Numerical Simulation and Experimental Investigation of the Viscoelastic Heating Mechanism in Ultrasonic Plasticizing of Amorphous Polymers for Micro Injection Molding

Abstract

:1. Introduction

2. Theoretical Modeling

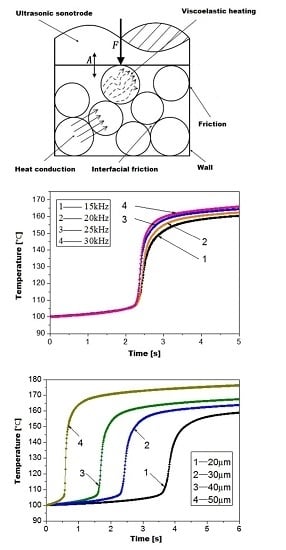

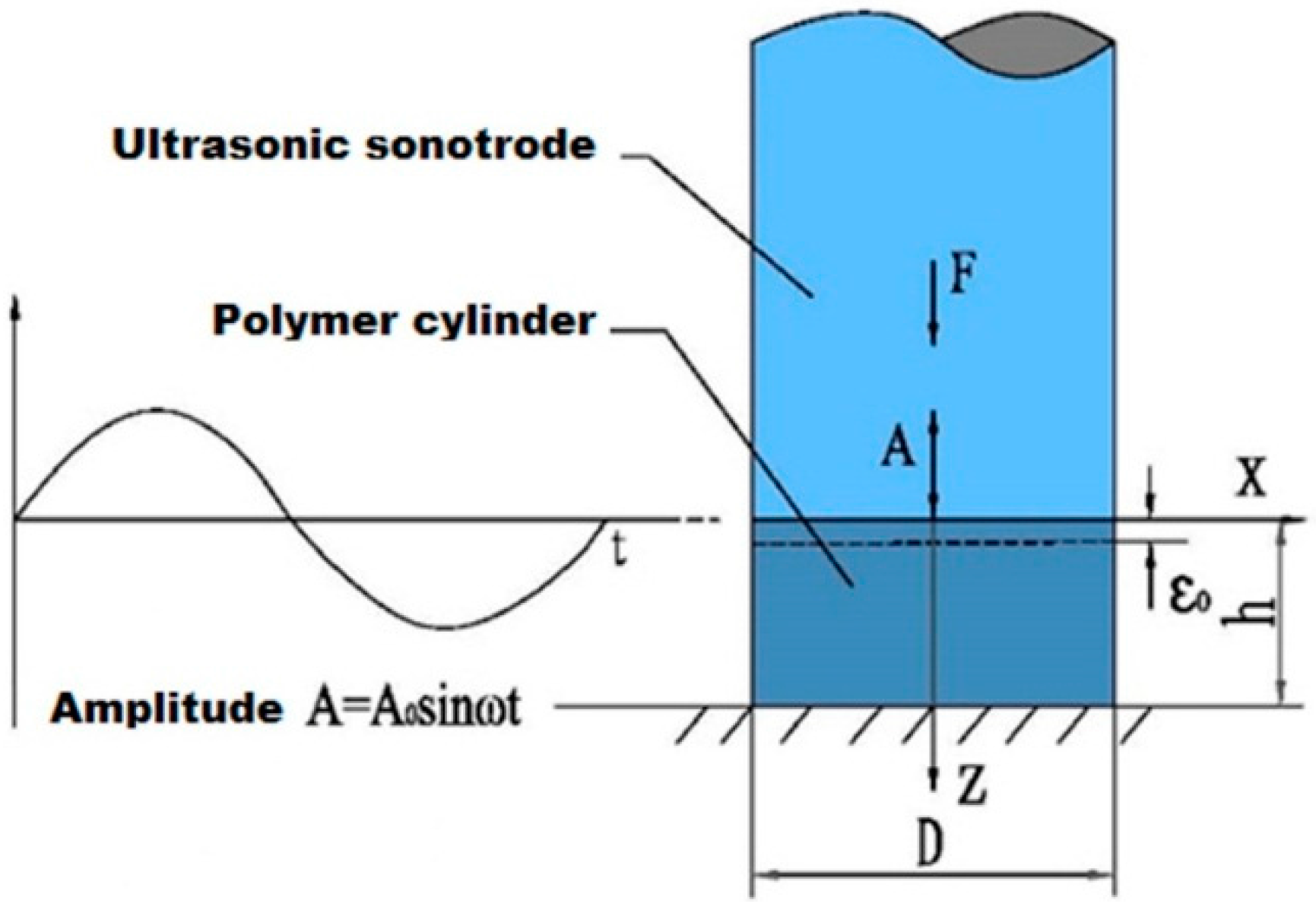

2.1. Problem Description

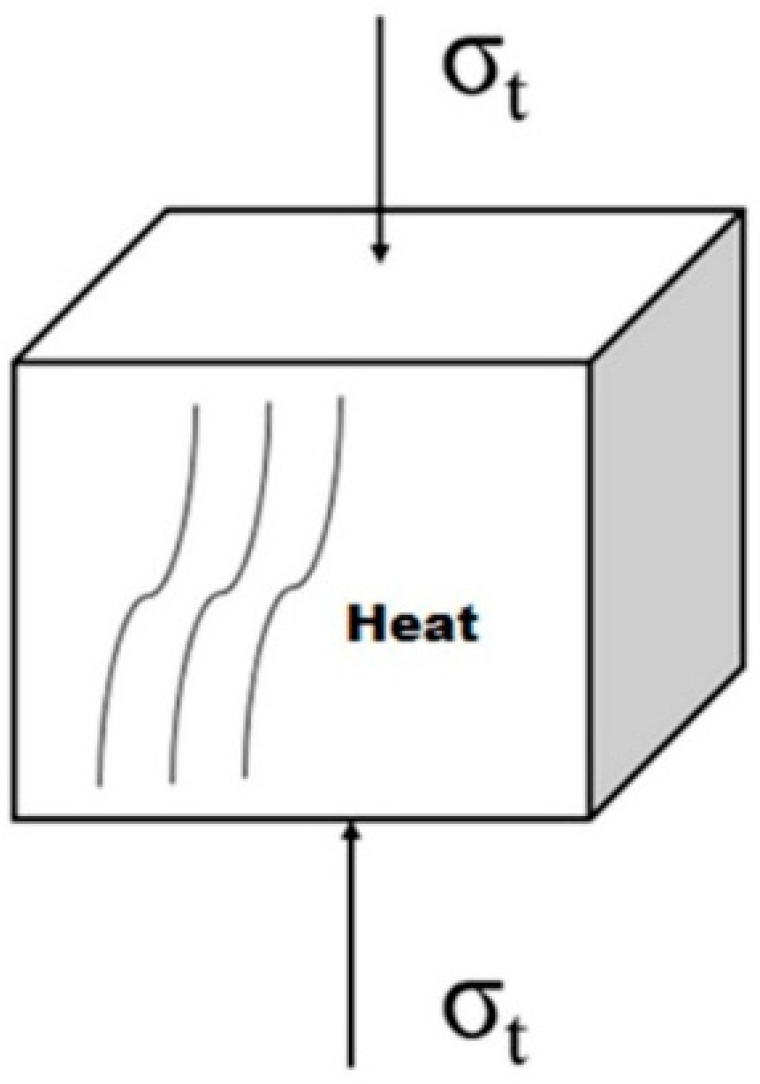

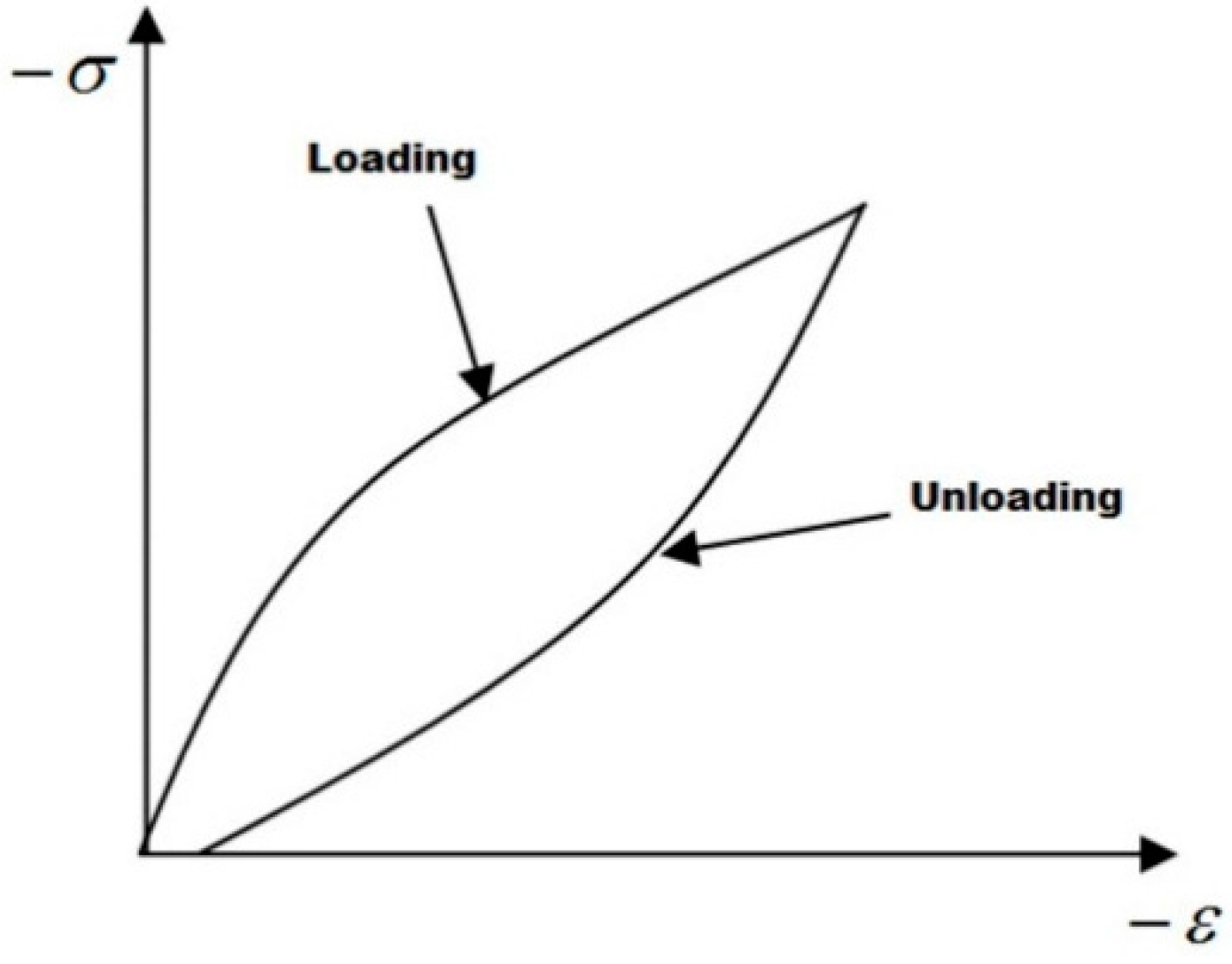

2.2. Theoretical Modeling

2.2.1. Physical model

2.2.2. Mathematical Modeling

2.2.3. Numerical Simulation

- Assumptions

- (1)

