Physical and Mechanical Evaluation of Five Suture Materials on Three Knot Configurations: An in Vitro Study

Abstract

:1. Introduction

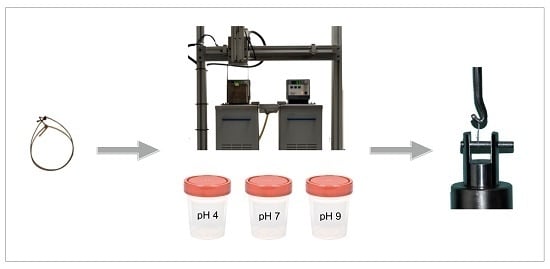

2. Material and Methods

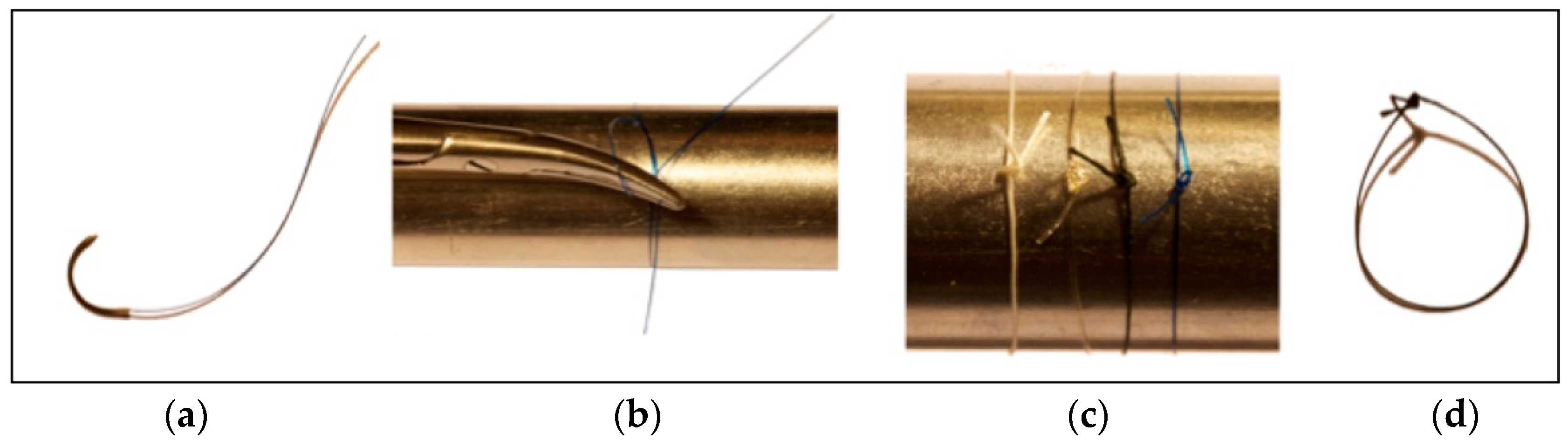

2.1. Sample Preparation

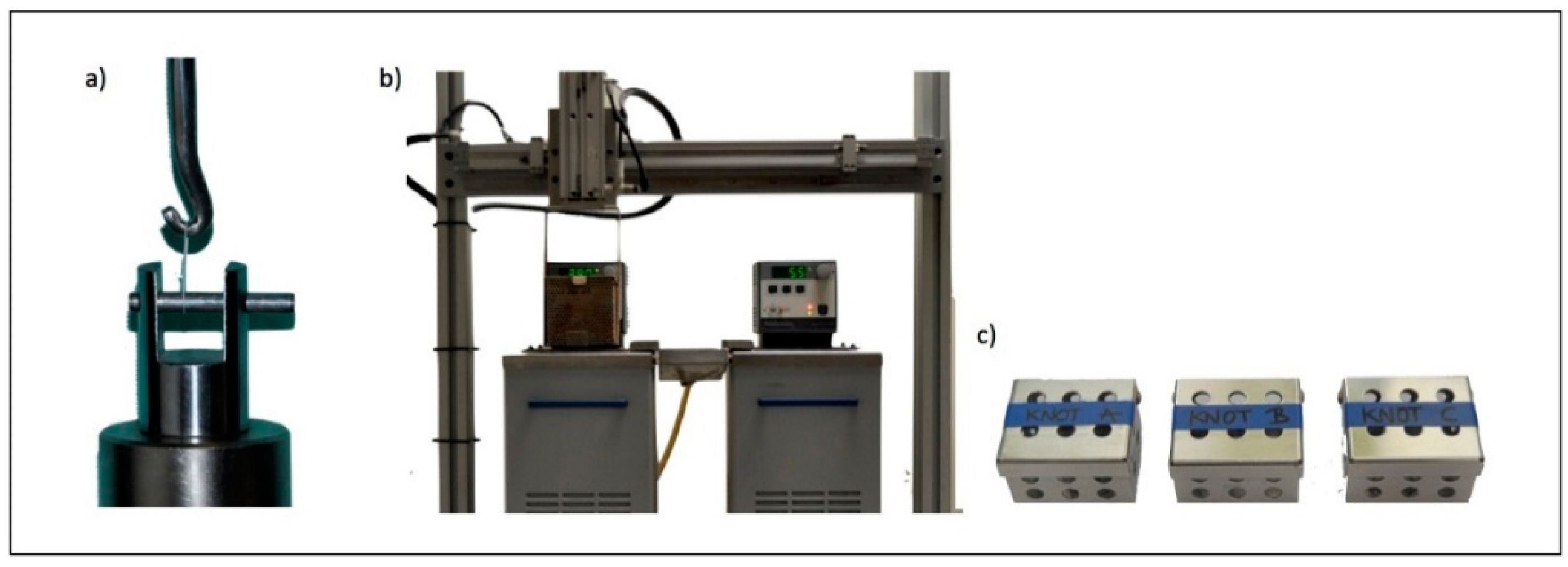

2.2. Mechanical Test

2.3. Physical Test

2.4. Study Groups

2.5. Statistical Analysis

3. Results

3.1. Mechanical Test

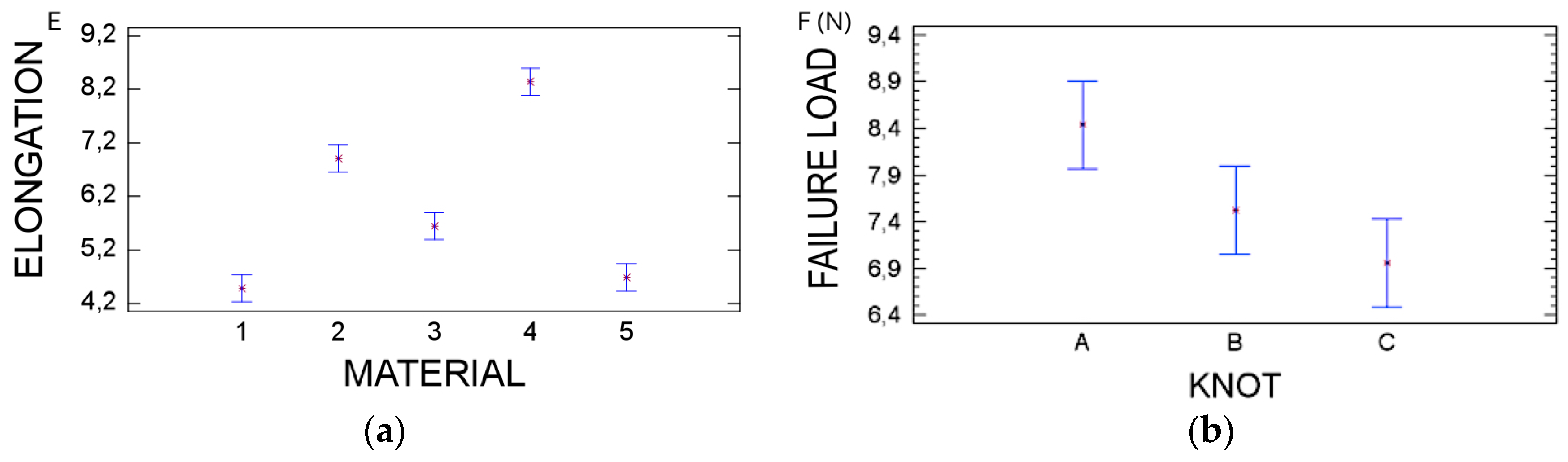

3.1.1. Analysis of Elongation

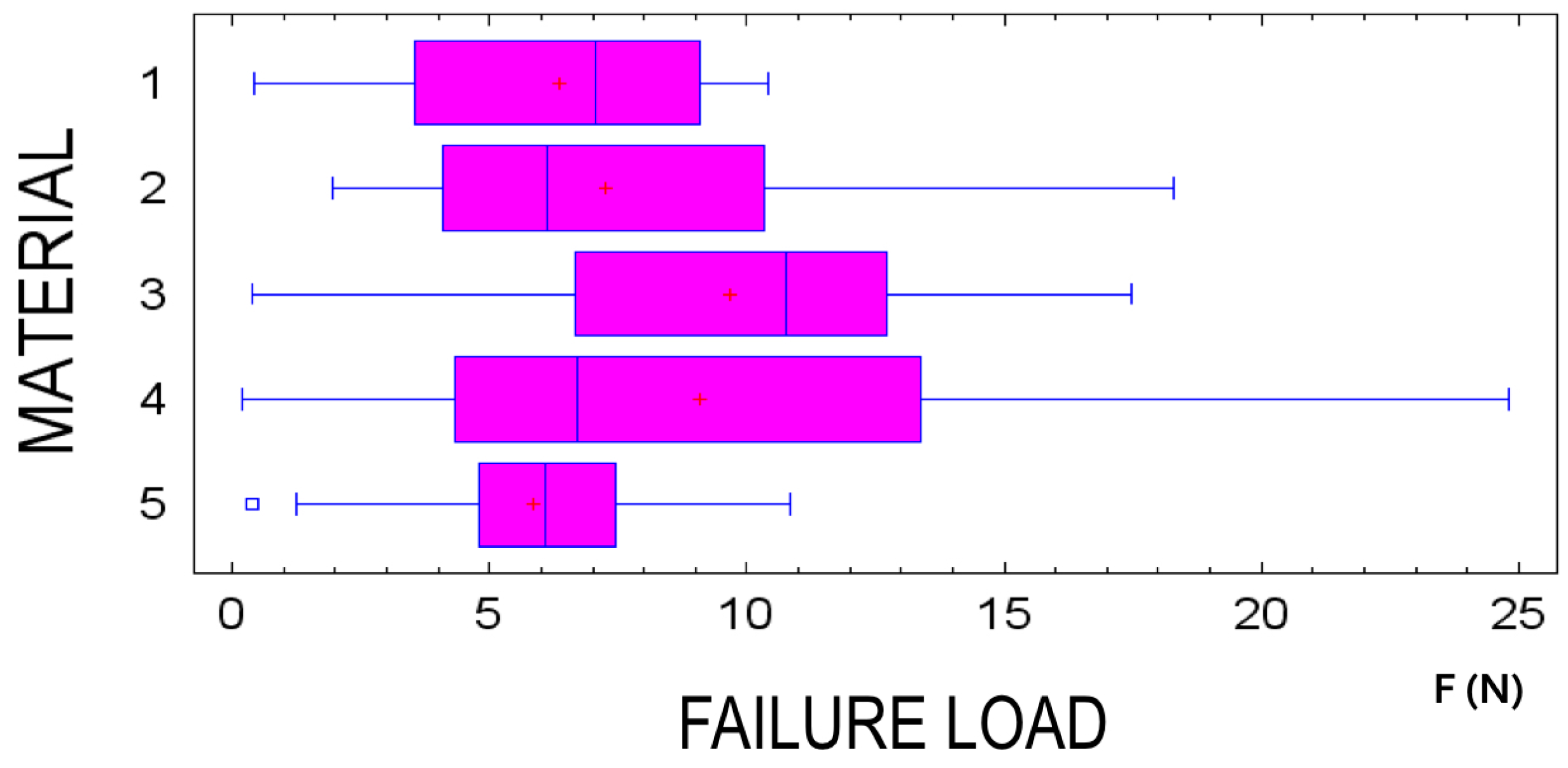

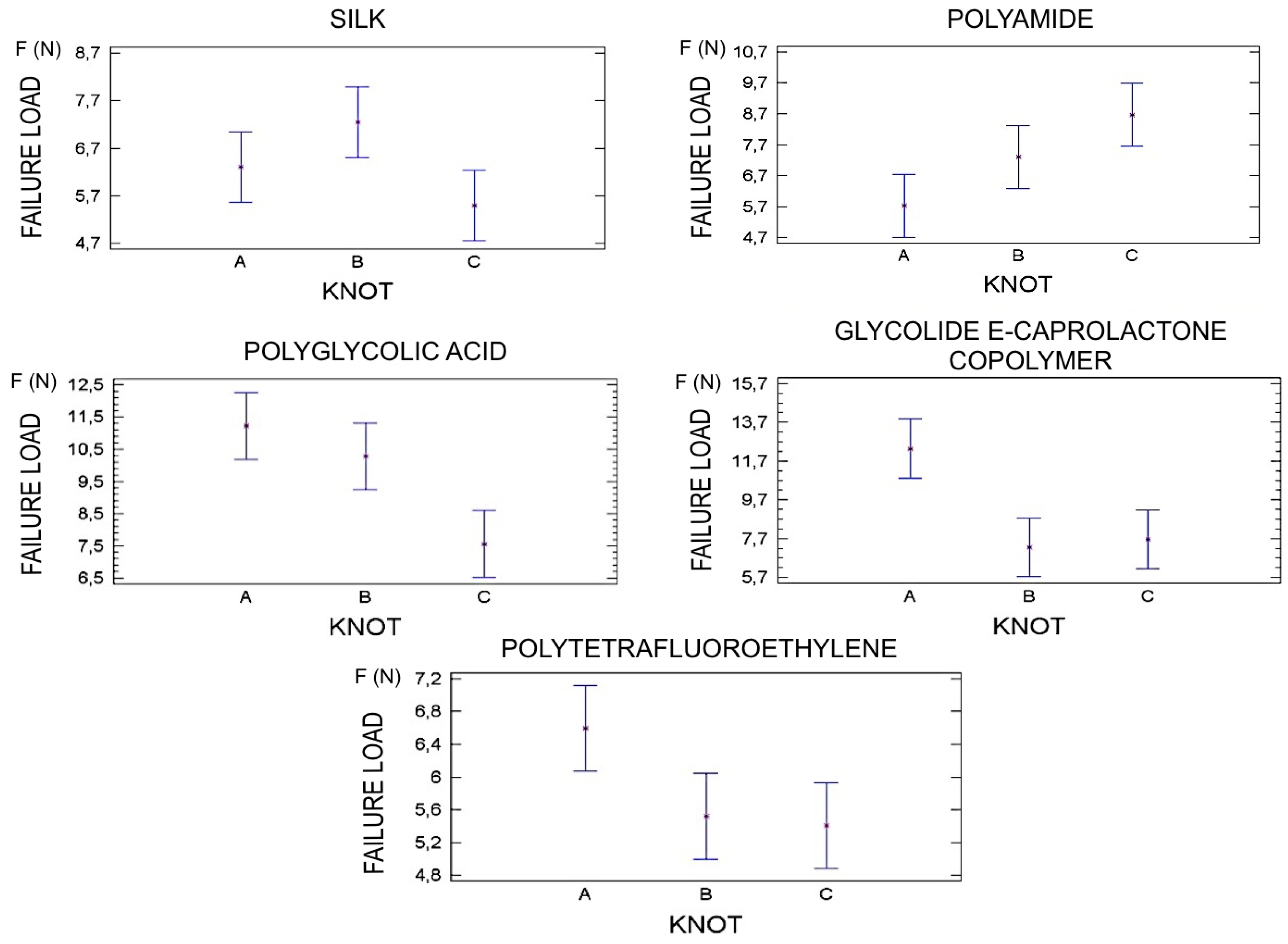

3.1.2. Failure Load Analysis

3.1.3. Physical Test

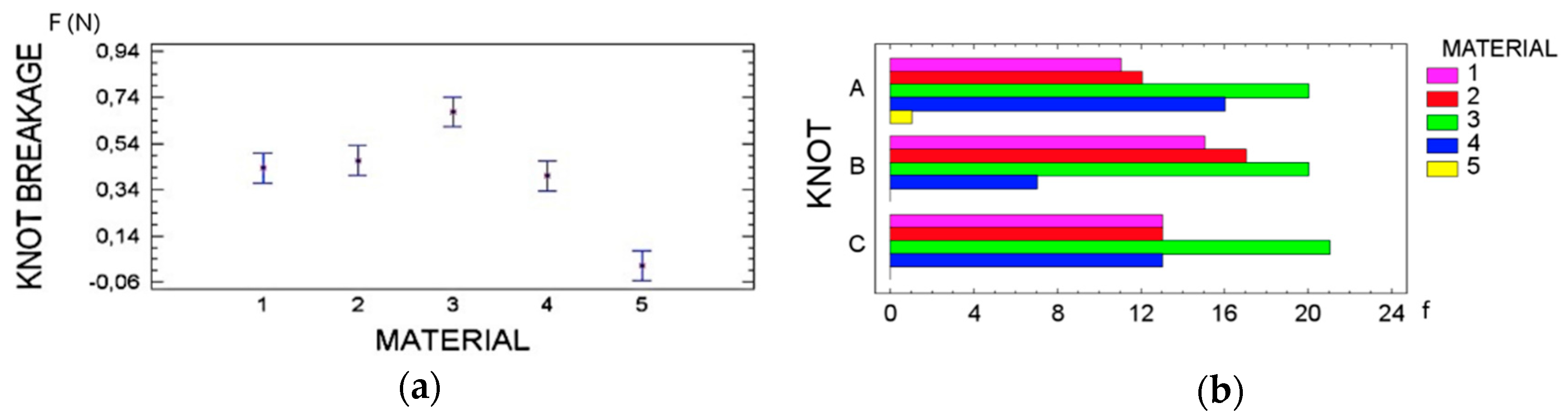

3.2. Influence of the Knot Configuration

