Effect of Crosslinking Temperature on the Insulation Performance of XLPE Secondary Crosslinking Insulation Interface Layer

Abstract

1. Introduction

2. Materials and Methods

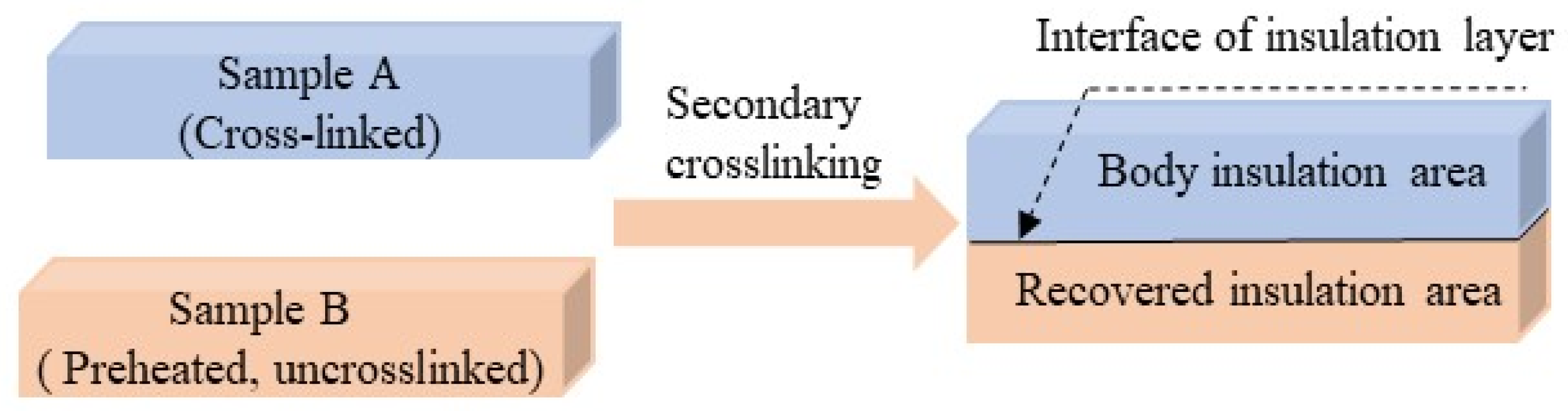

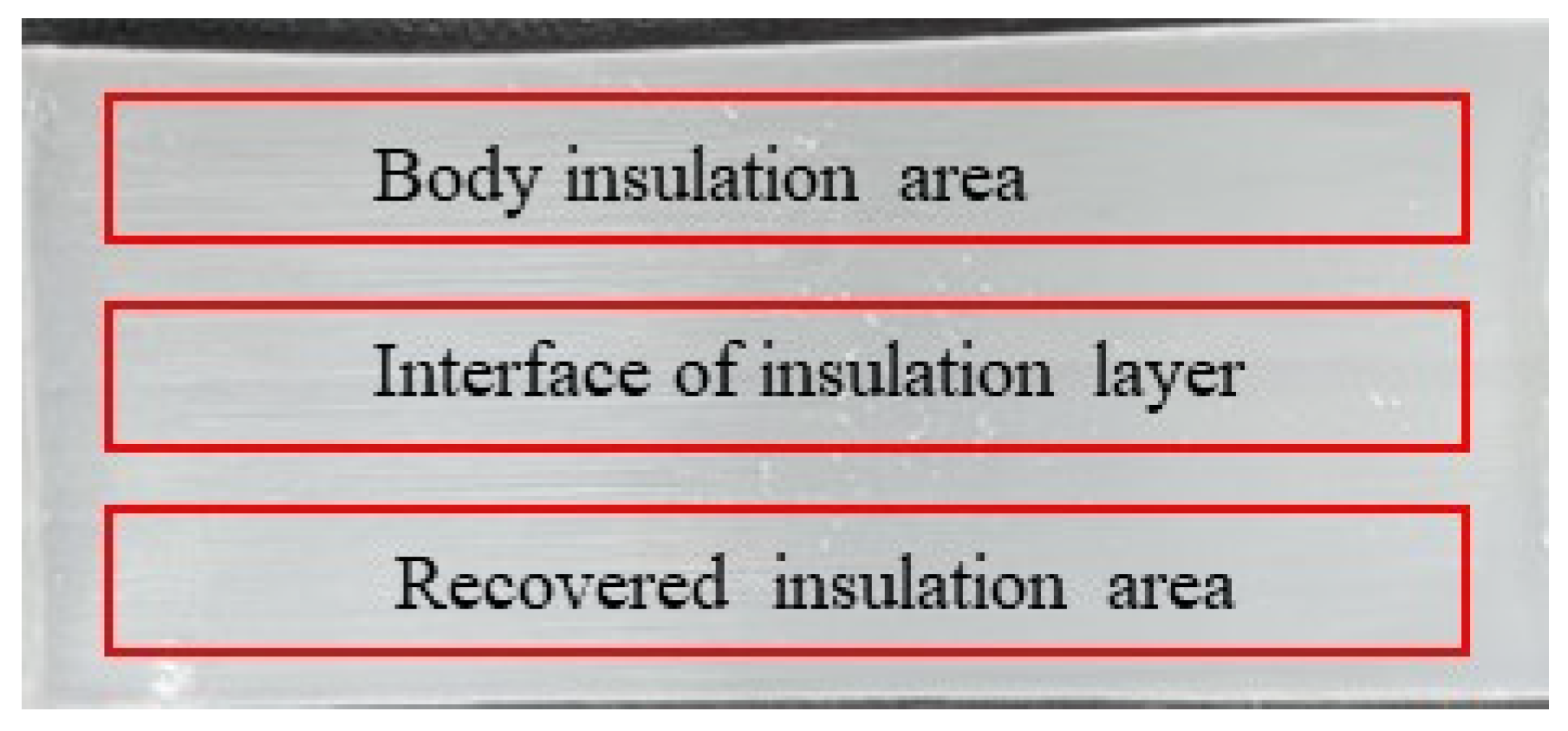

2.1. Materials and Sample Preparation

2.2. Calculation of the Crosslinking Degree

2.3. Crystallinity Test

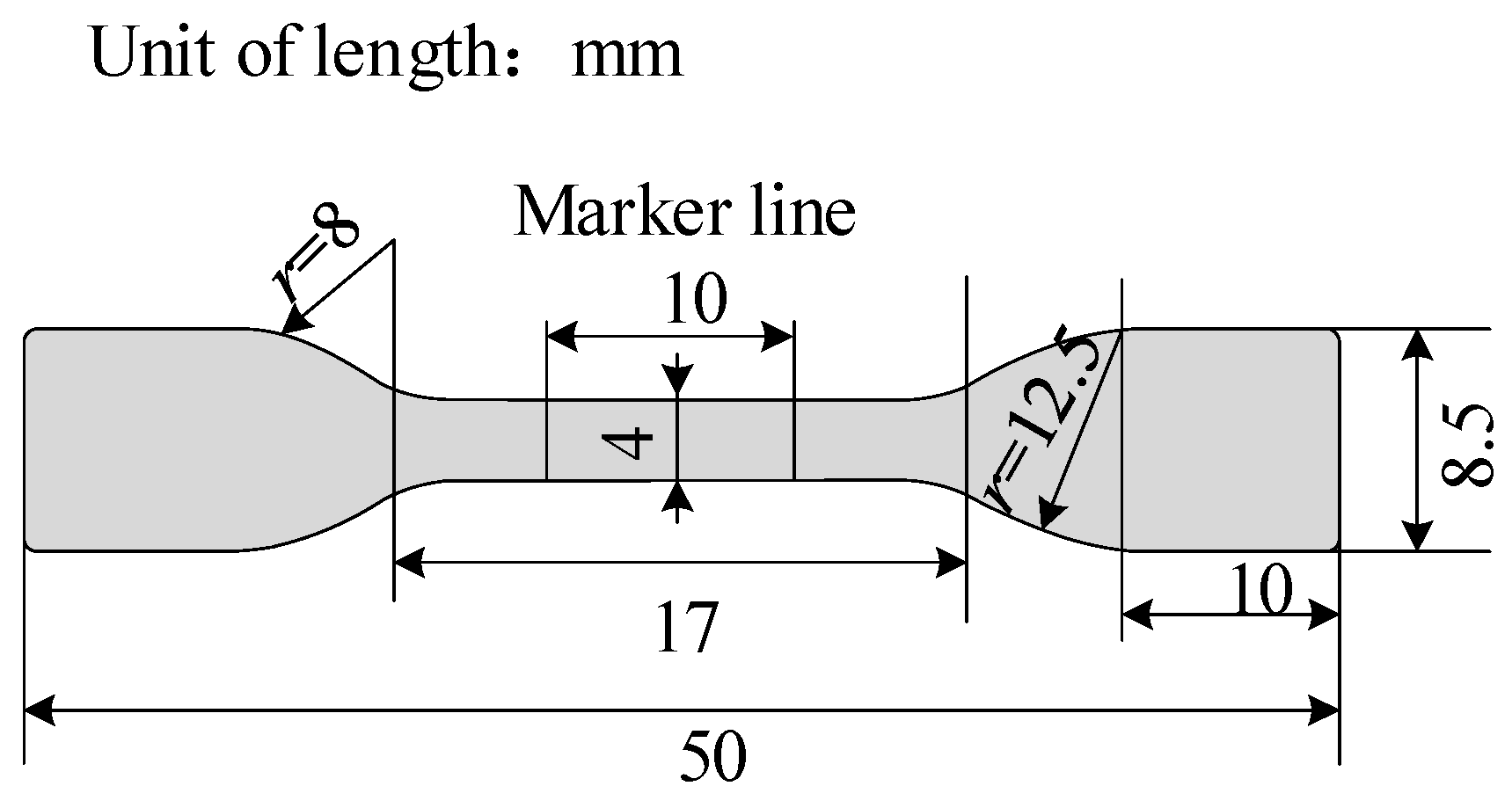

2.4. Thermal Extension Experiment

- A vernier caliper was used to measure the cross-sectional area of the prepared dumbbell-shaped samples. The corresponding load capacity was then calculated for the given size.

- The dumbbell-shaped samples were fixed onto the test bracket of the thermal extension experimental device, with a fixed mass applied below. Then the thermal extension experimental device was placed into an oven with temperature and humidity control (model: RGDJ-800, Yekeyin Experimental Equipment Co., Ltd., Chengdu, China), preheated to 200 °C. Timing began when the temperature reached 200 °C (approximately 10 min), accumulating for 15 min.

- The distance between the marked lines of the dumbbell-shaped samples was recorded after 15 min. The thermal elongation was calculated using the following Formula (3):

