Evaluating Environmental Performance of PLA–Cellulose-Based Biocomposites: A Comprehensive Study on Biodegradability, Compostability, and Ecotoxicity

Abstract

1. Introduction

- Chemical characterization: A minimum of volatile solids content of 50% (this parameter is used to estimate the amount of organic material susceptible of being degraded), and limit values for heavy metals (values listed in Annex A of EN 13432 [13]);

- Compost quality: The final quality of the mature compost should not negatively affect plant growth—plant ecotoxicity test (OECD 208 [19]).

2. Materials and Methods

2.1. Materials

2.2. Methods

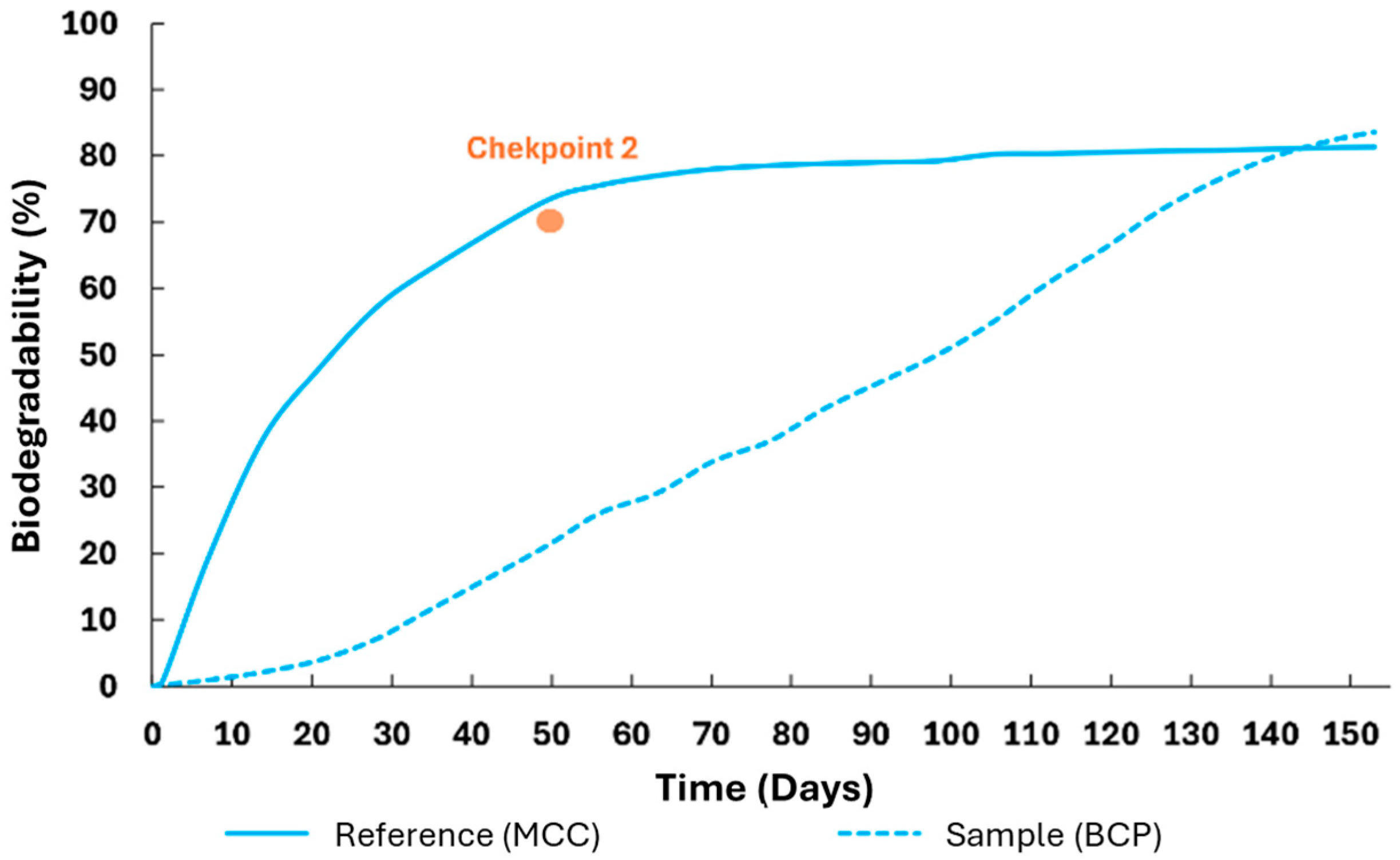

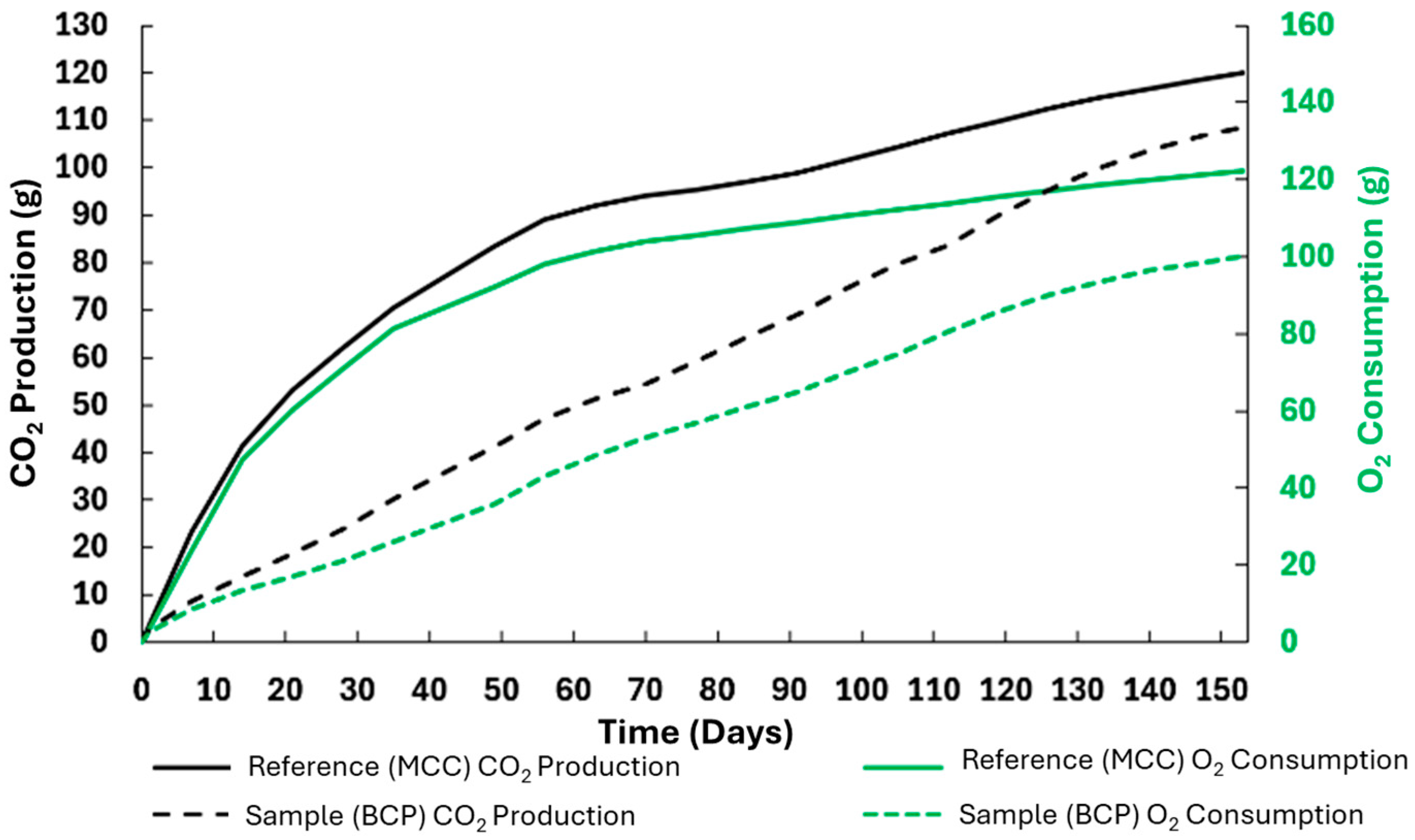

