The Effect of Acidic Immersion Media on the Flexural Properties of a High-Performance Fiber-Reinforced CAD/CAM Technopolymer

Abstract

1. Introduction

2. Materials and Methods

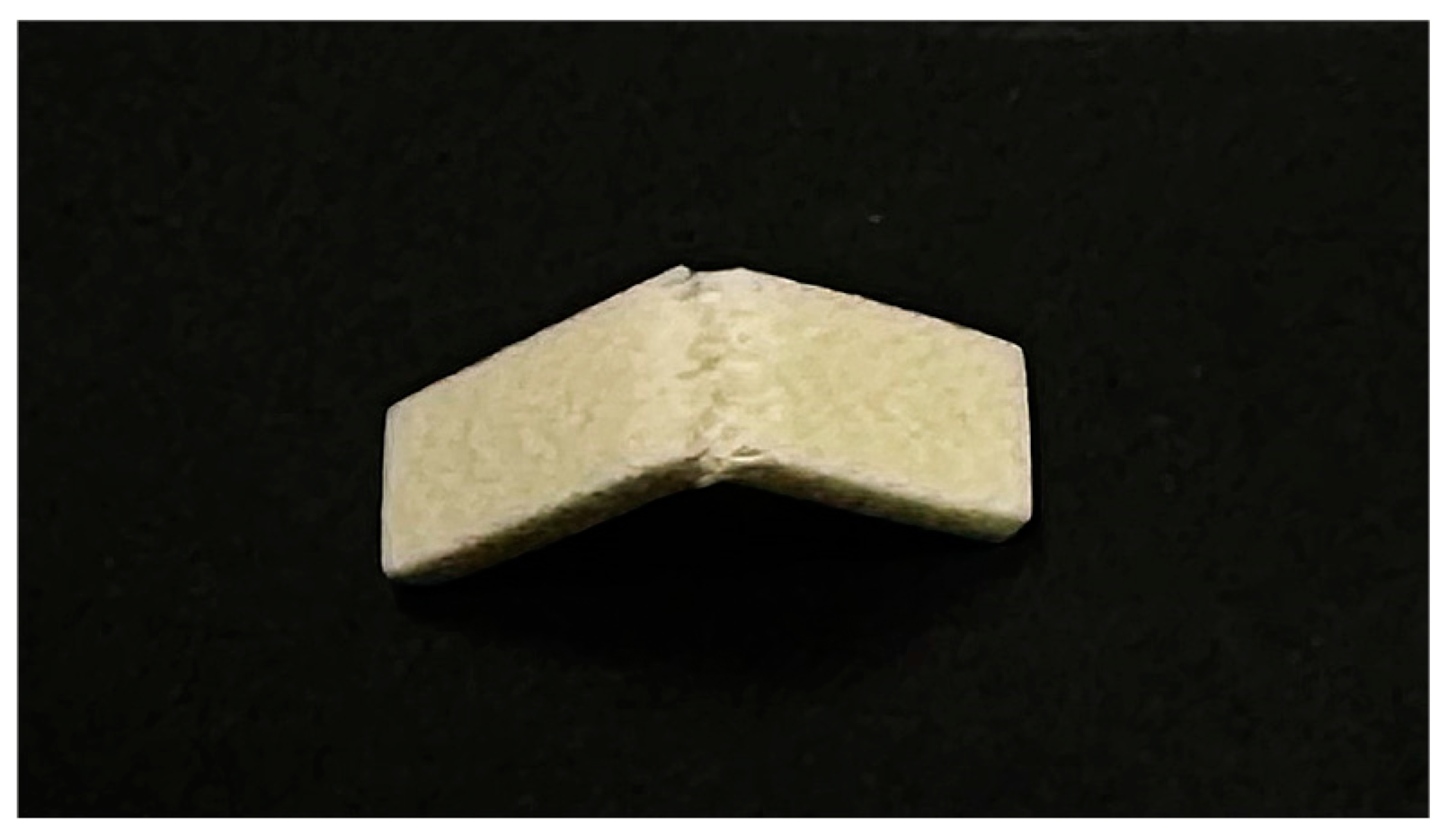

2.1. Specimen Preparation

2.2. Specimens Immersion

2.3. Flexural Strength and Modulus Testing

2.4. Statistical Analysis

3. Results

3.1. Flexural Strength Results

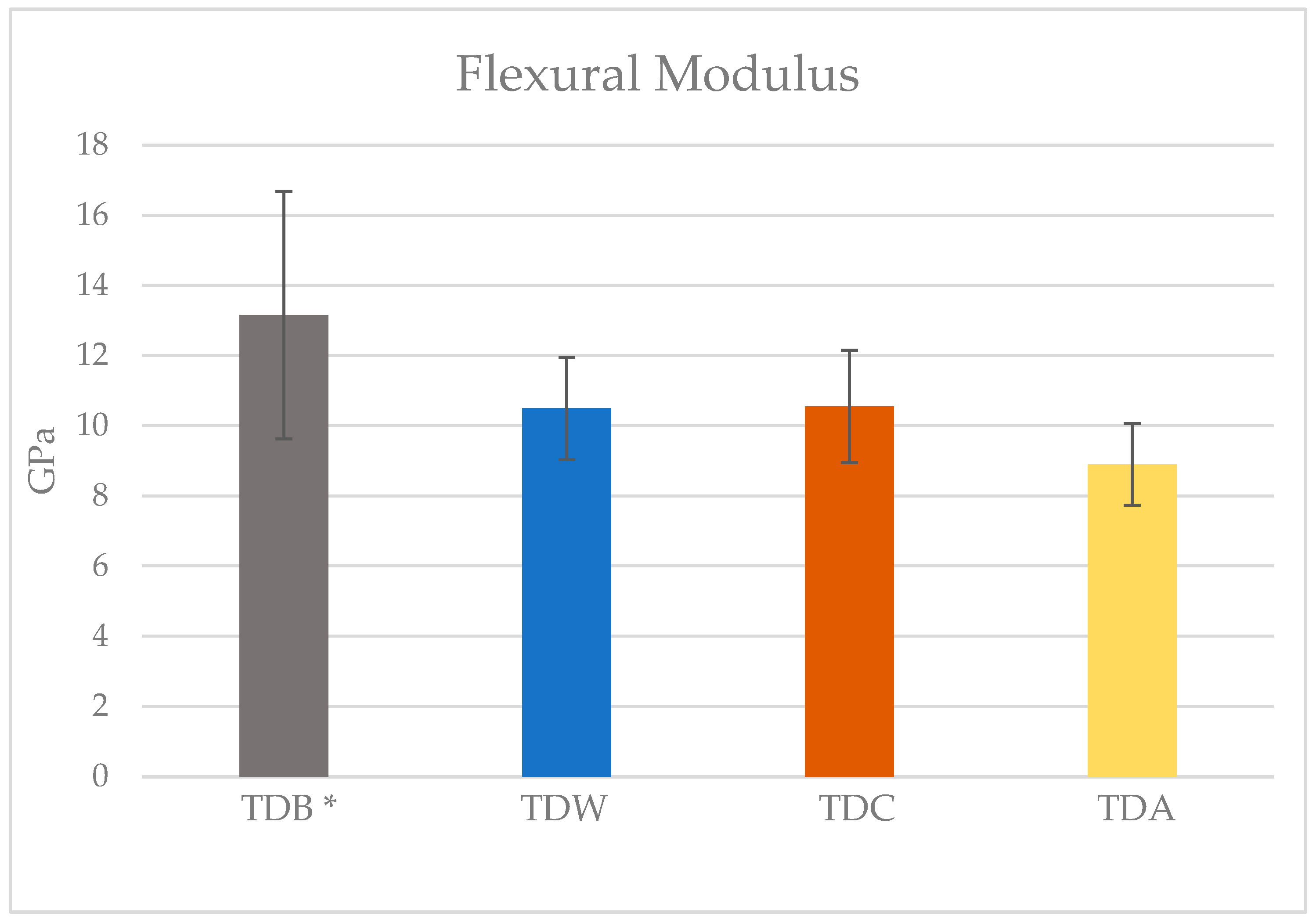

3.2. Flexural Modulus Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| °C | Degrees Celsius |

| %wt | Weight percentage |

| ANOVA | Analysis of variance |

| ATDRL | The Advanced Technology Dental Research Laboratory |

| CAD/CAM | Computer-aided design/computer-aided manufacturing |

| Flexural modulus | |

| FEA | Finite element analysis |

| FPD | Fixed partial denture |

| FRC | Fiber-reinforced composite |

| Flexural strength | |

| GPa | Gega Pascal |

| HCL | Hydrochloric acid |

| ISO | International Standards Organization |

| kN | Kilo Nuton |

| mm | Millimeter |

| mm/min | Millimeter/minute |

| MPa | Mega Pascal |

| SiC | Silicon carbide |

