The Thermal and Mechanical Performance of Leather Waste-Filled Bio-Based Thermoplastic Polyurethane Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Polymer Compounding

2.3. Characterisation Methods

3. Results and Discussions

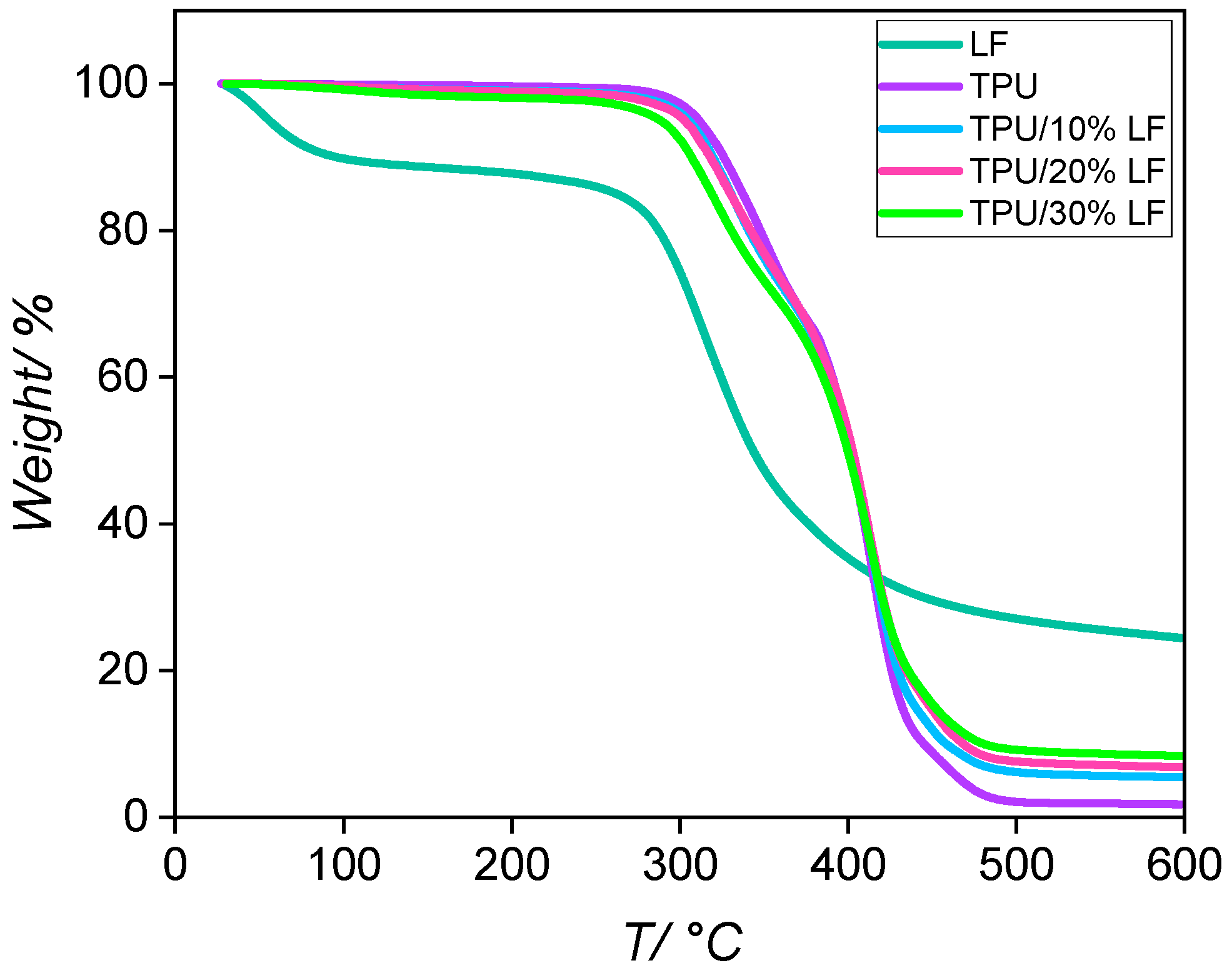

3.1. Thermal Stability

3.2. Thermal Properties

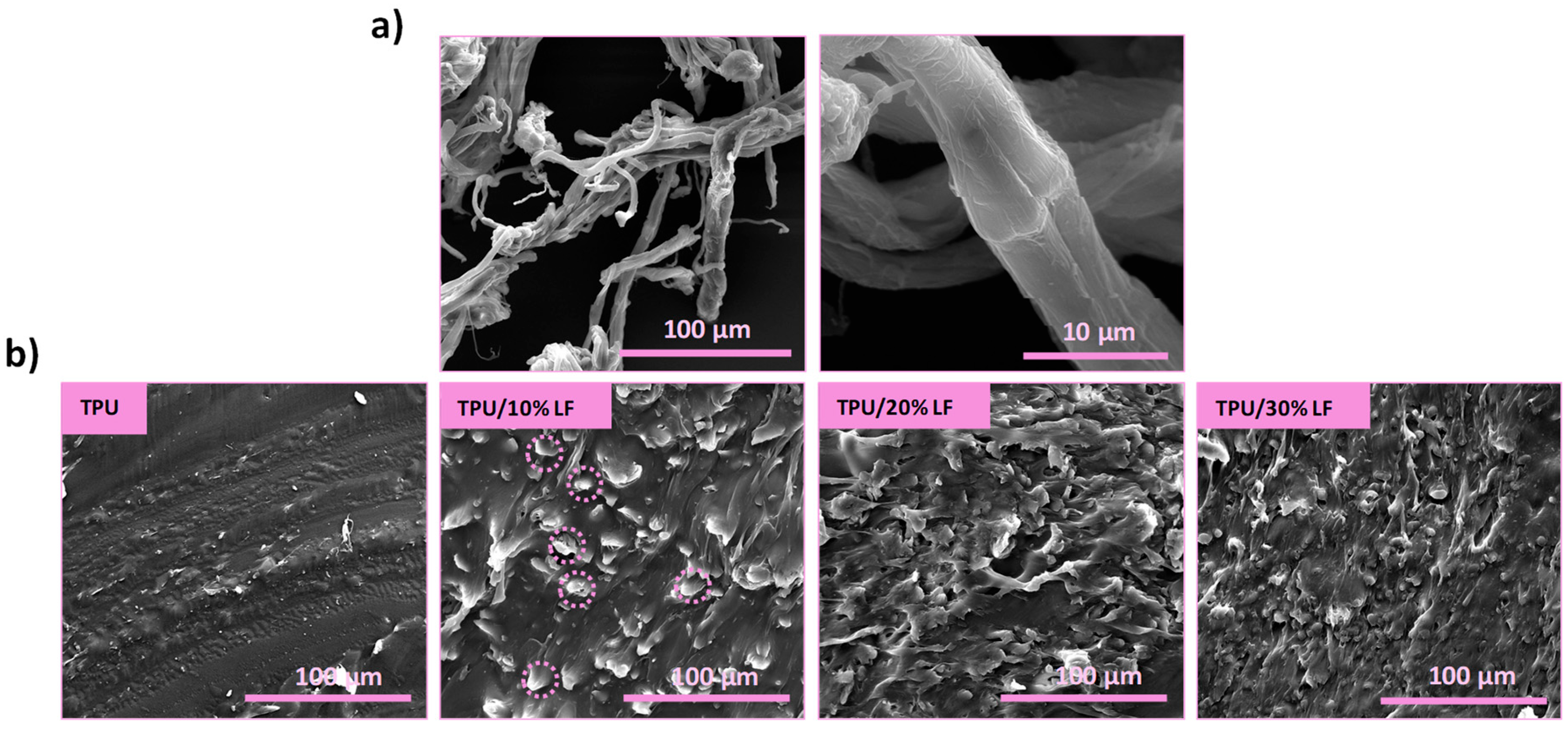

3.3. Morphology

3.4. Chemical Analysis

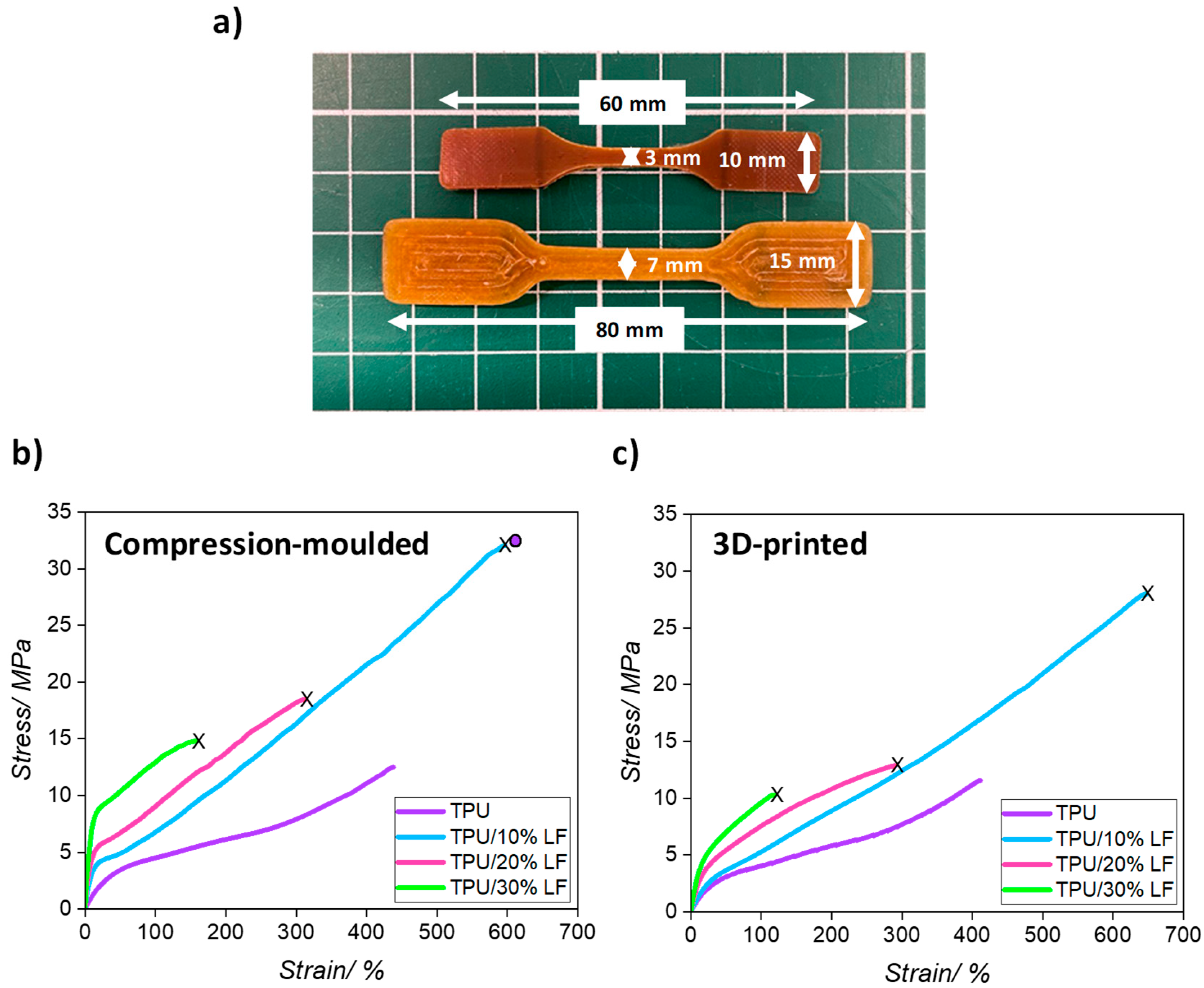

3.5. Mechanical Properties

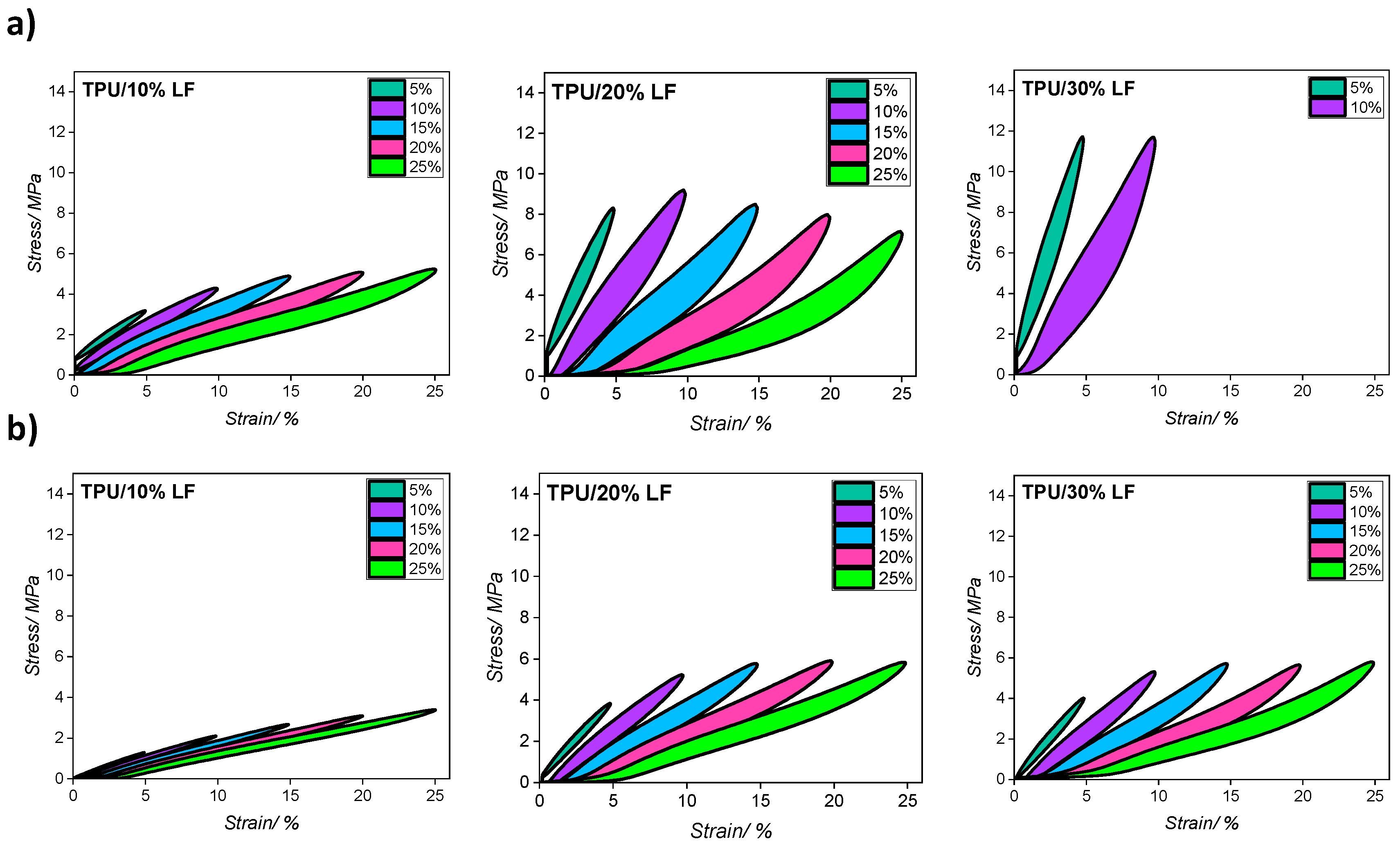

3.6. Cyclical Tensile Tests

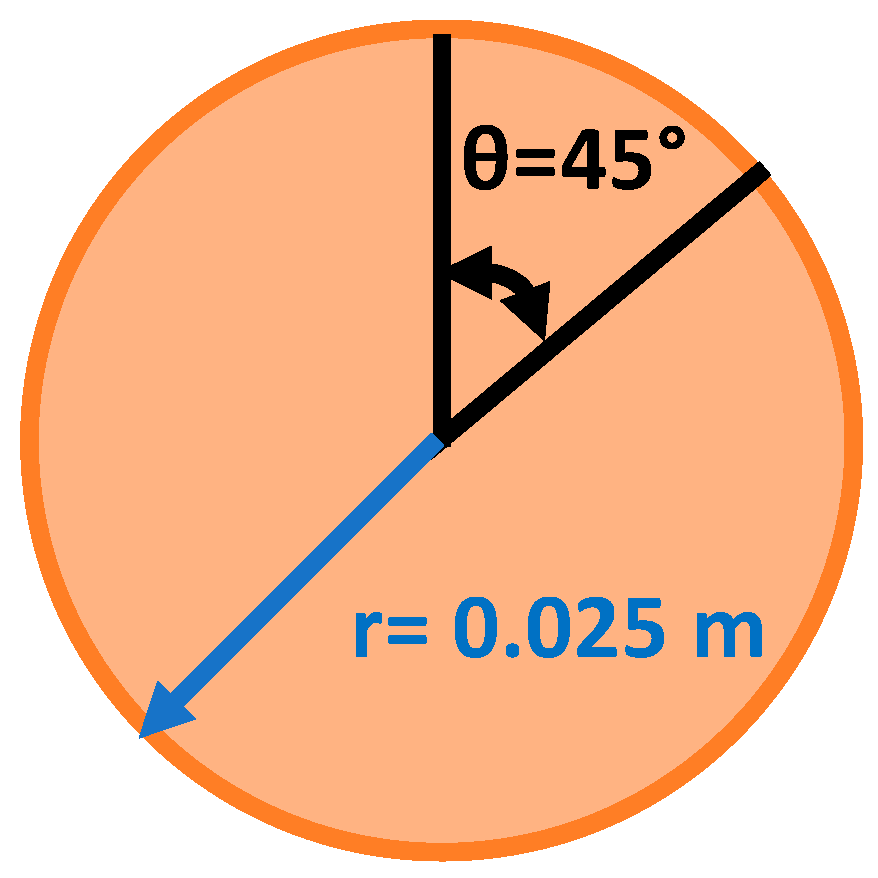

3.7. Abrasion Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Leather Footwear Market Size, Share and