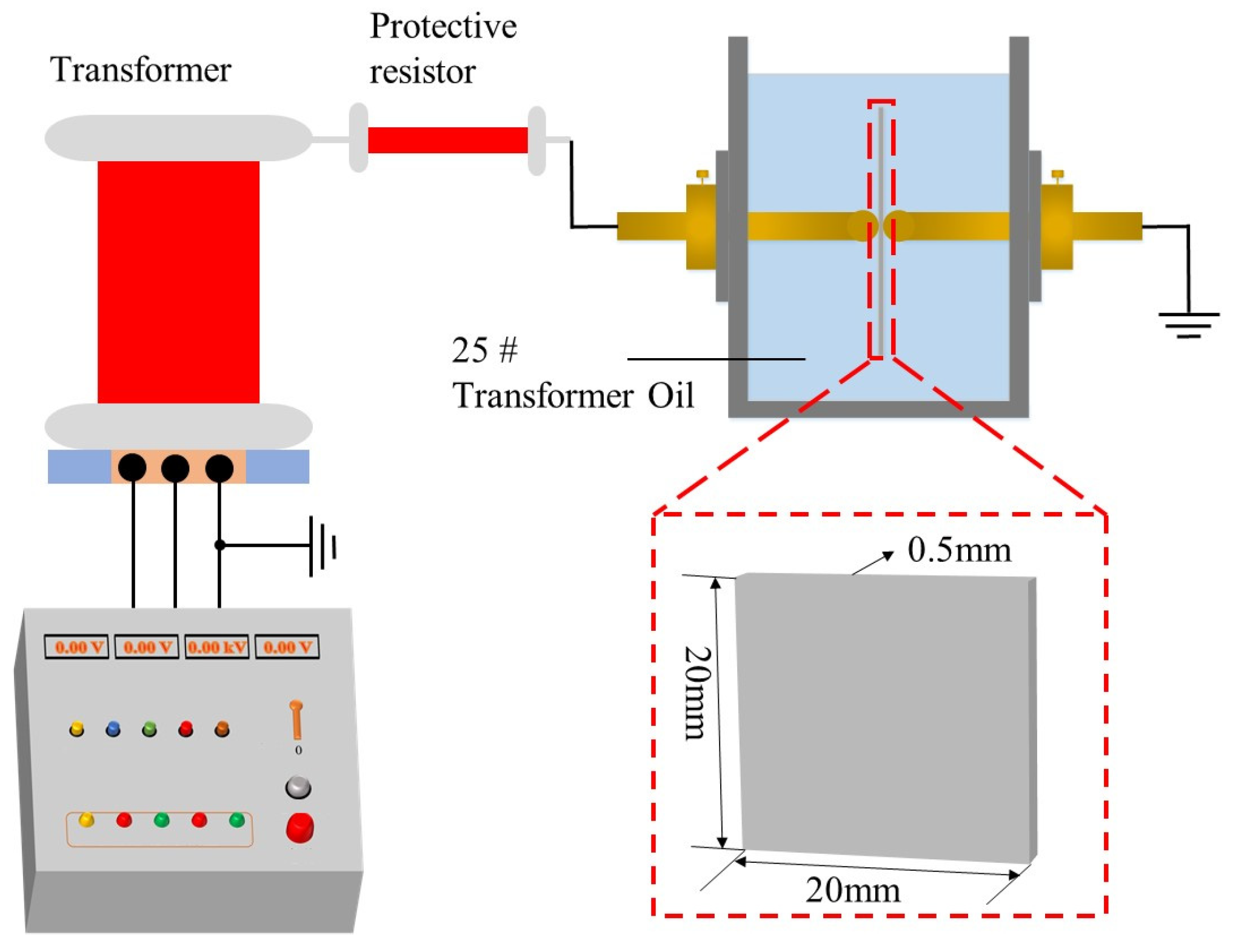

2.5. Breakdown Voltage Test

2.6. Scanning Electron Microscopy Observation

3. Results

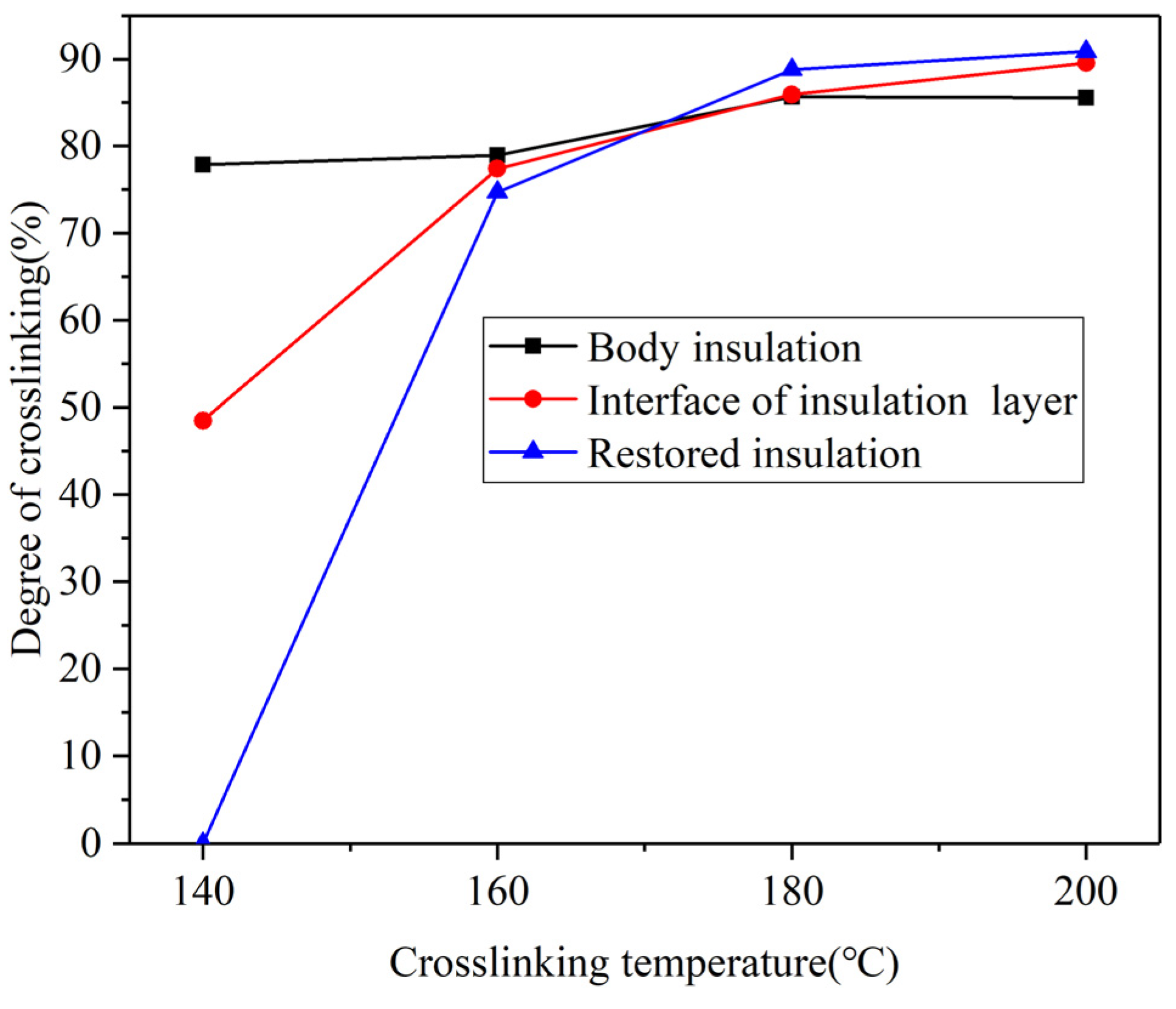

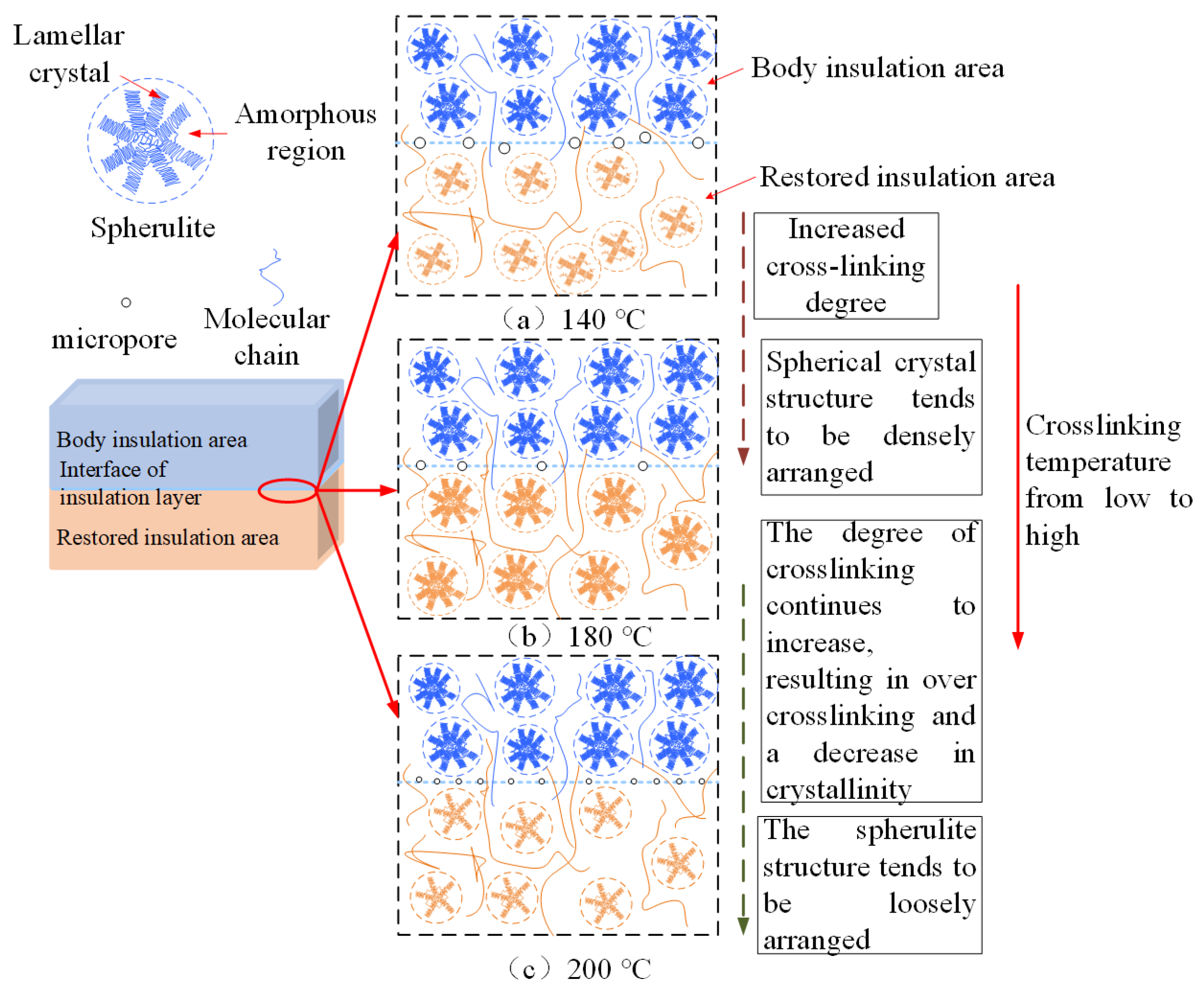

3.1. Analysis of Crosslinking Degree Test Results

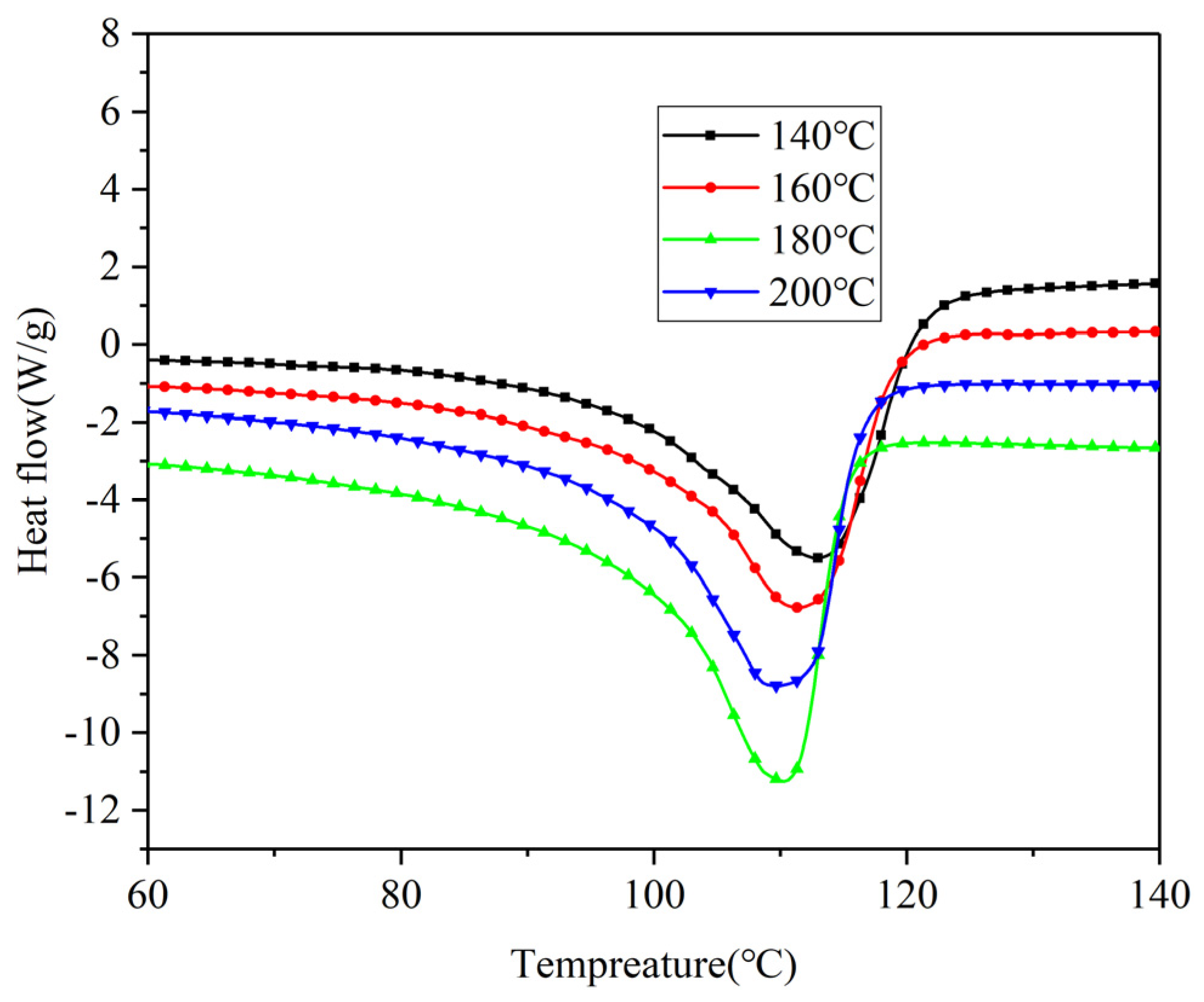

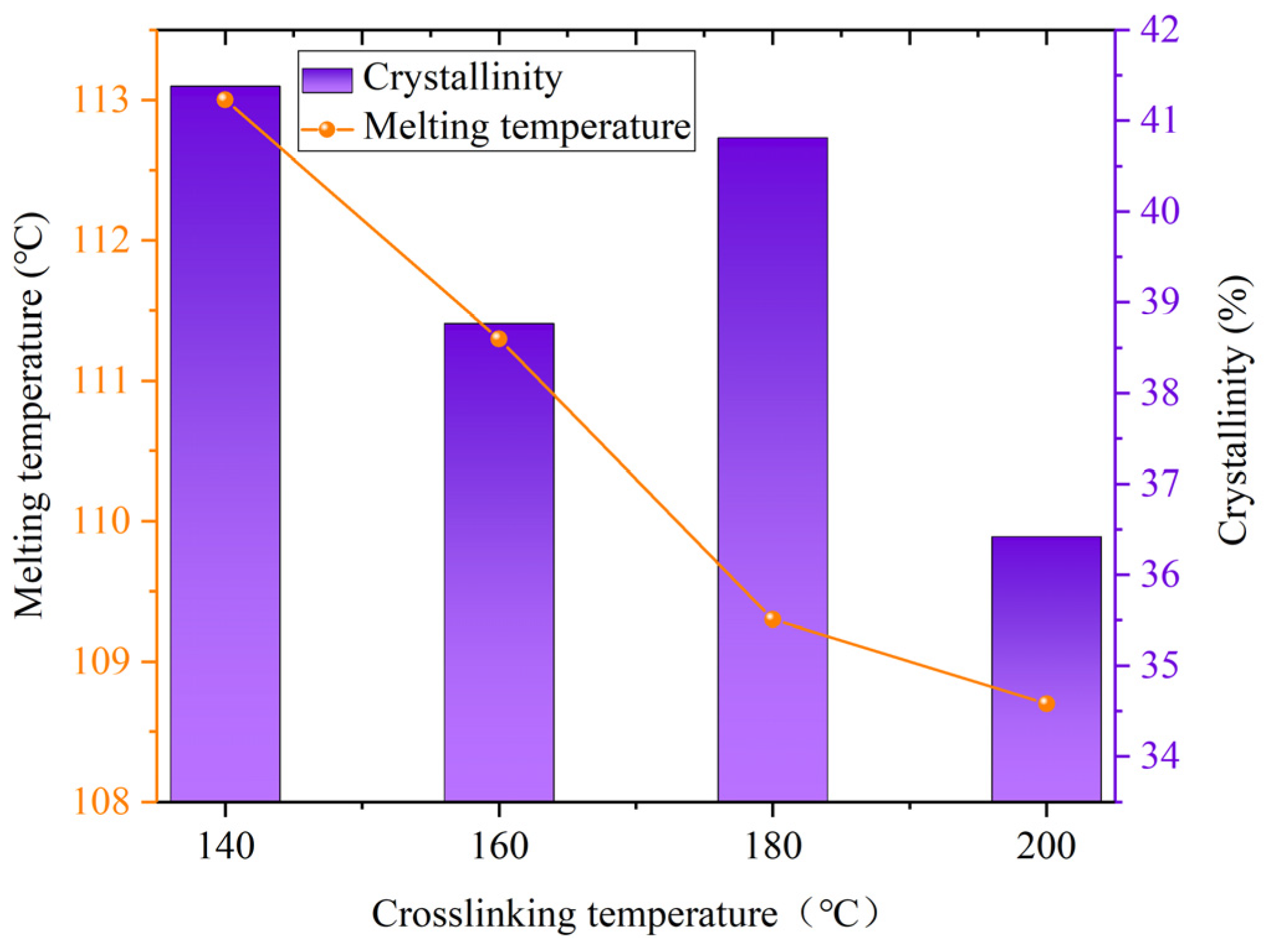

3.2. Analysis of DSC Test Results

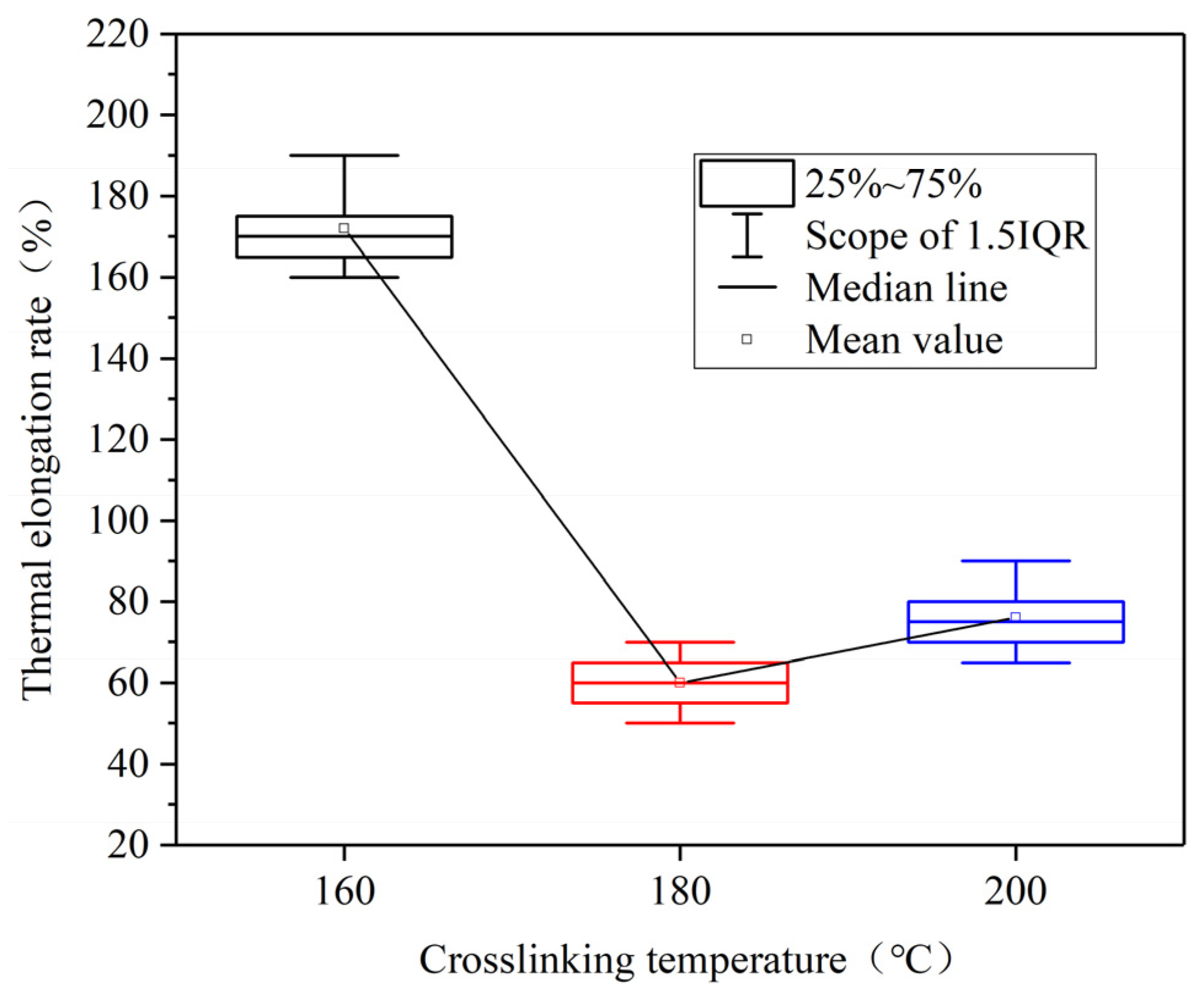

3.3. Analysis of Thermal Extension Experiment Results

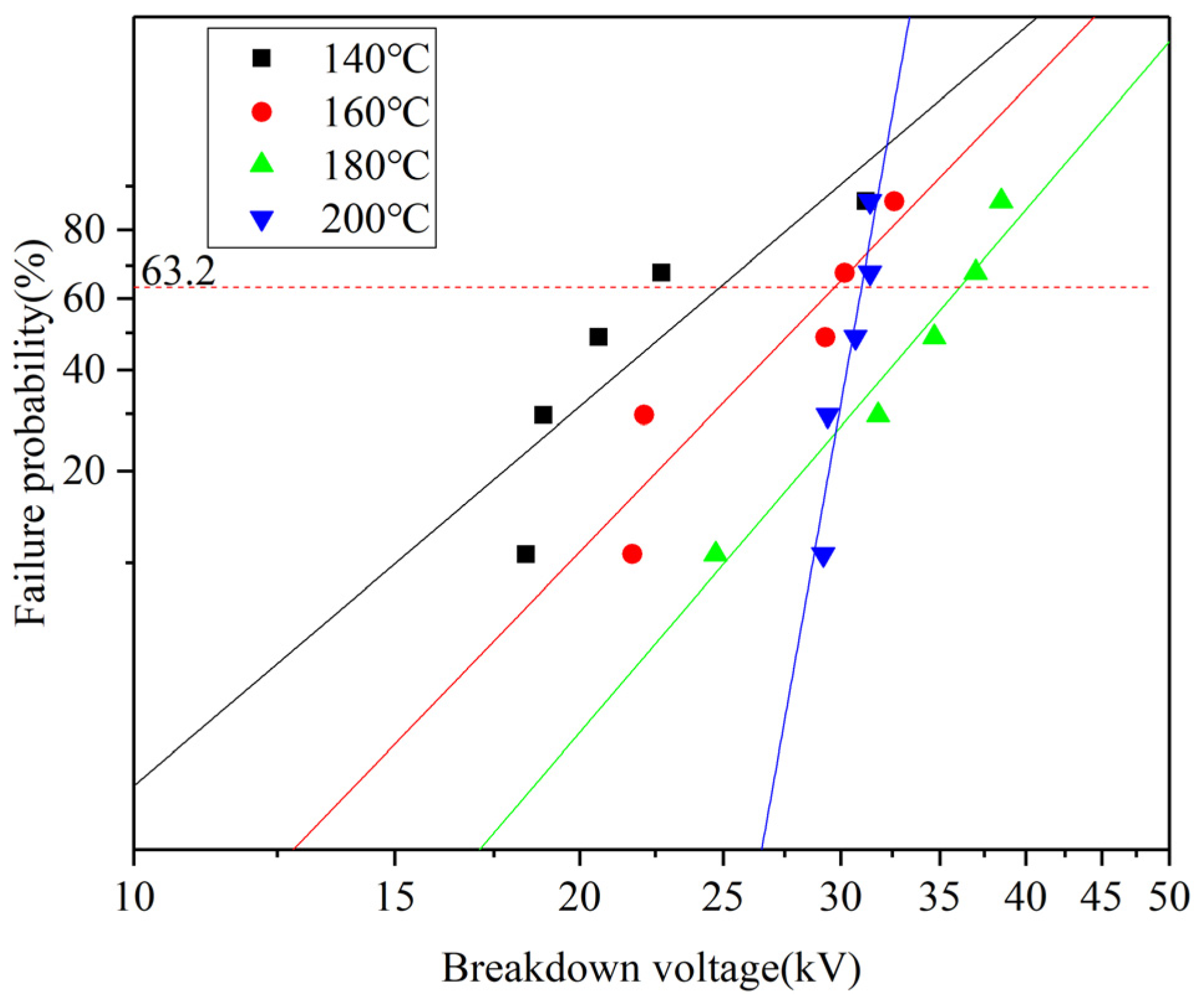

3.4. Analysis of Breakdown Voltage Test Results

3.5. Analysis of Scanning Electron Microscope Observation Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Alassi, A.; Bañales, S.; Ellabban, O.; Adam, G.; MacIver, C. HVDC Transmission: Technology Review, Market Trends and Future Outlook. Renew. Sustain. Energy Rev. 2019, 112, 530–554. [Google Scholar] [CrossRef]

- Sutton, S.J.; Lewin, P.L.; Swingler, S.G. Review of global HVDC subsea cable projects and the application of sea electrodes. Int. J. Electr. Power Energy Syst. 2017, 87, 121–135. [Google Scholar] [CrossRef]

