Investigation on Dynamic and Static Modulus and Creep of Bio-Based Polyurethane-Modified Asphalt Mixture

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Gradations

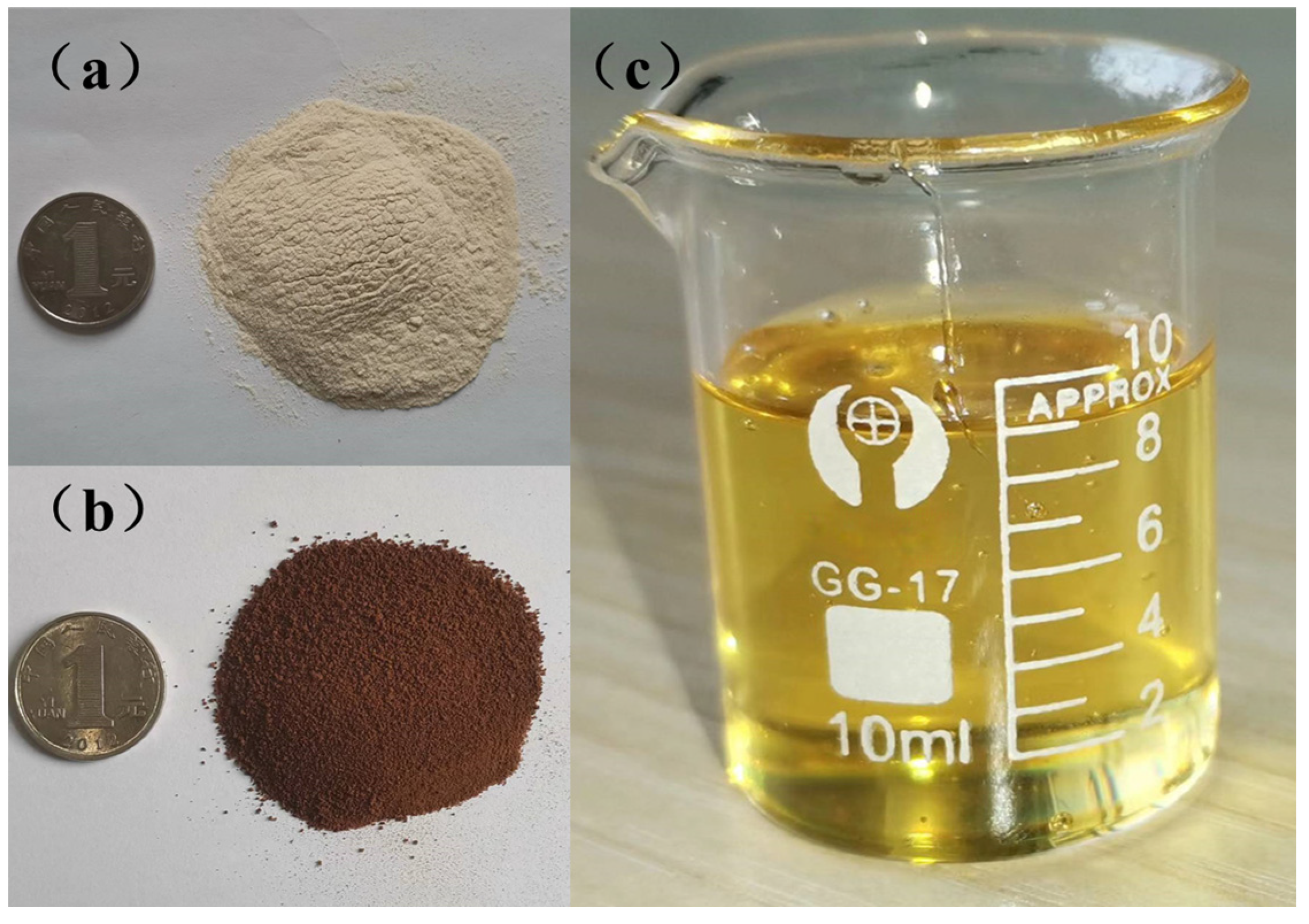

2.1.1. Raw Materials

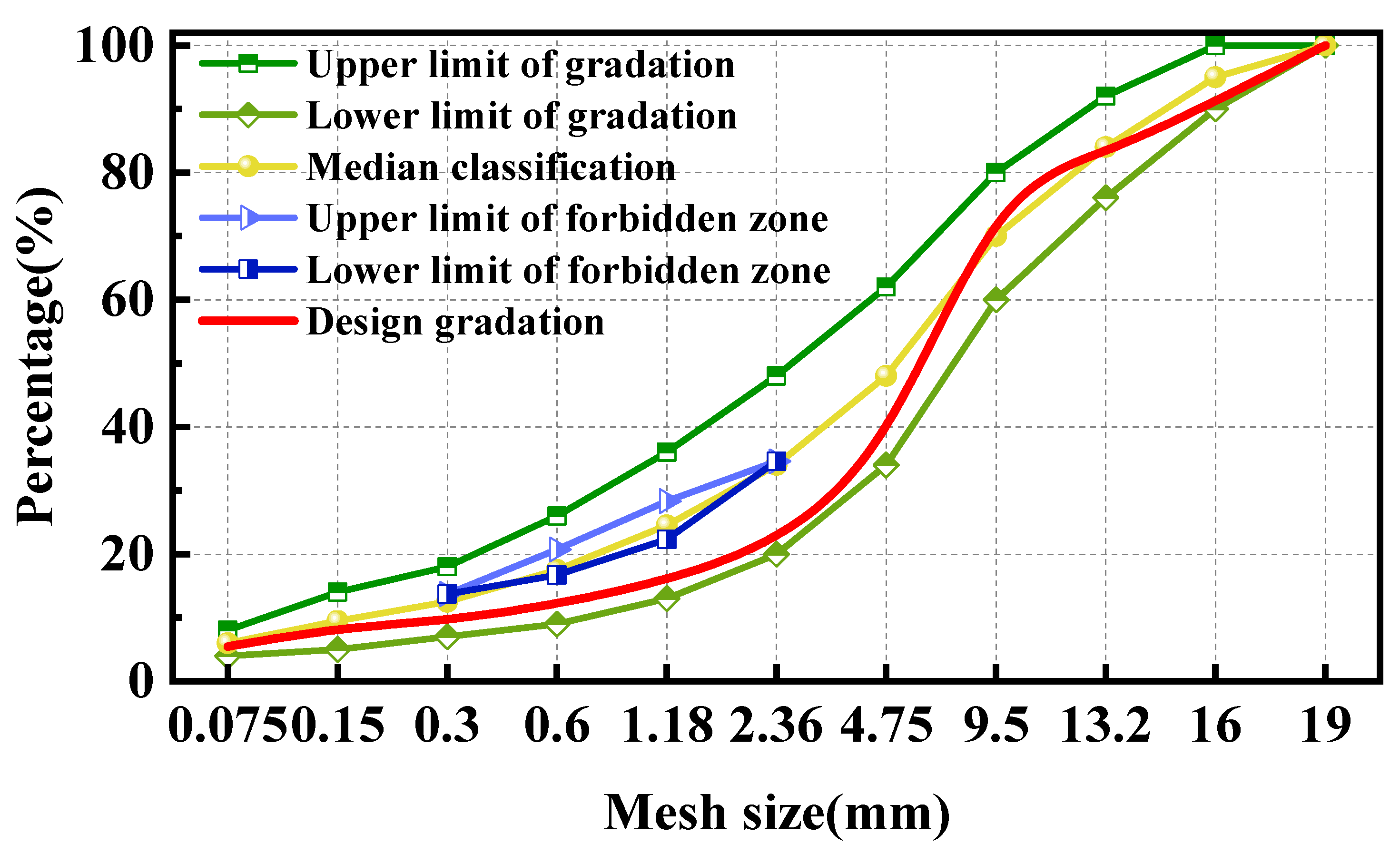

2.1.2. Gradations

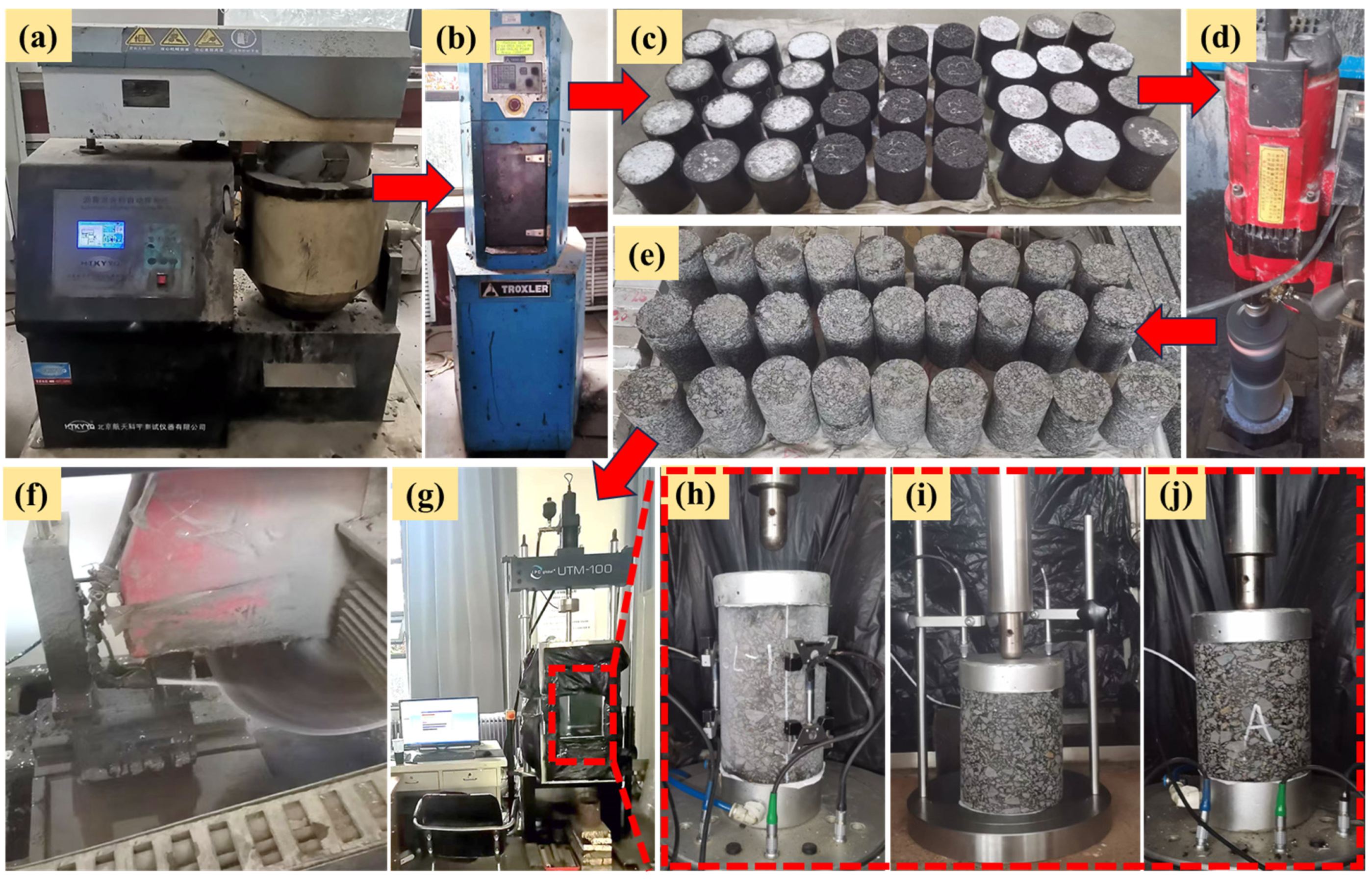

2.2. Specimen Preparation

2.3. Methods

2.3.1. Dynamic Modulus Test

2.3.2. Static Modulus Test

2.3.3. Uniaxial Static Load Creep Test

3. Dynamic Modulus of BPA Mixtures

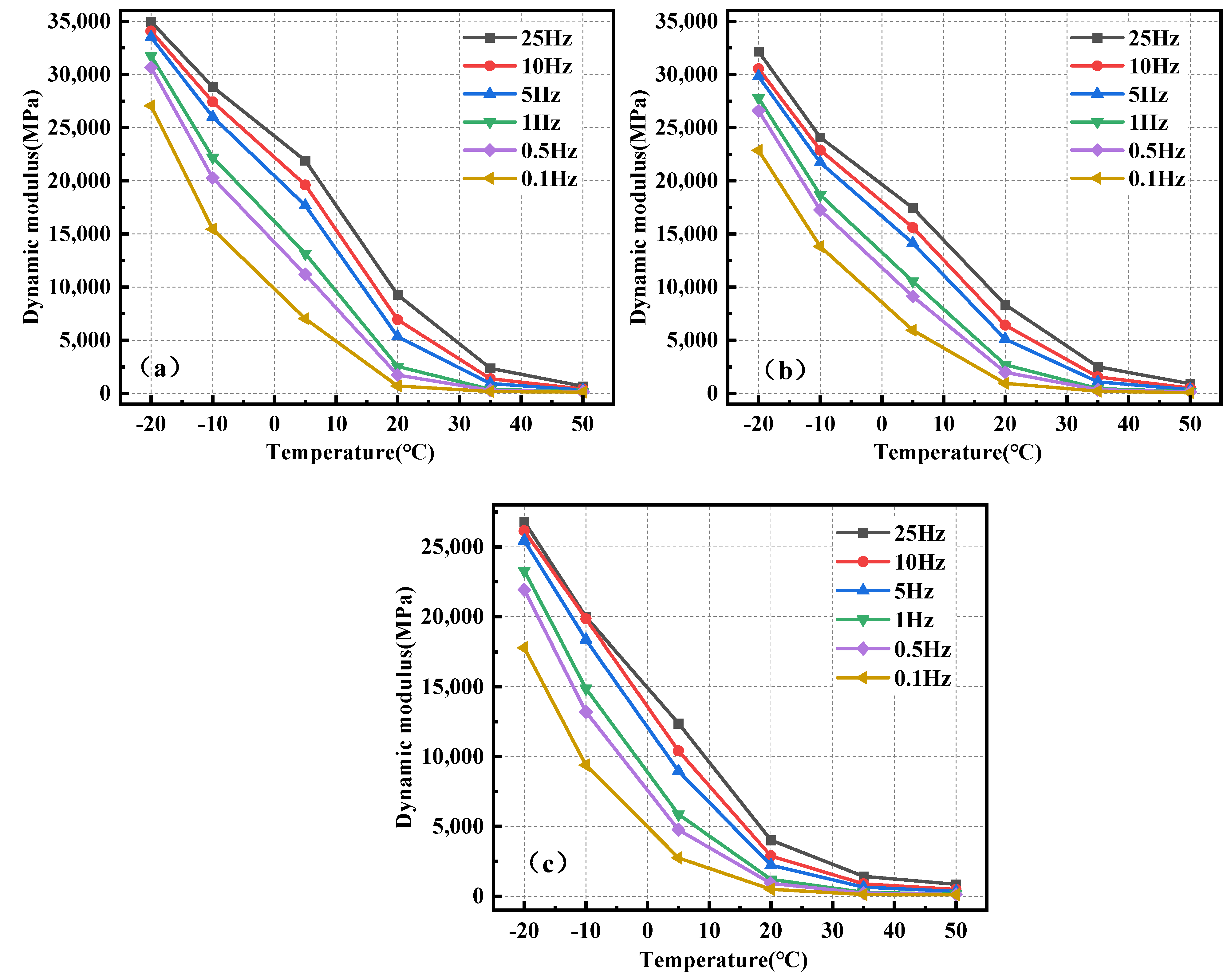

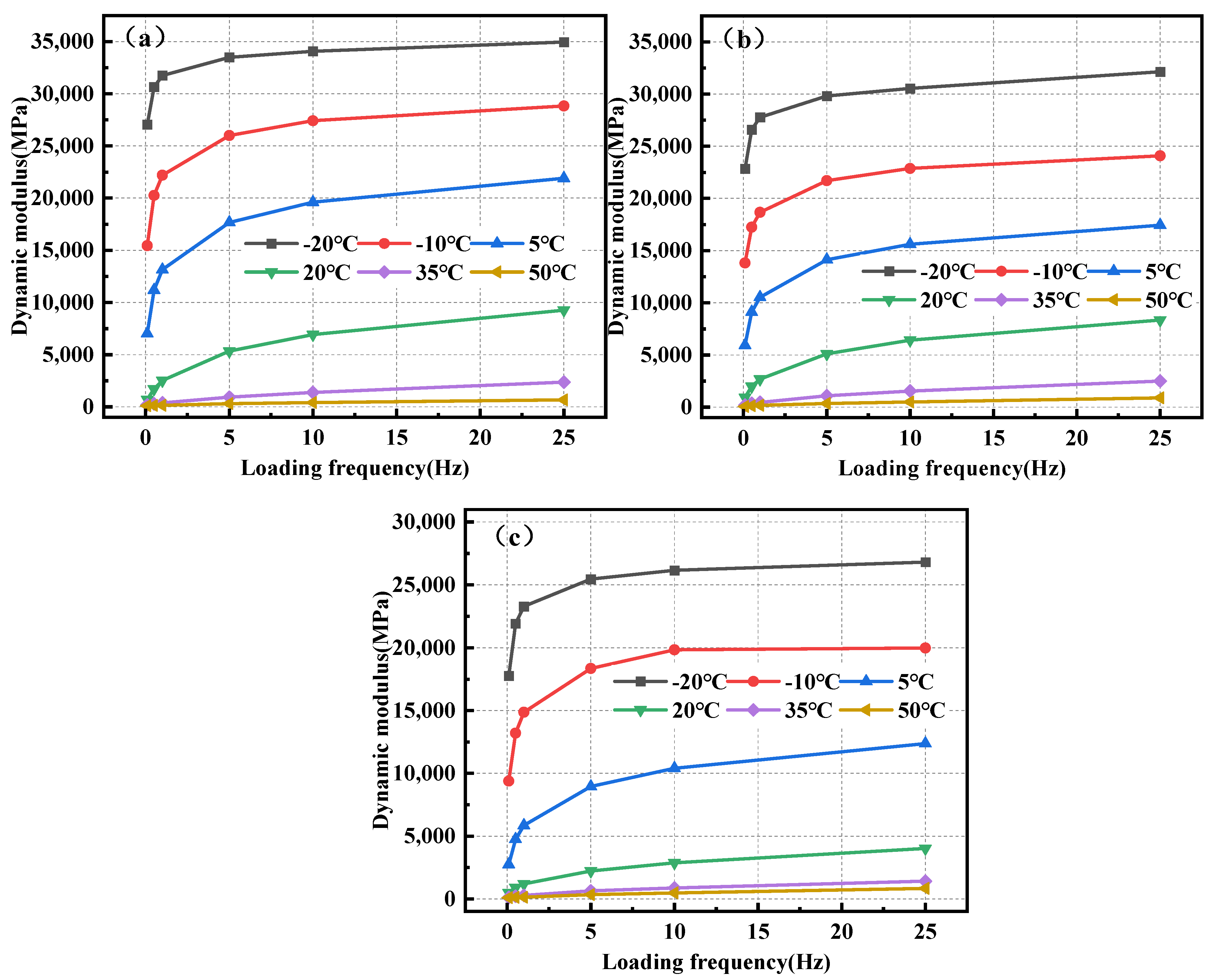

3.1. Dynamic Modulus

3.1.1. Correlation Between Dynamic Modulus and Temperature

3.1.2. Correlation Between Dynamic Modulus and Loading Frequency

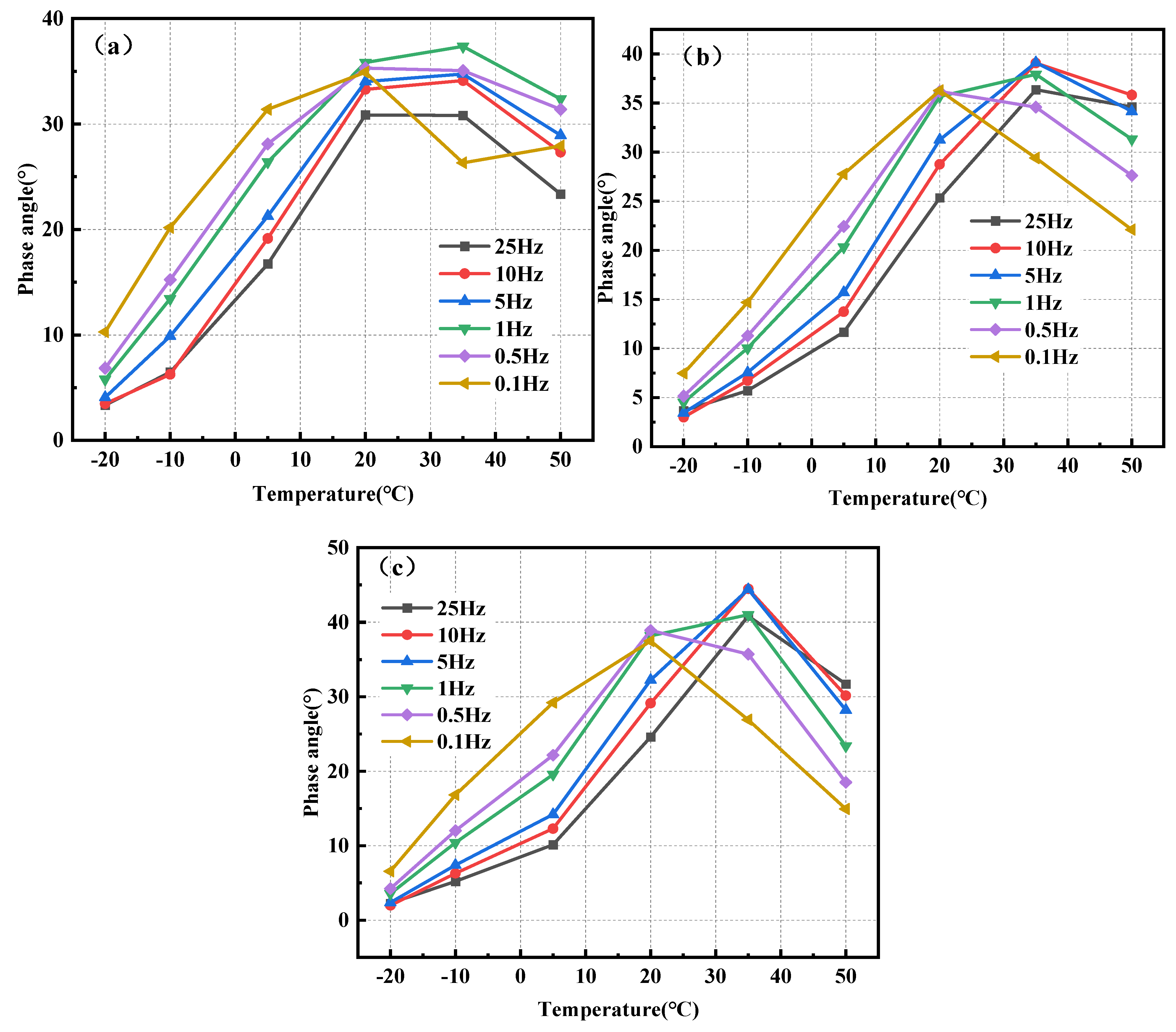

3.2. Phase Angle

3.2.1. Correlation Between Phase Angle and Temperature

3.2.2. Correlation Between Phase Angle and Loading Frequency

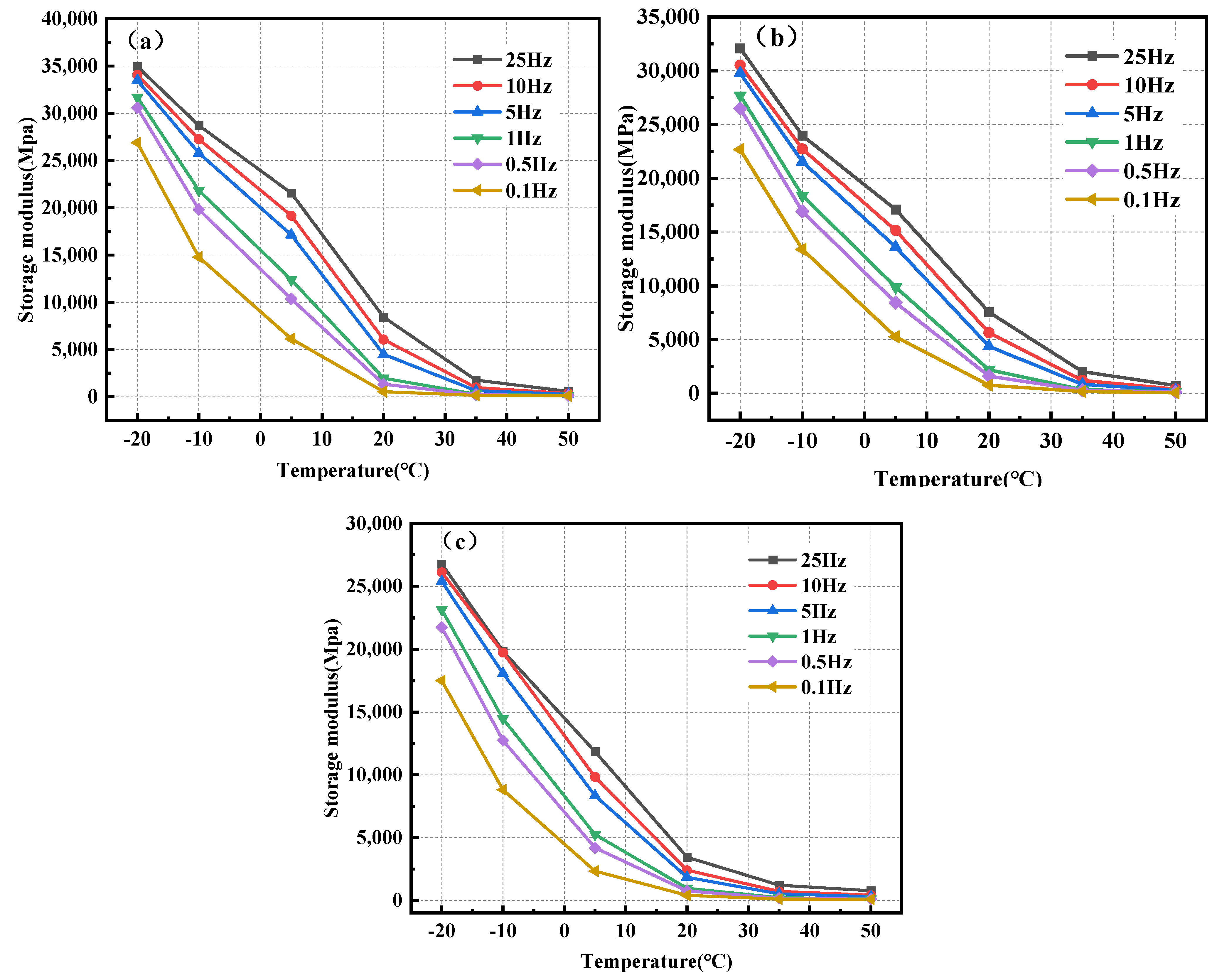

3.3. Storage Modulus

3.4. Loss Modulus