Trends Analysis Report by End User, (Male, Female, Kids), by Distribution Channel, by Region, and Segment Forecasts, 2024–2030. Available online: https://www.grandviewresearch.com/industry-analysis/leather-footwear-market (accessed on 21 February 2025).

- Santos, R.J.; Agostini, D.L.; Cabrera, F.C.; Budemberg, E.R.; Job, A.E. Recycling leather waste: Preparing and studying on the microstructure, mechanical, and rheological properties of leather waste/rubber composite. Polym. Compos. 2014, 36, 2275–2281. [Google Scholar] [CrossRef]

- Ward, A.G. The mechanical properties of leather. Rheol. Acta 1974, 13, 103–112. [Google Scholar] [CrossRef]

- Meyer, M.; Dietrich, S.; Schulz, H.; Mondschein, A. Comparison of the technical performance of leather, artificial leather, and trendy alternatives. Coatings 2021, 11, 226. [Google Scholar] [CrossRef]

- UNIC—Concerie Italiane, Tanning Waste Recovery, (n.d.). Available online: https://unic.it/storage/Report%20Sostenibilit%C3%A0%20UNIC%20Concerie%20Italiane%202022.pdf (accessed on 21 February 2025).

- Chojnacka, K.; Skrzypczak, D.; Mikula, K.; Witek-Krowiak, A.; Izydorczyk, G.; Kuligowski, K.; Bandrów, P.; Kułażyński, M. Progress in sustainable technologies of leather wastes valorization as solutions for the circular economy. J. Clean. Prod. 2021, 313, 127902. [Google Scholar] [CrossRef]

- Famielec, S. Chromium concentrate recovery from solid tannery waste in a thermal process. Materials 2020, 13, 1533. [Google Scholar] [CrossRef]

- Hassan, M.M.; Harris, J.; Busfield, J.J.C.; Bilotti, E. A review of the green chemistry approaches to leather tanning in imparting sustainable leather manufacturing. Green Chem. 2023, 25, 7441–7469. [Google Scholar] [CrossRef]

- Covington, A.D.; Wise, W.R. (Eds.) Collagen and Skin Structure. In Tanning Chemistry: The Science of Leather; The Royal Society of Chemistry: London, UK, 2019; pp. 1–31. [Google Scholar] [CrossRef]

- Wenger, M.P.; Bozec, L.; Horton, M.A.; Mesquida, P. Mechanical Properties of Collagen Fibrils. Biophys. J. 2007, 93, 1255–1263. [Google Scholar] [CrossRef]