- Wang, W.; Yan, X.; Li, S.; Zhang, L.; Ouyang, J.; Ni, X. Failure of submarine cables used in highvoltage power transmission: Characteristics mechanisms, key issues and prospects. IET Gener. Transm. Distrib. 2021, 15, 1387–1402. [Google Scholar] [CrossRef]

- Taormina, B.; Bald, J.; Want, A.; Thouzeau, G.; Lejart, M.; Desroy, N.; Carlier, A. A review of potential impacts of submarine power cables on the marine environment: Knowledge gaps, recommendations and future directions. Renew. Sustain. Energy Rev. 2018, 96, 380–391. [Google Scholar] [CrossRef]

- Santhakumar, S.; Smart, G.; Noonan, M.; Meerman, H.; Faaij, A. Technological progress observed for fixed-bottom offshore wind in the EU and UK. Technol. Forecast. Soc. Change 2022, 182, 121856. [Google Scholar] [CrossRef]

- Purvins, A.; Sereno, L.; Ardelean, M.; Covrig, C.F.; Efthimiadis, T.; Minnebo, P. Submarine Power Cable between Europe and North America: A Techno-economic Analysis. J. Clean. Prod. 2018, 186, 131–145. [Google Scholar] [CrossRef]

- Sonerud, B.; Mäkelä, T.; Kjellqvist, J. Peroxide Decomposition Products in Factory Joints for DC XLPE Submarine Cable. In Proceedings of the 2021 IEEE Electrical Insulation Conference (EIC), Denver, CO, USA, 7–28 June 2021; pp. 193–197. [Google Scholar]

- Mazzanti, G.; Castellon, J.; Chen, G.; Fothergill, J.C.; Fu, M.; Hozumi, N.; Lee, J.H.; Li, J.; Marzinotto, M.; Mauseth, F.; et al. The insulation of HVDC extruded cable system joints. Part 1: Review of materials, design and testing procedures. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 964–972. [Google Scholar]

- Ghorbani, H.; Gustafsson, A.; Saltzer, M.; Alapati, S. Extra High Voltage DC Extruded Cable System Qualification. In Proceedings of the 2015 International Conference on Condition, Bangalore, India, 10–12 December 2015. [Google Scholar]

