3.1. Thermo-Mechanical and Network Structure Properties

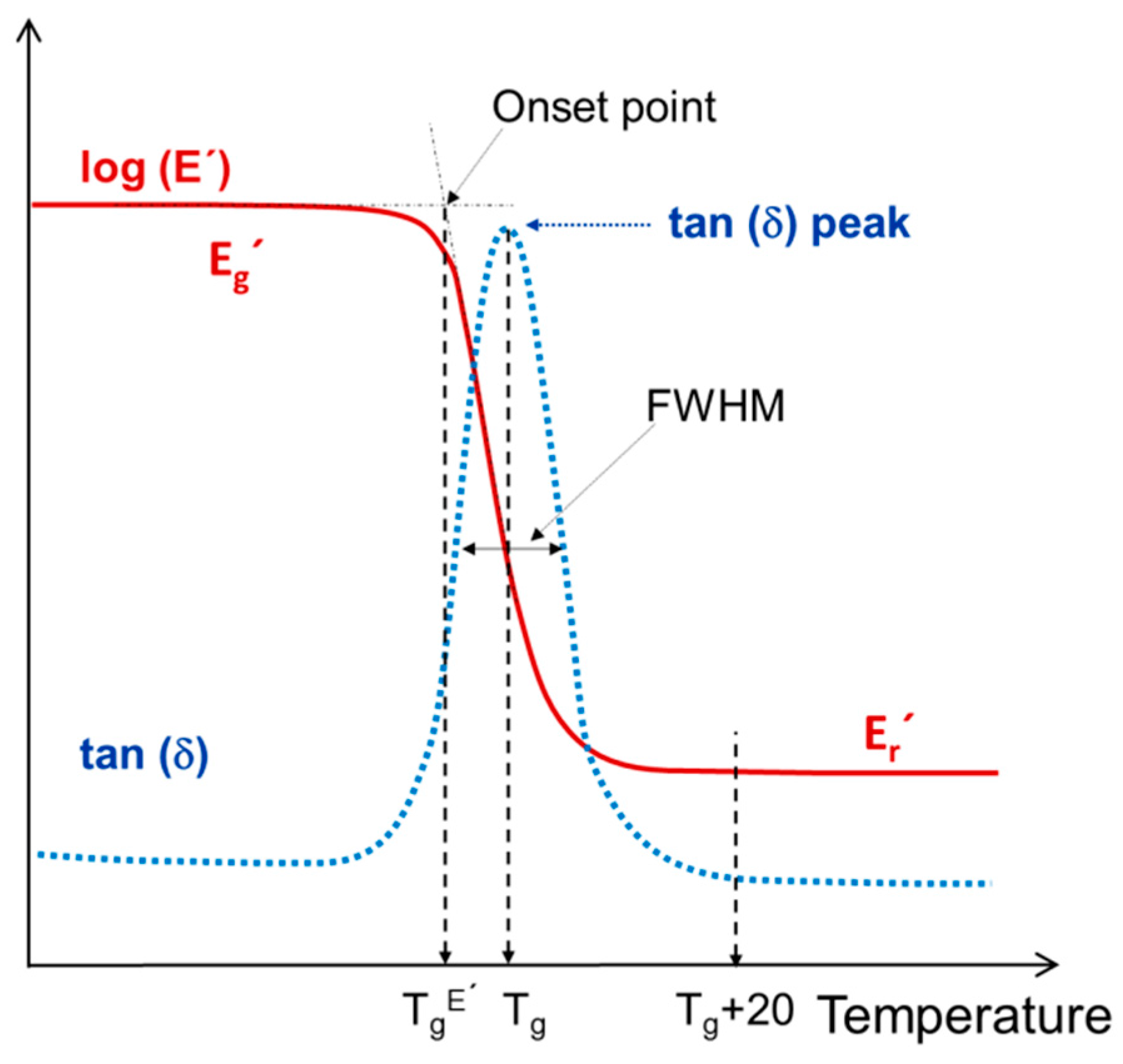

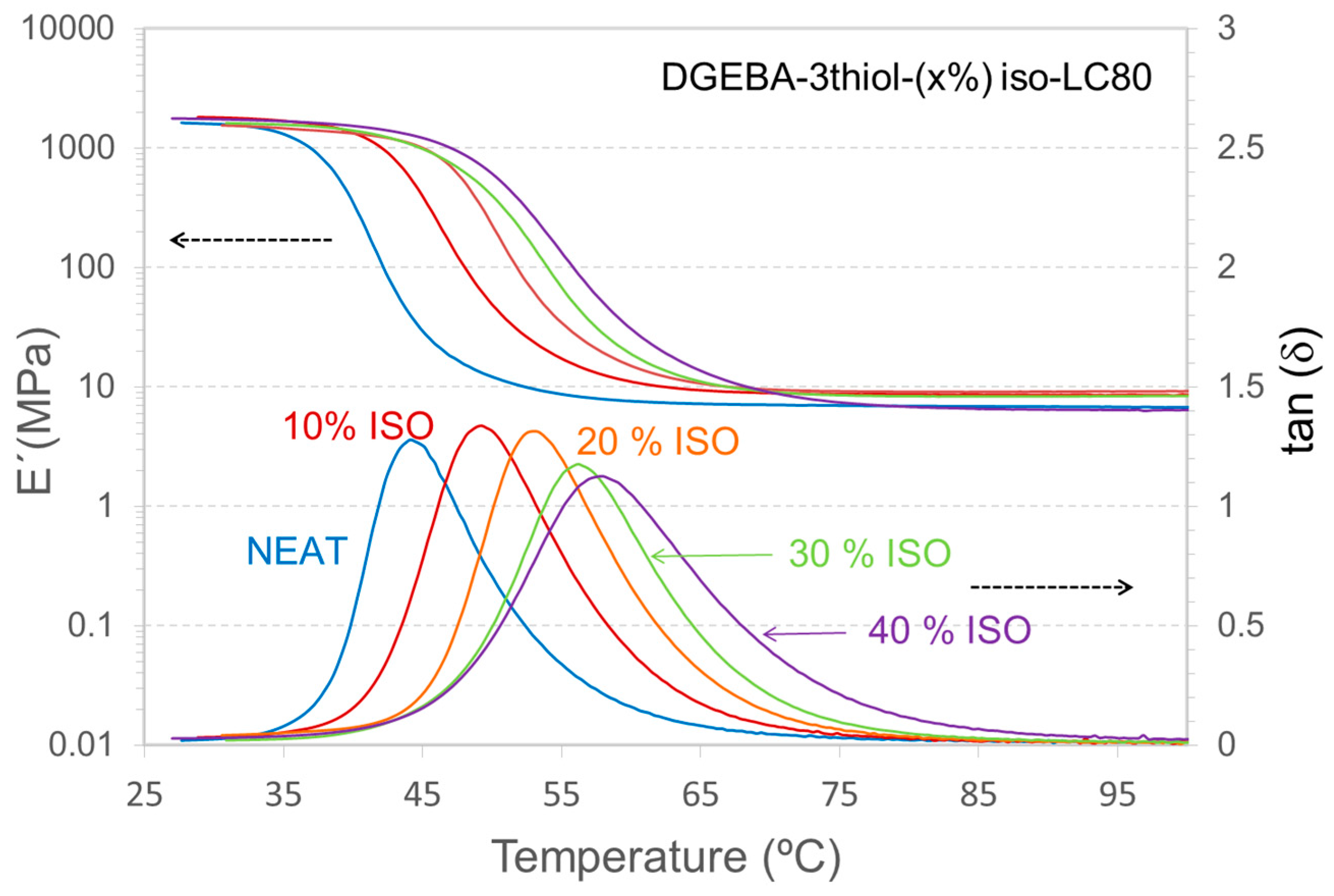

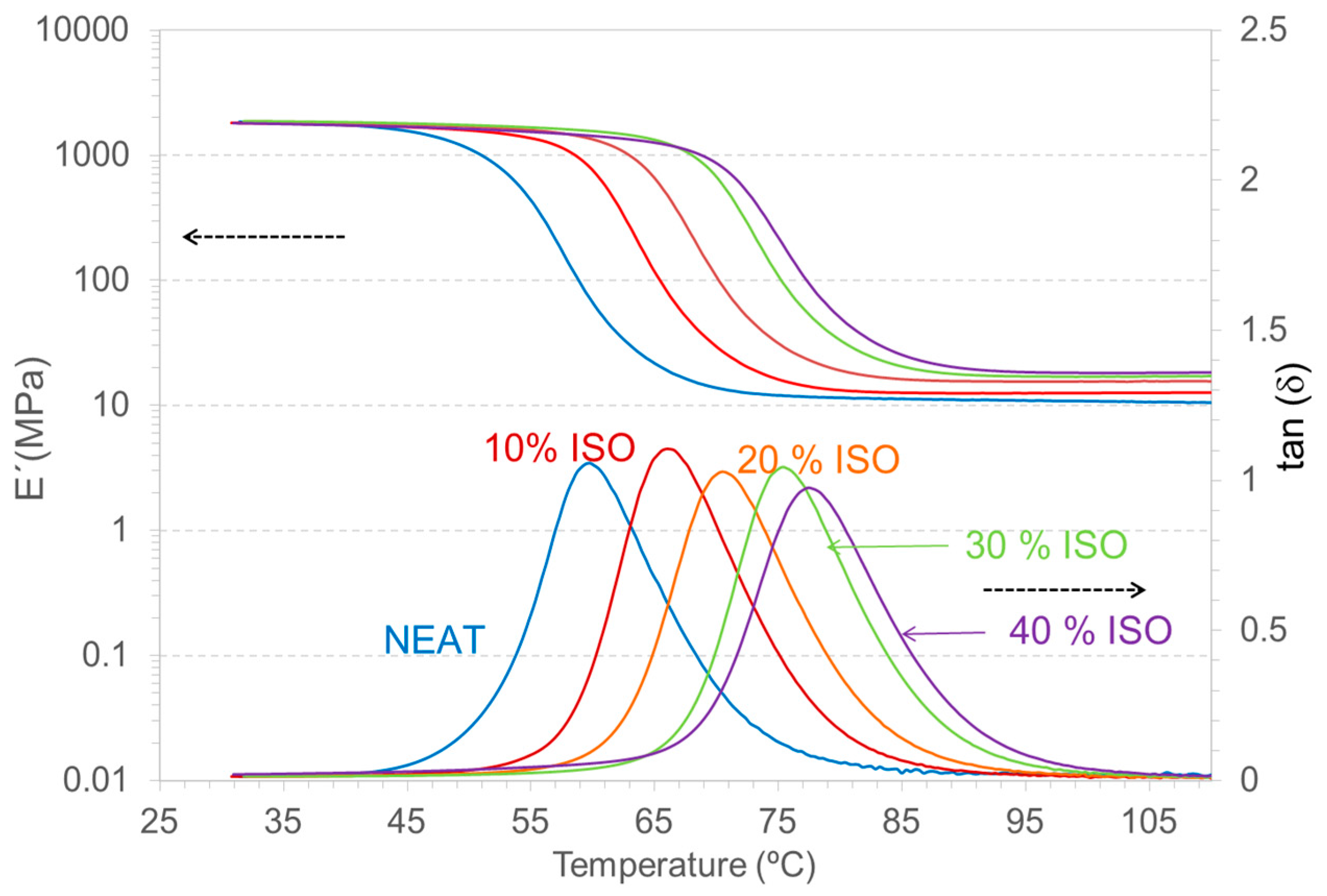

The thermo-mechanical and network structure properties were analyzed by dynamic-mechanical analyses. The results for the 3thiol and 4thiol systems are shown in

Figure 5 and

Figure 6, and some characteristic parameters of the network relaxation process (see

Figure 1) are summarized in

Table 2.

Figure 5.

Dynamic-mechanical analyses for the (3thiol) different formulations.

Figure 5.

Dynamic-mechanical analyses for the (3thiol) different formulations.

Figure 6.

Dynamic-mechanical analyses for the (4thiol) different formulations.

Figure 6.

Dynamic-mechanical analyses for the (4thiol) different formulations.

