Enhanced Mechanical Performance of Fluoroelastomer Composites with Boron–Gadolinium-Based Fillers for Cutting-Edge Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Gadolinium-Based-Materials Preparation

2.3. FKM-Based Composites Preparation

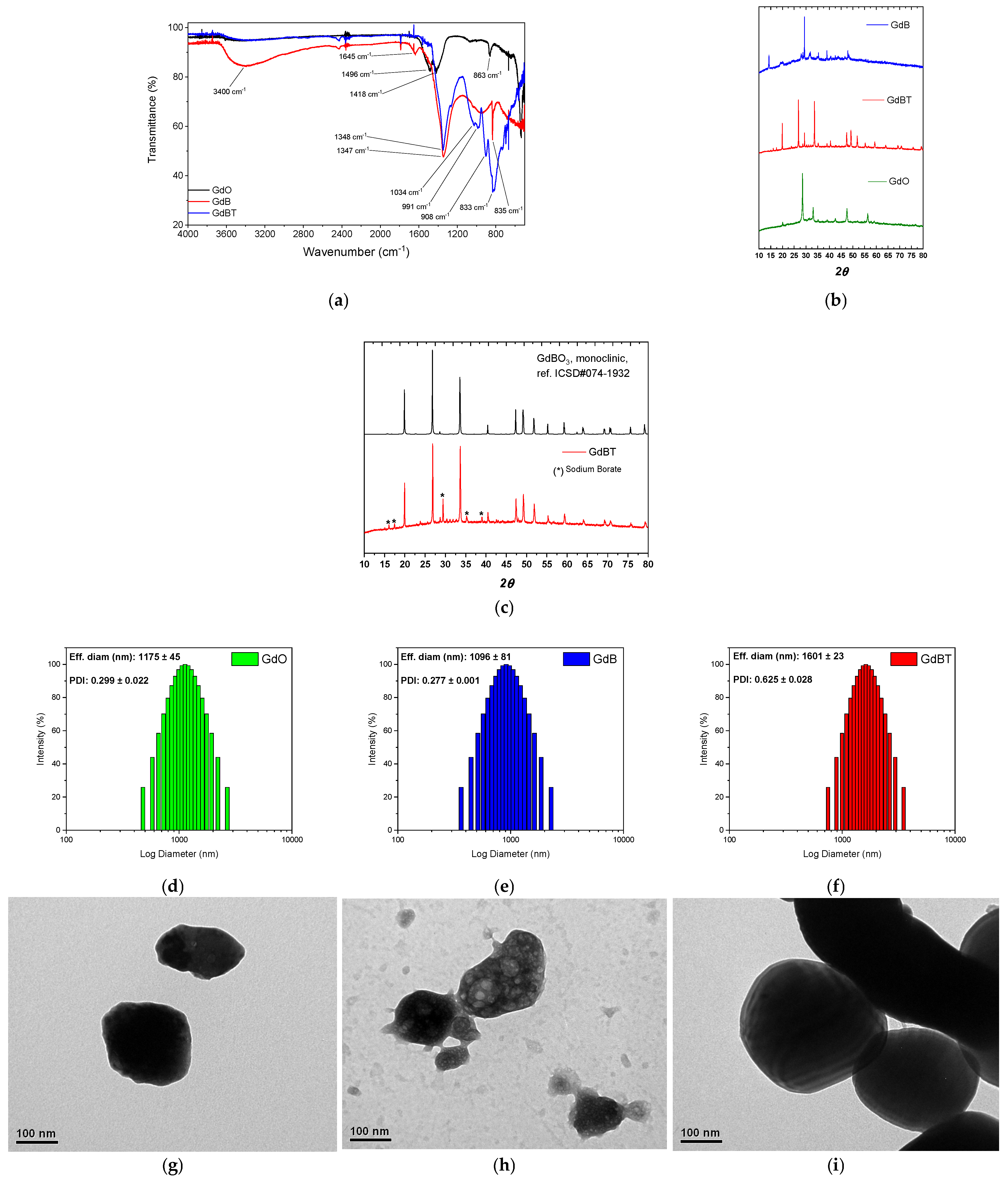

2.4. Characterization of Powder Materials

2.5. Characterization of Powder Fluoroelastomer Composites

3. Results and Discussion

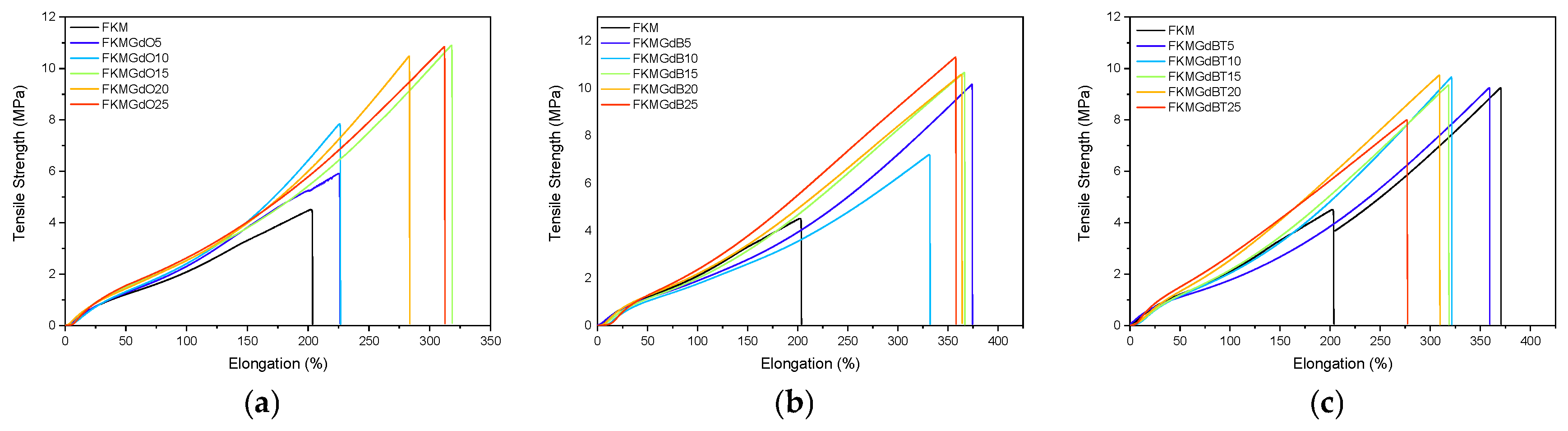

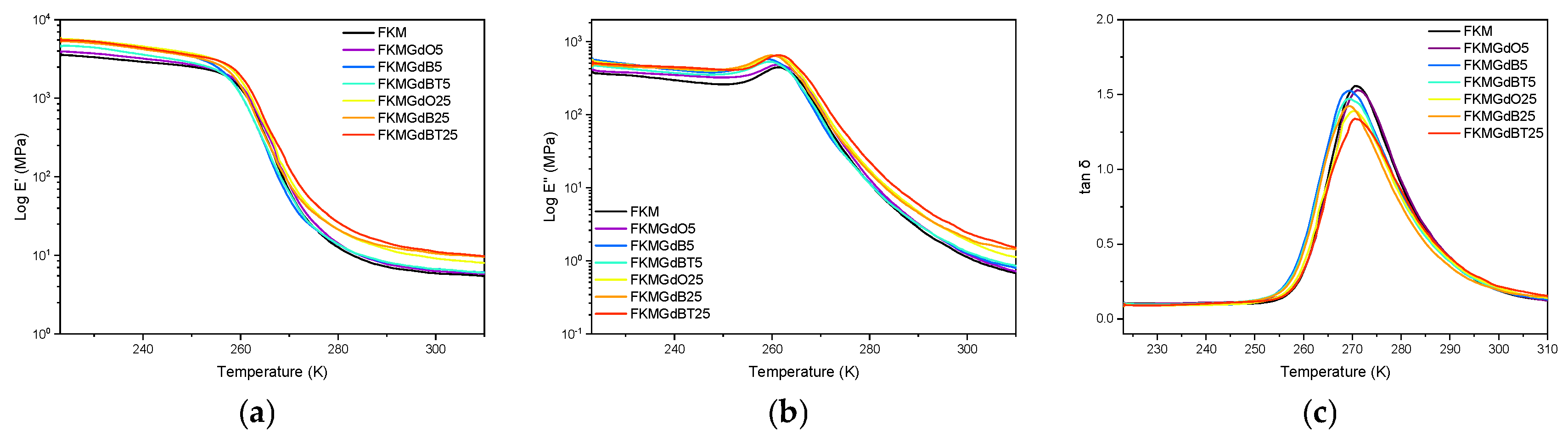

3.1. Curing, Mechanical and Dynamic Mechanical Properties of FKM-Based Composites

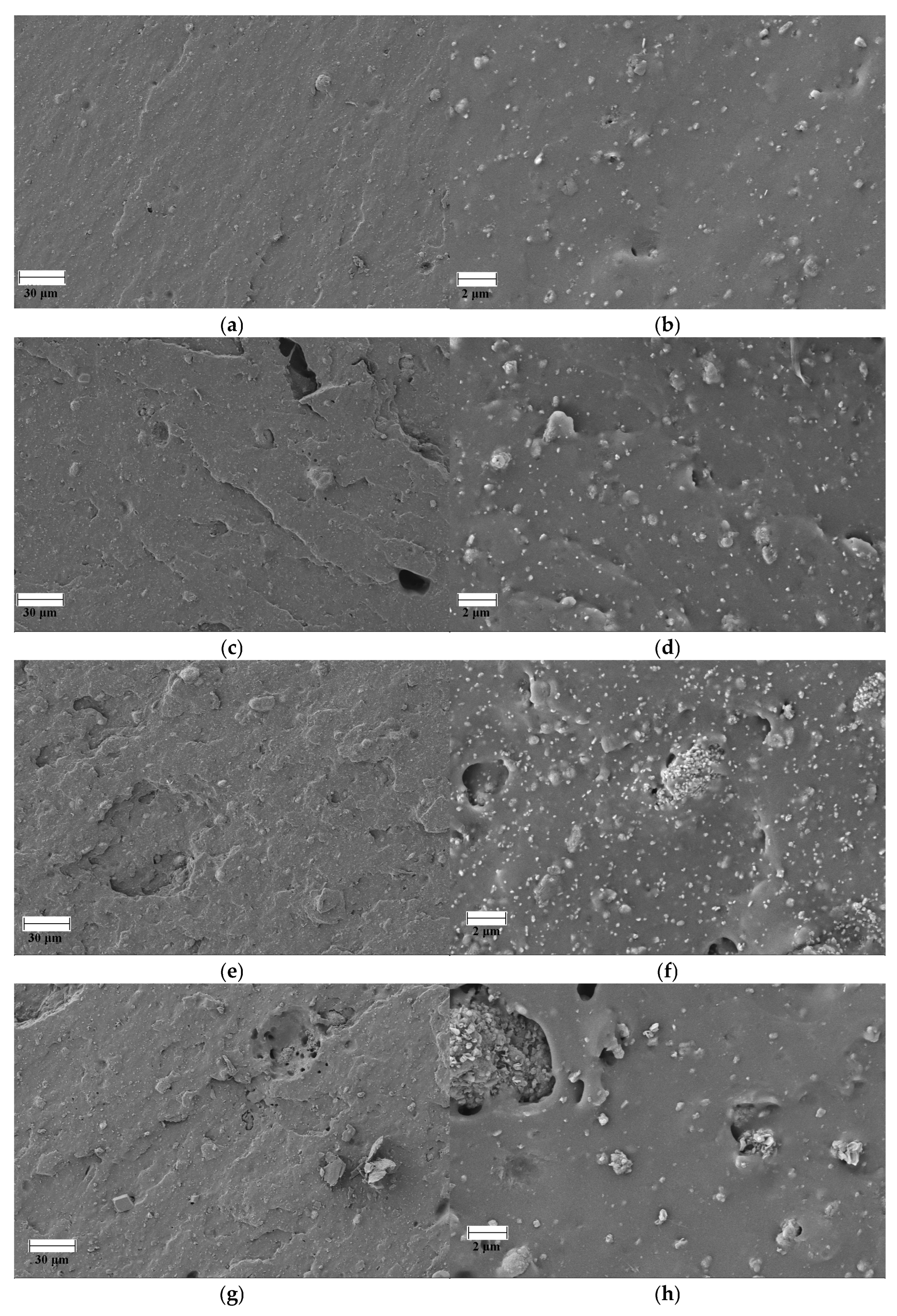

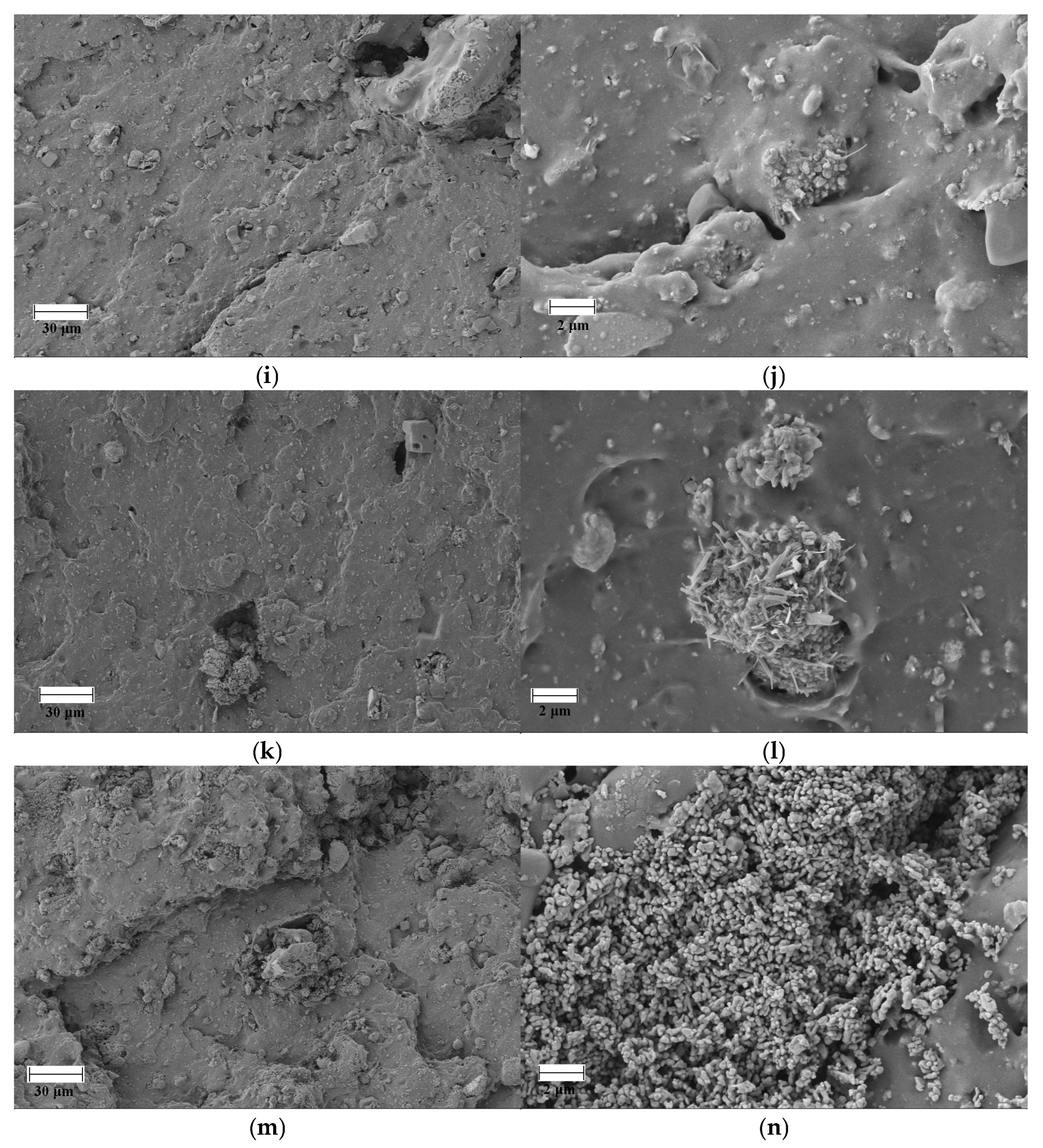

3.2. Morphology of Fluoroelastomers Based Composites

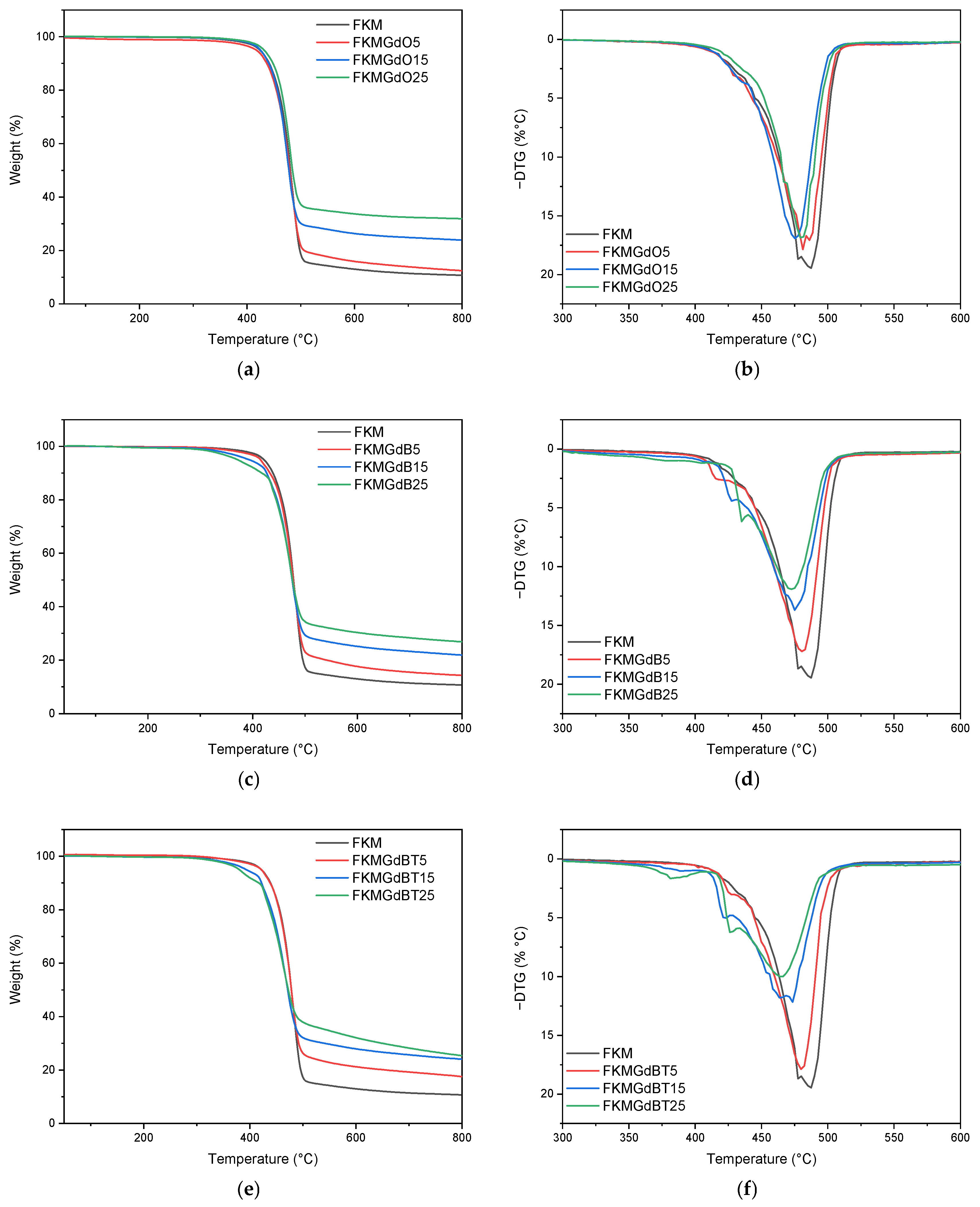

3.3. Thermogravimetric Analysis of Fillers and FKM Gadolinium Composites

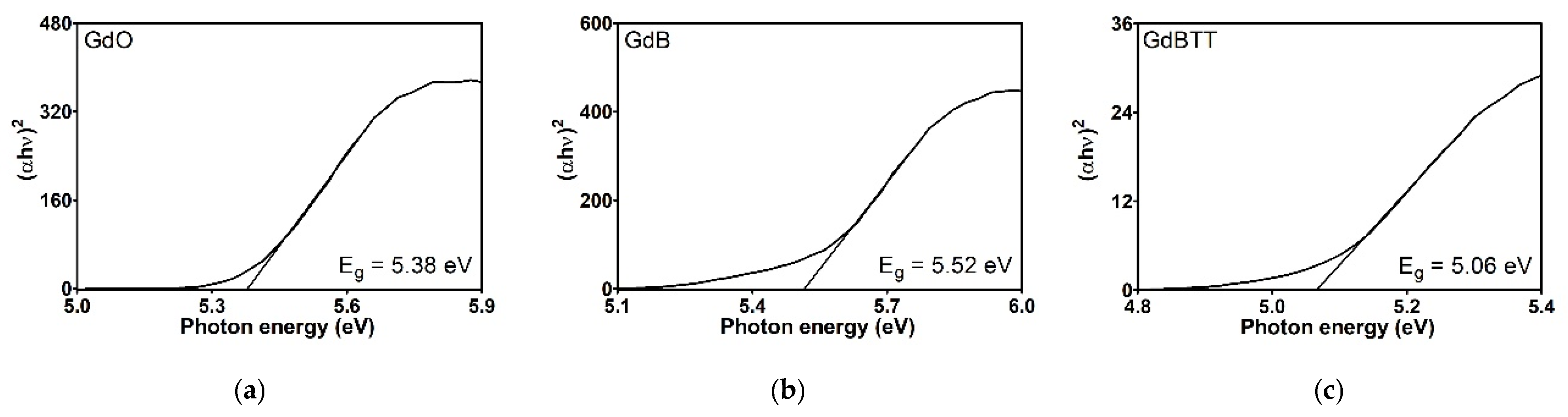

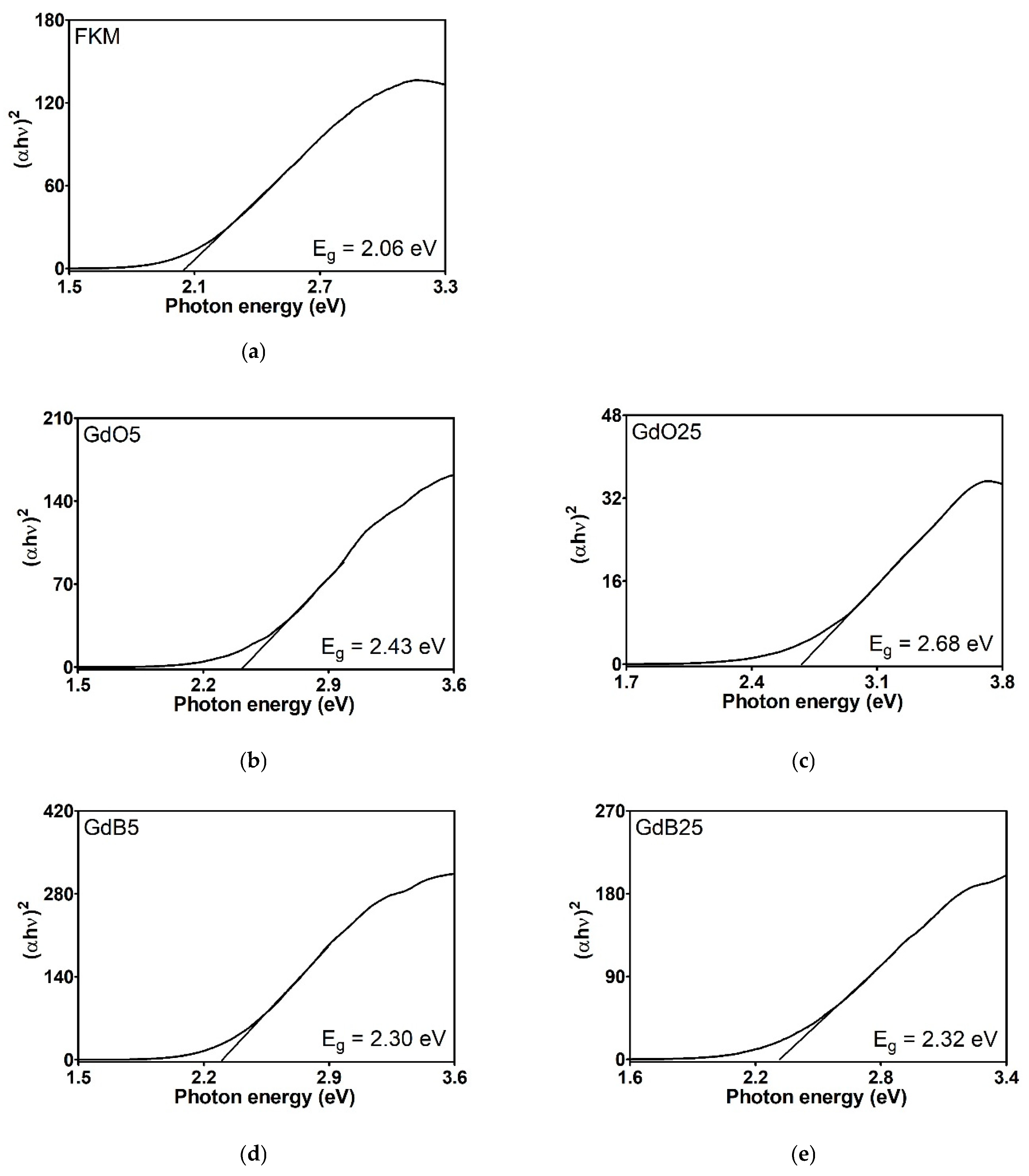

