Biodegradable Electret Filters Based on Beeswax-Modified Fibers: A Novel Production Strategy

Abstract

1. Introduction

2. Materials and Methods

2.1. Solution-Blowing Spinning (SBS)

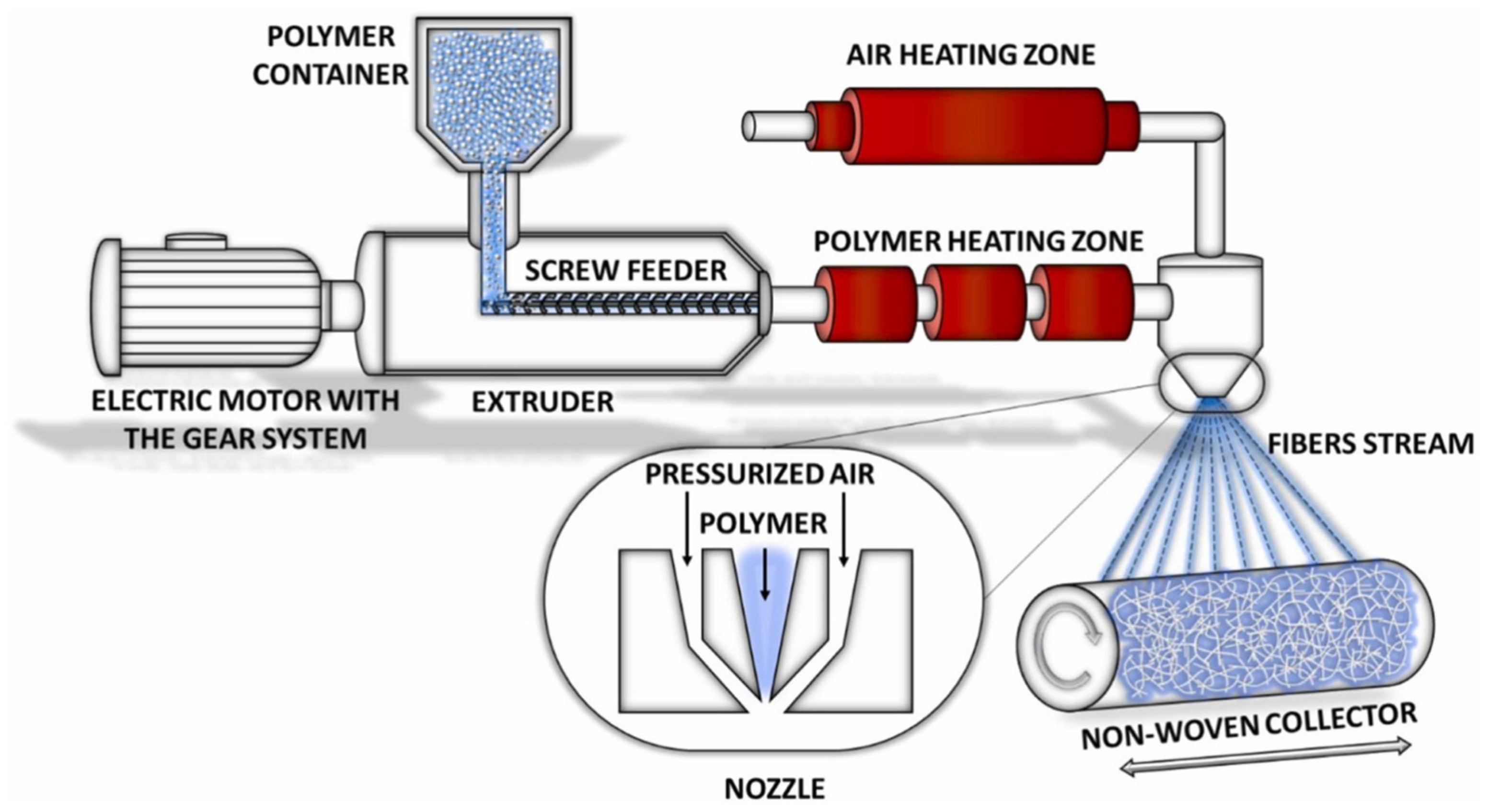

2.2. Melt-Blowing (MB)

2.3. Combining Solution-Blowing and Melt-Blowing

2.4. Fiber Characterization