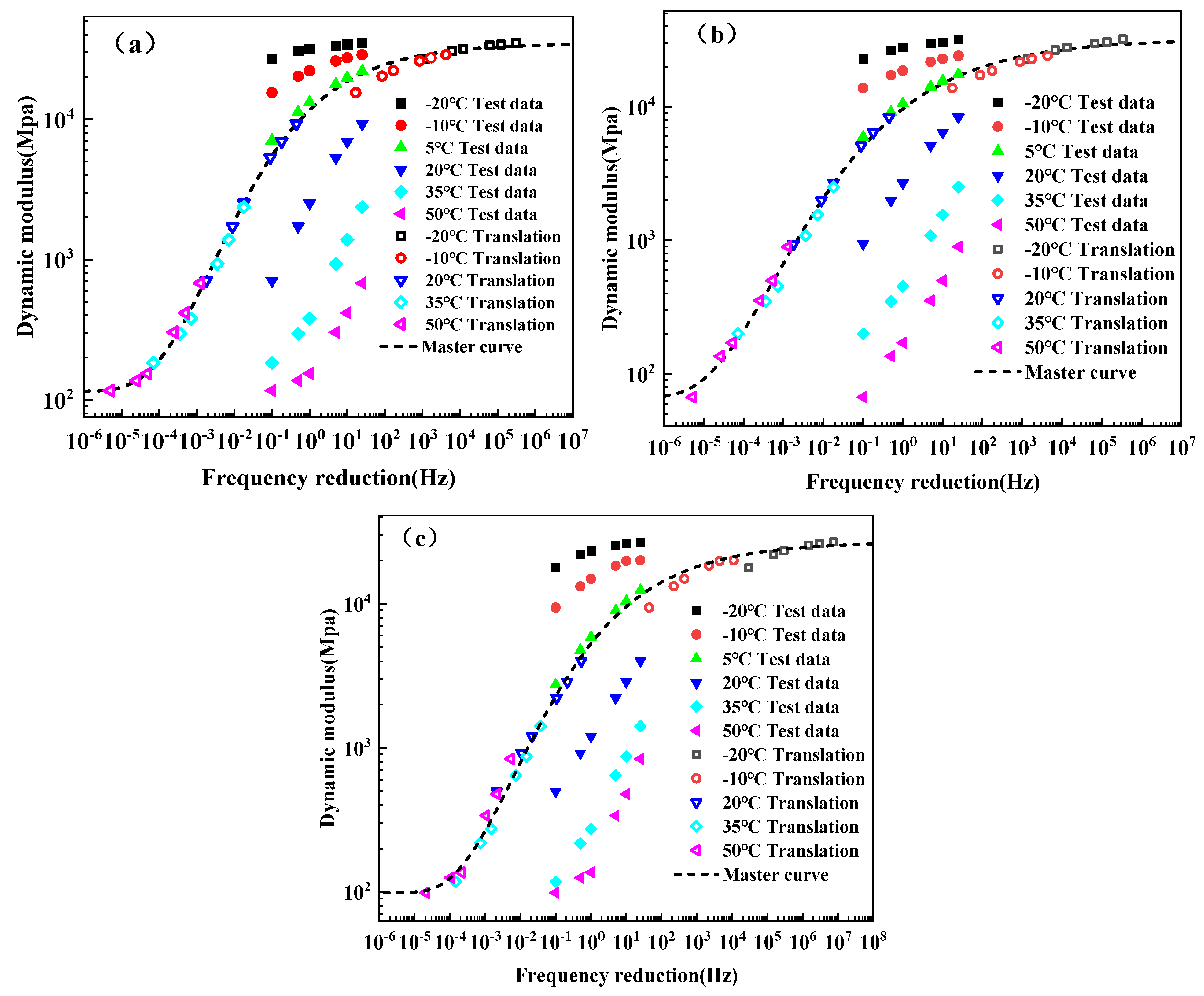

4. Dynamic Modulus Master Curve

5. Static Modulus of Mixtures

5.1. Static Modulus Test Results

5.2. Correlation Between Dynamic and Static Modulus

6. Creep Properties of the Mixtures

6.1. Creep Curve

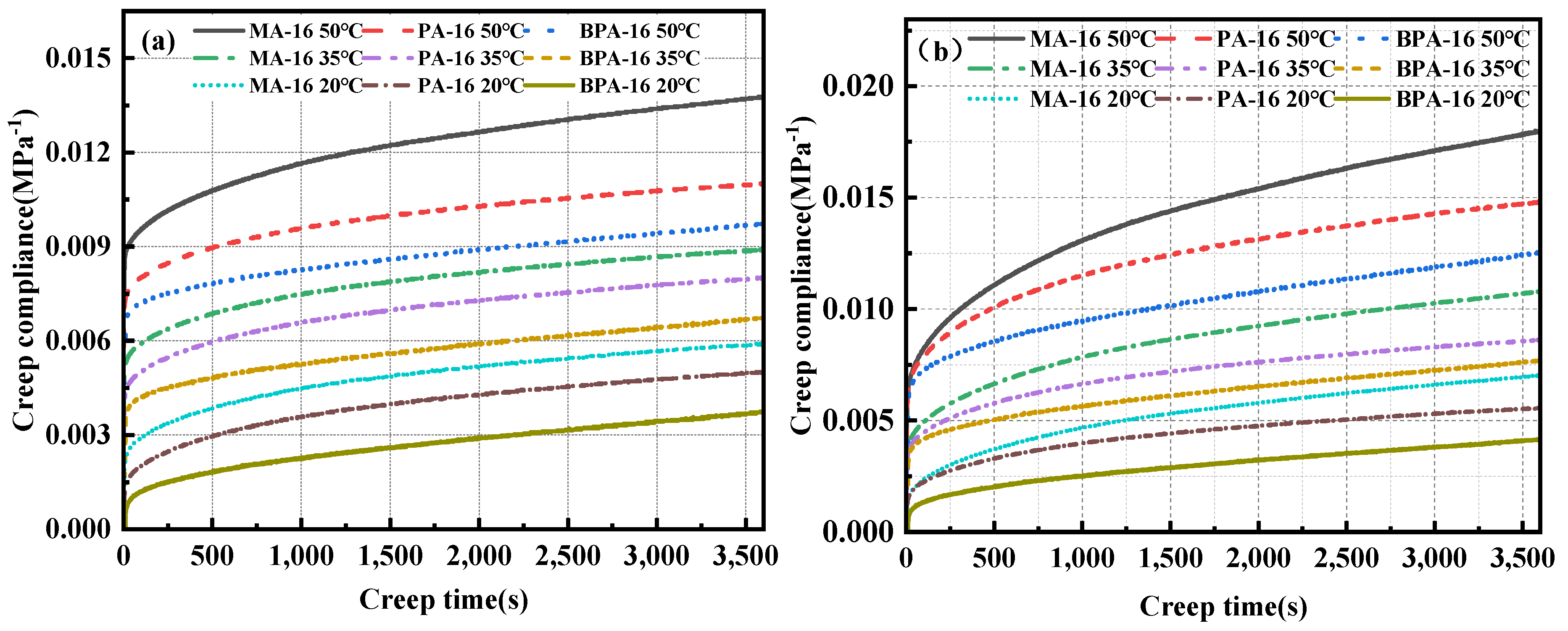

6.2. Creep Compliance Curve

7. Conclusions

- At a frequency of 25 Hz and a temperature of −20 °C, the dynamic modulus of BPA-16 increases by 8.7% and 30.4% compared to PA-16 and MA-16, respectively, indicating that the use of lignin and chitin as curing agents, in lieu of polyols, enhances the mechanical stability of asphalt mixtures under low-temperature conditions;

- Under the condition of 25 Hz and 50 °C, BPA-16 phase angle than MA-16 was reduced by 26.3%, proving that BPA-16 has low temperature sensitivity, explaining that bio-based polyurethane-modified asphalt mixture in a wider temperature range can maintain better elasticity mechanics performance;

