Influence of Cooling Rate on the Flexural and Impact Properties of Compression Molded Non-Woven Flax/PLA Biocomposites

Abstract

1. Introduction

2. Materials and Methods

2.1. Reinforcement and Matrix Materials

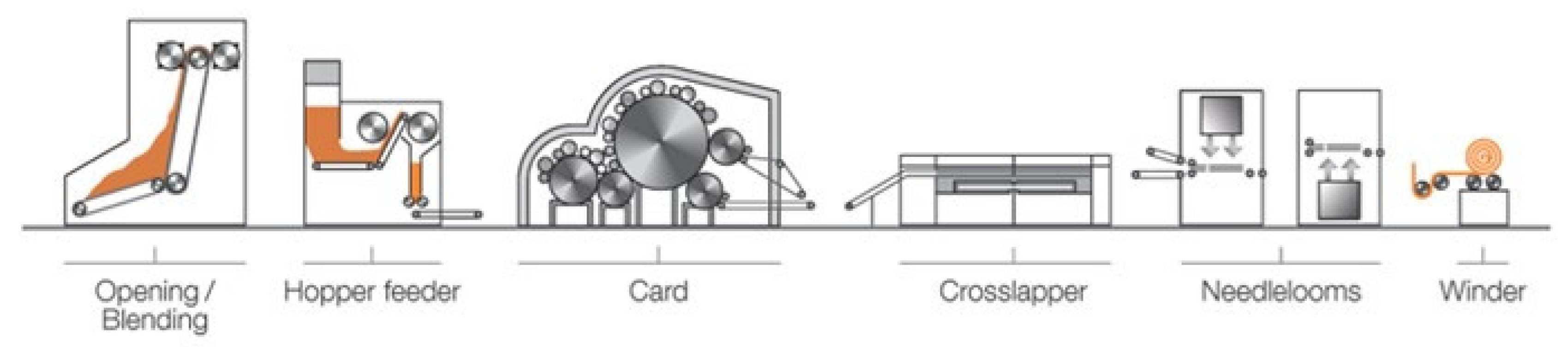

2.2. Fabrication of Composite Laminates

