Development of Plasma-Treated Corn-Starch-Based Film Incorporated with Acerola and Grape Pomace Extract Possessing pH-Sensing Capability

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Extraction of Anthocyanins and Carotenoids

2.3. Plasma Processing of Starch Granules

2.4. Production of Intelligent Starch-Based Films

2.5. Physical and Chemical Characterizations

2.5.1. Amylose Content

2.5.2. Solubility and Moisture

2.5.3. Hydrophobicity

2.5.4. Chemical Groups and Molecular Structure

2.5.5. Surface Morphology

2.5.6. Water Vapor Permeability (WVP)

2.6. Color Change Capacity of Films as a Function of pH

2.7. Statistical Analysis

3. Results

3.1. Amylose Content

3.2. Chemical Group Profile

3.3. Solubility and Moisture Content

3.4. Hydrophobicity

3.5. Surface Morphology

3.6. Water Vapor Permeability

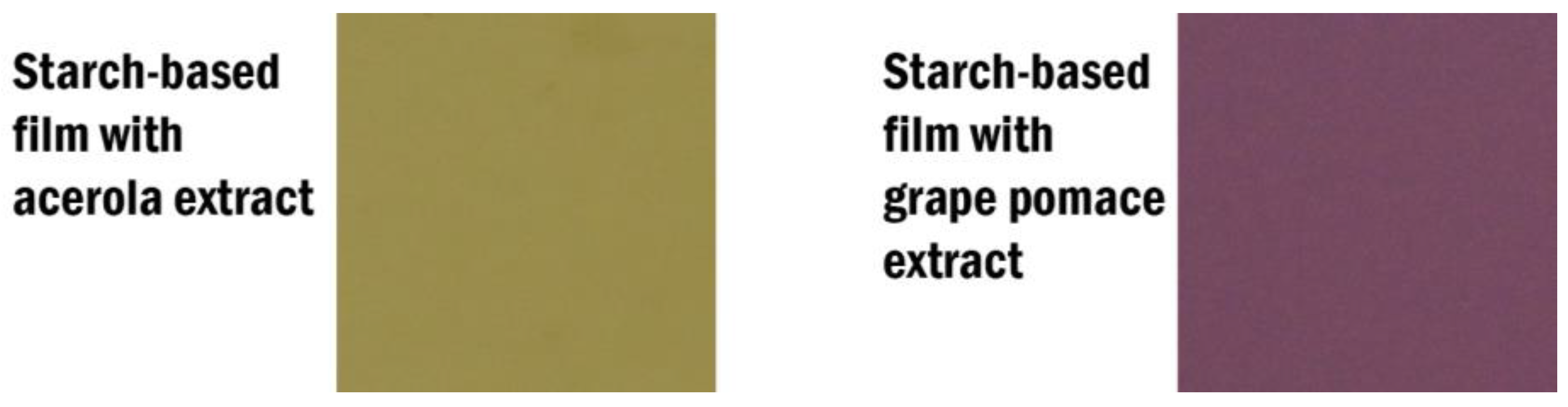

3.7. Color Sensing Property

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- D’Aniello, A.; Donato, C. Is It Recycled or Recyclable? Improving Consumers’ Perceptions of Recycled Plastic Packages for Food Products. Food Qual. Prefer. 2025, 127, 105438. [Google Scholar] [CrossRef]

- Gupta, R.K.; Guha, P.; Srivastav, P.P. Natural Polymers in Bio-Degradable/Edible Film: A Review on Environmental Concerns, Cold Plasma Technology and Nanotechnology Application on Food Packaging- A Recent Trends. Food Chem. Adv. 2022, 1, 100135. [Google Scholar] [CrossRef]

- Mangaraj, S.; Thakur, R.R.; Yadav, A. Development and Characterization of PLA and Cassava Starch-based Novel Biodegradable Film Used for Food Packaging Application. J. Food Process Preserv. 2022, 46, 16314. [Google Scholar] [CrossRef]

- Shanbhag, C.; Shenoy, R.; Shetty, P.; Srinivasulu, M.; Nayak, R. Formulation and Characterization of Starch-Based Novel Biodegradable Edible Films for Food Packaging. J. Food Sci. Technol. 2023, 60, 2858–2867. [Google Scholar] [CrossRef] [PubMed]

- Alqahtani, N.; Alnemr, T.; Ali, S. Development of Low-Cost Biodegradable Films from Corn Starch and Date Palm Pits (Phoenix Dactylifera). Food Biosci. 2021, 42, 101199. [Google Scholar] [CrossRef]