- The dynamic modulus master curves for three mixtures, BPA-16, PA-16, and MA-16, were constructed using the generalized Sigmoidal model based on the idea of time-temperature equivalence. The dynamic modulus may be forecasted across a broad spectrum of temperatures and loading frequencies utilizing the master curves;

- With BPA-16, PA-16 and MA-16, three maximum static moduli of asphalt mixture under the condition of temperature is 20 °C, measured, and the size of the static modulus sort of BPA-16 > PA-16 > MA-16, lignin and chitosan mass, reduce the temperature sensitivity of asphalt mixture;

- Between −20°C and 20 °C, it was found that BPA-16, PA-16 and MA-16 three mixture of dynamic and static linear correlation, dynamic and static modulus can be transformed using formulas under different frequencies;

- As the creep time, temperature and the increase of the creep stress, creep BPA-16, PA-16, and MA-16 three mixture creep strain increase, in the 3600 s the creep time of the destruction of the three kinds of mixture phase does not appear, and the creep strain of BPA-16 minimum, The results showed that lignin and chitin further improved the permanent deformation resistance of polyurethane-modified asphalt mixture;

- This paper opens up ideas and provides data support for finding bio-based alternatives to polyols for polyurethane curing agents; lignin and chitin are inexpensive, while polyols are derivatives of non-renewable energy sources, i.e., petroleum, which responds to the current trend of green recycling economy and low-carbon emission reduction, and will have great socio-economic value if it can be effectively promoted.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lv, S.; Liu, J.; Peng, X.; Liu, H.; Hu, L.; Yuan, J.; Wang, J. Rheological and microscopic characteristics of bio-oil recycled asphalt. J. Clean. Prod. 2021, 295, 126449. [Google Scholar] [CrossRef]

- China Moto Statistical Bulletin Development Transport Industry. Statistical Bulletin on the Development of Transport Industry in 2023. 2023. Available online: https://xxgk.mot.gov.cn/2020/jigou/zhghs/202406/t20240614_4142419.html (accessed on 20 December 2024).

