Development of Sustainable Polymer Composites Containing Waste Glass and Natural Fibers for Strengthening Purposes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

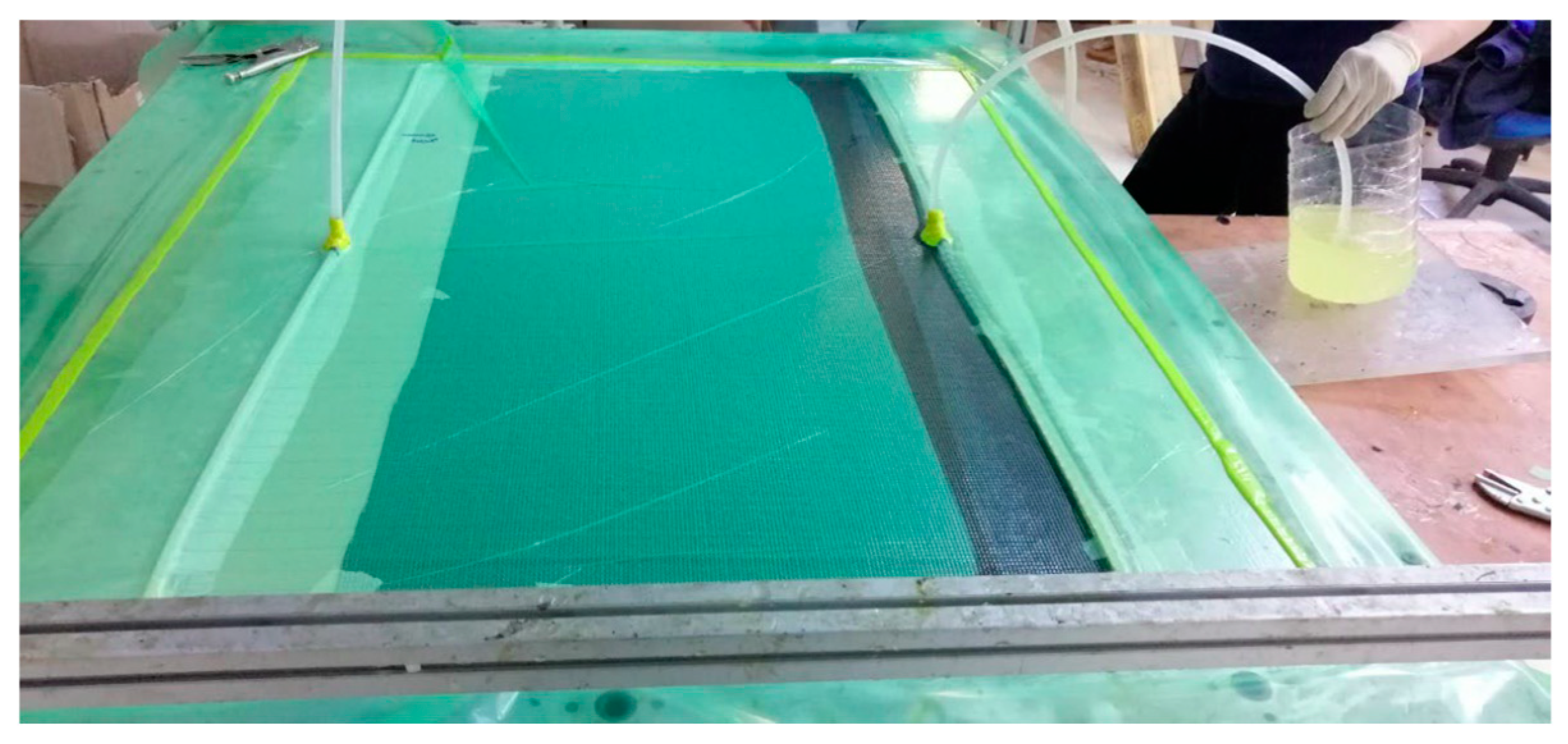

2.2. Preparation of Polymer Composites

2.3. Test Methods

3. Results and Discussion

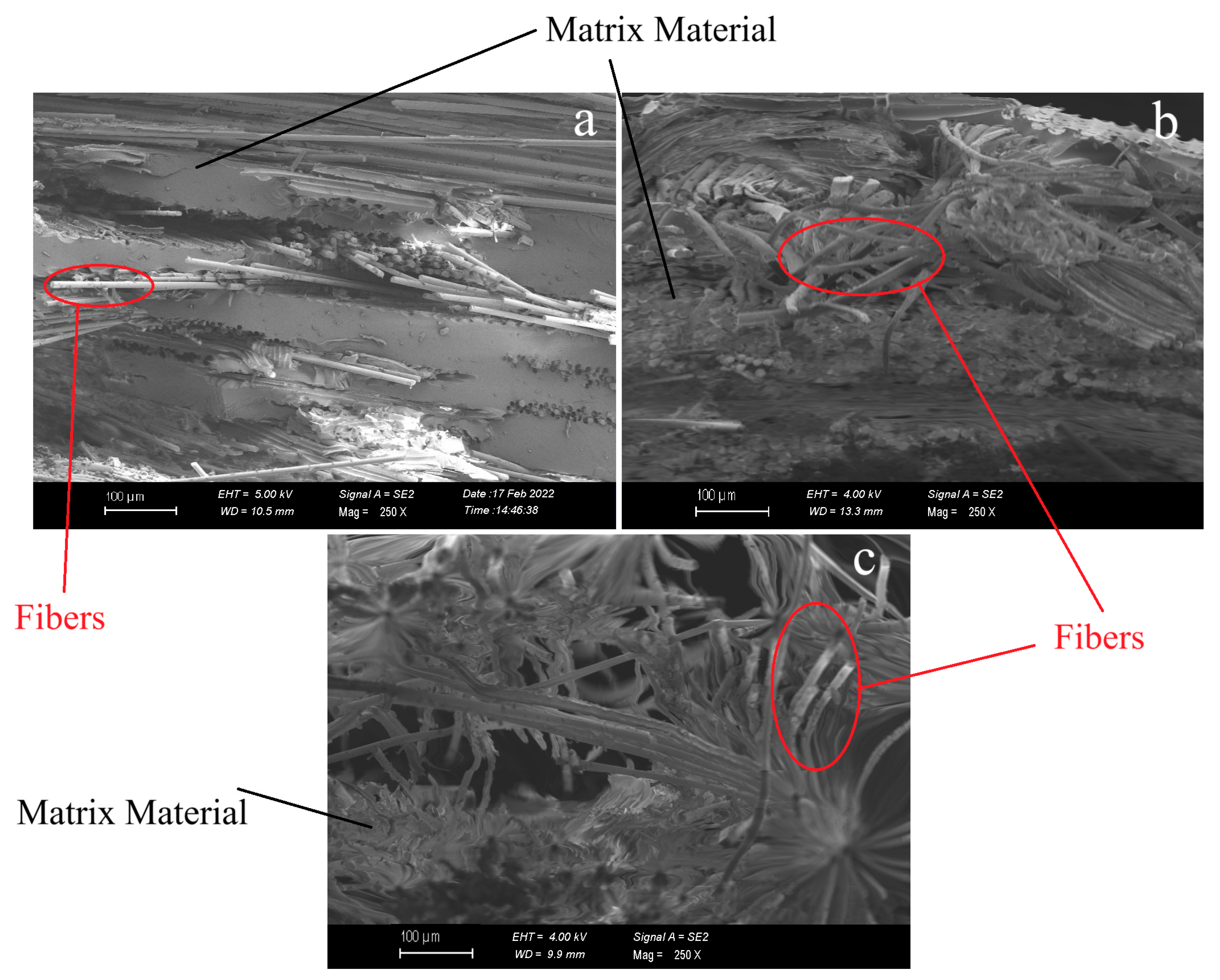

3.1. Tensile Test Results of the Composites

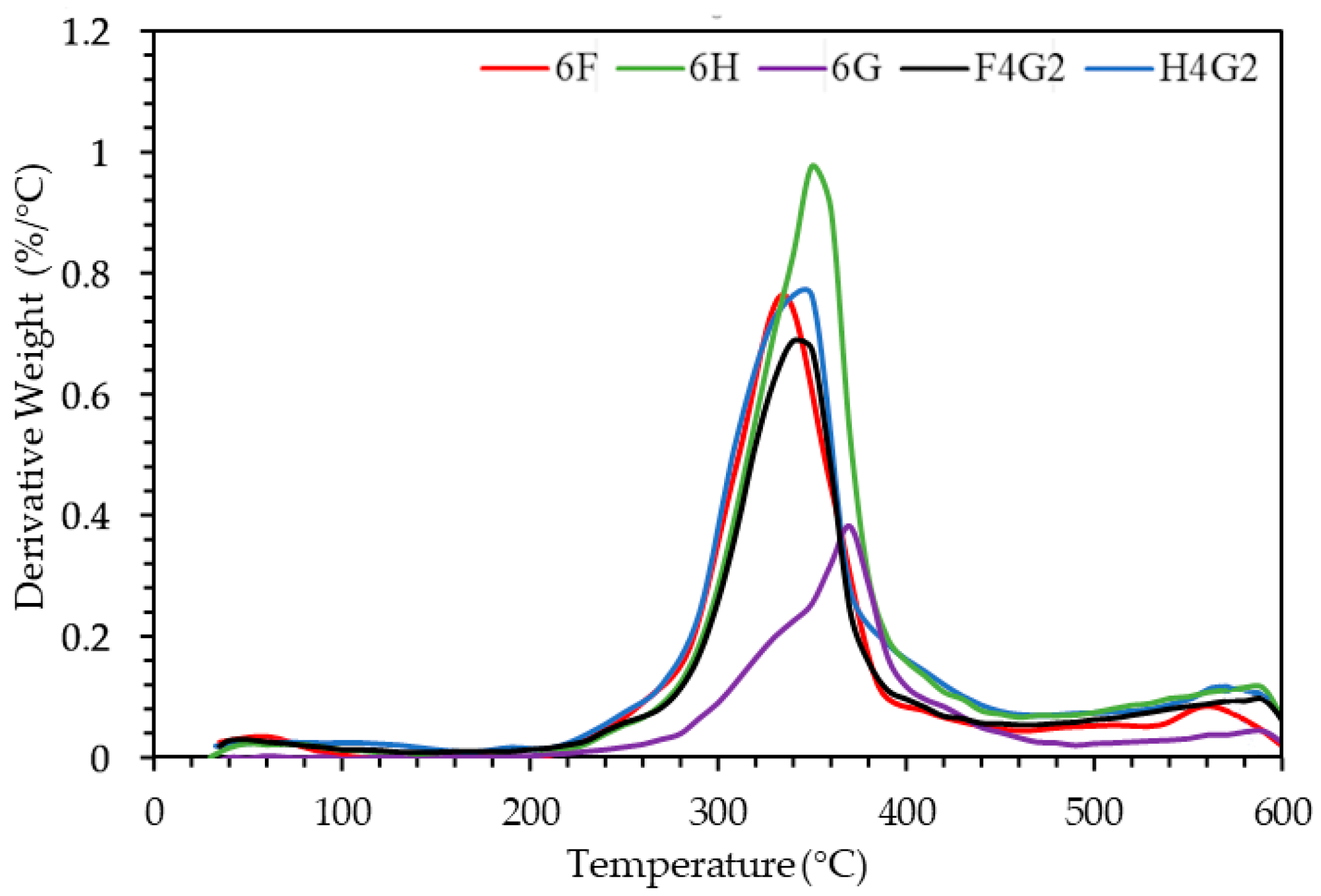

3.2. TGA of the Composites

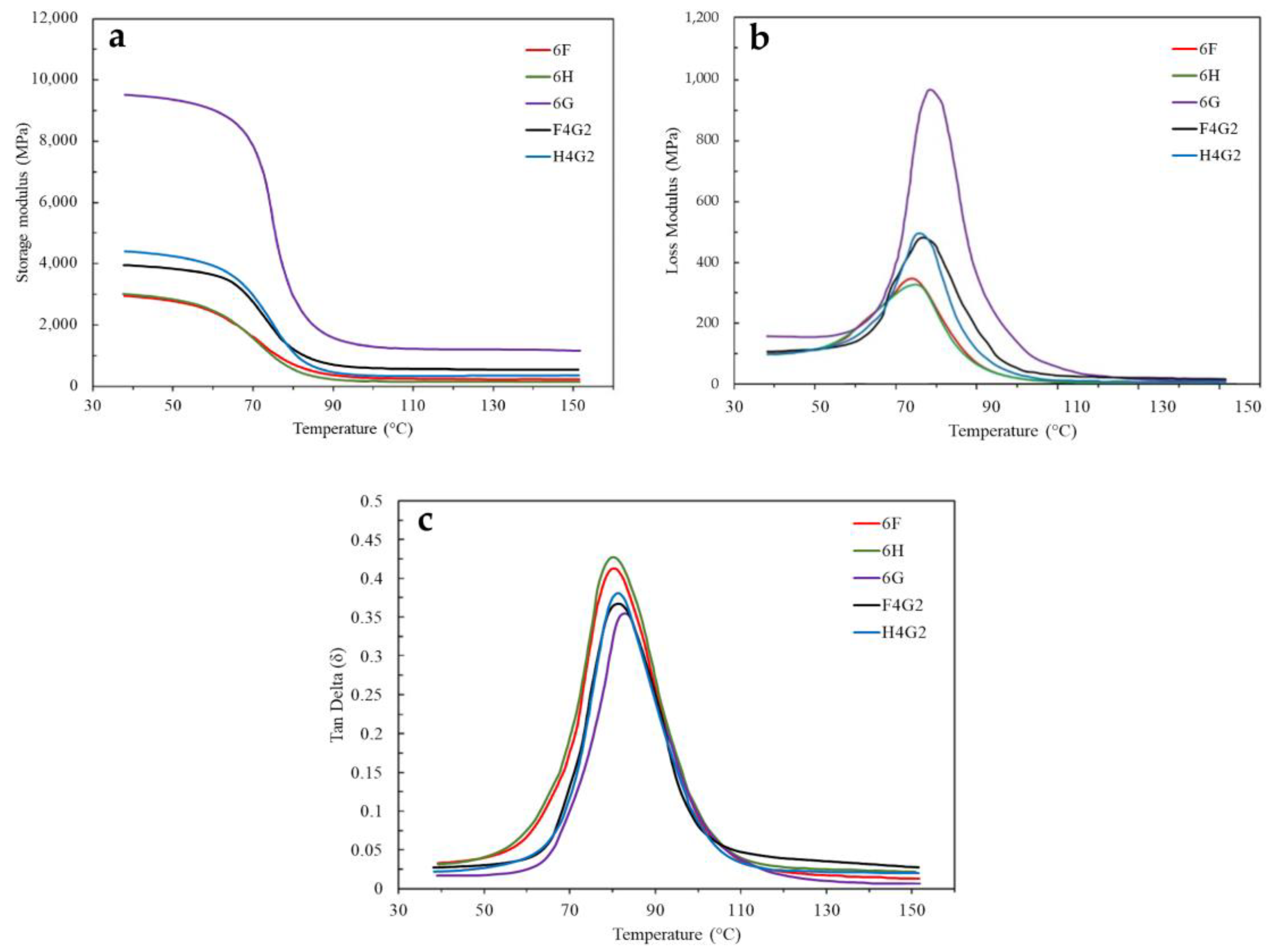

3.3. DMA of the Composites

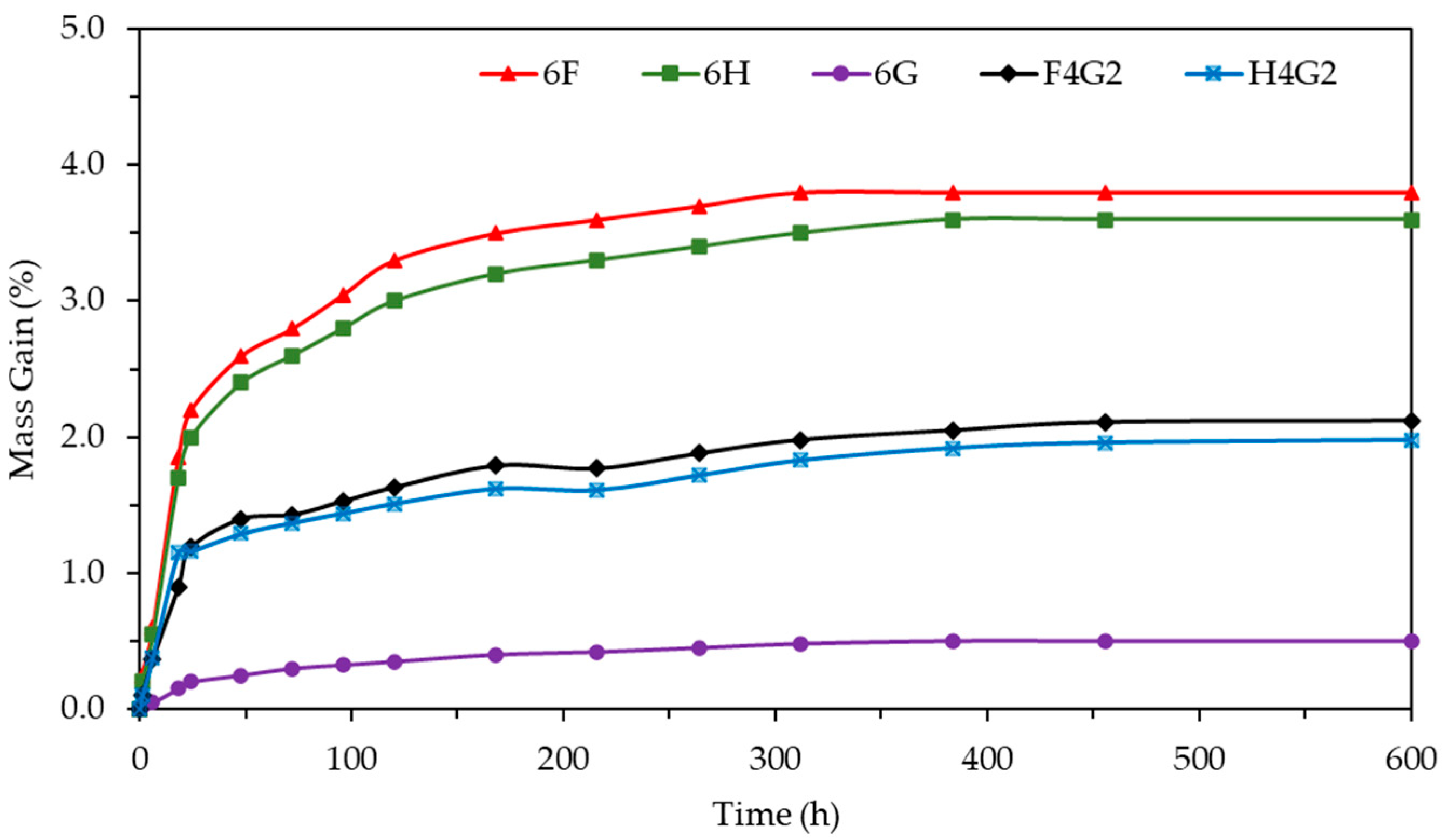

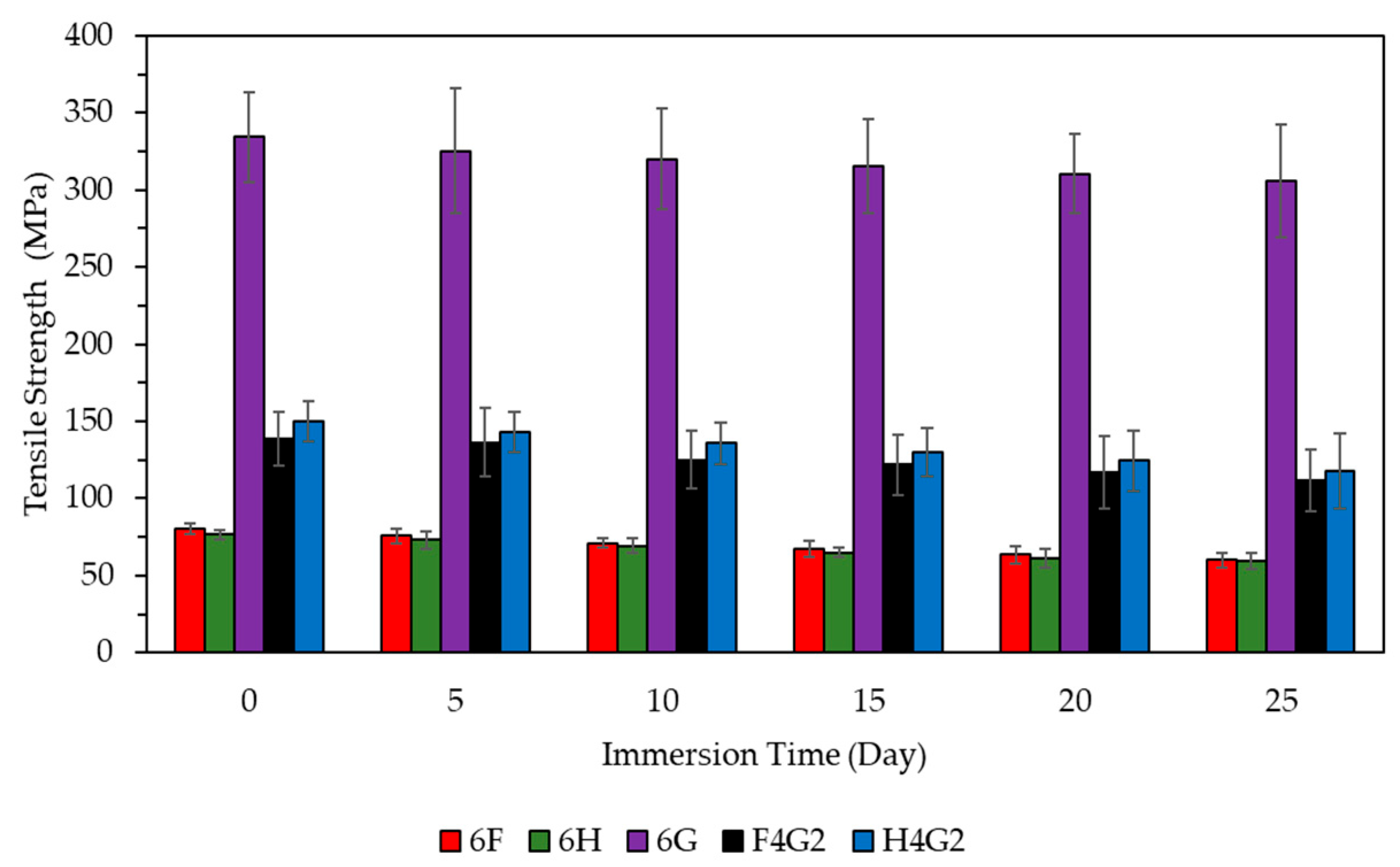

3.4. Water Absorption Behavior and Aging Test of Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Askar, M.K.; Hassan, A.F.; Al-Kamaki, Y.S.S. Flexural and Shear Strengthening of Reinforced Concrete Beams Using FRP Composites: A State of the Art. Case Stud. Constr. Mater. 2022, 17, e01189. [Google Scholar] [CrossRef]

