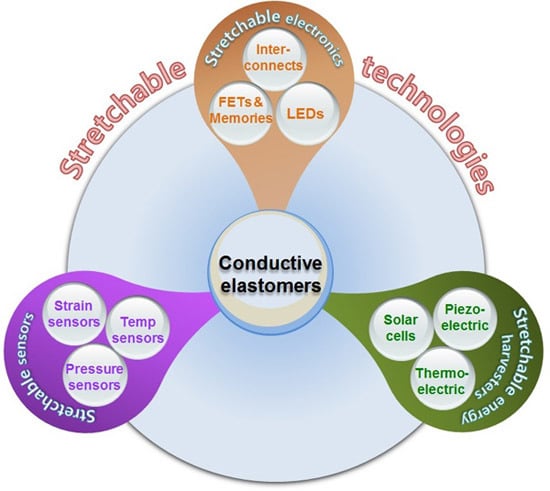

Conductive Elastomers for Stretchable Electronics, Sensors and Energy Harvesters

Abstract

:1. Introduction

2. Stretchable Electronics

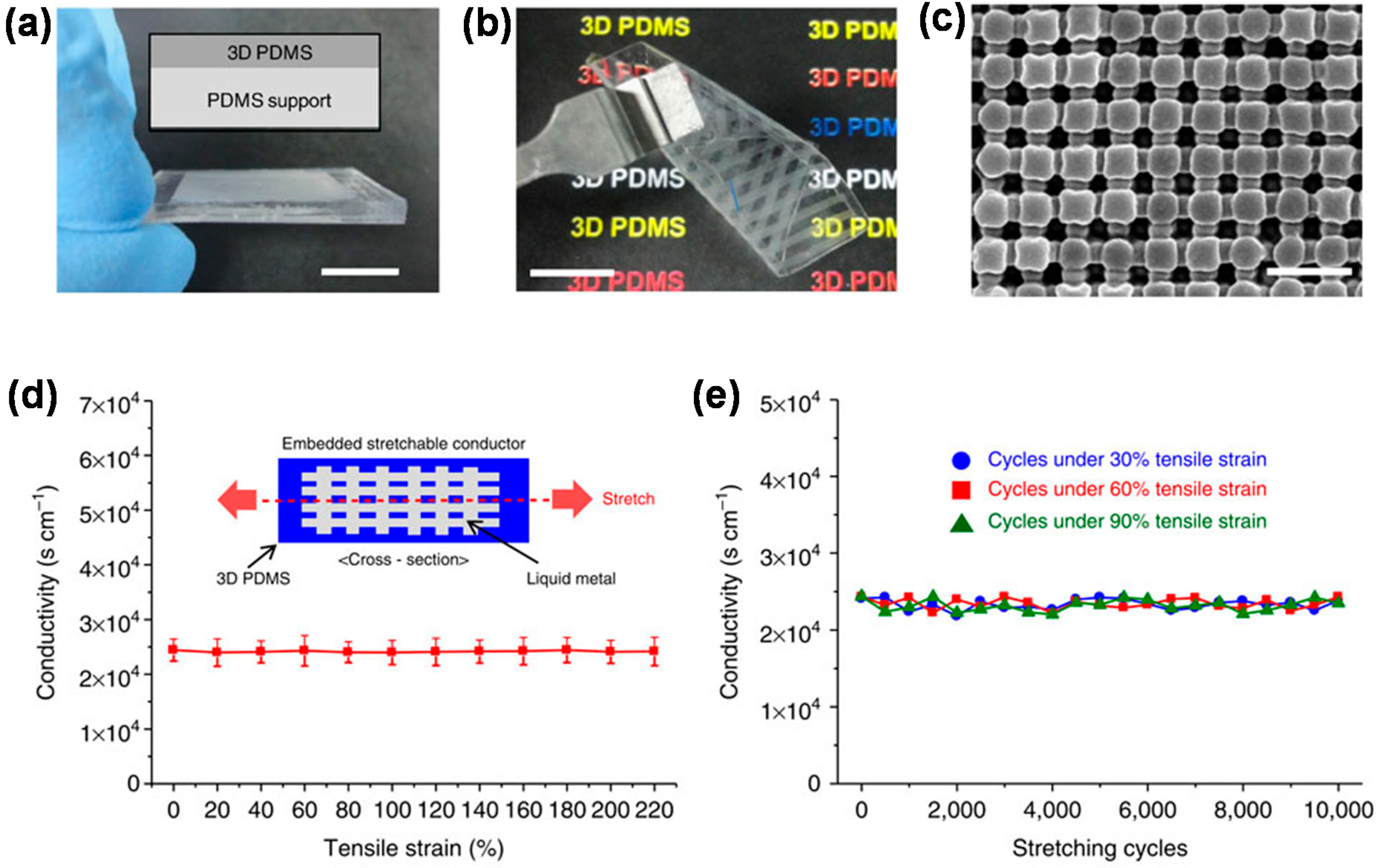

2.1. Stretchable Conductors

2.2. Stretchable Field-Effect Transistors and Memories

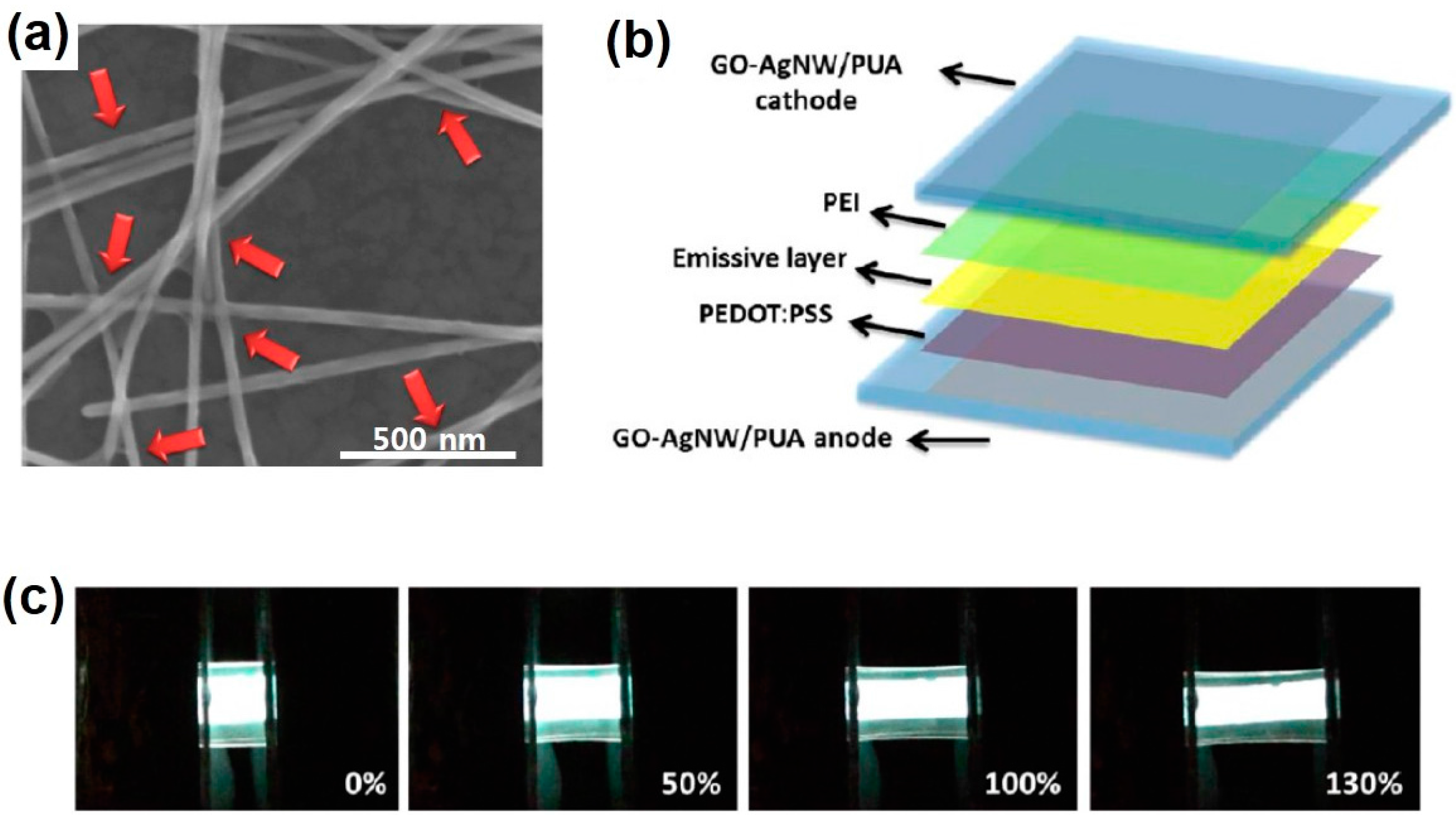

2.3. Stretchable Light-Emitting Diodes

2.4. Brief Summary

3. Stretchable Sensors

3.1. Stretchable Strain Sensors

3.2. Stretchable Pressure Sensors

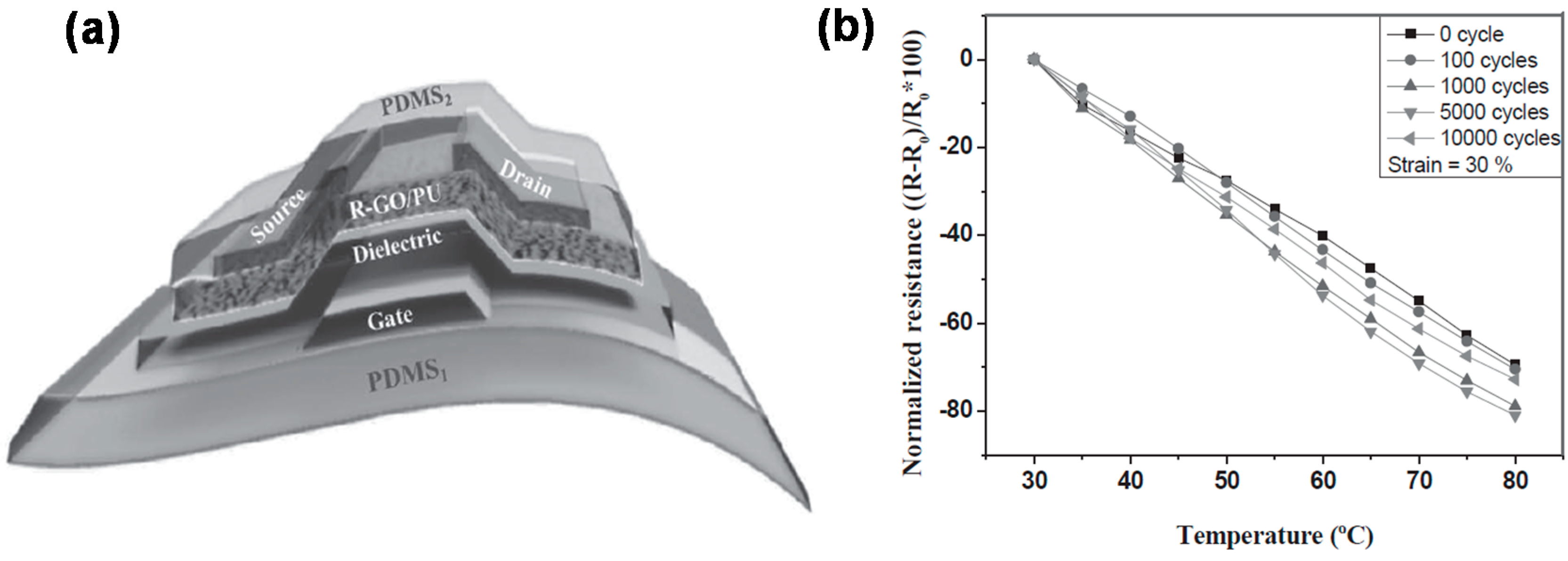

3.3. Stretchable Temperature Sensors

3.4. Brief Summary

4. Stretchable Energy Harvesters

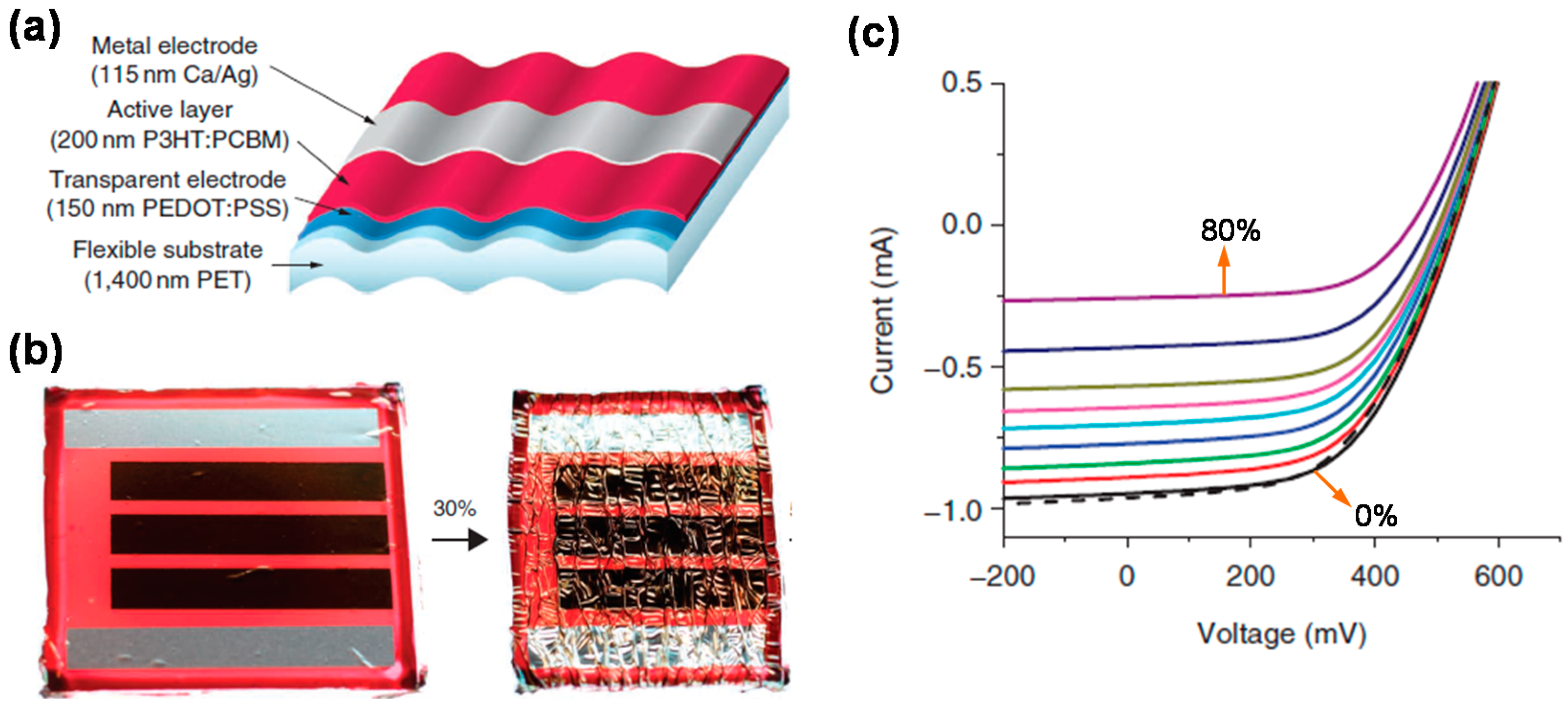

4.1. Stretchable Solar Cells

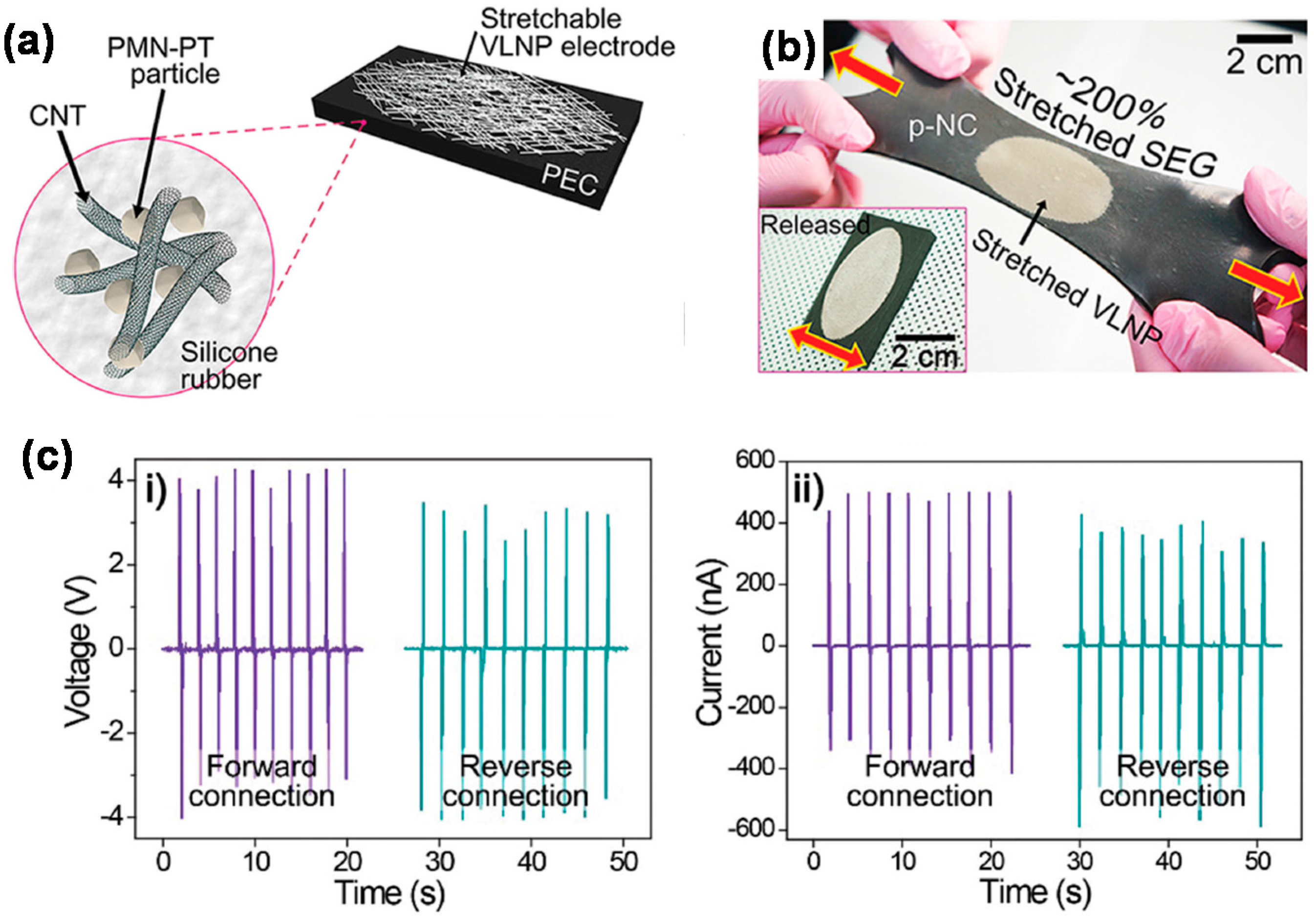

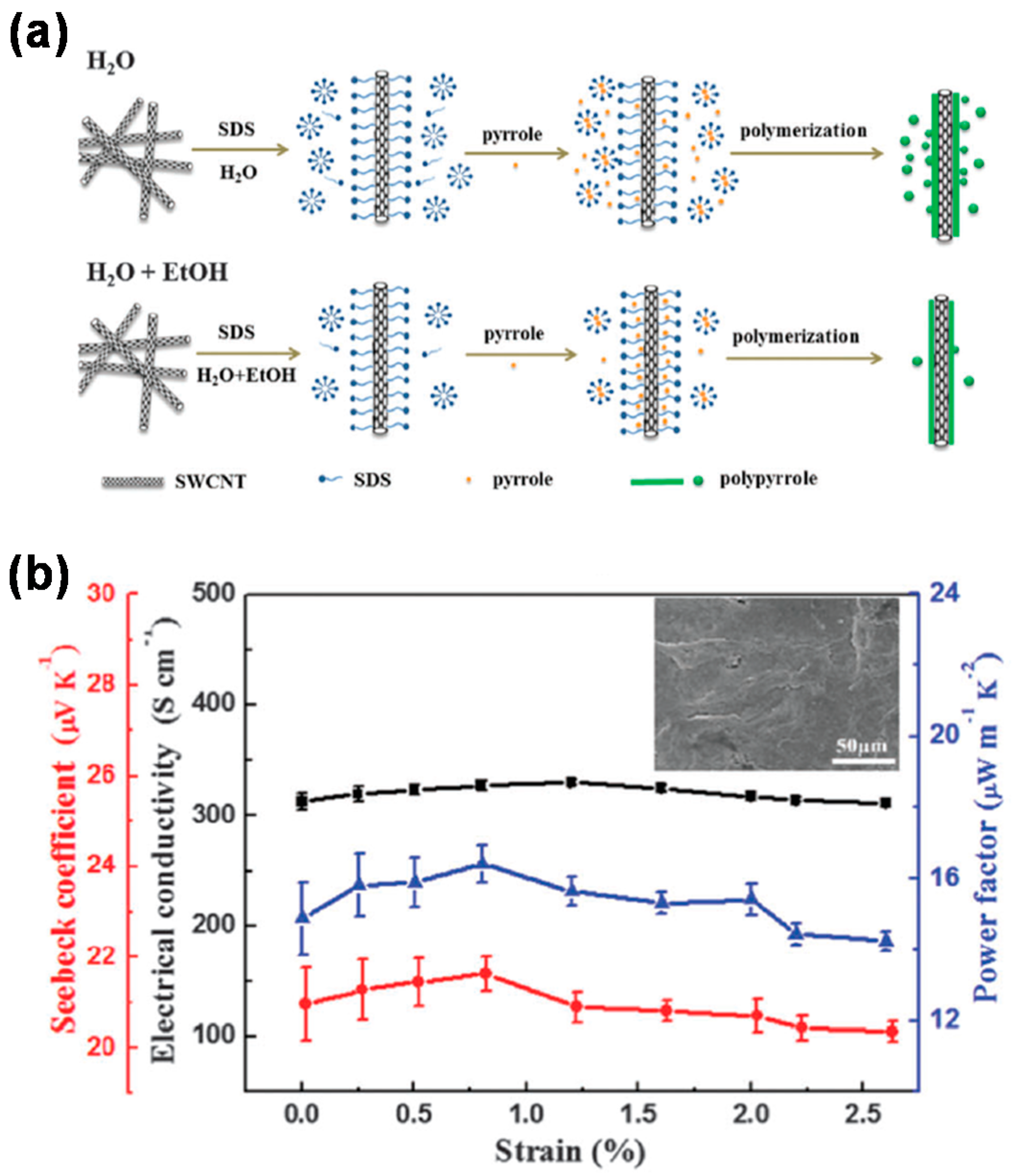

4.2. Other Stretchable Energy Harvesters

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and mechanics for stretchable electronics. Science 2010, 327, 1603–1607. [Google Scholar] [CrossRef] [PubMed]

- Someya, T.; Kato, Y.; Sekitani, T.; Iba, S.; Noguchi, Y.; Murase, Y.; Kawaguchi, H.; Sakurai, T. Conformable, flexible, large-area networks of pressure and thermal sensors with organic transistor active matrixes. Proc. Natl. Acad. Sci. USA 2005, 102, 12321–12325. [Google Scholar] [CrossRef] [PubMed]

