Tribological Behavior of the Laser Micro-Textured PEEK-1040 Steel Friction Pairs

Abstract

:1. Introduction

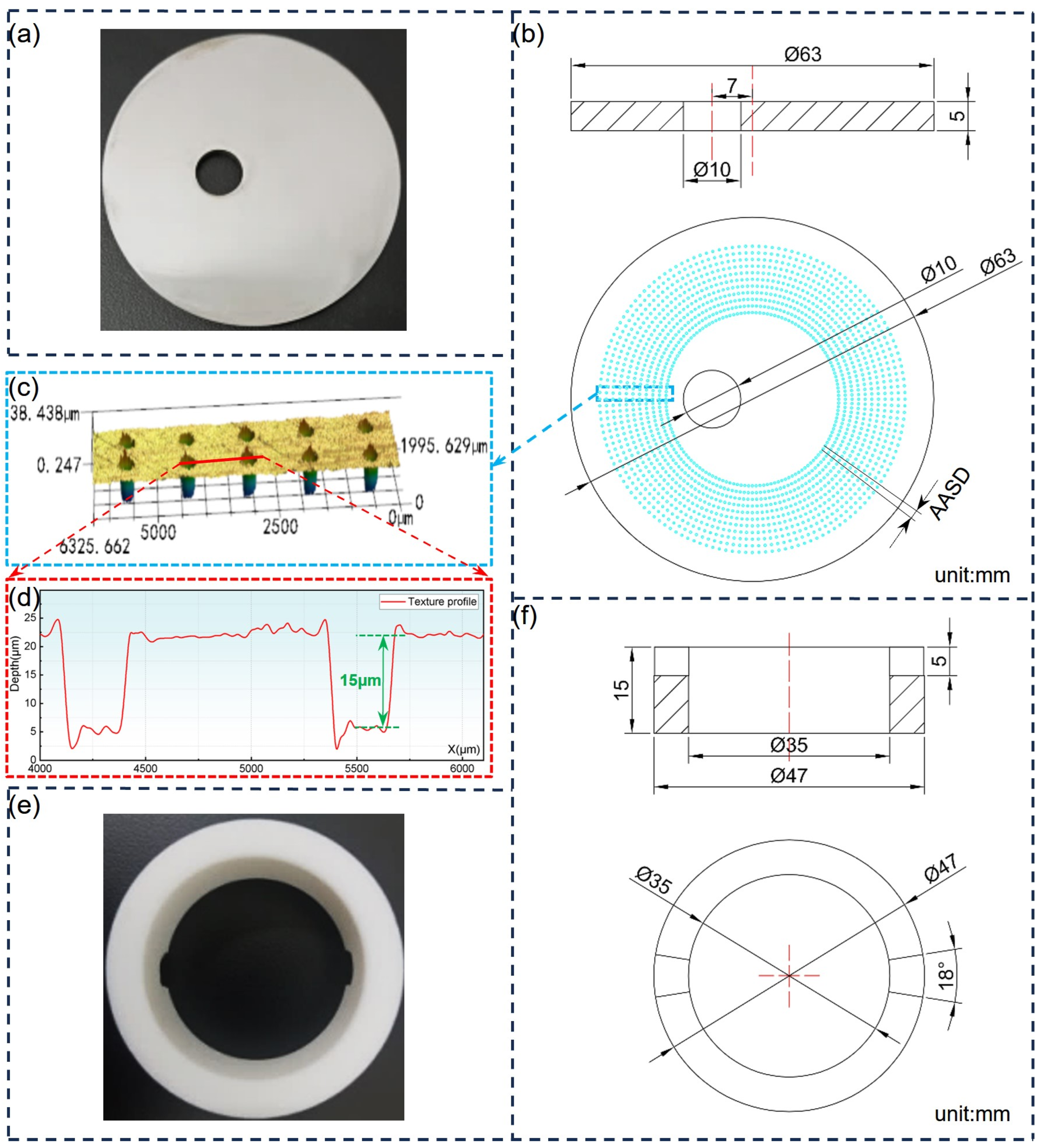

2. Materials and Methods

2.1. Materials and Pretreatment

2.2. Design of Experiment and Laser-Marking Process

2.3. Tribological Test and Characterization

3. Results and Discussion

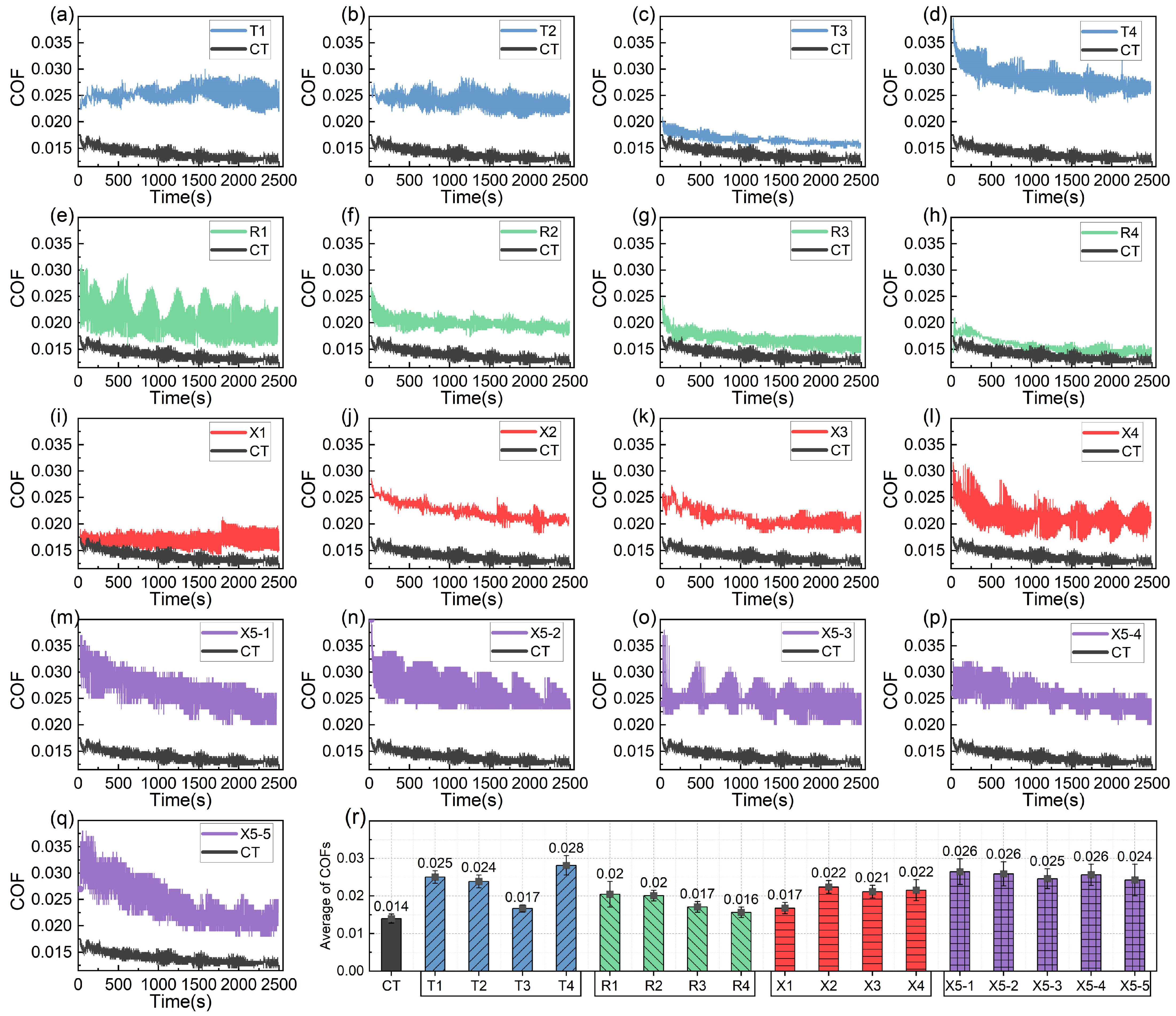

3.1. Coefficients of Friction

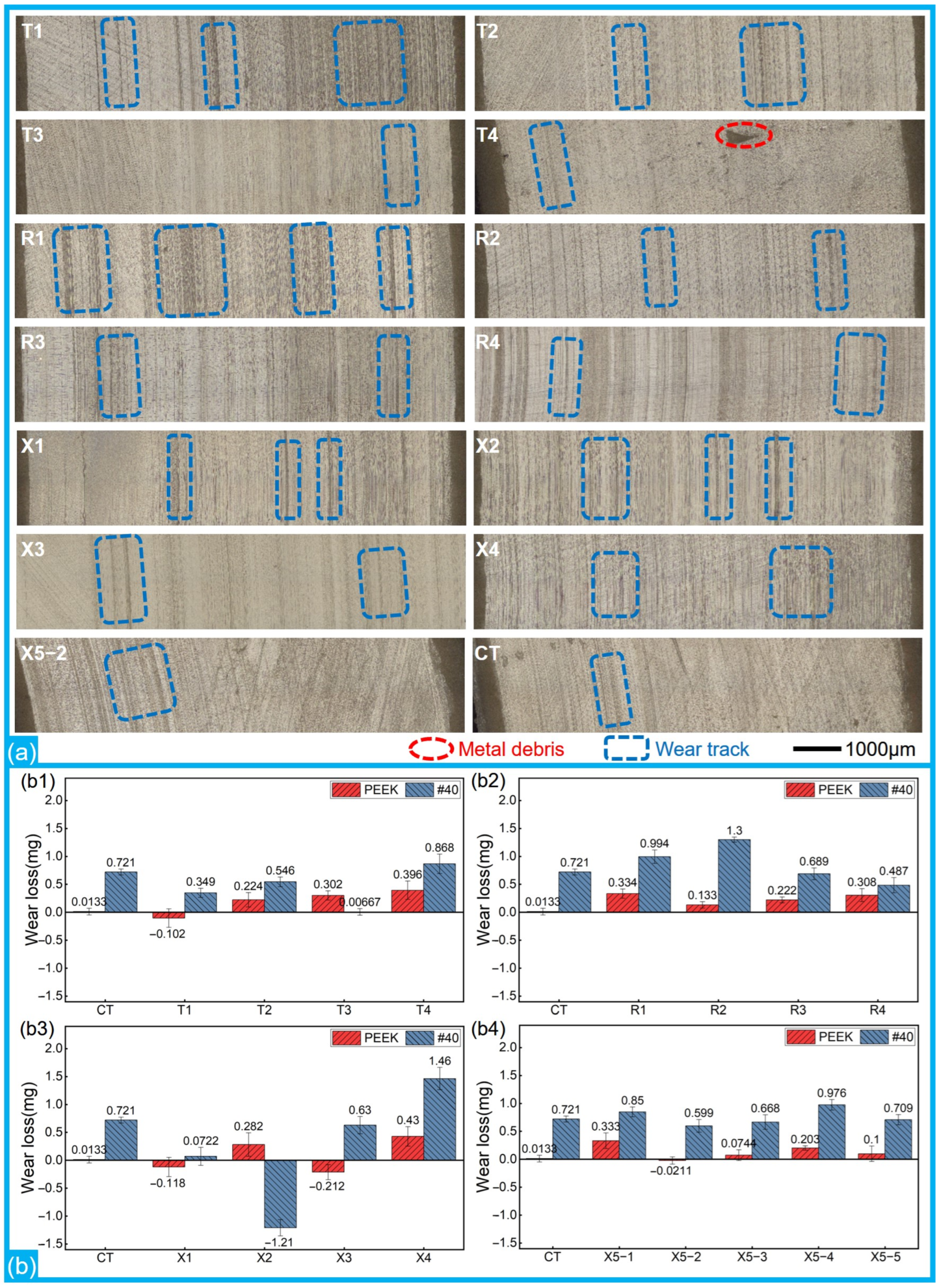

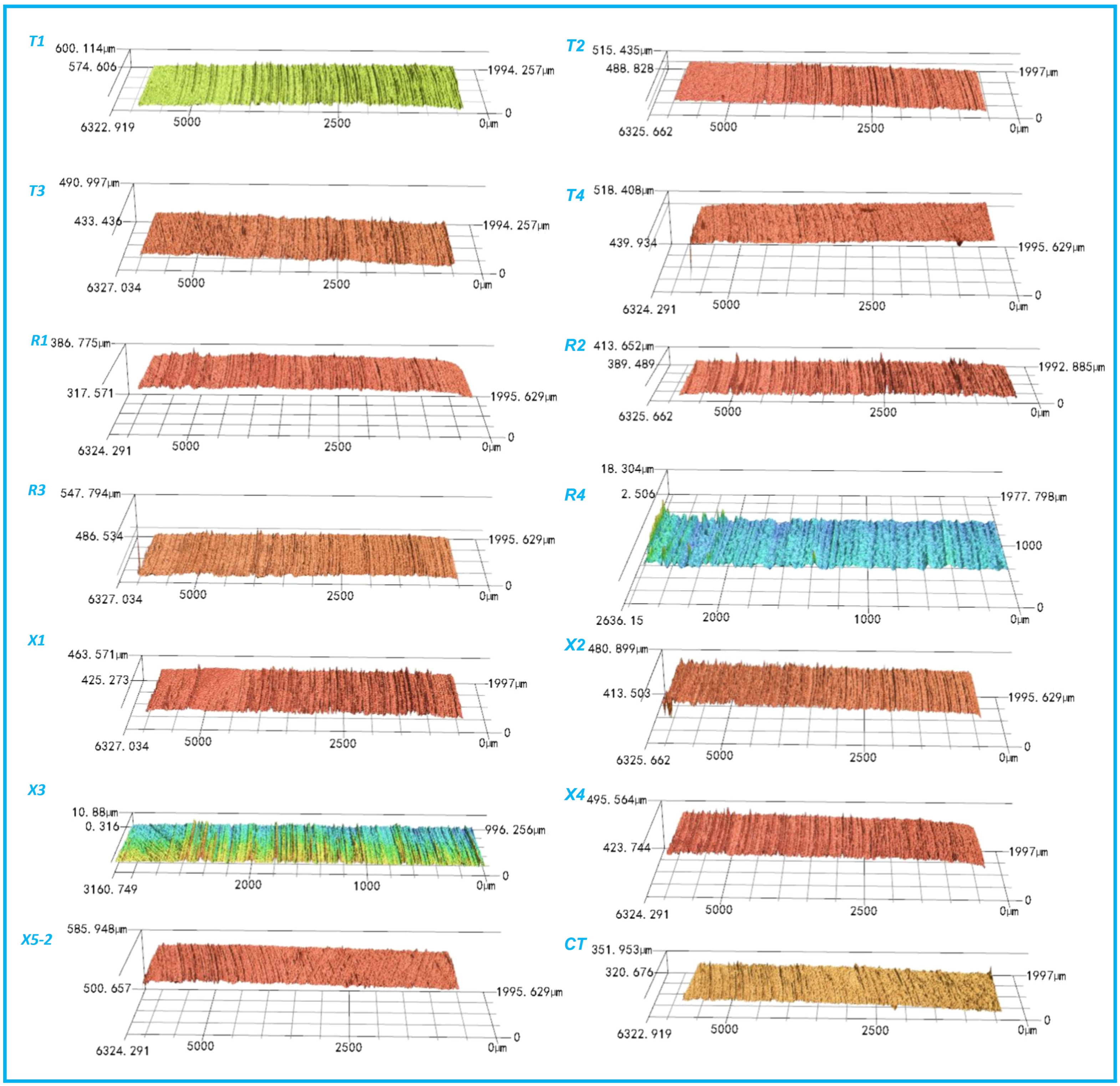

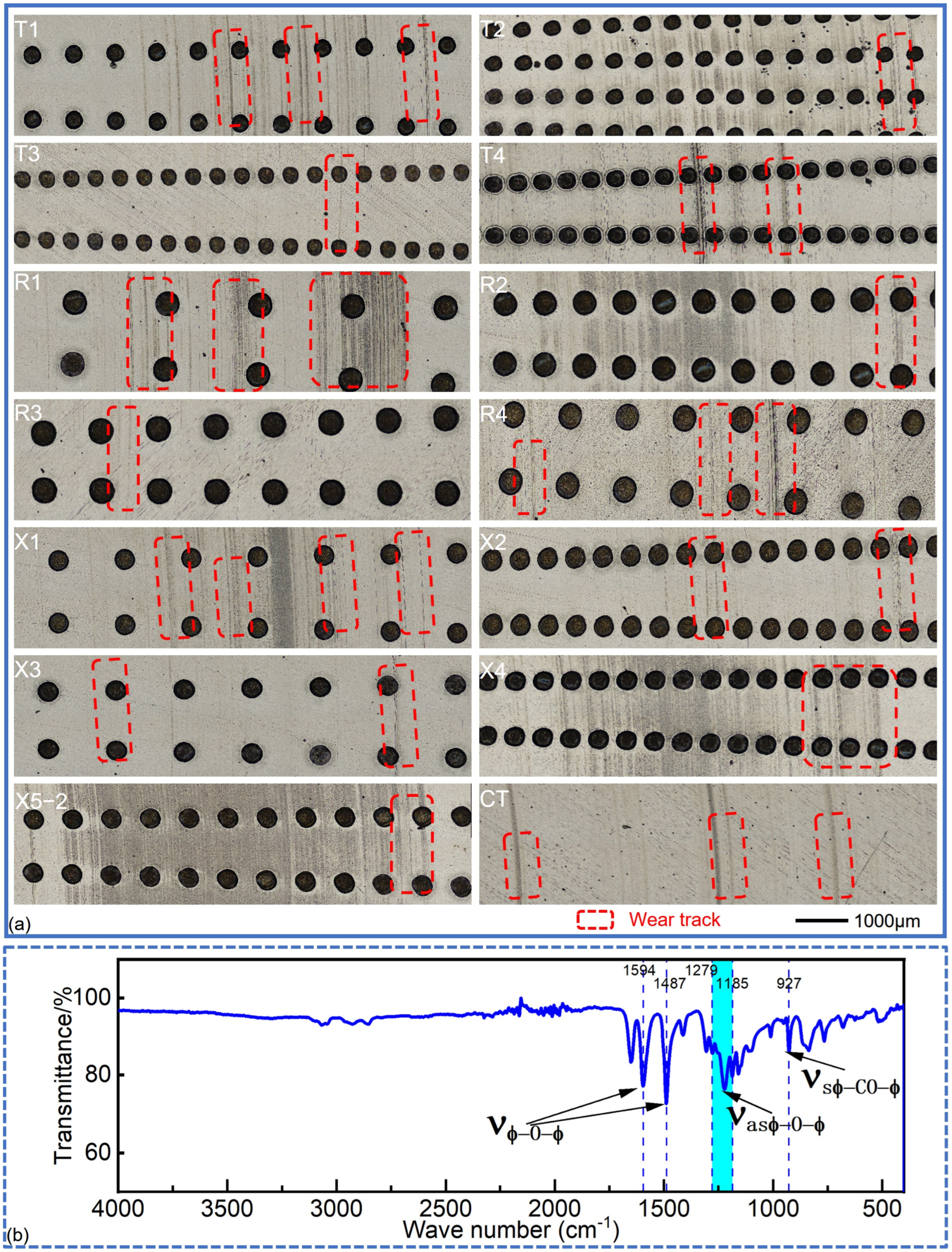

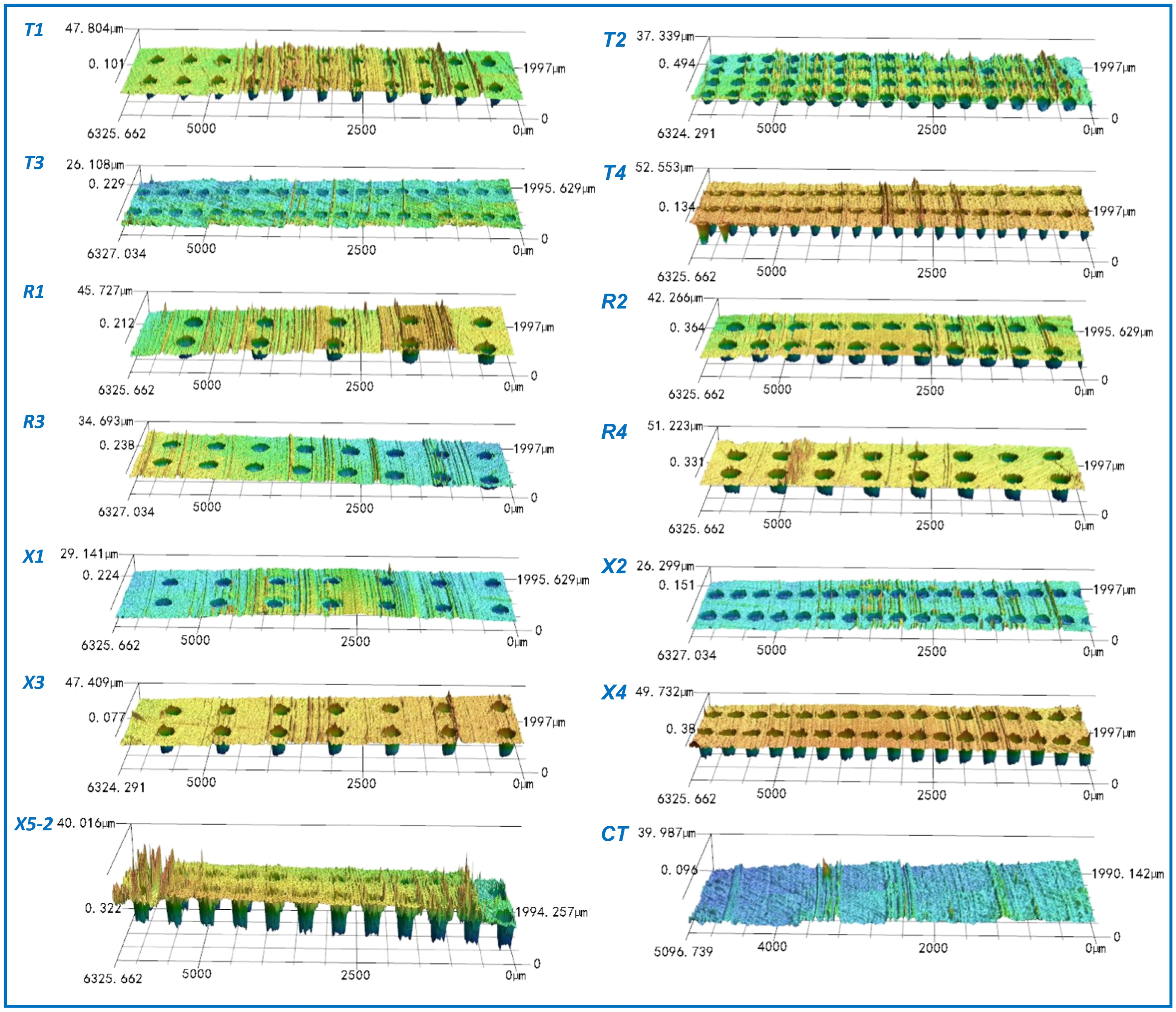

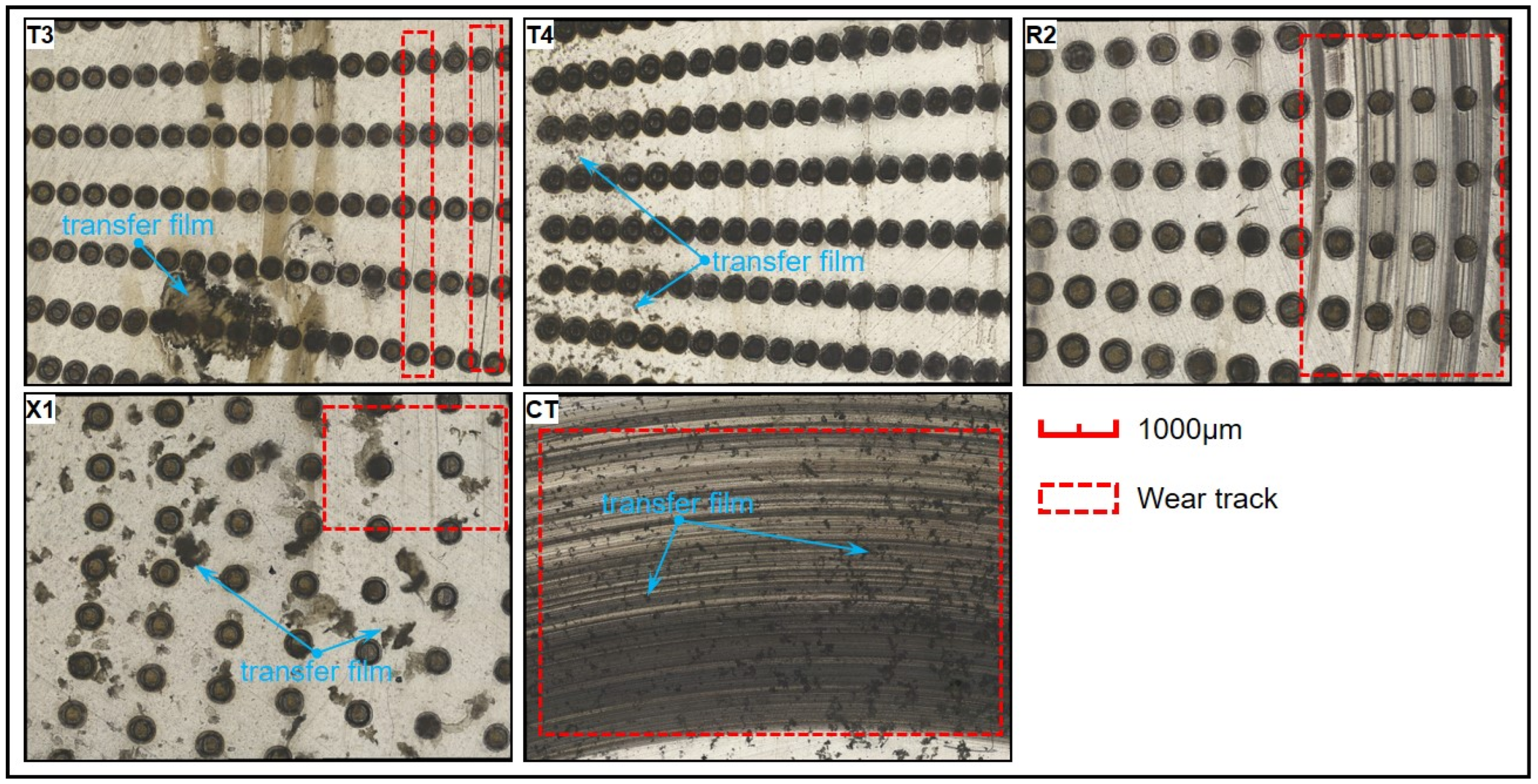

3.2. Wear Morphologies and Mass Losses

3.3. Discussion

- (1)