- Zhang, Z.; Huang, T.; Sun, J.; Wang, Z.; Wang, L.; Li, X.; Liu, H.; Zhang, D. Laboratory Study and Molecular Dynamics Simulation of High and Low-Temperature Properties of Polyurethane-Modified Asphalt. J. Mater. Civ. Eng. 2023, 35, 04023257. [Google Scholar] [CrossRef]

- Xu, S.; Liu, Z.; Guo, Q.; Ren, X.; Liang, H.; Zhang, Z.; Han, B. Determination of compaction timing of porous polyurethane mixture by multiscale testing and analysis. Transp. Geotech. 2023, 42, 101045. [Google Scholar] [CrossRef]

- Choi, J.H.; Kang, T.H.; Bang, Y.; Lee, J.K.; Song, J.C.; Song, I.K. Effect of metal-substitution on the redox behaviors of mono-transition metal-substituted Wells–Dawson tungstoarsenates. Catal. Commun. 2015, 65, 66–71. [Google Scholar] [CrossRef]

- Wallqvist, V.; Kjell, G.; Cupina, E.; Kraft, L.; Deck, C.; Willinger, R. New functional pavements for pedestrians and cyclists. Accid. Anal. Prev. 2017, 105, 52–63. [Google Scholar] [CrossRef] [PubMed]

