Thermal Comfort Properties of Biodegradable Hemp and Polylactide Fiber Knitted Fabrics

Abstract

1. Introduction

2. Materials and Methods

- Hemp (HA) spun yarns (raw white) 27.8 tex (manufacturer—MAEKO S.r.l., Milan, Italy);

- HA spun yarns (raw white and dyed) 19.2 tex (manufacturer—Linificio e Canapificio Nazionale S.r.l., Villa d’Almè, Bergamo, Italy);

- Polylactide (PLA) spun yarns (raw white) 19.7 tex (manufacturer—PT Kewalram Indonesia, Kab. Sumedang, Bandung, Indonesia);

- PLA textured yarns (raw white) 16.7 tex/36 filaments (manufacturer—Indorama Ventures Fibers Germany GmbH, Bobingen, Germany).

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salopek Čubrić, I.; Skenderi, Z. Evaluating Thermophysiological Comfort Using the Principle of Sensory Analysis. Coll. Antropol. 2013, 37, 57–64. Available online: https://hrcak.srce.hr/99509 (accessed on 24 March 2025).

- Uttam, D. Thermophysiological clothing comfort. J. Text. Eng. Fash. Technol. 2021, 7, 98–103. [Google Scholar] [CrossRef]

- Stygienė, L.; Varnaitė-Žuravliova, S.; Abraitienė, A.; Krauledas, S.; Baltušnikaitė-Guzaitienė, J.; Padleckienė, I. Investigation of thermoregulation properties of various ceramic-containing knitted fabric structures. J. Ind. Text. 2020, 50, 716–739. [Google Scholar] [CrossRef]

- Khan, M.Z.; Hussain, S.; Siddique, H.F.; Baheti, V.; Militky, J.; Azeem, M.; Ali, A. Improvement of liquid moisture management in plaited knitted fabrics. Tekst. Ve Konfeksiyon 2018, 28, 182–188. Available online: https://dergipark.org.tr/en/download/article-file/547322 (accessed on 24 March 2025).

- Zhao, Y.; Dong, Z.; He, H.; Cong, H. The Development and Performance of Knitted Cool Fabric Based on Ultra-High Molecular Weight Polyethylene. Polymers 2024, 16, 325. [Google Scholar] [CrossRef]

- Bivainytė, A.; Mikučionienė, D.; Milašienė, D. Influence of the knitting structure of double-layered fabrics on the heat transfer process. Fibres Text. East. Eur. 2012, 2, 40–43. Available online: http://www.fibtex.lodz.pl/article686.html (accessed on 24 March 2025).

- Basuk, M.; Choudhari, M.; Maiti, S.; Adivarekar, R.V. Moisture Management Properties of Textiles and its Evaluation. Cur. Trends Fash. Technol. Text. Eng. 2018, 3, 50–55. [Google Scholar]

- CEN/TR16422:2012; Classification of Thermoregulatory Properties (FprEN 16422:2024. Clothing-Physiological Effects-Classification of Thermoregulatory Properties). CEN: Brussels, Belgium, 2012.

- Suganthi, T.; Senthilkumar, P. Moisture-management properties of bi-layer knitted fabrics for sportswear. J. Ind. Text. 2018, 47, 1447–1463. [Google Scholar] [CrossRef]

- Babu, B.S.; Senthilkumar, P.; Senthilkumar, M. Effect of yarn linear density on moisture management characteristics of cotton/polypropylene double layer knitted fabrics. Ind. Text. 2015, 66, 123–130. Available online: https://www.scirp.org/reference/referencespapers?referenceid=3478261 (accessed on 24 March 2025).

- Krauledas, S.; Damalakas, V.; Abraitienė, A.; Stygienė, L. Double Layer Moisture Management Knitted Fabric. Patent LT6364B, 10 February 2017. Available online: https://patents.google.com/patent/LT6364B/en (accessed on 24 March 2025).

- Baltušnikaitė, J.; Abraitienė, A.; Stygienė, L.; Krauledas, S.; Rubežienė, V.; Varnaitė-Žuravliova, S. Investigation of moisture transport properties of knitted materials intended for warm underwear. Fibres Text. East. Eur. 2014, 4, 93–100. Available online: http://www.fibtex.lodz.pl/article1319.html (accessed on 24 March 2025).