- Kotynia, R. Debonding Phenomena in FRP-Strengthened Concrete Members. In Brittle Matrix Composites 8; Elsevier Ltd.: Amsterdam, The Netherlands, 2006; pp. 109–122. ISBN 9781845690311. [Google Scholar]

- Grelle, S.V.; Sneed, L.H. Review of Anchorage Systems for Externally Bonded FRP Laminates. Int. J. Concr. Struct. Mater. 2013, 7, 17–33. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Huang, Y. Hybrid Bonding of FRP to Reinforced Concrete Structures. J. Compos. Constr. 2008, 12, 266–273. [Google Scholar] [CrossRef]

- Hsissou, R.; Seghiri, R.; Benzekri, Z.; Hilali, M.; Rafik, M.; Elharfi, A. Polymer Composite Materials: A Comprehensive Review. Compos. Struct. 2021, 262, 113640. [Google Scholar] [CrossRef]

- Sajan, S.; Philip Selvaraj, D. A Review on Polymer Matrix Composite Materials and Their Applications. In Proceedings of the Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; Volume 47, pp. 5493–5498. [Google Scholar]

- Song, Y.S.; Youn, J.R.; Gutowski, T.G. Life Cycle Energy Analysis of Fiber-Reinforced Composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 1257–1265. [Google Scholar] [CrossRef]

- Chang, J.H.; Tsai, Y.S.; Yang, P.Y. A Review of Glass Fibre Recycling Technology Using Chemical and Mechanical Separation of Surface Sizing Agents. Recycling 2021, 6, 79. [Google Scholar] [CrossRef]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.J.; Kuiper, P.; de Wit, H. Recycling of Composite Materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Bank, L.C. A Critical Review of Research on Reuse of Mechanically Recycled FRP Production and End-of-Life Waste for Construction. Polymers 2014, 6, 1810–1826. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling Technologies for Thermoset Composite Materials-Current Status. Compos. Part. A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Tao, Y.; Hadigheh, S.A.; Wei, Y. Recycling of Glass Fibre Reinforced Polymer (GFRP) Composite Wastes in Concrete: A Critical Review and Cost Benefit Analysis. Structures 2023, 53, 1540–1556. [Google Scholar] [CrossRef]

- Wei, Y.; Hadigheh, S.A. Cost Benefit and Life Cycle Analysis of CFRP and GFRP Waste Treatment Methods. Constr. Build. Mater. 2022, 348, 128654. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A Critical Review on Recycling of End-of-Life Carbon Fibre/Glass Fibre Reinforced Composites Waste Using Pyrolysis towards a Circular Economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- Kerni, L.; Singh, S.; Patnaik, A.; Kumar, N. A Review on Natural Fiber Reinforced Composites. In Proceedings of the Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; Volume 28, pp. 1616–1621. [Google Scholar]

- Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a Potential Raw Material toward a Sustainable World: A Review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef]

