Technologies of Production of Materials Based on WPC: A Short Review

Abstract

1. Introduction

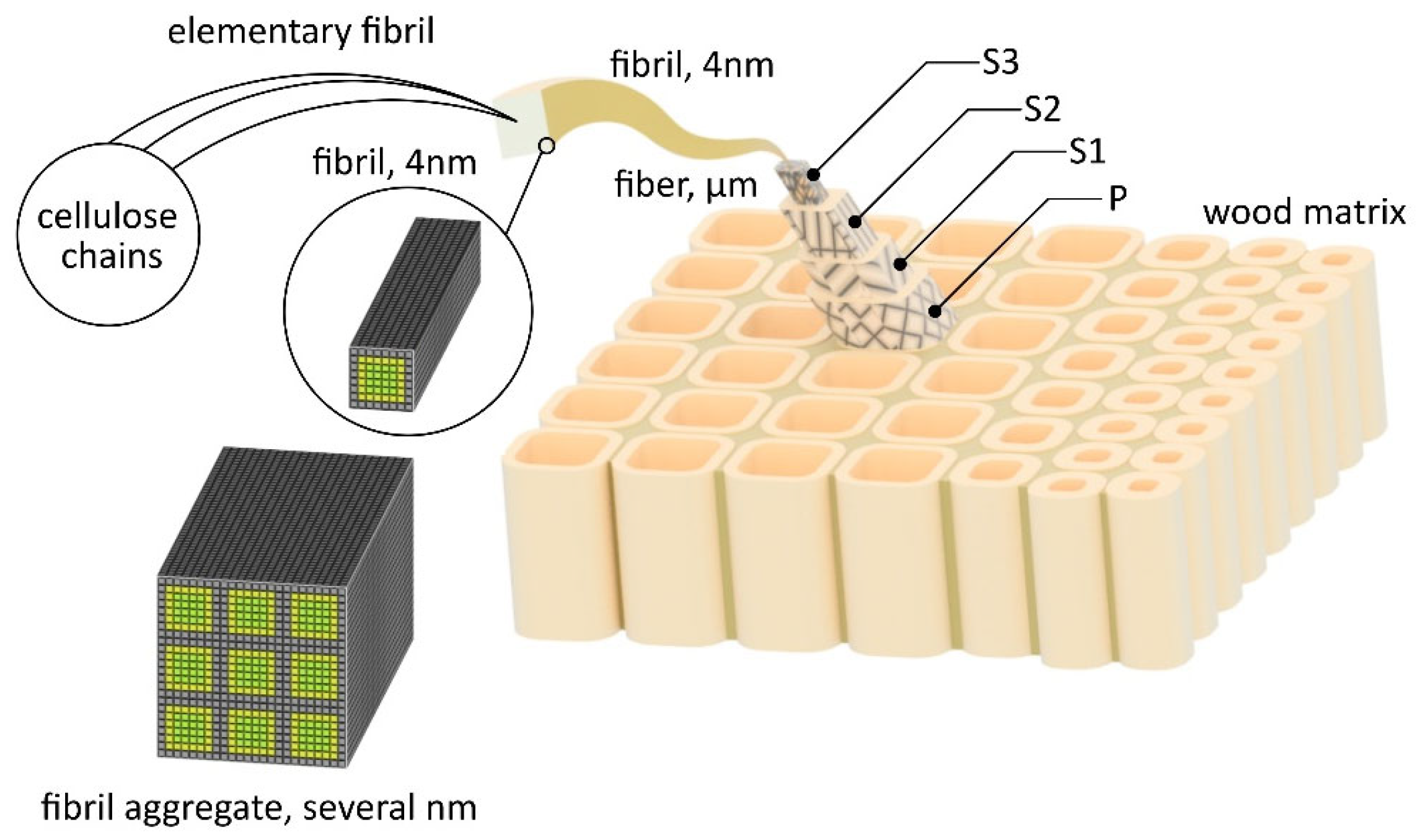

2. Components of WPC-Based Materials

- the type of polymer matrix applied;

- the percentage share of organic reinforcement—in addition to wood (it is possible to use plant fibers);

- morphology, physical properties, moisture content of the reinforcement particles themselves;

- quantity of individual additives;

- origin of input raw materials (location of natural fiber collection, type of tree, possibility of applying recycled material, etc.);

- technology and production conditions.

- 1906—first mention of the application of wood flour in a composite called Bakelite;

- 1983—production of materials for car interiors by Lear Corporation (Sheboygan, Wisconsin), a blend consisting of 50% PP + wood flour;

- early 1990s—Advanced Environmental Recycling Technologies (Texas) in cooperation with the division of Mobil Chemical Company (Virginia) produced WPC material with a high content of wood fibers;

- 1991—first conference on organic-filled plastics was held in Madison (Wisconsin);

- 1993—Andersen Corporation (Minnesota) started the production of wood-filled plastics with PVC matrix—applied to sub sills for French doors (the components contained 40% wooden reinforcement);

- 1996—the beginning of pellets production to produce WPC (a few U.S. companies).