- Ahn, J.H.; Je, J.H. Stretchable electronics: Materials, architectures and integrations. J. Phys. D Appl. Phys. 2012, 45, 103001. [Google Scholar] [CrossRef]

- Kim, D.H.; Rogers, J.H. Stretchable electronics: Materials strategies and devices. Adv. Mater. 2008, 20, 4887–4892. [Google Scholar] [CrossRef]

- Benight, S.J.; Wang, C.; Tok, J.B.H.; Bao, Z. Stretchable and self-healing polymers and devices for electronic skin. Prog. Polym. Sci. 2013, 38, 1961–1977. [Google Scholar] [CrossRef]

- Chortos, A.; Bao, Z. Skin-inspired electronic devices. Mater. Today 2014, 17, 321–331. [Google Scholar] [CrossRef]

- Chou, H.H.; Nguyen, A.; Chortos, A.; To, J.W.F.; Lu, C.; Mei, J.; Kurosawa, T.; Bae, W.G.; Tok, J.B.H.; Bao, Z. A chameleon-inspired stretchable electronic skin with interactive colour changing controlled by tactile sensing. Nat. Commun. 2015, 6, 8011. [Google Scholar] [CrossRef] [PubMed]

- Tamai, T. Electrical properties of conductive elastomer as electrical contact material. IEEE Trans. Compon. Hybrids Manuf. Technol. 1982, 5, 56–61. [Google Scholar] [CrossRef]

- Faez, R.; Schuster, R.H.; de Paoli, M.A. A conductive elastomer based on EPDM and polyaniline II. Effect of the crosslinking method. Eur. Polym. J. 2002, 38, 2459–2463. [Google Scholar] [CrossRef]