| TD | Trilor technopolymer disk (Bioloren, Saronno, Italy) |

| TDA | Trilor disk acid-immersion group |

| TDB | Trilor disk baseline group |

| TDC | Trilor disk cola-immersion group |

| TDW | Trilor disk water-immersion group |

| Tukey’s HSD | Tukey’s honestly significant difference |

References

- Hajjaj, M.S.; Alamoudi, R.A.A.; Babeer, W.A.; Rizg, W.Y.; Basalah, A.A.; Alzahrani, S.J.; Yeslam, H.E. Flexural strength, flexural modulus and microhardness of milled vs. fused deposition modeling printed Zirconia; effect of conventional vs. speed sintering. BMC Oral Health 2024, 24, 38. [Google Scholar] [CrossRef] [PubMed]

- Yeslam, H.E. Flexural Behavior of Biocompatible High-Performance Polymer Composites for CAD/CAM Dentistry. J. Compos. Sci. 2023, 7, 270. [Google Scholar] [CrossRef]

- Calamia, J.R. Advances in computer-aided design and computer-aided manufacture technology. Curr. Opin. Cosmet. Dent. 1994, 67–73. [Google Scholar]

- Bechir, F.; Bataga, S.M.; Tohati, A.; Ungureanu, E.; Cotrut, C.M.; Bechir, E.S.; Suciu, M.; Vranceanu, D.M. Evaluation of the Behavior of Two CAD/CAM Fiber-Reinforced Composite Dental Materials by Immersion Tests. Materials 2021, 14, 7185. [Google Scholar] [CrossRef]

- Kabbej, M.; Guillard, V.; Angellier-Coussy, H.; Wolf, C.; Gontard, N.; Gaucel, S. 3D Modelling of Mass Transfer into Bio-Composite. Polymers 2021, 13, 2257. [Google Scholar] [CrossRef] [PubMed]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Norström, A.; Watson, H.; Engström, B.; Rosenholm, J. Treatment of E-glass fibres with acid, base and silanes. Colloids Surf. A Physicochem. Eng. Asp. 2001, 194, 143–157. [Google Scholar] [CrossRef]

- Alfaer, A.; Aljabri, Y.; Alameer, A.; Illah, M.; Thubab, H.; Thubab, A.; Naseeb, W.; Ageel, S.; Juraybi, A.; Marwahi, W.; et al. Applications, benefits, and limitations of fiber-reinforced composites in fixed prosthodontics. Int. J. Community Med. Public Health 2023, 10, 4462–4467. [Google Scholar] [CrossRef]

- Cevik, P.; Schimmel, M.; Yilmaz, B. New generation CAD-CAM materials for implant-supported definitive frameworks fabricated by using subtractive technologies. Biomed. Res. Int. 2022, 2022, 3074182. [Google Scholar] [CrossRef]