- The heat exchange between the model and the environment is natural convection.

- (2)

- The contact between the sonotrode and the polymer cylinder stays unchanged during vibration due to the constant plasticizing pressure.

- (3)

- The density of the polymer bulk cylinder is assumed to be constant during viscoelastic heating to simplify the numerical simulation.

- (4)

- The heat generated by the sonotrode during ultrasonic plasticizing is neglected to focus on the polymer internal heat generation by viscoelastic heating.

- (5)

- The possible energy leak from the sensor insertion is neglected because the ultrasonic plasticizing is a transient process which usually lasts only a few seconds.

- Material properties

- (1)

- The material applied in the model is amorphous poly(methyl methacrylate) (PMMA) which has a glass transition temperature of 105 °C and a viscos flow temperature of 160 °C.

- (2)

- The relaxation modulus and relaxation time of the generalized Maxwell model at a reference temperature of 105 °C is defined according to [12].

- (3)

- The activation energy and the constants and in Equation (8) are defined as 335 KJ/mol, 17.6, and 65.5, respectively, according to [15].

- Initial conditions

- (1)

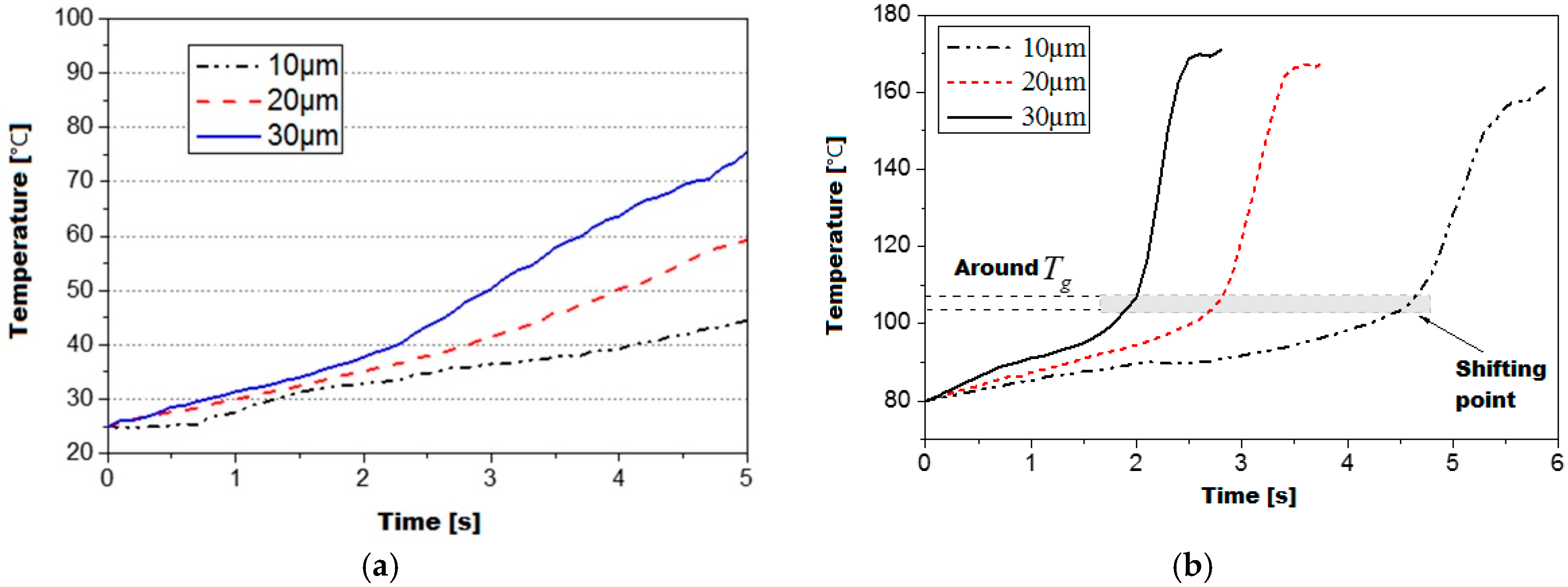

- For the study on the influence of the initial temperature of polymer on the viscoelastic heating, the initial temperature of the polymer was defined as 30, 96, and 100 °C, respectively.

- (2)

- For the study on the influence of the ultrasonic amplitude and frequency on the viscoelastic heating, the initial temperature was defined as 100 °C.

- Boundary conditions

- (1)

- The environment temperature is 25 °C.

- (2)

- There is thermal radiation to environment during viscoelastic heating which was considered by applying the convection and radiation heat transfer coefficient which is defined as 16 W/m2·°C.

