Mechanical Characterization of PLA+ Specimens with Different Geometries Using Experimental and Numerical Methods

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Design of Test Specimens

2.3. Printing Process

2.4. Tensile Testing

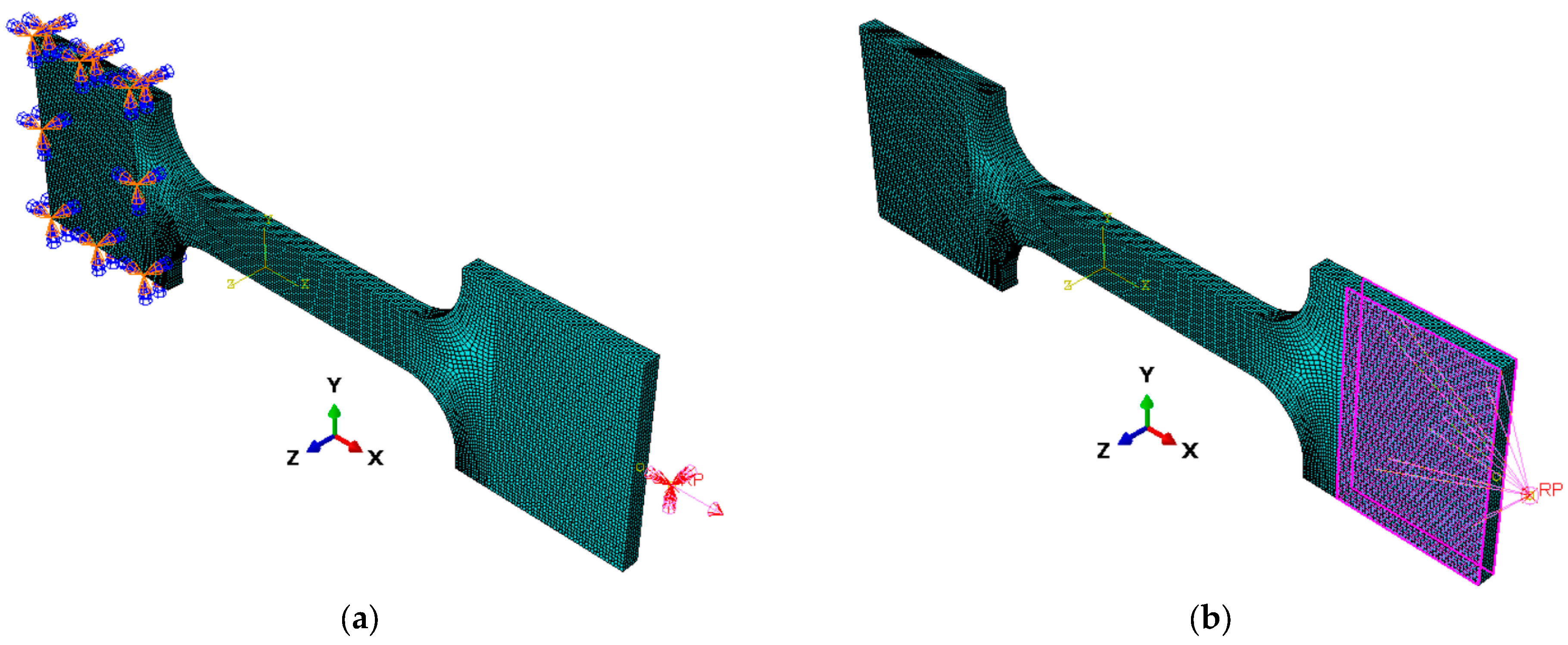

2.5. Finite Element Analysis

2.5.1. Material Model and Constitutive Equations

2.5.2. Material Parameters

- Young’s modulus, MPa, determined from the linear portion of the experimental stress–strain curve,

- Poisson’s ratio, ν = 0.35, consistent with values commonly reported for PLA-based polymers;

- Mass density, ρ = 1.23 g/cm3 according to the manufacturer’s specification.