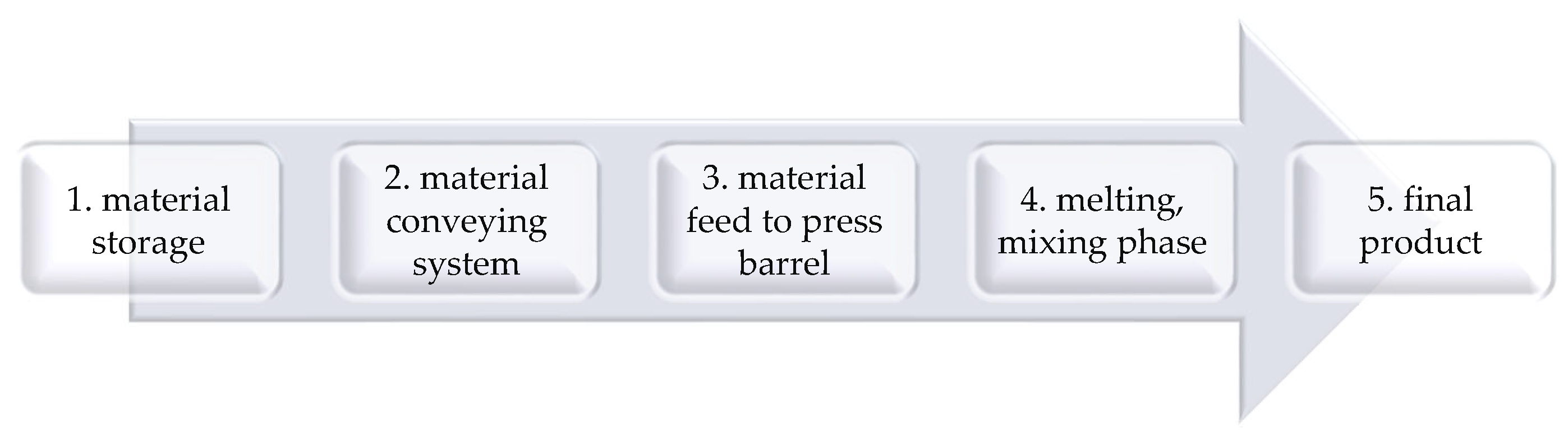

3. WPC Production Technology

- extrusion—for linear profiles, suitable technology for polymers with high molecular-weight, dominant technology in the production of WPC products in decking application and building industry;

- injection molding—for three-dimensional parts of regular and irregular shapes;

- compression molding—inexpensive production of complex parts, possibility to add special reinforcements in the production process, no need for skilled personnel;

- it is also possible to apply the little-mentioned rolling method—the so-called calendering—to the production of floorings.

- no pre-treating of the material by drying required (moisture is removed by a vacuum aeration mechanism) and mixing;

- ability to keep the melt temperature low with high head pressure;

- integrated process control system (feeding + extruder unit operations).