2.5. Filtration Efficiency and Pressure Drop

2.6. Quality Factor

3. Results and Discussion

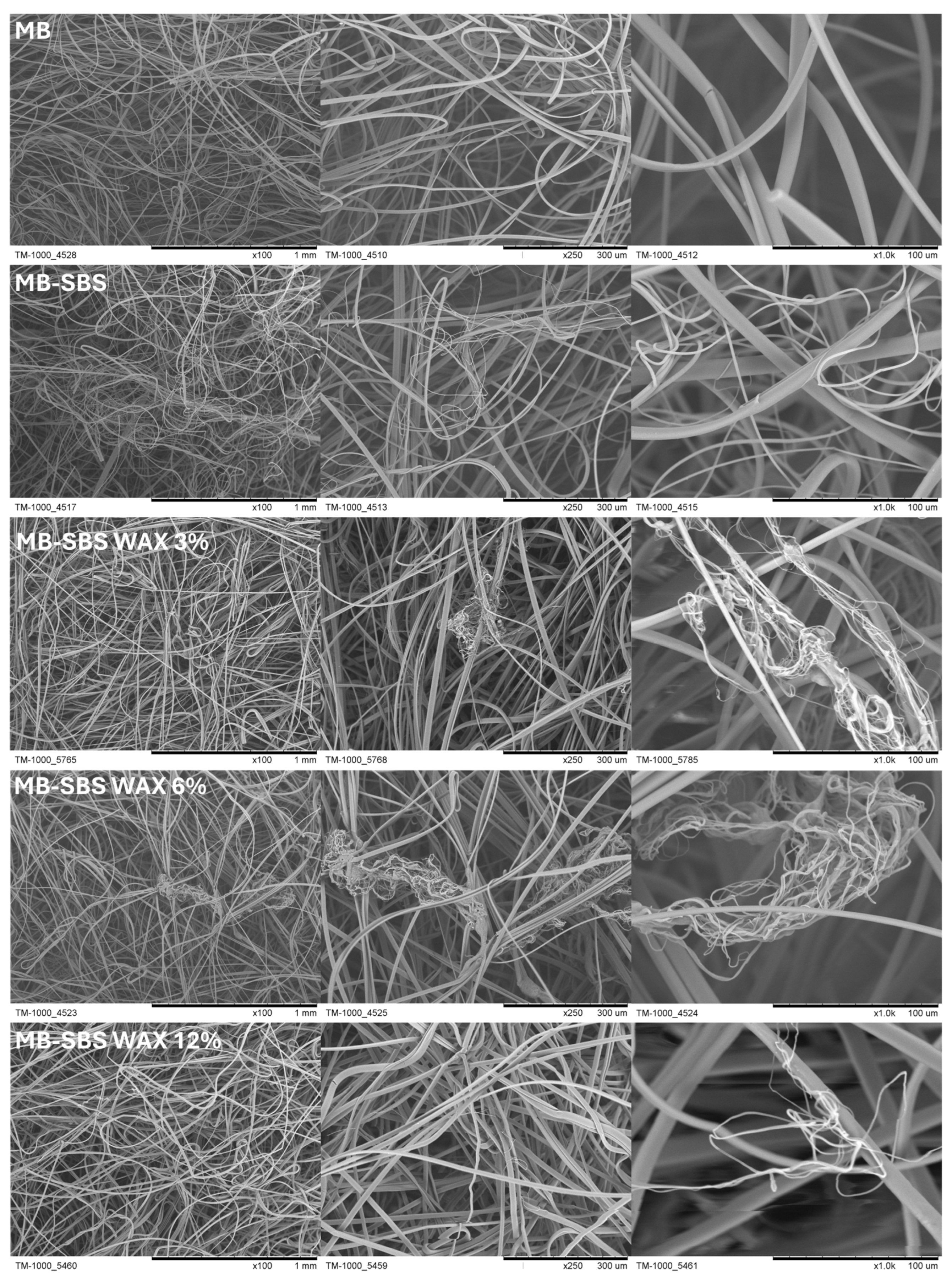

3.1. Morphology of Fibers

3.2. FTIR Analysis

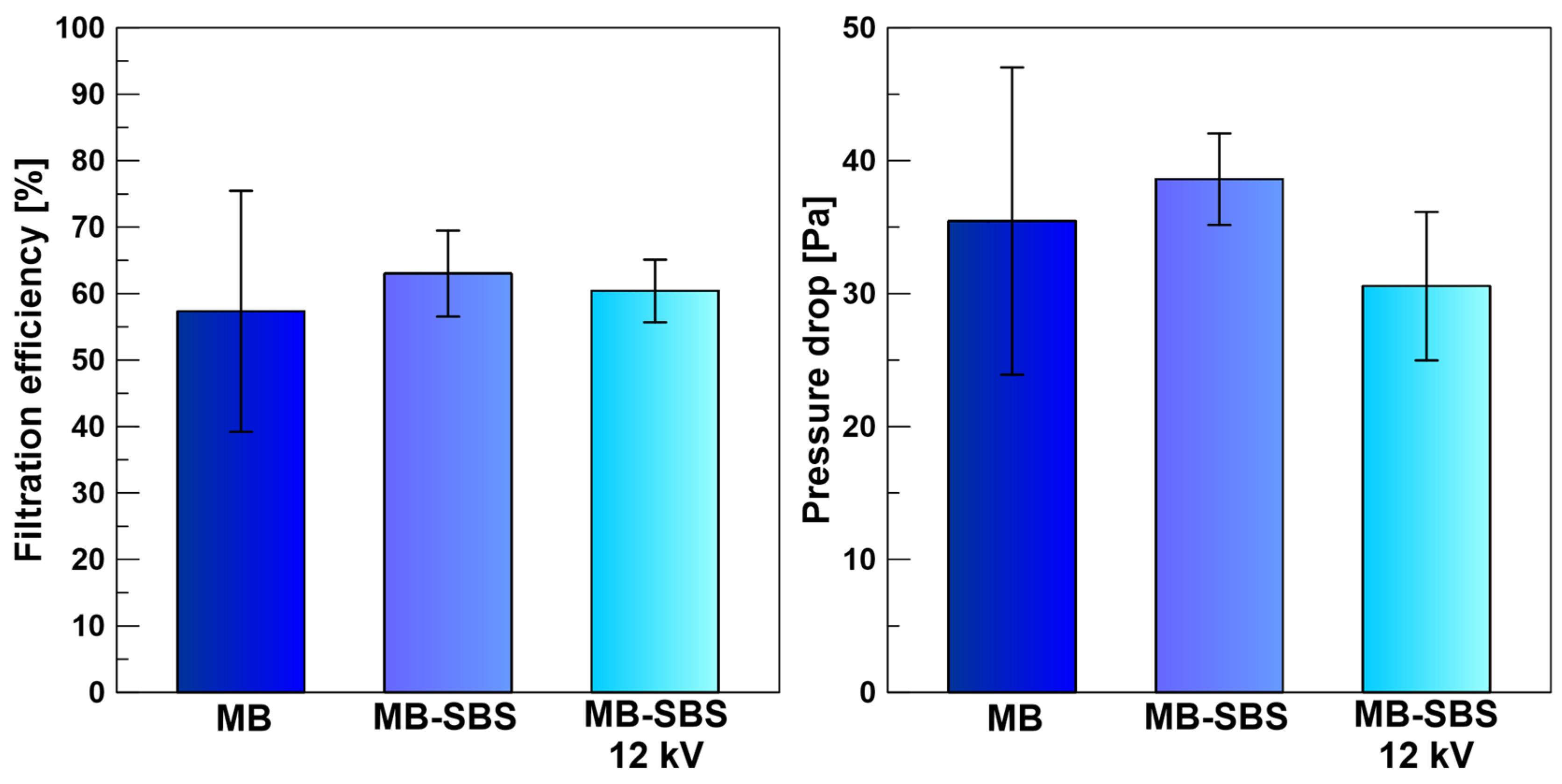

3.3. Filtration Efficiency

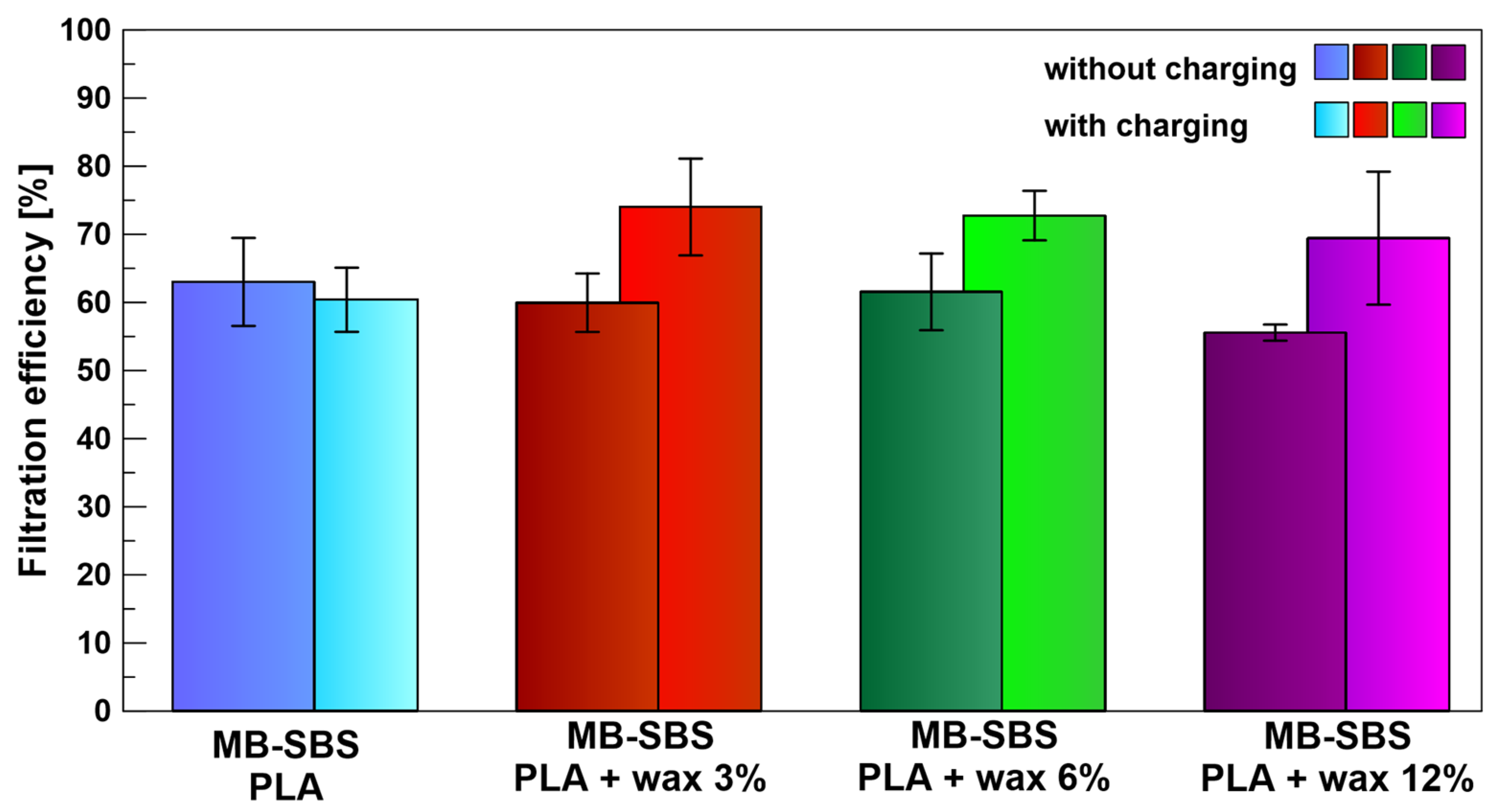

3.4. The Influence of Beeswax Concentration on Filtration Efficiency