- Strength coefficient, MPa

- Strain hardening exponent,

2.5.3. Finite Element Implementation

2.5.4. Model Validation and Output

2.5.5. Physical Interpretation

3. Results

3.1. Tensile Properties and Apparent Elastic Modulus for Different Geometries

3.2. Stress and Plastic Strain Distributions

3.3. Experimental–Numerical Correlation and Effect of Specimen Geometry

4. Discussion

5. Conclusions

- Baseline mechanical behavior:

- Effect of circular holes:

- Effect of U-notches:

- Experimental–numerical correlation:

- Design implications:

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, C.; Liu, J. 3D Printing of Scaffolds for Tissue Engineering. In 3D Printing; Cvetković, D., Ed.; IntechOpen: London, UK, 2018. [Google Scholar]

- Fu, H.; Kaewunruen, S. State-of-the-Art Review on Additive Manufacturing Technology in Railway Infrastructure Systems. J. Compos. Sci. 2022, 6, 7. [Google Scholar] [CrossRef]

- Martinez, D.W.; Espino, M.T.; Cascolan, H.M.; Crisostomo, J.L.; Dizon, J.R.C. A Comprehensive Review on the Application of 3D Printing in the Aerospace Industry. Key Eng. Mater. 2022, 913, 27–34. [Google Scholar] [CrossRef]

- Grygier, D.; Kujawa, M.; Kowalewski, P. Deposition of Biocompatible Polymers by 3D Printing (FDM) on Titanium Alloy. Polymers 2022, 14, 235. [Google Scholar] [CrossRef]

- Hsueh, M.-H.; Lai, C.-J.; Liu, K.-Y.; Chung, C.-F.; Wang, S.-H.; Pan, C.-Y.; Huang, W.-C.; Hsieh, C.-H.; Zeng, Y.-S. Effects of Printing Temperature and Filling Percentage on the Mechanical Behavior of Fused Deposition Molding Technology Components for 3D Printing. Polymers 2021, 13, 2910. [Google Scholar] [CrossRef]

- Saadi, M.A.S.R.; Maguire, A.; Pottackal, N.T.; Thakur, M.S.H.; Ikram, M.M.; Hart, A.J.; Ajayan, P.M.; Rahman, M.M. Direct Ink Writing: A 3D Printing Technology for Diverse Materials. Adv. Mater. 2022, 34, 2108855. [Google Scholar] [CrossRef]

- Aversa, A.; Fino, P. Special Issue on Materials Development by Additive Manufacturing Techniques. Appl. Sci. 2020, 10, 5119. [Google Scholar] [CrossRef]

- Mhetre, G.; Jadhav, V.; deshmukh, S.; Thakar, C. A Review on Additive Manufacturing Technology. ECS Trans. 2022, 107, 15355–15374. [Google Scholar] [CrossRef]

- Kadhum, A.H.; Al-Zubaidi, S.; Abdulkareem, S.S. Effect of the Infill Patterns on the Mechanical and Surface Characteristics of 3D Printing of PLA, PLA+ and PETG Materials. ChemEngineering 2023, 7, 46. [Google Scholar] [CrossRef]

- Akhoundi, B.; Nabipour, M.; Hajami, F.; Shakoori, D. An Experimental Study of Nozzle Temperature and Heat Treatment (Annealing) Effects on Mechanical Properties of High-Temperature Polylactic Acid in Fused Deposition Modeling. Polym. Eng. Sci. 2020, 60, 979–987. [Google Scholar] [CrossRef]

- Gangwar, S.; Saxena, P.; Biermann, T.; Steinnagel, C.; Lachmayer, R. Influence of Build Height on Quality of Additively Manufactured Thermoplastic Polyurethane Parts. Adv. Eng. Mater. 2024, 26, 2400293. [Google Scholar] [CrossRef]

- Nguyen, V.D.; Trinh, T.X.; Minh, P.S.; Nguyen, T.H. Influence of Layer Parameters in Fused Deposition Modeling Three-Dimensional Printing on the Tensile Strength of a Product. Key Eng. Mater. 2020, 861, 182–187. [Google Scholar] [CrossRef]

- Plamadiala, I.; Croitoru, C.; Pop, M.A.; Roata, I.C. Enhancing Polylactic Acid (PLA) Performance: A Review of Additives in Fused Deposition Modelling (FDM) Filaments. Polymers 2025, 17, 191. [Google Scholar] [CrossRef]

- Hanon, M.; Marczis, R.; Zsidai, L. Influence of the 3D printing process settings on tensile strength of PLA and HT-PLA. Period. Polytech. Mech. Eng. 2020, 65, 38–46. [Google Scholar] [CrossRef]