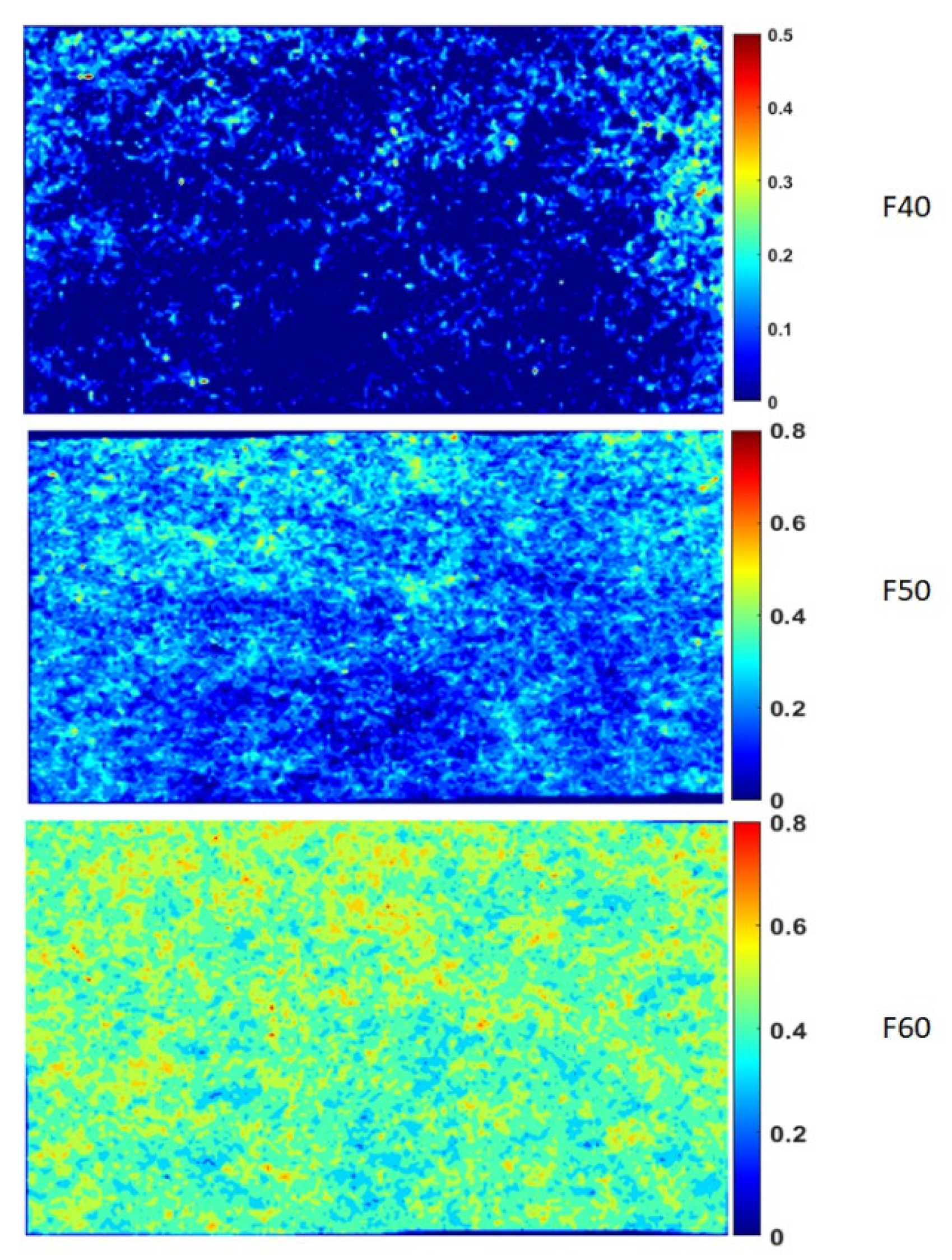

2.3. Flax Fiber Distribution

2.4. Void Content Measurement

2.5. Thermal Characterization

2.5.1. Differential Scanning Calorimetry (DSC)

2.5.2. Thermogravimetry (TGA) Analysis

2.6. Mechanical Tests

2.6.1. Flexural Test

2.6.2. Impact Test

3. Results and Discussion