3.5. The Influence of the Voltage of Corona Charging on Filtration Efficiency

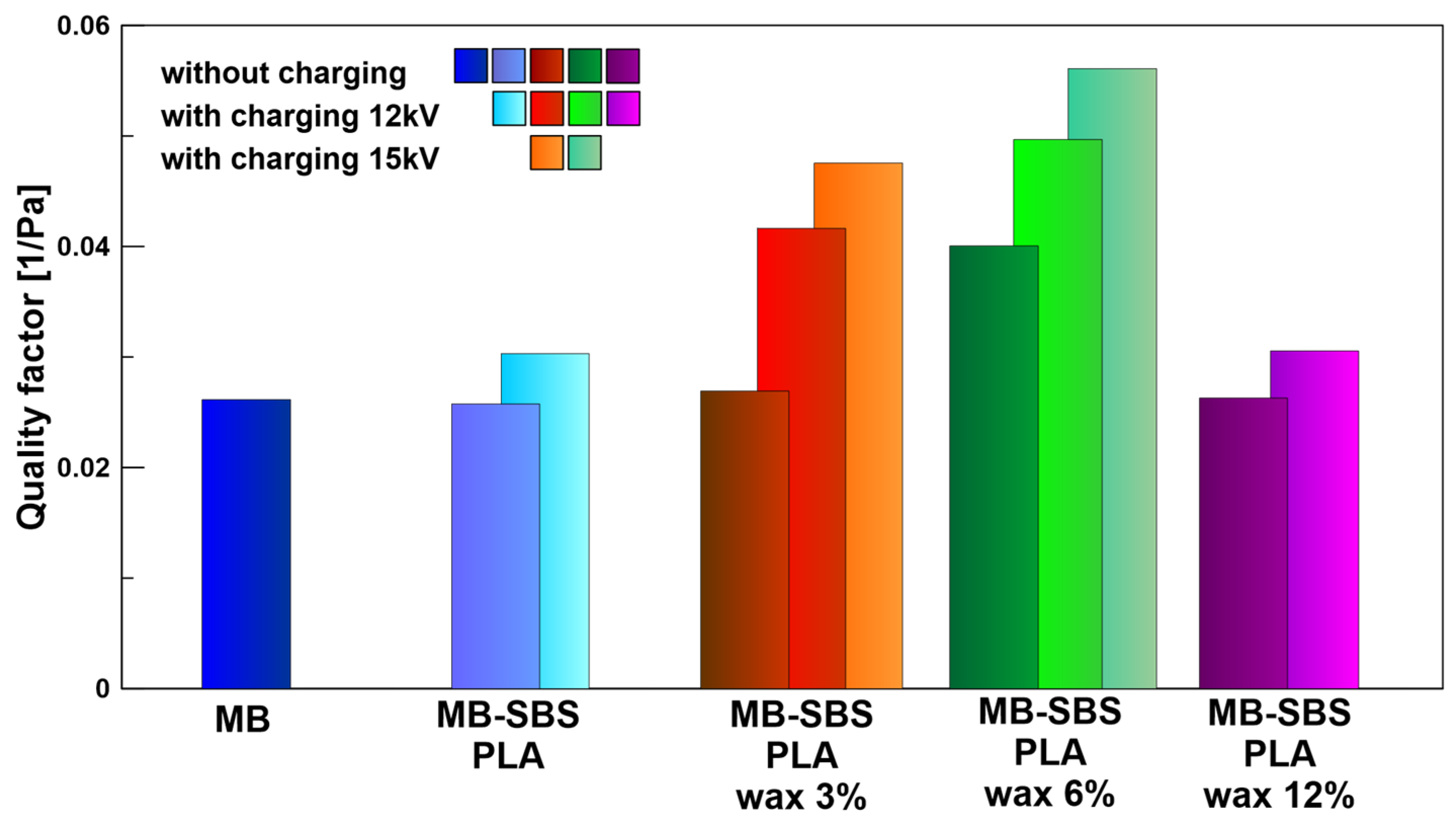

3.6. Quality Factor

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ji, X.; Huang, J.; Teng, L.; Li, S.; Li, X.; Cai, W.; Chen, Z.; Lai, Y. Advances in Particulate Matter Filtration: Materials, Performance, and Application. Green Energy Environ. 2023, 8, 673–697. [Google Scholar] [CrossRef]

- Atalie, D.; Chen, Z.-X.; Li, H.; Liang, C.-G.; Gao, M.-C.; Cheng, X.-X.; Ma, P.-C. Eco-Friendly and Highly Efficient PM0.3 Air Filter Made from Nonwoven Basalt Fiber and Electrospun Nanocellulose Fiber. J. Hazard. Mater. 2024, 478, 135608. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Li, Q.; Young, T.M.; Harper, D.P.; Wang, S. A Novel Method for Fabricating an Electrospun Poly(Vinyl Alcohol)/Cellulose Nanocrystals Composite Nanofibrous Filter with Low Air Resistance for High-Efficiency Filtration of Particulate Matter. ACS Sustain. Chem. Eng. 2019, 7, 8706–8714. [Google Scholar] [CrossRef]