- Thumsorn, S.; Prasong, W.; Kurose, T.; Ishigami, A.; Kobayashi, Y.; Ito, H. Rheological Behavior and Dynamic Mechanical Properties for Interpretation of Layer Adhesion in FDM 3D Printing. Polymers 2022, 14, 2721. [Google Scholar] [CrossRef]

- Boztepe, M.H. Effect of Infill Density and Raster Angle on the Flexural Properties of FDM-Printed PLA+ Specimens. Adıyaman Üniversitesi Mühendislik Bilim. Derg. 2025, 12, 451–462. [Google Scholar] [CrossRef]

- Boztepe, M.H. A Study on the Mechanical Properties of PLA+ Samples Manufactured Using 3d Printing with Different Raster Angles. Kahramanmaraş Sütçü İmam Üniversitesi Mühendislik Bilim. Derg. 2025, 28, 923–932. [Google Scholar] [CrossRef]

- Eyri, B.; Gul, O.; Yilmaz, S.; Karsli, N.G.; Yilmaz, T. Characterization of ABS/PETG multi-material composites 3D printed by print-pause-print method. Polym. Eng. Sci. 2025, 65, 2353–2369. [Google Scholar] [CrossRef]

- Shanmugam, V.; Babu, K.; Kannan, G.; Mensah, R.; Samantaray, S.K.; Das, O. The thermal properties of FDM printed polymeric materials: A review. Polym. Degrad. Stab. 2024, 228, 110902. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, D.; Chen, S.-C. A review of emission characteristics and control strategies for particles emitted from 3D fused deposition modeling (FDM) printing. Build. Environ. 2022, 221, 109348. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. An Overview of Polylactides as Packaging Materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Kulich, D.M.; Gaggar, S.K.; Lowry, V.; Stepien, R. Acrylonitrile–Butadiene–Styrene (ABS) Polymers. In Kirk-Othmer Encyclopedia of Chemical Technology; Wiley Online Library: Hoboken, NJ, USA, 2000. [Google Scholar]

- Jayanth, N.; Jaswanthraj, K.; Sandeep, S.; Mallaya, N.H.; Siddharth, S.R. Effect of heat treatment on mechanical properties of 3D printed PLA. J. Mech. Behav. Biomed. Mater. 2021, 123, 104764. [Google Scholar] [CrossRef]

- Ulkir, O.; Ertugrul, I.; Ersoy, S.; Yağımlı, B. The Effects of Printing Temperature on the Mechanical Properties of 3D-Printed Acrylonitrile Butadiene Styrene. Appl. Sci. 2024, 14, 3376. [Google Scholar] [CrossRef]

- Brenes, R.G.R.; Santos, I.M.T.S.; de Carvalho, L.d.S.C.; Bojorge Ramírez, N.I.; Pereira, N. Characterization of 3D-printed acrylonitrile butadiene styrene and polylactic acid carrier-beads for Gluconobacter oxydans immobilization. J. Biotechnol. 2025, 406, 154–167. [Google Scholar] [CrossRef]

- Yılmaz, M. Sustainable Recycling Pla and Abs Materials in Additive Manufacturing: Effects on Strength, Thermal Stability, and Environmental Impact. Int. J. 3D Print. Technol. Digit. Ind. 2025, 9, 142–154. [Google Scholar] [CrossRef]

- Pang, R.; Yong, Y.C.; Lai, M.K. Effect of humidity on the degradation of fused deposition modelling fabricated PLA parts. In Innovative Manufacturing, Mechatronics & Materials Forum 2022 (iM3F 2022); IET: Lucknow, India, 2022; Volume 2022, pp. 40–44. [Google Scholar]

- Molina, A.; Acosta-Sullcahuamán, J. Effect of the Process Parameters on the Mechanical Properties of 3D-Printed Specimens Fabricated by Material Extrusion 3D Printing. Eng. Proc. 2025, 83, 1. [Google Scholar]

- Ageyeva, T.; Kovács, J.G.; Tábi, T. Comparison of the efficiency of the most effective heterogeneous nucleating agents for Poly(lactic acid). J. Therm. Anal. Calorim. 2022, 147, 8199–8211. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A. The Influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A Comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef]