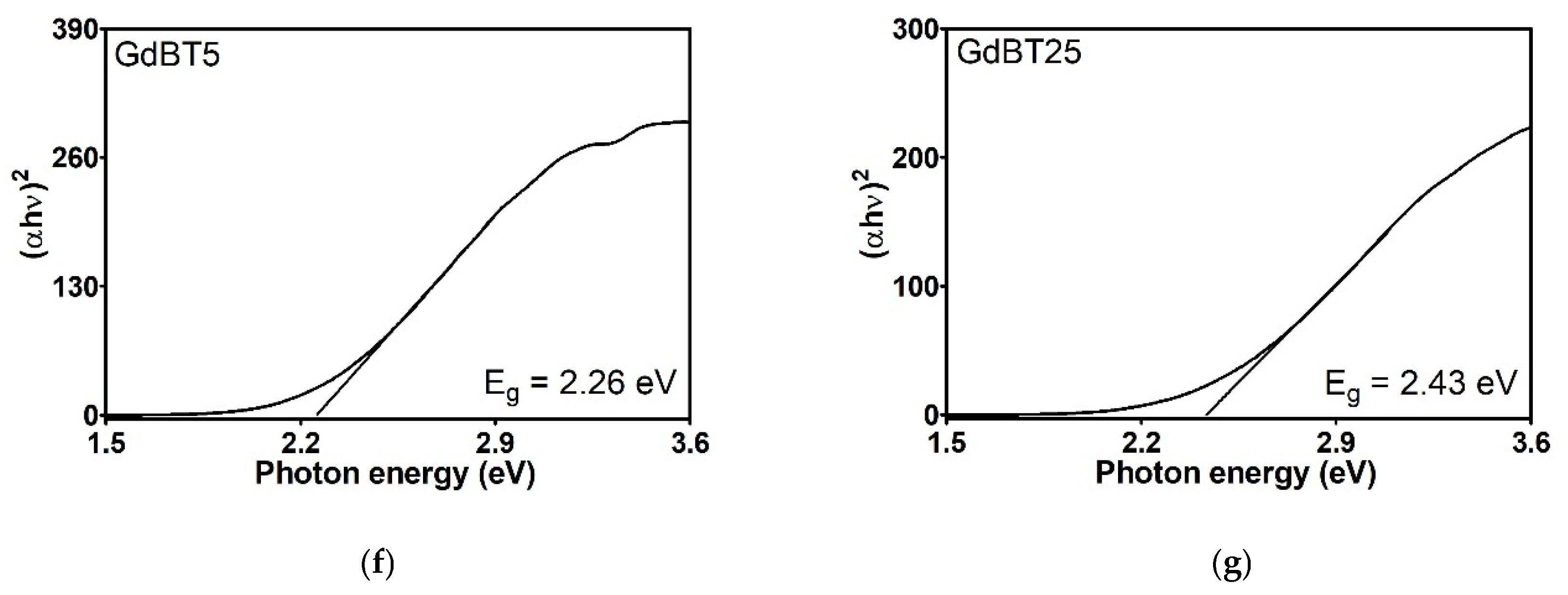

3.4. Surface Energy and Band Gap of Nanocomposites

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rodgers, B.; Waddell, W. The Science of Rubber Compounding. In Science and Technology of Rubber; Academic Press: Cambridge, MA, USA, 2005. [Google Scholar] [CrossRef]

- Aguilar-Bolados, H.; Yazdani-Pedram, M.; Verdejo, R. Thermal, Electrical, and Sensing Properties of Rubber Nanocomposites. In High-Performance Elastomeric Materials Reinforced by Nano-Carbons; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- ASTM D1418-22; Practice for Rubber and Rubber Latices Nomenclature. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Améduri, B.; Boutevin, B.; Kostov, G. Fluoroelastomers: Synthesis, properties and applications. Prog. Polym. Sci. 2001, 26, 105–187. [Google Scholar] [CrossRef]

