Predictive Modeling of Shear Strength of Enzyme-Induced Calcium Carbonate Precipitation (EICP)-Solidified Rubber–Clay Mixtures Using Machine Learning Algorithms

Abstract

1. Introduction

2. Materials and Methods

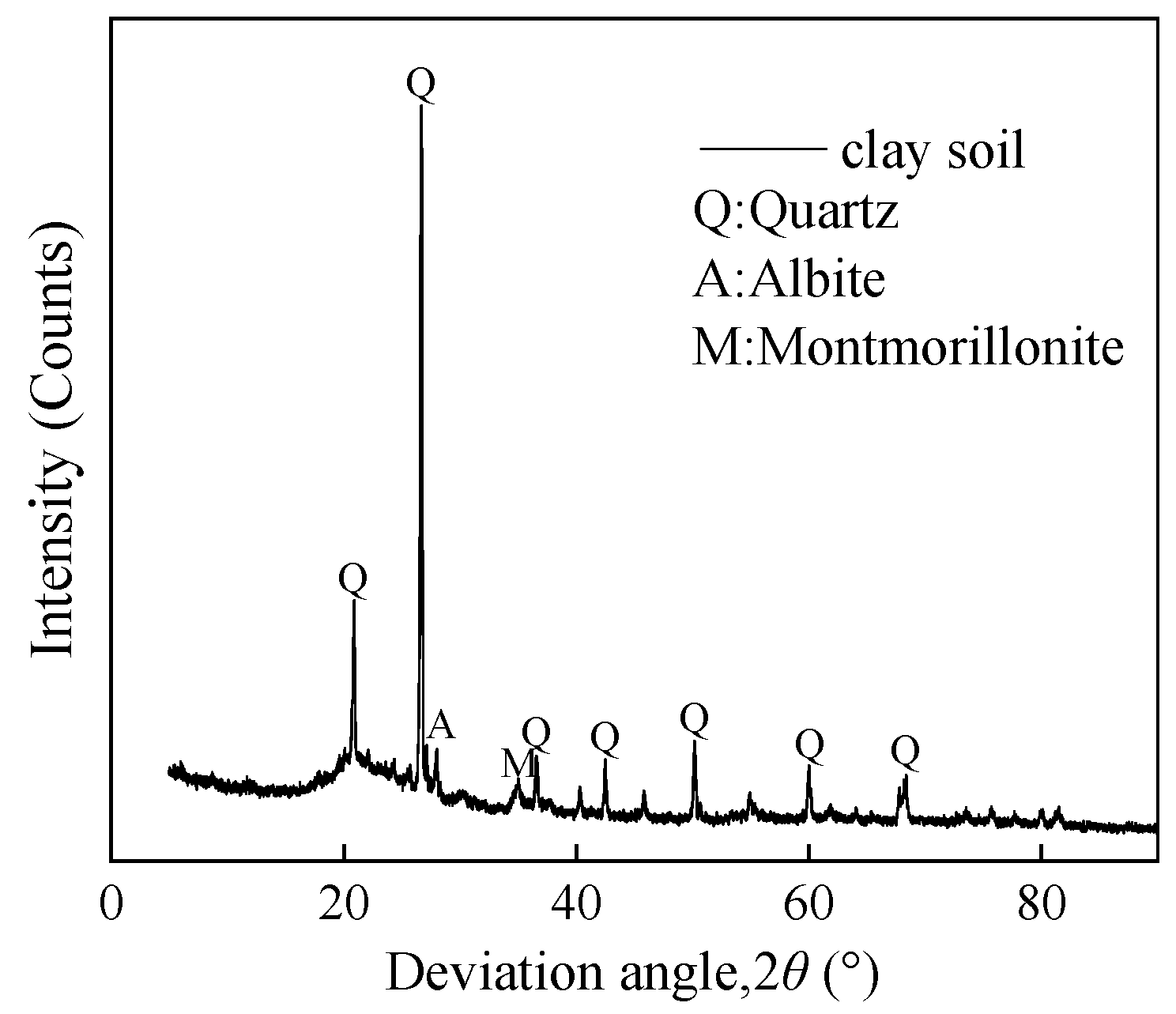

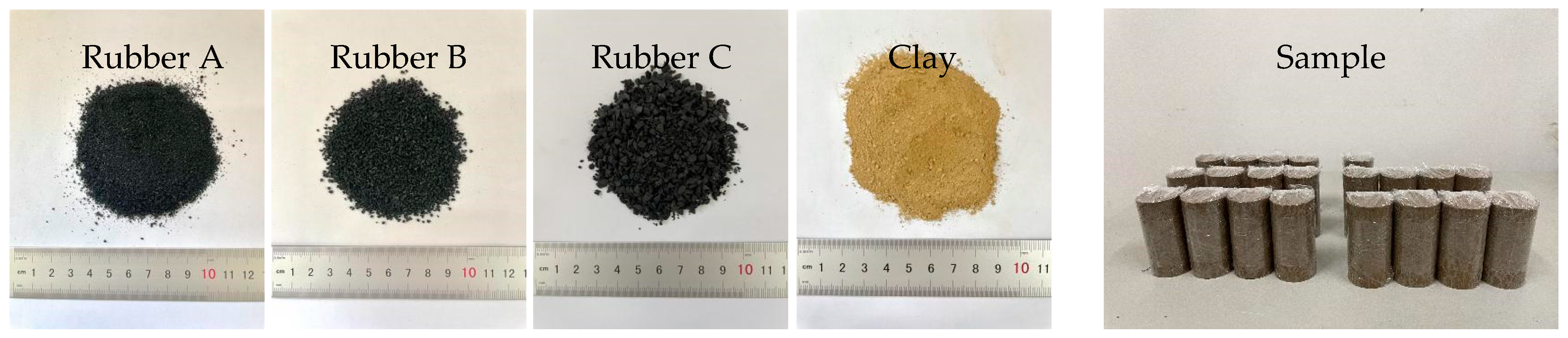

2.1. Test Material

2.2. Specimen Preparation

2.3. Triaxial Compressive Test

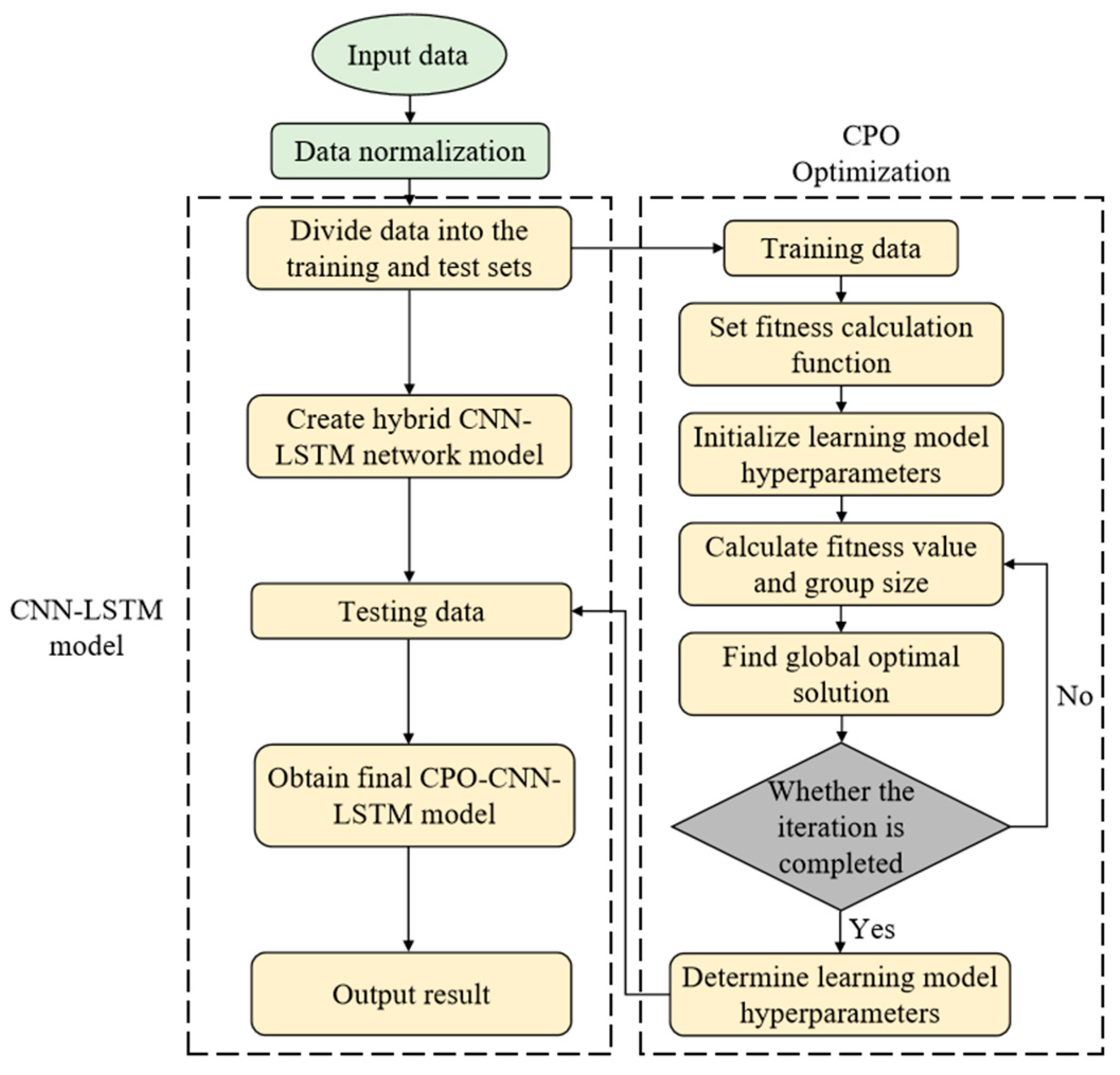

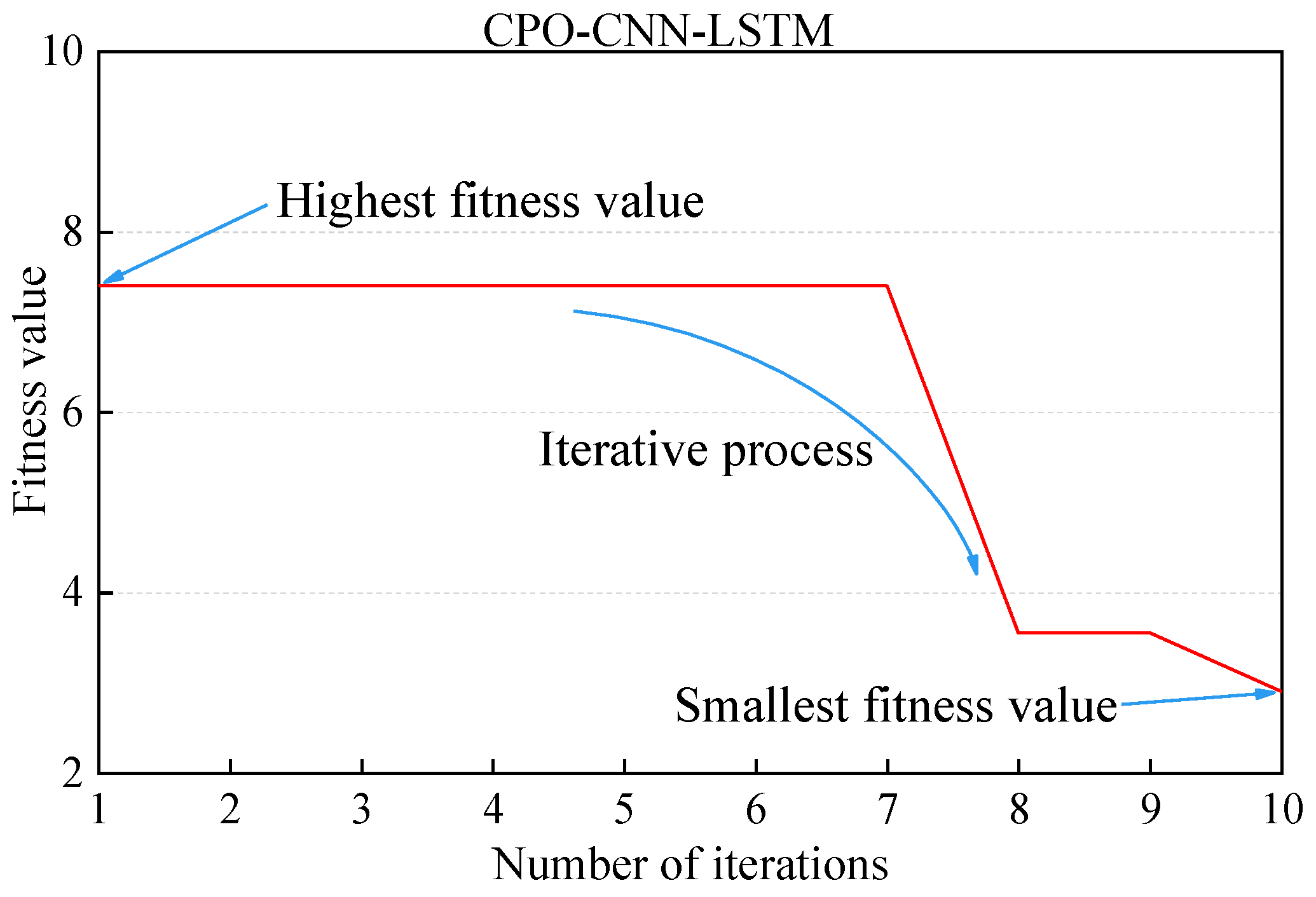

2.4. Crested Porcupine Optimizer (CPO)

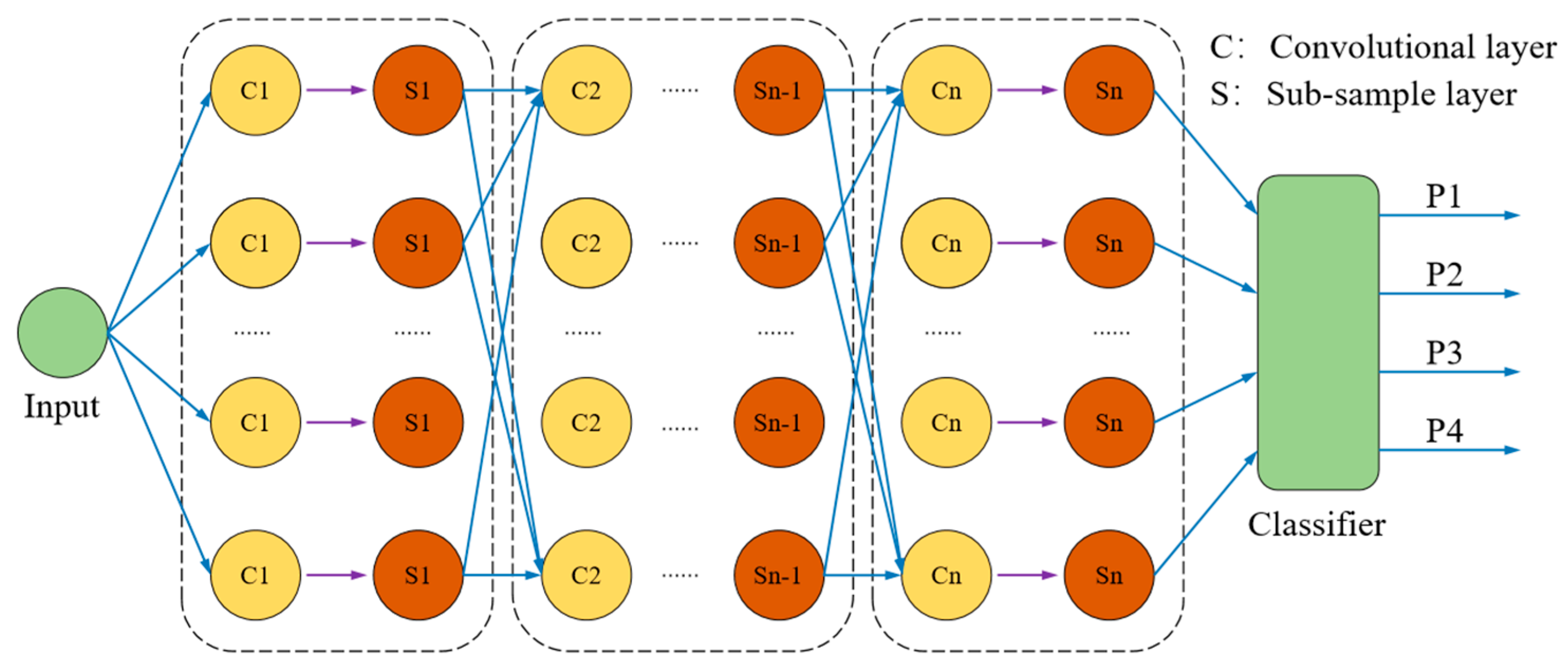