- (3)

- For the study on the influence of the initial temperature of polymer on the viscoelastic heating, the vibration frequency and amplitude at the end of the sonotrode were defined as 20 kHz and 40 μm, respectively.

- (4)

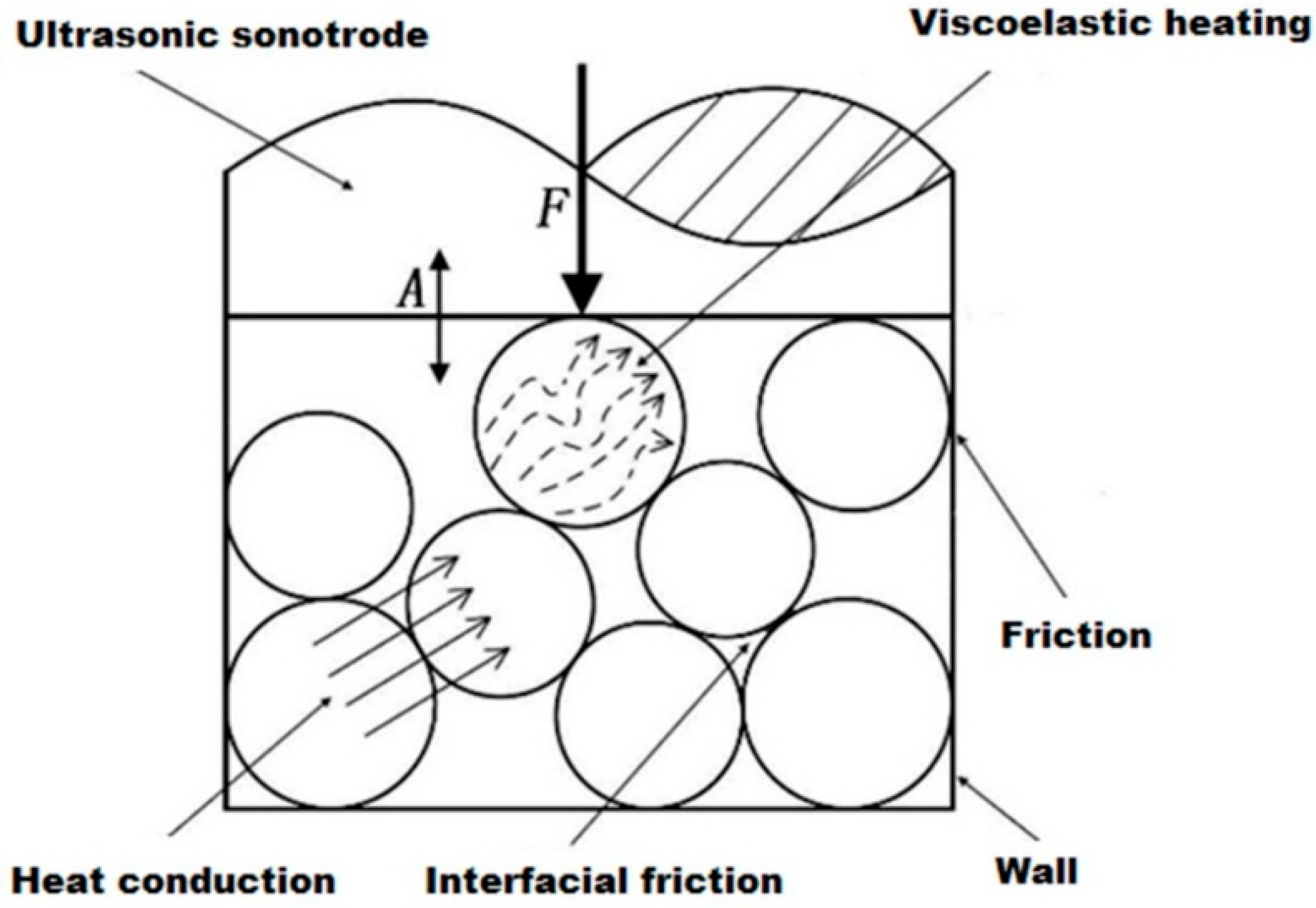

- For the study on the influence of ultrasonic frequency on the viscoelastic heating, a vibration frequency sweep from 15 to 30 kHz with a step of 5 kHz and an amplitude of 40 μm were set up for the end of the sonotrode.

- (5)