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PLA | Polylactic Acid |

| PS | Polystyrene |

| PET | Polyethylene Terephthalate |

| MFC | Micro-fibrillated cellulose |

| BEKP | Eucalyptus kraft pulp |

| MFI | Melt flow index |

| SSW | Synthetic Solid Waste |

| CO2 | Carbon Dioxide |

| EN | European Norm |

| ISO | International Standard Organization |

| OECD | Organization for Economic Cooperation and Development |

| SEM | Scanning Electron Microscopy |

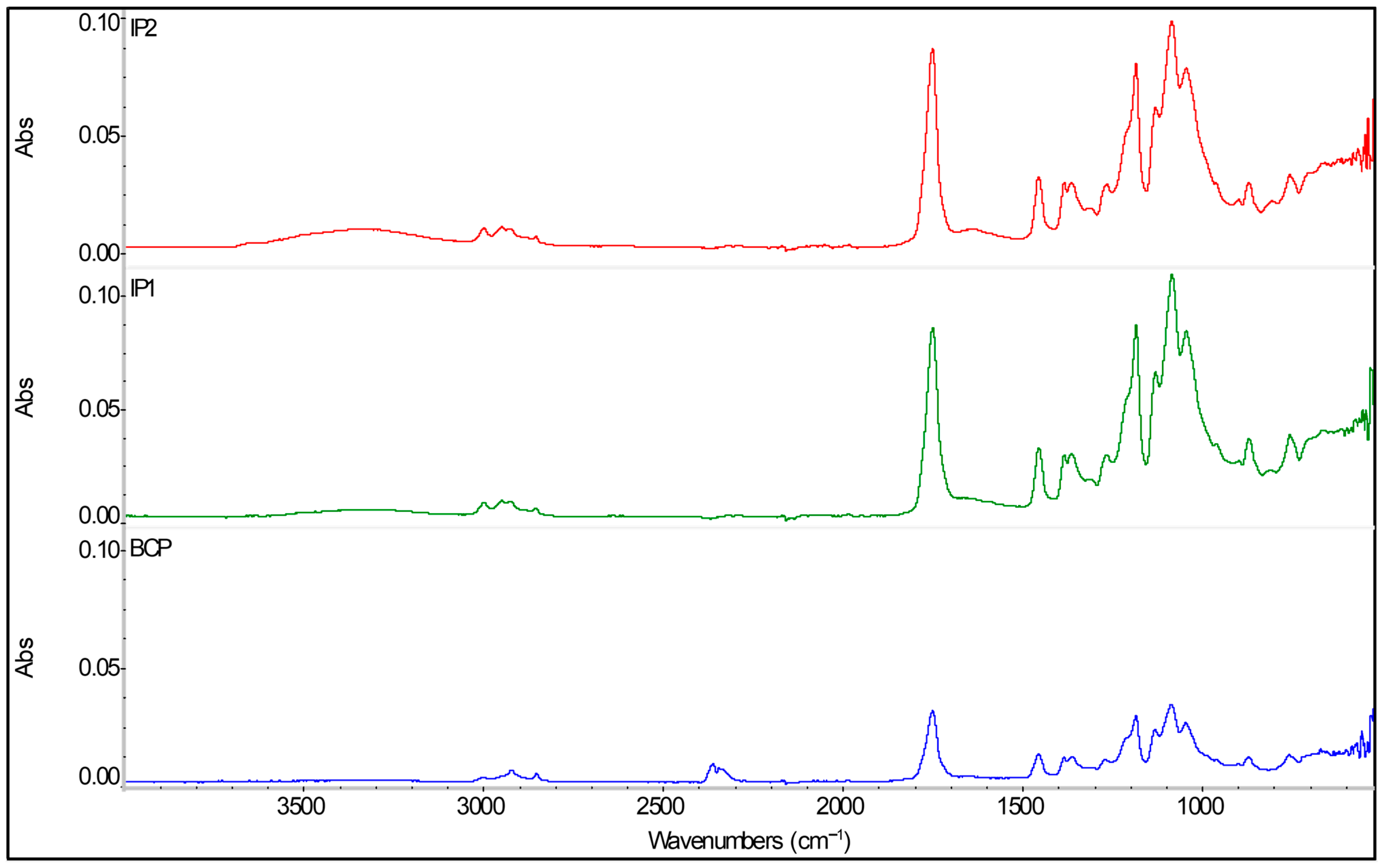

| FTIR-ATR | Attenuated Total Reflection Fourier Transform Infrared Spectroscopy |

| X-RD | X-ray Diffraction |

| CrI | Crystallinity Index |

| I002 | Maximum intensity of the crystalline peak |

| Iam | Minimum intensity in the amorphous region |

| BCP | Biocomposite Pellets Sample |

| IP1 | Injected Part 1 Sample |

| IP2 | Injected Part 2 Sample |

| ICP-AES | Inductively Coupled Plasma Atomic Emission Spectroscopy |

| F | Fluoride |

| As | Arsenic |

| Co | Cobalt |

| Cr | Chromium |

| Cu | Copper |

| Mo | Molybdenum |

| Ni | Nickel |

| Se | Selenium |

| Zn | Zinc |

| Cd | Cadmium |

| Hg | Mercury |

| Pb | Lead |

| TOC | Total Organic Carbon |

| MCC | Microcrystalline Cellulose Reference |

| C/N ratio | Carbon/Nitrogen ratio |

| GI | Germination Index |

| RG | Relative Germination |

| RRL | Relative Root Length |

| NGS,T | Arithmetic average of the number of germinated seeds from the test triplicate |