- Hada, T.; Suzuki, T.; Minakuchi, S.; Takahashi, H. Reduction in maxillary complete denture deformation using framework material made by computer-aided design and manufacturing systems. J. Mech. Behav. Biomed. Mater. 2020, 103, 103514. [Google Scholar] [CrossRef]

- Bioloren S.r.l. TRILOR®Manual The Solution for a Non-Metal Dentistry; Bioloren S.r.l.: Saronno, Italy, 2019; pp. 1–16. [Google Scholar]

- Yeslam, H.E.; Alharbi, S.; Albalawi, W.; Hasanain, F.A. The effect of thermal aging on flexural strength of CAD/CAM hybrid and polymeric materials. Mater. Res. Express 2023, 10, 095402. [Google Scholar] [CrossRef]

- Xavier, A.M.; Sunny, S.M.; Rai, K.; Hegde, A.M. Repeated exposure of acidic beverages on esthetic restorative materials: An in-vitro surface microhardness study. J. Clin. Exp. Dent. 2016, 8, e312–e317. [Google Scholar] [CrossRef]

- Elraggal, A.; Afifi, R.R.; Alamoush, R.A.; Raheem, I.A.; Watts, D.C. Effect of acidic media on flexural strength and fatigue of CAD-CAM dental materials. Dent. Mater. 2023, 39, 57–69. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.-Y.; Bae, H.-J.; Lee, H.-H.; Lee, J.-H.; Kim, Y.-J.; Choi, Y.-S.; Lee, J.-H.; Shin, S.-Y. The Effects of Thermocycling on the Physical Properties and Biocompatibilities of Various CAD/CAM Restorative Materials. Pharmaceutics 2023, 15, 2122. [Google Scholar] [CrossRef] [PubMed]

- Dathan, P.; Nair, C.; Kumar, A.; Ar, L. Flexural Strength is a Critical Property of Dental Materials-An Overview. Acta Sci. Dent. Scienecs 2023, 7, 99–103. [Google Scholar] [CrossRef]

- de Jager, N.; Münker, T.J.A.G.; Guilardi, L.F.; Jansen, V.J.; Sportel, Y.G.E.; Kleverlaan, C.J. The relation between impact strength and flexural strength of dental materials. J. Mech. Behav. Biomed. Mater. 2021, 122, 104658. [Google Scholar] [CrossRef]

- Babaier, R.S.; Haider, J.; Alshabib, A.; Silikas, N.; Watts, D.C. Mechanical behaviour of prosthodontic CAD/CAM polymer composites aged in three food-simulating liquids. Dent. Mater. 2022, 38, 1492–1506. [Google Scholar] [CrossRef]

- Alghazzawi, T.F. Relation of Crown Failure Load to Flexural Strength for Three Contemporary Dental Polymers. Polymers 2023, 15, 4312. [Google Scholar] [CrossRef]

- Elraggal, A.; Abdelraheem, I.M.; Watts, D.C.; Roy, S.; Dommeti, V.K.; Alshabib, A.; Althaqafi, K.A.; Afifi, R.R. Biomechanical reinforcement by CAD-CAM materials affects stress distributions of posterior composite bridges: 3D finite element analysis. Dent. Mater. 2024, 40, 869–877. [Google Scholar] [CrossRef]

- Alnsour, M.M.; Alamoush, R.A.; Silikas, N.; Satterthwaite, J.D. The Effect of Erosive Media on the Mechanical Properties of CAD/CAM Composite Materials. J. Funct. Biomater. 2024, 15, 292. [Google Scholar] [CrossRef]

- Backer, A.D.; Münchow, E.A.; Eckert, G.J.; Hara, A.T.; Platt, J.A.; Bottino, M.C. Effects of Simulated Gastric Juice on CAD/CAM Resin Composites-Morphological and Mechanical Evaluations. J. Prosthodont. 2017, 26, 424–431. [Google Scholar] [CrossRef] [PubMed]