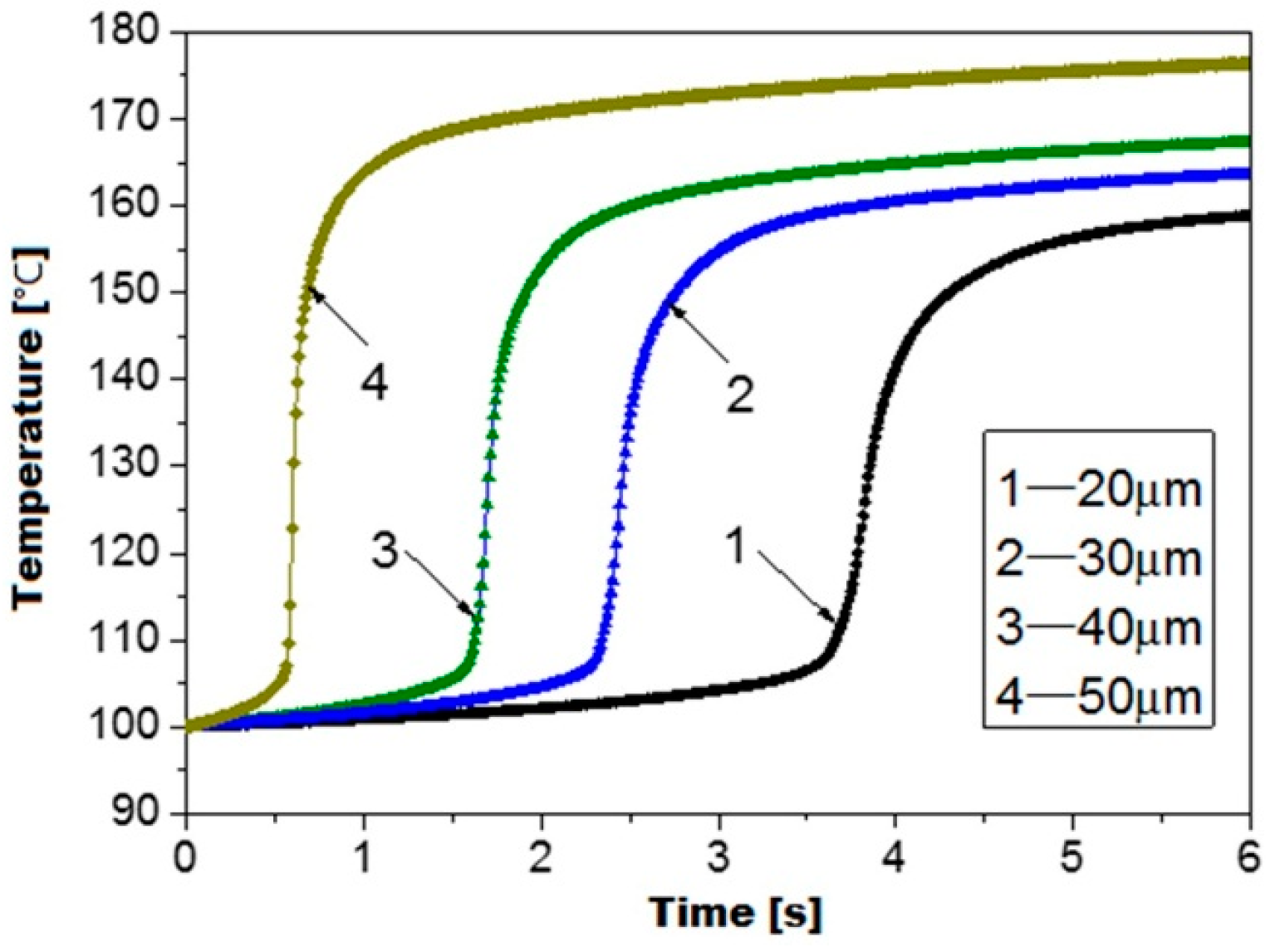

- For the study on the influence of ultrasonic amplitude on the viscoelastic heating, a vibration amplitude sweep from 20 to 50 μm with a step of 10 μm and a vibration frequency of 20 kHz were set up for the sonotrode.