3.2.1. Knot Failure Load

3.2.2. Knot Breakage or Slippage

4. Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Shaw, R.J.; Negus, T.W.; Mellor, T.K. A prospective clinical evaluation of the longevity of resorbable sutures in oral mucosa. Br. J. Oral Maxillofac. Surg. 1996, 34, 252–254. [Google Scholar] [CrossRef]

- Kim, J.C.; Lee, Y.K.; Lim, B.S.; Rhee, S.H.; Yang, H.C. Comparison of tensile and knot security properties of surgical sutures. J. Mater. Sci. Mater. Med. 2007, 18, 2363–2369. [Google Scholar] [CrossRef] [PubMed]

- Muffly, T.M.; Cook, C.; Distasio, J.; Bonham, A.J.; Blandon, R.E. Suture end length as a function of knot integrity. J. Surg. Educ. 2009, 66, 276–280. [Google Scholar] [CrossRef] [PubMed]

- Silverstein, L.H.; Kurtzman, G.M.; Shatz, P.C. Suturing for optimal soft tissue management. J. Oral Implantol. 2009, 35, 82–90. [Google Scholar] [CrossRef] [PubMed]

- Vasanthan, A.; Satheesh, K.; Hoopes, W.; Lucaci, P.; Williams, K.; Rapley, J. Comparing suture strengths for clinical applications: A novel in vitro study. J. Periodontol. 2009, 80, 618–624. [Google Scholar] [CrossRef] [PubMed]

- Moser, J.B.; Lautenschlager, E.P.; Horbal, B.J. Mechanical properties of polyglycolic acid sutures in oral surgery. J. Dent. Res. 1974, 53, 804–808. [Google Scholar] [CrossRef] [PubMed]

- Leknes, K.N.; Røynstrand, I.T.; Selvig, K.A. Human gingival tissue reactions to silk and expanded polytetrafluoroethylene sutures. J. Periodontol. 2005, 76, 34–42. [Google Scholar] [CrossRef] [PubMed]