- de Vasconcelos, B.F.; de Barros, M.M.L.; Borelli, C.; Gomes de Vasconcelos, F. Moisture Management Evaluation in Double Face Knitted Fabrics with Different Kind of Constructions and Fibers. J. Fash. Technol. Text. Eng. 2017, S3-009, 1–5. [Google Scholar] [CrossRef]

- Krithika, S.M.U.; Prakash, C.; Sampath, M.B.; Senthil Kumar, M. Thermal Comfort Properties of Bi-Layer Knitted Fabrics. Fibres Text. East. Eur. 2020, 28, 50. [Google Scholar] [CrossRef]

- Premalatha, C.; Kumar, M.R.; Udaya Krithika, S.M.; Prakash, C. Analysis of thermal comfort properties of tri-layer knitted fabrics. J. Nat. Fibers 2023, 20, 2164107. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Seshadri, S.A.; Devnani, G.; Sanjay, M.; Siengchin, S.; Maran, J.P.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment Friendly, Renewable and Sustainable Poly Lactic Acid (PLA) Based Natural Fiber Reinforced Composites—A Comprehensive Review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Farrington, D.W.; Lunt, J.; Davies, S.; Blackburn, R.S. Poly(lactic acid) fibers. In Biodegradable and Sustainable Fibres; Woodhead Publishing Ltd.: Cambridge, UK, 2006; ISBN 9781855739161. [Google Scholar]

- Yang, Y.; Zhang, M.; Ju, Z.; Tam, P.Y.; Hua, T.; Younas, M.W.; Kamrul, H.; Hu, H. Poly(Lactic Acid) Fibers, Yarns and Fabrics: Manufacturing, Properties and Applications. Text. Res. J. 2020, 91, 1641–1669. [Google Scholar] [CrossRef]

- Balla, E.; Daniilidis, V.; Karlioti, G.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Vlachopoulos, A.; Koumentakou, I.; Bikiaris, D.N. Poly(lactic Acid): A versatile biobased polymer for the future with multifunctional properties—From monomer synthesis, polymerization techniques and molecular weight increase to PLA applications. Polymers 2021, 13, 1822. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly (lactic acid)- mass production, processing, industrial applications, and end of life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Xu, S.; Chen, J.; Wang, B.; Yang, Y. Sustainable and hydrolysis-free dyeing process for polylactic acid using nonaqueous medium. ACS Sustain. Chem. Eng. 2015, 3, 1039–1046. [Google Scholar] [CrossRef]

- Mochizuki, M. Synthesis, properties and structure of polylactic acid fibres. In Handbook Textile Fibre Structure: Fundamentals and Manufactured Polymer Fibres; Woodhead Publishing Ltd.: Cambridge, UK, 2009; ISBN 9781845697310. [Google Scholar]

- Vandepitte, K.; Vasile, S.; Vermeire, S.; Vanderhoeven, M.; Van der Borght, W.; Latré, J.; De Raeve, A.; Troch, V. Hemp (Cannabis sativa L.) for high-value textile applications: The effective long fiber yield and quality of different hemp varieties, processed using industrial flax equipment. Ind. Crops Prod. 2020, 158, 112969. [Google Scholar] [CrossRef]

- Zimniewska, M. Hemp Fibre Properties and Processing Target Textile: A Review. Materials 2022, 15, 1901. [Google Scholar] [CrossRef]

- Gedik, G.; Avinc, O. Hemp fiber as a sustainable raw material source for textile industry: Can we use its potential for more eco-friendly production? In Sustainability in the Textile and Apparel Industries; Springer: Berlin/Heidelberg, Germany, 2020; pp. 87–109. Available online: https://link.springer.com/chapter/10.1007/978-3-030-38541-5_4 (accessed on 24 March 2025).