3.1. Properties of Flax/PLA Non-Wovens

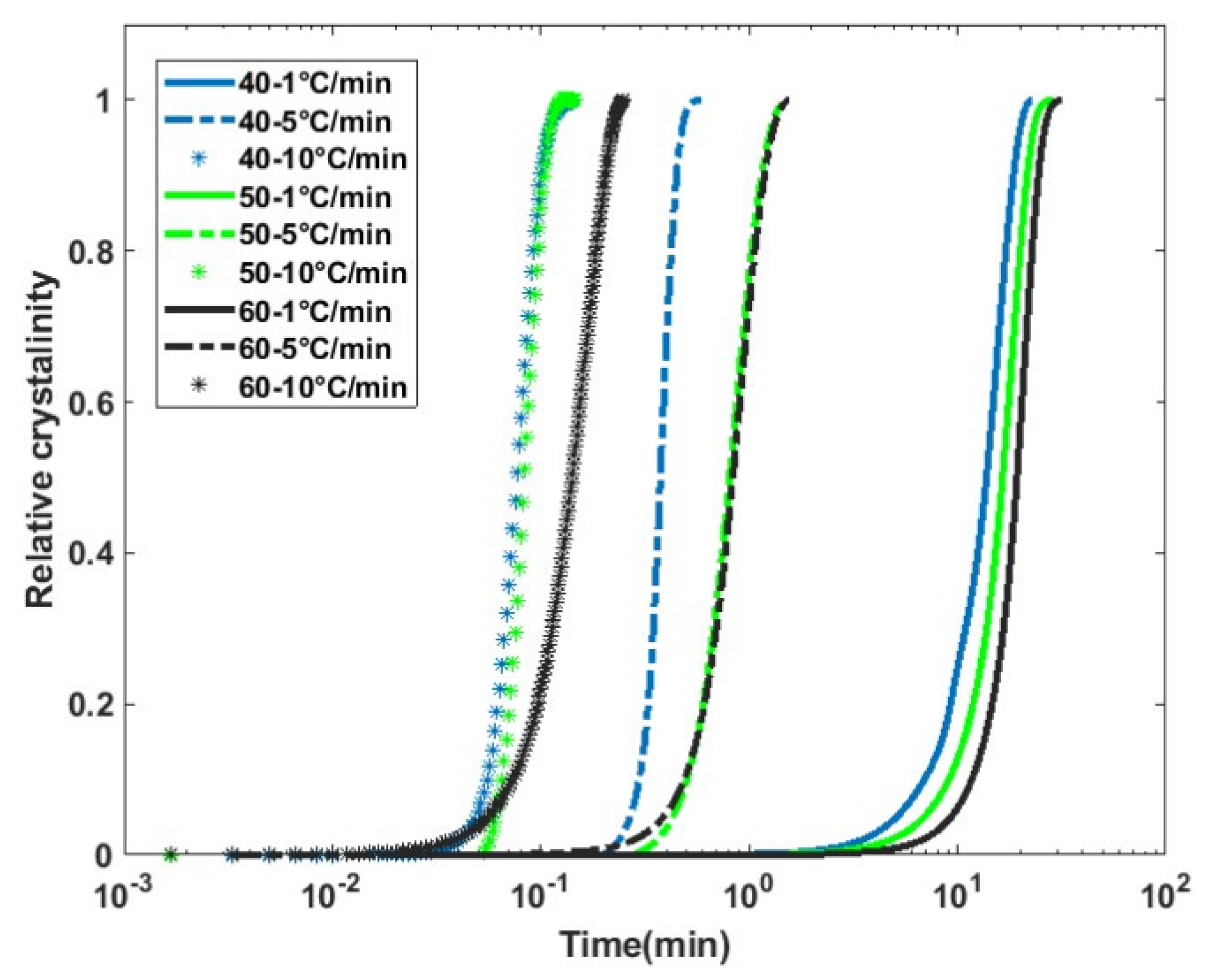

3.1.1. Crystallization Kinetics

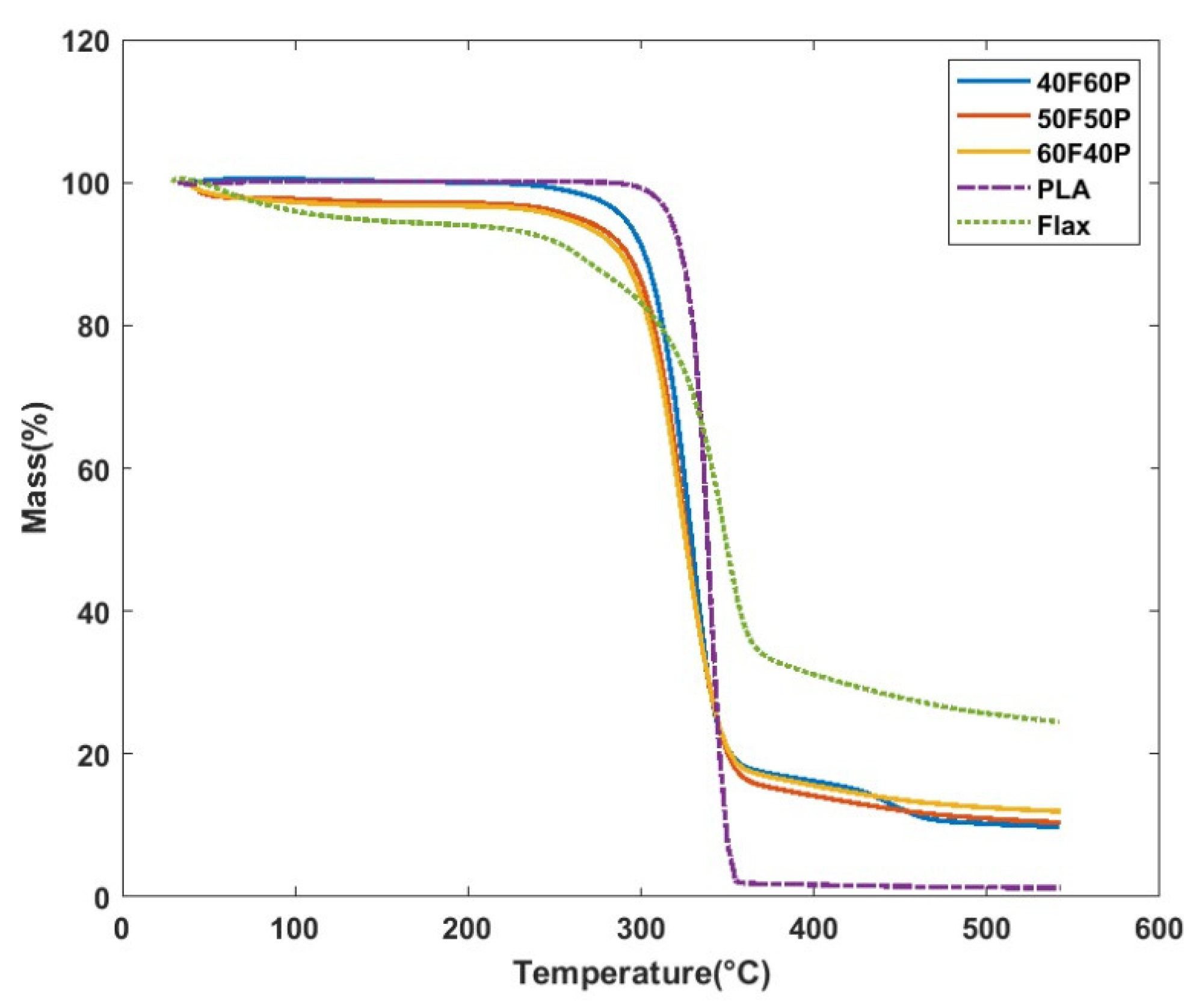

3.1.2. Thermal Degradation Analysis

3.2. Mechanical Properties of Flax/PLA Composites

3.2.1. Void Volume Fraction and Crystallinity of Composites

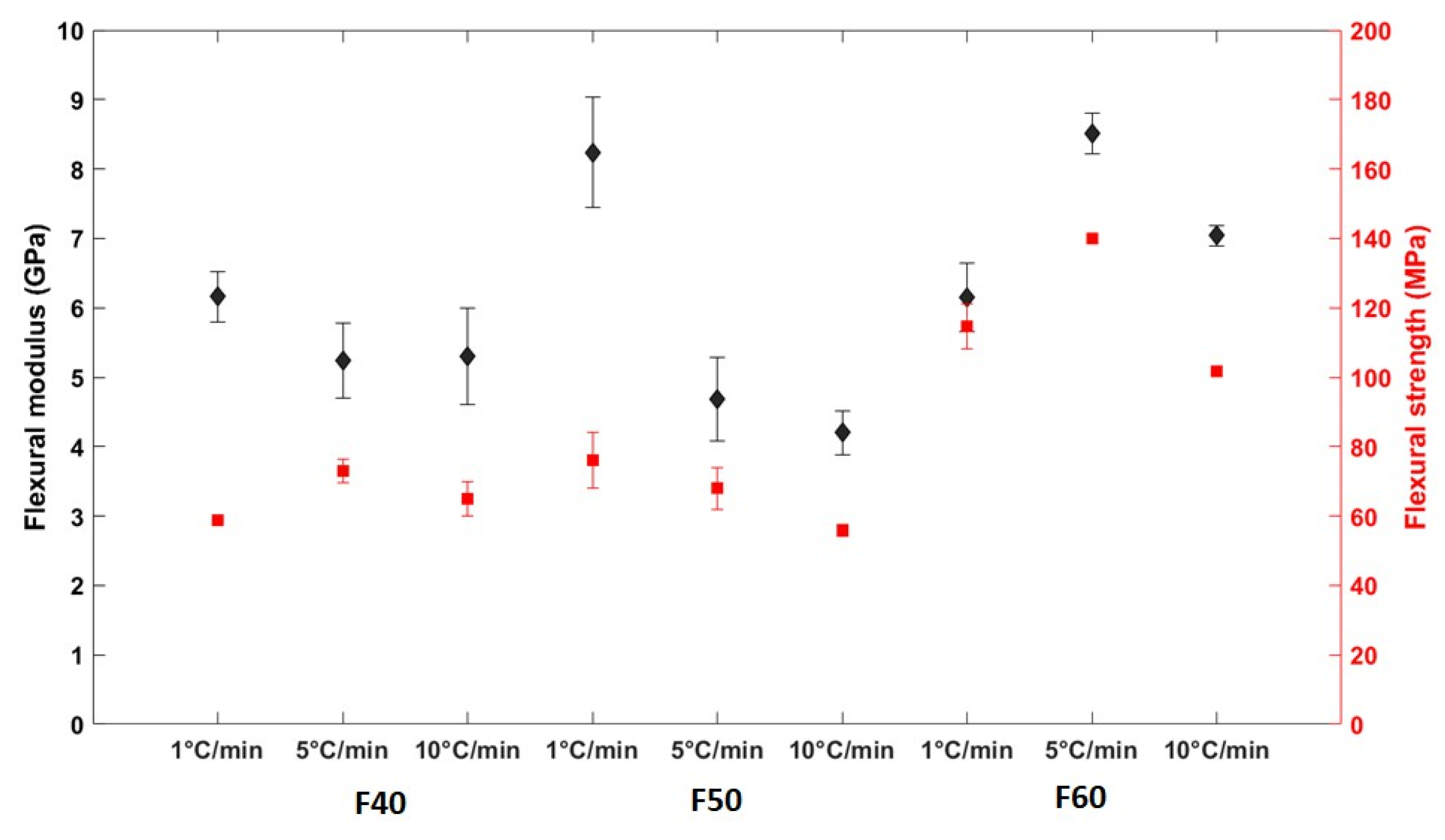