2.5. Convolutional Neural Network (CNN)

2.6. Long Short-Term Memory (LSTM) Network

2.7. CPO-Optimized CNN-LSTM Models

2.8. CPO-CNN-LSTM Model Training

3. Results and Discussion

3.1. Shear Strength

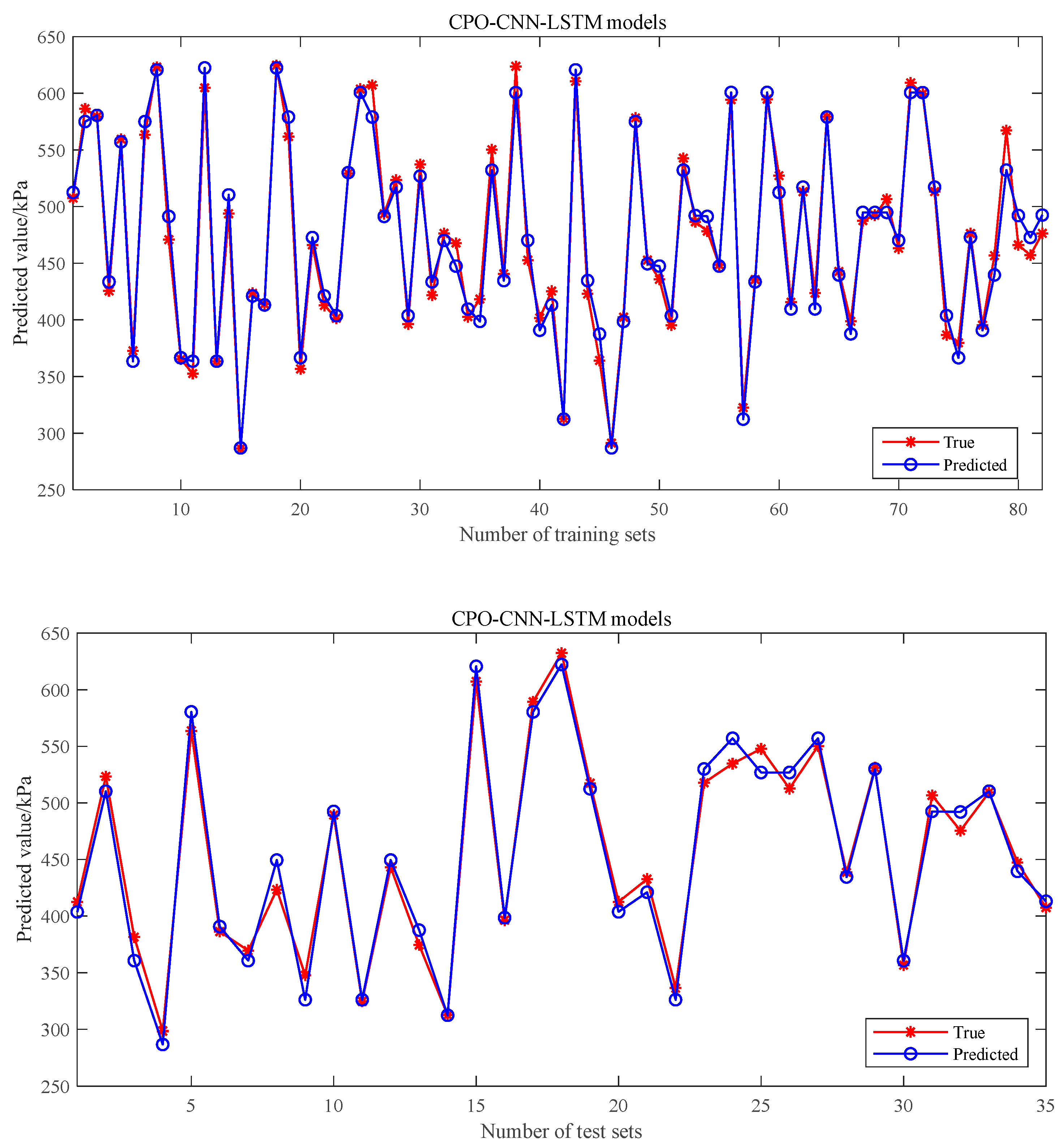

3.2. CPO-CNN-LSTM Model Prediction Results

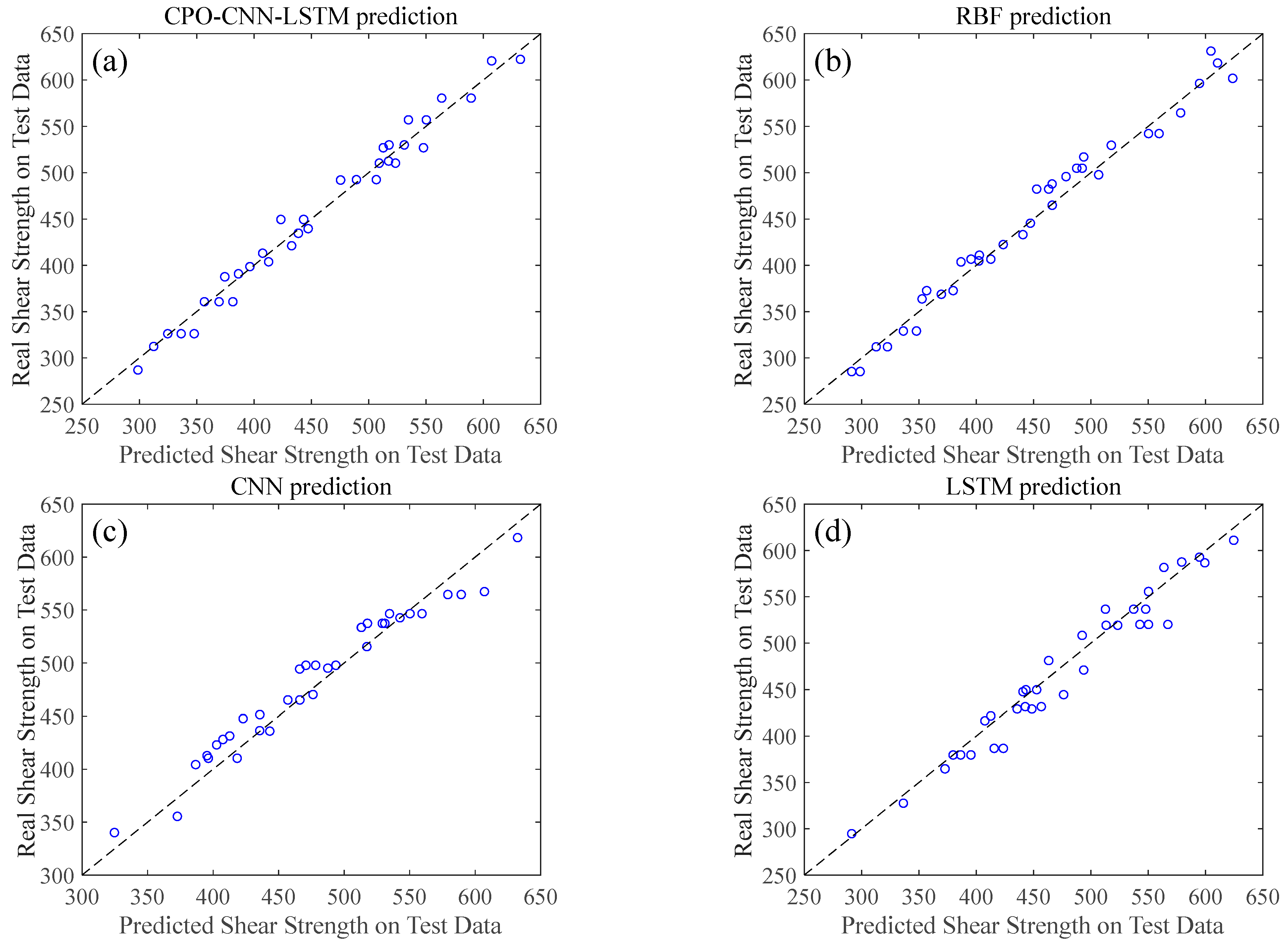

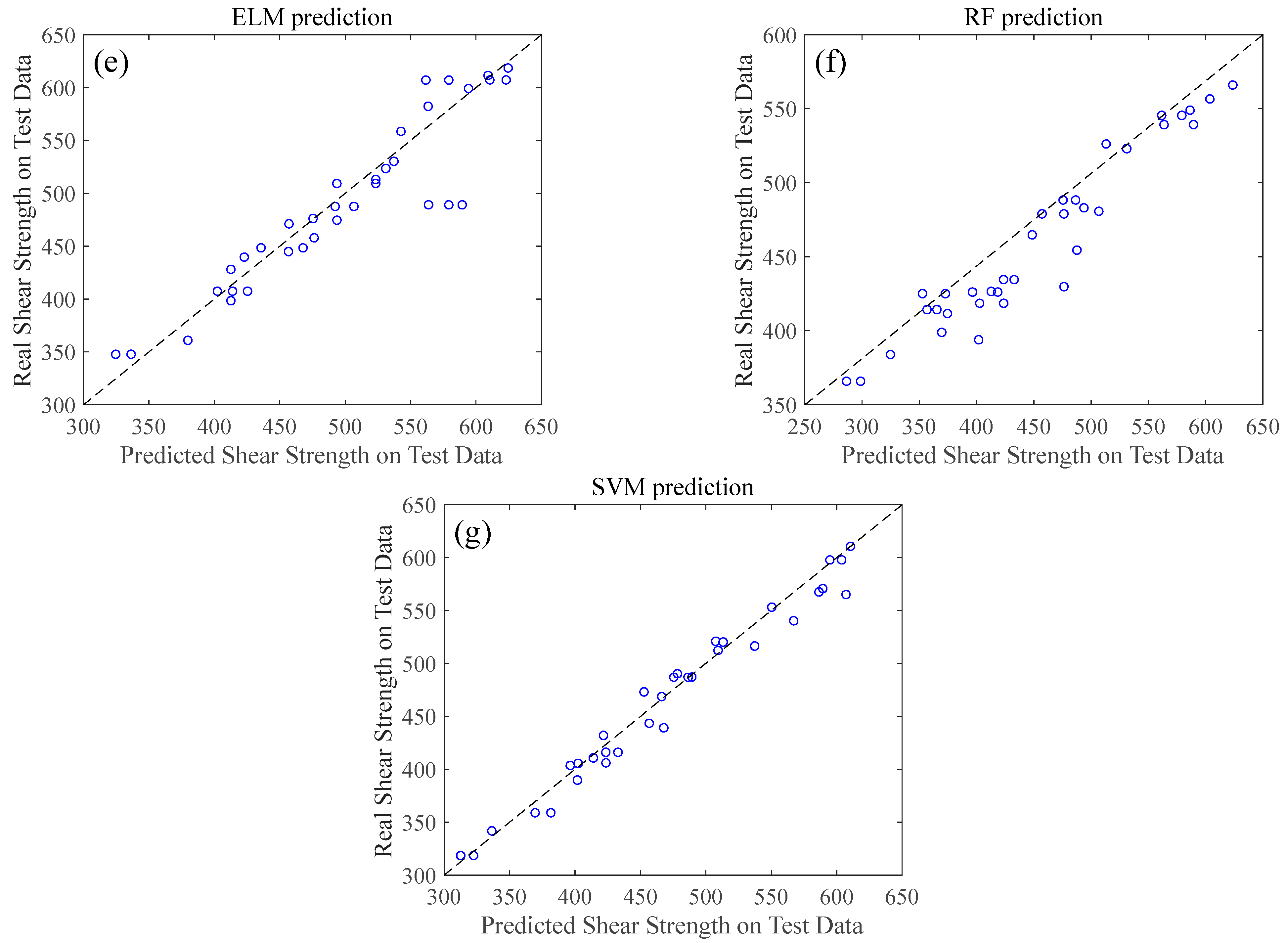

3.3. Comparative Discussions

4. Conclusions

- (1)

- The addition of rubber particles significantly improves the shear strength of EICP-treated