- Cruz, M.E.M.; Simões, R.; Martins, S.B.; Trindade, F.Z.; Dovigo, L.N.; Fonseca, R.G. Influence of simulated gastric juice on surface characteristics of CAD-CAM monolithic materials. J. Prosthet. Dent. 2020, 123, 483–490. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, J.R.; Cruz, M.E.M.D.; Dovigo, L.N.; Fonseca, R.G. Long-term effects of simulated gastric juice alternated with brushing on hardness, substance loss, flexural strength and reliability of CAD-CAM monolithic materials. J. Appl. Oral Sci. 2022, 30, e20210536. [Google Scholar] [CrossRef]

- Cekic-Nagas, I.; Nagas, E.; Egilmez, F.; Ergun, G.; Vallittu, P.; Lassila, L. Effect of Short-Term Aging on the Flexural Strength of a Novel Experimental CAD/CAM Fiber-Reinforced Composite Material: A Pilot Study. Int. J. Prosthodont. 2020, 33, 523–526. [Google Scholar] [CrossRef] [PubMed]

- Fadhil, N.; Zuhair, N. Effect of Beverage Solutions on Flexural Strength of PEEK CAD –CAM, 3D Printing Denture Base and Heat Cure Acrylic Resin Denture Base Materials. Tikrit J. Dent. Sci. 2024, 11, 188–197. [Google Scholar] [CrossRef]

- Elsaka, S.E.; Elnaghy, A.M. Mechanical properties of zirconia reinforced lithium silicate glass-ceramic. Dent. Mater. 2016, 32, 908–914. [Google Scholar] [CrossRef]

- Elraggal, A.; Afifi, R.; Abdelraheem, I. Effect of erosive media on microhardness and fracture toughness of CAD-CAM dental materials. BMC Oral Health 2022, 22, 191. [Google Scholar] [CrossRef]

- Matsou, E.; Vouroutzis, N.; Kontonasaki, E.; Paraskevopoulos, K.; Koidis, P. Investigation of the Influence of Gastric Acid on the Surface Roughness of Ceramic Materials of Metal-Ceramic Restorations. An In Vitro Study. Int. J. Prosthodont. 2011, 24, 26–29. [Google Scholar]

- Bechir, F.; Bataga, S.M.; Ungureanu, E.; Vranceanu, D.M.; Pacurar, M.; Bechir, E.S.; Cotrut, C.M. Experimental study regarding the behavior at different pH of two types of Co-Cr alloys used for prosthetic restorations. Materials 2021, 14, 4635. [Google Scholar] [CrossRef]

- Schnell, C.P.; Türp, J.C.; Kessler, P. The influence of carbonated beverages on direct dental restorative materials: A systematic review exemplified on Coca-Cola. Swiss Dent. J. SSO-Sci. Clin. Top. 2025, 135, 38–128. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Yahya, M.Y.; Karimzadeh, A.; Nikkhooyifar, M.; Ayob, A. Effects of temperature change and beverage on mechanical and tribological properties of dental restorative composites. Mater. Sci. Eng. C Mater. Biol. Appl. 2015, 54, 69–75. [Google Scholar] [CrossRef] [PubMed]

- Yenidunya, O.G.; Misilli, T.; Yilmaz, E. Gastric acid challenge: Mechanical proficiency and surface gloss of tooth-colored restorative materials. BMC Oral Health 2025, 25, 614. [Google Scholar] [CrossRef]

- Alqutaibi, A.Y.; Baik, A.; Almuzaini, S.A.; Farghal, A.E.; Alnazzawi, A.A.; Borzangy, S.; Aboalrejal, A.N.; AbdElaziz, M.H.; Mahmoud, I.I.; Zafar, M.S. Polymeric Denture Base Materials: A Review. Polymers 2023, 15, 3258. [Google Scholar] [CrossRef]

- ISO 4049:2019; Dentistry—Polymer-Based Restorative Materials. International Organization for Standardization: Geneva, Switzerland, 2019.