3.1. Injection Molding

3.2. Compression Molding

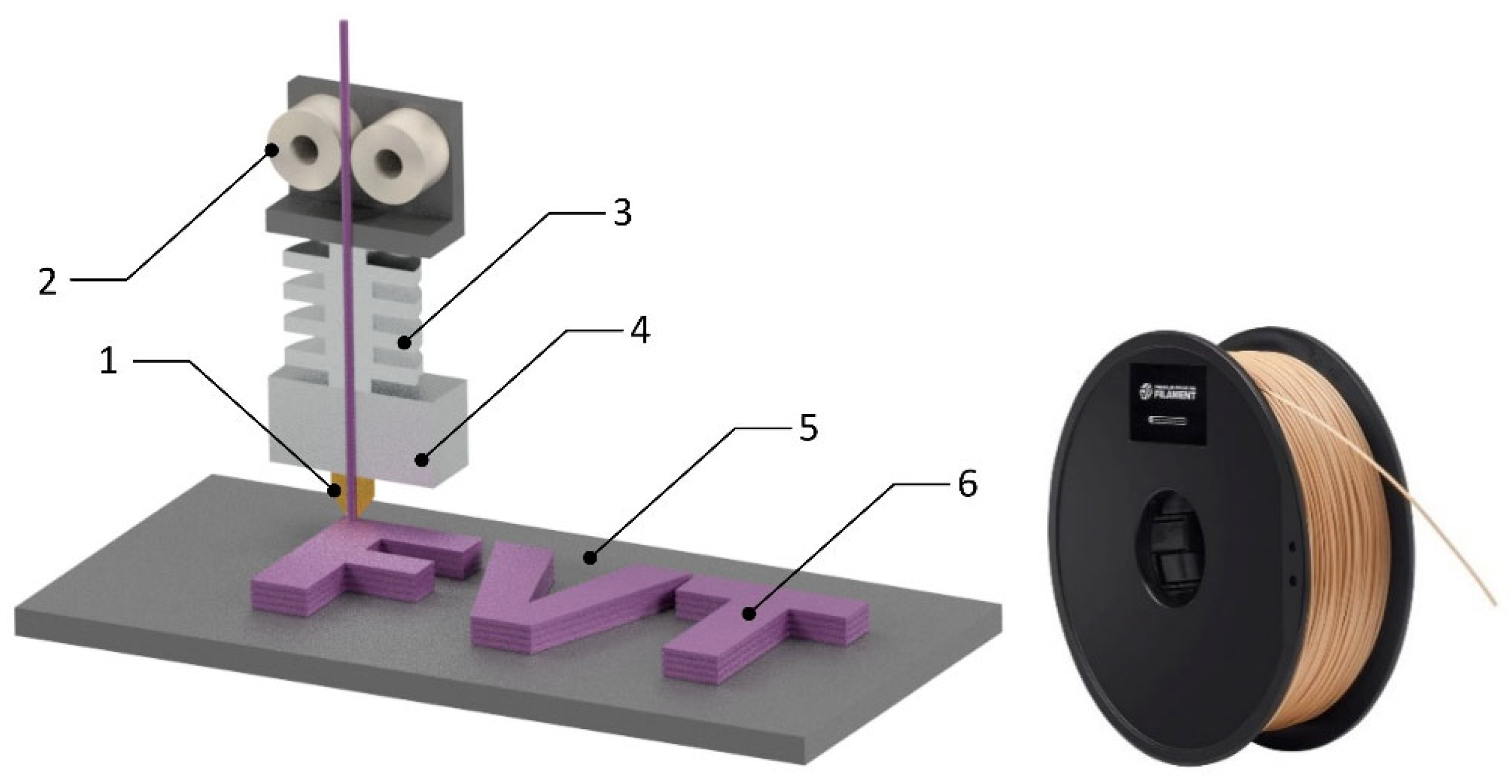

3.3. Fused Deposition Modeling

3.4. Applied Technologies for WPC-Based Materials with Thermosets Matrix

3.5. WPC Foams Production Technologies

3.6. Future Trends

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CBAs | Chemical Blowing Agents |

| CM | Composite Material |

| FDM | Fused Deposition Modeling |

| GFSMC | Glass Fiber Sheet Molding Compound |

| PBAs | Physical Blowing Agents |

| PE | Polyethylene |

| PHA | Polyhydroxyalkanoate |

| PHB | Polyhydroxybutyrate |

| PLA | Polylactide Acid |

| PMMA | Polymethylmethacrylate |

| PP | Polypropylene |

| PS | Polystyrene |

| PVC | Polyvinylchloride |

| RTM | Resin Transfer Molding |

| SMC | Sheet Molding Compound |

| WF | Wood Fiber |

| WPC | Wood Plastic Composite |

References

- Dai, A.; Fan, M. Wood fibres as reinforcements in natural fibre composites: Structure, properties, processing and applications. In Natural Fibre Composites, 1st ed.; Hodzic, A., Shanks, R., Eds.; Woodhead Publishing: Oxford, UK, 2014; pp. 3–65. [Google Scholar]

- Matuana, L.M.; Stark, N.M. The use of wood fibers as reinforcements in composites. In Biofiber Reinforcement in Composite Materials, 1st ed.; Faruk, O., Sain, M., Eds.; Woodhead Publishing: Cambridge, UK, 2015; pp. 648–688. [Google Scholar]

- Carus, M.; Gahle, C.; Korte, H. Market and future trends for wood–polymer composites in Europe: The example of Germany. In Wood–Polymer Composites; Woodhead Publishing: Cambridge, UK, 2008; pp. 300–330. [Google Scholar]

- Bledzki, A.K.; Faruk, O.; Huque, M. Physico-mechanical studies of wood fiber reinforced composites. Polym.-Plast. Technol. Eng. 2002, 41, 435–451. [Google Scholar] [CrossRef]

- Nicolais, L.; Borzacchiello, A.; Lee, S.M. (Eds.) Wiley Encyclopedia of Composites; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Mitaľová, Z.; Mitaľ, D.; Berladir, K. A Concise Review of the Components and Properties of Wood–Plastic Composites. Polymers 2024, 16, 1556. [Google Scholar] [CrossRef] [PubMed]