clays, with optimal enhancement observed at a 5% rubber particle content for all sizes. Moreover, smaller rubber particles exhibited superior improvement in shear strength for any given content.

- (2)

- In this study, a CPO-CNN-LSTM model was constructed by integrating CNN and LSTM algorithms and optimizing them using the CPO algorithm. The R2 values for the training and test datasets reached 0.98 and 0.97, respectively. Comparative analysis revealed that the CPO-CNN-LSTM model outperformed other commonly used models in predicting the shear strength of EICP-solidified rubber–clay mixtures.

- (3)

- We recognize that there may be some limitations in the experimental process, such as the relatively limited amount of data and the control of experimental conditions. In addition, certain assumptions and simplifications of the model may have some impact on the accuracy of the results. Based on the results and shortcomings of this study, we plan to carry out the following work in the future: first, to further expand the experimental dataset size to improve the reliability and generalization ability of the model; second, to explore more types of input variables and model structures to further improve prediction accuracy; and third, to apply the methodology of this study to other related fields to verify its generalizability and effectiveness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, N.; Tang, C.; Hata, T.; Courcelles, B.; Dawoud, O.; Singh, D.N. Bio-mediated Soil Improvement: The Way Forward. Soil Use Manag. 2020, 36, 185–188. [Google Scholar] [CrossRef]