- When there is a sufficient amount of hydraulic oil, the micro-dimples fill with oil, and a lubricating oil film gradually forms on the contact surfaces of the friction pair. In this case, the average COF of the smooth PEEK-1040 steel friction pair was quite low, with minimal fluctuations in its COF curve. In contrast, in the dimple-textured groups, hydraulic oil in micro-dimples could be squeezed out and replenished due to the combined effect of centrifugal force and the continuous pressing of the PEEK ring [37,41]. Through acting like numerous “micro-hydrodynamic bearings”, the micro-dimples can greatly slow down lubricant migration and improve the load-carrying capacity (LCC) of the oil film [37,39]. Despite the self-lubricating properties of PEEK, its relatively high surface hardness and the greater surface roughness of the textured surface still lead to severe wear on both the PEEK rings and the steel discs. This explains why dimples do not reduce the average COFs of the PEEK-1040 steel friction pairs under the conditions used in this work.

- (2)

- The static COF between PEEK and steel surface is around 0.3–0.4, which is much higher than the average COF (0.014–0.028) observed in this work. This is the primary cause of the “crawling” or “creeping” phenomena in PEEK-1040 steel friction pairs, resulting in large and obvious fluctuations in their COF curves. Compared to the smooth reference, some textured groups exhibited more-severe COF fluctuations and more significant wear marks on their contact surfaces, which also led to their higher average COFs. In addition, an appropriate TEVD (0.5–0.9) reduced the average COFs of the micro-textured groups in this work.