3.2.2. Flexural Properties

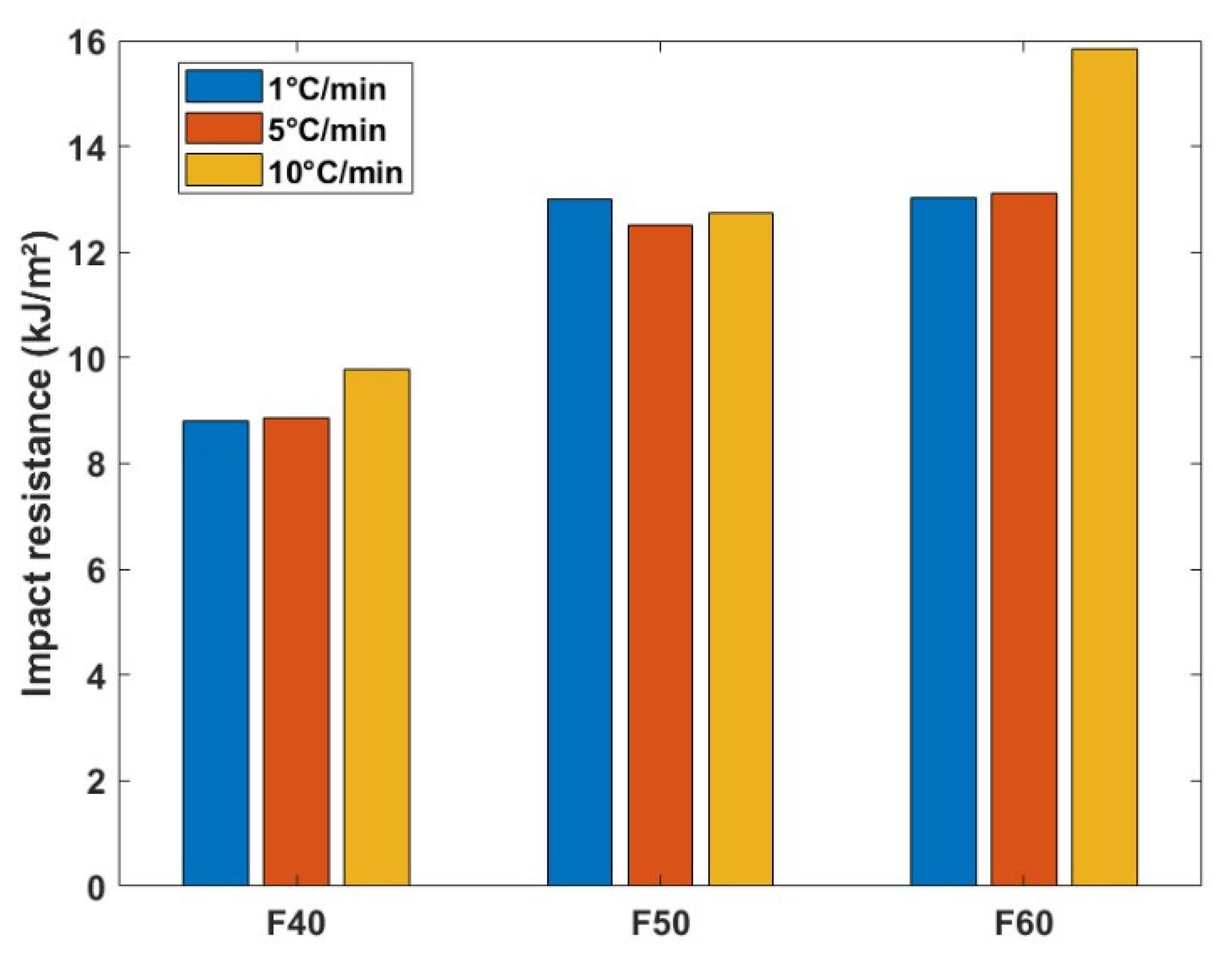

3.2.3. Impact Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Shah, D.U. Natural fibre composites: Comprehensive Ashby-type materials selection charts. Mater. Des. 1980–2015 2014, 62, 21–31. [Google Scholar] [CrossRef]