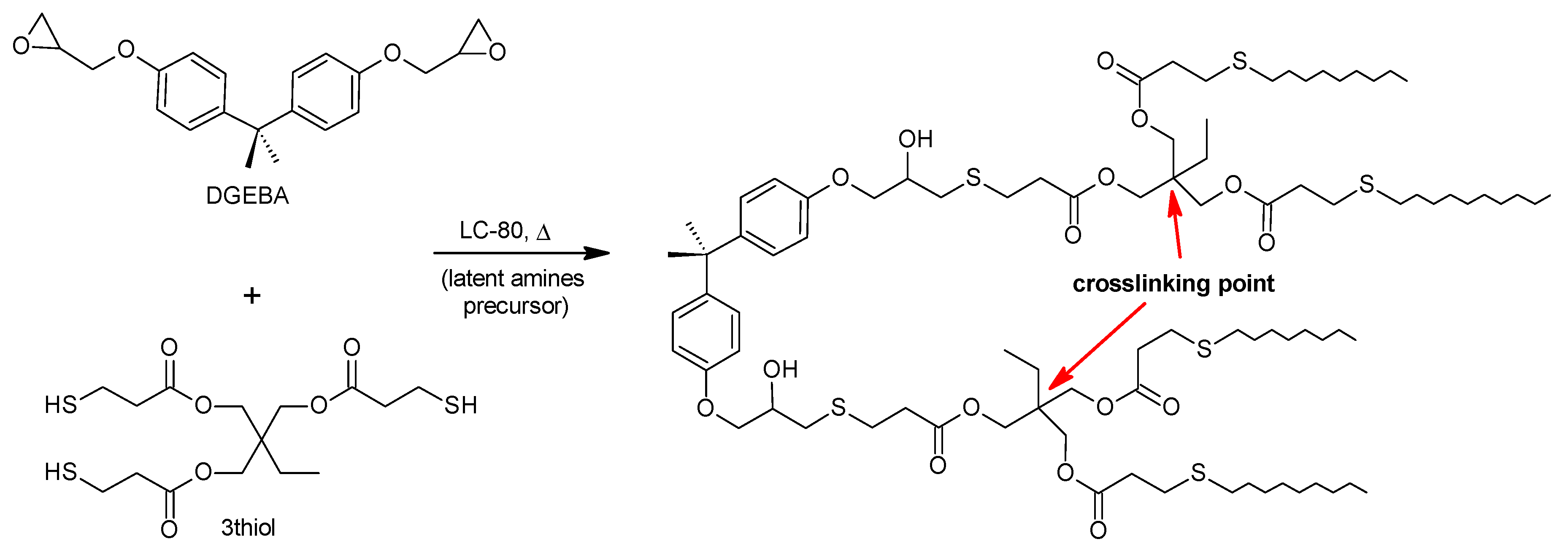

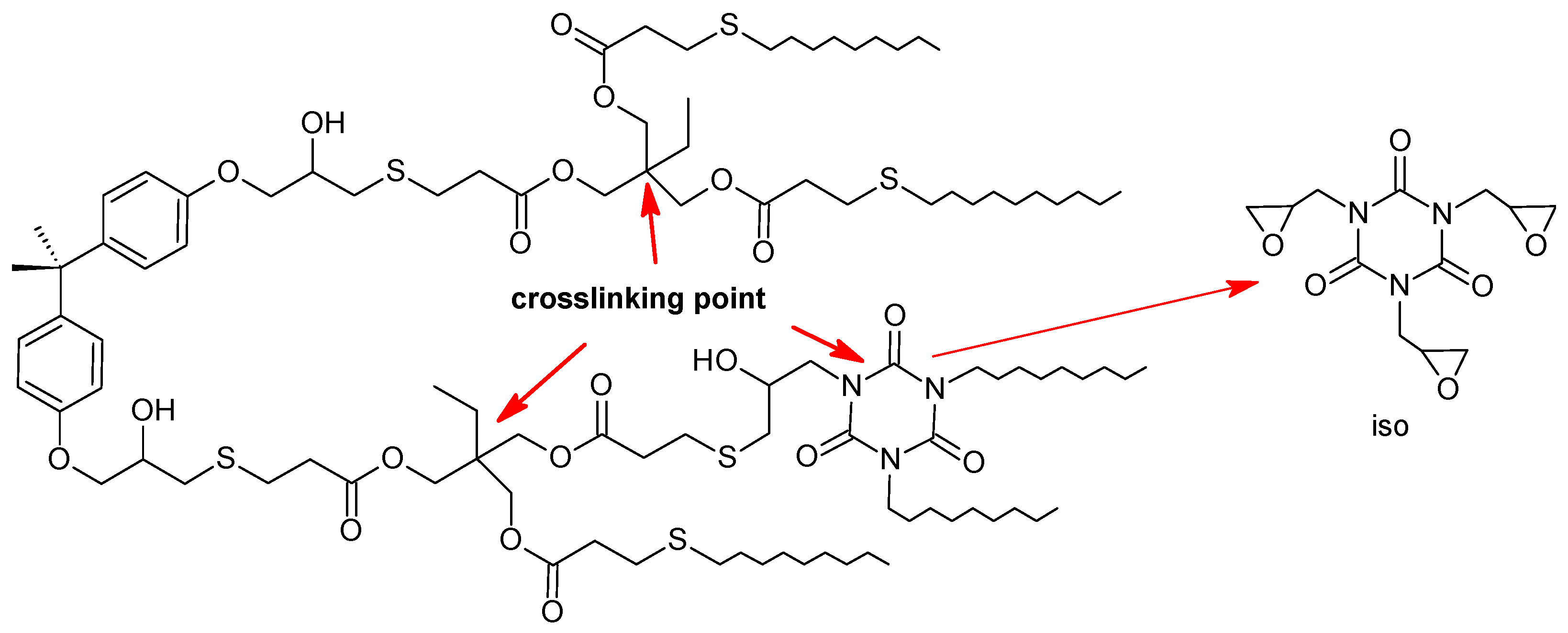

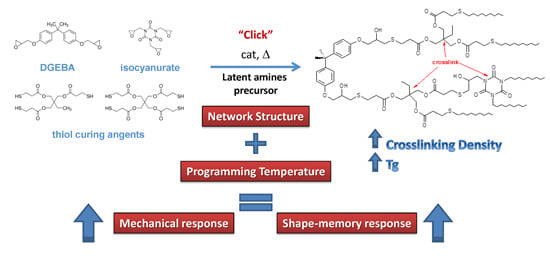

In general, the formulations with 3thiol have lower

Tg than those with 4thiol because of the reduction of free volume and hindrance of the molecular motion caused by the presence of crosslink junctions [

36], which becomes more relevant with increasing crosslink functionality [

33], as seen for other shape-memory materials [

37,

38]. On the other hand, adding the iso compound to the different systems tend to increase the

Tg. According to the expected network of the

Scheme 2, the iso component acts as a 3-functional crosslinking point, increasing the functionality of the system, thus, creating a more hindered network. Nevertheless, the

Tg increment tends to become less relevant especially above an iso content up to 30% for formulations containing 3thiol.