- Rheay, H.T.; Omondi, E.C.; Brewer, C.E. Research Review: Potential of Hemp (Cannabis sativa L.) for Paired Phytoremediation and Bioenergy Production. GCB Bioenergy 2020, 13, 525–536. [Google Scholar] [CrossRef]

- Averink, J. Global Water Footprint of Industrial Hemp Textile. Master’s Thesis, University of Twente, Enschede, The Netherlands, 2015. [Google Scholar]

- Visković, J.; Zheljazkov, V.D.; Sikora, V.; Noller, J.; Latković, D.; Ocamb, C.M.; Koren, A. Industrial Hemp (Cannabis sativa L.) Agronomy and Utilization: A Review. Agronomy 2023, 13, 931. [Google Scholar] [CrossRef]

- Which Fabric Is More Sustainable: Hemp or Linen. Available online: https://www.waterfrommars.com/blogs/blog/hemp-vs-linen-anything-you-can-do-i-can-do-better-i-can-do-anything-better-than-you (accessed on 23 February 2025).

- Nath, M.K. Benefits of Cultivating Industrial Hemp (Cannabis sativa ssp. sativa)—A Versatile Plant for a Sustainable Future. Chem. Proc. 2022, 10, 14. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0926669020308864?via%3Dihub (accessed on 24 March 2025). [CrossRef]

- Placido, D.F.; Lee, C.C. Potential of Industrial Hemp for Phytoremediation of Heavy Metals. Plants 2022, 11, 595. [Google Scholar] [CrossRef] [PubMed]

- Jonaitienė, V.; Jankauskienė, Z.; Stuogė, I. Hemp Cultivation Opportunities and Perspectives in Lithuania. Chapter, Part VI. In Natural Fibres: Advances in Science and Technology Towards Industrial Applications: From Science to Market. RILEM Bookseries 2016, 12, 407–414. [Google Scholar] [CrossRef]

- Hemp. Council of Fashion Designers of America (CFDA). Available online: https://cfda.com/resources/materials/detail/hemp (accessed on 23 February 2025).

- Rupasinghe, H.P.V.; Davis, A.; Kumar, S.K.; Murray, B.; Zheljazkov, V.D. Industrial Hemp (Cannabis sativa subsp. sativa) as an Emerging Source for Value-Added Functional Food Ingredients and Nutraceuticals. Molecules 2020, 25, 4078. [Google Scholar] [CrossRef]

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial Hemp Fibers: An Overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef]

- Manian, A.P.; Cordin, M.; Pham, T. Extraction of cellulose fibers from flax and hemp: A review. Cellulose 2021, 28, 8275–8294. [Google Scholar] [CrossRef]

- Dhondt, F.; Muthu, S.S. Hemp and Sustainability; Part of the book series: Sustainable Textiles: Production, Processing, Manufacturing & Chemistry; Springer: Berlin/Heidelberg, Germany, 2021; ISBN 9789811633331. [Google Scholar]

- Crini, G.; Lichtfouse, E.; Chanet, G.; Morin-Crini, N. Applications of Hemp in Textiles, Paper Industry, Insulation and Building Materials, Horticulture, Animal Nutrition, Food and Beverages, Nutraceuticals, Cosmetics and Hygiene, Medicine, Agrochemistry, Energy Production and Environment: A Review. Environ. Chem. Lett. 2020, 18, 1451–1476. [Google Scholar] [CrossRef]

- Ramachandran, M. Application of natural fibres in terry towel manufacturing. Inter. J. Text. Eng.Proces. 2015, 1, 87–91. [Google Scholar]

- Thygesen, A.; Daniel, G.; Lilholt, H.; Thomsen, A.B. Hemp Fiber Microstructure and Use of Fungal Defibration to Obtain Fibers for Composite Materials. J. Nat. Fibers 2006, 2, 19–37. [Google Scholar] [CrossRef]

- Hemp Vs Linen: Similarities And Differences. Available online: https://www.fibre2fashion.com/industry-article/9011/hemp-vs-linen-similarities-and-differences (accessed on 23 February 2025).

- Kumpikaitė, E.; Varnaitė-Žuravliova, S.; Tautkutė-Stankuvienė, I.; Laureckienė, G. Comparison of Mechanical and End-Use Properties of Grey and Dyed Cellulose and Cellulose/Protein Woven Fabrics. Materials 2021, 14, 2860. [Google Scholar] [CrossRef]

- Islam, S.; Hasan, B. An overview of the effects of water and moisture absorption on the performance of hemp fiber and its composites. SPE Polym. 2025, 6, e10167. [Google Scholar] [CrossRef]

- Hemp Fiber: Sustainable, Skin-Friendly and Durable/Manufactum. Available online: https://www.manufactum.com/hemp-fiber-c200989/ (accessed on 25 February 2025).