- Karimi, A.; Razaghi, R.; Sumikura, A. A 3-dimensional finite element model of a newly designed adjustable high-heeled shoe. Int. J. Ind. Ergon. 2018, 68, 304–310. [Google Scholar] [CrossRef]

- Rupérez, M.; Giner, E.; Monserrat, C.; Montiel, E. Simulation of the behavior of the calfskin used as shoe upper material in footwear CAD. Comput. Des. 2012, 44, 1205–1216. [Google Scholar] [CrossRef]

- Mihai, A.; Seul, A.; Curteza, A.; Costea, M. Mechanical Parameters of Leather in Relation to Technological Processing of the Footwear Uppers. Materials 2022, 15, 5107. [Google Scholar] [CrossRef] [PubMed]

- Pahlawan, I.F.; Sutyasmi, S.; Griyanitasari, G. Hydrolysis of leather shavings waste for protein binder. In IOP Conference Series: Earth and Environmental Science; International Cconference on Green Agro-Iindustry and Bbioeconomy; Universitas Brawijaya: East Java Indonesia, 2019. [Google Scholar] [CrossRef]

- Zhang, J.; Song, S.; Zhang, C.; Li, C.; Xu, J.; Xia, L.; Liu, X.; Xu, W. Fabrication of leather-like yarns using waste leather for textile application. Prog. Org. Coat. 2023, 186, 108053. [Google Scholar] [CrossRef]

- Hao, D.; Wang, X.; Liang, S.; Yue, O.; Liu, X.; Hao, D.; Dang, X. Sustainable leather making—An amphoteric organic chrome-free tanning agents based on recycling waste leather. Sci. Total Environ. 2023, 867, 161531. [Google Scholar] [CrossRef]

- Pan, F.; Xiao, Y.; Zhang, L.; Zhou, J.; Wang, C.; Lin, W. Leather wastes into high-value chemicals: Keratin-based retanning agents via UV-initiated polymerization. J. Clean. Prod. 2023, 383, 135492. [Google Scholar] [CrossRef]

- Ding, X.; Li, Y.; Chen, J.; Huang, X.; Chen, L.; Hu, Z. Sustainable utilization of finished leather wastes: A novel collagen hydrolysate-based gypsum additive with high-retarding performance. Process. Saf. Environ. Prot. 2023, 172, 451–461. [Google Scholar] [CrossRef]

- Mozhiarasi, V.; Natarajan, T.S.; Karthik, V.; Anburajan, P. Potential of biofuel production from leather solid wastes: Indian scenario. Environ. Sci. Pollut. Res. 2023, 30, 125214–125237. [Google Scholar] [CrossRef]

- He, Z.; Shen, J.; Zhang, J.; Lin, W.; Gu, H. Cleaner, High-Efficiency, and High-Value Conversion of Chrome-Containing Leather Solid Waste into Carbon Quantum Dots as Renewable Bimetallic Ions Detection Sensors. ACS Sustain. Chem. Eng. 2023, 11, 13126–13141. [Google Scholar] [CrossRef]

- Murugan, K.P.; Sabarinathan, S.; Prabhakaran, N.; Swarnalatha, S. Valorization of hazardous chrome tanned leather buffing waste for the production of Cr2O3/carbon/TiO2 composite semiconductors with the removal of chlorophenol from its wastewater. Chem. Eng. J. 2023, 468, 143547. [Google Scholar] [CrossRef]

- Zeng, S.; Ren, Y.; Liu, P.; Wang, Q.; He, L.; Wang, Q. Facile fabrication of chrome-tanned leather wastes/natural rubber composite: Mechanochemical de-crosslinking effect on collagen fibers and chrome complexation enabled in-situ compatibilization. Compos. Sci. Technol. 2021, 214, 108998. [Google Scholar] [CrossRef]

- Liu, B.; Li, Y.; Wang, Q.; Bai, S. Green fabrication of leather solid waste/thermoplastic polyurethanes composite: Physically de-bundling effect of solid-state shear milling on collagen bundles. Compos. Sci. Technol. 2019, 181, 107674. [Google Scholar] [CrossRef]

- Kiliç, E.; Tarrés, Q.; Delgado-Aguilar, M.; Espinach, X.; Fullana-I-Palmer, P.; Puig, R. Leather Waste to Enhance Mechanical Performance of High-Density Polyethylene. Polymers 2020, 12, 2016. [Google Scholar] [CrossRef]

- Nanni, A.; Parisi, M.; Colonna, M.; Messori, M. Thermo-Mechanical and Morphological Properties of Polymer Composites Reinforced by Natural Fibers Derived from Wet Blue Leather Wastes: A Comparative Study. Polymers 2021, 13, 1837. [Google Scholar] [CrossRef] [PubMed]

- Parisi, M.; Nanni, A.; Colonna, M. Recycling of Chrome-Tanned Leather and Its Utilization as Polymeric Materials and in Polymer-Based Composites: A Review. Polymers 2021, 13, 429. [Google Scholar] [CrossRef] [PubMed]

- El-Sabbagh, S.H.; Mohamed, O.A. Recycling of chrome-tanned leather waste in acrylonitrile butadiene rubber. J. Appl. Polym. Sci. 2011, 121, 979–988. [Google Scholar] [CrossRef]