- Ye, H.; Han, Z.; Luo, Y.; Zhuang, Q.; Fechner, T.; Wang, H.; Lei, X. Design Aspects on HVDC Cable Joints. In Proceedings of the 2018 International Conference on the Properties and Applications of Dielectric Materials, Xi’an, China, 20–24 May 2018; pp. 300–304. [Google Scholar]

- Nakabasami, T.; Karasaki, T.; Sekii, Y.; Kitai, S. Investigations for Commercial Use of 275 KV XLPE Cables and Development of Extrusion Type Molded Joint. IEEE Power Eng. Rev. 1985, PER-5, 19–20. [Google Scholar] [CrossRef]

- Li, J.; Du, B.X.; Xu, H. Suppressing interface charge between LDPE and EPDM for HVDC cable accessory insulation. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1331–1339. [Google Scholar] [CrossRef]

- Qin, Y.; Lv, Z.; Wu, K. Study on Interfacial Charges of Double-layer Cross-linked Polyethylene. In Proceedings of the 2023 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), East Rutherford, NJ, USA, 15–19 October 2023; pp. 1–4. [Google Scholar]

- Zhang, Z.P.; Zhao, H.; Xu, M.-Z.; Zhao, J.-K.; Li, W.-J.; Yang, X. Light Scattering Characteristics of Interface Micro-Defects in Factory Joints of High-Voltage Submarine Cables. In Proceedings of the 2022 7th Asia Conference on Power and Electrical Engineering (ACPEE), Hangzhou, China, 15–17 April 2022; pp. 970–975. [Google Scholar]

- Sun, Y.; Zheng, Z.; Huang, Y. Research on overvoltage withstand level of ultra-high voltage submarine cable flexible joints. In Proceedings of the Annual Meeting of CSEE Study Committee of HVDC and Power Electronics (HVDC 2023), Nanjing, China, 22–25 October 2023; pp. 404–409. [Google Scholar]

- Gustafsson, A.; Jeroense, M.; Sunnegårdh, P.; Saltzer, M.; Ghorbani, H.; Rapp, H. New developments within the area of extruded HVDC cables. In Proceedings of the 11th IET International Conference on AC and DC Power Transmission, Birmingham, UK, 10–12 February 2015; pp. 1–5. [Google Scholar]

- Ouyang, B.; Li, H.; Li, J. Study on Difference in Micro-structure of XLPE Cable Insulation Materials with Different Cross-linking Processes. Insul. Mater. 2019, 52, 13–17. [Google Scholar]