- Saleem, A.; Frormann, L.; Soever, A. Fabrication of extrinsically conductive silicone rubbers with high elasticity and analysis of their mechanical and electrical characteristics. Polymers 2010, 2, 200–210. [Google Scholar] [CrossRef]

- Lam, J.W.Y.; Tang, B.Z. Functional polyacetylenes. Acc. Chem. Res. 2005, 38, 745–754. [Google Scholar] [CrossRef] [PubMed]

- Bhadra, S.; Khastgir, D.; Singha, N.K.; Lee, J.H. Progress in preparation, processing and applications of polyaniline. Prog. Polym. Sci. 2009, 34, 783–810. [Google Scholar] [CrossRef]

- Wang, L.X.; Li, X.G.; Yang, Y.L. Preparation, properties and applications of polypyrroles. React. Funct. Polym. 2001, 47, 125–139. [Google Scholar] [CrossRef]

- Das, T.K.; Prusty, S. Review on conducting polymers and their applications. Polym. Plast. Technol. Eng. 2012, 51, 1487–1500. [Google Scholar] [CrossRef]

- Balint, R.; Cassidy, N.J.; Cartmell, S.H. Conductive polymers: Towards a smart biomaterial for tissue engineering. Acta Biomater. 2014, 10, 2341–2353. [Google Scholar] [CrossRef] [PubMed]

- Lang, U.; Naujoks, N.; Dual, J. Mechanical characterization of PEDOT:PSS thin films. Synth. Met. 2009, 159, 473–479. [Google Scholar] [CrossRef]

- Sadhu, S.; Bhowmick, A.K. Preparation and properties of nanocomposites based on acrylonitrile–butadiene rubber, styrene–butadiene rubber, and polybutadiene rubber. J. Polym. Sci. B Polym. Phys. 2004, 42, 1573–1585. [Google Scholar] [CrossRef]