- Ferreira, M.J.; Freitas, F.; Almeida, M.F. The Effect of Leather Fibers on the Properties of Rubber-Leather Composites. J. Compos. Mater. 2010, 44, 2801–2817. [Google Scholar] [CrossRef]

- Torney, F.; Trewyn, B.G.; Lin, V.S.-Y.; Wang, K. Mesoporous silica nanoparticles deliver DNA and chemicals into plants. Nat. Nanotechnol. 2007, 2, 295–300. [Google Scholar] [CrossRef]

- Zhao, X.; Shou, T.; Liang, R.; Hu, S.; Yu, P.; Zhang, L. Bio-based thermoplastic polyurethane derived from polylactic acid with high-damping performance. Ind. Crop. Prod. 2020, 154, 112619. [Google Scholar] [CrossRef]

- Giehl, D.; Hansen, É.; Robinson, L.C.; de Aquim, P.M. Reusing finished leather waste to produce pigmented thermoplastic polyurethane composite. Collagen Leather 2024, 6, 5. [Google Scholar] [CrossRef]

- Nazir, M.U.; Mascolo, R.; Bouic, P.; Hassan, M.M.; Harris, J.; Naderizadeh, S.; Busfield, J.J.; Zhang, H.; Papageorgiou, D.; Bilotti, E. Upcycling leather waste: The effect of leather type and aspect ratio on the performance of thermoplastic polyurethane composites. Sustain. Mater. Technol. 2024, 43, e01221. [Google Scholar] [CrossRef]

- Kiliç, E.; Oliver-Ortega, H.; Tarrés, Q.; Delgado-Aguilar, M.; Fullana-I-Palmer, P.; Puig, R. Valorization Strategy for Leather Waste as Filler for High-Density Polyethylene Composites: Analysis of the Thermal Stability, Insulation Properties and Chromium Leaching. Polymers 2021, 13, 3313. [Google Scholar] [CrossRef]

- Joseph, S.; Ambone, T.S.; Salvekar, A.V.; Jaisankar, S.; Saravanan, P.; Deenadayalan, E. Processing and characterization of waste leather based polycaprolactone biocomposites. Polym. Compos. 2015, 38, 2889–2897. [Google Scholar] [CrossRef]

- Madera-Santana, T.J.; Torres, A.C.; Lucero, A.M. Extrusion and mechanical characterization of PVC-leather fiber composites. Polym. Compos. 1998, 19, 431–439. [Google Scholar] [CrossRef]

- Cruz, S.M.; Viana, J.C. Melt blending and characterization of carbon nanoparticles-filled thermoplastic polyurethane elastomers. J. Elastomers Plast. 2014, 47, 647–665. [Google Scholar] [CrossRef]

- Kanbur, Y.; Tayfun, U. Development of multifunctional polyurethane elastomer composites containing fullerene: Mechanical, damping, thermal, and flammability behaviors. J. Elastomers Plast. 2018, 51, 262–279. [Google Scholar] [CrossRef]

- El-Shekeil, Y.A.; Sapuan, S.M.; Abdan, K.; Zainudin, E.S. Influence of fiber content on the mechanical and thermal properties of Kenaf fiber reinforced thermoplastic polyurethane composites. Compos. Part B Eng. 2012, 43, 245–254. [Google Scholar] [CrossRef]

- Beckermann, G.; Pickering, K. Engineering and evaluation of hemp fibre reinforced polypropylene composites: Fibre treatment and matrix modification. Compos. Part A Appl. Sci. Manuf. 2008, 39, 979–988. [Google Scholar] [CrossRef]

- Dev, B.; Rahman, A.; Repon, R.; Rahman, M.M.; Haji, A.; Nawab, Y. Recent progress in thermal and acoustic properties of natural fiber reinforced polymer composites: Preparation, characterization, and data analysis. Polym. Compos. 2023, 44, 7235–7297. [Google Scholar] [CrossRef]

- Meşe, P.; Karaağaç, B.; Uyanık, N. Investigating Effect of Chrome Tanned Leather Scraps in Ethylene Propylene Diene Monomer Rubber. Prog. Rubber Plast. Recycl. Technol. 2018, 34, 89–103. [Google Scholar] [CrossRef]

- Naderizadeh, S.; Santagiuliana, G.; Tu, W.; Marsh, D.; Bilotti, E.; Busfield, J.J.C. Piezoresistive Elastomer Composites Used for Pressure Sensing. IEEE Sens. J. 2023, 23, 18013–18021. [Google Scholar] [CrossRef]

- Kale, R.D.; Jadhav, N.C. Utilization of waste leather for the fabrication of composites and to study its mechanical and thermal properties. SN Appl. Sci. 2019, 1, 1231. [Google Scholar] [CrossRef]

- Rajaram, J.; Rajnikanth, B.; Gnanamani, A. Preparation, Characterization and Application of Leather Particulate-Polymer Composites (LPPCs). J. Polym. Environ. 2009, 17, 181–186. [Google Scholar] [CrossRef]

- Mehta, M.; Naffa, R.; Maidment, C.; Holmes, G.; Waterland, M. Raman and Atr-Ftir spectroscopy towards classification of wet blue bovine leather using ratiometric and chemometric analysis. J. Leather Sci. Eng. 2020, 2, 3. [Google Scholar] [CrossRef]