- Özsoy, K.; Erçetin, A.; Çevik, Z.A. Comparison of Mechanical Properties of PLA and ABS Based Structures Produced by Fused Deposition Modelling Additive Manufacturing. Avrupa Bilim Teknol. Derg. 2021, 27, 802–809. [Google Scholar] [CrossRef]

- Romadhon, S.R.; Hidayat, W.; Widagdo, B.S. The Effect of Infill Variation on the Tensile, Bending, Impact, Hardness, and Density Properties of PLA and ABS Materials Produced by FDM. Multidiscip. Innov. Res. Appl. Eng. 2025, 2, 97–111. [Google Scholar] [CrossRef]

- Umer, M.H.; Rehman, M.-U.; Ali, S.; Raza, A.; Muzammil, L.; Ijaz, M.S.; Khan, M.B.; Zafar, M.Q. Significance of Infill Density on Mechanical Performance in Fused Deposition Modeling. In Proceedings of the 2nd International Conference on Modern Technologies in Mechanical & Materials Engineering (MTME-2024), Topi, Pakistan, 20 April 2024. [Google Scholar] [CrossRef]

- Dağlı, S. Mechanical Characterization and Interface Evaluation of Multi-Material Composites Manufactured by Hybrid Fused Deposition Modeling (HFDM). Polymers 2025, 17, 1631. [Google Scholar] [CrossRef]

- Suder, J.; Bobovský, Z.; Mlotek, J.; Vocetka, M.; Zeman, Z.; Šafář, M. Experimental Analysis of Temperature Resistance of 3d Printed Pla Components. MM Sci. J. 2021, 2021, 4322–4327. [Google Scholar] [CrossRef]

- Tábi, T.; Ageyeva, T.; Kovács, J.G. Improving the ductility and heat deflection temperature of injection molded Poly(lactic acid) products: A comprehensive review. Polym. Test. 2021, 101, 107282. [Google Scholar] [CrossRef]

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Olaya-Rincon, M.; Serra-Rada, J.; Da Silva, C.; Barcelona, P.; Dosta, J.; Astals, S.; Martínez, M. Thermophilic anaerobic biodegradation of commercial polylactic acid products. Bioresour. Technol. 2025, 425, 132296. [Google Scholar] [CrossRef] [PubMed]

- Karamanlioglu, M.; Preziosi, R.; Robson, G.D. Abiotic and biotic environmental degradation of the bioplastic polymer poly(lactic acid): A review. Polym. Degrad. Stab. 2017, 137, 122–130. [Google Scholar] [CrossRef]

- Da Silva, D.; Kaduri, M.; Poley, M.; Adir, O.; Krinsky, N.; Shainsky-Roitman, J.; Schroeder, A. Biocompatibility, biodegradation and excretion of polylactic acid (PLA) in medical implants and theranostic systems. Chem. Eng. J. 2018, 340, 9–14. [Google Scholar] [CrossRef]

- Kumar, P.; Gupta, P.; Singh, I. Empirical Study on Thermomechanical Properties of 3D Printed Green, Renewable, and Sustainable Acrylonitrile Butadiene Styrene/Polylactic Acid Blended Parts. J. Mater. Eng. Perform. 2024, 33, 9255–9266. [Google Scholar] [CrossRef]

- Munshi, G.; Kulkarni, V. A comprehensive study on restoring properties in expired/aged ABS materials: Advanced techniques, additive integration and challenges for sustainable industrial reuse and manufacturing. J. Mater. Sci. Mater. Eng. 2025, 20, 48. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Sarkar, A.; Dasgupta, A.; Dutta, P.; Paul, S. Exploring the Applications and Constraints of PLA and ABS Materials in Structural Additive Manufacturing: A Review. J. Adv. Manuf. Syst. 2025, 24, 1–35. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Kuznetsov, V.E.; Solonin, A.N.; Urzhumtsev, O.D.; Schilling, R.; Tavitov, A.G. Strength of PLA Components Fabricated with Fused Deposition Technology Using a Desktop 3D Printer as a Function of Geometrical Parameters of the Process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef]

- Gomez-Gras, G.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Lluma-Fuentes, J. Fatigue performance of fused filament fabrication PLA specimens. Mater. Des. 2018, 140, 278–285. [Google Scholar] [CrossRef]