- Meng, F.B.; Chen, X.; Hong, Z.; Shi, Y.; Zhu, H.; Muhammad, A.; Paramane, A.; Huang, R.; Han, Z. Insulation Properties and Interfacial Quantum Chemical Analysisof Cross-Linked Polyethylene Under Different Degassing Time for HVDC Cable Factory Joint Applications. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 271–278. [Google Scholar]

- Meng, F.B.; Chen, X.; Dai, C.; Zhang, M.; Shi, Y.; Paramane, A.; Muhammad, A. Interfacial microstructure and insulation properties of 500 kV EHVDC XLPE cable factory joint under different roughness and degassing durations. Polym. Degrad. Stab. 2021, 192, 109688. [Google Scholar]

- Ding, M.; Zheng, Q.; Wang, J.; He, W.; Dai, C.; Wen, D. Effects of Degassing Treatment on the Dielectric Properties of XLPE Insulation Used in High-Voltage DC Power Cables. Polymers 2025, 17, 431. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Sun, M.; Zhao, K.; Wang, X.; Xu, Q.; Wang, W.; Li, C. High-Voltage FDS of Thermally Aged XLPE Cable and Its Correlation with Physicochemical Properties. Polymers 2022, 14, 3519. [Google Scholar] [CrossRef]

- Meng, F.-B.; Chen, X.; Shi, Y.; Zhu, H.; Hong, Z.; Muhammad, A.; Paramane, A.; Chen, L.; Zhang, Y.; Huang, R.; et al. Temperature-Dependent Charge Dynamics of Double Layer Interface in 500 k V HVDC XLPE Cable Factory Joint With Different Interfacial Roughness. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 655–662. [Google Scholar]

- Zhang, L.; Wang, Z.; Tian, J.; Meng, S.; Zhou, Y. Thermal Aging Properties of 500 kV AC and DC XLPE Cable Insulation Materials. Polymers 2022, 14, 5400. [Google Scholar] [CrossRef]

- Li, J.; Du, B.X.; Kong, X.X.; Li, Z.L. Nonlinear conductivity and interface charge behaviors between LDPE and EPDM/SiC composite for HVDC cable accessory. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1566–1573. [Google Scholar] [CrossRef]

- Gao, M.; Yang, J.; Zhao, H.; He, H.; Hu, M.; Xie, S. Preparation Methods of Polypropylene/Nano-Silica/Styrene-Ethylene-Butylene-Styrene Composite and Its Effect on Electrical Properties. Polymers 2019, 11, 797. [Google Scholar] [CrossRef]

- Lin, S.; Zhou, K.; Li, Y. Investigating the Impact of γ-Ray Radiation on the Aggregate Structure and Interfacial Polarization Properties of XLPE. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 1856–1863. [Google Scholar]

- JB/T 10437-2004; Cross-Linkable Polyethylene Compounds for Wire and Cables. National Development and Reform Commission of the People’s Republic of China: Beijing, China, 2004.

- Youn, D.J.; Li, J.; Livazovic, S.; Sun, Y.; Sun, S. Controlling Factors of Degassing in Crosslinked Polyethylene Insulated Cables. Polymers 2019, 11, 1439. [Google Scholar] [CrossRef]

- Pleşa, I.; Noţingher, P.V.; Schlögl, S.; Sumereder, C.; Muhr, M. Properties of Polymer Composites Used in High-Voltage Applications. Polymers 2016, 8, 173. [Google Scholar] [CrossRef] [PubMed]

- GB/T 2951.11-2008; Common Test Methods for Insulating and Sheathing Materials of Electric and Optical Cables—Part 11: Methods for General Application—Measurement of Thickness and Overall Dimensions—Tests for Determining the Mechanical Properties. National Standard of the People’s Republic of China: Beijing, China, 2008.

- IEC 930; Guide for the Statistical Analysis of Electrical Insulation Breakdown Data. International Standard: New York, NY, USA, 2007.

- GB/T 29310-2012; Guide for the Statistical Analysis of Electrical Insulation Breakdown Data. Standardization Administration of China: Beijing, China, 2012.

- Zhu, X.H. Effects of Crosslinking Method on Insulation Properties of Crosslinked Polyethylene; Tianjing University: Tianjing, China, 2010; pp. 1–10. [Google Scholar]

- Li, Z.; Zheng, Z.; Wu, Y.; Du, B. Space Charge and Electric Field Characteristics in XLPE-Insulated Extrusion Molded Joint for HVDC Submarine Cables: Experiment and Simulation. IEEE Trans. Power Deliv. 2024, 39, 2317–2326. [Google Scholar] [CrossRef]

| Sample Type | Characteristic Breakdown Voltage/kV |

|---|---|

| 140 °C crosslinking sample | 24.89 |

| 160 °C crosslinking sample | 29.72 |

| 180 °C crosslinking sample | 36.23 |

| 200 °C crosslinking sample | 30.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, M.; Zhang, H.; Ge, X.; Hu, X.; Zhang, Z.; Cao, X.; Li, Z.; Huo, W. Effect of Crosslinking Temperature on the Insulation Performance of XLPE Secondary Crosslinking Insulation Interface Layer. Polymers 2025, 17, 936. https://doi.org/10.3390/polym17070936

Hu M, Zhang H, Ge X, Hu X, Zhang Z, Cao X, Li Z, Huo W. Effect of Crosslinking Temperature on the Insulation Performance of XLPE Secondary Crosslinking Insulation Interface Layer. Polymers. 2025; 17(7):936. https://doi.org/10.3390/polym17070936

Chicago/Turabian StyleHu, Ming, Hongliang Zhang, Xufei Ge, Xiping Hu, Zehao Zhang, Xiaoyan Cao, Zerui Li, and Wenbo Huo. 2025. "Effect of Crosslinking Temperature on the Insulation Performance of XLPE Secondary Crosslinking Insulation Interface Layer" Polymers 17, no. 7: 936. https://doi.org/10.3390/polym17070936

APA StyleHu, M., Zhang, H., Ge, X., Hu, X., Zhang, Z., Cao, X., Li, Z., & Huo, W. (2025). Effect of Crosslinking Temperature on the Insulation Performance of XLPE Secondary Crosslinking Insulation Interface Layer. Polymers, 17(7), 936. https://doi.org/10.3390/polym17070936