- Onyeaka, H.; Obileke, K.; Makaka, G.; Nwokolo, N. Current Research and Applications of Starch-Based Biodegradable Films for Food Packaging. Polymers 2022, 14, 1126. [Google Scholar] [CrossRef]

- Pająk, P.; Przetaczek-Rożnowska, I.; Juszczak, L. Development and Physicochemical, Thermal and Mechanical Properties of Edible Films Based on Pumpkin, Lentil and Quinoa Starches. Int. J. Biol. Macromol. 2019, 138, 441–449. [Google Scholar] [CrossRef]

- Agarwal, S. Major Factors Affecting the Characteristics of Starch Based Biopolymer Films. Eur. Polym. J. 2021, 160, 110788. [Google Scholar] [CrossRef]

- Wan, S.; Liu, Q.; Yang, D.; Guo, P.; Gao, Y.; Mo, R.; Zhang, Y. Characterization of High Amylose Corn Starch-Cinnamaldehyde Inclusion Films for Food Packaging. Food Chem. 2022, 403, 134219. [Google Scholar]

- Martins, P.C.; Latorres, J.M.; Martins, V.G. Impact of Starch Nanocrystals on the Physicochemical, Thermal and Structural Characteristics of Starch-Based Films. LWT 2022, 156, 113041. [Google Scholar] [CrossRef]

- Marenco-Orozco, G.A.; Rosa, M.F.; Fernandes, F.A.N. Effects of Multiple-step Cold Plasma Processing on Banana (Musa Sapientum) Starch-based Films. Packag. Technol. Sci. 2022, 35, 589–601. [Google Scholar] [CrossRef]

- Bertuzzi, M.A.; Armada, M.; Gottifredi, J.C. Physicochemical Characterization of Starch Based Films. J. Food Eng. 2007, 82, 17–25. [Google Scholar] [CrossRef]

- Yadav, P.; Gautam, S.; Bosco, S.J.D. Amaranthus Paniculatus (Rajgeera) a Non-Conventional Source of Starch: Effect of Oxidation and Heat Moisture Treatment and Its Application in Edible Film. Biomass Convers. Biorefin. 2024, 14, 23733–23741. [Google Scholar] [CrossRef]

- Sifuentes-Nieves, I.; Hernández-Hernández, E.; Neira-Velázquez, G.; Morales-Sánchez, E.; Mendez-Montealvo, G.; Velazquez, G. Hexamethyldisiloxane Cold Plasma Treatment and Amylose Content Determine the Structural, Barrier and Mechanical Properties of Starch-Based Films. Int. J. Biol. Macromol. 2019, 124, 651–658. [Google Scholar] [CrossRef] [PubMed]

- Hernandez-Perez, P.; Flores-Silva, P.C.; Velazquez, G.; Morales-Sanchez, E.; Rodríguez-Fernández, O.; Hernández-Hernández, E.; Mendez-Montealvo, G.; Sifuentes-Nieves, I. Rheological Performance of Film-Forming Solutions Made from Plasma-Modified Starches with Different Amylose/Amylopectin Content. Carbohydr. Polym. 2021, 255, 117349. [Google Scholar] [CrossRef]

- Guo, Z.; Gou, Q.; Yang, L.; Yu, Q.; Han, L. Dielectric Barrier Discharge Plasma: A Green Method to Change Structure of Potato Starch and Improve Physicochemical Properties of Potato Starch Films. Food Chem. 2022, 370, 130992. [Google Scholar] [CrossRef]

- Goiana, M.L.; de Brito, E.S.; Alves Filho, E.G.; Miguel, E.d.C.; Fernandes, F.A.N.; Azeredo, H.M.C.d.; Rosa, M.d.F. Corn Starch Based Films Treated by Dielectric Barrier Discharge Plasma. Int. J. Biol. Macromol. 2021, 183, 2009–2016. [Google Scholar] [CrossRef]

- Malien-Aubert, C.; Dangles, O.; Amiot, M.J. Color Stability of Commercial Anthocyanin-Based Extracts in Relation to the Phenolic Composition. Protective Effects by Intra- and Intermolecular Copigmentation. J. Agric. Food Chem. 2001, 49, 170–176. [Google Scholar] [CrossRef]

- Castañeda-Ovando, A.; Pacheco-Hernández, M.L.; Páez-Hernández, M.E.; Rodríguez, J.A.; Galán-Vidal, C.A. Chemical Studies of Anthocyanins: A Review. Food Chem. 2009, 113, 859–871. [Google Scholar] [CrossRef]