- (3)

- During the continuous radial migration of the lubricant, micro-dimples can effectively trap and store particles or debris carried by oil, reducing the amount of rigid metal debris left on the contact surfaces. Given the relatively high surface hardness of PEEK, only a small amount of metal debris was embedded in the contact zones of the PEEK rings. This explains the negative mass losses of some of the PEEK rings (T1, X1, and X3 in Figure 3b), notably different from the morphologies observed for PTFE rings in ref. [37]. Additionally, discontinuous PEEK transfer films form on the steel disc (see Figure 7) [18,19]. These transfer films directly affect the tribological properties of PEEK-1040 steel friction pairs, whether smooth or dimple-textured. Due to the higher surface energy of PEEK, the bond between PEEK transfer films and the steel discs is relatively strong, particularly under the continuous compression of the PEEK rings. This explains why some PEEK residues stick on the steel discs after ultrasonic washing. Regarding the textured groups, due to the collection and storage of wear debris in the micro-dimples, fewer and more uneven-distributed PEEK transfer films remain on the contact surfaces, contributing to their higher average COFs, especially when the dimple diameter is relatively small (T1–T4, X1–X4, and X5-1~X5-5). When the dimple diameter is larger (300 μm), the presence of a residual transfer film on the surface is almost invisible, which explains the lower average COFs and COF curves for these groups.