- Fan, X.; Wang, Y.; Zheng, M.; Dunne, F.; Liu, T.; Fu, X.; Kong, L.; Pan, S.; Zhong, W.-H. Morphology Engineering of Protein Fabrics for Advanced and Sustainable Filtration. J. Mater. Chem. A 2018, 6, 21585–21595. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, Z.-G.; Yan, X.; Wang, X.-X.; Zhao, H.; Guo, J.; Feng, J.-Y.; Long, Y.-Z. Chitosan Nanostructures by in Situ Electrospinning for High-Efficiency PM2.5 Capture. Nanoscale 2017, 9, 4154–4161. [Google Scholar] [CrossRef] [PubMed]

- Kalouta, K.; Stie, M.B.; Sun, X.; Foderà, V.; Vetri, V. Eco-Friendly Electrospun Nanofibers Based on Plant Proteins as Tunable and Sustainable Biomaterials. ACS Sustain. Chem. Eng. 2024, 12, 10118–10129. [Google Scholar] [CrossRef]

- Penconek, A.; Kasak, D.; Moskal, A. Soy Protein Nanofibers Obtained by Solution Blow Spinning. Processes 2023, 11, 2310. [Google Scholar] [CrossRef]

- Kolbasov, A.; Sinha-Ray, S.; Joijode, A.; Hassan, M.A.; Brown, D.; Maze, B.; Pourdeyhimi, B.; Yarin, A.L. Industrial-Scale Solution Blowing of Soy Protein Nanofibers. Ind. Eng. Chem. Res. 2016, 55, 323–333. [Google Scholar] [CrossRef]

- Zhang, T.; Tian, H.; Yin, X.; Li, Z.; Zhang, X.; Yang, J.; Zhu, L. Solution Blow Spinning of Polylactic Acid to Prepare Fibrous Oil Adsorbents Through Morphology Optimization with Response Surface Methodology. J. Polym. Environ. 2020, 28, 812–825. [Google Scholar] [CrossRef]

- Cerqueira, G.R.C.; Gomes, D.S.; Victor, R.S.; Figueiredo, L.R.F.; Medeiros, E.S.; Neves, G.A.; Menezes, R.R.; Silva, S.M.L. Development of PVA/Chitosan Nanofibers by a Green Route Using Solution Blow Spinning. J. Polym. Environ. 2024, 32, 1489–1499. [Google Scholar] [CrossRef]

- Czarnecka, K.; Wojasiński, M.; Ciach, T.; Sajkiewicz, P. Solution Blow Spinning of Polycaprolactone—Rheological Determination of Spinnability and the Effect of Processing Conditions on Fiber Diameter and Alignment. Materials 2021, 14, 1463. [Google Scholar] [CrossRef]

- Penconek, A.; Jackiewicz-Zagórska, A.; Przekop, R.; Moskal, A. Fibrous Structures Produced Using the Solution Blow-Spinning Technique for Advanced Air Filtration Process. Materials 2023, 16, 7118. [Google Scholar] [CrossRef] [PubMed]

- Przekop, R.; Gradoń, L. Deposition and Filtration of Nanoparticles in the Composites of Nano- and Microsized Fibers. Aerosol Sci. Technol. 2008, 42, 483–493. [Google Scholar] [CrossRef]

- Thakur, R.; Das, D.; Das, A. Electret Air Filters. Sep. Purif. Rev. 2013, 42, 87–129. [Google Scholar] [CrossRef]

- Myers, D.L.; Arnold, B.D. Electret Media for HVAC Filtration Applications. Int. Nonwovens J. 2003, 12(4), 43–54. [Google Scholar] [CrossRef]

- Tien, C.-Y.; Chen, J.-P.; Li, S.; Li, Z.; Zheng, Y.-M.; Peng, A.S.; Zhou, F.; Tsai, C.-J.; Chen, S.-C. Experimental and Theoretical Analysis of Loading Characteristics of Different Electret Media with Various Properties toward the Design of Ideal Depth Filtration for Nanoparticles and Fine Particles. Sep. Purif. Technol. 2020, 233, 116002. [Google Scholar] [CrossRef]

- Brown, R.C.; Wake, D.; Gray, R.; Blackford, D.B.; Bostock, G.J. Effect of Industrial Aerosols on the Performance of Electrically Charged Filter Material. Ann. Occup. Hyg. 1988, 32, 271–294. [Google Scholar] [CrossRef]