- Ranieri, N. Elastomers in extreme environments applications. In High-Performance Elastomeric Materials Reinforced by Nano-Carbons: Multifunctional Properties and Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Magnere, S.M.; Toledo, E.A.; Yazdani-Pedram, M.; Fuentealba, P.; Contreras-Soto, A.; Bascuñan-Heredia, A.; Alvarez-Cortes, G.; Zagal, A.; Molina, F.; Hernández-Santana, M.; et al. High performance fluoroelastomer composites filled with graphite and/or bismuth oxide for applications in gamma-ray shielding. Polym. Compos. 2024, 45, 6901–6913. [Google Scholar] [CrossRef]

- Güngör, A.; Akbay, K.; Yaşar, D.; Özdemir, T. Flexible X/Gamma ray shielding composite material of EPDM rubber with bismuth trioxide: Mechanical, thermal investigations and attenuation tests. Prog. Nucl. Energy 2018, 106, 262–269. [Google Scholar] [CrossRef]

- Álvarez-Cortez, G.; Molina, F.; Urbano, B.F.; Dahrouch, M.; Santana, M.H.; Manchado, M.A.L.; Verdejo, R.; Bolados, H.A. Design and Study of Novel Composites Based on EPDM Rubber Containing Bismuth (III) Oxide and Graphene Nanoplatelets for Gamma Radiation Shielding. Polymers 2024, 16, 633. [Google Scholar] [CrossRef]

- Kalkornsuranee, E.; Intom, S.; Lehman, N.; Johns, J.; Kothan, S.; Sengloyluan, K.; Chaiphaksa, W.; Kaewkhao, J. Mechanical and gamma radiation shielding properties of natural rubber composites: Effects of bismuth oxide (Bi2O3) and lead oxide (PbO). Mater. Res. Innov. 2020, 26, 8–15. [Google Scholar] [CrossRef]

- Zhou, Q.; Yan, L.; Lai, X.; Li, H.; Zeng, X. The effect of lanthanum trimethacrylate on the mechanical properties and flame retardancy of dynamically vulcanized PP/EPDM thermoplastic vulcanizates. J. Elastomers Plast. 2018, 50, 339–353. [Google Scholar] [CrossRef]

- Iacob, M.; Airinei, A.; Asandulesa, M.; Dascalu, M.; Tudorachi, N.; Hernandez, L.; Cazacu, M. Silicone elastomers filled with rare earth oxides. Mater. Res. Express 2020, 7, 035703. [Google Scholar] [CrossRef]

- Abdulrahman, S.T.; Ahmad, Z.; Thomas, S.; Rahman, A.A. Introduction to neutron-shielding materials. In Micro and Nanostructured Composite Materials for Neutron Shielding Applications; Woodhead Publishing: Cambridge, UK, 2020. [Google Scholar] [CrossRef]

- Qi, Z.; Yang, Z.; Li, J.; Guo, Y.; Yang, G.; Yu, Y.; Zhang, J. The Advancement of Neutron-Shielding Materials for the Transportation and Storage of Spent Nuclear Fuel. Materials 2022, 15, 3255. [Google Scholar] [CrossRef]

- Spinosa, D.J.; Angle, J.F.; Hartwell, G.D.; Hagspiel, K.D.; Leung, D.A.; Matsumoto, A.H. Gadolinium-based contrast agents in angiography and interventional radiology. Clin. N. Am. 2002, 40, 693–710. [Google Scholar] [CrossRef]

- Gadolinium—An Overview|ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/medicine-and-dentistry/gadolinium (accessed on 3 November 2025).