- Miura, D.; Ishida, Y.; Miyasaka, T.; Aoki, H.; Shinya, A. Reliability of Different Bending Test Methods for Dental Press Ceramics. Materials 2020, 13, 5162. [Google Scholar] [CrossRef]

- Calabrese, L.; Fabiano, F.; Bonaccorsi, L.M.; Fabiano, V.; Borsellino, C. Evaluation of the Clinical Impact of ISO 4049 in Comparison with Miniflexural Test on Mechanical Performances of Resin Based Composite. Int. J. Biomater. 2015, 2015, 149798. [Google Scholar] [CrossRef]

- Vila-Nova, T.E.L.; Gurgel de Carvalho, I.H.; Moura, D.M.D.; Batista, A.U.D.; Zhang, Y.; Paskocimas, C.A.; Bottino, M.A.; de Assunção, E.S.R.O. Effect of finishing/polishing techniques and low temperature degradation on the surface topography, phase transformation and flexural strength of ultra-translucent ZrO2 ceramic. Dent. Mater. 2020, 36, e126–e139. [Google Scholar] [CrossRef] [PubMed]

- Egilmez, F.; Ergun, G.; Cekic-Nagas, I.; Vallittu, P.K.; Lassila, L.V.J. Does artificial aging affect mechanical properties of CAD/CAM composite materials. J. Prosthodont. Res. 2018, 62, 65–74. [Google Scholar] [CrossRef] [PubMed]

- Saba, D.A.; Salama, R.A.; Haridy, R. Effect of different beverages on the color stability and microhardness of CAD/CAM hybrid versus feldspathic ceramic blocks: An in-vitro study. Future Dent. J. 2017, 3, 61–66. [Google Scholar] [CrossRef]

- Zaki, D.; Hamzawy, E.; Halim, S.; Amer, M. Effect of simulated gastric juice on surface characteristics of direct esthetic restorations. Aust. J. Basic Appl. Sci. 2012, 6, 686–694. [Google Scholar]

- Kim, S.H.; Choi, Y.S.; Kang, K.H.; Att, W. Effects of thermal and mechanical cycling on the mechanical strength and surface properties of dental CAD-CAM restorative materials. J. Prosthet. Dent. 2022, 128, 79–88. [Google Scholar] [CrossRef]

- Gulakar, T.L.; Comert, G.N.; Karaman, E.; Cakan, U.; Ozel, G.S.; Ahmet, S.O. Effect of simulated gastric acid on aesthetical restorative CAD-CAM materials’ microhardness and flexural strength. Niger. J. Clin. Pr. 2023, 26, 1505–1511. [Google Scholar] [CrossRef] [PubMed]

- Grzebieluch, W.; Kowalewski, P.; Sopel, M.; Mikulewicz, M. Influence of Artificial Aging on Mechanical Properties of Six Resin Composite Blocks for CAD/CAM Application. Coatings 2022, 12, 837. [Google Scholar] [CrossRef]

- Grzebieluch, W.; Mikulewicz, M.; Kaczmarek, U. Resin Composite Materials for Chairside CAD/CAM Restorations: A Comparison of Selected Mechanical Properties. J. Heal. Eng. 2021, 2021, 8828954. [Google Scholar] [CrossRef] [PubMed]

- Ajaj-Alkordy, N.; Al-Saadi, M. Elastic modulus and flexural strength comparisons of high-impact and traditional denture base acrylic resins. Saudi Dent. J. 2013, 26, 15–18. [Google Scholar] [CrossRef]

- Nasr, D.M.; Abdelraheem, I.M.; Watts, D.C.; Silikas, N.; Borba, M.; Alharbi, N.; Althaqafi, K.A.; Elraggal, A. Effect of preparation designs and CAD-CAM materials on step-stress fatigue survival of premolar partial coverage restorations: An in-vitro study with fractographic analysis. Dent. Mater. 2025, 41, 122–133. [Google Scholar] [CrossRef]

- Scribante, A.; Bollardi, M.; Chiesa, M.; Poggio, C.; Colombo, M. Flexural Properties and Elastic Modulus of Different Esthetic Restorative Materials: Evaluation after Exposure to Acidic Drink. BioMed Res. Int. 2019, 2019, 5109481. [Google Scholar] [CrossRef]