| NGS,C | Arithmetic average of the number of germinated seeds from the control |

| LR,T | Mean root length of the test triplicate |

| LR,C | Mean root length of the control |

| GR | Growth Rate |

| PLT | Arithmetic average of the plant length from the test triplicate |

| PLC | Arithmetic average of the plant length from the control |

| SR | Survival Rate |

| NPE | Number of Plants that Emerged |

| NPW | Number of Plants that Withered |

| O2 | Oxygen |

References

- Gadaleta, G.; Andrade-Chapal, J.C.; López-Ibáñez, S.; Mozo-Toledo, M.; Navarro-Calderón, Á. Biodegradability of Bioplastics in Managed and Unmanaged Environments: A Comprehensive Review. Materials 2025, 18, 2382. [Google Scholar] [CrossRef] [PubMed]

- Radu, E.-R.; Panaitescu, D.M.; Nicolae, C.-A.; Gabor, R.A.; Rădiţoiu, V.; Stoian, S.; Alexandrescu, E.; Fierăscu, R.; Chiulan, I. The Soil Biodegradability of Structured Composites Based on Cellulose Cardboard and Blends of Polylactic Acid and Polyhydroxybutyrate. J. Polym. Environ. 2021, 29, 2310–2320. [Google Scholar] [CrossRef]

- Islam, M.M.; Islam, M.A.; Rahman, A.N.M.M.; Xuepeng, Z.; Li, J.; Liu, L. Development of hybrid nanocellulose-reinforced PLA biocomposites from waste jute bags and ramie fabric with enhanced mechanical and thermal properties. Biomass Convers. Biorefinery 2025, 15, 19263–19281. [Google Scholar] [CrossRef]

- Kalita, N.K.; Damare, N.A.; Hazarika, D.; Bhagabati, P.; Kalamdhad, A.; Katiyar, V. Biodegradation and characterization study of compostable PLA bioplastic containing algae biomass as potential degradation accelerator. Environ. Chall. 2021, 3, 100067. [Google Scholar] [CrossRef]

- Trivedi, A.K.; Gupta, M.K.; Singh, H. PLA based biocomposites for sustainable products: A review. Adv. Ind. Eng. Polym. Res. 2023, 6, 382–395. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Lavoine, N.; Lucia, L.A.; Dou, C. Formulating bioplastic composites for biodegradability, recycling, and performance: A Review. BioResources 2020, 16, 2021–2083. [Google Scholar] [CrossRef]

- Vieira, A.C.; Vieira, J.C.; Guedes, R.M.; Marques, A.T. Degradation Characterization of Aliphatic Polyesters—In Vitro Study. In Proceedings of the AIP Conference Proceedings, Ischia, Italy, 28 August 2008; Volume 1042, pp. 309–311. [Google Scholar]

- Brunšek, R.; Kopitar, D.; Schwarz, I.; Marasović, P. Biodegradation Properties of Cellulose Fibers and PLA Biopolymer. Polymers 2023, 15, 3532. [Google Scholar] [CrossRef]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. Environmental Impact of Food Packaging Materials: A Review of Contemporary Development from Conventional Plastics to Polylactic Acid Based Materials. Materials 2020, 13, 4994. [Google Scholar] [CrossRef]

- Yetiş, F.; Liu, X.; Sampson, W.W.; Gong, R.H. Biodegradation of Composites of Polylactic Acid and Microfibrillated Lignocellulose. J. Polym. Environ. 2023, 31, 698–708. [Google Scholar] [CrossRef]

- Jacob, J.; Linson, N.; Mavelil-Sam, R.; Maria, H.J.; Pothan, L.A.; Thomas, S.; Kabdrakhmanova, S.; Laroze, D. Poly (lactic acid)/nanocellulose biocomposites for sustainable food packaging. Cellulose 2024, 31, 5997–6042. [Google Scholar] [CrossRef]

- Rosa, D.d.S.; Lenz, D.M. Biocomposites: Influence of Matrix Nature and Additives on the Properties and Biodegradation Behaviour. In Biodegradation-Engineering and Technology; InTech: Toulon, France, 2013; ISBN 978-953-51-1153-5. [Google Scholar]

- NP EN 13432; Requisitos Para Embalagens Valorizáveis por Compostagem e Biodegradação. European Committee for Standardization: Brussels, Belgium, 2015.

