anchorage, spacings and orientations |

| Observed failure mode | Shear cracking | Shear cracking, and FRP debonding | Shear cracking, and FRP rupture | Shear-flexural cracking |

| Increase in ultimate load | 83% (averaged) | 22%–44% | 66%–85% | 25%–48% |

| Reference | [17] | [18] | [19] | [20] |

| Test type | Prestressing | |||

| Specimen | Simply-supported RC beam | Simply-supported RC beam | Simply-supported RC beam | Simply supported RC slab |

| Cross-section dimensions, l × w × d (mm) | 3300 × 300 × 350 | 3200 × 200 × 300 | 5150 × 200 × 400 | 2600 × 600 × 120 |

| f'c (MPa) | 31 | 27 | 40 | 46.7 |

| Test method | Three-point bending | Four-point bending | Four-point bending | Four-point bending |

| FRP saterial sype and sonfiguration | NSM CFRP laminate strips (sand coated) | NSM CFRP plates | NSM CFRP strips | NSM CFRP laminates |

| FRP cross-Section hf × tf (mm) a | 25 × 2 | 25 × 1.4 | 16 × 2 | 20 × 1.4 |

| Prestressing strain levels (%) | 5, 20 and 30 | 0–50 | 0, 20, 40, 60 | 20 and 40 |

| Test variables | Prestressing levels under service-load state | Prestressing levels and transverse grooves | Fatigue, in-service loading conditions | Prestressing levels, under service and ultimate loads |

| Observed failure mode | FRP rupture | FRP debonding, and concrete cover seperation | FRP debonding and FRP slippage at end anchorages | FRP rupture |

| Increase in ultimate load | 11.5%–15% | 42%–96% | 44.1–88.2 kN | 136%–152% |

| Reference | [21] | [22] | [23] | [24] |

| Test type | Prestressing | |||

| Specimen | Simply supported, RC slab | Simply supported, RC slab | Simply supported, stone slab | Simply supported, RC slab |

| Cross-section dimensions, l × w × d (mm) | 2600 × 600 × 120 | 2400 × 150 × 300 | 3400 × 450 × 100 | 1800 × 150 × 300 |

| f'c (MPa) | 15 | 32.2 | 142.4 | 27.7 |

| Test method | 4-Point bending | 4-Point bending | 4-Point bending | 4-Point bending |

| FRP material type and configuration | NSM CFRP laminates | NSM CFRP laminates | NSM CFRP bars (rough surfaces) | NSM CFRP bars (spirally wound) |

| FRP diameter df (mm) a | - | - | 7 | 7.9 |

| FRP cross-section hf × tf (mm) a | 20 × 1.4 | 20 × 1.4 | - | - |

| Groove dimensions hg × tg (mm) a | - | 24 × 6 | 27 × 14 | 20 × 20 |

| Prestressing strain levels (%) | 20 and 40 | 0, 20, 30, and 40 | 0, 15 and 30 | 40 |

| Test variables | Low concrete compressive strength, serviceability limit states | Prestressing levels, low steel reinforcement ratio of 0.39% | Prestressing levels, no steel reinforcement | Number of FRP bars, end treatments, and prestressing levels |

| Observed failure mode | FRP rupture | Concrete crushing and FRP rupture | FRP rupture, and excessive deflection | FRP bar slippage, and concrete crushing |

| Increase in ultimate load | 125% and 134% | 32%, 47%, 55% and 63% | 30%–60% (Cracking load) | 71% |

| Reference | [33] | [34] | [35] | [36] | [37] | |

| Test type | In plane shear | |||||

| Specimen | URM walls | URM walls | URM walls | URM walls | URM walls | |

| Wall dimensions, h × l (mm) | 1200 × 1200 | 1200 × 1200 | 1170 × 1170, and 1170 × 1075 | 1200 × 1200 | 1204 × 1190, and 1032 × 1910 | |

| Masonry brick compressive strength f'b (MPa) | 8.8–19.4 | N/A b | 11.2–21.2 | 28.6 | 21.3 | |

| Test method | Diagonal tension | Diagonal tension | Diagonal compression | Cyclic shear and vertical compression | Cyclic shear | |

| FRP material type and configuration | NSM CFRP strips | NSM CFRP strips | Anchored EB CFRP plates, and GFRP fabrics and strips | NSM CFRP strips | NSM CFRP strips | NSM CFRP strips |