3. Experimentation

3.1. Materials

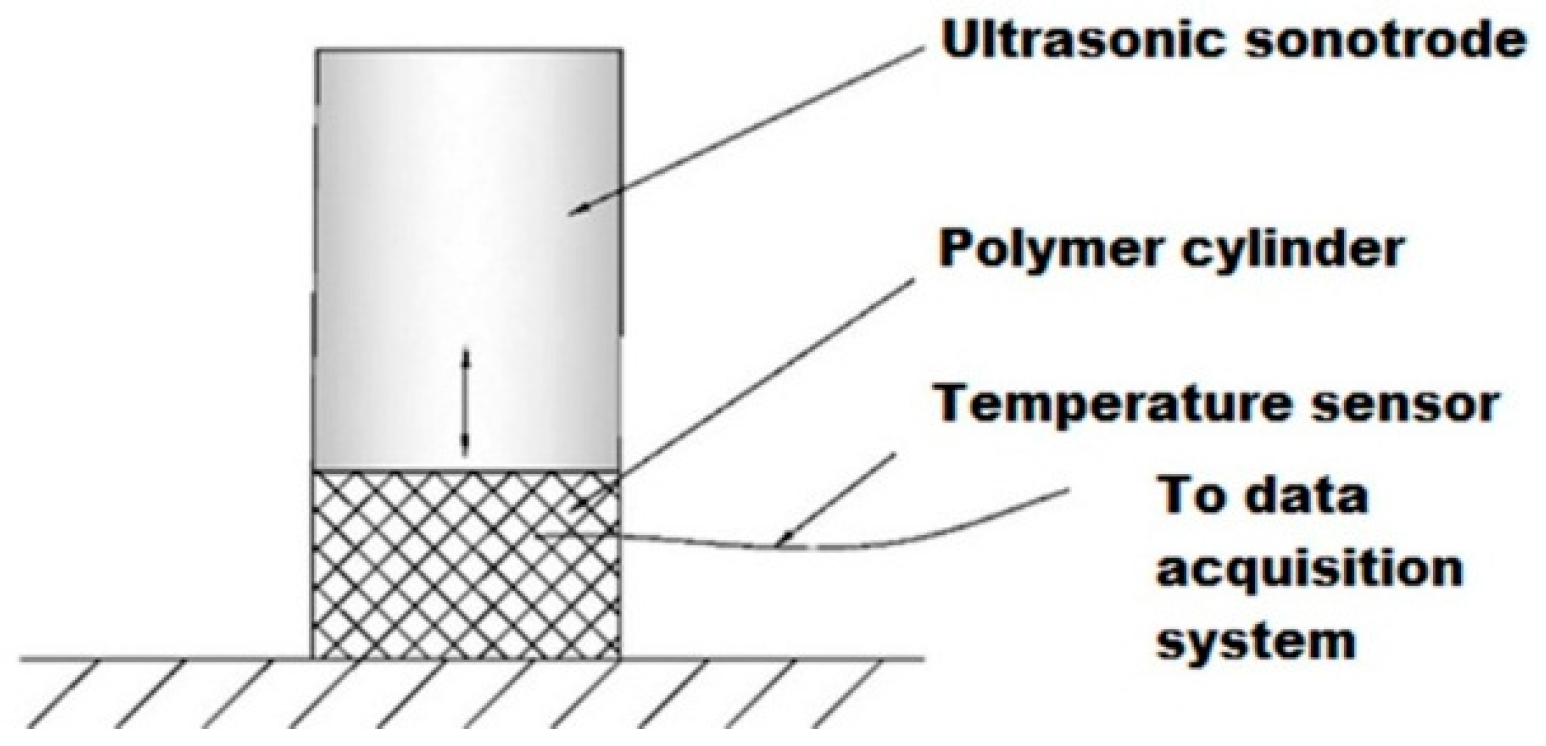

3.2. Ultrasonic Plasticization System

3.3. Methodology

4 Results and Discussion

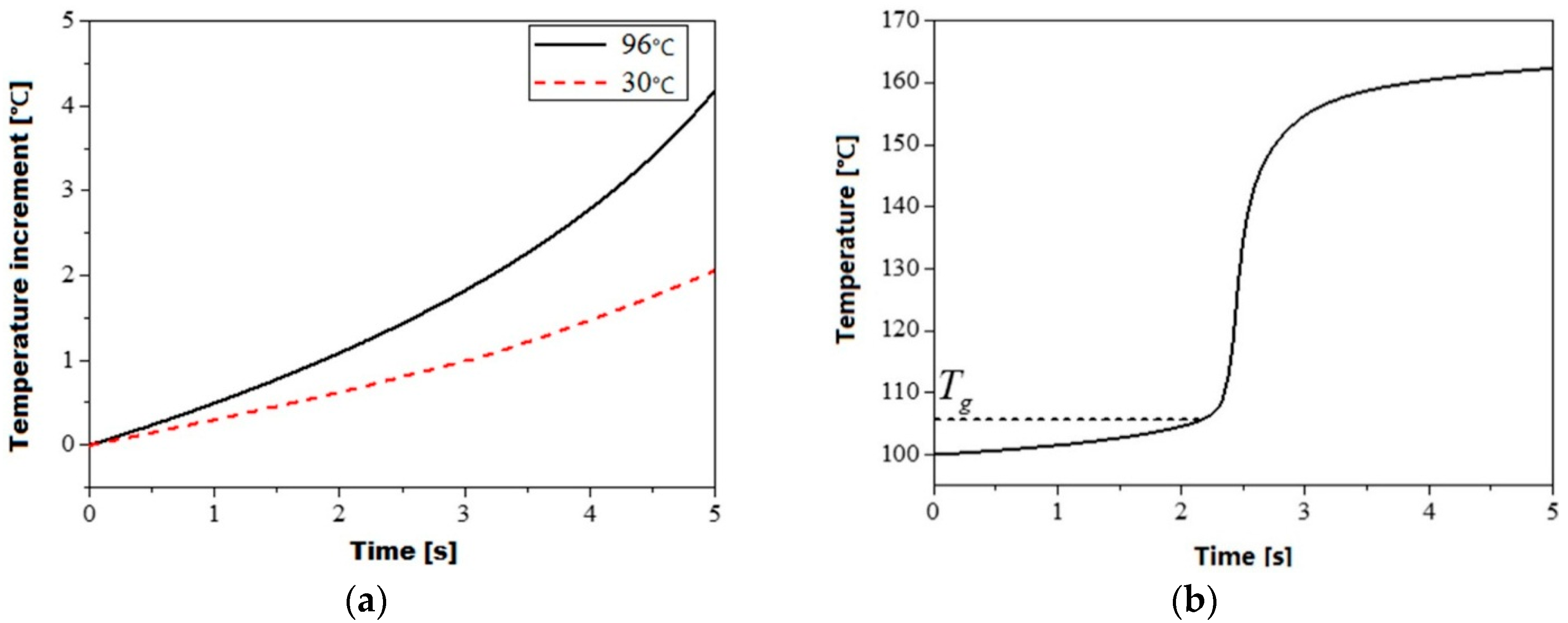

4.1. Influence of the Initial Temperature of Polymer

4.2. Influence of the Ultrasonic Frequency

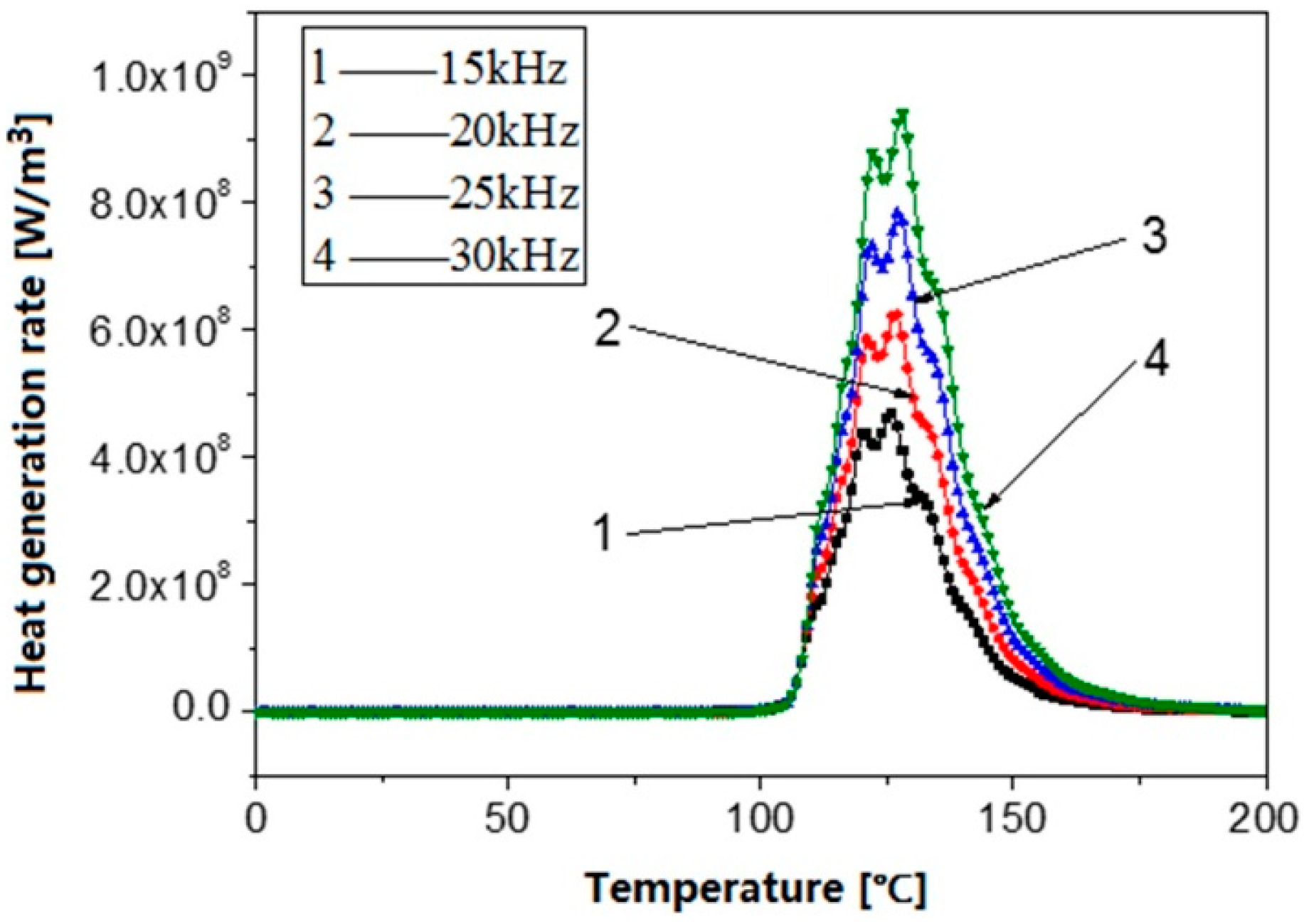

4.3. Influence of the Ultrasonic Amplitude

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Michaeli, W.; Spennemann, A.; Gärtner, R. New plastification concepts for micro injection moulding. Microsyst. Technol. 2002, 8, 55–57. [Google Scholar] [CrossRef]

- Michaeli, W.; Opfermann, D. Ultrasonic plasticising for micro injection moulding. In Proceedings of the 4 m 2006—Second International Conference on Multi-Material Micro Manufacture, Grenoble, France, 20–22 September 2006; Fillon, W.M.D., Ed.; Elsevier: Oxford, UK, 2006; pp. 345–348. [Google Scholar]

- Michaeli, W.; Kamps, T. Heating and plasticizing polymers with energetic ultrasound for micro injection molding. In Proceedings of the Annual Technical Conference (ANTEC) of the Society of Plastics Engineers (SPE), Orlando, FL, USA, 16–20 May 2010.

- Michaeli, W.; Kamps, T.; Hopmann, C. Manufacturing of polymer micro parts by ultrasonic plasticization and direct injection. Microsyst. Technol. 2011, 17, 243–249. [Google Scholar] [CrossRef]

- Wu, W.; Peng, H.; Jia, Y.; Jiang, B. Characteristics and mechanisms of polymer interfacial friction heating in ultrasonic plasticization for micro injection molding. Microsyst. Technol. 2016. [Google Scholar] [CrossRef]

- Sacristán, M.; Plantá, X.; Morell, M.; Puiggalí, J. Effects of ultrasonic vibration on the micro-molding processing of polylactide. Ultrason. Sonochem. 2014, 21, 376–386. [Google Scholar] [CrossRef] [PubMed]