- Hertweck, S.P.; von Fraunhofer, J.A.; Masterson, B.J. Tensile characteristics of PTFE sutures. Biomaterials 1988, 9, 457–459. [Google Scholar] [CrossRef]

- Edlich, R.F.; Panek, P.H.; Rodeheaver, G.T.; Turnbull, V.G.; Kurtz, L.D.; Edgerton, M.T. Physical and chemical configuration of sutures in the development of surgical infection. Ann. Surg. 1973, 177, 679–687. [Google Scholar] [CrossRef] [PubMed]

- Holmlund, W. Physical properties of surgical suture materials: Stress-strain relationship. Stress-relaxation and irreversible elongation. Ann. Surg. 1976, 184, 189–193. [Google Scholar] [CrossRef] [PubMed]

- Gale, M.S.; Darvell, B.W. Thermal cycling procedures for laboratory testing of dental restorations. J. Dent. 1999, 27, 89–99. [Google Scholar] [CrossRef]

- Selvig, K.A.; Biagiotti, G.R.; Leknes, K.N.; Wiskejo, U.M. Oral tissue reactions to suture materials. Int. J. Periodontics Restor. Dent. 1998, 8, 475–487. [Google Scholar]

- Yaltirik, M.; Dedeoglu, K.; Bilgi, B.; Koray, M.; Ersev, H.; Issever, H.; Dulger, O.; Soley, S. Comparison of four different suture materials in soft tissues of rats. Oral Dis. 2003, 9, 284–286. [Google Scholar] [CrossRef] [PubMed]

- Muffly, T.M.; Boyce, J.; Kieweg, S.L.; Bonham, A.J. Tensile strength of a surgeon’s or a square knot. J. Surg. Educ. 2010, 67, 222–226. [Google Scholar] [CrossRef] [PubMed]