- Xu, S.; Lu, G.; Hong, B.; Jiang, X.; Peng, G.; Wang, D.; Oeser, M. Experimental investigation on the development of pore clogging in novel porous pavement based on polyurethane. Constr. Build. Mater. 2020, 258, 120378. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Z.; Zhang, S.; Chang, P.; Liang, Y.; Wang, Z.; Ban, X.; Guo, Y.; Liu, X. Study on the effect of soft segment length on the performance of polyether-based polyurethane modified asphalt. Int. J. Adhes. Adhes. 2024, 130, 103642. [Google Scholar] [CrossRef]

- Liu, T.; Guo, N.; You, Z.; Tan, Y.; Fang, C. Thermal and mechanical properties of PEG4000 and PUSSPCMs for thermoregulation of asphalt. Constr. Build. Mater. 2024, 412, 134776. [Google Scholar] [CrossRef]

- Ding, H.; Gong, H.; Cong, L.; Hou, Y.; E, G. Investigating influence of hard segment content on rheological behavior of thermosetting PU modified asphalt. Constr. Build. Mater. 2024, 420, 135129. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, J.; Xie, Y.; Yao, M.; Jiang, Z. Preparation of Polyurethane Binders and Their Performance for Fast Pothole Patching. J. Mater. Civ. Eng. 2023, 35, 04023127. [Google Scholar] [CrossRef]

- Talledo Baila, G.A.; Ruiz Pico, Á.A. Influence of Thermoplastic Polyurethane on the Properties of Asphalt Cement and the Elastic Behavior of Asphalt Mixtures. Period. Polytech. Civ. Eng. 2024, 68, 833–841. [Google Scholar] [CrossRef]

- Kong, L.; Wang, Z.; Su, S.; Yue, J.; Luo, W.; Zhou, S.; Ren, D.; Ai, C. Exploring the interplay between thermo-oxidative degradation and asphalt aging in thermoplastic polyurethane-modified asphalt: Mechanisms, properties, and performance evolution. Constr. Build. Mater. 2024, 412, 134694. [Google Scholar] [CrossRef]

- Zhao, Y.; Gong, X.; Liu, Q. Research on rheological properties and modification mechanism of waterborne polyurethane modified bitumen. Constr. Build. Mater. 2023, 371, 130775. [Google Scholar] [CrossRef]

- Xu, P.; Wang, Y.; Cheng, P.; Cong, P.; Li, D.; Zhang, Z.; Hui, J.; Ye, M. Toughness modification of waterborne epoxy emulsified asphalt by waterborne polyurethane elastomer. Constr. Build. Mater. 2023, 386, 131547. [Google Scholar] [CrossRef]

- Gong, X.; Liu, Q.; Huang, W.; Wang, J.; Cao, Z.; Wu, S. Green synthesis of polyurethane with reversible oxime-urethane bond to enhance the self-healing properties of asphalt binder at room temperature. Constr. Build. Mater. 2024, 412, 134766. [Google Scholar] [CrossRef]

- Hao, Z.; Shan, B.; Liu, P.; Wu, Y.; Cao, X. Preparation and Characterization of a Novel Self-Healing Polyurethane-Modified Asphalt Based on Dynamic Disulfide Bond. J. Mater. Civ. Eng. 2024, 36, 04023627. [Google Scholar] [CrossRef]

- Li, K.; Xie, J.; Liu, Y.; Pan, Y.; Tan, Y. Development and characterization of anti-cracking epoxy asphalt for steel deck pavement. Constr. Build. Mater. 2024, 438, 137047. [Google Scholar] [CrossRef]

- Jin, X.; Li, D.; Fu, H.; Sun, B.; Yang, Y.; Guo, N.; Zhang, J. Research on fatigue self-healing of asphalts modified by thermoplastic polyurethane (TPU) with different soft segments. Constr. Build. Mater. 2024, 420, 135574. [Google Scholar] [CrossRef]

- Wei, K.; Cao, X.; Tang, B.; Wu, Y.; Jiang, T. Castor oil-based polyurethane Vitrimer modified asphalts regulated by dual dynamic reversible reactions and crosslinking density: Preparation, basic assessment and self-healing behavior. Constr. Build. Mater. 2024, 429, 136430. [Google Scholar] [CrossRef]

- Xia, W.; Chen, X.; Xu, T. Development of shape memory polyurethane/SBS compositely modified asphalt and synergistic modification mechanism. Constr. Build. Mater. 2023, 364, 129936. [Google Scholar] [CrossRef]

- Wei, K.; Wu, Y.; Cao, X.; Yang, X.; Tang, B.; Deng, L. Preparation and characterization of vanillin-based self-healing polyurethane-modified asphalts based on acylhydrazone chemistry. Eur. Polym. J. 2024, 211, 113010. [Google Scholar] [CrossRef]

- Duan, S.; Wu, X.; Wang, H.; Hu, J.; Luan, Y.; Ma, T. Design and evaluation of semi self-compacting cold mix polyurethane mixture for steel bridge deck pavement. Constr. Build. Mater. 2024, 419, 135490. [Google Scholar] [CrossRef]

- Zhang, Q.; Huang, T.; Wu, J.; Zhang, L.; Lan, Y. Cohesion Performance of Tack Coat Materials between Polyurethane Mixture and Asphalt Mixture. J. Mater. Civ. Eng. 2024, 36, 04023534. [Google Scholar] [CrossRef]

- Wang, Y.; Pei, Z.; Wang, G.; Zou, Y.; Yi, J.; Feng, D. Study on the influence factors on the design and road performance of high-performance waterproof adhesive material for concrete bridge decks. Constr. Build. Mater. 2024, 413, 134838. [Google Scholar] [CrossRef]

- Xu, Y.; Fan, Z.; Wang, Z.; Shan, H.; Lyu, X.; Liu, Z.; Xu, S. Research on anti-shear performance of waterproof adhesive layer (WAL) in polyurethane-mixture steel-bridge pavement structure. Constr. Build. Mater. 2024, 417, 135314. [Google Scholar] [CrossRef]

- Duan, S.; Hu, J.; Cui, J.; Chen, Y.; Ma, T.; Wu, X. Acrylate composite polyurethane binder for steel bridge deck pavements: Process optimization by response surface methodology and microanalysis. J. Appl. Polym. Sci. 2024, 141, e55228. [Google Scholar] [CrossRef]

- Wang, S.; Lv, C.; Jiang, K.; Xu, X.; Tong, T.; Wang, T. Superior Polyurethane-Based Seamless Expansion Joints for Bridges: Mechanical Properties, Full-Scale Test, and Finite Element Modeling. J. Mater. Civ. Eng. 2024, 36, 04024055. [Google Scholar] [CrossRef]

- Yang, X.; Fan, Z.; He, Y.; Cui, K.; Liao, Z.; Hong, B.; Wang, D. Mechanical properties, luminescent properties, and durability of solvent-free polyurethane-based phosphorescent road markings on asphalt pavements. Constr. Build. Mater. 2024, 414, 135053. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhou, J.; Wu, D.; Zheng, J.; Zhang, L. Preparation and performance evaluation of rubber powder-polyurethane composite modified cold patch asphalt and cold patch asphalt mixture. Constr. Build. Mater. 2023, 369, 130473. [Google Scholar] [CrossRef]

- Chen, J.; Liu, Y.; Rong, H.; Liang, M.; Liu, Y.; Huang, R. Research on high and low temperature rheological properties of TPU/SBR composite modified asphalt. Mater. Res. Express 2024, 11, 025301. [Google Scholar] [CrossRef]

- Kabir, T.; Al-Bayati, H.K.; Tighe, S. Laboratory mix preparation and investigation of mechanical behaviour of polyurethane-bound porous rubber pavement. Can. J. Civ. Eng. 2024, 51, 1350–1368. [Google Scholar] [CrossRef]