- Bambach, M.R. Direct Comparison of the Structural Compression Characteristics of Natural and Synthetic Fiber-Epoxy Composites: Flax, Jute, Hemp, Glass and Carbon Fibers. Fibers 2020, 8, 62. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Mohd Basri, M.S.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H.; et al. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef]

- Aravinth, K.; Sathish, R.; Ramakrishnan, T.; Balu Mahandiran, S.; Shiyam Sundhar, S. Mechanical Investigation of Agave Fiber Reinforced Composites Based on Fiber Orientation, Fiber Length, and Fiber Volume Fraction. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, H.; Njuguna, J.; Abhyankar, H. Recent Development of Flax Fibres and Their Reinforced Composites Based on Different Polymeric Matrices. Materials 2013, 6, 5171–5198. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Boonyasopon, P.; Rangappa, S.M.; Khan, A.; Siengchin, S. Recent Developments and Challenges in Natural Fiber Composites: A Review. Polym. Compos. 2022, 43, 2545–2561. [Google Scholar] [CrossRef]

- Patel, R.V.; Yadav, A.; Winczek, J. Physical, Mechanical, and Thermal Properties of Natural Fiber-Reinforced Epoxy Composites for Construction and Automotive Applications. Appl. Sci. 2023, 13, 5126. [Google Scholar] [CrossRef]

- Asim, M.; Paridah, M.T.; Chandrasekar, M.; Shahroze, R.M.; Jawaid, M.; Nasir, M.; Siakeng, R. Thermal Stability of Natural Fibers and Their Polymer Composites. Iran. Polym. J. (Engl. Ed.) 2020, 29, 625–648. [Google Scholar] [CrossRef]

- Islam, T.; Chaion, M.H.; Jalil, M.A.; Rafi, A.S.; Mushtari, F.; Dhar, A.K.; Hossain, S. Advancements and Challenges in Natural Fiber-Reinforced Hybrid Composites: A Comprehensive Review. SPE Polym. 2024, 5, 481–506. [Google Scholar] [CrossRef]

- Kumar, A.; Srivastava, A. Preparation and Mechanical Properties of Jute Fiber Reinforced Epoxy Composites. Ind. Eng. Manag. 2017, 6, 4. [Google Scholar] [CrossRef]

- Ramful, R. Mechanical Performance and Durability Attributes of Biodegradable Natural Fibre-Reinforced Composites—A Review. J. Mater. Sci. Mater. Eng. 2024, 19, 50. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; Elayaperumal, A.; Sathiya, G.K. Prediction of Tensile Properties of Hybrid-Natural Fiber Composites. Compos. B Eng. 2012, 43, 793–796. [Google Scholar] [CrossRef]

- Padanattil, A.; Karingamanna, J.; Mini, K.M. Novel Hybrid Composites Based on Glass and Sisal Fiber for Retrofitting of Reinforced Concrete Structures. Constr. Build. Mater. 2017, 133, 146–153. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Yang, L.; Du, J. Research on Mechanical Properties and Durability of Flax/Glass Fiber Bio-Hybrid FRP Composites Laminates. Compos. Struct. 2022, 290, 115566. [Google Scholar] [CrossRef]

- Neto, J.; Queiroz, H.; Aguiar, R.; Lima, R.; Cavalcanti, D.; Banea, M.D. A Review of Recent Advances in Hybrid Natural Fiber Reinforced Polymer Composites. J. Renew. Mater. 2022, 10, 561–589. [Google Scholar] [CrossRef]

- Mahmud, S.; Konlan, J.; Deicaza, J.; Li, G. Hybrid Hemp/Glass Fiber Reinforced High-Temperature Shape Memory Photopolymer with Mechanical and Flame-Retardant Analysis. Sci. Rep. 2023, 13, 17830. [Google Scholar] [CrossRef]

- Pisupati, A.; Deléglise Lagardère, M. Mechanical Performance of Flax Fiber Composites with Waste Glass Fibers as a Core Structure. Materials 2022, 15, 9017. [Google Scholar] [CrossRef]

- Pulleti, S.S.; Singh, S.B. Development and Characterization of Hemp/Carbon and Hemp/Glass Hybrid and Novel Functionally Graded Hybrid Composites for Structural Applications. Polym. Compos. 2024, 45, 11178–11199. [Google Scholar] [CrossRef]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant Fibre Based Bio-Composites: Sustainable and Renewable Green Materials. Renew. Sustain. Energy Rev. 2017, 79, 558–584. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A Review on Basalt Fibre and Its Composites. Compos. B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/Synthetic Fibre Reinforced Polymer Hybrid Composites: A Review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. Recycling Carbon Fibre Reinforced Polymers for Structural Applications: Technology Review and Market Outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current Status of Recycling of Fibre Reinforced Polymers: Review of Technologies, Reuse and Resulting Properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. Glass-Basalt/Epoxy Hybrid Composites for Marine Applications. Mater. Des. 2011, 32, 2091–2099. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Naveen, J.; Satheeshkumar, S. Hybrid Fiber Reinforced Polymer Composites-A Review. J. Reinf. Plast. Compos. 2014, 33, 454–471. [Google Scholar] [CrossRef]

- Abdur Rahman, M.; Haque, S.; Athikesavan, M.M.; Kamaludeen, M.B. A Review of Environmental Friendly Green Composites: Production Methods, Current Progresses, and Challenges. Environ. Sci. Pollut. Res. 2023, 30, 16905–16929. [Google Scholar] [CrossRef]

- Mugdha Bhat, K.; Rajagopalan, J.; Mallikarjunaiah, R.; Nagaraj Rao, N.; Sharma, A. Eco-Friendly and Biodegradable Green Composites. In Biocomposites; IntechOpen: London, UK, 2022. [Google Scholar]

- Samir, A.; Ashour, F.H.; Hakim, A.A.A.; Bassyouni, M. Recent Advances in Biodegradable Polymers for Sustainable Applications. Npj Mater. Degrad. 2022, 6, 68. [Google Scholar] [CrossRef]

- TSE TS EN ISO 13934-1; Textiles-Tensile Properties of Fabrics-Part 1: Determination of Maximum Force and Elongation at Maximum Force Using the Strip Method. TSE: Turkish Standards Institution, Ankara, 2013.