- Einbond, L.S.; Reynertson, K.A.; Luo, X.D.; Basile, M.J.; Kennelly, E.J. Anthocyanin Antioxidants from Edible Fruits. Food Chem. 2004, 84, 23–28. [Google Scholar] [CrossRef]

- Kähkönen, M.P.; Heinonen, M. Antioxidant Activity of Anthocyanins and Their Aglycons. J. Agric. Food Chem. 2003, 51, 628–633. [Google Scholar] [CrossRef] [PubMed]

- Jomova, K.; Valko, M. Health Protective Effects of Carotenoids and Their Interactions with Other Biological Antioxidants. Eur. J. Med. Chem. 2013, 70, 102–110. [Google Scholar] [CrossRef] [PubMed]

- Goiana, M.L.; Mattos, A.L.A.; Rosa, M.F.; Fernandes, F.A.N. Use of Cold Plasma as an Alternative to Improve Corn Starch-Based Films: Effect of the Plasma Application Strategy. Processes 2024, 12, 1429. [Google Scholar] [CrossRef]

- Hu, J.; Cheng, F.; Lin, Y.; Zhao, K.; Zhu, P. Dissolution of Starch in Urea/NaOH Aqueous Solutions. J. Appl. Polym. Sci. 2016, 133, 43390. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Surface Wettability and Adsorbency of Sheeted Materials Using an Automated Contact Angle Tester; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- Warren, F.J.; Gidley, M.J.; Flanagan, B.M. Infrared Spectroscopy as a Tool to Characterise Starch Ordered Structure—A Joint FTIR–ATR, NMR, XRD and DSC Study. Carbohydr. Polym. 2016, 139, 35–42. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Water Vapor Transmission of Materials. E96-00. In Annual Book of ASTM Standards; American Society for Testing and Materials: Philadelphia, PA, USA, 2000; pp. 907–914. [Google Scholar]

- Bie, P.; Pu, H.; Zhang, B.; Su, J.; Chen, L.; Li, X. Structural Characteristics and Rheological Properties of Plasma-Treated Starch. Innov. Food Sci. Emerg. Technol. 2016, 34, 196–204. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, W.; Cao, J.; Jiang, W. Development of Biodegradable Active Films Based on Longan Seed Starch Incorporated with Banana Flower Bract Anthocyanin Extracts and Applications in Food Freshness Indication. Int. J. Biol. Macromol. 2023, 251, 126372. [Google Scholar] [CrossRef]

- Qin, Y.; Liu, Y.; Yong, H.; Liu, J.; Zhang, X.; Liu, J. Preparation and Characterization of Active and Intelligent Packaging Films Based on Cassava Starch and Anthocyanins from Lycium Ruthenicum Murr. Int. J. Biol. Macromol. 2019, 134, 80–90. [Google Scholar] [CrossRef]

- Romani, V.P.; Olsen, B.; Pinto Collares, M.; Meireles Oliveira, J.R.; Prentice, C.; Martins, V.G. Cold Plasma and Carnauba Wax as Strategies to Produce Improved Bi-Layer Films for Sustainable Food Packaging. Food Hydrocoll. 2020, 108, 106087. [Google Scholar] [CrossRef]

- Cui, C.; Ji, N.; Wang, Y.; Xiong, L.; Sun, Q. Bioactive and Intelligent Starch-Based Films: A Review. Trends Food Sci. Technol. 2021, 116, 854–869. [Google Scholar] [CrossRef]

- Oh, Y.A.; Roh, S.H.; Min, S.C. Cold Plasma Treatments for Improvement of the Applicability of Defatted Soybean Meal-Based Edible Film in Food Packaging. Food Hydrocoll. 2016, 58, 150–159. [Google Scholar] [CrossRef]

- Sani, I.K.; Aminoleslami, L.; Mirtalebi, S.S.; Sani, M.A.; Mansouri, E.; Eghbaljoo, H.; Jalil, A.T.; Thanoon, R.D.; Khodaei, S.M.; Mohammadi, F.; et al. Cold Plasma Technology: Applications in Improving Edible Films and Food Packaging. Food Packag. Shelf Life 2023, 37, 101087. [Google Scholar] [CrossRef]