- Zhou, J.; Wang, B.; Xu, C.; Xu, Y.; Tan, H.; Zhang, X.; Zhang, Y. Performance of composite materials by wood fiber/polydopamine/silver modified PLA and the antibacterial property. J. Mater. Res. Technol. 2022, 18, 428–438. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A review of natural fiber composites: Properties, modification and processing techniques, characterization, applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Mitaľová, Z. Hodnotenie Topografie Povrchu Drevom Plnených Plastov po Obrábaní Konvenčnými/Nekonvenčnými Technológiami Obrábania. Habilitation Thesis, Technical University of Košice, Košice, Slovakia, 2023. [Google Scholar]

- Dobransky, J.; Behalek, L.; Baron, P.; Kocisko, M.; Dulebova, L.; Dobos, Z. The influence of the use of technological waste on the mechanical behavior of fibrous polymer composite. Compos. Part B Eng. 2019, 166, 162–168. [Google Scholar] [CrossRef]

- Islam, M.R. Profile Extrusion of Wood Plastic Cellular Composites and Formulation Evaluation Using Compression Molding. Master’s Thesis, University of Ontario Institute of Technology, Oshawa, ON, Canada, 2010. [Google Scholar]

- Clemons, C.M. Woodfiber-plastic composites in the United States–History and current and future markets. In Proceedings of the 3rd International Wood and Natural Fiber Composites Symposium, Kassel, Germany, 19–20 September 2020. [Google Scholar]

- Joost, W.J. Reducing vehicle weight and improving US energy efficiency using integrated computational materials engineering. JOM 2012, 64, 1032–1038. [Google Scholar] [CrossRef]

- Khatri, H.; Naveen, J.; Jawaid, M.; Jayakrishna, K.; Norrrahim, M.N.F.; Reshedi, A. Potential of natural fiber based polymeric composites for cleaner automotive component production-a comprehensive review. J. Mater. Res. Technol. 2023, 25, 1086–1104. [Google Scholar]

- Toghyani, A. Effect of Temperature on the Shaping Process of an Extruded Wood-Plastic Composite (WPC) Profile in a Novel Post-Production Process. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2017. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Niska, K.O.; Sain, M. (Eds.) Wood-Polymer Composites; Woodhead Publishing: Cambridge, UK, 2008. [Google Scholar]

- Hodzic, A.; Shanks, R. (Eds.) Natural Fibre Composites: Materials, Processes, and Properties; Woodhead Publishing: Cambridge, UK, 2014. [Google Scholar]

- Tabari, H.Z.; Nourbakhsh, A.; Ashori, A. Effect of nanoclay and coupling agent on the physico-mechanical, morphological, and thermal properties of wood flour/polypropylene composites. Polym. Eng. Sci. 2011, 51, 272–277. [Google Scholar] [CrossRef]

- Park, B.D.; Balatinecz, J.J. A comparison of compounding process for wood-fiber/thermoplastic composites. Polym. Compos. 1997, 18, 425–431. [Google Scholar] [CrossRef]

- Wolcott, M.P.; Englund, K. A Technology Review of Wood-Plastic Composites. In Proceedings of the 33rd International Particleboard/Composite Materials Symposium, Washington State University, Washington, DC, USA, 13–15 April 1999. [Google Scholar]

- Liukko, T.; Salila, T.; Platt, S.; Kärki, T. Wood plastic composites in Europe: An introduction to wood plastic composite markets and products. Balt. For. 2007, 13, 131–136. [Google Scholar]

- Elsheikh, A.H.; Panchal, H.; Shanmugan, S.; Muthuramalingam, T.; El-Kassas, A.M.; Ramesh, B. Recent progresses in wood-plastic composites: Pre-processing treatments, manufacturing techniques, recyclability and eco-friendly assessment. Clean. Eng. Technol. 2022, 8, 100450. [Google Scholar] [CrossRef]

- Gardner, D.J.; Han, Y.; Wang, L. Wood-plastic composite technology. Curr. For. Rep. 2015, 1, 139–150. [Google Scholar] [CrossRef]

- Gallos, A.; Paës, G.; Allais, F.; Beaugrand, J. Lignocellulosic fibers: A critical review of the extrusion process for enhancement of the properties of natural fiber composites. RSC Adv. 2017, 7, 34638–34654. [Google Scholar] [CrossRef]

- Hutyrová, Z.; Litecká, J.; Harničárová, M. Technológia Zmeny Tvaru, 1st ed.; FVT TU: Prešov, Slovakia, 2014; p. 77. [Google Scholar]

- Segerholm, K. Wood Plastic Composites Made from Modified Wood: Aspects on Moisture Sorption, Micromorphology and Durability. Licentiate Thesis, KTH-Stockholm, Stockholm, Sweden, 2007. [Google Scholar]

- Bledzki, A.K.; Faruk, O. Injection moulded microcellular wood fibre–polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1358–1367. [Google Scholar] [CrossRef]

- Special Injection Molding Processes. Available online: https://www.arburg.com/en/solutions/by-technology/special-injection-moulding-processes/ (accessed on 17 January 2025).