- Dezaki, M.; Ariffin, M.; Hatami, S. An overview of fused deposition modelling (FDM): Research, development and process optimisation. Rapid Prototyp. J. 2021, 27, 562–582. [Google Scholar] [CrossRef]

- Vyavahare, S.; Teraiya, S.; Panghal, D.; Kumar, S. Fused deposition modelling: A review. Rapid Prototyp. J. 2020, 26, 176–201. [Google Scholar] [CrossRef]

- Rajan, K.; Samykano, M.; Kadirgama, K.; Harun, W.; Rahman, M.M. Fused deposition modeling: Process, materials, parameters, properties, and applications. Int. J. Adv. Manuf. Technol. 2022, 120, 1531–1570. [Google Scholar] [CrossRef]

- Galetto, M.; Verna, E.; Genta, G. Effect of process parameters on parts quality and process efficiency of fused deposition modeling. Comput. Ind. Eng. 2021, 156, 107238. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of Strength Properties of FDM Printed Parts—A Critical Review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef]

- Dey, A.; Yodo, N. A Systematic Survey of FDM Process Parameter Optimization and Their Influence on Part Characteristics. J. Manuf. Mater. Process. 2019, 3, 64. [Google Scholar] [CrossRef]

- Boztepe, M.H. Investigation of Tensile Strength in 3D Printed PLA+ Samples: Influence of Raster Angle and Infill Density. Çukurova Üniversitesi Mühendislik Fakültesi Derg. 2025, 40, 937–948. [Google Scholar] [CrossRef]

- Raza, U.; Ahmed, A.; Waheed, S.; Abid, M.; Tahir, M.; Zahid, A.; Ahmed, A.; Bilal, M.; Hussain, T.; Mustafa, G. Recent Advancements in Fused Deposition Modeling. Polym. Adv. Technol. 2025, 36, e70028. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C. Optimization of printing parameters in fused deposition modeling for improving part quality and process sustainability. Int. J. Adv. Manuf. Technol. 2020, 108, 2131–2147. [Google Scholar] [CrossRef]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of fused deposition modeling process parameters: A review of current research and future prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- Prayitno, G.; Imaduddin, F.; Ubaidillah; Arifin, Z. Recent Progress of Fused Deposition Modeling (FDM) 3D Printing: Constructions, Parameters and Processings. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1096. [Google Scholar] [CrossRef]

- Gordeev, E.; Galushko, A.; Ananikov, V. Improvement of quality of 3D printed objects by elimination of microscopic structural defects in fused deposition modeling. PLoS ONE 2018, 13, e0198370. [Google Scholar] [CrossRef]

- Li, H.; Wang, T.; Joshi, S.; Yu, Z. The quantitative analysis of tensile strength of additively manufactured continuous carbon fiber reinforced polylactic acid (PLA). Rapid Prototyp. J. 2019, 25, 1624–1636. [Google Scholar] [CrossRef]

- Hart, K.R.; Wetzel, E.D. Fracture behavior of additively manufactured acrylonitrile butadiene styrene (ABS) materials. Eng. Fract. Mech. 2017, 177, 1–13. [Google Scholar] [CrossRef]

- McLouth, T.D.; Severino, J.V.; Adams, P.M.; Patel, D.N.; Zaldivar, R.J. The impact of print orientation and raster pattern on fracture toughness in additively manufactured ABS. Addit. Manuf. 2017, 18, 103–109. [Google Scholar] [CrossRef]

- ASTM D5045-14(2022); Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials. ASTM: West Conshohocken, PA, USA, 2022.

- Rankouhi, B.; Javadpour, S.; Delfanian, F.; Letcher, T. Failure Analysis and Mechanical Characterization of 3D Printed ABS With Respect to Layer Thickness and Orientation. J. Fail. Anal. Prev. 2016, 16, 467–481. [Google Scholar] [CrossRef]

- Aliheidari, N.; Tripuraneni, R.; Ameli, A.; Nadimpalli, S. Fracture resistance measurement of fused deposition modeling 3D printed polymers. Polym. Test. 2017, 60, 94–101. [Google Scholar] [CrossRef]

- Mishra, V.; Ror, C.K.; Negi, S.; Kar, S. Enhanced fracture toughness and tensile strength of 3D printed recycled ABS composites reinforced with continuous metallic fiber for load-bearing application. Rapid Prototyp. J. 2024, 30, 760–769. [Google Scholar] [CrossRef]