- Pantaloni, D.; Shah, D.; Baley, C.; Bourmaud, A. Monitoring of mechanical performances of flax non-woven biocomposites during a home compost degradation. Polym. Degrad. Stab. 2020, 177, 109166. [Google Scholar] [CrossRef]

- Martin, N.; Davies, P.; Baley, C. Comparison of the properties of scutched flax and flax tow for composite material reinforcement. Ind. Crops Prod. 2014, 61, 284–292. [Google Scholar] [CrossRef]

- Bourmaud, A.; Le Duigou, A.; Baley, C. What is the technical and environmental interest in reusing a recycled polypropylene–hemp fibre composite? Polym. Degrad. Stab. 2011, 96, 1732–1739. [Google Scholar] [CrossRef]

- Bar, M.; Alagirusamy, R.; Das, A.; Ouagne, P. Low velocity impact response of flax/polypropylene hybrid roving based woven fabric composites: Where does it stand with respect to GRPC? Polym. Test. 2020, 89, 106565. [Google Scholar] [CrossRef]

- Kim, S.H.; Park, C.H. Direct impregnation of thermoplastic melt into flax textile reinforcement for semi-structural composite parts. Ind. Crops Prod. 2017, 95, 651–663. [Google Scholar] [CrossRef]

- Azka, M.A.; Sapuan, S.M.; Abral, H.; Zainudin, E.S.; Aziz, F.A. An examination of recent research of water absorption behavior of natural fiber reinforced polylactic acid (PLA) composites: A review. Int. J. Biol. Macromol. 2024, 268, 131845. [Google Scholar] [CrossRef] [PubMed]

- Oksman, K.; Skrifvars, M.; Selin, J.F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Bax, B.; Müssig, J. Impact and tensile properties of PLA/Cordenka and PLA/flax composites. Compos. Sci. Technol. 2008, 68, 1601–1607. [Google Scholar] [CrossRef]

- Bodros, E.; Pillin, I.; Montrelay, N.; Baley, C. Could biopolymers reinforced by randomly scattered flax fibre be used in structural applications? Compos. Sci. Technol. 2007, 67, 462–470. [Google Scholar] [CrossRef]

- Nassiopoulos, E.; Njuguna, J. Thermo-mechanical performance of poly(lactic acid)/flax fibre-reinforced biocomposites. Mater. Des. 2015, 66, 473–485. [Google Scholar] [CrossRef]

- Rubio-López, A.; Artero-Guerrero, J.; Pernas-Sánchez, J.; Santiuste, C. Compression after impact of flax/PLA biodegradable composites. Polym. Test. 2017, 59, 127–135. [Google Scholar] [CrossRef]

- Le Duigou, A.; Bourmaud, A.; Davies, P.; Baley, C. Long term immersion in natural seawater of Flax/PLA biocomposite. Ocean Eng. 2014, 90, 140–148. [Google Scholar] [CrossRef]

- Gautreau, M.; Kervoelen, A.; Barteau, G.; Delattre, F.; Colinart, T.; Pierre, F.; Hauguel, M.; Le Moigne, N.; Guillon, F.; Bourmaud, A.; et al. Fibre individualisation and mechanical properties of a flax-PLA non-woven composite following physical pre-treatments. Coatings 2021, 11, 846. [Google Scholar] [CrossRef]

- Wang, X.-Y.; Wang, Q.-H.; Gu, H. Research on Mechanical Behavior of the Flax/Polyactic Acid Composites. J. Reinf. Plast. Compos. 2010, 29, 2561–2567. [Google Scholar] [CrossRef]

- Khanlou, H.M.; Woodfield, P.; Summerscales, J.; Hall, W. Consolidation process boundaries of the degradation of mechanical properties in compression moulding of natural-fibre bio-polymer composites. Polym. Degrad. Stab. 2017, 138, 115–125. [Google Scholar] [CrossRef]

- Couture, A.; Lebrun, G.; Laperrière, L. Mechanical properties of polylactic acid (PLA) composites reinforced with unidirectional flax and flax-paper layers. Compos. Struct. 2016, 154, 286–295. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Guthrie, R.; MacMullen, J.; Bennett, N. Development of flax/carbon fibre hybrid composites for enhanced properties. Carbohydr. Polym. 2013, 96, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Woigk, W.; Fuentes, C.A.; Rion, J.; Hegemann, D.; van Vuure, A.W.; Kramer, E.; Dransfeld, C.; Masania, K. Fabrication of flax fibre-reinforced cellulose propionate thermoplastic composites. Compos. Sci. Technol. 2019, 183, 107791. [Google Scholar] [CrossRef]