- Fisher, A.R.; Siegelman, E.S. Magnetic resonance imaging: Techniques. Clin. Liver Dis. 2002, 6, 53–72. [Google Scholar] [CrossRef]

- Sethi, A.N.; Kohli, J.; Patel, A.M.; Rudnick, M.R. Contrast-induced nephropathy. In Nephrology Secrets, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 94–98. [Google Scholar] [CrossRef]

- Klassen, C.; Nguyen, M.; Siuciak, A.; Wilke, N.M. Magnetic resonance first pass perfusion imaging for detecting coronary artery disease. Eur. J. Radiol. 2006, 57, 412–416. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Singh, R.K.; Kumar, K.; Kumar, N.; Aman, A.K.; Bikramaditya, B. Structural, opto-electronic, magnetic and photoluminescence properties of samarium and gadolinium iron garnet nanomaterials for LED and opto-electronics applications. Discov. Mater. 2025, 5, 160. [Google Scholar] [CrossRef]

- Deliormanlı, A.M.; Ensoylu, M.; Issa, S.A.M.; Rammah, Y.S.; ALMisned, G.; Tekin, H.O. A thorough examination of gadolinium (III)-containing silicate bioactive glasses: Synthesis, physical, mechanical, elastic and radiation attenuation properties. Appl. Phys. A 2022, 128, 266. [Google Scholar] [CrossRef]

- GB/T 16584; Rubber. Measurement of Vulcanization Characteristics with Rotorless Curemeters. National Standards of the People′s Republic of China: Beijing, China, 1996.

- ISO 6504; Paints and Varnishes—Determination of hiding Power. International Organization for Standardization: Geneva, Switzerland, 2019.

- ASTM D412; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension. ASTM International: West Conshohocken, PA, USA, 2021.

- Fröhlich, J.; Niedermeier, W.; Luginsland, H.D. The effect of filler-filler and filler-elastomer interaction on rubber reinforcement. Compos. Part A Appl. Sci. Manuf. 2005, 36, 449–460. [Google Scholar] [CrossRef]

- Pergal, M.V.; Dzunuzovic, J.V.; Poreba, R.; Micic, D.; Stefanov, P.; Pezo, L.; Spirkova, M. Surface and thermomechanical characterization of polyurethane networks based on poly(dimethylsiloxane) and hyperbranched polyester. Express Polym. Lett. 2013, 7, 806–820. [Google Scholar] [CrossRef]

- Dobson, K.D.; McQuillan, A.J. An infrared spectroscopic study of carbonate adsorption to zirconium dioxide sol-gel films from aqueous solutions. Langmuir 1997, 13, 3392–3396. [Google Scholar] [CrossRef]

- Ma, J.; La, L.T.B.; Zaman, I.; Meng, Q.; Luong, L.; Ogilvie, D.; Kuan, H. Fabrication, structure and properties of epoxy/metal nanocomposites. Macromol. Mater. Eng. 2011, 296, 465–474. [Google Scholar] [CrossRef]

- Madkhali, O.; Kaynar, Ü.H.; Alajlani, Y.; Coban, M.; Guinea, J.G.; Ayvacikli, M.; Pierson, J.; Can, N. Structural and temperature dependence luminescence characteristics of RE (RE = Eu3+, Dy3+, Sm3+ and Tb3+) in the new gadolinium aluminate borate phosphor. Ceram. Int. 2023, 49, 19982–19995. [Google Scholar] [CrossRef]

- Aguila-Toledo, E.; Maldonado-Magnere, S.; Yazdani-Pedram, M.; Bascuñan-Heredia, A.; Dahrouch, M.R.; Molina, F.; Santana, M.H.; Verdejo, R.; Lopez-Manchado, M.A.; Aguilar-Bolados, H. Fluorosilicone Composites with Functionalized Graphene Oxide for Advanced Applications. ACS Appl. Polym. Mater. 2023, 5, 7755–7765. [Google Scholar] [CrossRef]

- Veiga, M.; Mattiazzi, P.; de Gois, J.S.; Nascimento, P.C.; Borges, D.L.G.; Bohrer, D. Presence of other rare earth metals in gadolinium-based contrast agents. Talanta 2020, 216, 120940. [Google Scholar] [CrossRef]

- Simon, A.; Pepin, J.; Berthier, D.; Méo, S. Degradation mechanism of FKM during thermo-oxidative aging from mechanical and network structure correlations. Polym. Degrad. Stab. 2023, 208, 110271. [Google Scholar] [CrossRef]

- Byrne, R.H.; Li, B. Comparative complexation behavior of the rare earths. Geochim. Cosmochim. Acta 1995, 59, 4575–4589. [Google Scholar] [CrossRef]

- Maldonado-Magnere, S.; Yazdani-Pedram, M.; Fuentealba, P.; Neira-Carrillo, A.; Lopez-Manchado, M.A.; Hernandez-Villar, H.; Bascuñan-Heredia, A.; Dahrouch, M.; Aguilar-Bolados, H. Understanding the Effect of Graphene Nanoplatelet Size on the Mechanical and Thermal Properties of Fluoroelastomer-Based Composites. Polymers 2025, 17, 2534. [Google Scholar] [CrossRef] [PubMed]

- Loss Modulus—An Overview|ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/chemistry/loss-modulus (accessed on 17 October 2025).