- Fong, T.C.; Saba, N.; Liew, C.K.; De Silva, M.; Enamul Hoque, M.; Goh, K.L. Yarn flax fibres for polymer-coated sutures and hand layup polymer composite laminates. In Manufacturing of Natural Fibre Reinforced Polymer Composites; Springer International Publishing: Cham, Switzerland, 2015; pp. 155–173. [Google Scholar]

- Lim, B.H.; Ooi, L.H.; Chou, S.M.; Goh, K.L. Biomechanical properties of extensor tendon repair using the six-strand single-loop suture technique: A comparative analysis with three other techniques in cadaveric models. J. Mech. Med. Biol. 2011, 11, 845–855. [Google Scholar] [CrossRef]

- Chu, C.C.; Moncrief, G. An in vitro evaluation of the stability of mechanical properties of surgical suture materials in various pH conditions. Ann. Surg. 1983, 198, 223–228. [Google Scholar] [CrossRef] [PubMed]

- Chu, C.C. A comparison of the effect of pH on the biodegradation of two syntethic absorbable sutures. Ann. Surg. 1982, 195, 55–59. [Google Scholar] [CrossRef] [PubMed]

| Suture material | Codification | Composition | Structure | Degradation |

|---|---|---|---|---|

| Silk 1 | SILK | Natural | Multifilament | Non absorbable |

| Polyamide 2 | PV | Synthetic | Monofilament | Non absorbable |

| Polyglycolic acid 3 | AP7 | Synthetic | Multifilament | Absorbable |

| Glycolide-e-caprolactone copolymer 4 | GC7 | Synthetic | Monofilament | Absorbable |

| Polytetrafluoroethylene 5 | PTFE | Synthetic | Monofilament | Non absorbable |

| Variables | Interactions | p-Value |

|---|---|---|

| A: material | AB | <0.001 * |

| B: knot | CF | 0.404 |

| C: group | DA | <0.001 * |

| D: knot breakage | DB | <0.001 * |

| E: elongation | AE | <0.001 * |

| F: failure load | FB | 0.008 * |

| F: failure load | FA | <0.001 * |

| Material | Knot configuration | Analysis of failure load (N) | ||

|---|---|---|---|---|

| Mean | Variance | Standard deviation | ||

| SILK | A | 6.298 | 8.477 | 2.911 |

| SILK | B | 7.242 | 7.941 | 2.818 |

| SILK | C | 5.494 | 8.534 | 2.921 |

| PV | A | 5.738 | 6.435 | 2.536 |

| PV | B | 7.301 | 18.288 | 4.276 |

| PV | C | 8.665 | 22.652 | 4.759 |

| AP7 | A | 11.218 | 15.528 | 3.94 |

| AP7 | B | 10.276 | 19.614 | 4.428 |

| AP7 | C | 7.557 | 13.912 | 3.729 |

| GC7 | A | 12.342 | 48.637 | 6.974 |

| GC7 | B | 7.252 | 24.767 | 4.976 |

| GC7 | C | 7.668 | 31.942 | 5.651 |

| PTFE | A | 6.593 | 2.593 | 1.61 |

| PTFE | B | 5.521 | 3.55 | 1.884 |

| PTFE | C | 5.41 | 6.414 | 2.532 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abellán, D.; Nart, J.; Pascual, A.; Cohen, R.E.; Sanz-Moliner, J.D. Physical and Mechanical Evaluation of Five Suture Materials on Three Knot Configurations: An in Vitro Study. Polymers 2016, 8, 147. https://doi.org/10.3390/polym8040147

Abellán D, Nart J, Pascual A, Cohen RE, Sanz-Moliner JD. Physical and Mechanical Evaluation of Five Suture Materials on Three Knot Configurations: An in Vitro Study. Polymers. 2016; 8(4):147. https://doi.org/10.3390/polym8040147

Chicago/Turabian StyleAbellán, Desire, José Nart, Andrés Pascual, Robert E. Cohen, and Javier D. Sanz-Moliner. 2016. "Physical and Mechanical Evaluation of Five Suture Materials on Three Knot Configurations: An in Vitro Study" Polymers 8, no. 4: 147. https://doi.org/10.3390/polym8040147

APA StyleAbellán, D., Nart, J., Pascual, A., Cohen, R. E., & Sanz-Moliner, J. D. (2016). Physical and Mechanical Evaluation of Five Suture Materials on Three Knot Configurations: An in Vitro Study. Polymers, 8(4), 147. https://doi.org/10.3390/polym8040147