- Benthien, J.T.; Thoemen, H. Effects of agglomeration and pressing process on the properties of flat pressed WPC panels. J. Appl. Polym. Sci. 2013, 129, 3710–3717. [Google Scholar] [CrossRef]

- Inamuddin; Altalhi, T. (Eds.) Handbook of Bioplastics and Biocomposites Engineering Applications; Scrivener Publishing: Beverly, CA, USA, 2023. [Google Scholar]

- Feldmann, M.; Heim, H.P.; Zarges, J.C. Influence of the process parameters on the mechanical properties of engineering biocomposites using a twin-screw extruder. Compos. Part A Appl. Sci. Manuf. 2016, 83, 113–119. [Google Scholar] [CrossRef]

- Yallew, T.B.; Kassegn, E.; Aregawi, S.; Gebresias, A. Study on effect of process parameters on tensile properties of compression molded natural fiber reinforced polymer composites. SN Appl. Sci. 2020, 2, 338. [Google Scholar] [CrossRef]

- Ovlaque, B.; Bayart, M.; Cousin, P.; Durand, J.; Mercusot, G.; Elkoun, S.; Robert, M. Mechanical & Interfacial Properties of Bamboo Lamella-PP Composites—Effect of Lamella Treatment. Fibers Polym. 2020, 21, 1086–1095. [Google Scholar]

- Prajwal, B.; Giridharan, B.V.; Vamshi, K.K.; Muzamil, H.R.; Mohan, C.B. Sisal fiber reinforced polypropylene bio-composites for inherent applications. Int. J. Recent Technol. Eng. 2019, 8, 305–309. [Google Scholar]

- Mir, S.S.; Nafsin, N.; Hasan, M.; Hasan, N.; Hassan, A. Improvement of physico-mechanical properties of coir-polypropylene biocomposites by fiber chemical treatment. Mater. Des. 2013, 52, 251–257. [Google Scholar] [CrossRef]

- Takemura, K.; Minekage, Y. Effect of molding condition on tensile properties of hemp fiber reinforced composite. Adv. Compos. Mater. 2007, 16, 385–394. [Google Scholar] [CrossRef]

- Koroľ, M.; Török, J.; Goryl, K.; Vodilka, A. Research of Selected TPMS Structures Made of ABS and Nylon 12 CF Material Using the FDM. In Proceedings of the International Scientific-Technical Conference MANUFACTURING, Poznan, Poland, 14–16 May 2024. [Google Scholar]

- Hui, Z.; Yuan, Z.H.; Long, Z.Y.; Wang, Q. Research of Wood Plastic Composites application based on Fused Deposition Modeling technology. In Proceedings of the 2011 International Conference on Electronic & Mechanical Engineering and Information Technology, Harbin, China, 12–14 August 2011. [Google Scholar]

- Gregor-Svetec, D.; Leskovšek, M.; Brodnjak, U.V.; Elesini, U.S.; Muck, D.; Urbas, R. Characteristics of HDPE/cardboard dust 3D printable composite filaments. J. Mater. Process. Technol. 2020, 276, 116379. [Google Scholar] [CrossRef]

- Parikh, H.H.; Chokshi, S.; Chaudhary, V.; Khan, A.; Mistry, J. Flexural response of 3D printed wood dust reinforced polymer composite. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Wood Filament for 3D Printer. Available online: https://3dpblock.com/product/wood-filament/ (accessed on 15 January 2025).

- Poomathi, N.; Singh, S.; Prakash, C.; Subramanian, A.; Sahay, R.; Cinappan, A.; Ramakrishna, S. 3D printing in tissue engineering: State of the art review of technologies and biomaterials. Rapid Prototyp. J. 2020, 26, 131–1334. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, H.; Li, Z.; Li, P.; Shi, S.Q. Development and application of wood flour-filled polylactic acid composite filament for 3D printing. Materials 2017, 10, 339. [Google Scholar] [CrossRef]

- Deb, D.; Jafferson, J.M. Natural fibers reinforced FDM 3D printing filaments. In Proceedings of the 28th International Conference on Processing and Fabrication of Advanced Materials, Chennai, India, 7–9 December 2020. [Google Scholar]

- Bhayana, M.; Singh, J.; Sharma, A.; Gupta, M. A review on optimized FDM 3D printed Wood/PLA bio composite material characteristics. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Qian, F.; Jia, R.; Cheng, M.; Chaudhary, A.; Melhi, S.; Mekkey, S.D.; Zhu, N.; Wang, C.; Razak, F.; Xu, X.; et al. An overview of polylactic acid (PLA) nanocomposites for sensors. Adv. Compos. Hybrid Mater. 2024, 7, 75. [Google Scholar] [CrossRef]