- Ghosh, P.; Chakrabarti, A. Conducting carbon black filled EPDM vulcanizates: Assessment of dependence of physical and mechanical properties and conducting character on variation of filler loading. Eur. Polym. J. 2000, 36, 1043–1054. [Google Scholar] [CrossRef]

- Kojio, K.; Furukawa, M.; Nonaka, Y.; Nakamura, S. Control of mechanical properties of thermoplastic polyurethane elastomers by restriction of crystallization of soft segment. Materials 2010, 3, 5097–5110. [Google Scholar] [CrossRef]

- Kim, T.K.; Kim, J.K.; Jeong, O.C. Measurement of nonlinear mechanical properties of PDMS elastomer. Microelectron. Eng. 2011, 88, 1982–1985. [Google Scholar] [CrossRef]

- Bhattacharyya, S.; Sinturel, C.; Bahloul, O.; Saboungi, M.L.; Thomas, S.; Salvetat, J.P. Improving reinforcement of natural rubber by networking of activated carbon nanotubes. Carbon 2008, 46, 1037–1045. [Google Scholar] [CrossRef]

- Xiong, J.; Zheng, Z.; Qin, X.; Li, M.; Li, H.; Wang, X. The thermal and mechanical properties of a polyurethane/multiwalled carbon nanotube composite. Carbon 2006, 44, 2701–2707. [Google Scholar] [CrossRef]

- Bokobza, L. Multiwall carbon nanotube elastomeric composites: A review. Polymer 2007, 48, 4907–4920. [Google Scholar] [CrossRef]