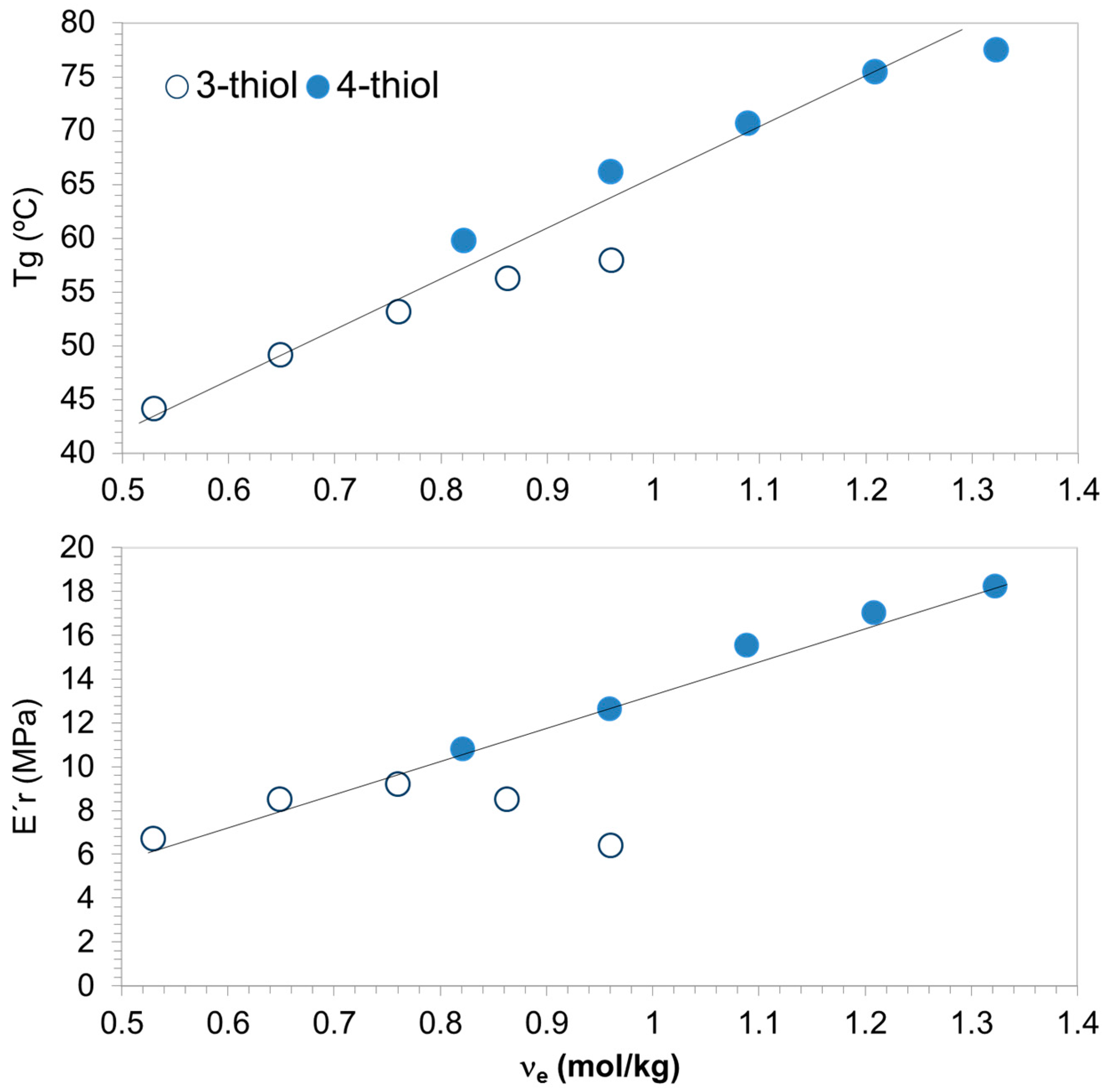

Figure 7 shows a good correlation between the

Tg and the effective strand density

ve (calculated taking into account crosslink functionality and fluctuation, using Equation (3)), showing a fairly linear trend as predicted by Equation (5). However, some non-idealities appear for both 3thiol and 4thiol formulations with increasing iso content and, consequently,

ve. It must be taken into account that the increase in the content of iso also changes the type of network structure, introducing crosslinks with a non-negligible mass, and the size and rigidity of the network strands [

25].

Figure 7.

(Tg) and (Er′) with respect to the effective strand density (ve) corresponding to each % of iso content.

Figure 7.

(Tg) and (Er′) with respect to the effective strand density (ve) corresponding to each % of iso content.

FWHM and tanδ peak values are characteristics of the relaxation and can be related to the crosslinking density and the network homogeneity of the material. It is commonly observed that the relaxation peaks broaden and decrease its intensity with increasing crosslinking density [

15] a phenomenon that is inherently related to the increase in crosslinking density and

Tg [

34]. Although the trend is not well defined, because of the discrete increase in crosslinking density, the same is observed in the present case. The effect of iso on the shape of the relaxation in 4thiol systems is very limited in comparison with 3thiol and, in fact, the broadening of the relaxation when 40% of iso is used with 3thiol is too large and may have a detrimental effect on the SMR of the material.

Table 2.

Network structure and thermo-mechanical properties of the different materials of study.

Table 2.

Network structure and thermo-mechanical properties of the different materials of study.

| Formulation | Eg′ (MPa) | Er′ (MPa) | Eg′/Er′ | FWHM (°C) | tanδ peak | Tg (°C) | TgE′ (°C) | ve (mol/kg) a |

|---|

| 3thiol-NEAT | 1,590 | 6.7 | 237 | 10.3 | 1.28 | 44.1 | 37.7 | 0.530 |

| 3thiol-(10%)iso | 1,804 | 8.5 | 211 | 11.9 | 1.34 | 49.1 | 42.0 | 0.649 |

| 3thiol-(20%)iso | 1,540 | 9.2 | 167 | 11.7 | 1.31 | 53.1 | 46.3 | 0.760 |

| 3thiol-(30%)iso | 1,616 | 8.5 | 191 | 12.5 | 1.18 | 56.2 | 46.6 | 0.863 |

| 3thiol-(40%)iso | 1,744 | 6.4 | 271 | 15.7 | 1.13 | 57.9 | 47.9 | 0.961 |

| 4thiol-NEAT | 1,850 | 10.8 | 171 | 12.0 | 1.06 | 59.7 | 52.0 | 0.822 |

| 4thiol-(10%)iso | 1,815 | 12.6 | 145 | 12.1 | 1.11 | 66.1 | 58.8 | 0.960 |

| 4thiol-(20%)iso | 1,855 | 15.5 | 120 | 12.1 | 1.03 | 70.6 | 62.9 | 1.089 |

| 4thiol-(30%)iso | 1,870 | 17.0 | 110 | 11.8 | 1.05 | 75.4 | 68.2 | 1.209 |

| 4thiol-(40%)iso | 1,800 | 18.2 | 99 | 12.6 | 0.98 | 77.4 | 69.7 | 1.323 |

The effective strand density ve (calculated taking into account crosslink functionality and fluctuation, using Equation (3)) shows an increasing trend with the addition of iso and with the increase in the thiol functionality from 3thiol to 4thiol, as expected. The measured values of the relaxed modulus Er′ have a very good agreement with this trend except 3thiol formulations with 30% and 40% of iso, that show decreasing values of Er′. Such discrepancies are in line with the non-idealities observed in the Tg and the broadening of the relaxation peak in 3thiol formulations with higher iso content.

Differences between 3thiol and 4thiol formulations may be consequence of the different structure of both crosslinking agents. Setting aside the different functionality, 3thiol has a pendant ethyl group that may produce a certain distortion in the network structure and the network relaxation dynamics, thus affecting the whole of the measured parameters. In addition, one must consider that the introduction of iso produces not only an increase in crosslinking density but also a significant change in the network structure. Such considerations fall out the scope of the simple theoretical expressions used in this work. Furthermore, it is possible that this also results from a certain incompatibility between iso and 3thiol or a difference in the reactivity of the epoxy groups of iso and DGEBA, leading to an inhomogeneous distribution of the different types of network strands and crosslinking points.

3.2. SMR Qualitative Study: Comparison with Thermo-Mechanical Properties and Network Structure

From the previous thermo-mechanical analysis, a series of general considerations can be made in terms of the SMR of the different materials. The capability of a material to show shape-recovery is usually quantified by the

Eg′

/Er′ ratio [

15].

Table 2 shows that the

Eg′

/Er′ ratio is over 2 orders of magnitude or above for all the formulations, a high enough value. The drop of the modulus from

Eg′ to

Er′ during the network relaxation is steep enough to expect high rates during the shape-recovery process (see

Figure 5 and

Figure 6). In addition, there is a plateau zone of

Eg′ at the

Ts (temperature at which the temporary shape is fixed) sufficiently away from the modulus drop zone to avoid premature shape-recovery and consequently allow good shape-fixation. Overall, the shape of the network relaxation process, represented by the tanδ curve, is well-defined along the glass transition (no noise is noticed) and it is similar for all the formulations, expecting a similar SMR.