- Okyay, N.; Işık, F. Investigation of yarn and fabric performance properties of upholstery fabrics developed by using environmentally friendly sustainable hemp fiber at different ratios. In Proceedings of the 3rd International Congress of Innovative Textiles ICONTEX 2022, Online, 18–19 May 2022; Available online: https://icontex.meetinghand.net/en/ (accessed on 26 February 2025).

- Zimniewska, M.; Wladyka-Przybylak, M.; Mankowski, J. Cellulose Fibers, Bio-, and Nano- Polymer Composites. In Cellulosic Bast Fibers, their Structure and Properties suitable for Composite Applications; Chapter: Cellulosic Bast Fibres, their Structure and Properties suitable for Composite Applications; Springer: Berlin/Heidelberg, Germany, 2011; pp. 97–119. [Google Scholar]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibers: Can they replace glass in fiber reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Shah, J.N.; Padhye, R.; Pachauri, R.D. Studies on UV protection and antimicrobial functionality of textiles. J. Nat. Fibers 2022, 19, 6810–6821. [Google Scholar] [CrossRef]

- Ahmed, A.T.M.F.; Islam, M.Z.; Mahmud, M.S.; Sarker, M.E.; Islam, M.R. Hemp as a Potential Raw Material toward a Sustainable World: A Review. Heliyon 2022, 8, e08753. [Google Scholar] [CrossRef] [PubMed]

- Gedik, G.; Avinc, O. Bleaching of hemp (Cannabis sativa L.) fibers with peracetic acid for textiles industry purposes. Fibers Polym. 2018, 19, 82–93. [Google Scholar] [CrossRef]

- Lukesova, H.; Holst, B. Is cross-section shape a distinct feature in plant fibre identification? Archaeometry 2020, 63, 216–226. [Google Scholar] [CrossRef]

- Stanković, S.B.; Novaković, M.; Popović, D.M.; Poparić, G.B.; Bizjak, M. Novel engineering approach to optimization of thermal comfort properties of hemp containing textiles. J. Text. Inst. 2019, 110, 1271–1279. [Google Scholar] [CrossRef]

- EN ISO 4921; Knitting—Basic concepts—Vocabulary. ISO: Geneva, Switzerland, 2001.

- EN 14971:2006; Textiles—Knitted Fabrics—Determination of Number of Stitches Per Unit Length and Unit Area. British Standards Institution (BSI): London, UK, 2006.

- EN 12127:1999; Textiles—Fabrics—Determination of Mass Per Unit Area Using Small Samples. British Standards Institution (BSI): London, UK, 1999.

- Abramavičiūtė, J.; Mikučionienė, D.; Čiukas, R. Structure properties of knits from natural yarns and their combination with elastane and polyamide threads. Mater. Sci. 2011, 17, 43–46. [Google Scholar] [CrossRef]

- Au, K.F. Advances in Knitting Technology; Woodhead Publishing Limited: Cambridge, UK, 2011; 336p. [Google Scholar]

- AATCC 195:2017; Test Method for Liquid Moisture Management Properties of Textile Fabrics. American Association of Textile Chemists and Colorists (AATCC): Charlotte, NC, USA, 2020.

- EN ISO 6330; Textiles – Domestic washing and drying procedures for textile testing. ISO: Geneva, Switzerland, 2021.

- EN ISO 11092:2014; Textiles—Physiological Effects—Measurement of Thermal and Water-Vapour Resistance Under Steady-State Conditions (Sweating Guarded-Hotplate Test). ISO: Geneva, Switzerland, 2014.

- EN ISO 9237:1995; Textiles. Determination of the Permeability of Fabrics to Air. ISO: Geneva, Switzerland, 1995.

- Kanakaraj, P.; Dasaradan, B.S.; Ramachandran, R. The influence of double layer knit fabric structures on air and water vapor permeability. J. Text. Appar. Technol. Manag. 2013, 8, 1–9. Available online: https://www.researchgate.net/publication/287564218_The_influence_of_double_layer_knit_fabric_structures_on_air_and_water_vapor_permeability (accessed on 24 March 2025).