- EN 14995; Plastics-Evaluation of Compostability-Test Scheme and Specifications. European Committee for Standardization: Brussels, Belgium, 2006.

- ISO 14855-1; Determination of the Ultimate Aerobic Biodegradability of Plastic Materials Under Controlled Composting Conditions—Method by Analysis of Evolved Carbon Dioxide-Part 1: General Method. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 14855-2; Determination of the Ultimate Aerobic Biodegradability of Plastic Materials Under Controlled Composting Conditions—Method by Analysis of Evolved Carbon Dioxide-Part 2: Gravimetric Measurement of Carbon Dioxide Evolved in a Laboratory-Scale Test. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 20200; Plastics—Determination of the Degree of Disintegration of Plastic Materials Under Composting Conditions in a Laboratory-Scale Test. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 16929; Plastics—Determination of the Degree of Disintegration of Plastic Materials Under Defined Composting Conditions in a Pilot-Scale Test. International Organization for Standardization: Geneva, Switzerland, 2021.

- OECD. Test No. 208: Terrestrial Plant Test: Seedling Emergence and Seedling Growth Test; OECD Guidelines for the Testing of Chemicals, Section 2; OECD: Paris, France, 2006; ISBN 978-92-64-07006-6. [Google Scholar]

- Pires, J.R.A.; Souza, V.G.L.; Fuciños, P.; Pastrana, L.; Fernando, A.L. Methodologies to Assess the Biodegradability of Bio-Based Polymers—Current Knowledge and Existing Gaps. Polymers 2022, 14, 1359. [Google Scholar] [CrossRef] [PubMed]

- Chomnutcha Boonmee, C.K. Degradation of Poly (lactic acid) under Simulated Landfill Conditions. Environ. Nat. Resour. J. 2016, 14, 2. [Google Scholar] [CrossRef]

- ASTM D6400-21; D20 Committee Specification for Labeling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities. ASTM: West Conshohocken, PA, USA. [CrossRef]

- Pérez-Fonseca, A.A.; González-López, M.E.; Robledo-Ortíz, J.R. Reprocessing and Recycling of Poly (Lactic Acid): A Review. J. Polym. Environ. 2023, 31, 4143–4159. [Google Scholar] [CrossRef]

- Macedo, J.R.N.; Barbosa, R.R.S.; Rosa, D.S. Macro, Micro e Nano Compósitos de PLA: Degradação Biótica e Abiótica. In Proceedings of the 14th Brazilian Congress on Polymers, Águas de Lindóia, SP, Brazil, 19–23 October 2017; p. 6. Available online: https://www.researchgate.net/publication/339596109_MACRO_MICRO_E_NANO_COMPOSITOS_DE_PLA_DEGRADACAO_BIOTICA_E_ABIOTICA_MACRO_MICRO_AND_NANO_PLA_COMPOSITES_BIOTIC_AND_ABYOTIC_DEGRADATION (accessed on 30 November 2025).

- Sanson, E.L. Caracterização Térmica, Mecânica e Morfológica de Compósitos Biodegradáveis de PLA-Celulose. In Proceedings of the XXVI Encontro Anual de Iniciação Científica e III Encontro Anual de Iniciação Científica Júnior, Universidade Estadual de Ponta Grossa-UEPG, Ponta Grossa, Parana, Brazil, 19–20 October 2017; p. 4. [Google Scholar]

- Mujtaba, M.; Fernandes Fraceto, L.; Fazeli, M.; Mukherjee, S.; Savassa, S.M.; Araujo De Medeiros, G.; Do Espírito Santo Pereira, A.; Mancini, S.D.; Lipponen, J.; Vilaplana, F. Lignocellulosic biomass from agricultural waste to the circular economy: A review with focus on biofuels, biocomposites and bioplastics. J. Clean. Prod. 2023, 402, 136815. [Google Scholar] [CrossRef]

- ISO 18602; Packaging and the Environment—Optimization of the Packaging System. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 18763; Soil Quality—Determination of the Toxic Effects of Pollutants on Germination and Early Growth of Higher Plants. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 10694; Soil Quality—Determination of Organic and Total Carbon After Dry Combustion (Elementary Analysis). International Organization for Standardization: Geneva, Switzerland, 1995.