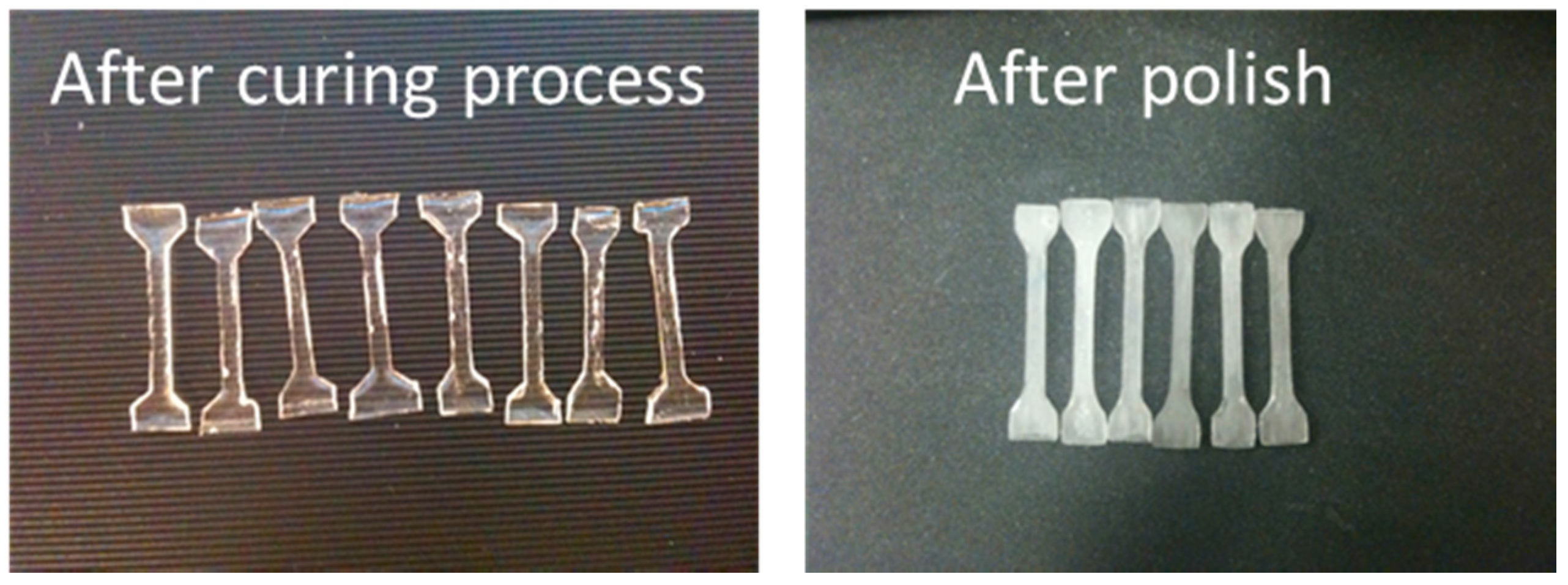

In the qualitative study, the SMR has been analyzed through the tsr parameter (see Equation (7)), since no losing of the temporary shape was visually appreciated after cooling and releasing the stress applied to the sample. In addition, the programmed samples showed good retention of the temporary shape during the 5–10 min of holding time at room temperature before the shape-recovery was triggered inside the oven. Moreover, at the end of the process, the recovery of the original shape was quantitative %SR ≈ 100% (Equation (8)), leaving no appreciable permanent strain.

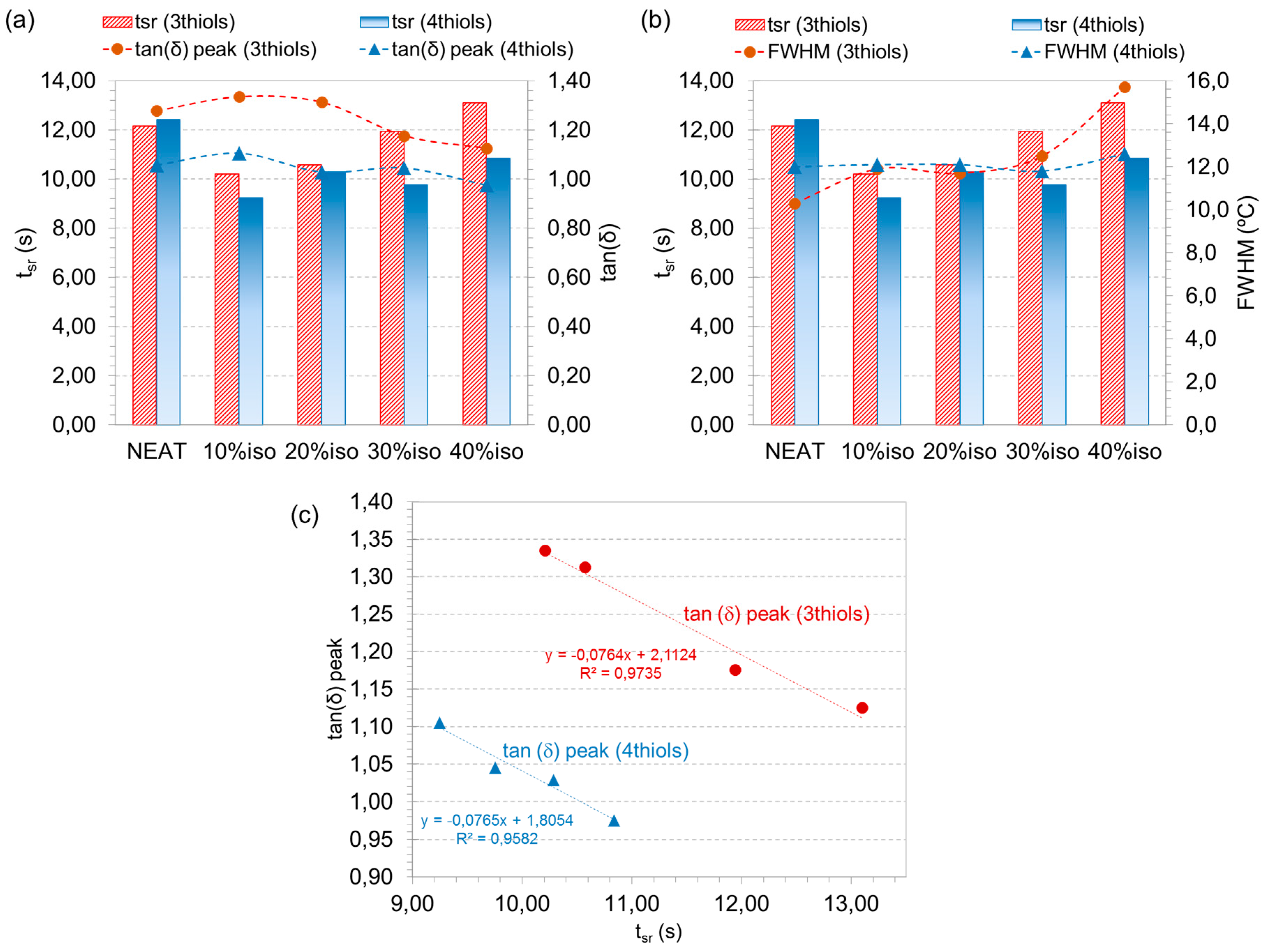

As it can be seen in

Figure 8, overall the

tsr is excellent for all the formulations as expected from the

Eg′

/Er′ ratio and the sharp relaxation. The materials are capable of recovering from the 15% to the 85% of their original shape in less than 14 s when heated on air (note that, in many applications such as security devices, the heating process is on air through isothermal conditions). The NEAT formulations show a similar response, about 12 s of

tsr, while the addition of 10% of iso accelerates the shape-recovery process for both systems (

tsr falls to 10–9 s). In contrast, increasing the amount of iso from 10% to 40% slows down the process in the case of the 3thiol formulations (

tsr increases from 10 s at 10% of iso up to 13 s at 40% of iso), while for the 4thiol ones it remains almost constant.