- Abdurohman, K.; Satrio, T.; Muzayadah, N.L.; Teten. A Comparison Process between Hand Lay-up, Vacuum Infusion and Vacuum Bagging Method toward e-Glass EW 185/Lycal Composites. J. Phys. Conf. Ser. 2018, 1130, 012018. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M−08; Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM D 7028–07; Standard Test Method for Glass Transition Temperature (DMA Tg) of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA) 1. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM E1131−20; Test Method for Compositional Analysis by Thermogravimetry. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D570−22; Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- Pawar, U.S.; Chavan, S.S.; Mohite, D.D. Synthesis of Glass FRP-Natural Fiber Hybrid Composites (NFHC) and Its Mechanical Characterization. Discov. Sustain. 2024, 5, 44. [Google Scholar] [CrossRef]

- Zhao, D.Y.; Zeng, Y.; Lin, H.; Lei, J.; Zhong, G.J.; Li, Z.M. Molecular Dynamics Simulation of Stretching-Induced Ductility for Polystyrene. Polymer 2024, 305, 127182. [Google Scholar] [CrossRef]

- Wu, W. Tensile Failure Behaviors and Theories of Carbon/Glass Hybrid Interlayer and Intralayer Composites. Coatings 2023, 13, 774. [Google Scholar] [CrossRef]

- Sherif, G.; Chukov, D.I.; Tcherdyntsev, V.V.; Stepashkin, A.A.; Zadorozhnyy, M.Y.; Shulga, Y.M.; Kabachkov, E.N. Surface Treatment Effect on the Mechanical and Thermal Behavior of the Glass Fabric Reinforced Polysulfone. Polymers 2024, 16, 864. [Google Scholar] [CrossRef]

- Kumar, M.S.; Raghavendra, K.; Venkataswamy, M.A.; Ramachandra, H.V. Fractographic Analysis of Tensile Failures of Aerospace Grade Composites. Mater. Res. 2012, 15, 990–997. [Google Scholar] [CrossRef]

- Chen, C.; Yang, Y.; Yu, J.; Yu, J.; Tan, H.; Sui, L.; Zhou, Y. Eco-Friendly and Mechanically Reliable Alternative to Synthetic FRP in Externally Bonded Strengthening of RC Beams: Natural FRP. Compos. Struct. 2020, 241, 112081. [Google Scholar] [CrossRef]

- Li, X.; Gao, Z.; Zhou, Y.; Sui, L.; Chen, C. Optimizing Natural Fiber Reinforced Polymer Strengthening of RC Beams. Mater. Struct./Mater. Constr. 2021, 54, 66. [Google Scholar] [CrossRef]

- Yinh, S.; Hussain, Q.; Joyklad, P.; Chaimahawan, P.; Rattanapitikon, W.; Limkatanyu, S.; Pimanmas, A. Strengthening Effect of Natural Fiber Reinforced Polymer Composites (NFRP) on Concrete. Case Stud. Constr. Mater. 2021, 15, e00653. [Google Scholar] [CrossRef]

- Alam, M.A.; Hassan, A.; Muda, Z.C. Development of Kenaf Fibre Reinforced Polymer Laminate for Shear Strengthening of Reinforced Concrete Beam. Mater. Struct./Mater. Constr. 2016, 49, 795–811. [Google Scholar] [CrossRef]

- Alam, M.A.; Al Riyami, K. Shear Strengthening of Reinforced Concrete Beam Using Natural Fibre Reinforced Polymer Laminates. Constr. Build. Mater. 2018, 162, 683–696. [Google Scholar] [CrossRef]

- Siriluk, S.; Hussin, Q.; Rattanapitikorn, W.; Pimanmas, A. Behaviours of RC Deep Beams Strengthened in Shear Using Hemp Fiber Reinforced Polymer Composites. Int. J. Geomate 2018, 15, 89–94. [Google Scholar] [CrossRef]

- Saingam, P.; Ejaz, A.; Gadagamma, C.K.; Hussain, Q.; Sua-iam, G.; Chatveera, B.; Maneengamlert, B.; Joyklad, P. Innovative Approaches to RC Deep Beam Strengthening: Evaluating Low-Cost Glass Fiber Wraps Against Traditional CFRP Solutions. Polymers 2025, 17, 807. [Google Scholar] [CrossRef]

- Djeddi, F.; Ghernouti, Y.; Abdelaziz, Y.; Alex, L. Strengthening in Flexure-Shear of RC Beams with Hybrid FRP Systems: Experiments and Numerical Modeling. J. Reinf. Plast. Compos. 2016, 35, 1642–1660. [Google Scholar] [CrossRef]

- Rodsin, K.; Ejaz, A.; Hussain, Q.; Parichatprecha, R. Experimental and Analytical Studies on Low-Cost Glass-Fiber-Reinforced-Polymer-Composite-Strengthened Reinforced Concrete Beams: A Comparison with Carbon/Sisal Fiber-Reinforced Polymers. Polymers 2023, 15, 4027. [Google Scholar] [CrossRef]

- Kalyani, G.; Pannirselvam, N. Experimental and Numerical Investigations on RC Beams Flexurally Strengthened Utilizing Hybrid FRP Sheets. Results Eng. 2023, 19, 101337. [Google Scholar] [CrossRef]

- Maciel, L.P.; Leão Júnior, P.S.B.; Pereira Filho, M.J.M.; El Banna, W.R.; Fujiyama, R.T.; Ferreira, M.P.; Lima Neto, A.F. Experimental Analysis of Shear-Strengthened RC Beams with Jute and Jute–Glass Hybrid FRPs Using the EBR Technique. Buildings 2024, 14, 2893. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Calado, V.; Rodriguez, R.J.S.; Margem, F.M. Thermogravimetric Behavior of Natural Fibers Reinforced Polymer Composites-An Overview. Mater. Sci. Eng. A 2012, 557, 17–28. [Google Scholar] [CrossRef]

- Kim, H.-S.; Yang, H.-S.; Kim, H.-J.; Park, H.-J. Thermogravimetric Analysis of Rice Husk Flour Filled Thermoplastic Polymer Composites. J. Therm. Anal. Calorim. 2004, 76, 395–404. [Google Scholar]

- Hassan, M.Z.; Sapuan, S.M.; Rasid, Z.A. Thermal Degradation and Mechanical Behavior of Banana Pseudo-Stem Reinforced Composites. Int. J. Recent Technol. Eng. (IJRTE) 2019, 8, 5899–5902. [Google Scholar] [CrossRef]

- Chandra Sekhar, V.; Pandurangadu, V.; Subba Rao, T.; Prof, A. TGA, DSC, DTG Properties of Epoxy Composites Reinforced with Feather Fibers of “Emu” Bird. Int. J. Innov. Res. Sci. Eng. Technol. 2007, 3297, 13017–13023. [Google Scholar]

- Braga, R.A.; Magalhaes, P.A.A. Analysis of the Mechanical and Thermal Properties of Jute and Glass Fiber as Reinforcement Epoxy Hybrid Composites. Mater. Sci. Eng. C 2015, 56, 269–273. [Google Scholar] [CrossRef] [PubMed]