- Xu, S.; Liu, H.; Guo, Q.; Zhang, Z.; Han, B.; Liu, H. Evaluation on Moisture Susceptibility of Stone Mastic Polyurethane Concrete. J. Mater. Civ. Eng. 2024, 36, 04023599. [Google Scholar] [CrossRef]

- Sun, Z.; Chen, B.; Liu, S.; Zhou, T.; Huang, R. Polyurethane modified asphalt mixture incorporating waste glass with a wide particle size range: Preparation and performance evaluation. Case Stud. Constr. Mater. 2024, 20, e03119. [Google Scholar] [CrossRef]

- Yang, T.; He, Z.; Huang, G.; Zhao, Y.; Fu, J.; Xiang, H.; Zhou, Y. Study on materials composition and process parameters of polyurethane-modified asphalt synthesized in-situ by the one-shot process. Constr. Build. Mater. 2023, 374, 130661. [Google Scholar] [CrossRef]

- Li, K.; Yan, X.; Wang, Y.; Ai, T.; Niu, Y.; Chen, Y. Design and modification mechanism of a novel high-viscosity thermoplastic polyurethane modified asphalt. Constr. Build. Mater. 2024, 433, 136585. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Z.; Yu, X.; Kan, S.; Luo, Y.; Han, K.; Liang, Y.; Gao, J. Preparation of polyol from waste polyethylene terephthalate (PET) and its application to polyurethane (PU) modified asphalt. Constr. Build. Mater. 2024, 427, 136286. [Google Scholar] [CrossRef]

- Novikov, V.Y.; Rysakova, K.S.; Shumskaya, N.V.; Mukhortova, A.M.; Kesarev, K.A. King crab gills as a new source of chitin/chitosan and protein hydrolysates. Int. J. Biol. Macromol. 2023, 232, 123346. [Google Scholar] [CrossRef]

- Rawlins, E.; De Giorgio, E.; Giannios, P.; Espinàs, M.L.; Llimargas, M. A dynamic interplay between chitin synthase and the proteins Expansion/Rebuf reveals that chitin polymerisation and translocation are uncoupled in Drosophila. PLoS Biol. 2023, 21, e3001978. [Google Scholar] [CrossRef]

- Yan, N.; Chen, X. Sustainability: Don’t waste seafood waste. Nature 2015, 524, 155–157. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Negi, T.; Sagar, N.A.; Kumar, Y.; Tarafdar, A.; Sirohi, R.; Sindhu, R.; Pandey, A. Sustainable processes for treatment and management of seafood solid waste. Sci. Total Environ. 2022, 817, 152951. [Google Scholar] [CrossRef] [PubMed]

- Maalihan, R.D.; Chen, Q.; Tamura, H.; Agueda, J.R.H.S.; Pajarito, B.B.; Caldona, E.B.; Advincula, R.C. Mechanically and Thermally Enhanced 3D-Printed Photocurable Polymer Nanocomposites Containing Functionalized Chitin Nanowhiskers by Stereolithography. ACS Appl. Polym. Mater. 2022, 4, 2513–2526. [Google Scholar] [CrossRef]

- Hassan, M.M.; Koyama, K. Thermomechanical and viscoelastic properties of green composites of PLA using chitin micro-particles as fillers. J. Polym. Res. 2020, 27, 27. [Google Scholar] [CrossRef]

- Chen, F.; Wang, C.; Liu, X.; Wang, Z.; Fang, L.; Zhang, Y. Flame-retardant properties of chitin liquefaction-based polyurethane foam. J. Polym. Res. 2023, 30, 143. [Google Scholar] [CrossRef]

- Zheng, C.; Huang, J.; Bin-Shafique, S.; Matamoros, A. Performance Evaluation for Cohesionless Soil Stabilized with Lignin and Polymerized Lignin. Geotech. Test. J. 2023, 47, 254–274. [Google Scholar] [CrossRef]

- O’Dea, R.M.; Pranda, P.A.; Luo, Y.; Amitrano, A.; Ebikade, E.O.; Gottlieb, E.R.; Ajao, O.; Benali, M.; Vlachos, D.G.; Ierapetritou, M.; et al. Ambient-pressure lignin valorization to high-performance polymers by intensified reductive catalytic deconstruction. Sci. Adv. 2022, 8, eabj7523. [Google Scholar] [CrossRef] [PubMed]

- Kurańska, M.; Pinto, J.A.; Salach, K.; Barreiro, M.F.; Prociak, A. Synthesis of thermal insulating polyurethane foams from lignin and rapeseed based polyols: A comparative study. Ind. Crops Prod. 2020, 143, 111882. [Google Scholar] [CrossRef]

- Zhuang, W.; Ren, S.; Liu, B.; Ding, T.; Liu, L.; Gu, L.; Sun, M. Modification Mechanism and Performance of High-Content Polyurethane-Modified Asphalt. Coatings 2025, 15, 75. [Google Scholar] [CrossRef]

- JTG E20-2011; Test Specification for Asphalt and Asphalt Mixture in Highway Engineering. Ministry of Transport and Export Engineering of the People’s Republic of China: Beijing, China, 2011.

- JTG E42-2019; Test Methods of Aggregate for Highway Engineering. People’s Communications Press: Beijing, China, 2019.

- JTG F40-2017; Test Specification for Asphalt and Asphalt mixtures for Highway Engineering. Ministry of Transport and Export Engineering of the People’s Republic of China: Beijing, China, 2017.

- Bartczak, P.; Wysokowski, M.; Szylińczuk, K.; Odalanowska, M.; Jesionowski, T.; Borysiak, S. Green synthesis of chitin/lignin based-polyurethane composites. Ind. Crops Prod. 2023, 204, 117237. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, S.; Lv, R.; Wu, J.; Qi, H. Viscoelastic mechanical performance of dense polyurethane mixtures based on dynamic and static modulus testing and creep testing. Constr. Build. Mater. 2022, 320, 126207. [Google Scholar] [CrossRef]

- Zhaoyi, H.; Jinfeng, L.; Wen, Z. Dynamic modulusof porous asphalt mixture and its prediction model. J. Jilin Univ. (Eng. Technol.) 2022, 52, 1375–1385. [Google Scholar]

- Irfan, M.; Waraich, A.S.; Ahmed, S.; Ali, Y. Characterization of Various Plant-Produced Asphalt Concrete Mixtures Using Dynamic Modulus Test. Adv. Mater. Sci. Eng. 2016, 2016, 5618427. [Google Scholar] [CrossRef][Green Version]

- Zho, J.; Wang, D.; Bai, Q. Research on master curve of dynamic modulus of asphalt mixture. Highw. Eng. 2009, 34, 60–62. [Google Scholar]

- Chen, H.; Luo, R.; Liu, H. Research on dynamic modulus master curve and phase angle master curve of asphalt mixture based on generalized logistic sigmoidal model. J. Wuhan Univ. Technol. (Transp. Sci. Eng.) 2017, 41, 141–145. [Google Scholar]

- Ma, L.; Wang, H.; Ma, Y. Viscoelasticity of asphalt mixture based on the dynamic modulus test. J. Mater. Civ. Eng. 2024, 36, 04023624. [Google Scholar] [CrossRef]

- Zhao, Z.; Xiao, F.; Toraldo, E.; Crispino, M.; Ketabdari, M. Effect of crumb rubber and reclaimed asphalt pavement on viscoelastic property of asphalt mixture. J. Clean. Prod. 2023, 428, 139422. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, H.; Song, W.; Yin, J.; Zhan, Y.; Yu, J.; Wada, S.A. Thermal fatigue and cracking behaviors of asphalt mixtures under different temperature variations. Constr. Build. Mater. 2023, 369, 130623. [Google Scholar] [CrossRef]

- De Carolis, S.; Putignano, C.; Soria, L.; Carbone, G. Effect of porosity and pore size distribution on elastic modulus of foams. Int. J. Mech. Sci. 2024, 261, 108661. [Google Scholar] [CrossRef]