- Bokobza, L.; Garnaud, G.; Mark, J.E. Effects of filler particle/elastomer distribution and interaction on composite mechanical properties. Chem. Mater. 2002, 14, 162–167. [Google Scholar] [CrossRef]

- Liu, X.; Kuang, W.; Guo, B. Preparation of rubber/graphene oxide composites with in-situ interfacial design. Polymer 2015, 56, 553–562. [Google Scholar] [CrossRef]

- Chen, L.; Lu, L.; Wu, D.; Chen, G. Silicone rubber/graphite nanosheet electrically conducting nanocomposite with a low percolation threshold. Polym. Compos. 2007, 28, 493–498. [Google Scholar] [CrossRef]

- Araby, S.; Meng, Q.; Zhang, L.; Kang, H.; Majewski, P.; Tang, Y.; Ma, J. Electrically and thermally conductive elastomer/graphene nanocomposites by solution mixing. Polymer 2014, 55, 201–210. [Google Scholar] [CrossRef]

- Perez, L.D.; Zuluaga, M.A.; Kyu, T.; Mark, J.E.; Lopez, B.L. Preparation, characterization, and physical properties of multiwall carbon nanotube/elastomer composites. Polym. Eng. Sci. 2009, 49, 866–874. [Google Scholar] [CrossRef]

- Thakur, M. A class of conducting polymers having nonconjugated backbones. Macromolecules 1988, 21, 661–664. [Google Scholar] [CrossRef]

- Faseena, N.M.; Santhamma, G.; Mathew, A.M.; Padmanabhan, P. Styrene butadiene copolymer-based transparent conducting thin films: Effect of dopants. J. Elastom. Plast. 2014, 46, 325–337. [Google Scholar] [CrossRef]

- Carone, E.; D’Ilario, L.; Martinelli, A. New conducting thermoplastic elastomers. I. Synthesis and chemical characterization. J. Appl. Polym. Sci. 2002, 83, 857–867. [Google Scholar] [CrossRef]

- Abbati, G.; Carone, E.; D’Ilario, L.; Martinelli, A. Polyurethane–polyaniline conducting graft copolymer with improved mechanical properties. J. Appl. Polym. Sci. 2003, 89, 2516–2521. [Google Scholar] [CrossRef]

- Vicentini, D.S.; Barra, G.M.O.; Bertolino, J.R.; Pires, A.T.N. Polyaniline/thermoplastic polyurethane blends: Preparation and evaluation of electrical conductivity. Eur. Polym. J. 2007, 43, 4565–4572. [Google Scholar] [CrossRef]

- Yoshikawa, H.; Hino, T.; Kuramoto, N. Effect of temperature and moisture on electrical conductivity in polyaniline/polyurethane (PANI/PU) blends. Synth. Met. 2006, 156, 1187–1193. [Google Scholar] [CrossRef]

- Hansen, T.S.; West, K.; Hassager, O.; Larsen, N.B. Highly stretchable and conductive polymer material made from poly(3,4-ethylenedioxythiophene) and polyurethane elastomers. Adv. Funct. Mater. 2007, 17, 3069–3073. [Google Scholar] [CrossRef]

- Lacour, S.P.; Jones, J.; Wagner, S.; Li, T.; Suo, Z. Stretchable interconnects for elastic electronic surfaces. Proc. IEEE 2005, 93, 1459–1467. [Google Scholar] [CrossRef]

- Lacour, S.P.; Tsay, C.; Wagner, S. An elastically stretchable TFT circuit. IEEE Electron Device Lett. 2004, 25, 792–794. [Google Scholar] [CrossRef]

- Kim, D.H.; Ahn, J.H.; Choi, W.M.; Kim, H.S.; Kim, T.H.; Song, J.; Huang, Y.Y.; Liu, Z.; Lu, C.; Rogers, J.A. Stretchable and foldable silicon integrated circuits. Science 2008, 320, 507–511. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Choi, W.M.; Jiang, H.; Huang, Y.Y.; Rogers, J.A. Controlled buckling of semiconductor nanoribbons for stretchable electronics. Nat. Nanotechnol. 2006, 1, 201–207. [Google Scholar] [CrossRef] [PubMed]

- Rogers, J.A.; Huang, Y. A curvy, stretchy future for electronics. Proc. Natl Acad. Sci. USA 2009, 106, 10875–10876. [Google Scholar] [CrossRef] [PubMed]

- Park, C.W.; Jung, S.W.; Lim, S.C.; Oh, J.Y.; Na, B.S.; Lee, S.S.; Chu, H.Y.; Koo, J.B. Fabrication of well-controlled wavy metal interconnect structures on stress-free elastomeric substrates. Microelectron. Eng. 2014, 113, 55–60. [Google Scholar] [CrossRef]

- Brosteaux, D.; Axisa, F.; Gonzalez, M.; Vanfleteren, J. Design and fabrication of elastic interconnections for stretchable electronic circuits. IEEE Electron Device Lett. 2007, 28, 552–554. [Google Scholar] [CrossRef]

- Hilbich, D.; Yu, G.; Gray, B.L.; Shannon, L. Characterization of stretchable interconnects fabricated using a low cost metallization transfer process onto PDMS. ECS J. Solid State Sci. Technol. 2015, 4, S3030–S3033. [Google Scholar] [CrossRef]

- Hsu, Y.Y.; Gonzalez, M.; Bossuyt, F.; Vanfleteren, J.; de Wolf, I. Polyimide-enhanced stretchable interconnects: Design, fabrication, and characterization. IEEE Trans. Electron Devices 2011, 58, 2680–2688. [Google Scholar] [CrossRef]

- Faez, R.; Gazotti, W.A.; De Paoli, M.A. An elastomeric conductor based on polyaniline prepared by mechanical mixing. Polymer 1999, 40, 5497–5503. [Google Scholar] [CrossRef]

- Stoyanov, H.; Kollosche, M.; Risse, S.; Waché, R.; Kofod, G. Soft conductive elastomer materials for stretchable electronics and voltage controlled artificial muscles. Adv. Mater. 2013, 25, 578–583. [Google Scholar] [CrossRef] [PubMed]

- El-Tantawy, F.; Aal, N.A.; Al-Ghamdi, A.A.; El-Moss, E.H. New smart conducting elastomer blends of Bi-based superconductor ceramics nanoparticles reinforced natural rubber/low-density polyethylene for double thermistors, antistatic protectors, and electromagnetic interference shielding effectiveness applications. Polym. Eng. Sci. 2009, 49, 592–601. [Google Scholar] [CrossRef]

- Khan, U.; May, P.; O’Neill, A.; Coleman, J.N. Development of stiff, strong, yet tough composites by the addition of solvent exfoliated graphene to polyurethane. Carbon 2010, 48, 4035–4041. [Google Scholar] [CrossRef]

- Shang, S.; Zeng, W.; Tao, X. High stretchable MWNTs/polyurethane conductive nanocomposites. J. Mater. Chem. 2011, 21, 7274–7280. [Google Scholar] [CrossRef]

- Lee, J.B.; Khang, D.Y. Electrical and mechanical characterization of stretchable multi-walled carbon nanotubes/polydimethylsiloxane elastomeric composite conductors. Compos. Sci. Technol. 2012, 72, 1257–1263. [Google Scholar] [CrossRef]