- Bivainytė, A.; Mikučionienė, D. Investigation on the air and water vapour permeability of double-layered weft knitted fabrics. Fibres Text. East. Eur. 2011, 3, 69–73.Available. Available online: http://www.fibtex.lodz.pl/article526.html (accessed on 24 March 2025).

- Toma, D. Evaluation of the comfort properties of functional knitted fabrics for people with special needs. Ind. Textila. 2023, 74, 753–759. [Google Scholar] [CrossRef]

| Fabric No. | Type of Separate Layers | Type of Yarns, Linear Density, tex | Arrangement of Yarns in Repeat of Knitted Fabric Pattern: Pattern Feeds (See Figure 3) | Content of Yarn in the Knitted Fabric, % | Number of Stitches per Unit Length and Unit Area of the Knitted Fabric, cm−1 | Mean Loop Length, lm, mm | Tightness Factor TF, tex1/2/mm | Mass per Unit Area of the Knitted Fabric, g/m2 | |

|---|---|---|---|---|---|---|---|---|---|

| Courses, Pv | Wales, Ph | ||||||||

| 1 | I—inner II—middle III—outer | PLA spun yarns, 19.7 PLA textured yarns, 16.7/36f HA spun yarns (raw white + dyed) 19.2 | E2, E5 E3, E6 E1, E4 | 35 29 36 | 11 | 13 | 4.337 | 1.719 | 345 |

| 2 | I—inner II—middle III—outer | PLA spun yarns, 19.7 PLA textured yarns, 16.7/36f HA spun yarns (raw white) 27.8 + Hemp (HA) spun yarns (dyed) 19.2 | E2, E5 E3, E6 E1, E4 | 32 28 40 | 11 | 13 | 4.493 | 1.745 | 380 |

| 3 | I—inner II—middle III—outer | PLA spun yarns, 19.7 PLA textured yarns, 16.7/36f HA spun yarns (dyed) 27.8 | E2, E5 E3, E6 E1, E4 | 29 27 44 | 11 | 13 | 4.573 | 1.752 | 420 |

| 4 | I—inner II—middle III—outer | PLA spun yarns, 19.7 PLA textured yarns, 16.7/36f Twisted HA spun yarns (raw white + dyed), 19.2 x2 | E2, E5 E3, E6 E1, E4 | 24 21 55 | 12 | 12 | 4.499 | 1.922 | 485 |