- (4)

- A high area ratio corresponds to a greatly reduced contact area. In this work, as the area ratio remained constant, an increase in dimple diameter resulted in fewer micro-dimples (see Table 1) and a great distance between adjacent micro-dimples. Therefore, when the area ratio was relatively small (6.6%), more PEEK transfer films and debris remained on the contact surfaces, and the degree of improvement in the load-bearing capacity due to the micro-eddies in the dimples was limited. This led to a deterioration tribological behavior of the PEEK-1040 steel friction pairs, especially when the dimple diameter was 300 μm, which is the primary reason for the poor tribological performance of R1 (D300-P6.6-H5). A moderate area ratio (10.75%) and smaller dimple depth (5 μm) tend to reduce average COFs, COF fluctuations, and wear losses (T3 and R3). This is because the transfer films on the contact surfaces are more uniform, and the micro-eddies in the dimples are more effective in this case. As the area ratio is large (14.9%), fewer PEEK transfer films and less debris remain on the contact surfaces, and the load-bearing capacity is improved by the micro-eddies in the dimples too. As a result, the tribological properties of the PEEK-1040 steel friction pairs improve, particularly when the dimple depth is 5 μm, as seen in X2, although the surface roughness of the contact surfaces increases. The good tribological performance of X1 can be attributed to its greater number of micro-dimples (compared to R1) and its shallower dimple depth.

- (5)

- When the dimple depth is greater (15 and 25 μm), the transfer films become more uneven, and the efficiency of the “micro-hydrodynamic bearings” decreases for the “self-sealing” effect [18,19], especially when the dimple depth is 25 μm. As a result, the average COFs and the fluctuation in COF curves worsen, particularly when the diameter of the dimple is relatively small (T1–T2, T4, and X3–X4). This also explains the relatively higher mass losses for this group. The good tribological performance of R4 can mainly be attributed to its large dimple diameter (300 μm) and moderate area ratio (10.75%). In addition, the formation of “U-shaped thin-wall embedded units” [42] and laser-induced phase transitions may also refine the intrinsic material structure, increasing the surface-hardness and enhancing the anti-wear performance of micro-textured discs [18].

4. Conclusions

- (1)

- Micro-dimples did not effectively reduce the average COFs or the COF fluctuations of the PEEK-1040 steel friction pairs under full-film-lubrication conditions. Despite their poor friction-reducing properties, the mass losses in most of the dimple-textured groups were lower than those in the CT group, suggesting that micro-dimples could enhance the anti-wear performance of the PEEK-1040 steel friction pairs in this case. Among the 17 groups, X1 exhibited the best anti-wear properties.

- (2)

- When the dimple diameter is 300 μm, the COF curves of R1–R4 are much closer to that of the smooth reference, and their average COFs are significantly lower than those of the other textured groups. When the area ratio is moderate (10.75%) and the dimple depth is shallow (5 μm), as seen in T3, the dimple-textured PEEK-1040 steel friction pair demonstrates acceptable tribological properties. Its average COF (0.017) is only 0.003 higher than that of the CT group, while its mass loss for the 1040 steel disc is much lower than the loss (0.87 mg) of the smooth reference.

- (3)

- The average COFs and mass losses of the PEEK-1040 steel friction pairs were lower than those of the PTFE-1040 steel tribo-pairs under the same conditions. The smooth PEEK-1040 steel friction pair demonstrated excellent overall tribological performance, with only small fluctuations in its COF curve. Parameter optimization could not effectively reduce the average COF of the PEEK-1040 steel friction pair, but the wear amounts of PEEK rings and 1040 steel discs after optimization were only 0.025 mg and 0.045 mg, respectively, both of which are significantly lower than the mass losses of the PTFE ring and 1040 steel disc in the optimized PTFE-1040 steel tribo-pair.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Deaconescu, A.; Deaconescu, T. Tribological Behavior of Hydraulic Cylinder Coaxial Sealing Systems Made from PTFE and PTFE Compounds. Polymers 2020, 12, 155. [Google Scholar] [CrossRef]

- Pan, Q.; Zeng, Y.L.; Li, Y.B.; Jiang, X.P.; Huang, M.H. Experimental investigation of friction behaviors for double-acting hydraulic actuators with different reciprocating seals. Tribol. Int. 2021, 153, 106506. [Google Scholar] [CrossRef]

- Deaconescu, T.; Deaconescu, A.; Sârbu, F. Contact mechanics and friction in PTFE coaxial sealing systems. Int. J. Mech. Mater. Des. 2018, 14, 635–646. [Google Scholar] [CrossRef]

- Chen, X.L.; Zeng, L.C.; Chen, X.B. Eccentric correction of piston based on bionic micro-texture technology for the gap seal hydraulic cylinder. Micro Nano Lett. 2019, 14, 33–37. [Google Scholar] [CrossRef]

- Anno, J.N.; Walowit, J.A.; Allen, C.M. Load Support and Leakage from Microasperity-Lubricated Face Seals. J. Lubr. Tech. 1969, 91, 726–731. [Google Scholar] [CrossRef]

- Li, Y.H.; Chen, K.S.; Zhan, C.C.; Fu, L.D. Research on a kind of self-compensation variable-clearance sealing hydraulic cylinder with a thin shell structure. AIP Adv. 2018, 8, 115330. [Google Scholar] [CrossRef]

- Kamga, L.S.; Nguyen, T.D.; Emrich, S.; Oehler, M.; Schmidt, T.; Gedan-Smolka, M.; Kopnarski, M.; Sauer, B. The effect of irradiated PTFE on the friction and wear behavior of chemically bonded PA46-PTFE-cb and PA66-PTFE-cb compounds. Wear 2022, 502–503, 204380. [Google Scholar] [CrossRef]

- Unal, H.; Mimaroglu, A.; Kadioglu, U.; Ekiz, H. Sliding friction and wear behavior of polytetrafluoroethylene and its composites under dry conditions. Mater. Des. 2004, 25, 239–245. [Google Scholar] [CrossRef]

- Greco, A.C.; Erck, R.; Ajayi, O.; Fenske, G. Effect of reinforcement morphology on high-speed sliding friction and wear of PEEK polymers. Wear 2011, 271, 2222–2229. [Google Scholar] [CrossRef]