- Zhang, J.; Su, P.; Wen, K.; Li, Y.; Li, L. Environmental Impact and Mechanical Improvement of Microbially Induced Calcium Carbonate Precipitation-Treated Coal Fly Ash–Soil Mixture. Environ. Geotech. 2024, 11, 29–39. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, N.; Cai, G.; Jin, Y.; Ding, N.; Shen, D. Review of Ground Improvement Using Microbial Induced Carbonate Precipitation (MICP). Mar. Georesources Geotechnol. 2017, 35, 1135–1146. [Google Scholar] [CrossRef]

- Meng, H.; Shu, S.; Gao, Y.; Yan, B.; He, J. Multiple-Phase Enzyme-Induced Carbonate Precipitation (EICP) Method for Soil Improvement. Eng. Geol. 2021, 294, 106374. [Google Scholar] [CrossRef]

- Almajed, A.; Khodadadi Tirkolaei, H.; Kavazanjian, E. Baseline Investigation on Enzyme-Induced Calcium Carbonate Precipitation. J. Geotech. Geoenviron. Eng. 2018, 144, 04018081. [Google Scholar] [CrossRef]

- Neupane, D.; Yasuhara, H.; Kinoshita, N.; Ando, Y. Distribution of Mineralized Carbonate and Its Quantification Method in Enzyme Mediated Calcite Precipitation Technique. Soils Found. 2015, 55, 447–457. [Google Scholar] [CrossRef]

- Oliveira, P.J.V.; Freitas, L.D.; Carmona, J.P.S.F. Effect of Soil Type on the Enzymatic Calcium Carbonate Precipitation Process Used for Soil Improvement. J. Mater. Civ. Eng. 2017, 29, 04016263. [Google Scholar] [CrossRef]

- Yuan, H.; Liu, K.; Zhang, C.; Zhao, Z. Mechanical Properties of Na-Montmorillonite-Modified EICP-Treated Silty Sand. Environ. Sci. Pollut. Res. 2022, 29, 10332–10344. [Google Scholar] [CrossRef]

- Krishnan, V.; Khodadadi Tirkolaei, H.; Martin, K.; Hamdan, N.; Van Paassen, L.A.; Kavazanjian, E. Variability in the Unconfined Compressive Strength of EICP-Treated “Standard” Sand. J. Geotech. Geoenviron. Eng. 2021, 147, 06021001. [Google Scholar] [CrossRef]

- Hamdan, N.; Kavazanjian, E. Enzyme-Induced Carbonate Mineral Precipitation for Fugitive Dust Control. Géotechnique 2016, 66, 546–555. [Google Scholar] [CrossRef]

- Almajed, A.; Abbas, H.; Arab, M.; Alsabhan, A.; Hamid, W.; Al-Salloum, Y. Enzyme-Induced Carbonate Precipitation (EICP)-Based Methods for Ecofriendly Stabilization of Different Types of Natural Sands. J. Clean. Prod. 2020, 274, 122627. [Google Scholar] [CrossRef]

- Hosseinpour, I.; Almeida, M.S.S.; Riccio, M.; Baroni, M. Strength and Compressibility Characteristics of a Soft Clay Subjected to Ground Treatment. Geotech. Geol. Eng. 2017, 35, 1051–1066. [Google Scholar] [CrossRef]

- Rezaei, M.; Ajalloeian, R.; Ghafoori, M. Geotechnical Properties of Problematic Soils Emphasis on Collapsible Cases. Int. J. Geosci. 2012, 3, 105–110. [Google Scholar] [CrossRef]

- Yilmaz, I.; Civelekoglu, B. Gypsum: An Additive for Stabilization of Swelling Clay Soils. Appl. Clay Sci. 2009, 44, 166–172. [Google Scholar] [CrossRef]

- Tang, A.-M.; Cui, Y.-J.; Trinh, V.-N.; Szerman, Y.; Marchadier, G. Analysis of the Railway Heave Induced by Soil Swelling at a Site in Southern France. Eng. Geol. 2009, 106, 68–77. [Google Scholar] [CrossRef]

- Tajdini, M.; Nabizadeh, A.; Taherkhani, H.; Zartaj, H. Effect of Added Waste Rubber on the Properties and Failure Mode of Kaolinite Clay. Int. J. Civ. Eng. 2017, 15, 949–958. [Google Scholar] [CrossRef]

- Cetin, H.; Fener, M.; Gunaydin, O. Geotechnical Properties of Tire-Cohesive Clayey Soil Mixtures as a Fill Material. Eng. Geol. 2006, 88, 110–120. [Google Scholar] [CrossRef]

- Soltani, A.; Deng, A.; Taheri, A.; Mirzababaei, M. Rubber Powder–Polymer Combined Stabilization of South Australian Expansive Soils. Geosynth. Int. 2018, 25, 304–321. [Google Scholar] [CrossRef]

- Bosscher, P.J.; Edil, T.B.; Kuraoka, S. Design of Highway Embankments Using Tire Chips. J. Geotech. Geoenviron. Eng. 1997, 123, 295–304. [Google Scholar] [CrossRef]

- Tsang, H.; Lo, S.H.; Xu, X.; Neaz Sheikh, M. Seismic Isolation for Low-to-medium-rise Buildings Using Granulated Rubber–Soil Mixtures: Numerical Study. Earthq. Engng. Struct. Dyn. 2012, 41, 2009–2024. [Google Scholar] [CrossRef]

- Wang, F.-C.; Li, J.; Lin, Z.-H.; Tian, P.-P.; Zhao, H.-Y. Research on Hoop Capacity of Composite Foundation of Discarded Rubber Tires. Eur. J. Environ. Civ. Eng. 2022, 26, 779–801. [Google Scholar] [CrossRef]

- Neaz Sheikh, M.; Mashiri, M.S.; Vinod, J.S.; Tsang, H.-H. Shear and Compressibility Behavior of Sand–Tire Crumb Mixtures. J. Mater. Civ. Eng. 2013, 25, 1366–1374. [Google Scholar] [CrossRef]

- Angelin, A.F.; Andrade, M.F.F.; Bonatti, R.; Cecche Lintz, R.C.; Gachet-Barbosa, L.A.; Osório, W.R. Effects of Spheroid and Fiber-like Waste-Tire Rubbers on Interrelation of Strength-to-Porosity in Rubberized Cement and Mortars. Constr. Build. Mater. 2015, 95, 525–536. [Google Scholar] [CrossRef]