- Mitaľová, Z.; Mitaľ, D.; Simkulet, V. Application of Composite Materials Natural Fibers in Automotive Industry—Short Review. In Proceedings of the EAI International Conference on Automation and Control in Theory and Practice, Vysoké Tatry, Slovakia, 8–10 February 2023. [Google Scholar]

- Gartner, B.; Yadama, V.; Smith, L. Resin transfer molding of wood strand composite panels. Forests 2022, 13, 278. [Google Scholar] [CrossRef]

- Kim, J.K.; Pal, K. Recent Advances in Processing of Wood-Plastic Composites; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Lim, S.T.; Lee, W.I. An analysis of the three-dimensional resin-transfer mold filling process. Compos. Sci. Technol. 2000, 60, 961–975. [Google Scholar] [CrossRef]

- Elseify, L.A.; Midani, M.; El-Badawy, A.; Jawaid, M. (Eds.) Manufacturing Automotive Components from Sustainable Natural Fiber Composites; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Orgéas, L.; Dumont, P.J. Sheet molding compounds. In Wiley Encyclopedia of Composites; Nicolais, L., Borzacchiello, A., Lee, S.M., Eds.; Wiley: Hoboken, NJ, USA, 2012; pp. 238–2718. [Google Scholar]

- Voorn, B.; Smit, H.H.G.; Sinke, R.J.; Klerk, B. Natural fibre reinforced sheet moulding compound. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1271–1279. [Google Scholar] [CrossRef]

- Ren, G.; Patel, H.; Hapuarachchi, D.; Crowther, S. Development of natural HEMP fibre sheet mould composites (NF-SMC). In Proceedings of the 17th International Conference on Composite Materials, Edinburgh, UK, 27–31 July 2009. [Google Scholar]

- Yoon, J.D.; Kuboki, T.; Jung, P.U.; Wang, J.; Park, C.B. Injection molding of wood–fiber/plastic composite foams. Compos. Interfaces 2009, 16, 797–811. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