- Huang, S.; Fu, Q.; Yan, L.; Kasal, B. Characterization of interfacial properties between fibre and polymer matrix in composite materials—A critical review. J. Mater. Res. Technol. 2021, 13, 1441–1484. [Google Scholar] [CrossRef]

- Calheiros, F.C.; Pfeifer, C.S.C.; BrandÃO, L.L.; Agra, C.M.; Ballester, R.Y. Flexural properties of resin composites: Influence of specimen dimensions and storage conditions. Dent. Mater. J. 2013, 32, 228–232. [Google Scholar] [CrossRef][Green Version]

- Sonmez, N.; Gultekin, P.; Turp, V.; Akgungor, G.; Sen, D.; Mijiritsky, E. Evaluation of five CAD/CAM materials by microstructural characterization and mechanical tests: A comparative in vitro study. BMC Oral Health 2018, 18, 5. [Google Scholar] [CrossRef]

- Hammel, C.; Pandis, N.; Pieper, D.; Faggion, C.M., Jr. Methodological assessment of systematic reviews of in-vitro dental studies. BMC Med. Res. Methodol. 2022, 22, 110. [Google Scholar] [CrossRef]

| Material | Abb | Type/Chemical Composition | Manufacturer | Shade/Size | Flexural Modulus (GPa) | Flexural Strength (Mpa) |

|---|---|---|---|---|---|---|

| Trilor disk | TD | Pre-polymerized glass fiber-reinforced composite/ high-performance techno-polymer matrix with multi-directional glass fiber reinforcement; made up of about 74%wt of glass fibers | Bioloren, Saronno, Italy | FDS18 Ivory/18 mm disk | 26 GPa | Biaxial 540 MPa |

| Material Name | pH | Contents | Manufacturer |

|---|---|---|---|

| Water | 7 | Deionized water | Advanced Technology Dental Research Laboratory (ADTRL), Faculty of Dentistry, King Abdulaziz University, Jeddah, Saudi Arabia |

| Artificial gastric acid | 1.3 | Deionized water (100 mL) and hydrochloric acid (20 mL) | Central Drug House (P) Ltd.—CDH, Delhi, India |

| Regular Coca-Cola | 2.6 | Carbonated water, sugar, caramel color, acidifier: phosphoric acid, natural cola flavors, caffeine. | Coca-Cola, Aujan Coca-Cola Beverages Company, Jeddah, Saudi Arabia |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yeslam, H.E.; Alqahtani, H.H.; Filemban, A.M.; Jiffri, S.O.; Tashkandi, A.K. The Effect of Acidic Immersion Media on the Flexural Properties of a High-Performance Fiber-Reinforced CAD/CAM Technopolymer. Polymers 2025, 17, 1216. https://doi.org/10.3390/polym17091216

Yeslam HE, Alqahtani HH, Filemban AM, Jiffri SO, Tashkandi AK. The Effect of Acidic Immersion Media on the Flexural Properties of a High-Performance Fiber-Reinforced CAD/CAM Technopolymer. Polymers. 2025; 17(9):1216. https://doi.org/10.3390/polym17091216

Chicago/Turabian StyleYeslam, Hanin E., Hazzaa H. Alqahtani, Aws M. Filemban, Sultan O. Jiffri, and Abeer K. Tashkandi. 2025. "The Effect of Acidic Immersion Media on the Flexural Properties of a High-Performance Fiber-Reinforced CAD/CAM Technopolymer" Polymers 17, no. 9: 1216. https://doi.org/10.3390/polym17091216

APA StyleYeslam, H. E., Alqahtani, H. H., Filemban, A. M., Jiffri, S. O., & Tashkandi, A. K. (2025). The Effect of Acidic Immersion Media on the Flexural Properties of a High-Performance Fiber-Reinforced CAD/CAM Technopolymer. Polymers, 17(9), 1216. https://doi.org/10.3390/polym17091216