- Ji, G.; Zhang, P.; Nji, J.; John, M.; Li, G. Shape memory polymer-based self-healing composites. In Recent Advances in Smart Self-healing Polymers and Composites; Woodhead Publishing: Cambridge, UK, 2015; pp. 293–363. [Google Scholar] [CrossRef]

- Leblanc, J.L. Rubber-filler interactions and rheological properties in filled compounds. Prog. Polym. Sci. 2002, 27, 627–687. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Pongwisuthiruchte, A.; Potiyaraj, P. Up-to-date review on the development of high performance rubber composites based on halloysite nanotube. Appl. Clay Sci. 2019, 183, 105300. [Google Scholar] [CrossRef]

- Filled Rubber—An Overview|ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/engineering/filled-rubber (accessed on 17 October 2025).

- Nagaraja, S.M.; Henning, S.; Ilisch, S.; Beiner, M. Common origin of filler network related contributions to reinforcement and dissipation in rubber composites. Polymers 2021, 13, 2534. [Google Scholar] [CrossRef]

- Shaikh, H.; Alothman, O.Y.; Alshammari, B.A.; Jawaid, M. Dynamic and thermo-mechanical properties of polypropylene reinforced with date palm nano filler. J. King Saud Univ.—Sci. 2023, 35, 102561. [Google Scholar] [CrossRef]

- Montazeri, A.; Pourshamsian, K.; Riazian, M. Viscoelastic properties and determination of free volume fraction of multi-walled carbon nanotube/epoxy composite using dynamic mechanical thermal analysis. Mater. Des. 2012, 36, 408–414. [Google Scholar] [CrossRef]

- Eslami, Z.; Elkoun, S.; Robert, M.; Adjallé, K. A Review of the Effect of Plasticizers on the Physical and Mechanical Properties of Alginate-Based Films. Molecules 2023, 28, 6637. [Google Scholar] [CrossRef]

- Hagita, K.; Morita, H. Effects of polymer/filler interactions on glass transition temperatures of filler-filled polymer nanocomposites. Polymer 2019, 178, 121615. [Google Scholar] [CrossRef]

- Yang, S.; Liang, P.; Peng, X.; Zhou, Y.; Hua, K.; Wu, W.; Cai, Z. Improvement in mechanical properties of SBR/Fly ash composites by in-situ grafting-neutralization reaction. Chem. Eng. J. 2018, 354, 849–855. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J.; Peng, Z.; Xiong, Z.; Zeng, Y.; Fu, X.; Zhang, R.; Hu, S.; Liu, H.; Liu, Q. Advanced coal fly ash modification by using corrosive microorganisms as alternative filler-reinforcing fluororubbers. Mater. Lett. 2019, 246, 32–35. [Google Scholar] [CrossRef]

- Filler Interaction—An Overview|ScienceDirect Topics. Available online: https://www.sciencedirect.com/topics/engineering/filler-interaction (accessed on 17 October 2025).

- Waclawska, I. Thermal decomposition of borax. J. Therm. Anal. Calorim. 1995, 43, 261–269. [Google Scholar] [CrossRef]

| Composite | ts2 (min:sec) | t90 (min:sec) | ML (Nm) | MH (Nm) | MH–ML (Nm) |

|---|---|---|---|---|---|

| FKM0 | 1:18 ± 0:02 | 3:13 ± 0:59 | 0.1825 ± 0.052 | 0.988 ± 0.095 | 0.806 |

| FKMGdO5 | 1:42 ± 0:01 | 4:38 ± 0:29 | 0.149 ± 0.004 | 1.022 ± 0.013 | 0.873 |

| FKMGdO10 | 1:32 ± 0:00 | 4:05 ± 0:07 | 0.182 ± 0.007 | 1.041 ± 0.008 | 0.859 |

| FKMGdO15 | 1:38 ± 0:02 | 3:45 ± 0:14 | 0.334 ± 0.022 | 1.307 ± 0.057 | 0.973 |

| FKMGdO20 | 1:22 ± 0:02 | 3:53 ± 0:09 | 0.250 ± 0.071 | 1.181 ± 0.099 | 0.931 |

| FKMGdO25 | 1:20 ± 0:01 | 4:26 ± 0:04 | 0.225 ± 0.004 | 1.151 ± 0.051 | 0.926 |

| FKMGdB5 | 1:30 ± 0:01 | 3:49 ± 0:05 | 0.199 ± 0.021 | 0.951 ± 0.019 | 0.752 |

| FKMGdB10 | 1:51 ± 0:01 | 5:34 ± 0:07 | 0.187 ± 0.040 | 0.919 ± 0.013 | 0.732 |

| FKMGdB15 | 1:43 ± 0:02 | 6:16 ± 0:44 | 0.199 ± 0.010 | 0.943 ± 0.052 | 0.744 |

| FKMGdB20 | 2:00 ± 0:07 | 8:17 ± 1:02 | 0.205 ± 0.006 | 0.931 ± 0.025 | 0.726 |

| FKMGdB25 | 1:40 ± 0:02 | 6:31 ± 0:21 | 0.227 ± 0.003 | 0.994 ± 0.018 | 0.767 |

| FKMGdBT5 | 1:36 ± 0:07 | 5:02 ± 0:56 | 0.213 ± 0.045 | 0.971 ± 0.053 | 0.758 |

| FKMGdBT10 | 1:42 ± 0:01 | 5:31 ± 0:33 | 0.175 ± 0.003 | 0.940 ± 0.039 | 0.765 |

| FKMGdBT15 | 1:55 ± 0:03 | 6:50 ± 0:44 | 0.175 ± 0.011 | 0.957 ± 0.010 | 0.782 |

| FKMGdBT20 | 1:44 ± 0:00 | 5:30 ± 0:17 | 0.179 ± 0.004 | 1.029 ± 0.004 | 0.850 |

| FKMGdBT25 | 2:00 ± 0:12 | 7:05 ± 0:35 | 0.203 ± 0.012 | 1.151 ± 0.023 | 0.948 |

| Composites | E50 (MPa) | E100 (MPa) | E200 (MPa) | E300 (MPa) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|---|---|---|