- Kilic, A.; Shim, E.; Pourdeyhimi, B. Electrostatic Capture Efficiency Enhancement of Polypropylene Electret Filters with Barium Titanate. Aerosol Sci. Technol. 2015, 49, 666–673. [Google Scholar] [CrossRef]

- Guliakova, A.A.; Galikhanov, M.F.; Galeeva, L.R.; Gilfanova, S.V.; Fang, P. Investigation of Electret and Filtering Properties of Polypropylene-Based Nonwoven Fabrics and Its Composites with 2 Vol% of Silicon Dioxide Inclusions. IEEE Trans. Dielect. Electr. Insul. 2020, 27, 1656–1661. [Google Scholar] [CrossRef]

- Gutmann, F. The Electret. Rev. Mod. Phys. 1948, 20, 457–472. [Google Scholar] [CrossRef]

- Fratini, F.; Cilia, G.; Turchi, B.; Felicioli, A. Beeswax: A Minireview of Its Antimicrobial Activity and Its Application in Medicine. Asian Pac. J. Trop. Med. 2016, 9, 839–843. [Google Scholar] [CrossRef] [PubMed]

- Penconek, A.; Werner, Ł.; Moskal, A. Combining Solution-Blowing and Melt-Blowing Techniques to Produce an Efficient Non-Woven Filter. Processes 2024, 12, 857. [Google Scholar] [CrossRef]

- Werner, Ł.; Nowak, B.; Jackiewicz-Zagórska, A.; Gołofit-Szymczak, M.; Górny, R.L. Functionalized Zinc Oxide Nanorods—Polypropylene Nonwoven Composite with High Biological and Photocatalytic Activity. J. Environ. Chem. Eng. 2023, 11, 111079. [Google Scholar] [CrossRef]

- Lee, J.; Lee, K.; Park, H.; Kim, J. Environmental Storage Conditions Influencing the Filtration Behavior of Electret Filters with Repeated Use. J. Ind. Text. 2022, 52, 15280837221119411. [Google Scholar] [CrossRef]

- Lee, J.; Kim, J. Material Properties Influencing the Charge Decay of Electret Filters and Their Impact on Filtration Performance. Polymers 2020, 12, 721. [Google Scholar] [CrossRef]

- Chmielewska, D.; Werner, Ł.; Gryczka, U.; Migdał, W. Effect of Electron Beam Irradiation on Filtering Facepiece Respirators Integrity and Filtering Efficiency. Nukleonika 2022, 67, 23–33. [Google Scholar] [CrossRef]

- Viscusi, D.J.; Bergman, M.; Sinkule, E.; Shaffer, R.E. Evaluation of the Filtration Performance of 21 N95 Filtering Face Piece Respirators after Prolonged Storage. Am. J. Infect. Control 2009, 37, 381–386. [Google Scholar] [CrossRef] [PubMed]

- Chieng, B.; Ibrahim, N.; Yunus, W.; Hussein, M. Poly(Lactic Acid)/Poly(Ethylene Glycol) Polymer Nanocomposites: Effects of Graphene Nanoplatelets. Polymers 2013, 6, 93–104. [Google Scholar] [CrossRef]

- Dobrosielska, M.; Dobrucka, R.; Kozera, P.; Brząkalski, D.; Gabriel, E.; Głowacka, J.; Jałbrzykowski, M.; Kurzydłowski, K.J.; Przekop, R.E. Beeswax as a Natural Alternative to Synthetic Waxes for Fabrication of PLA/Diatomaceous Earth Composites. Sci. Rep. 2023, 13, 1161. [Google Scholar] [CrossRef]

- Badia, J.D.; Reig-Rodrigo, P.; Teruel-Juanes, R.; Kittikorn, T.; Strömberg, E.; Ek, M.; Karlsson, S.; Ribes-Greus, A. Effect of Sisal and Hydrothermal Ageing on the Dielectric Behaviour of Polylactide/Sisal Biocomposites. Compos. Sci. Technol. 2017, 149, 1–10. [Google Scholar] [CrossRef]

- Penconek, A.; Kilarski, M.; Soczewka, A.; Wojasiński, M.; Moskal, A. Production of Nanofibers by Blow Spinning from Polylactide Containing Propolis and Beeswax. Fibers 2024, 12, 8. [Google Scholar] [CrossRef]