- Planellas, M.; Sacristán, M.; Rey, L.; Olmo, C.; Aymamí, J.; Casas, M.T.; del Valle, L.J.; Franco, L.; Puiggalí, J. Micro-molding with ultrasonic vibration energy: New method to disperse nanoclays in polymer matrices. Ultrason. Sonochem. 2014, 21, 1557–1569. [Google Scholar] [CrossRef] [PubMed]

- Nonhof, C.J.; Luiten, G.A. Estimates for process conditions during the ultrasonic welding of thermoplastics. Polym. Eng. Sci. 1996, 36, 1177–1183. [Google Scholar] [CrossRef]

- Tolunay, M.N.; Dawson, P.R.; Wang, K.K. Heating and bonding mechanisms in ultrasonic welding of thermoplastics. Polym. Eng. Sci. 1983, 23, 726–733. [Google Scholar] [CrossRef]

- Suresh, K.S.; Rani, M.R.; Prakasan, K.; Rudramoorthy, R. Modeling of temperature distribution in ultrasonic welding of thermoplastics for various joint designs. J. Mater. Process. Technol. 2007, 186, 138–146. [Google Scholar] [CrossRef]

- Mano, J.F.; Viana, J.C. Stress–strain experiments as a mechanical spectroscopic technique to characterise the glass transition dynamics in poly(ethylene terephthalate). Polym. Test. 2006, 25, 953–960. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Luo, Y.; Zhang, Z.; Wang, L. Study on heating process of ultrasonic welding for thermoplastics. J. Thermoplast. Compos. Mater. 2010, 23, 647–664. [Google Scholar] [CrossRef]

- Siddiq, A.; Ghassemieh, E. Thermomechanical analyses of ultrasonic welding process using thermal and acoustic softening effects. Mech. Mater. 2008, 40, 982–1000. [Google Scholar] [CrossRef]

- Benatar, A.; Gutowski, T.G. Ultrasonic welding of peek graphite apc-2 composites. Polym. Eng. Sci. 1989, 29, 1705–1721. [Google Scholar] [CrossRef]

- Lu, H.; Leng, J.; Du, S. A phenomenological approach for the chemo-responsive shape memory effect in amorphous polymers. Soft Matter 2013, 9, 3851–3858. [Google Scholar] [CrossRef]

- Ham, J.H.; Platzer, B. Semi-empirical equations for the residence time distributions in disperse systems—Part 1: Continuous phase. Chem. Eng. Technol. 2004, 27, 1172–1178. [Google Scholar] [CrossRef]

- Lionetto, F.; Maffezzoli, A. Polymer characterization by ultrasonic wave propagation. Adv. Polym. Technol. 2008, 27, 63–73. [Google Scholar] [CrossRef]

- Reynolds, W.N.; Scudder, L.P.; Pressman, H. The use of ultrasonic wave attenuation to monitor polymer and composite quality. Polym. Test. 1986, 6, 325–336. [Google Scholar] [CrossRef]

- Wortmann, F.J.; Schulz, K.V. Stress relaxation and time/temperature superposition of polypropylene fibres. Polymer 1995, 36, 315–321. [Google Scholar] [CrossRef]

- Schapery, R.A. Application of thermodynamics to thermomechanical, fracture, and birefringent phenomena in viscoelastic media. J. Appl. Phys. 1964, 35, 1451–1465. [Google Scholar] [CrossRef]

- Plazek, D.J. The temperature dependence of the viscoelastic behavior of poly(vinyl acetate). Polym. J. 1980, 12, 43–53. [Google Scholar] [CrossRef]

| Density [Kg/m3] | Heat conduction coefficient [W/m·°C] | Specific heat capacity [J/Kg·°C] | Glass transition temperature [°C] | E-modulus [GPa] | Poisson’s ratio |

|---|---|---|---|---|---|

| 1,166 | 0.18 | 1,828 | 105 | 3.3 | 0.345 |

| Parameter | Power (W) | Frequency (kHz) | Amplitude (μm) | Pressure (Mpa) |

|---|---|---|---|---|

| Value | 0–500 | 20 | 0–30 | 0–30 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, B.; Peng, H.; Wu, W.; Jia, Y.; Zhang, Y. Numerical Simulation and Experimental Investigation of the Viscoelastic Heating Mechanism in Ultrasonic Plasticizing of Amorphous Polymers for Micro Injection Molding. Polymers 2016, 8, 199. https://doi.org/10.3390/polym8050199

Jiang B, Peng H, Wu W, Jia Y, Zhang Y. Numerical Simulation and Experimental Investigation of the Viscoelastic Heating Mechanism in Ultrasonic Plasticizing of Amorphous Polymers for Micro Injection Molding. Polymers. 2016; 8(5):199. https://doi.org/10.3390/polym8050199

Chicago/Turabian StyleJiang, Bingyan, Huajian Peng, Wangqing Wu, Yunlong Jia, and Yingping Zhang. 2016. "Numerical Simulation and Experimental Investigation of the Viscoelastic Heating Mechanism in Ultrasonic Plasticizing of Amorphous Polymers for Micro Injection Molding" Polymers 8, no. 5: 199. https://doi.org/10.3390/polym8050199

APA StyleJiang, B., Peng, H., Wu, W., Jia, Y., & Zhang, Y. (2016). Numerical Simulation and Experimental Investigation of the Viscoelastic Heating Mechanism in Ultrasonic Plasticizing of Amorphous Polymers for Micro Injection Molding. Polymers, 8(5), 199. https://doi.org/10.3390/polym8050199