- Lee, Y.R.; Raghu, A.V.; Jeong, H.M.; Kim, B.K. Properties of waterborne polyurethane/functionalized graphene sheet nanocomposites prepared by an in situ method. Macromol. Chem. Phys. 2009, 210, 1247–1254. [Google Scholar] [CrossRef]

- Chen, M.; Tao, T.; Zhang, L.; Gao, W.; Li, C. Highly conductive and stretchable polymer composites based on graphene/MWCNT network. Chem. Commun. 2013, 49, 1612–1614. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.P.; Weiss, R.A.; Gan, P.P.; Bessette, M.D. Conductive elastomeric foams prepared by in situ vapor phase polymerization of pyrrole and copolymerization of pyrrole and N-methyl pyrrole. Polym. Eng. Sci. 1998, 38, 857–862. [Google Scholar] [CrossRef]

- Ge, J.; Yao, H.B.; Wang, X.; Ye, Y.D.; Wang, J.L.; Wu, Z.Y.; Liu, J.W.; Fan, F.J.; Gao, H.L.; Zhang, C.L.; et al. Stretchable conductors based on silver nanowires: Improved performance through a binary network design. Angew. Chem. Int. Ed. 2013, 52, 1654–1659. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Wang, S.; Li, M.; Ahn, C.; Hyun, J.K.; Kim, D.S.; Kim, D.K.; Rogers, J.A.; Huang, Y.; Jeon, S. Three-dimensional nanonetworks for giant stretchability in dielectrics and conductors. Nat. Commun. 2012, 3, 916. [Google Scholar] [CrossRef] [PubMed]

- Noh, J.S. Highly conductive and stretchable poly(dimethylsiloxane):poly(3,4-ethylenedioxythiophene): poly(styrene sulfonic acid) blends for organic interconnects. RSC Adv. 2014, 4, 1857–1863. [Google Scholar] [CrossRef]

- Kim, K.H.; Vural, M.; Islam, M.F. Single-walled carbon nanotube aerogel-based elastic conductors. Adv. Mater. 2011, 23, 2865–2869. [Google Scholar] [CrossRef] [PubMed]

- Shin, M.K.; Oh, J.; Lima, M.; Kozlov, M.E.; Kim, S.J.; Baughman, R.H. Elastomeric conductive composites based on carbon nanotube forests. Adv. Mater. 2010, 22, 2663–2667. [Google Scholar] [CrossRef] [PubMed]

- Kuilla, T.; Bhadra, S.; Yao, D.; Kim, N.H.; Bose, S.; Lee, J.H. Recent advances in graphene based polymer composites. Prog. Polym. Sci. 2010, 35, 1350–1375. [Google Scholar] [CrossRef]

- Xu, F.; Zhu, Y. Highly conductive and stretchable silver nanowire conductors. Adv. Mater. 2012, 24, 5117–5122. [Google Scholar] [CrossRef] [PubMed]

- Lee, P.; Lee, J.; Lee, H.; Yeo, J.; Hong, S.; Nam, K.H.; Lee, D.; Lee, S.S.; Ko, S.H. Highly stretchable and highly conductive metal electrode by very long metal nanowire percolation network. Adv. Mater. 2012, 24, 3326–3332. [Google Scholar] [CrossRef] [PubMed]

- Araki, T.; Nogi, M.; Suganuma, K.; Kogure, M.; Kirihara, O. Printable and stretchable conductive wirings comprising silver flakes and elastomers. IEEE Electron Device Lett. 2011, 32, 1424–1426. [Google Scholar] [CrossRef]

- Kim, Y.; Zhu, J.; Yeom, B.; Prima, M.D.; Su, X.; Kim, J.G.; Yoo, S.J.; Uher, C.; Kotov, N.A. Stretchable nanoparticle conductors with self-organized conductive pathways. Nature 2013, 500, 59–64. [Google Scholar] [CrossRef] [PubMed]

- Shin, G.; Yoon, C.H.; Bae, M.Y.; Kim, Y.C.; Hong, S.K.; Rogers, J.A.; Ha, J.S. Stretchable field-effect-transistor array of suspended SnO2 nanowires. Small 2011, 7, 1181–1185. [Google Scholar] [CrossRef] [PubMed]

- Sekitani, T.; Noguchi, Y.; Hata, K.; Fukushima, T.; Aida, T.; Someya, T. A rubberlike stretchable active matrix using elastic conductors. Science 2008, 321, 1468–1472. [Google Scholar] [CrossRef] [PubMed]

- Shin, M.; Song, J.H.; Lim, G.H.; Lim, B.; Park, J.J.; Jeong, U. Highly stretchable polymer transistors consisting entirely of stretchable device components. Adv. Mater. 2014, 26, 3706–3711. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, J.; Chu, C.W.; Szmanda, C.R.; Ma, L.; Yang, Y. Programmable polymer thin film and non-volatile memory device. Nat. Mater. 2004, 3, 918–922. [Google Scholar] [CrossRef] [PubMed]

- Ji, Y.; Zeigler, D.F.; Lee, D.S.; Choi, H.; Jen, A.K.Y.; Ko, H.C.; Kim, T.W. Flexible and twistable non-volatile memory cell array with all-organic one diode-one resistor architecture. Nat. Commun. 2013, 4, 2707. [Google Scholar] [CrossRef] [PubMed]

- Lai1, Y.C.; Huang, Y.C.; Lin, T.Y.; Wang, Y.X.; Chang, C.Y.; Li, Y.; Lin, T.Y.; Ye, B.W.; Hsieh, Y.P.; Su, W.F.; et al. Stretchable organic memory: Toward learnable and digitized stretchable electronic applications. NPG Asia Mater. 2014, 6, e87. [Google Scholar] [CrossRef]

- Kim, R.H.; Bae, M.H.; Kim, D.G.; Cheng, H.; Kim, B.H.; Kim, D.H.; Li, M.; Wu, J.; Du, F.; Kim, H.S.; et al. Stretchable, transparent graphene interconnects for arrays of microscale inorganic light emitting diodes on rubber substrates. Nano Lett. 2011, 11, 3881–3886. [Google Scholar] [CrossRef] [PubMed]

- Park, S.I.; Xiong, Y.; Kim, R.H.; Elvikis, P.; Meitl, M.; Kim, D.H.; Wu, J.; Yoon, J.; Yu, C.J.; Liu, Z.; et al. Printed assemblies of inorganic light-emitting diodes for deformable and semitransparent displays. Science 2009, 325, 977–981. [Google Scholar] [CrossRef] [PubMed]

- Filiatrault, H.L.; Porteous, G.C.; Carmichael, R.S.; Davidson, G.J.E.; Carmichael, T.B. Stretchable light-emitting electrochemical cells using an elastomeric emissive material. Adv. Mater. 2012, 24, 2673–2678. [Google Scholar] [CrossRef] [PubMed]

- Liang, J.; Li, L.; Niu, X.; Yu, Z.; Pei, Q. Elastomeric polymer light-emitting devices and displays. Nat. Photonics 2013, 7, 817–824. [Google Scholar] [CrossRef]

- Liang, J.; Li, L.; Tong, K.; Ren, Z.; Hu, W.; Niu, X.; Chen, Y.; Pei, Q. Silver nanowire percolation network soldered with graphene oxide at room temperature and its application for fully stretchable polymer light-emitting diodes. ACS Nano 2014, 8, 1590–1600. [Google Scholar] [CrossRef] [PubMed]