- Ouagne, P.; Bizet, L.; Baley, C.; Bréard, J. Analysis of the Film-stacking Processing Parameters for PLLA/Flax Fiber Biocomposites. J. Compos. Mater. 2010, 44, 1201–1215. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, S.; Ma, Y.; Pan, B.; Sun, M.; Zhang, G.; Chai, H.; Li, J.; Jiang, S. Laser-assisted thermoplastic composite automated fiber placement robot for bonding GF/PP unidirectional composites and braided composites. Compos. Part B Eng. 2024, 287, 111798. [Google Scholar] [CrossRef]

- Islam, M.A.; Islam, M.M.; Yang, C.; Wodag, A.F.; Wang, R.; Chen, W.; Zhou, B.; Gao, S.; Xu, F. Development of three dimensional (3D) woven flax/PLA composites with high mechanical and thermal properties using braided yarns. Ind. Crops Prod. 2024, 222, 119580. [Google Scholar] [CrossRef]

- Pisupati, A.; Boivin, A.; Beigbeder, A.; Méndez-Rial, R.; Le Goff, R. Applicability of circularity protocols to extend the lifetime of a thermoplastic pultrusion line: A case study. Manuf. Lett. 2024, 42, 56–60. [Google Scholar] [CrossRef]

- Linganiso, L.Z.; Bezerra, R.; Bhat, S.; John, M.; Braeuning, R.; Anandjiwala, R.D. Pultrusion of flax/poly(lactic acid) commingled yarns and nonwoven fabrics. J. Thermoplast. Compos. 2013, 27, 1553–1572. [Google Scholar] [CrossRef]

- Minchenkov, K.; Vedernikov, A.; Kuzminova, Y.; Gusev, S.; Sulimov, A.; Gulyaev, A.; Kreslavskaya, A.; Prosyanoy, I.; Xian, G.; Akhatov, I.; et al. Effects of the quality of pre-consolidated materials on the mechanical properties and morphology of thermoplastic pultruded flat laminates. Compos. Commun. 2022, 35, 101281. [Google Scholar] [CrossRef]

- Bi, Z.; Li, Q.; Zhang, Z.; Zhang, Z.; Yang, W.; Li, Y. Experimental and numerical evaluation of the influence of voids on sound absorption behaviors of 3D printed continuous flax fiber reinforced PLA composites. Compos. Sci. Technol. 2024, 255, 110720. [Google Scholar] [CrossRef]

- Bar, M.; Alagirusamy, R.; Das, A. Properties of flax-polypropylene composites made through hybrid yarn and film stacking methods. Compos. Struct. 2018, 197, 63–71. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Licence, P.; Clifford, M.J. Determining the minimum, critical and maximum fibre content for twisted yarn reinforced plant fibre composites. Compos. Sci. Technol. 2012, 77, 1909–1917. [Google Scholar] [CrossRef]

- Zhang, L.; Miao, M. Commingled natural fibre/polypropylene wrap spun yarns for structured thermoplastic composites. Compos. Sci. Technol. 2010, 70, 130–135. [Google Scholar] [CrossRef]

- Guillou, E.; King, A.; Perrin, J.; Proudhon, H.; Weitkamp, T.; Shah, D.U.; Beigbeder, A.; Ouagne, P.; Bourmaud, A. Impact of flax fibre micro-structural features on composite damage observed through micro-CT characterisation. Compos. Part Appl. Sci. Manuf. 2024, 181, 108118. [Google Scholar] [CrossRef]

- Bayart, M.; Foruzanmehr, M.R.; Vuillaume, P.Y.; Ovlaque, P.; Robert, M.; Elkoun, S. Poly(lactic acid)/flax composites: Effect of surface modification and thermal treatment on interfacial adhesion, crystallization, microstructure, and mechanical properties. Compos. Interfaces 2021, 29, 17–36. [Google Scholar] [CrossRef]

- Xia, X.; Shi, X.; Liu, W.; Zhao, H.; Li, H.; Zhang, Y. Effect of flax fiber content on polylactic acid (PLA) crystallization in PLA/flax fiber composites. Iran. Polym. J. 2017, 26, 693–702. [Google Scholar] [CrossRef]

- Mahato, B.; Babarinde, V.O.; Abaimov, S.G.; Lomov, S.V.; Akhatov, I. Interface strength of glass fibers in polypropylene: Dependence on the cooling rate and the degree of crystallinity. Polym. Compos. 2020, 41, 1310–1322. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Seggiani, M. Thermo-mechanical properties of PLA/short flax fiber biocomposites. Appl. Sci. 2019, 9, 3797. [Google Scholar] [CrossRef]

- Jin, X.; Chen, X.; Cheng, Q.; Zhang, N.; Cai, S.; Ren, J. Non-isothermal crystallization kinetics of ramie fiber-reinforced polylactic acid biocomposite. RSC Adv. 2017, 7, 46014–46021. [Google Scholar] [CrossRef]

- Lee, S.H.; Wang, S.; Teramoto, Y. Isothermal crystallization behavior of hybrid biocomposite consisting of regenerated cellulose fiber, clay, and poly(lactic acid). J. Appl. Polym. Sci. 2008, 108, 870–875. [Google Scholar] [CrossRef]

- Cai, J.; Liu, M.; Wang, L.; Yao, K.; Li, S.; Xiong, H. Isothermal crystallization kinetics of thermoplastic starch/poly(lactic acid) composites. Carbohydr. Polym. 2011, 86, 941–947. [Google Scholar] [CrossRef]