| FKM0 | 1.139 ± 0.015 | 1.948 ± 0.032 | 4.245 ± 0.043 | - | 4.325 ± 0.081 | 201 ± 5 |

| FKMGdO5 | 1.142 ± 0.083 | 2.091 ± 0.119 | 5.008 ± 0.074 | - | 5.897 ± 0.458 | 221 ± 6 |

| FKMGdO10 | 1.238 ± 0.008 | 2.271 ± 0.005 | 5.974 ± 0.128 | - | 7.483 ± 0.123 | 234 ± 11 |

| FKMGdO15 | 1.397 ± 0.057 | 2.384 ± 0.054 | 5.112 ± 0.093 | 9.496 ± 0.444 | 10.325 ± 0.533 | 312 ± 9 |

| FKMGdO20 | 1.456 ± 0.022 | 2.542 ± 0.021 | 5.640 ± 0.051 | - | 10.049 ± 0.422 | 288 ± 3 |

| FKMGdO25 | 1.470 ± 0.016 | 2.631 ± 0.017 | 5.939 ± 0.154 | - | 10.943 ± 0.750 | 292 ± 11 |

| FKMGdB5 | 0.973 ± 0.013 | 1.683 ± 0.022 | 3.588 ± 0.086 | 6.760 ± 0.373 | 10.015 ± 0.181 | 386 ± 4 |

| FKMGdB10 | 1.017 ± 0.010 | 1.762 ± 0.024 | 3.637 ± 0.051 | 6.421 ± 0.118 | 7.594 ± 0.124 | 321 ± 13 |

| FKMGdB15 | 1.126 ± 0.008 | 1.971 ± 0.023 | 4.412 ± 0.171 | 7.888 ± 0.299 | 10.750 ± 0.417 | 381 ± 16 |

| FKMGdB20 | 1.193 ± 0.039 | 2.103 ± 0.054 | 4.701 ± 0.114 | 8.143 ± 0.161 | 10.667 ± 0.324 | 372 ± 9 |

| FKMGdB25 | 1.339 ± 0.038 | 2.396 ± 0.059 | 5.402 ± 0.252 | 9.023 ± 0.400 | 11.313 ± 0.244 | 370 ± 15 |

| FKMGdBT5 | 1.013 ± 0.012 | 1.702 ± 0.011 | 3.689 ± 0.115 | 6.795 ± 0.338 | 9.433 ± 0.364 | 371 ± 2 |

| FKMGdBT10 | 1.134 ± 0.025 | 1.970 ± 0.059 | 4.580 ± 0.129 | 8.284 ± 0.249 | 9.580 ± 0.130 | 326 ± 10 |

| FKMGdBT15 | 1.246 ± 0.035 | 2.245 ± 0.089 | 5.139 ± 0.073 | 8.713 ± 0.202 | 9.229 ± 0.179 | 316 ± 8 |

| FKMGdBT20 | 1.389 ± 0.036 | 2.577 ± 0.037 | 5.673 ± 0.108 | 9.295 ± 0.360 | 9.638 ± 0.445 | 310 ± 5 |

| FKMGdBT25 | 1.481 ± 0.062 | 2.675 ± 0.100 | 5.621 ± 0.111 | - | 8.122 ± 0.271 | 285 ± 8 |

| Sample | Tg-DMA (°C) | FWHM (°C) | Maximum Height | (mol/m3) | (g/mol) |

|---|---|---|---|---|---|

| FKM0 | −2.14 | 17.2 | 1.41 | 699 | 2615 |

| FKMGdO5 | −2.14 | 17.2 | 1.42 | 725 | 2560 |

| FKMGdB5 | −3.62 | 18.1 | 1.42 | 766 | 2444 |

| FKMGdBT5 | −3.62 | 17.9 | 1.36 | 750 | 2448 |

| FKMGdO25 | −2.63 | 18.0 | 1.26 | 954 | 2217 |

| FKMGdB25 | −3.62 | 17.4 | 1.29 | 1042 | 1854 |

| FKMGdBT25 | −2.63 | 18.5 | 1.21 | 1080 | 1858 |

| Sample | FKM | FKMGdO5 | FKMGdB5 | FKMGdBT5 | FKMGdO25 | FKMGdB25 | FKMGdBT25 |

|---|---|---|---|---|---|---|---|

| Tg | −13.7 ± 0.9 | −14.6 ± 0.8 | −15.5 ± 0.9 | −16.0 ± 0.8 | −14.9 ± 0.1 | −17.0 ± 0.3 | −13.5 ± 0.3 |

| Sample | (mJ/m2) | (mJ/m2) | (mJ/m2) | Eg (eV) |

|---|---|---|---|---|

| FKM | 24.1 ± 1.8 | 1.8 ± 0.5 | 25.9 ± 1.5 | 2.06 |

| FKMGdO5 | 22.2 ± 1.1 | 4.7 ± 2.9 | 26.9 ± 2.1 | 2.43 |

| FKMGdB5 | 24.3 ± 2.8 | 5.1 ± 1.1 | 30.3 ± 1.4 | 2.30 |

| FKMGdBT5 | 23.2 ± 1.6 | 6.7 ± 1.6 | 29.9 ± 2.1 | 2.26 |

| FKMGdO25 | 20.0 ± 3.1 | 2.1 ± 1.7 | 22.1 ± 1.7 | 2.68 |

| FKMGdB25 | 19.3 ± 0.7 | 1.5 ± 0.9 | 20.8 ± 0.2 | 2.32 |

| FKMGdBT25 | 22.6 ± 1.0 | 2.0 ± 0.4 | 24.6 ± 1.1 | 2.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Bascuñan-Heredia, A.; Molina, F.; Inestrosa-Izurieta, M.J.; Dahrouch, M.; Henriquez, A.; Cortés, C.; Lopez-Manchado, M.A.; Aguilar-Bolados, H. Enhanced Mechanical Performance of Fluoroelastomer Composites with Boron–Gadolinium-Based Fillers for Cutting-Edge Applications. Polymers 2026, 18, 6. https://doi.org/10.3390/polym18010006

Bascuñan-Heredia A, Molina F, Inestrosa-Izurieta MJ, Dahrouch M, Henriquez A, Cortés C, Lopez-Manchado MA, Aguilar-Bolados H. Enhanced Mechanical Performance of Fluoroelastomer Composites with Boron–Gadolinium-Based Fillers for Cutting-Edge Applications. Polymers. 2026; 18(1):6. https://doi.org/10.3390/polym18010006

Chicago/Turabian StyleBascuñan-Heredia, Allan, Francisco Molina, Maria José Inestrosa-Izurieta, Mohamed Dahrouch, Adolfo Henriquez, Catalina Cortés, Miguel Angel Lopez-Manchado, and Héctor Aguilar-Bolados. 2026. "Enhanced Mechanical Performance of Fluoroelastomer Composites with Boron–Gadolinium-Based Fillers for Cutting-Edge Applications" Polymers 18, no. 1: 6. https://doi.org/10.3390/polym18010006

APA StyleBascuñan-Heredia, A., Molina, F., Inestrosa-Izurieta, M. J., Dahrouch, M., Henriquez, A., Cortés, C., Lopez-Manchado, M. A., & Aguilar-Bolados, H. (2026). Enhanced Mechanical Performance of Fluoroelastomer Composites with Boron–Gadolinium-Based Fillers for Cutting-Edge Applications. Polymers, 18(1), 6. https://doi.org/10.3390/polym18010006