- Qian, G.; Shi, C.; Yu, H.; Yao, D.; Zhu, X.; Li, X. Evaluation of different modulus input on the mechanical responses of asphalt pavement based on field measurements. Constr. Build. Mater. 2021, 312, 125299. [Google Scholar] [CrossRef]

- Li, P.; Jiang, X.; Guo, K.; Xue, Y.; Dong, H. Analysis of viscoelastic response and creep deformation mechanism of asphalt mixture. Constr. Build. Mater. 2018, 171, 22–32. [Google Scholar] [CrossRef]

- Han, L.; Zhu, J.; Li, F.; Yang, Y.; Zheng, M.; Zhou, X. Conversion from Shear Creep Compliance to Relaxation Modulus of Asphalt Binder Using Cauchy Residue Method and Experimental Validation. J. Mater. Civ. Eng. 2024, 36, 04023494. [Google Scholar] [CrossRef]

| Performance Index | Unit | Examination Outcomes | Standard |

|---|---|---|---|

| Penetration (25 °C) | 0.1 mm | 86 | 80–100 |

| Ductility (15 °C) | cm | >100 | ≥100 |

| Solubility | v | 99.71 | ≥99.5 |

| Softening point | °C | 47.3 | ≥45 |

| Flash point | °C | 281 | ≥245 |

| Kinetic Viscosity (60 °C) | Pa·s | 182 | ≥160 |

| Species | Technical Index | Examination Outcomes |

|---|---|---|

| Lignin | Average molecular weight | 10,000 |

| PH | 5.5–7.5 | |

| Sulfur content | <3.6% | |

| Chitin | Source | Shrimp shell |

| Particle size | <20 μm | |

| H2O2 | Concentration | 30% |

| Performance Index | Unit | Examination Outcomes | Standard |

|---|---|---|---|

| Isocyanato (–NCO) content | % | 16.53 | 15.6–16.6 |

| Viscosity (25 °C) | MPa∙s | 2862 | 2500–4500 |

| Density (25 °C) | g/cm3 | 1.09 | - |

| Exterior | - | Brown liquid | Liquid |

| Performance Index | Unit | Examination Outcomes | Standard |

|---|---|---|---|

| Water absorption | % | 0.92 | ≤2 |

| Bulk specific density | g·cm3 | 2.796 | - |

| Los Angeles abrasion loss | % | 20.1 | ≤28 |

| <0.075 mm particle content | - | 0.5 | ≤1 |

| Apparent gravity | g·cm3 | 2.891 | ≥2.6 |

| Performance Index | Unit | Examination Outcomes | Standard |

|---|---|---|---|

| Water absorption | % | 0.88 | - |

| Bulk specific density | g·cm3 | 2.701 | - |

| Sand equivalent | % | 70 | ≥60 |

| Apparent gravity | g·cm3 | 2.754 | ≥2.50 |

| BPA Content (%) | Bulk Density (g/cm3) | Void Ratio (%) | Saturation (%) | Marshall Stability (kN) | Flow Value (mm) |

|---|---|---|---|---|---|

| 3.9 | 2.439 | 7.1 | 56.7 | 18.65 | 1.6 |

| 4.4 | 2.461 | 5.4 | 67.1 | 21.32 | 1.8 |

| 4.9 | 2.488 | 4.3 | 74.6 | 24.52 | 2.0 |

| 5.4 | 2.492 | 3.6 | 76.7 | 26.19 | 2.1 |

| 5.9 | 2.479 | 2.5 | 84.5 | 25.47 | 2.2 |

| Standards | - | 3–4 | 75–85 | ≥6.0 | - |

| BPA Content (%) | Bulk Density (g/cm3) | Void Ratio (%) | Saturation (%) | Marshall Stability (kN) | Flow Value (mm) |

|---|---|---|---|---|---|

| 3.7 | 2.438 | 7.3 | 55.6 | 16.32 | 1.8 |

| 4.2 | 2.467 | 6.0 | 66.1 | 18.25 | 1.9 |

| 4.7 | 2.489 | 4.9 | 74.1 | 21.64 | 2.1 |

| 5.2 | 2.498 | 3.9 | 75.6 | 22.19 | 2.2 |

| 5.7 | 2.481 | 3.0 | 83.4 | 20.37 | 2.3 |

| Standards | - | 3–4 | 75–85 | ≥6.0 | - |

| BPA Content (%) | Bulk Density (g/cm3) | Void Ratio (%) | Saturation (%) | Marshall Stability (kN) | Flow Value (mm) |

|---|---|---|---|---|---|

| 4.9 | 2.475 | 3.2 | 76.7 | 11.91 | 3.1 |

| Standards | - | 3–4 | 75–85 | ≥6.0 | 2–4 |

| Mixture Type | Model Parameters | R Square | ||||||

|---|---|---|---|---|---|---|---|---|

| C1 | C2 | α | δ | β | γ | λ | ||

| BPA-16 | 16.13 | 123.64 | 2.06 | 4.54 | −1.05 | −0.13 | −0.78 | R2 > 0.99 |

| PA-16 | 15.74 | 120.31 | 1.827 | 4.51 | −1.54 | −0.49 | −0.14 | R2 > 0.99 |

| MA-16 | 13.17 | 110.25 | 1.99 | 4.43 | −1.01 | −0.49 | −0.01 | R2 > 0.99 |

| Temperature | BPA-16 (MPa) | PA-16 (MPa) | MA-16 (MPa) |

|---|---|---|---|

| −20 °C | 2705 | 2285 | 1778 |

| −10 °C | 1544 | 1382 | 1088 |

| 5 °C | 1027 | 943 | 842 |

| 20 °C | 706 | 685 | 497 |

| Type | Loading Frequency | 25 | 10 | 5 | 1 | 0.5 | 0.1 |

|---|---|---|---|---|---|---|---|

| BPA-16 | Intercept | 6836.71 | 3944.90 | 1653.06 | −2890.14 | −4425.20 | −6636.79 |

| Slope | 11.31 | 12.08 | 12.69 | 13.57 | 13.63 | 12.84 | |

| R square | 0.901 | 0.908 | 0.921 | 0.952 | 0.932 | 0.964 | |

| PA-16 | Intercept | 2328.67 | 404.14 | −1334.08 | −4798.91 | −5772.62 | −6911.36 |

| Slope | 13.73 | 13.94 | 14.37 | 14.90 | 14.74 | 13.45 | |

| R square | 0.956 | 0.951 | 0.96 | 0.971 | 0.956 | 0.960 | |

| MA-16 | Intercept | −2594.99 | −4238.03 | −5436.030 | −7289.46 | −7599.87 | −7225.65 |

| Slope | 17.49 | 18.13 | 18.24 | 17.68 | 16.93 | 14.11 | |

| R square | 0.965 | 0.957 | 0.967 | 0.978 | 0.963 | 0.952 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, B.; Xing, Y.; Li, C. Investigation on Dynamic and Static Modulus and Creep of Bio-Based Polyurethane-Modified Asphalt Mixture. Polymers 2025, 17, 359. https://doi.org/10.3390/polym17030359

Han B, Xing Y, Li C. Investigation on Dynamic and Static Modulus and Creep of Bio-Based Polyurethane-Modified Asphalt Mixture. Polymers. 2025; 17(3):359. https://doi.org/10.3390/polym17030359

Chicago/Turabian StyleHan, Biao, Yongming Xing, and Chao Li. 2025. "Investigation on Dynamic and Static Modulus and Creep of Bio-Based Polyurethane-Modified Asphalt Mixture" Polymers 17, no. 3: 359. https://doi.org/10.3390/polym17030359

APA StyleHan, B., Xing, Y., & Li, C. (2025). Investigation on Dynamic and Static Modulus and Creep of Bio-Based Polyurethane-Modified Asphalt Mixture. Polymers, 17(3), 359. https://doi.org/10.3390/polym17030359