- Yi, F.; Hou, F.; Zhan, S.; Song, L.; Zhang, R.; Han, X.; Sun, X.; Liu, Z. Preparation, Characterization and Application of PH-Responsive Smart Film Based on Chitosan/Zein and Red Radish Anthocyanin. Int. J. Biol. Macromol. 2023, 253, 127037. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, S.; Lan, W.; Qin, W. Development of Ultrasound Treated Polyvinyl Alcohol/Tea Polyphenol Composite Films and Their Physicochemical Properties. Ultrason. Sonochem. 2019, 51, 386–394. [Google Scholar] [CrossRef]

- Heidemann, H.M.; Dotto, M.E.R.; Laurindo, J.B.; Carciofi, B.A.M.; Costa, C. Cold Plasma Treatment to Improve the Adhesion of Cassava Starch Films onto PCL and PLA Surface. Colloids Surf. A Physicochem. Eng. Asp. 2019, 580, 123739. [Google Scholar] [CrossRef]

- Karthik, C.; Mavelil-Sam, R.; Thomas, S.; Thomas, V. Cold Plasma Technology Based Eco-Friendly Food Packaging Biomaterials. Polymers 2024, 16, 230. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Gao, Y.; Li, C. Preparation and Characterization of Smart Indicator Films Based on Gellan Gum/Modified Black Rice Anthocyanin/Curcumin for Improving the Stability of Natural Anthocyanins. Int. J. Biol. Macromol. 2023, 253, 127436. [Google Scholar] [CrossRef]

- Xiao, Z.; Han, L.; Gu, M.; Zhu, Y.; Zhang, Y.; Li, Z.; Xie, T.; Lu, F. Performance Comparison of Anthocyanin-Based Smart Indicator Films. Food Packag. Shelf Life 2023, 40, 101187. [Google Scholar] [CrossRef]

- Azeredo, H.M.C.; Morrugares-Carmona, R.; Wellner, N.; Cross, K.; Bajka, B.; Waldron, K.W. Development of Pectin Films with Pomegranate Juice and Citric Acid. Food Chem. 2016, 198, 101–106. [Google Scholar] [CrossRef]

- Slavutsky, A.M.; Gamboni, J.E.; Bertuzzi, M.A. Formulation and Characterization of Bilayer Films Based on Brea Gum and Pectin. Braz. J. Food Technol. 2018, 21, e2017213. [Google Scholar] [CrossRef]

- Bertuzzi, M.A.; Castro Vidaurre, E.F.; Armada, M.; Gottifredi, J.C. Water Vapor Permeability of Edible Starch Based Films. J. Food Eng. 2007, 80, 972–978. [Google Scholar] [CrossRef]

- Choi, I.; Lee, J.Y.; Lacroix, M.; Han, J. Intelligent PH Indicator Film Composed of Agar/Potato Starch and Anthocyanin Extracts from Purple Sweet Potato. Food Chem. 2017, 218, 122–128. [Google Scholar] [CrossRef] [PubMed]