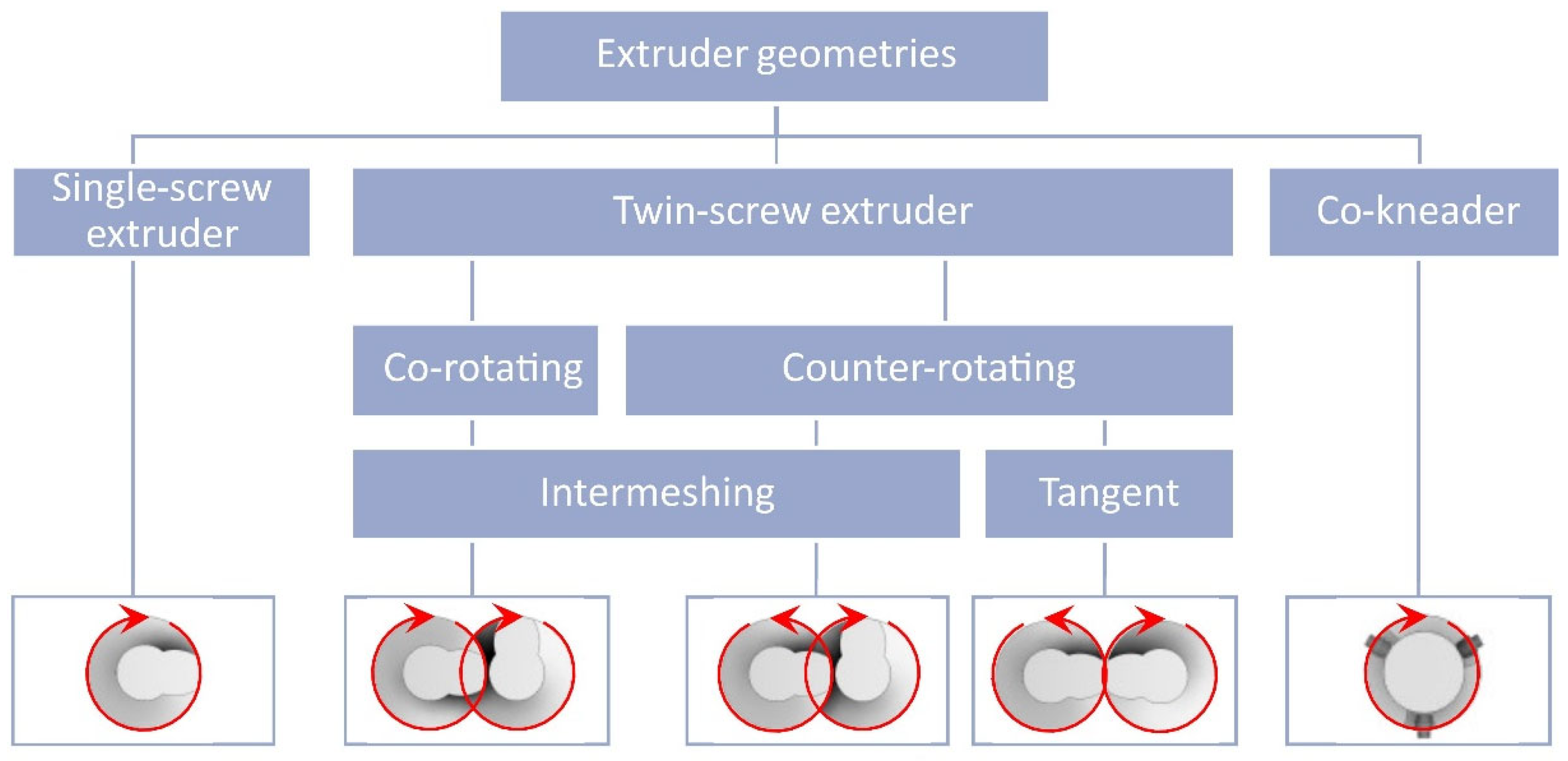

| Single-Screw Extruder (Screw Speed Range: 60–250 rpm) | ||

|---|---|---|

| Designed by German machine manufacturer Paul Troestar in 1935, primarily for thermoplastics. The design of the extruder is relatively simple, suitable for both extrusion and injection molding. Barrel length to diameter ratio: . The materials are fed into the extruder via a gravity hopper (feeders are not required). To remove unwanted volatile substances, the extruder is equipped with a vent unit. | ||

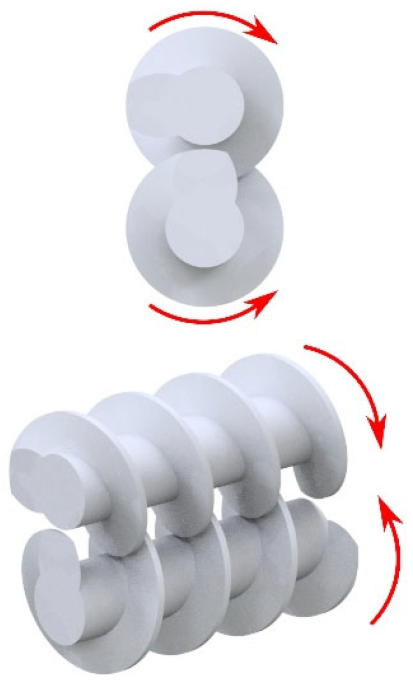

| Pros | Cons | Dynamic Principle |

| Low investment costs, proven production technology. | Necessity of a pre-treatment phase: drying, granules preparation—premixed blend—(application of thermokinetic mixers), low production rate, high screw speed, inability to maintain low melt temperature with higher head pressure. |  |

| Twin-Screw Extruder with Co-Rotating Screws (Screw Speed Range: 100–1200 rpm) | ||

| Werner & Pfleiderer (nowadays Coperion) delivered the first co-rotating, closely intermeshing ZSK twin-screw extruder in 1957. The ZSK designation is derived from the German name Zwein Schnecken Kneter and has long been synonymous with this type of extruder. The materials are fed into the extruder using double-screw side feeders or gravimetric feeders. To remove moisture from the process, the extruder is equipped with atmospheric vacuum vents. | ||

| Pros | Cons | Dynamic Principle |

| No material pre-treatment required (fibers with a moisture content of 6% ± 1 can be applied), variable drives. | High speed of screw rotation, no screw cooling, inability to maintain low melt temperature with higher head pressure. |  |

| Twin-Screw Extruder with Counter-Rotating Screws (Screw Speed Range: 25–80 rpm) | ||

| Especially for WPC products with PVC matrices that need degassing during extrusion process. Their screw configuration is either parallel or conical. | ||

| Pros | Cons | Dynamic Principle |

| Low screw revolution per minute (rpm) → reduces the risk of burning the materials, low induced shear produced by mixing process, proven production technology. | Requires a blend-drying system, mixing the blend, higher purchase price (compared to a single-screw press), and operating costs. |  |

| Type of Fiber/ Volume of Fiber (wt%) | Pressure | Temperature (°C) | Study/References |

|---|---|---|---|

| Hemp/jute/sisal | 0.5/1.0/1.5 | 165/175/185 | Yallew, et al. (2020) [33] |

| The optimal parameters for achieving the desired properties → pressure 1 MPa/temperature 175 °C. | |||