- Koike, H.; Kida, K.; Mizobe, K.; Matsumura, T.; Inagaki, M. PEEK/graphite film formation on microgrooves of PEEK-hybrid radial Al2O3 ball bearings under rolling contact in dry condition. Tribol. Int. 2022, 172, 107583. [Google Scholar] [CrossRef]

- Lin, Z.B.; Zhang, K.; Ye, J.X.; Li, X.J.; Zhao, X.G.; Qu, T.; Liu, Q.F.; Gao, B.Z. The effects of filler type on the friction and wear performance of PEEK and PTFE composites under hybrid wear conditions. Wear 2022, 490–491, 204178. [Google Scholar] [CrossRef]

- Hamilton, D.B.; Walowit, J.A.; Allen, C.M. A theory of lubrication by micro irregularities. J. Basic Eng. 1966, 88, 177–185. [Google Scholar] [CrossRef]

- Etsion, I. State of the Art in Laser Surface Texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I. Some innovative surface texturing techniques for tribological purposes. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 429–448. [Google Scholar] [CrossRef]

- Gachot, C.; Rosenkranz, A.; Hsu, S.M.; Costa, H.L. A critical assessment of surface texturing for friction and wear improvement. Wear 2017, 372–373, 21–41. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Grützmacher, G.P.; Gachot, C.; Costa, H.L. Surface Texturing in Machine Elements—A Critical Discussion for Rolling and Sliding Contacts. Adv. Eng. Mater. 2019, 86, 1900194. [Google Scholar] [CrossRef]

- Long, R.S.; Pan, Z.; Jin, Z.H.; Zhang, Y.M.; Sun, S.N.; Wang, Y.Y.; Wang, Y.B.; Li, M.H. Tribological Behavior of Grooves Textured Thrust Cylindrical Roller Bearings Under Dry Wear. Adv. Mech. Eng. 2021, 13, 16878140211067284. [Google Scholar] [CrossRef]

- Long, R.S.; Shang, Q.Y.; Jin, Z.H.; Zhang, Y.M.; Ju, Z.C.; Li, M.H. Tribological behavior of laser textured rolling element bearings under starved lubrication. Ind. Lubr. Tribol. 2022, 74, 453–462. [Google Scholar] [CrossRef]

- Long, R.S.; Sun, Y.H.; Zhang, Y.M.; Shang, Q.Y.; Ramteke, S.M.; Marian, M. Influence of micro-texture radial depth variations on the tribological and vibration characteristics of rolling bearings under starved lubrication. Tribol. Int. 2024, 194, 109545. [Google Scholar] [CrossRef]

- Bruzzone, A.; Costa, H.L.; Lonardo, P.M.; Lucca, D.A. Advances in engineered surfaces for functional performance. CIRP Ann. 2008, 57, 750–769. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J.K. Tribological performance of surface texturing in mechanical applications—A review. Surf. Topogr. Metrol. Prop. 2020, 8, 43001. [Google Scholar] [CrossRef]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef]

- Coblas, D.G.; Fatu, A.; Maoui, A.; Hajjam, M. Manufacturing textured surfaces: State of art and recent developments. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 229, 3–29. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Marian, M. Combining surface textures and MXene coatings—Towards enhanced wear-resistance and durability. Surf. Topog. Metrol. Prop. 2022, 10, 33001. [Google Scholar] [CrossRef]

- Long, R.S.; Yao, Y.; Zhang, L.E.; Shang, Q.Y.; Sun, S.N.; Hu, J.S.; Pape, F.; Marian, M. Synergistic Effects of Graphene-added Lubricants and Surface Micro-texturing on the Tribological Behavior of Thrust Roller Bearings. Tribol. Int. 2024, 198, 109908. [Google Scholar] [CrossRef]

- Kelley, J.; Poll, G.; Pape, F. Investigation of the possible applications for microtextured rolling bearings. Front. Manuf. Technol. 2022, 2, 1012343. [Google Scholar] [CrossRef]

- Zhao, C.; Long, R.S.; Zhang, Y.M.; Wang, Y.B.; Wang, Y.Y. Influence of characteristic parameters on the tribological properties of vein-bionic textured cylindrical roller thrust bearings. Tribol. Int. 2022, 175, 107861. [Google Scholar] [CrossRef]

- Long, R.S.; Shang, Q.Y.; Sun, S.N.; Wang, S.W.; Ma, C.; Zhang, J.W.; Marian, M. Influence of Monstera riedrichsthalii bionic textures on the tribological and vibration behavior of rolling bearings. Friction 2024, 13, 9440949. [Google Scholar] [CrossRef]

- Rosenkranz, A.; Grützmacher, P.G.; Murzyn, K.; Mathieu, C.; Mücklich, F. Multi-scale surface patterning to tune friction under mixed lubricated conditions. Appl. Nanosci. 2021, 11, 751–762. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Profito, F.J.; Rosenkranz, A. Multi-Scale Surface Texturing in Tribology—Current Knowledge and Future Perspectives. Lubricants 2019, 7, 95. [Google Scholar] [CrossRef]

- Guo, Q.G.; Zheng, L.; Zhong, Y.H.; Wang, S.K.; Ren, L.Q. Numerical simulation of hydrodynamic lubrication performance for continuous groove-textured surface. Tribol. Int. 2022, 167, 107411. [Google Scholar] [CrossRef]

- Marian, M.; Almqvist, A.; Rosenkranz, A.; Fillon, M. Numerical micro-texture optimization for lubricated contacts—A critical discussion. Friction 2022, 10, 1772–1809. [Google Scholar] [CrossRef]

- Costa, H.L.; Schille, J.; Rosenkranz, A. Tailored surface textures to increase friction—A review. Friction 2022, 10, 1285–1304. [Google Scholar] [CrossRef]

- Yu, X.Q.; He, S.; Cai, R.L. Frictional characteristics of mechanical seals with a laser-textured seal face. J. Mater. Process. Technol. 2002, 129, 463–466. [Google Scholar] [CrossRef]