- Pattanawanidchai, S.; Sae-Oui, P.; Na-Lumpang, T.; Loykulnant, S.; Kuankhamnuan, T. Reduction in Soil Compaction by Utilization of Waste Tire Rubber. Sustainability 2023, 15, 12174. [Google Scholar] [CrossRef]

- Hajiazizi, M.; Mirnaghizadeh, M.H.; Nasiri, M. Experimental Study of Sand Slopes Reinforced by Waste Tires. Int. J. Min. Geo-Eng. 2019, 53, 183–191. [Google Scholar]

- Saberian, M.; Li, J.; Thach Nguyen, B.; Setunge, S. Estimating the Resilient Modulus of Crushed Recycled Pavement Materials Containing Crumb Rubber Using the Clegg Impact Value. Resour. Conserv. Recycl. 2019, 141, 301–307. [Google Scholar] [CrossRef]

- Hoppe, E.J. Field Study of Shredded-Tire Embankment. Transp. Res. Rec. J. Transp. Res. Board 1998, 1619, 47–54. [Google Scholar] [CrossRef]

- Saberian, M.; Mehrinejad Khotbehsara, M.; Jahandari, S.; Vali, R.; Li, J. Experimental and Phenomenological Study of the Effects of Adding Shredded Tire Chips on Geotechnical Properties of Peat. Int. J. Geotech. Eng. 2018, 12, 347–356. [Google Scholar] [CrossRef]

- Cui, M.-J.; Zheng, J.-J.; Dahal, B.K.; Lai, H.-J.; Huang, Z.-F.; Wu, C.-C. Effect of Waste Rubber Particles on the Shear Behaviour of Bio-Cemented Calcareous Sand. Acta Geotech. 2021, 16, 1429–1439. [Google Scholar] [CrossRef]

- Chen, Y.; Chai, S.; Cai, D.; Wang, W.; Li, X.; Liu, J. Experimental Study on Shear Mechanical Properties of Improved Loess Based on Rubber Particle Incorporation and EICP Technology. Front. Earth Sci. 2023, 11, 1270102. [Google Scholar] [CrossRef]

- Dao, D.V.; Jaafari, A.; Bayat, M.; Mafi-Gholami, D.; Qi, C.; Moayedi, H.; Phong, T.V.; Ly, H.-B.; Le, T.-T.; Trinh, P.T.; et al. A Spatially Explicit Deep Learning Neural Network Model for the Prediction of Landslide Susceptibility. CATENA 2020, 188, 104451. [Google Scholar] [CrossRef]

- Rashidi Shikhteymour, S.; Borji, M.; Bagheri-Gavkosh, M.; Azimi, E.; Collins, T.W. A Novel Approach for Assessing Flood Risk with Machine Learning and Multi-Criteria Decision-Making Methods. Appl. Geogr. 2023, 158, 103035. [Google Scholar] [CrossRef]

- Khoshdel Sangdeh, M.; Salimi, M.; Hakimi Khansar, H.; Dokaneh, M.; Zanganeh Ranjbar, P.; Payan, M.; Arabani, M. Predicting the Precipitated Calcium Carbonate and Unconfined Compressive Strength of Bio-Mediated Sands through Robust Hybrid Optimization Algorithms. Transp. Geotech. 2024, 46, 101235. [Google Scholar] [CrossRef]

- Ngo, H.T.T.; Pham, T.A.; Vu, H.L.T.; Giap, L.V. Application of Artificial Intelligence to Determined Unconfined Compressive Strength of Cement-Stabilized Soil in Vietnam. Appl. Sci. 2021, 11, 1949. [Google Scholar] [CrossRef]

- Niyogi, A.; Ansari, T.A.; Sathapathy, S.K.; Sarkar, K.; Singh, T.N. Machine Learning Algorithm for the Shear Strength Prediction of Basalt-Driven Lateritic Soil. Earth Sci. Inform. 2023, 16, 899–917. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, Z.; Liu, F.; Yang, Y.; Wan, Y.; Huo, W.; Yang, L. Efficient Machine Learning Method for Evaluating Compressive Strength of Cement Stabilized Soft Soil. Constr. Build. Mater. 2023, 392, 131887. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Abegaz, K.A. Prediction of Compaction and Strength Properties of Amended Soil Using Machine Learning. Buildings 2022, 12, 613. [Google Scholar] [CrossRef]

- Ahmad, M.; Al-Mansob, R.A.; Ramli, A.B.B.; Ahmad, F.; Khan, B.J. Unconfined Compressive Strength Prediction of Stabilized Expansive Clay Soil Using Machine Learning Techniques. Multiscale and Multidiscip. Model. Exp. Des. 2024, 7, 217–231. [Google Scholar] [CrossRef]

- Talamkhani, S. Machine Learning-Based Prediction of Unconfined Compressive Strength of Sands Treated by Microbially-Induced Calcite Precipitation (MICP): A Gradient Boosting Approach and Correlation Analysis. Adv. Civ. Eng. 2023, 2023, 3692090. [Google Scholar] [CrossRef]

- Wang, H.-L.; Yin, Z.-Y. Unconfined Compressive Strength of Bio-Cemented Sand: State-of-the-Art Review and MEP-MC-Based Model Development. J. Clean. Prod. 2021, 315, 128205. [Google Scholar] [CrossRef]

- Ikeagwuani, C.C.; Akanno, C.C. Taguchi Regression Analysis and Constrained Particle Swarm Optimization for Amended Unconfined Compressive Strength (UCS) of Expansive Subgrade Soil. Arab. J. Geosci. 2023, 16, 390. [Google Scholar] [CrossRef]

- Xi, B.; He, J.; Li, H. Integration of Machine Learning Models and Metaheuristic Algorithms for Predicting Compressive Strength of Waste Granite Powder Concrete. Mater. Today Commun. 2023, 35, 106403. [Google Scholar] [CrossRef]

- Shamshirband, S.; Tavakkoli, A.; Roy, C.B.; Motamedi, S.; Ki-Il, S.; Hashim, R.; Islam, S.M. Hybrid Intelligent Model for Approximating Unconfined Compressive Strength of Cement-Based Bricks with Odd-Valued Array of Peat Content (0–29%). Powder Technol. 2015, 284, 560–570. [Google Scholar] [CrossRef]