Figure 8 compares the

tsr along with the tanδ peak (a) and

FWHM (b) values in order to relate the SMR with the network structure. As it can be seen,

tsr decreases when the tanδ peak increases and when

FWHM decreases. These results point at a strong relationship between the sharpness of the relaxation process and the rate of the shape-recovery process. Materials with a more heterogeneous network structure and a broader relaxation profile (higher

FWHM and lower tanδ peak) have a slower relaxation process, thus limiting the chain motion and shape-recovery. This trend is well-appreciated in the case of 3thiol formulations between 20% and 40% of iso, showing an increase in

FWHM from 11.7 to 15.7 °C and an increase in

tsr from 11 to 13 s. In the case of the 4thiol formulations this trend is also observed from 30% to 40% of iso. The value of the tanδ peak clarifies the situation when

FHWM values are similar. In

Figure 8c it is seen that

tsr decreases when the tanδ peak increases showing a linear correlation for both the 3thiol and 4thiol systems with isocyanurate. In contrast, other network structure parameters, such as the crosslinking density given by

ve or

Er′, do not have an influence on the recovery rate. As discussed in the preceding section,

ve increases with the amount of iso (see

Table 2), but changes in

tsr follow the trend dictated by

FWHM and tanδ peak instead, regardless of the values of

ve or

Er′. These results are in agreement with Yackaki

et al. suggesting that on unconstrained experiments the main responsible of the shape-recovery process is the network relaxation process [

17].

Figure 8.

Relation between the shape-memory response (in terms of tsr) and the network relaxation dynamics; (a) tsr against tanδ peak as a function of the composition; (b) tsr against FWHM as a function of the composition; (c) tanδ peak against the tsr for both, 3thiol and 4thiol with isocyanurate formulations (10%,20%,30% and 40%).

Figure 8.

Relation between the shape-memory response (in terms of tsr) and the network relaxation dynamics; (a) tsr against tanδ peak as a function of the composition; (b) tsr against FWHM as a function of the composition; (c) tanδ peak against the tsr for both, 3thiol and 4thiol with isocyanurate formulations (10%,20%,30% and 40%).

To sum up, these results evidence the dependence of the shape-recovery with the network relaxation on unconstrained experiments and suggesting that

FWHM and tanδ peak can be used to estimate, at least from a comparative point of view, the velocity of the shape-recovery process [

39]. From the shape of the modulus curve (the steepness of the drop and the plateau zone at the glassy state), one can also obtain a qualitative view of the speed of the recovery process and the capability of the material to retain the temporary shape.

Finally, the best candidates have been chosen by applying the next criteria: the higher glass transition reached by adding the iso component to maximize temporary shape retention along with a homogeneous network structure to have fast recovery process. Therefore, the 3thiol-30%iso and 4thiol-30%iso formulations, along with the NEAT ones, have been chosen for further analysis in the quantitative study. While there is no doubt in the case of 4thiol formulations, the decision was more complicated in the case of the 3thiol ones. The formulations with 10% and 20% of iso are better candidates from the point of view of the recovery speed, but the formulations with 30% of iso has shown a higher Tg value and its tsr is similar to the NEAT formulation which, overall, is excellent. In addition, as commented above, the Rr and Rf, as well as the shape-fixation were excellent for all the formulations. Therefore, for a proper comparative study, the same amount of isocyanurate should be used for both systems.

3.3. Mechanical Analysis: Influence of the Network Structure and Programming Temperature

One of the most important capabilities of a SMP during the programming process is the mechanical response (in terms of ultimate strain and stress), described by the σ

b and ε

b parameters.

Figure 9 summarizes the σ

b and ε

b values obtained for the different formulations and the relation with the crosslinking density as a function of the

Tprog. In general, both parameters have shown a high dependence on temperature and network structure. In accordance with Rousseau and Yackaki [

9,

10], the optimal mechanical point for all the formulations is found at the onset point (

TgE′), where the material combines both properties: high resistance and molecular mobility, therefore leading to higher values of σ

b and ε

b. As the

Tprog increases from

TgE′ to

Tg + 20, the σ

b and ε

b tend to decrease because of the material becomes weaker (

i.e., for the 4thiol-NEAT system, σ

b and ε

b are 39 MPa and 66% respectively, when programming at

TgE′, while programming at

Tg decreases σ

b and ε

b down to 9 MPa and 42%, respectively). On the other hand, the effect of the crosslinking density of the materials on the σ

b and ε

b is clearly appreciated when

Tprog is well above the

Tg. At this temperature, conformational rearrangement of network chains take place quickly in response to the stress applied, and therefore the deformation achieved ε

b is mainly limited by the crosslinking density. As can be seen, the higher the molecular weight between crosslinking points (lower

ve), the higher the strain at break. In contrast, the trend is not well-defined for the σ

b. The explanation must be connected with the heterogeneity of the crosslinking points and thus the differences on the physical nature of the chains created among the different formulations [

8].

Figure 9.

Mechanical response and crosslinking density as a function of the programming temperature for all the formulations of study; (a) strain at break values; (b) stress at break values.

Figure 9.

Mechanical response and crosslinking density as a function of the programming temperature for all the formulations of study; (a) strain at break values; (b) stress at break values.

Overall, it should be pointed out the mechanical performance of these materials, in terms of σ

b and ε

b, they are superior to other epoxy-based SMPs. Williams

et al. [

14] reported an epoxy-amine system (based on a long aliphatic chain

n-dodecylamine) with large tensile elongations (up to 75%) and high recovered stresses (over 4 MPa), when programming at a temperature close to the

Tg. Rousseau

et al. [

10] reported epoxy-amine systems (based on long flexible polyetheramines) with higher values of σ

b (up to 8 MPa) and large ultimate strain (over 60%), when programming at

TgE′, the optimal mechanical point. In addition, our group [

15] reported epoxy-amine materials (based on polyetheramines and hyperbranched poly(ethyleneimine)s) with σ

b over 12 MPa while maintaining large ultimate strain (ε

b up to 60%). In general terms, while the tensile elongation is enhanced by adjusting the programming temperature and the network structure, the mechanical work remains limited by the low tensile strength obtained. In the present case, the thiol-epoxy materials under study fulfil both the requirements of high tensile strain and enhanced tensile stress, thus, enhancing the energy storage capacity and therefore the expected performance on constrained experiments [

40]. The 3thiol-NEAT system reaches values of almost 100% of ε

b (comparable with those reports by the mentioned authors [

10,

14,

15]) and 55 MPa of σ

b (which is over 4 times higher than those reported by [

15]) when programming at

TgE′. Furthermore, when programming at

Tg, the σ

b (over 23 MPa) is still higher than those reported by the mentioned authors [

10,

14,

15] and ε

b is considerably high (up to 82%). The excellent mechanical properties found between

TgE′ and

Tg + 20 broaden the applicability of our materials, since

Tprog not only modifies the mechanical response, but also affects the SMR [

41]. In this sense, it is possible to obtain materials with specific SMR maintaining and excellent mechanical response.