- Razzaque, M.M.; Faisal, M.T.R. Performance of Mechanical Face Seals with Surface Micropores. J. Mech. Eng. 2008, 37, 77–80. [Google Scholar] [CrossRef]

- Wang, T.; Huang, W.F.; Liu, X.F.; Li, Y.J.; Wang, Y.M. Experimental study of two-phase mechanical face Seals with laser surface texturing. Tribol. Int. 2014, 72, 90–97. [Google Scholar] [CrossRef]

- Long, R.S.; Hou, J.C.; Zhang, Y.M.; Shang, Q.Y.; Ma, C.; Pape, F.; Marian, M. From Experimentation to Optimization: Surface Micro-Texturing for Low-Friction and Durable PTFE-Steel Interfaces under Full Film Lubrication. Polymers 2024, 16, 3505. [Google Scholar] [CrossRef]

- Long, R.S.; Ma, Q.; Jin, Z.H.; Zhang, Y.M.; Han, H.; Sun, S.N.; Du, X.Y. Tribological behavior of dimples textured rolling element bearings under stepped load and starved lubrication. Ind. Lubr. Tribol. 2022, 74, 876–883. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Rosenkranz, A.; Szurdak, A.; Grüber, M.; Gachot, C.; Hirt, G.; Mücklich, F. Multi-scale surface patterning-an approach to control friction and lubricant migration in lubricated systems. Ind. Lubr. Tribol. 2019, 71, 1007–1016. [Google Scholar] [CrossRef]

- Moynihan, R.E. The Molecular Structure of Perfluorocarbon Polymers. Infrared Studies on Polytetrafluoroethylene1. J. Am. Chem. Soc. 1959, 81, 1045–1050. [Google Scholar] [CrossRef]

- Grützmacher, P.G.; Rosenkranz, A.; Rammacher, S.; Gachot, C.; Frank, M. The influence of centrifugal forces on friction and wear in rotational sliding. Tribol. Int. 2017, 116, 256–263. [Google Scholar] [CrossRef]

- Long, R.S.; Zhao, C.; Jin, Z.H.; Zhang, Y.M.; Pan, Z.; Sun, S.N.; Gao, W.H. Influence of Groove Dimensions on the Tribological Behavior of Textured Cylindrical Roller Thrust Bearings under Starved Lubrication. Ind. Lubr. Tribol. 2021, 73, 971–979. [Google Scholar] [CrossRef]

| 1040 Steel Disc | PEEK Ring | ||||||

|---|---|---|---|---|---|---|---|

| Diameter, mm | 63 | Outer diameter, mm | 47 | ||||

| Thickness, mm | 5 | Inner diameter, mm | 35 | ||||

| Thickness, mm | 15 | ||||||

| Factor | Level | ||||||

| −1 | 0 | 1 | |||||

| Dimple diameter/D, μm | 200 | 250 | 300 | ||||

| Dimple depth/H, μm | 5 | 15 | 25 | ||||

| Area ratio/P, % | 6.6 | 10.75 | 14.9 | ||||

| Group ID | D/μm | P/% | H/μm | Sets | Dimples of one set | Total Dimples, T | TEVD * |

| T1 | 200 | 6.6 | 15 | 144 | 24 | 3456 | 1.628 |

| T2 | 200 | 14.9 | 15 | 240 | 32 | 7680 | 3.617 |

| T3 | 200 | 10.75 | 5 | 144 | 39 | 5616 | 0.882 |

| T4 | 200 | 10.75 | 25 | 144 | 39 | 5616 | 4.409 |

| R1 | 300 | 6.6 | 15 | 144 | 11 | 1584 | 1.679 |

| R2 | 300 | 14.9 | 15 | 144 | 24 | 3456 | 3.662 |

| R3 | 300 | 10.75 | 5 | 144 | 17 | 2448 | 0.865 |

| R4 | 300 | 10.75 | 25 | 144 | 17 | 2448 | 4.324 |

| X1 | 250 | 6.6 | 5 | 144 | 15 | 2160 | 0.530 |

| X2 | 250 | 14.9 | 5 | 144 | 34 | 4896 | 1.201 |

| X3 | 250 | 6.6 | 25 | 144 | 15 | 2160 | 2.649 |

| X4 | 250 | 14.9 | 25 | 144 | 34 | 4896 | 6.005 |

| X5-1 | 250 | 10.75 | 15 | 144 | 25 | 3600 | 2.649 |

| X5-2 | 250 | 10.75 | 15 | 144 | 25 | 3600 | 2.649 |

| X5-3 | 250 | 10.75 | 15 | 144 | 25 | 3600 | 2.649 |

| X5-4 | 250 | 10.75 | 15 | 144 | 25 | 3600 | 2.649 |

| X5-5 | 250 | 10.75 | 15 | 144 | 25 | 3600 | 2.649 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, R.; Wang, H.; Hou, J.; Shang, Q.; Zhang, Y.; Zong, L.; Zhang, Z. Tribological Behavior of the Laser Micro-Textured PEEK-1040 Steel Friction Pairs. Polymers 2025, 17, 645. https://doi.org/10.3390/polym17050645

Long R, Wang H, Hou J, Shang Q, Zhang Y, Zong L, Zhang Z. Tribological Behavior of the Laser Micro-Textured PEEK-1040 Steel Friction Pairs. Polymers. 2025; 17(5):645. https://doi.org/10.3390/polym17050645

Chicago/Turabian StyleLong, Risheng, Haiming Wang, Jincheng Hou, Qingyu Shang, Yimin Zhang, Lin Zong, and Zhijun Zhang. 2025. "Tribological Behavior of the Laser Micro-Textured PEEK-1040 Steel Friction Pairs" Polymers 17, no. 5: 645. https://doi.org/10.3390/polym17050645

APA StyleLong, R., Wang, H., Hou, J., Shang, Q., Zhang, Y., Zong, L., & Zhang, Z. (2025). Tribological Behavior of the Laser Micro-Textured PEEK-1040 Steel Friction Pairs. Polymers, 17(5), 645. https://doi.org/10.3390/polym17050645