- Oh, Y.-W.; Jeon, K.-J.; Jung, A.-I.; Jung, Y.-W. A Simulation Study on the Collection of Submicron Particles in a Unipolar Charged Fiber. Aerosol Sci. Technol. 2002, 36, 573–582. [Google Scholar] [CrossRef]

- Lundgren, D.A.; Whitby, K.T. Effect of Particle Electrostatic Charge on Filtration by Fibrous Filters. Ind. Eng. Chem. Proc. Des. Dev. 1965, 4, 345–349. [Google Scholar] [CrossRef]

- Kerner, M.; Schmidt, K.; Schumacher, S.; Puderbach, V.; Asbach, C.; Antonyuk, S. Evaluation of Electrostatic Properties of Electret Filters for Aerosol Deposition. Sep. Purif. Technol. 2020, 239, 116548. [Google Scholar] [CrossRef]

- Chen, C.; Chen, G.; Zhang, J.; Lin, Y.; Yu, Y.; Gao, X.; Zhu, L. Study on Corona Charging Characteristic of Melt-Blown Polypropylene Electret Fabrics. J. Electrost. 2023, 121, 103782. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, N.; Zeng, Q.; Liu, J.; Zhang, X.; Ge, M.; Zhang, W.; Li, S.; Fu, Y.; Zhang, Y. Design of Polypropylene Electret Melt Blown Nonwovens with Superior Filtration Efficiency Stability through Thermally Stimulated Charging. Polymers 2020, 12, 2341. [Google Scholar] [CrossRef]

- Hinds, W.C.; Zhu, Y. Aerosol Technology: Properties, Behavior, and Measurement of Airborne Particles, 3rd ed.; Wiley: Hoboken, NJ, USA, 2022. [Google Scholar]

- Woon-Fong Leung, W. Fundamentals of Gas Filtration of Submicron Aerosols and Nanoaerosols. In Nanofiber Filter Technologies for Filtration of Submicron Aerosols and Nanoaerosols; Elsevier: Amsterdam, The Netherlands, 2022; pp. 45–88. [Google Scholar] [CrossRef]

- Zhang, W.; He, Z.; Han, Y.; Jiang, Q.; Zhan, C.; Zhang, K.; Li, Z.; Zhang, R. Structural Design and Environmental Applications of Electrospun Nanofibers. Compos. A Appl. Sci. Manuf. 2020, 137, 106009. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, J.; Zhang, H.; Hou, J.; Wang, Y.; Deng, C.; Huang, C.; Jin, X. Multi-Layered, Corona Charged Melt Blown Nonwovens as High Performance PM0.3 Air Filters. Polymers 2021, 13, 485. [Google Scholar] [CrossRef]

| Pressure Drop [Pa] | ||||

|---|---|---|---|---|

| Without Charging | With Charging | |||

| Mean | SD | Mean | SD | |

| MB-SBS (PLA) | 38.61 | 3.44 | 30.56 | 5.58 |

| MB-SBS (PLA + wax 3%) | 34.00 | 7.29 | 32.36 | 6.61 |

| MB-SBS (PLA + wax 6%) | 23.86 | 2.62 | 26.17 | 3.86 |

| MB-SBS (PLA + wax 12%) | 30.86 | 6.83 | 38.80 | 11.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Penconek, A.; Werner, Ł.; Bojarska, Z.; Moskal, A. Biodegradable Electret Filters Based on Beeswax-Modified Fibers: A Novel Production Strategy. Polymers 2025, 17, 813. https://doi.org/10.3390/polym17060813

Penconek A, Werner Ł, Bojarska Z, Moskal A. Biodegradable Electret Filters Based on Beeswax-Modified Fibers: A Novel Production Strategy. Polymers. 2025; 17(6):813. https://doi.org/10.3390/polym17060813

Chicago/Turabian StylePenconek, Agata, Łukasz Werner, Zuzanna Bojarska, and Arkadiusz Moskal. 2025. "Biodegradable Electret Filters Based on Beeswax-Modified Fibers: A Novel Production Strategy" Polymers 17, no. 6: 813. https://doi.org/10.3390/polym17060813

APA StylePenconek, A., Werner, Ł., Bojarska, Z., & Moskal, A. (2025). Biodegradable Electret Filters Based on Beeswax-Modified Fibers: A Novel Production Strategy. Polymers, 17(6), 813. https://doi.org/10.3390/polym17060813