3.4. SMR Quantitative Study: Influence of the Programming Temperature

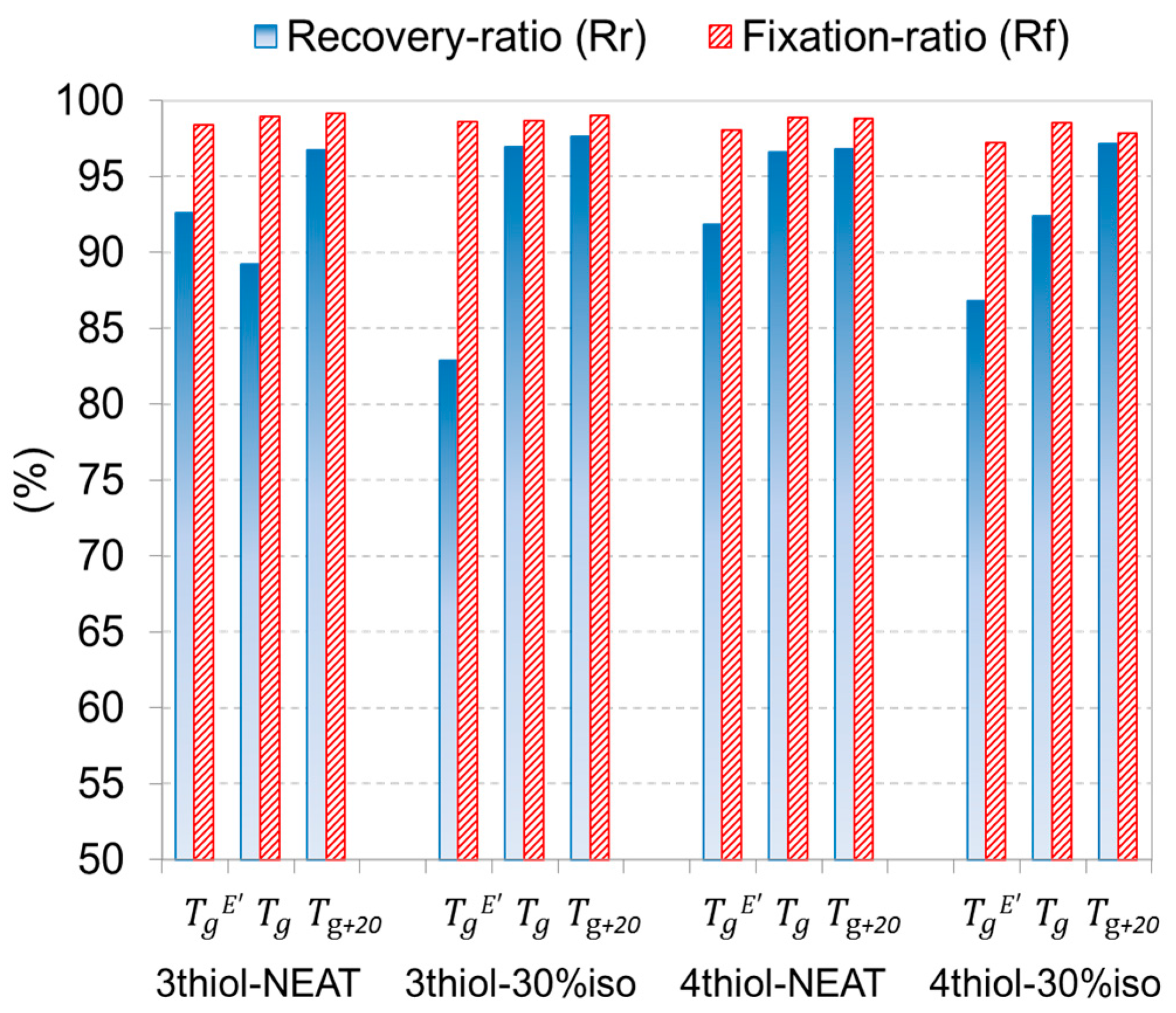

In the quantitative study, the SMR has been investigated through the

Rr and

Rf ratios (see Equations (8) and (9)). The results are represented in

Figure 10.

Figure 10.

Recovery-ratio and fixation-ratio as a function of the programming temperature for all the formulations of study.

Figure 10.

Recovery-ratio and fixation-ratio as a function of the programming temperature for all the formulations of study.

The capability to retain the temporary shape, quantified by the fixation-ratio,

Rf, is excellent for the different materials of study with values of almost 100% regardless of the

Tprog applied. The

Rf basically depends on the mechanical response of the material during the unloading process, which occurs at

Ts (the temperature at which the temporary shape is fixed). At

Ts the material is in the glassy state and the modulus (

Eg′) is higher than 1500 MPa for all the formulations (see in

Table 2) thus, the chain mobility is strongly hindered and the differences in the network structure do not affect the mechanical response. Accordingly, the

Tprog, which probably introduces changes in the network structure after loading and fixing the temporary shape, does not affect the

Rf for the same reason. In contrast, the recovery of the original shape, quantified by the recovery-ratio,

Rr, depends on the

Tprog: when programming at

Tg or

Tg + 20 the values are higher (over 90%–96% at

Tg and almost 100% at

Tg + 20) than those when programming at

TgE′ (falling down to 83% for 3thiol-30%iso and 87% for 4thiol-30%iso). Furthermore, the differences in

Rr between the different formulations when they are programmed at

TgE′ are higher than when they are programmed at

Tg + 20. According to Pandini

et al. [

41], loading at a temperature below the

Tg involves more energetic changes (elastic and hardening processes) while loading at a temperature above the

Tg involves mostly entropic changes. The energy lost during the loading process is higher when the loading involves more energetic molecular changes (at

TgE′) [

42] because of molecular friction. The low initial chain mobility and the activation of the chain relaxation during programming at this temperature, result in some inter-molecular flow friction. Part of the deformation work corresponds to viscous flow and cannot be recovered, therefore the energy available for the recovery process is not enough to lead it to completion, resulting in a decrease in

Rr. In addition, depending on the nature of the chains (molecular structure), the energy lost during the loading process at

TgE′ is different. In the case of the NEAT formulations, the

Rr is higher and similar for both systems, 3thiol and 4thiol, while adding the isocyanurate decreases the

Rr in both systems probably due to the increase in the rigidity of the chains. Moreover, the 3thiol-30%iso shows a lower value of

Rr than the 4thiol-30%iso. This must be connected with the previous results of the thermo-mechanical characterization of the materials. Both the presence of the side ethyl chain in the structure of 3thiol and some reactivity and compatibility issues, resulting in a distortion of the network structure and mobility and a broadening of the relaxation, may explain the higher energy losses in the 3thiol formulation with 30% iso. These results suggests that by properly varying the

Tprog a balance enhancing both, the mechanical response and the shape-recovery capability is possible.