| FRP cross-section hf × tf (mm) or w (mm) a | 12 × 1.2, 30 × 1.2 | 15 × 2.8 | Width ranging from 50–150 | 15 × 1.2 | 10 × 1.4 | 15 × 2.8 |

| Groove dimensions hg × tg (mm) a | 20 × 8, 35 × 8 | 20 × 6 | N/A b | N/A b | 15 × 8 | |

| Orientation of FRP | Vertical and diagonal | Vertical and horizontal | Vertical, horizontal and diagonal | Vertical and horizontal | Vertical and horizontal | |

| Test variables | FRP orientation, number of strips, and position | FRP orientation, number of strips, and position | FRP form, orientation, number of strips, and position | FRP orientation, pre-compression levels, number of strips, and position | FRP orientation, and boundary conditions | |

| Observed failure mode | Diagonal cracking, sliding and FRP debonding | Diagonal cracking, sliding and FRP debonding | Diagonal cracking, sliding and FRP debonding | Diagonal cracking | Diagonal cracking, and sliding | |

| Increase in wall strength | 1.3–3.7 times | 1%–46% | 31%–325% | 9.30% | 1%–9% | |

| Reference | [38] | [39] | [40] | [41] |

| Test type | Out of plane flexure | |||

| Specimen | URM wall, and column | URM walls | URM walls | URM walls |

| Wall dimensions, h × l (mm) | 2313 × 1070, and 1710 × 355 | 3000–4100 × 1150, and 2700–4000 × 1170 × 1250 | 3900 × 2800 | 1170 × 1250 |

| Masonry brick compressive strength f'b (MPa) | 17 | 17.1–39.5 | 16.9–27.6 | 8.8–32 |

| Test method | Three and four-point bending | Three and four-point bending | Monotonically increasing lateral pressure | Lateral pressure |

| Material type and configuration | NSM CFRP strips | NSM CFRP strips | NSM CFRP cable | NSM CFRP strips, and NSM twisted steel bars |

| FRP diameter df (mm) a | - | - | 5 | - |

| FRP cross-section hf × tf (mm) a | 10 × 4.2, 10 × 3.6, 10 × 7.2, 7.5 × 4.8, and 5 × 4.8 | 15 × 1.2 | - | 15 × 1.2 |

| Groove dimensions hg × tg (mm) a | N/A b | 20 × 8 | N/A b | N/A b |

| Orientation of FRP | Vertical | Vertical | Vertical and horizontal | Vertical |

| Test variables | FRP spacing, reinforcement ratio, and cyclic and pre-compression loadings | Wall dimensions, one-or two-sided FRP retrofit | Low FRP reinforcement ratios, pre-compression loads, various support conditions | In-situ and pre-compression loads |

| Observed failure mode | IC debonding | Displacement Induced (DI) debonding | Diagonal cracking, compressive crushing of masonry, FRP slip, and shear rupture | FRP debonding, and FRP pull-out |

| Increase in wall strength | up to 20 times | 3.05–6.21 times | 25%–291% | 440%–830% |

| Reference | [43] | [44,45] | [4] | [46] | |

| Test type | Temperature | ||||

| specimen | N/A | Simply-supported RC beam | Simply-supported RC beam | Simply-supported RC beam | |

| Cross-section dimensionsl × w × d (mm) | N/A | 3150 × 200 × 300 | 1524 × 254 × 102 | 4100 × 200 × 450 | |

| Temperature range (°C) | 20–600 | ISO 834 | 21–200 | ISO 834 | |

| Insulation type | N/Ab | Glass-fiber cement, CS c, two component system and ceramic | Ceramic | Rock-wool and CS c | |

| Insulation length (mm) | N/A b | 2900 | FRP bonded length | 225–850 | |

| Test method | Tension test | Service load and EN 1363-1 standard fire | Monotonic or service load, and transient high temperature | Four-point bending, and standard fire | |

| FRP Material type and configuration | CFRP strips and rods | CFRP and GFRP rods | CFRP fabric and tape | Basalt FRP bars | |

| FRP Tg (°C) | 80 | 82 | 59 and 122 | N/A b | |

| FRP diameter df (mm) a | 6.4 | 9.5–16 | - | 10 | |

| FRP cross-section hf × tf (mm) a | 13.5 × 4.5 | - | 235 × 0.381, 16 × 2 | - | |