- Almajed, A.; Tirkolaei, H.K.; Kavazanjian, E.; Hamdan, N. Enzyme Induced Biocementated Sand with High Strength at Low Carbonate Content. Sci. Rep. 2019, 9, 1135. [Google Scholar] [CrossRef]

- Cardoso, R.; Pires, I.; Duarte, S.O.D.; Monteiro, G.A. Effects of Clay’s Chemical Interactions on Biocementation. Appl. Clay Sci. 2018, 156, 96–103. [Google Scholar] [CrossRef]

- Whiffin, V.S.; Van Paassen, L.A.; Harkes, M.P. Microbial Carbonate Precipitation as a Soil Improvement Technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Montoya, B.M.; DeJong, J.T. Stress-Strain Behavior of Sands Cemented by Microbially Induced Calcite Precipitation. J. Geotech. Geoenviron. Eng. 2015, 141, 04015019. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Mohamed, R.; Abouhawwash, M. Crested Porcupine Optimizer: A New Nature-Inspired Metaheuristic. Knowl. Based Syst. 2024, 284, 111257. [Google Scholar] [CrossRef]

- Lu, C.; Wang, Z.; Zhou, B. Intelligent Fault Diagnosis of Rolling Bearing Using Hierarchical Convolutional Network Based Health State Classification. Adv. Eng. Inform. 2017, 32, 139–151. [Google Scholar] [CrossRef]

- Qiu, K.; Li, J.; Chen, D. Optimized Long Short-Term Memory (LSTM) Network for Performance Prediction in Unconventional Reservoirs. Energy Rep. 2022, 8, 15436–15445. [Google Scholar] [CrossRef]

- Kim, H.-K.; Santamarina, J.C. Sand–Rubber Mixtures (Large Rubber Chips). Can. Geotech. J. 2008, 45, 1457–1466. [Google Scholar] [CrossRef]

- Gao, M.; Jin, X.; Zhao, T.; Li, H.; Zhou, L. Study on the Strength Mechanism of Red Clay Improved by Waste Tire Rubber Powder. Case Stud. Constr. Mater. 2022, 17, e01416. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K. A Study on the Potential Utilization of Crumb Rubber in Cement Treated Soft Clay. J. Build. Eng. 2017, 9, 177–191. [Google Scholar] [CrossRef]

- Zhao, Y.; Meng, F.; Fan, P.; Li, H.; Niu, Y.; Liu, P. Surface Improvement of Scrap Rubber by Microbially Induced Carbonate Precipitation and Its Effect on Mechanical Behavior of Rubberised Mortar. Constr. Build. Mater. 2022, 323, 126526. [Google Scholar] [CrossRef]

- Cui, M.-J.; Zheng, J.-J.; Zhang, R.-J.; Lai, H.-J.; Zhang, J. Influence of Cementation Level on the Strength Behaviour of Bio-Cemented Sand. Acta Geotech. 2017, 12, 971–986. [Google Scholar] [CrossRef]

- An, R.; Gao, H.; Zhang, X.; Chen, X.; Wang, Y.; Xu, H. Mechanical Behaviour and Microstructure of Granite Residual Bio-Cemented Soil by Microbially Induced Calcite Precipitation with Different Cementation–Solution Concentrations. Environ. Earth Sci. 2024, 83, 31. [Google Scholar] [CrossRef]

- Tajabadipour, M.; Marandi, M. Effect of Rubber Tire Chips-Sand Mixtures on Performance of Geosynthetic Reinforced Earth Walls. Period. Polytech. Civ. Eng. 2016, 61, 322. [Google Scholar] [CrossRef]

| Liquid Limit (%) | Plastic Limit (%) | Plasticity Index (%) | Specific Gravity |

|---|---|---|---|

| 42.80 | 24.06 | 18.74 | 2.69 |

| Component | SiO2 | Al2O3 | CaO | Fe2O3 | MgO | K2O | TiO2 | Na2O | P2O5 | SrO | Rb2O |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mass (%) | 52.96 | 18.75 | 11.80 | 7.36 | 3.86 | 3.42 | 0.79 | 0.40 | 0.21 | 0.05 | 0.01 |

| Property | Rubber A | Rubber B | Rubber C |

|---|---|---|---|

| Density (g/cm3) | 1.09 | 1.11 | 1.13 |

| Elastic modulus (MPa) | 11.97 | 16.72 | 22.96 |

| Softening temperature (°C) | 175 | 175 | 175 |

| R2 | CPO-CNN-LSTM | RBF | CNN | LSTM | ELM | RF | SVM |

|---|---|---|---|---|---|---|---|

| Training | 0.98 | 0.97 | 0.96 | 0.96 | 0.95 | 0.92 | 0.97 |

| Testing | 0.97 | 0.96 | 0.94 | 0.94 | 0.85 | 0.82 | 0.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Q.; Li, M.; Shu, H.; Xi, L. Predictive Modeling of Shear Strength of Enzyme-Induced Calcium Carbonate Precipitation (EICP)-Solidified Rubber–Clay Mixtures Using Machine Learning Algorithms. Polymers 2025, 17, 976. https://doi.org/10.3390/polym17070976

Ma Q, Li M, Shu H, Xi L. Predictive Modeling of Shear Strength of Enzyme-Induced Calcium Carbonate Precipitation (EICP)-Solidified Rubber–Clay Mixtures Using Machine Learning Algorithms. Polymers. 2025; 17(7):976. https://doi.org/10.3390/polym17070976

Chicago/Turabian StyleMa, Qiang, Meng Li, Hang Shu, and Lei Xi. 2025. "Predictive Modeling of Shear Strength of Enzyme-Induced Calcium Carbonate Precipitation (EICP)-Solidified Rubber–Clay Mixtures Using Machine Learning Algorithms" Polymers 17, no. 7: 976. https://doi.org/10.3390/polym17070976

APA StyleMa, Q., Li, M., Shu, H., & Xi, L. (2025). Predictive Modeling of Shear Strength of Enzyme-Induced Calcium Carbonate Precipitation (EICP)-Solidified Rubber–Clay Mixtures Using Machine Learning Algorithms. Polymers, 17(7), 976. https://doi.org/10.3390/polym17070976