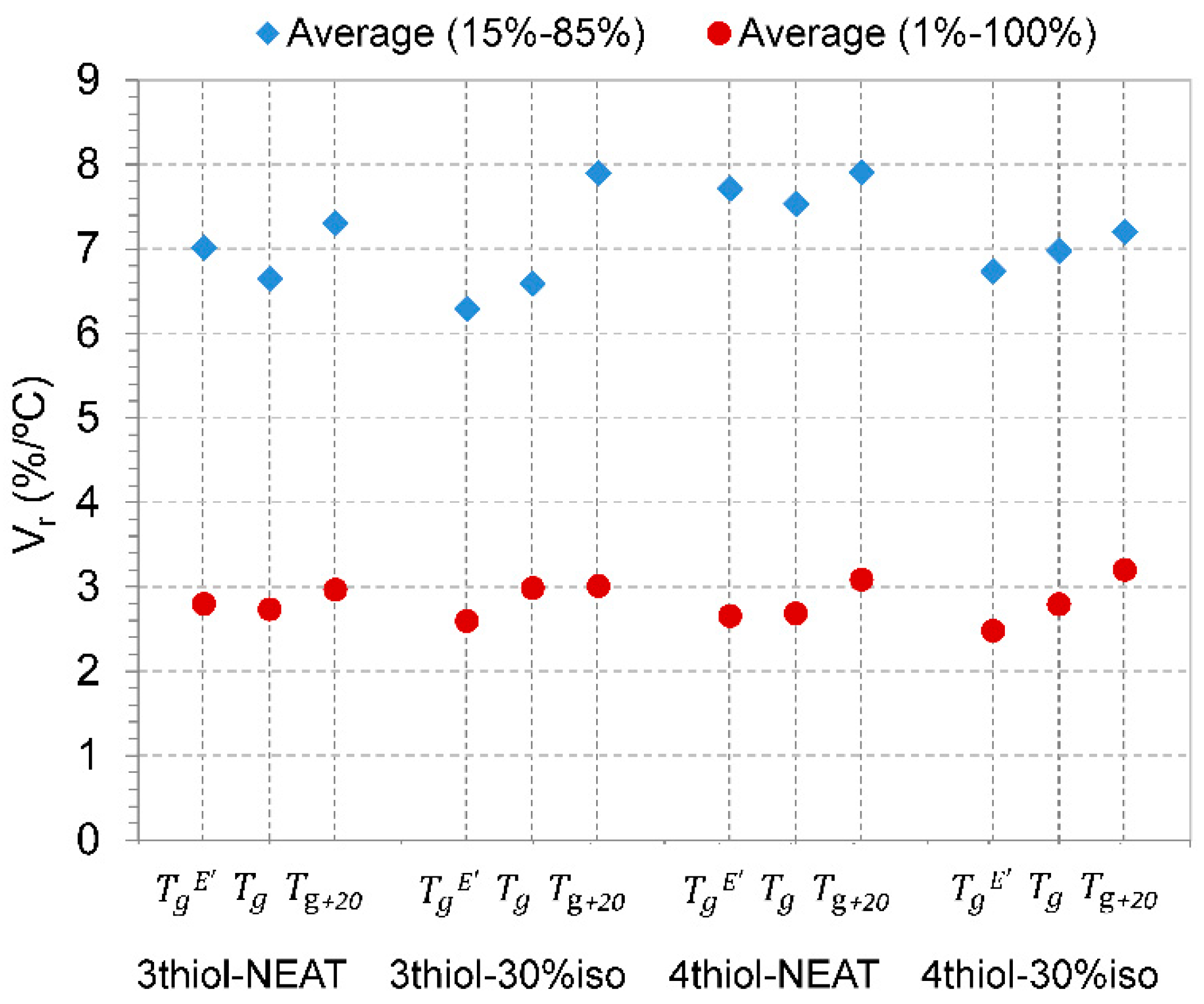

In

Figure 11, the shape-recovery process is analyzed by means of

Vr (through 3 consecutive cycles), enclosing the whole process (from 1% to 100% of the original shape recovered), or avoiding the early and final stages (from 15% to 85%). In general, as it was expected from the results of the qualitative study, all the formulations have shown very high values. If one focuses on the middle stage (15%–85%), the values range from 6.3%/°C to 8%/°C which are comparable with those reported by [

15], thus, allowing almost fully recover of the original shape in very few minutes. On the other hand, using the average (1%–100%), the effect of both the early and final stages is incorporated. As it can be seen, the time needed to fully recover the original shape is 2 or 3 times higher. These results evidence that the shape-recovery process is limited by the early and final stages and therefore the control of these stages is crucial to adjust the shape-recovery process as desired.

Figure 11.

Shape-recovery rate (%/°C), enclosing the whole shape-recovery process (1%–100%) and avoiding the early and final stages (15%–85%), as a function of the programming temperature for all the formulations of study.

Figure 11.

Shape-recovery rate (%/°C), enclosing the whole shape-recovery process (1%–100%) and avoiding the early and final stages (15%–85%), as a function of the programming temperature for all the formulations of study.

On analyzing the effect of the programming temperature with the

Vr, it is seen an increment of the

Vr with the temperature. This phenomenon is well appreciated if one encloses the whole process (1%–100%) (

i.e., the 4thiol-30%iso increases the

Vr from 2.5%/°C up to 3.2%/°C and the 3thiol-30%iso from 2.6%/°C up to 3.0%/°C)., This is probably connected with the lower rate of recovery

Rr when programming at

TgE (see

Figure 10). Following the same line of reasoning as above, the lower amount of energy that is effectively stored and available for the recovery process (due to molecular friction losses) decreases both the recovery ratio

Rr and the

Vr, thus increasing the time needed to fully recover the original shape. It may be speculated that the resulting stretched network structure of the temporary shape is somewhat altered when programming at

TgE and this may also have an effect on the recovery rate. Whatever the specific cause, this is of particular importance in the case of the 3thiol-30%iso, being the effect of the programming temperature very strong in the central part of the process (15%–85%), and this may be connected with the lowering and broadening of the relaxation described above for the 3thiol-30% (see

Table 2 and

Figure 8).

In spite of the differences in the relaxation process of the different formulations described in the previous sections, the average recovery speed is similar among the different formulations, especially if one encloses the whole process (1% to 100%). The overall trends with respect to the network structure and the shape of the relaxation process are not as clearly defined as in the qualitative study and depend also on the programming temperature. The recovery process in the qualitative study was analyzed under isothermal conditions, using a fixed programming and recovery temperature relative to the network relaxation determined by DMA. Therefore, the time/velocity effect, which is connected with the relaxation dynamics, could be analyzed independently. In contrast, the shape-recovery takes place with increasing temperature in the quantitative study. In this case, there is a time-temperature coupling that adds complexity to the process and makes it more difficult to interpret the average recovery speed data, especially taking into account that there are small differences in terms of relaxation shape but clearly different relaxation temperatures. However, it has been observed that during the recovery process there is indeed a strong effect of the network relaxation dynamics, especially when temperature is still below Tg. There is an excellent correspondence between the early stage of the recovery process and the early stage of the relaxation process determined from the DMA experiments (data not shown). Afterwards, at some point, the temperature enhances the molecular mobility and the recovery process is able to proceed more freely causing acceleration and minimizing the effect of the network structure. Therefore, enclosing the whole process, the effect of the relaxation process is clearly minimized, while focusing on the central part (15%–85%) this effect on the early stage has a major role. To this end, by properly tailoring the network structure and programming temperature, the effect at the early stage of the shape-recovery process can be tuned as desired, obtaining higher or lower rates which at the end of the process will be adjusted.

In conclusion, these results evidence the possibility to tailor the early stage and eventually the whole shape-recovery process by properly modifying the network structure and its relaxation dynamics, and the programming temperature. Moreover, the effect on the mechanical properties (stress and strain at break) is also investigated, thus, making possible a balance between mechanical performance and shape-memory performance.