- Cosson, B. Optical measurement of local permeability of flax fiber fabrics before liquid composite molding. J. Compos. Mater. 2018, 52, 3289–3297. [Google Scholar] [CrossRef]

- Pisupati, A.; Leroy, M.; Laurent, T.; Park, C.H. Development and investigation of nonwoven preforms for self-reinforced polylactic acid composites. J. Reinf. Plast. Compos. 2024, 43, 72–83. [Google Scholar] [CrossRef]

- Jabeen, R.; Cosson, B.; Akué Asséko, A.C.; Verstraete, S.; Desplentere, F.; Park, C.H. Effect of fibre orientation on the light scattering during laser transmission welding. J. Manuf. Process. 2023, 86, 1–9. [Google Scholar] [CrossRef]

- Cosson, B.; Akué Asséko, A.C.; Dauphin, M. A non-destructive optical experimental method to predict extinction coefficient of glass fibre-reinforced thermoplastic composites. Opt. Laser Technol. 2018, 106, 215–221. [Google Scholar] [CrossRef]

- Kretsis, G.; He, Y.; Makeev, A.; Concrete, R.; Goh, G.D.L.; Dikshit, V.; Nagalingam, A.P.; Goh, G.D.L.; Agarwala, S.; Sing, S.L.; et al. CRAG (Composite Research Advisory Group) Test Methods for the Measurement of the Engineering Properties of Fibre Reinforced Plastics. Fifth Conf. Compos. Mater. Test. Des. 1988, 18, 631–738. [Google Scholar]

- Gall, M.L.; Davies, P.; Martin, N.; Baley, C. Recommended flax fibre density values for composite property predictions. Ind. Crops Prod. 2018, 114, 52–58. [Google Scholar] [CrossRef]

- Foglia, F.; De Meo, A.; Iozzino, V.; Volpe, V.; Pantani, R. Isothermal crystallization of PLA: Nucleation density and growth rates of α and α’ phases. Can. J. Chem. Eng. 2020, 98, 1998–2007. [Google Scholar] [CrossRef]

- Velisaris, C.N.; Seferis, J.C. Crystallization kinetics of polyetheretherketone (peek) matrices. Polym. Eng. Sci. 1986, 26, 1574–1581. [Google Scholar] [CrossRef]

- Liao, R.; Yang, B.; Yu, W.; Zhou, C. Isothermal cold crystallization kinetics of polylactide/nucleating agents. J. Appl. Polym. Sci. 2007, 104, 310–317. [Google Scholar] [CrossRef]

- Yu, L.; Liu, H.; Dean, K.; Chen, L. Cold crystallization and postmelting crystallization of PLA plasticized by compressed carbon dioxide. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 2630–2636. [Google Scholar] [CrossRef]

- Liu, T.; Mo, Z.; Wang, S.; Zhang, H. Nonisothermal melt and cold crystallization kinetics of poly(Aryl Ether Ether Ketone Ketone). Polym. Eng. Sci. 1997, 37, 568–575. [Google Scholar] [CrossRef]

- BS EN ISO 178:2003; Plastics. Determination of Flexural Properties. BSI: London, UK, 2003.

- ISO 179-2:2020; Plastics—Determination of Charpy Impact properties. Part 2: Instrumented Impact Test. ISO: Geneva, Switzerland, 2020.

- Pisupati, A.; Deléglise Lagardère, M. Mechanical Performance of Flax Fiber Composites with Waste Glass Fibers as a Core Structure. Materials 2022, 15, 9017. [Google Scholar] [CrossRef]

- Boztepe, S.; Šimáček, P.; Labastie, K.; Chevalier, M.; Sandre, P.; Des, J.-M.; Advani, S.G. Effect of the initial resin distribution in partially impregnated thermoplastic prepregs on consolidation. Compos. Sci. Technol. 2022, 225, 109488. [Google Scholar] [CrossRef]

- Saeidlou, S.; Huneault, M.A.; Li, H.; Park, C.B. Poly(lactic acid) crystallization. Prog. Polym. Sci. 2012, 37, 1657–1677. [Google Scholar] [CrossRef]

- Gumus, S.; Ozkoc, G.; Aytac, A. Plasticized and unplasticized PLA/organoclay nanocomposites: Short- and long-term thermal properties, morphology, and nonisothermal crystallization behavior. J. Appl. Polym. Sci. 2012, 123, 2837–2848. [Google Scholar] [CrossRef]

- Pickering, K.L.; Sawpan, M.A.; Jayaraman, J.; Fernyhough, A. Influence of loading rate, alkali fibre treatment and crystallinity on fracture toughness of random short hemp fibre reinforced polylactide bio-composites. Compos. Part Appl. Sci. Manuf. 2011, 42, 1148–1156. [Google Scholar] [CrossRef]

- Waters, C.L.; Janupala, R.R.; Mallinson, R.G.; Lobban, L.L. Staged thermal fractionation for segregation of lignin and cellulose pyrolysis products: An experimental study of residence time and temperature effects. J. Anal. Appl. Pyrolysis 2017, 126, 380–389. [Google Scholar] [CrossRef]

- Pisupati, A.; Ayadi, A.; Deléglise-Lagardère, M.; Park, C.H. Influence of resin curing cycle on the characterization of the tensile properties of flax fibers by impregnated fiber bundle test. Compos. Part Appl. Sci. Manuf. 2019, 126, 105572. [Google Scholar] [CrossRef]

- O’Donnell, A.; Dweib, M.A.; Wool, R.P. Natural fiber composites with plant oil-based resin. Compos. Sci. Technol. 2004, 64, 1135–1145. [Google Scholar] [CrossRef]

- Pervaiz, M.; Sain, M.M. Sheet-Molded Polyolefin Natural Fiber Composites for Automotive Applications. Macromol. Mater. Eng. 2003, 288, 553–557. [Google Scholar] [CrossRef]

- Glass Fibre Reinforced PA 66—TECAMID 66 GF30 Black|Ensinger. Available online: https://www.ensingerplastics.com/en/shapes/pa66-tecamid-66-gf30-black (accessed on 12 January 2025).