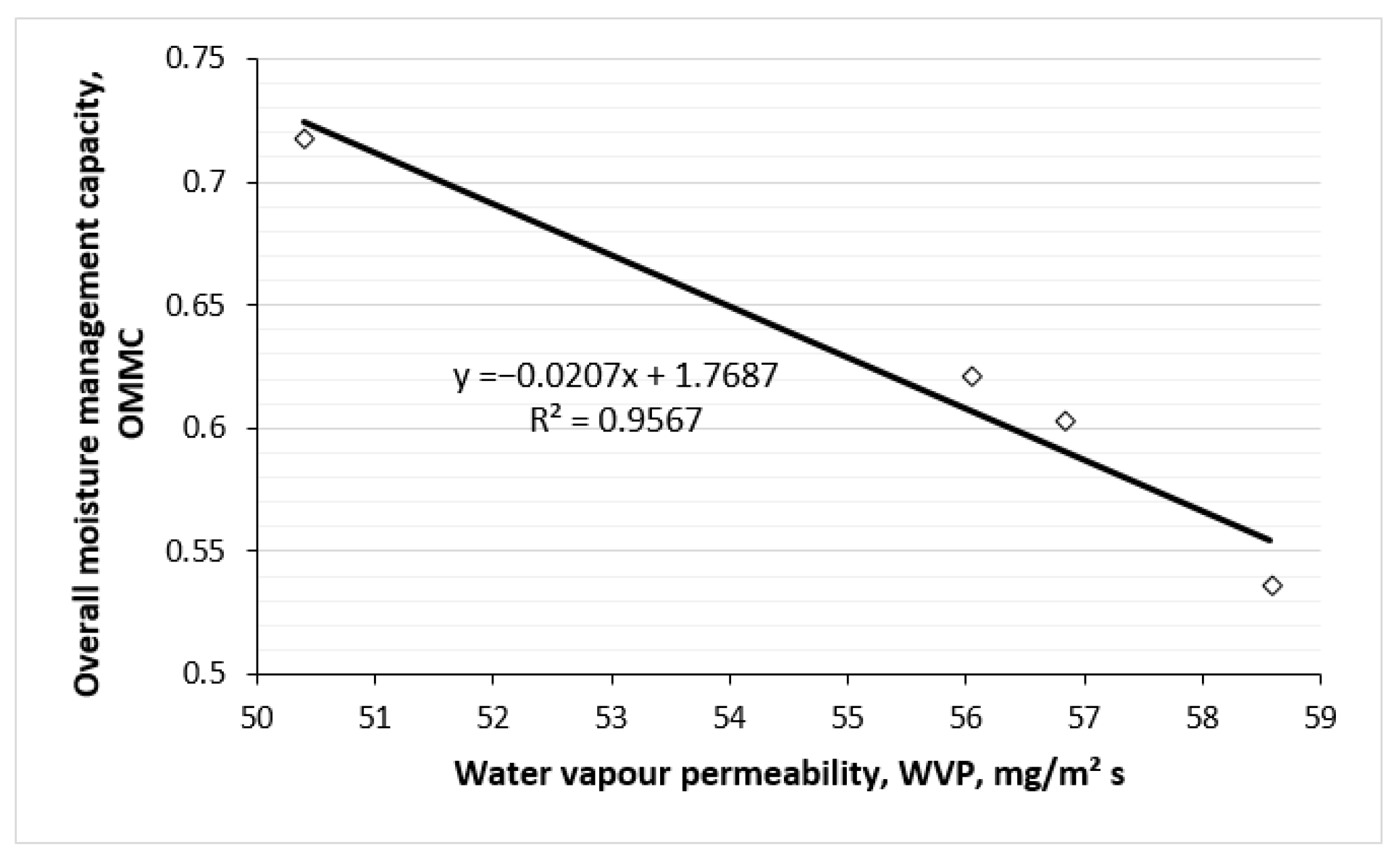

| Fabric No. | Wetting Time (Top), WTT, s Rate-Index | Wetting Time (Bottom), WTB, s Rate-Index | Absorption Rate (Top), ART, %/s Rate-Index | Absorption Rate (Bottom), ARB, %/s Rate-Index | Max Wetted Radius (Top), MWRT, mm Rate-Index | Max Wetted Radius (Bottom), MWRB, mm Rate-Index | Spreading Speed (Top), SST, mm/s Rate-Index | Spreading Speed (Bottom), SSB, mm/s Rate-Index | Accumulative One-Way Transport Capability, AOTC, %, Rate-Index | Overall Moisture Management Capacity, OMMC Rate-Index |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 12.66 Medium—3 | 7.00 Medium—3 | 24.76 Slow—2 | 49.14 Medium—3 | 10 Small—2 | 16.67 Medium—3 | 0.83 Very slow—1 | 1.90 Slow—2 | 267.08 Very good—4 | 0.5359 Good—3 |

| 2 | 16.11 Medium—3 | 5.20 Medium—3 | 10.30 Slow—2 | 23.03 Slow—2 | 6.67 No wetting—1 | 15 Medium—3 | 0.44 Very slow—1 | 2.01 Medium—3 | 385.29 Very good—4 | 0.6026 Very good—4 |

| 3 | 7.18 Medium—3 | 2.94 Very fast—5 | 22.68 Slow—2 | 40.79 Medium—3 | 10 Small—2 | 16.67 Medium—3 | 1.34 Slow—2 | 3.08 Fast—4 | 275.79 Very good—4 | 0.6210 Very good—4 |

| 4 | 6.94 Medium—3 | 2.69 Very fast—5 | 23.5 8 Slow—2 | 45.97 Medium—3 | 11.67 Small—2 | 16.67 Medium—3 | 1.66 Slow—2 | 3.96 Fast—4 | 306.75 Very good—4 | 0.7175 Very good—4 |

| Fabric No. | WTT, s | WTB, s | ART, %/s | ARB, %/s | MWRT, mm | MWRB, mm | SST, mm/s | SSB, mm/s | AOTI, % | OMMC | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | average | 12.66 | 7.00 | 24.76 | 49.14 | 10 | 16.67 | 0.83 | 1.90 | 267.08 | 0.5359 |