- Hassan, M.M. Enhanced antistatic and mechanical properties of corona plasma treated wool fabrics treated with 2,3-epoxypropyltrimethylammonium chloride. Ind. Eng. Chem. Res. 2014, 53, 10954–10964. [Google Scholar] [CrossRef]

- Lluch, C.; Esteve-Zarzoso, B.; Bordons, A.; Lligadas, G.; Ronda, J.C.; Galià, M.; Cádiz, V. Antimicrobial polyurethane thermosets based on undecylenic acid: Synthesis and evaluation. Macromol. Biosci. 2014, 14, 1170–1180. [Google Scholar] [CrossRef]

- Kirpluks, M.; Cabulis, U.; Ivdre, A.; Kuranska, M.; Zieleniewska, M.; Auguscik, M. Mechanical and thermal properties of high-density rigid polyurethane foams from renewable resources. J. Renew. Mater. 2016, 4, 86–100. [Google Scholar] [CrossRef]

- Galuska, L.A.; Ocheje, M.U.; Ahmad, Z.C.; Rondeau-Gagné, S.; Gu, X. Elucidating the role of hydrogen bonds for improved mechanical properties in a high-performance semiconducting polymer. Chem. Mater. 2022, 34, 2259–2267. [Google Scholar] [CrossRef]

- Sun, Z.; Chen, Y.; Tang, W.; Qiu, Y.; Qian, L. Strategies for simultaneously improving the mechanical properties and flame retardancy of TPU through hydrogen bonding. J. Therm. Anal. Calorim. 2023, 148, 9843–9855. [Google Scholar] [CrossRef]

- Available online: https://www.lubrizol.com/-/media/Lubrizol/Engineered-Polymers/Documents/Engineered-Polymer-TDS/ESTANE_ECO_12T80E.pdf (accessed on 15 October 2023).

- Ashokkumar, M.; Thanikaivelan, P.; Chandrasekaran, B. Modulating Chromium Containing Leather Wastes into Improved Composite Sheets Using Polydimethylsiloxane. Polym. Polym. Compos. 2011, 19, 497–504. [Google Scholar] [CrossRef]

- Senthil, R.; Hemalatha, T.; Kumar, B.S.; Uma, T.S.; Das, B.N.; Sastry, T.P. Recycling of finished leather wastes: A novel approach. Clean Technol. Environ. Policy 2014, 17, 187–197. [Google Scholar] [CrossRef]

- Ding, C.; Zhang, M.; Dai, L.; Qi, Y.; Shi, R.; Yang, J. Fabrication and Characterization of Regenerated Leather Using Chrome Shavings as Raw Materials. J. Am. Leather Chem. Assoc 2017, 112, 5. [Google Scholar]

- Ruiz, M.R.; Budemberg, E.R.; da Cunha, G.P.; Bellucci, F.S.; da Cunha, H.N.; Job, A.E. An innovative material based on natural rubber and leather tannery waste to be applied as antistatic flooring. J. Appl. Polym. Sci. 2014, 132. [Google Scholar] [CrossRef]

- Dargazany, R.; Itskov, M. Constitutive modeling of the Mullins effect and cyclic stress softening in filled elastomers. Phys. Rev. E 2013, 88, 012602. [Google Scholar] [CrossRef] [PubMed]

- Bai, L.; Qv, P.; Zheng, J. Colorless, transparent, and healable silicone elastomers by introducing Zn(II)–carboxylate interactions via aza-Michael reaction. J. Mater. Sci. 2020, 55, 14045–14057. [Google Scholar] [CrossRef]

- Carleo, F.; Plagge, J.; Whear, R.; Busfield, J.; Klüppel, M. Modeling the Full Time-Dependent Phenomenology of Filled Rubber for Use in Anti-Vibration Design. Polymers 2020, 12, 841. [Google Scholar] [CrossRef] [PubMed]

- Kahraman, H.; Weinhold, G.; Haberstroh, E.; Itskov, M. Anisotroper Mullins-Effekt bei russgefüllten Elastomeren: Experimentelle und phänomenologische Beschreibung, Kgk-Kautschuk Gummi Kunststoffe. J. Matter. Sci. 2010, 63, 64–69. Available online: https://api.semanticscholar.org/CorpusID:138899781 (accessed on 9 September 2024).

- Klüppel, M. The Role of Disorder in Filler Reinforcement of Elastomers on Various Length Scales. In Filler-Reinforced Elastomers Scanning Force Microscopy. Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2003; pp. 1–86. [Google Scholar] [CrossRef]

- Meissner, B.; Matějka, L. A structure-based constitutive equation for filler-reinforced rubber-like networks and for the description of the Mullins effect. Polymer 2006, 47, 7997–8012. [Google Scholar] [CrossRef]