- Mahar, B.; Laslau, C.; Yip, R.; Sun, Y. Development of carbon nanotube-based sensors—A review. IEEE Sens. J. 2007, 7, 266–284. [Google Scholar] [CrossRef]

- Pandey, S.; Goswami, G.K.; Nanda, K.K. Nanocomposite based flexible ultrasensitive resistive gas sensor for chemical reactions studies. Sci. Rep. 2013, 3, 2082. [Google Scholar] [CrossRef] [PubMed]

- Puers, R. Capacitive sensors: When and how to use them. Sens. Actuators A 1993, 37, 93–105. [Google Scholar] [CrossRef]

- Gauglitz, G. Direct optical sensors: Principles and selected applications. Anal. Bioanal. Chem. 2005, 381, 141–155. [Google Scholar] [CrossRef] [PubMed]

- Dobie, W.B.; Isaac, P.C.G. Electric Resistance Strain Gauges; English Universities Press Limited: Madison, WI, USA, 1948. [Google Scholar]

- Window, A.L. Strain Gauge Technology; Springer: Berlin, Germany, 1992. [Google Scholar]

- Eswaraiah, V.; Balasubramaniam, K.; Ramaprabhu, S. Functionalized graphene reinforced thermoplastic nanocomposites as strain sensors in structural health monitoring. J. Mater. Chem. 2011, 21, 12626–12628. [Google Scholar] [CrossRef]

- Hempel, M.; Nezich, D.; Kong, J.; Hofmann, M. A novel class of strain gauges based on layered percolative films of 2D materials. Nano Lett. 2012, 12, 5714–5718. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, R.; Yu, W.; Wang, K.; Wei, J.; Wu, D.; Cao, A.; Li, Z.; Cheng, Y.; Zheng, Q.; et al. Stretchable and highly sensitive graphene-on-polymer strain sensors. Sci. Rep. 2012, 2, 870. [Google Scholar] [CrossRef] [PubMed]

- Fan, Q.; Qin, Z.; Gao, S.; Wu, Y.; Pionteck, J.; Mäder, E.; Zhu, M. The use of a carbon nanotube layer on a polyurethane multifilament substrate for monitoring strains as large as 400%. Carbon 2012, 50, 4085–4092. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301. [Google Scholar] [CrossRef] [PubMed]

- Noh, J.S. Cracked titanium film on an elastomeric substrate for highly flexible, transparent, and low-power strain sensors. Nanoscale Res. Lett. 2013, 8, 441. [Google Scholar] [CrossRef] [PubMed]

- Lacour, S.P.; Chan, D.; Wagner, S.; Li, T.; Suo, Z. Mechanisms of reversible stretchability of thin metal films on elastomeric substrates. Appl. Phys. Lett. 2006, 88, 204103. [Google Scholar] [CrossRef]

- Lee, H.; Seong, B.; Moon, H.; Byun, D. Directly printed stretchable strain sensor based on ring and diamond shaped silver nanowire electrodes. RSC Adv. 2015, 5, 28379–28384. [Google Scholar] [CrossRef]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly stretchable and sensitive strain sensor based on silver nanowire-elastomer nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef] [PubMed]

- Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.L.; Wang, P.; Ding, T.H. Piezoresistivity of silicone-rubber/carbon black composites excited by AC electrical field. J. Appl. Polym. Sci. 2009, 113, 337–341. [Google Scholar] [CrossRef]

- Hwang, J.; Jang, J.; Hong, K.; Kim, K.N.; Han, J.H.; Shin, K.; Park, C.E. Poly(3-hexylthiophene) wrapped carbon nanotube/poly(dimethylsiloxane) composites for use in finger-sensing piezoresistive pressure sensors. Carbon 2011, 49, 106–110. [Google Scholar] [CrossRef]

- Brady, S.; Diamond, D.; Lau, K.T. Inherently conducting polymer modified polyurethane smart foam for pressure sensing. Sens. Actuators A 2005, 119, 398–404. [Google Scholar] [CrossRef]

- Joo, Y.; Byun, J.; Seong, N.; Ha, J.; Kim, H.; Kim, S.; Kim, T.; Im, H.; Kim, D.; Hong, Y. Silver nanowire-embedded PDMS with a multiscale structure for a highly sensitive and robust flexible pressure sensor. Nanoscale 2015, 7, 6208–6215. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Jeong, Y.R.; Yun, J.; Hong, S.Y.; Jin, S.; Lee, S.J.; Zi, G.; Ha, J.S. Stretchable array of highly sensitive pressure sensors consisting of polyaniline nanofibers and Au-coated polydimethylsiloxane micropillars. ACS Nano 2015, 9, 9974–9985. [Google Scholar] [CrossRef] [PubMed]

- Choong, C.L.; Shim, M.B.; Lee, B.S.; Jeon, S.; Ko, D.S.; Kang, T.H.; Bae, J.; Lee, S.H.; Byun, K.E.; Im, J.; et al. Highly stretchable resistive pressure sensors using a conductive elastomeric composite on a micropyramid array. Adv. Mater. 2014, 26, 3451–3458. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Lu, B.; Chen, Y.; Feng, X. Breathable and stretchable temperature sensors inspired by skin. Sci. Rep. 2015, 5, 11505. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Wang, J.; Lee, P.S. Stretchable graphene thermistor with tunable thermal index. ACS Nano 2015, 9, 2130–2137. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.Y.; Lee, Y.H.; Park, H.; Jin, S.W.; Jeong, Y.R.; Yun, J.; You, I.; Zi, G.; Ha, J.S. Stretchable active matrix temperature sensor array of polyaniline nanofibers for electronic skin. Adv. Mater. 2016, 28, 930–935. [Google Scholar] [CrossRef] [PubMed]

- Trung, T.Q.; Ramasundaram, S.; Hwang, B.U.; Lee, N.E. An all-elastomeric transparent and stretchable temperature sensor for body-attachable wearable electronics. Adv. Mater. 2016, 28, 502–509. [Google Scholar] [CrossRef] [PubMed]

- Hoppe, H.; Sariciftci, N.S. Organic solar cells: An overview. J. Mater. Res. 2004, 19, 1924–1945. [Google Scholar] [CrossRef]

- Service, R.F. Outlook brightens for plastic solar cells. Science 2011, 332, 293. [Google Scholar] [CrossRef] [PubMed]

- Scharber, M.C.; Sariciftci, N.S. Efficiency of bulk-heterojunction organic solar cells. Prog. Polym. Sci. 2013, 38, 1929–1940. [Google Scholar] [CrossRef] [PubMed]

- Riviére, G.A.; Simon, J.J.; Escoubas, L.; Vervisch, W.; Pasquinelli, M. Photo-electrical characterizations of plastic solar modules. Solar Energy Mater. Solar Cells 2012, 102, 19–25. [Google Scholar] [CrossRef]

- Shaheen, S.E.; Brabec, C.J.; Sariciftci, N.S.; Padinger, F.; Fromherz, T.; Hummelen, J.C. 2.5% efficient organic plastic solar cells. Appl. Phys. Lett. 2001, 78, 841–843. [Google Scholar] [CrossRef]

- Lee, J.; Wu, J.; Shi, M.; Yoon, J.; Park, S.I.; Li, M.; Liu, Z.; Huang, Y.; Rogers, J.A. Stretchable GaAs photovoltaics with designs that enable high areal coverage. Adv. Mater. 2011, 23, 986–991. [Google Scholar] [CrossRef] [PubMed]