| max | 15.09 | 7.88 | 37.35 | 53.87 | 10 | 20 | 1.01 | 2.21 | 339.25 | 0.6301 | |

| min | 9.75 | 5.72 | 15.61 | 43.96 | 10 | 15 | 0.70 | 1.58 | 187.62 | 0.4588 | |

| SD | 2.70 | 1.14 | 11.27 | 4.97 | 0 | 2.89 | 0.16 | 0.32 | 76.07 | 0.0862 | |

| CV | 0.21 | 0.16 | 0.46 | 0.10 | 0 | 0.17 | 0.19 | 0.16 | 0.28 | 0.16 | |

| CI | ±3.06 | ±1.29 | ±12.75 | ±5.63 | ±0 | ±3.27 | ±0.18 | ±0.36 | ±86.09 | ±0.0976 | |

| 2 | average | 16.11 | 5.20 | 10.30 | 23.03 | 6.67 | 15 | 0.44 | 2.01 | 385.29 | 0.6026 |

| max | 18.05 | 7.64 | 10.83 | 25.14 | 10 | 15 | 0.73 | 2.37 | 403.65 | 0.6529 | |

| min | 14.39 | 3.44 | 9.73 | 20.07 | 5 | 15 | 0.27 | 1.44 | 361.69 | 0.5218 | |

| SD | 1.84 | 2.18 | 0.55 | 2,64 | 2.89 | 0 | 0.25 | 0.50 | 21.47 | 0.0706 | |

| CV | 0.11 | 0.42 | 0.05 | 0.11 | 0.43 | 0 | 0.58 | 0.25 | 0.06 | 0.1172 | |

| CI | ±2.08 | ±2.47 | ±0.63 | ±2.99 | ±3.27 | ±0 | ±0.29 | ±0.57 | ±24.29 | ±0.0799 | |

| 3 | average | 7.18 | 2.94 | 22.68 | 40.79 | 10 | 16.67 | 1.34 | 3.08 | 275.79 | 0.621 |

| max | 8.47 | 3.06 | 28.38 | 42.38 | 10 | 20 | 1.47 | 3.25 | 335.82 | 0.7058 | |

| min | 6.09 | 2.73 | 19.48 | 38.51 | 10 | 15 | 1.21 | 2.87 | 237.73 | 0.5551 | |

| SD | 1.20 | 0.18 | 4.95 | 2.03 | 0 | 2.89 | 0.13 | 0.19 | 52.61 | 0.0771 | |

| CV | 0.17 | 0.06 | 0.22 | 0.05 | 0 | 0.17 | 0.10 | 0.06 | 0.19 | 0.12 | |

| CI | ±1.33 | ±0.20 | ±5.61 | ±2.29 | ±0 | ±3.27 | ±0.15 | ±0.21 | ±59.53 | ±0.0872 | |

| 4 | average | 6.94 | 2.69 | 23.58 | 45.97 | 11,677 | 16.67 | 1.66 | 3.96 | 306.75 | 0.7175 |

| max | 8.16 | 2.83 | 30.00 | 48.54 | 15 | 20 | 2.44 | 4.92 | 321.40 | 0.7697 | |

| min | 5.16 | 3.63 | 16.90 | 41.71 | 10 | 15 | 1.16 | 3.09 | 284.50 | 0.6672 | |