- Ejaz, M.; Azad, M.M.; Shah, A.U.R.; Afaq, S.K.; Song, J. Mechanical and Biodegradable Properties of Jute/Flax Reinforced PLA Composites. Fibers Polym. 2020, 21, 2635–2641. [Google Scholar] [CrossRef]

- Foruzanmehr, M.; Vuillaume, P.Y.; Elkoun, S.; Robert, M. Physical and mechanical properties of PLA composites reinforced by TiO2 grafted flax fibers. Mater. Des. 2016, 106, 295–304. [Google Scholar] [CrossRef]

- Sanivada, U.K.; Mármol, G.; Brito, F.P.; Fangueiro, R. Pla composites reinforced with flax and jute fibers—A review of recent trends, processing parameters and mechanical properties. Polymers 2020, 12, 2373. [Google Scholar] [CrossRef] [PubMed]

| Non-Woven | Areal Weight (g/m2) | Thickness (mm) | Strength (N/50 mm) | Elongation (%) | ||

|---|---|---|---|---|---|---|

| MD | CD | MD | CD | |||

| F40 | 161.67 ± 4.19 | 1.80 ± 0.045 | 64.0 | 117.9 | 73.0 | 43.5 |

| F50 | 183.16 ± 0.86 | 1.88 ± 0.01 | 52.0 | 85.9 | 70.7 | 43.1 |

| F60 | 171.67 ± 1.24 | 1.78 ± 0.02 | 41.2 | 63.9 | 72.1 | 44.3 |

| Non-Woven | Temperature (°C) | w1 | k1 (10−7 s−1) | n1 | w2 | k2(10−7 s−1) | n2 |

|---|---|---|---|---|---|---|---|

| F40 | 80 | 0.65 | 1.083 | 2.182 | 0.344 | 2.179 | 1.369 |

| 100 | 0.63 | 1.285 | 2.311 | 0.363 | 2.415 | 1.457 | |

| 120 | 0.62 | 1.251 | 2.314 | 0.372 | 3.343 | 1.413 | |

| F50 | 80 | 0.64 | 0.961 | 2.19 | 0.353 | 2.496 | 1.346 |

| 100 | 0.62 | 1.284 | 2.307 | 0.371 | 3.071 | 1.414 | |

| 120 | 0.62 | 1.253 | 2.311 | 0.376 | 3.975 | 1.382 | |

| F60 | 80 | 0.64 | 0.965 | 2.195 | 0.353 | 2.336 | 1.357 |

| 100 | 0.62 | 1.272 | 2.311 | 0.371 | 2.702 | 1.437 | |

| 120 | 0.62 | 1.264 | 2.312 | 0.378 | 3.801 | 1.389 |

| F40 | F50 | F60 | PLA | |||||

|---|---|---|---|---|---|---|---|---|

| χ (%) | F (T) | a | F (T) | a | F (T) | a | F (T) | a |

| 20 | 1.042 | 0.46 | 0.9328 | 0.3723 | 1.01 | 0.3618 | 1.409 | 0.4873 |

| 40 | 1.138 | 0.448 | 1.289 | 0.444 | 1.395 | 0.4704 | 1.526 | 0.4794 |

| 60 | 1.193 | 0.4419 | 1.348 | 0.44 | 1.47 | 0.4969 | 1.606 | 0.4765 |

| 80 | 1.242 | 0.4395 | 1.393 | 0.4303 | 1.54 | 0.4835 | 1.681 | 0.4814 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pisupati, A.; Curto, M.; Laurent, T.; Cosson, B.; Park, C.H.; Dhakal, H.N. Influence of Cooling Rate on the Flexural and Impact Properties of Compression Molded Non-Woven Flax/PLA Biocomposites. Polymers 2025, 17, 493. https://doi.org/10.3390/polym17040493

Pisupati A, Curto M, Laurent T, Cosson B, Park CH, Dhakal HN. Influence of Cooling Rate on the Flexural and Impact Properties of Compression Molded Non-Woven Flax/PLA Biocomposites. Polymers. 2025; 17(4):493. https://doi.org/10.3390/polym17040493

Chicago/Turabian StylePisupati, Anurag, Marco Curto, Thomas Laurent, Benoit Cosson, Chung Hae Park, and Hom Nath Dhakal. 2025. "Influence of Cooling Rate on the Flexural and Impact Properties of Compression Molded Non-Woven Flax/PLA Biocomposites" Polymers 17, no. 4: 493. https://doi.org/10.3390/polym17040493

APA StylePisupati, A., Curto, M., Laurent, T., Cosson, B., Park, C. H., & Dhakal, H. N. (2025). Influence of Cooling Rate on the Flexural and Impact Properties of Compression Molded Non-Woven Flax/PLA Biocomposites. Polymers, 17(4), 493. https://doi.org/10.3390/polym17040493