- Senatov, F.S.; Niaza, K.V.; Zadorozhnyy, M.Y.; Maksimkin, A.V.; Kaloshkin, S.D.; Estrin, Y.Z. Mechanical properties and shape memory effect of 3D-printed PLA-based porous scaffolds. J. Mech. Behav. Biomed. Mater. 2016, 57, 139–148. [Google Scholar] [CrossRef] [PubMed]

- Tamburrino, F.; Graziosi, S.; Bordegoni, M. The influence of slicing parameters on the multi-material adhesion mechanisms of FDM printed parts: An exploratory study. Virtual Phys. Prototyp. 2019, 14, 316–332. [Google Scholar] [CrossRef]

- Rojas-Martínez, L.E.; Flores-Hernandez, C.G.; López-Marín, L.M.; Martinez-Hernandez, A.L.; Thorat, S.B.; Reyes Vasquez, C.D.; Del Rio-Castillo, A.E.; Velasco-Santos, C. 3D printing of PLA composites scaffolds reinforced with keratin and chitosan: Effect of geometry and structure. Eur. Polym. J. 2020, 141, 110088. [Google Scholar] [CrossRef]

- Brischetto, S.; Torre, R. Tensile and Compressive Behavior in the Experimental Tests for PLA Specimens Produced via Fused Deposition Modelling Technique. J. Compos. Sci. 2020, 4, 140. [Google Scholar] [CrossRef]

- Obaidat, S.; Tamimi, M.F.; Mumani, A.; Alkhaleel, B. An artificial neural network-based predictive model for tensile behavior estimation under uncertainty for fused deposition modeling. Rapid Prototyp. J. 2024, 30, 2056–2070. [Google Scholar] [CrossRef]

- Alaimo, G.; Marconi, S.; Costato, L.; Auricchio, F. Influence of meso-structure and chemical composition on FDM 3D-printed parts. Compos. Part B Eng. 2017, 113, 371–380. [Google Scholar] [CrossRef]

- Duan, X.; Yuan, H.; Tang, W.; He, J.; Guan, X. A General Temperature-Dependent Stress–Strain Constitutive Model for Polymer-Bonded Composite Materials. Polymers 2021, 13, 1393. [Google Scholar] [CrossRef]

- Sweeney, J.; Spencer, P.; Thompson, G.; Barker, D.; Coates, P. Constitutive Modelling of Polylactic Acid at Large Deformation Using Multiaxial Strains. Polymers 2021, 13, 2967. [Google Scholar] [CrossRef]

- Slavković, V.; Hanželič, B.; Plesec, V.; Milenković, S.; Harih, G. Thermo-Mechanical Behavior and Strain Rate Sensitivity of 3D-Printed Polylactic Acid (PLA) below Glass Transition Temperature (Tg). Polymers 2024, 16, 1526. [Google Scholar] [CrossRef]

- Nakai, K.; Yokoyama, T. High strain-rate compressive behavior and constitutive modeling of selected polymers. EPJ Web Conf. 2012, 26, 01061. [Google Scholar] [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- Kadhum, A.; Al-Zubaidi, S.; AlKareem, S. Optimization of Mechanical Properties and Surface Characteristics of PLA+ 3D Printing Materials. Int. J. Chem. Eng. 2023, 2023, 8887905. [Google Scholar] [CrossRef]

- Sukindar, N.; Yasir, A.S.H.M.; Azhar, M.D.; Azhar, M.A.M.; Halim, N.F.H.A.; Sulaiman, M.H.; Sabli, A.S.H.A.; Ariffin, M.K.A.M. Evaluation of the surface roughness and dimensional accuracy of low-cost 3D-printed parts made of PLA–aluminum. Heliyon 2024, 10, e25508. [Google Scholar] [CrossRef]

- Kartal, F.; Kaptan, A. Response of PLA material to 3D printing speeds: A comprehensive examination on mechanical properties and production quality. Eur. Mech. Sci. 2024, 8, 137–144. [Google Scholar] [CrossRef]