| SD | 1.58 | 0.12 | 6.55 | 3.72 | 2.89 | 2.89 | 0.68 | 0.92 | 19.59 | 0.05 | |

| CV | 0.23 | 0.04 | 0.28 | 0.08 | 0.25 | 0.17 | 0.41 | 0.23 | 0.06 | 0.0715 | |

| CI | ±1.79 | ±0.13 | ±7.42 | ±4.21 | ±3.27 | ±3.27 | ±0.77 | ±1.04 | ±22.17 | ±0.06 |

| Fabric No. | WVP, mg/m2 s | Air Permeability, mm/s | Rct, m2K/W | |

|---|---|---|---|---|

| 1 | average | 58.57 | 819.1 | 0.024 |

| max | 62.78 | 875.6 | 0.025 | |

| min | 54.36 | 762.6 | 0.023 | |

| SD | 4.21 | 56.5 | 0.001 | |

| CV | 0.072 | 0.068 | 0.042 | |

| CI | ±4.76 | ±63.94 | ±0.001 | |

| 2 | average | 56.83 | 796.4 | 0.034 |

| max | 61.06 | 851.6 | 0.035 | |

| min | 52.60 | 741.2 | 0.033 | |

| SD | 4.23 | 55.2 | 0.029 | |

| CV | 0.074 | 0.069 | 0.029 | |

| CI | ±4.79 | ±62.47 | ±0.001 | |

| 3 | average | 56.04 | 686.2 | 0.038 |

| max | 60.25 | 735.9 | 0.039 | |

| min | 51.83 | 636.5 | 0.037 | |

| SD | 4.21 | 49.7 | 0.001 | |

| CV | 0.075 | 0.072 | 0.026 | |

| CI | ±4.764 | ±56.24 | ±0.001 | |

| 4 | average | 50.39 | 571.7 | 0.040 |

| max | 54.20 | 611.8 | 0.042 | |

| min | 46.58 | 531.6 | 0.038 | |

| SD | 3.81 | 40.1 | 0.002 | |

| CV | 0.076 | 0.070 | 0.050 | |

| CI | ±4.31 | ±45.38 | ±0.002 |

| Fabric No. | Moisture Management Parameters | Water Vapour Permeability, WVP, mg/m2 s | Thermal Resistance (Rct), m2K/W | Air Permeability, mm/s | Performance Level (CEN/TR 16422) | ||||

|---|---|---|---|---|---|---|---|---|---|

| One-Way Transport Capability, AOTC, %, Rate-Index | Overall Moisture Management Capability (OMMC) | For Skin Contact Materials | For Second (Intermediate) Layer Materials | ||||||

| According to Rct Value | According to OMMC and Their Index Value | According to Rct Value | According to OMMC and Their Index Value | ||||||

| 1 | 267.08 Very good—index 4 | 0.5359 Good—index 3 | 58.57 | 0.024 | 819.1 | Warm climate—B (good); Cold climate C (medium) | Warm/cold climate—B (good) | Warm climate—B (good); Cold climate C (medium) | Warm/cold climate—A (very good) |

| 2 | 385.29 Very good—index 4 | 0.6026 Very good—index 4 | 56.83 | 0.027 | 796.4 | Warm/cold climate—C (medium) | Warm/cold climate—A (very good) | Warm climate—B (good); Cold climate C (medium) | Warm/cold climate—A (very good) |

| 3 | 275.79 Very good—index 4 | 0.621 Very good—index 4 | 56.04 | 0.038 | 586.2 | Warm/cold climate—C (medium) | Warm/cold climate—A (very good) | Warm/cold climate—C (medium) | Warm/cold climate—A (very good) |

| 4 | 306.75 Very good index—4 | 0.7175 Very good—index 4 | 50.39 | 0.040 | 571.7 | Warm/cold climate—C (medium) | Warm/cold climate—A (very good) | Warm/cold climate—C (medium) | Warm/cold climate—A (very good) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Padleckienė, I.; Stygienė, L.; Krauledas, S.; Abraitienė, A.; Sankauskaitė, A. Thermal Comfort Properties of Biodegradable Hemp and Polylactide Fiber Knitted Fabrics. Polymers 2025, 17, 903. https://doi.org/10.3390/polym17070903

Padleckienė I, Stygienė L, Krauledas S, Abraitienė A, Sankauskaitė A. Thermal Comfort Properties of Biodegradable Hemp and Polylactide Fiber Knitted Fabrics. Polymers. 2025; 17(7):903. https://doi.org/10.3390/polym17070903

Chicago/Turabian StylePadleckienė, Ingrida, Laimutė Stygienė, Sigitas Krauledas, Aušra Abraitienė, and Audronė Sankauskaitė. 2025. "Thermal Comfort Properties of Biodegradable Hemp and Polylactide Fiber Knitted Fabrics" Polymers 17, no. 7: 903. https://doi.org/10.3390/polym17070903

APA StylePadleckienė, I., Stygienė, L., Krauledas, S., Abraitienė, A., & Sankauskaitė, A. (2025). Thermal Comfort Properties of Biodegradable Hemp and Polylactide Fiber Knitted Fabrics. Polymers, 17(7), 903. https://doi.org/10.3390/polym17070903