- Lipomi, D.J.; Tee, B.C.K.; Vosgueritchian, M.; Bao, Z. Stretchable organic solar cells. Adv. Mater. 2011, 23, 1771–1775. [Google Scholar] [CrossRef] [PubMed]

- Kaltenbrunner, M.; White, M.S.; Głowacki, E.D.; Sekitani, T.; Someya, T.; Sariciftci, N.S.; Bauer, S. Ultrathin and lightweight organic solar cells with high flexibility. Nat. Commun. 2012, 3, 770. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L.; Song, J. Piezoelectric nanogenerators based on zinc oxide nanowire arrays. Science 2006, 312, 242–246. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Y.; Zhang, H.; Hu, L.; Yang, D.; Wang, L.; Wang, B.; Ji, J.; Liu, G.; Liu, X.; Lin, J.; et al. Flexible piezoelectric nanogenerators based on ZnO nanorods grown on common paper substrates. Nanoscale 2012, 4, 6568–6573. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Tang, H.; Sodano, H.A. Scalable synthesis of morphotropic phase boundary lead zirconium titanate nanowires for energy harvesting. Adv. Mater. 2014, 26, 7547–7554. [Google Scholar] [CrossRef] [PubMed]

- Chang, C.; Tran, V.H.; Wang, J.; Fuh, Y.K.; Lin, L. Direct-write piezoelectric polymeric nanogenerator with high energy conversion efficiency. Nano Lett. 2010, 10, 726–731. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Lee, K.Y.; Gupta, M.K.; Kim, T.Y.; Lee, D.Y.; Oh, J.; Ryu, C.; Yoo, W.J.; Kang, C.Y.; Yoon, S.J.; et al. Highly stretchable piezoelectric-pyroelectric hybrid nanogenerator. Adv. Mater. 2014, 26, 765–769. [Google Scholar] [CrossRef] [PubMed]

- Jeong, C.K.; Lee, J.; Han, S.; Ryu, J.; Hwang, G.T.; Park, D.Y.; Park, J.H.; Lee, S.S.; Byun, M.; Ko, S.H.; et al. A hyper-stretchable elastic-composite energy harvester. Adv. Mater. 2015, 27, 2866–2875. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Sun, Y.; Xu, W.; Zhu, D. Organic thermoelectric materials: Emerging green energy materials converting heat to electricity directly and efficiently. Adv. Mater. 2014, 26, 6829–6851. [Google Scholar] [CrossRef] [PubMed]

- Bubnova, O.; Crispin, X. Towards polymer-based organic thermoelectric generators. Energy Environ. Sci. 2012, 5, 9345–9362. [Google Scholar] [CrossRef]

- Kim, S.J.; We, J.H.; Cho, B.J. A wearable thermoelectric generator fabricated on a glass fabric. Energy Environ. Sci. 2014, 7, 1959–1965. [Google Scholar] [CrossRef]

- Liang, L.; Gao, C.; Chen, G.; Guo, C.Y. Large-area, stretchable, super flexible and mechanically stable thermoelectric films of polymer/carbon nanotube composites. J. Mater. Chem. C 2016, 4, 526–532. [Google Scholar] [CrossRef]

| Application | Material | Mechanical properties | Electrical properties | Reference |

|---|---|---|---|---|

| Stretchable conductors | PU-PPY composites | εb = 160% | σ = 10−5 S/cm | [53] |

| 3D PDMS-EGaIn | εb = 220% | σ = 24,100 S/cm | [55] | |

| PU-PEDOT blends | ε = 200% | σ = 10–50 S/cm | [35] | |

| Graphene sheets–PU composites | εb = 374% | σ = 1.2 × 10−5 S/cm | [51] | |

| Ag flakes–PU composites | εb = 600% | ρ = 2.8 × 10−4 Ω·cm | [62] | |

| Stretchable FETs and memories | SnO2 NWs/wavy interconnects | εb = 40% | On/Off ratio = 106 | [64] |

| SWCNT–elastomer composites | εb = 70% | On/Off ratio > 103 | [65] | |

| SBS fiber mat/P3HT nanofibers/polyelectrolyte gel | ε = 70% | On/Off ratio = 105 | [66] | |

| P3HT/PS–PCBM/PEN | εb = 2.03% | On/Off ratio > 103 | [68] | |

| PMMA–P3BT/PDMS | εb = 50% | Data retention = 104 s | [69] | |

| Stretchable LEDs | Ru-PDMS/Au–PDMS | εb = 27% | EQE < 1% | [72] |

| AuNW–PUA composites | εb = 120% | EQE = 4% | [73] | |

| GO–AgNW–PUA composites/PEDOT:PSS/PEI | εb = 130% | Current efficiency = 2.0 cd/A | [74] |

| Application | Material | Mechanical properties | Sensing properties | Reference |

|---|---|---|---|---|

| Stretchable strain sensors | Graphene woven fabric/PDMS | εb = 10% | Gauge factor = ~106 | [83] |

| CNT networks/PU multifilament | εb = 400% | Gauge factor = ~5 | [84] | |

| AgNWs/PDMS | ε = 0%–50% | Gauge factor = ~1 | [60] | |

| PDMS/AgNWs/PDMS | ε = 0%–70% | Gauge factor = ~5 | [89] | |

| Stretchable pressure sensors | PPY-coated PU foam | ε > 1,000% | Sensitivity = 0.0007 mS/N | [93] |

| AgNW-embedded PDMS/PMMA | Not stretchable | Sensitivity > 3.8 kPa−1 | [94] | |

| Au-coated PDMS micropillars/PANI nanofibers | εb (biaxial) = 15% | Sensitivity = 2.0 kPa−1 Detection limit = 15 Pa | [95] | |

| Micro-pyramid PDMS/PEDOT:PSS-PUD blend | ε > 40% | Sensitivity = 10.32 kPa−1 Detection limit = 23 Pa | [96] | |

| Stretchable temperature sensors | Graphene embedded in PDMS | εb = 50% | Nonlinear R versus T in 30–100 °C | [98] |

| SWCNT TFT-PANI nanofiber/PET/Ecoflex | εb (biaxial) = 30% | Sensitivity = 1.0% °C−1 | [99] | |

| PDMS/PEDOT:PSS-PUD composite/PU/(R-GO)-PU composite | εb = 70% | Sensitivity = 1.34% °C−1 | [100] |

© 2016 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noh, J.-S. Conductive Elastomers for Stretchable Electronics, Sensors and Energy Harvesters. Polymers 2016, 8, 123. https://doi.org/10.3390/polym8040123

Noh J-S. Conductive Elastomers for Stretchable Electronics, Sensors and Energy Harvesters. Polymers. 2016; 8(4):123. https://doi.org/10.3390/polym8040123

Chicago/Turabian StyleNoh, Jin-Seo. 2016. "Conductive Elastomers for Stretchable Electronics, Sensors and Energy Harvesters" Polymers 8, no. 4: 123. https://doi.org/10.3390/polym8040123

APA StyleNoh, J.-S. (2016). Conductive Elastomers for Stretchable Electronics, Sensors and Energy Harvesters. Polymers, 8(4), 123. https://doi.org/10.3390/polym8040123