- Lei, M.; Liu, P.; Niu, C.; Xu, Y.; Li, Q.; Liang, X.; Chen, H. Characteristics of the Mesostructure of 3D-Printed PLA/GNP Composites. J. Compos. Sci. 2025, 9, 585. [Google Scholar] [CrossRef]

| Property | PLA | ABS | Key References |

|---|---|---|---|

| Chemical nature | Polylactic acid (biodegradable polyester) | Acrylonitrile–butadiene–styrene (petroleum-based polymer) | [17,18,21,22,23,24] |

| Print temperature (°C) | 190–220 | 230–270 | [18,25] |

| Glass transition temperature (°C) | ~60–65 | ~105 | [26,27,28] |

| Tensile strength (MPa) | 50–70 | 30–50 | [18,25,29] |

| Elongation at break (%) | 2–10 | 20–40 | [18,30,31,32] |

| Density (g/cm3) | ~1.25 | ~1.05 | [25,32,33] |

| Impact resistance | Low | Moderate to high | [30,31,32,34,35,36] |

| Thermal resistance (°C) | Poor (~50–60) | Better (~70–80) | [13,37,38] |

| Biodegradability | High | Non-biodegradable | [38,39,40,41,42,43,44] |

| Typical issues in FDM printing | Brittle behavior, low heat resistance | Warping, odor emission | [13,19,20,39,45,46,47] |

| Need for improvement | Improved PLA+ | - | Present study |

| Density (g/cm3) | 1.23 |

| Tensile Strength (MPa) | 60 |

| Flexural Strength (MPa) | 74 |

| Flexural Modulus (MPa) | 1973 |

| Elongation at Break (%) | 20 |

| Extruder Temperature (°C) | 210–230 |

| Bed Temperature (°C) | 45–60 |

| Printing Speed (mm/s) | 40–100 |

| Layer Thickness (mm) | 0.2 |

| Printer Resolution (mm) | 0.2 |

| Elastic Properties | |||

|---|---|---|---|

| Property | Symbol | Value | Unit |

| Young’s Modulus | E | 3061.7 | MPa |

| Poisson’s Ratio | ν | 0.35 | - |

| Density | ρ | 1.23 | g/cm3 |

| ) | |||

| Property | Symbol | Value | Unit |

| Strength Coefficient | K | 45 | MPa |

| Strain Hardening Exponent | n | 0.014 | - |

| Tabular Plastic Data For Abaqus (Hardening Region) | |||

| True Stress (MPa) | Plastic Strain | ||

| 41.11 | 0.00263 | ||

| 41.67 | 0.00335 | ||

| 41.73 | 0.00345 | ||

| 41.79 | 0.00369 | ||

| 41.83 | 0.00398 | ||

| 41.73 | 0.00465 | ||

| 41.64 | 0.00490 | ||

| 41.40 | 0.00545 | ||

| 40.53 | 0.00703 | ||

| 38.48 | 0.00882 | ||

| Specimen Type | Samples | Ultimate Tensile Strength (MPa) | Elongation at Max. Stress (%) |

|---|---|---|---|

| Dog-bone | 1 | 41.13 | 1.7 |

| Dog-bone | 2 | 42.75 | 1.8 |

| Dog-bone | 3 | 42.80 | 1.7 |

| Circular hole | 1 | 41.56 | 1.4 |

| Circular hole | 2 | 38.50 | 1.6 |

| Circular hole | 3 | 40.02 | 1.4 |

| U-notch | 1 | 47.15 | 1.0 |

| U-notch | 2 | 48.49 | 1.0 |

| U-notch | 3 | 46.92 | 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Boztepe, M.H.; Haskul, M. Mechanical Characterization of PLA+ Specimens with Different Geometries Using Experimental and Numerical Methods. Polymers 2026, 18, 243. https://doi.org/10.3390/polym18020243

Boztepe MH, Haskul M. Mechanical Characterization of PLA+ Specimens with Different Geometries Using Experimental and Numerical Methods. Polymers. 2026; 18(2):243. https://doi.org/10.3390/polym18020243

Chicago/Turabian StyleBoztepe, Mete Han, and Mehmet Haskul. 2026. "Mechanical Characterization of PLA+ Specimens with Different Geometries Using Experimental and Numerical Methods" Polymers 18, no. 2: 243. https://doi.org/10.3390/polym18020243

APA StyleBoztepe, M. H., & Haskul, M. (2026). Mechanical Characterization of PLA+ Specimens with Different Geometries Using Experimental and Numerical Methods. Polymers, 18(2), 243. https://doi.org/10.3390/polym18020243