| Adhesive or resin type | High strength epoxy and expansive cement | Epoxy | Epoxy and cementitious material | Vinyl, heat resistance vinyl, and epoxy | |

| Adhesive Tg (°C) | N/A b | 62–65 | 59 and 69 | 127, 174, and 210 | |

| Groove dimensions hg × tg (mm) a | N/A b | N/A b | 21 × 5 | 20 × 20 | |

| Test variables | High temperature, various epoxy and FRP forms | Various insulation systems | High temperature, various adhesive, and insulation lengths | High Tg resin, and insulation thickness | |

| Observed failure mode (s) | Splitting or rupture of FRP fibers, resin decomposition | FRP debonding, and concrete crushing | FRP debonding | Flexural | |

| Thermal performance | N/A b | 1–2 h | 4 h at 100 °C, and 70 min at 200 °C | 88–147 min | |

| Reference | [47] | [48] | [49] | [50] | [51] |

| Test type | Temperature | ||||

| Specimen | Simply-supported RC beam | Simply-supported RC beam | Simply-supported RC T-beams | RC Concrete blocks | Simply-supported RC beam |

| Cross-section dimensions l × w × d (mm) | 2100 × 100 × 120 | 1350 × 120 × 200 | Span = 3962, flange 432 × 127, web = 229 × 279 | 350 × 120 × 120 | 1450 × 150 × 150 |

| Temperature range (°C) | ISO 834 | ISO 834 | ASTM E119 | 20–150 | N/A b |

| Insulation type | CS c, and VP d mortar | CS c | U-shaped Tyfo®CFP e | - | N/A b |

| Insulation length (mm) | Anchorage zones | Anchorage zones | 3180 | - | Anchorage zones |

| Test method | Four-point bending, and standard fire | Four-point bending, and standard fire | Four-point bending, and standard fire | Double-lap shear test, and high temperature | DMA f, TGA g and thermal conductivity, and four-point bending test, and thermal load |

| FRP material type and configuration | CFRP laminate | CFRP strips | CFRP strips | CFRP strips | CFRP bar |

| FRP Tg (°C) | N/A b | 83 | N/A b | 83 | 220 |

| FRP diameter df (mm) a | - | - | - | - | N/A b |

| FRP cross-section hf × tf (mm) a | 50 × 1.2 | 10 × 1.2 | 13.5 × 4.5 | 10 × 1.2 | - |

| Adhesive or resin type | Epoxy | Epoxy, and mixed grout | Epoxy | Epoxy, and mixed grout | Cementitious grout |

| Adhesive Tg (°C) | 55 | 47 and 44 | N/A b | 47 and 44 | N/A b |

| Groove dimensions hg × tg (mm) a | N/A b | N/A b | N/A b | 15 × 5 | N/A b |

| Test variables | Fire protection schemes, and Tg of epoxy | Adhesive type, and fire protection schemes | Fire protection zones, and schemes | Adhesive type, bonded length | Material testing procedures, and fire protection schemes |

| Observed failure mode (s) | Structural failure | FRP debonding | FRP decomposition | Shear failure, and adhesive failure | FRP debonding |

| Thermal performance | 60–90 min | 114 min | 3 h | N/A | 90 min |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Parvin, A.; Syed Shah, T. Fiber Reinforced Polymer Strengthening of Structures by Near-Surface Mounting Method. Polymers 2016, 8, 298. https://doi.org/10.3390/polym8080298

Parvin A, Syed Shah T. Fiber Reinforced Polymer Strengthening of Structures by Near-Surface Mounting Method. Polymers. 2016; 8(8):298. https://doi.org/10.3390/polym8080298

Chicago/Turabian StyleParvin, Azadeh, and Taqiuddin Syed Shah. 2016. "Fiber Reinforced Polymer Strengthening of Structures by Near-Surface Mounting Method" Polymers 8, no. 8: 298. https://doi.org/10.3390/polym8080298

APA StyleParvin, A., & Syed Shah, T. (2016). Fiber Reinforced Polymer Strengthening of Structures by Near-Surface Mounting Method. Polymers, 8(8), 298. https://doi.org/10.3390/polym8080298