- Gargol, M.; Klepka, T.; Klapiszewski, Ł.; Podkościelna, B. Synthesis and Thermo-Mechanical Study of Epoxy Resin-Based Composites with Waste Fibers of Hemp as an Eco-Friendly Filler. Polymers 2021, 13, 503. [Google Scholar] [CrossRef] [PubMed]

- Haris, N.I.N.; Ilyas, R.A.; Hassan, M.Z.; Sapuan, S.M.; Afdzaluddin, A.; Jamaludin, K.R.; Zaki, S.A.; Ramlie, F. Dynamic Mechanical Properties and Thermal Properties of Longitudinal Basalt/Woven Glass Fiber Reinforced Unsaturated Polyester Hybrid Composites. Polymers 2021, 13, 3343. [Google Scholar] [CrossRef]

- Sadashiva, K.; Mater; Sadashiva, J.; Prashanth, K.; Balaji, A.S.; Kishan, J.; Chaturvedi, P. V Dynamic Mechanical Analysis of Natural Fiber Reinforced Epoxy Hybrid Composites. J. Mater. Environ. Sci. 2023, 2023, 671–677. [Google Scholar]

- Manoharan, S.; Suresha, B.; Ramadoss, G.; Bharath, B. Effect of Short Fiber Reinforcement on Mechanical Properties of Hybrid Phenolic Composites. J. Mater. 2014, 2014, 478549. [Google Scholar] [CrossRef]

- Nurazzi, N.M.; Khalina, A.; Sapuan, S.M.; Ilyas, R.A.; Rafiqah, S.A.; Hanafee, Z.M. Thermal Properties of Treated Sugar Palm Yarn/Glass Fiber Reinforced Unsaturated Polyester Hybrid Composites. J. Mater. Res. Technol. 2020, 9, 1606–1618. [Google Scholar] [CrossRef]

- Mohanty, S.; Verma, S.K.; Nayak, S.K. Dynamic Mechanical and Thermal Properties of MAPE Treated Jute/HDPE Composites. Compos. Sci. Technol. 2006, 66, 538–547. [Google Scholar] [CrossRef]

- Bharathi, M.; Kumaran, S.S.; Samson, P.E. Effect of Silica Nanoparticles on Mechanical and Thermal Properties of Intra-Inter Ply Hybrid Laminated Composites. Mater. Res. Express 2021, 8, 045306. [Google Scholar] [CrossRef]

- Negawo, T.A.; Polat, Y.; Akgul, Y.; Kilic, A.; Jawaid, M. Mechanical and Dynamic Mechanical Thermal Properties of Ensete Fiber/Woven Glass Fiber Fabric Hybrid Composites. Compos. Struct. 2021, 259, 113221. [Google Scholar] [CrossRef]

- Joliff, Y.; Belec, L.; Chailan, J.F. Modified Water Diffusion Kinetics in an Unidirectional Glass/Fibre Composite Due to the Interphase Area: Experimental, Analytical and Numerical Approach. Compos. Struct. 2013, 97, 296–303. [Google Scholar] [CrossRef]

- Wong, E.H. Characterizing the Kinetics of Free and Bound Water Using a Non-Isothermal Sorption Technique. Dry. Technol. 2017, 35, 46–54. [Google Scholar] [CrossRef]

- Bratasyuk, N.A.; Latyshev, A.V.; Zuev, V.V. Water in Epoxy Coatings: Basic Principles of Interaction with Polymer Matrix and the Influence on Coating Life Cycle. Coatings 2024, 14, 54. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive Manufacturing of Natural Fiber Reinforced Polymer Composites: Processing and Prospects. Compos. B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Gu, H. Behaviours of Glass Fibre/Unsaturated Polyester Composites under Seawater Environment. Mater. Des. 2009, 30, 1337–1340. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Scalici, T.; Valenza, A. Experimental Assessment of the Improved Properties during Aging of Flax/Glass Hybrid Composite Laminates for Marine Applications. J. Appl. Polym. Sci. 2019, 136, 47203. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N. Effect of Water, Seawater and Alkaline Solution Ageing on Mechanical Properties of Flax Fabric/Epoxy Composites Used for Civil Engineering Applications. Constr. Build. Mater. 2015, 99, 118–127. [Google Scholar] [CrossRef]

- Bodur, M.S.; Englund, K.; Bakkal, M. Water Absorption Behavior and Kinetics of Glass Fiber/Waste Cotton Fabric Hybrid Composites. J. Appl. Polym. Sci. 2017, 134, 45506. [Google Scholar] [CrossRef]

- Verma, R.; Shukla, M.; Shukla, D.K. Effect of Glass Fibre Hybridization on the Water Absorption and Thickness of Alkali Treated Kenaf-Epoxy Composites. In Proceedings of the Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; Volume 44, pp. 2093–2096. [Google Scholar]

- Guo, R.; Li, C.; Xian, G. Water Absorption and Long-Term Thermal and Mechanical Properties of Carbon/Glass Hybrid Rod for Bridge Cable. Eng. Struct. 2023, 274, 115176. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Echtermeyer, A.T. Mechanism of Yellowing: Carbonyl Formation during Hygrothermal Aging in a Common Amine Epoxy. Polymers 2018, 10, 1017. [Google Scholar] [CrossRef]

| Specification | Layered Glass Fiber Waste | Hemp Fabric | Flax Fabric |

|---|---|---|---|

| Mass per unit area (g/m2) | 200 | 165 | 179 |

| Density of fiber (g/cm3) | 2.54 | 1.48 | 1.50 |

| Weaving type | Approximately oriented | Multidirectional | Multidirectional |

| Fabric Type | Direction | Breaking Load (N) | Elongation at Break (%) |

|---|---|---|---|

| Hemp | Warp | 804.2 ± 77.7 | 26.7 ± 1.2 |

| Hemp | Weft | 764.6 ± 66.4 | 23.7 ± 0.8 |

| Flax | Warp | 397.8 ± 42.3 | 23.3 ± 2.8 |

| Flax | Weft | 388.0 ± 47.1 | 23.8 ± 5.0 |

| Composite | Thickness (t) (mm) | Layer Configuration | Natural Fiber Volume (%) | Glass Fiber Volume (%) |

|---|---|---|---|---|

| F6 | 1.8 ± 0.07 | F + F + F + F + F + F | 47.9 | - |

| H6 | 1.9 ± 0.02 | H + H + H + H + H + H | 42.7 | - |

| G6 | 2.2 ± 0.10 | G + G + G +G + G + G | - | 39.1 |

| F4G2 | 2.3 ± 0.13 | F + F + G + G + F + F | 24.6 | 13.8 |

| H4G2 | 2.2 ± 0.11 | H + H + G + G + H + H | 23.7 | 14.4 |

| Sample | Thickness (mm) | Elongation at Break (%) | Young’s Modulus (GPa) | Toughness (N.mm) | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| 6F | 1.8 | 10.8 | 2.2 | 19,897.8 | 80.7 ± 3.6 |