| Film | Plasma Application | Amylose Content (%) |

|---|---|---|

| Starch film | No | 22.6 a ± 0.1 |

| Starch film | Yes | 23.4 b ± 0.1 |

| Starch film with acerola extract | No | 23.2 ab ± 1.4 |

| Starch film with acerola extract | Yes | 21.9 a ± 0.7 |

| Starch film with grape pomace extract | No | 24.2 b ± 0.6 |

| Starch film with grape pomace extract | Yes | 21.0 a ± 1.2 |

| Film | Plasma Application | 930 cm−1 | 995 cm−1/ 1022 cm−1 |

|---|---|---|---|

| Starch film | No | 0.35 | 1.46 |

| Starch film | Yes | 0.33 | 1.43 |

| Starch film with acerola extract | No | 0.67 | 1.28 |

| Starch film with acerola extract | Yes | 0.70 | 1.32 |

| Starch film with grape pomace extract | No | 0.74 | 1.32 |

| Starch film with grape pomace extract | Yes | 0.70 | 1.32 |

| Film | Plasma Application | Solubility (%) | Moisture Content (%) |

|---|---|---|---|

| Starch film | No | 79.3 a ± 2.2 | 20.6 a ± 3.0 |

| Starch film | Yes | 76.5 a ± 3.7 | 18.0 a ± 1.4 |

| Starch film with acerola extract | No | 70.5 ab ± 3.7 | 17.5 a ± 1.0 |

| Starch film with acerola extract | Yes | 61.1 b ± 2.5 | 15.0 b ± 1.2 |

| Starch film with grape pomace extract | No | 74.1 a ± 2.8 | 16.8 b ± 0.1 |

| Starch film with grape pomace extract | Yes | 66.8 bc ± 0.1 | 16.6 ab ± 0.8 |

| Film | Plasma Application | Contact Angle (°) |

|---|---|---|

| Starch film | No | 54.2 a ± 1.1 |

| Starch film | Yes | 55.4 a ± 2.2 |

| Starch film with acerola extract | No | 57.5 ab ± 2.1 |

| Starch film with acerola extract | Yes | 61.7 b ± 1.5 |

| Starch film with grape pomace extract | No | 56.4 a ± 1.3 |

| Starch film with grape pomace extract | Yes | 63.6 ab ± 1.6 |

| Film | Plasma Application | Water Vapor Permeability (g mm/kPa h m2) |

|---|---|---|

| Starch film | No | 1.57 a ± 0.33 |

| Starch film | Yes | 1.55 a ± 0.44 |

| Starch film with acerola extract | No | 3.29 b ± 2.54 |

| Starch film with acerola extract | Yes | 4.59 b ± 2.58 |

| Starch film with grape pomace extract | No | 1.71 ab± 0.81 |

| Starch film with grape pomace extract | Yes | 2.74 b ± 1.87 |

| Wavelength (nm) | Reflected Color | pH 3 | pH 5 | pH 7 | pH 9 |

|---|---|---|---|---|---|

| Starch-based film with acerola residue extract without plasma treatment | |||||

| 400 | Yellow-Green | 0.85 | 0.85 | 0.83 | 0.86 |

| 500 | Red-Purple | 0.42 | 0.45 | 0.35 | 0.35 |

| 600 | Blue-Green | 0.29 | 0.34 | 0.23 | 0.21 |

| 700 | Cyan | 0.24 | 0.30 | 0.19 | 0.16 |

| Starch-based film with acerola residue extract subjected to plasma treatment | |||||

| 400 | Yellow-Green | 0.83 | 0.80 | 0.77 | 0.89 |

| 500 | Red-Purple | 0.37 | 0.30 | 0.21 | 0.37 |

| 600 | Blue-Green | 0.24 | 0.17 | 0.10 | 0.21 |

| 700 | Cyan | 0.19 | 0.13 | 0.07 | 0.15 |

| Wavelength (nm) | Reflected Color | pH 3 | pH 5 | pH 7 | pH 9 |

|---|---|---|---|---|---|

| Starch-based film with grape pomace extract without plasma treatment | |||||

| 400 | Yellow-Green | 0.95 | 0.90 | 0.90 | 0.90 |

| 500 | Red-Purple | 0.87 | 0.80 | 0.71 | 0.62 |

| 600 | Blue-Green | 0.64 | 0.64 | 0.61 | 0.59 |

| 700 | Cyan | 0.67 | 0.56 | 0.49 | 0.43 |

| Starch-based film with grape pomace extract subjected to plasma treatment | |||||

| 400 | Yellow-Green | 0.91 | 0.80 | 0.93 | 0.89 |

| 500 | Red-Purple | 0.75 | 0.62 | 0.75 | 0.63 |

| 600 | Blue-Green | 0.56 | 0.44 | 0.64 | 0.55 |

| 700 | Cyan | 0.47 | 0.32 | 0.54 | 0.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Goiana, M.L.; Rosa, M.d.F.; Mattos, A.L.A.; Fernandes, F.A.N. Development of Plasma-Treated Corn-Starch-Based Film Incorporated with Acerola and Grape Pomace Extract Possessing pH-Sensing Capability. Polymers 2025, 17, 938. https://doi.org/10.3390/polym17070938

Goiana ML, Rosa MdF, Mattos ALA, Fernandes FAN. Development of Plasma-Treated Corn-Starch-Based Film Incorporated with Acerola and Grape Pomace Extract Possessing pH-Sensing Capability. Polymers. 2025; 17(7):938. https://doi.org/10.3390/polym17070938

Chicago/Turabian StyleGoiana, Mayara Lima, Morsyleide de Freitas Rosa, Adriano Lincoln Albuquerque Mattos, and Fabiano André Narciso Fernandes. 2025. "Development of Plasma-Treated Corn-Starch-Based Film Incorporated with Acerola and Grape Pomace Extract Possessing pH-Sensing Capability" Polymers 17, no. 7: 938. https://doi.org/10.3390/polym17070938

APA StyleGoiana, M. L., Rosa, M. d. F., Mattos, A. L. A., & Fernandes, F. A. N. (2025). Development of Plasma-Treated Corn-Starch-Based Film Incorporated with Acerola and Grape Pomace Extract Possessing pH-Sensing Capability. Polymers, 17(7), 938. https://doi.org/10.3390/polym17070938