- Plaschka, E.; Akutagawa, K.; Di Federico, E.; Busfield, J. Developing a more representative friction and wear simulator for tire tread compounds. Polym. Test. 2025, 143, 108688. [Google Scholar] [CrossRef]

| Samples | T5 (°C) | T20 (°C) | Residual (%) |

|---|---|---|---|

| LF | 55.9 ± 1.1 | 287.4 ± 5.7 | 24.4 ± 0.1 |

| TPU | 311.3 ± 6.2 | 347.7 ± 6.5 | 1.8 ± 0.1 |

| TPU/10% LF | 305.0 ± 6.1 | 340.9 ± 6.5 | 2.1 ± 0.2 |

| TPU/20% LF | 302.7 ± 6.1 | 339.6 ± 6.8 | 2.8 ± 0.1 |

| TPU/30% LF | 288.3 ± 5.8 | 330.5 ± 6.6 | 3.7 ± 0.2 |

| Samples | Tg (°C) | Tc (°C) | Tm (°C) |

|---|---|---|---|

| TPU | −46.1 ± 1.2 | 37.8 ± 1.7 | 142.3 ± 3.6 |

| TPU/10% LF | −42.6 ± 0.8 | 38.4 ± 1.8 | 149.6 ± 3.7 |

| TPU/20% LF | −42.5 ± 0.7 | 39.1 ± 1.7 | 150.7 ± 3.7 |

| TPU/30% LF | −41.8 ± 1.1 | 44.4 ± 2.2 | NA |

| Scheme 25. | E at 25% Strain (MPa) | TS (MPa) | Ɛb (%) |

|---|---|---|---|

| TPU | 4.0 ± 0.3 | 33.0 ± 3.5 | 604.0 ± 36.2 |

| TPU/10% LW | 5.7 ± 0.5 | 32.0 ± 2.8 | 596.7 ± 38.0 |

| TPU/20% LW | 37.3 ± 3.7 | 18.4 ± 1.7 | 312.9 ± 21.9 |

| TPU/30% LW | 74.3 ± 7.3 | 14.8 ± 1.6 | 157.1 ± 10.2 |

| 3D-printed TPU/10% LW | 4.9 ± 0.5 | 27.9 ± 2.8 | 647.0 ± 41.8 |

| 3D-printed TPU/20% LW | 22.1 ± 2.3 | 12.8 ± 1.3 | 290.1 ± 20.3 |

| 3D-printed TPU/30% LW | 36.3 ± 3.6 | 10.3 ± 1.0 | 119.8 ± 8.3 |

| Samples | HA at 5% Ɛ (%) | HA at 10% Ɛ (%) | HA at 15% Ɛ (%) | HA at 20% Ɛ (%) | HA at 25% Ɛ (%) |

|---|---|---|---|---|---|

| TPU/10% LF | 18.3 ± 0.8 | 26.0 ± 1.1 | 29.7 ± 1.2 | 31.7 ± 0.6 | 34.4 ± 1.7 |

| TPU/20% LF | 26.1 ± 1.0 | 45.9 ± 1.8 | 48.2 ± 2.4 | 51.3 ± 2.6 | 52.7 ± 2.5 |

| TPU/30% LF | 35.8 ± 1.1 | 56.2 ± 2.4 | NA | NA | NA |

| TPU/10% LF | 11.9 ± 0.4 | 16.9 ± 0.2 | 18.1 ± 0.8 | 14.1 ± 0.6 | 16.0 ± 0.6 |

| TPU/20% LF | 20.4 ±0.7 | 31.0 ± 1.0 | 27.6 ± 1.1 | 32.2 ± 0.9 | 31.3 ± 1.1 |

| TPU/30% LF | 23.7 ± 0.6 | 33.2± 1.3 | 32,4 ± 1.7 | 33.1 ± 1.0 | 33.0 ± 1.5 |

| Samples | Abrasion Resistance (%) |

|---|---|

| TPU | 21.8 |

| TPU/10% LF | 16.2 |

| TPU/20% LF | 13.4 |

| TPU/30% LF | 11.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Naderizadeh, S.; Faggionato, A.; Nazir, M.U.; Mascolo, R.; Hassan, M.M.; Bilotti, E.; Busfield, J.J.C. The Thermal and Mechanical Performance of Leather Waste-Filled Bio-Based Thermoplastic Polyurethane Composites. Polymers 2025, 17, 1202. https://doi.org/10.3390/polym17091202

Naderizadeh S, Faggionato A, Nazir MU, Mascolo R, Hassan MM, Bilotti E, Busfield JJC. The Thermal and Mechanical Performance of Leather Waste-Filled Bio-Based Thermoplastic Polyurethane Composites. Polymers. 2025; 17(9):1202. https://doi.org/10.3390/polym17091202

Chicago/Turabian StyleNaderizadeh, Sara, Anna Faggionato, Muhammad Umar Nazir, Rosario Mascolo, Mohammad Mahbubul Hassan, Emiliano Bilotti, and James J. C. Busfield. 2025. "The Thermal and Mechanical Performance of Leather Waste-Filled Bio-Based Thermoplastic Polyurethane Composites" Polymers 17, no. 9: 1202. https://doi.org/10.3390/polym17091202

APA StyleNaderizadeh, S., Faggionato, A., Nazir, M. U., Mascolo, R., Hassan, M. M., Bilotti, E., & Busfield, J. J. C. (2025). The Thermal and Mechanical Performance of Leather Waste-Filled Bio-Based Thermoplastic Polyurethane Composites. Polymers, 17(9), 1202. https://doi.org/10.3390/polym17091202