| 6H | 1.9 | 7.9 | 2.4 | 15,125.8 | 76.6 ± 2.9 |

| 6G | 2.2 | 4.6 | 9.4 | 40,969.5 | 334.2 ± 28.9 |

| F4G2 | 2.3 | 4.8 | 3.5 | 21,967.0 | 149.8 ± 12.9 |

| H4G2 | 2.2 | 4.7 | 3.2 | 18,963.4 | 138.6 ± 17.4 |

| Fiber | Matrix | Tensile Strength (MPa) | Young’s Modulus (GPa) | Strengthening Performance | Ref. |

|---|---|---|---|---|---|

| Jute and Flax | Epoxy | 35.2–39.2 for jute FRP 55.9–123.0 for flax FRP | 1.42–2.03 for Jute FRP 1.34–5.76 for flax FRP | Cost-efficient strengthening and NFRP matched synthetic FRP performance, showing a strengthening effect close to CFRP. | [55] |

| Flax | Epoxy | 123.0–252.0 | 5.8–10.5 | Cost-effective and sustainable strengthening, NFRP provided comparable performance to synthetic FRP, demonstrating significant flexural stiffness improvement and enhanced load-bearing capacity. | [56] |

| Sisal | Epoxy and polyester | 80–104 | Sisal FRP (polyester 3 GPa) Sisal FRP (Epoxy 3.2 GPa) | Natural sisal fiber-reinforced polymer (NFRP) composites are effective in enhancing the flexural strength of reinforced concrete beams. | [57] |

| Kenaf | Epoxy | 44.5–119.6 | 11.7 | The structural behavior of beams reinforced with KFRP was found to be close to that of beams reinforced with CFRP. | [58] |

| Kenaf and Jute | Epoxy | 131 for kenaf FRP 136 for jute FRP | 13.2 for kenaf FRP 14.54 for jute FRP | NFRP-reinforced beams were found to increase shear loads by 34–36% and to perform similarly to CFRP by increasing their ductility. | [59] |

| Hemp | Epoxy | 156 | 6.4 | Hemp fiber-reinforced composites increased the shear strength and ductility of reinforced concrete deep beams. | [60] |

| Low-cost Glass | Epoxy | 377 MPa | 19 | Low-cost and efficient strengthening, Lo-G FRP provided significant shear capacity improvement, outperforming CFRP in energy dissipation and peak load enhancement. | [61] |

| Jute and Glass | Epoxy | 29.6 for jute FRP 124.5 for glass FRP | 2.8 for jute FRP 5.8 for glass FRP | GFRP increased the bearing capacity of the beams, JFRP increased the ductility, and hybrid GFRP-JFRP systems balanced both properties. | [62] |

| Low-cost Glass and Sisal | Epoxy | 377.6 for glass FRP 79.4 for sisal FRP | 18.7 for glass FRP 13.8 for sisal FRP | The natural sisal fiber and glass fiber-reinforced polymer (LC-GFRP) materials significantly enhanced the shear strength and ductility of reinforced concrete beams, reducing the risk of brittle failure and increasing the load-carrying capacity. | [63] |

| Glass and Aramid | Epoxy | 212–302 | 10.2–14.2 | Hybrid FRP (HFRP) laminates significantly increase the flexural strength of reinforced concrete beams reinforced with HFRP laminates, and additional thickness does not increase the strength much when the optimum thickness is exceeded. | [64] |

| Jute, Jute, and Glass and Glass | Epoxy | 17–24 for jute FRP 175 for glass FRP 59–86 for HFRP | 2.2–2.5 for jute FRP 13.6 for glass FRP 2.8–3.8 for HFRP | Effective shear strengthening, jute, and jute–glass hybrid FRP enhanced beam performance, providing significant strength gains, improved crack control, and increased deformation capacity. | [65] |

| Composites | Temperature at 5% Mass Loss (°C) | Maximum Decomposition Temperature (°C) | Ash Content (%) |

|---|---|---|---|

| 6F | 237.68 | 332.75 | 18.48 |

| 6H | 284.54 | 350.96 | 16.20 |

| 6G | 326.04 | 369.98 | 67.34 |

| F4G2 | 264.64 | 342.75 | 35.15 |

| H4G2 | 286.57 | 346.15 | 33.55 |

| Composites | E′ (MPa) at 40 °C | E″ (MPa) at 40 °C | E″ (MPa) | Tg (°C) | Tan δ | Tg (°C) |

|---|---|---|---|---|---|---|

| 6F | 2923.2 | 99.4 | 346.59 | 73.82 | 0.41 | 80.29 |

| 6H | 2979.3 | 92.4 | 326.97 | 75.04 | 0.43 | 80.76 |

| 6G | 9535.1 | 162.1 | 967.84 | 78.46 | 0.36 | 83.51 |

| F4G2 | 3932.5 | 98.3 | 492.09 | 75.77 | 0.37 | 81.29 |

| H4G2 | 4471.7 | 89.4 | 480.65 | 76.87 | 0.38 | 81.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karademir, C.; Tanarslan, H.M.; Yalçınkaya, Ç.; Güler, M.F.; Ateş, H.; Sever, K.; Seki, Y.; Atagür, M. Development of Sustainable Polymer Composites Containing Waste Glass and Natural Fibers for Strengthening Purposes. Polymers 2025, 17, 1116. https://doi.org/10.3390/polym17081116

Karademir C, Tanarslan HM, Yalçınkaya Ç, Güler MF, Ateş H, Sever K, Seki Y, Atagür M. Development of Sustainable Polymer Composites Containing Waste Glass and Natural Fibers for Strengthening Purposes. Polymers. 2025; 17(8):1116. https://doi.org/10.3390/polym17081116

Chicago/Turabian StyleKarademir, Cihan, Hasan Murat Tanarslan, Çağlar Yalçınkaya, Mustafa Furkan Güler, Hasan Ateş, Kutlay Sever, Yasemin Seki, and Metehan Atagür. 2025. "Development of Sustainable Polymer Composites Containing Waste Glass and Natural Fibers for Strengthening Purposes" Polymers 17, no. 8: 1116. https://doi.org/10.3390/polym17081116

APA StyleKarademir, C., Tanarslan, H. M., Yalçınkaya, Ç., Güler, M. F., Ateş, H., Sever, K., Seki, Y., & Atagür, M. (2025). Development of Sustainable Polymer Composites Containing Waste Glass and Natural Fibers for Strengthening Purposes. Polymers, 17(8), 1116. https://doi.org/10.3390/polym17081116