| Bamboo | 0 ton (5 min), 4 tons (1 min), 5 tons (1 min) | 200 | Ovlaque, et al. (2020) [34] |

| The optimal parameters for achieving the desired properties → not specified. | |||

| Sisal/50, 60, 70, 80 | 13.8 MPa | – | Prajwal, et al. (2019) [35] |

| Coir/0, 10, 15, 20 | 30 KN | 170 | Mir, et al. (2013) [36] |

| Hemp | 0.8 MPa | 160–190 | Takemura and Minekage (2012) [37] |

| The optimal parameters for achieving the desired properties → temperature below 180 °C. | |||

| RTM Injection | Study/References |

|---|---|

| Forming of composite parts carried out using a closed mold. The low-pressure pump injects resin and hardener into the mold. Subsequently, the blend is injected into the reinforcement pre-form. The resulting part is cured at room temperature (or above till the end of the curing reaction). The method is applied to the production of car interior parts with relatively high strength, rigidity, and dimensional stability. Wood chips with a high ratio of are used for reinforcement, similarly to OSB boards. This high aspect ratio causes efficient transfer of shear forces from the matrix to the fiber. The advantage in the application of natural fibers (compared to synthetic ones) is their ability to act as an “absorber” of the resin to → absorb fluids as it flows (consequence—natural fiber preforms require additional injection time). The advantages of the RTM technology are a short production time (compared to hand lay-up technology), low clamping pressure, no need for skilled personnel, excellent surface finish, the possibility of producing complex geometries. Disadvantages: high-cost process of production and limited to manufacturing of small-dimensional parts. A critical aspect of the RTM process is mold filling, especially for parts with greater thickness. Models simulating resin flow in the mold can prevent defects such as voids or poor wetting of the fibers, similarly to the application of resins with low viscosity values (to ensure proper fiber wetting—e.g., epoxy, phenolic, polyester/acrylic). The company Bcomp provides specially spun fibers PowerRibs™/ampliTex™ in prepreg form, applicable for the production of automotive parts (as well) via RTM technology. These are a replacement for monolithic carbon fiber car parts, offering the same stiffness but reduced weight. Additionally, the newly created prepreg (made from natural fibers and resin) is formable and produces no toxic waste. | Mitaľová, et al. (2023) [48] Gartner, et al. (2022) [49] Kim and Pal (2010) [50] Lim and Lee (1999) [51] |

| SMC | Elseifi, et al. (2021) [52] Orgéas and Dumont (2012) [53] Voorn, et al. (2001) [54] Ren, et al. (2009) [55] |

| Method of pressing a composite blend with short fibers saturated with a thermoset matrix. The process consists of two steps: prepreg production and compression (pressing). Natural-based fibers are good substitution candidates to glass fibers for SMC. Several studies support the claim regarding the mechanical properties of natural-fiber-reinforced SMC material. The study by Voorn, et al.—application of flax fiber SMC materials—as a replacement for glass fibers—achieved approximately 20% lower weight, with relatively the same stiffness, but lower impact property values (caused by the anisotropic nature of natural fibers). Similarly, the study by Ren, et al. showed tensile strength values (44 MPa) and Young’s modulus of elasticity (14 GPa), similar to GFSMC composites. The SMC technology is frequently applied in the automotive industry for the production of bumpers, trunk covers, and spoilers. | |

| Pressing | Hodzic and Shanks (2014) [18] |

| Processing of the semi-finished product by the application of pressure and temperature: measured amount of pressed mass is fed into the heated mold and then, under the action of the aforementioned factors, it turns into a liquid state, fills the mold, and hardens. Mechanical properties of the WPC molding are influenced by the mold cavity design and the process parameters—blend temperature, mold heating and cooling, mold closing speed, etc. (technology also suitable for thermoplastics). |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitaľová, Z.; Litecká, J.; Kočiško, M.; Berladir, K. Technologies of Production of Materials Based on WPC: A Short Review. Polymers 2025, 17, 1025. https://doi.org/10.3390/polym17081025

Mitaľová Z, Litecká J, Kočiško M, Berladir K. Technologies of Production of Materials Based on WPC: A Short Review. Polymers. 2025; 17(8):1025. https://doi.org/10.3390/polym17081025

Chicago/Turabian StyleMitaľová, Zuzana, Juliána Litecká, Marek Kočiško, and Khrystyna Berladir. 2025. "Technologies of Production of Materials Based on WPC: A Short Review" Polymers 17, no. 8: 1025. https://doi.org/10.3390/polym17081025

APA StyleMitaľová, Z., Litecká, J., Kočiško, M., & Berladir, K. (2025). Technologies of Production of Materials Based on WPC: A Short Review. Polymers, 17(8), 1025. https://doi.org/10.3390/polym17081025