- ISO 10693; Soil Quality—Determination of Carbonate Content—Volumetric Method. International Organization for Standardization: Geneva, Switzerland, 1995.

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Uzun, İ. Methods of determining the degree of crystallinity of polymers with X-ray diffraction: A review. J. Polym. Res. 2023, 30, 394. [Google Scholar] [CrossRef]

- Ranucci, E.; Treccani, S.; Ferruti, P.; Alongi, J. The Seed Germination Test as a Valuable Tool for the Short-Term Phytotoxicity Screening of Water-Soluble Polyamidoamines. Polymers 2024, 16, 1744. [Google Scholar] [CrossRef]

- Singh, A.A.; Genovese, M.E.; Mancini, G.; Marini, L.; Athanassiou, A. Green Processing Route for Polylactic Acid–Cellulose Fiber Biocomposites. ACS Sustain. Chem. Eng. 2020, 8, 4128–4136. [Google Scholar] [CrossRef]

- Rosa, M.F.; Medeiros, E.S.; Malmonge, J.A.; Gregorski, K.S.; Wood, D.F.; Mattoso, L.H.C.; Glenn, G.; Orts, W.J.; Imam, S.H. Cellulose nanowhiskers from coconut husk fibers: Effect of preparation conditions on their thermal and morphological behavior. Carbohydr. Polym. 2010, 81, 83–92. [Google Scholar] [CrossRef]

- O’Loughlin, J.; McDonnell, H.; Lawless, R.; Kelleher, S.M.; Fahy, S.; Freeland, B.; Rochfort, K.D.; Gaughran, J. Manufacturing process significantly impacts the rate of degradation of polylactic acid (PLA) under controlled composting conditions. RSC Sustain. 2026. [Google Scholar] [CrossRef]

- Withana, P.A.; Yuan, X.; Im, D.; Choi, Y.; Bank, M.S.; Lin, C.S.K.; Hwang, S.Y.; Ok, Y.S. Biodegradable plastics in soils: Sources, degradation, and effects. Environ. Sci. Process. Impacts 2025, 27, 3321–3343. [Google Scholar] [CrossRef] [PubMed]

- Liang, Q.; Xu, Y.; Lu, Y.; Liu, P.; Jiang, Y.; Yao, Y.; Sheng, J. Improved crystallinity and biodegradability of 3D printable polylactic acid composite filaments filled with cellulose-enriched Huangjiu (Chinese rice wine) distillers’ grains as sustainable nucleating agents. Cellulose 2025, 32, 7415–7428. [Google Scholar] [CrossRef]

- Wietecha, J.; Kazimierczak, J.; Jeziorna, A. Effect of the Surface modification of Cellulose nanofibers on the Mechanical Properties and Disintegrability of Specific PLA/Cellulose Composites. Fibres Text. East. Eur. 2023, 31, 15–29. [Google Scholar] [CrossRef]

- Galera Manzano, L.M.; Ruz Cruz, M.Á.; Moo Tun, N.M.; Valadez González, A.; Mina Hernandez, J.H. Effect of Cellulose and Cellulose Nanocrystal Contents on the Biodegradation, under Composting Conditions, of Hierarchical PLA Biocomposites. Polymers 2021, 13, 1855. [Google Scholar] [CrossRef]

- Sourkouni, G.; Jeremić, S.; Kalogirou, C.; Höfft, O.; Nenadovic, M.; Jankovic, V.; Rajasekaran, D.; Pandis, P.; Padamati, R.; Nikodinovic-Runic, J.; et al. Study of PLA pre-treatment, enzymatic and model-compost degradation, and valorization of degradation products to bacterial nanocellulose. World J. Microbiol. Biotechnol. 2023, 39, 161. [Google Scholar] [CrossRef]

- Hajilou, N.; Mostafayi, S.S.; Yarin, A.L.; Shokuhfar, T. A Comparative Review on Biodegradation of Poly (Lactic Acid) in Soil, Compost, Water, and Wastewater Environments: Incorporating Mathematical Modeling Perspectives. AppliedChem 2024, 5, 1. [Google Scholar] [CrossRef]

- Wan Ishak, W.H.; Rosli, N.A.; Ahmad, I. Influence of amorphous cellulose on mechanical, thermal, and hydrolytic degradation of poly (lactic acid) biocomposites. Sci. Rep. 2020, 10, 11342. [Google Scholar] [CrossRef]

- Quintana, M.C.; Frontini, P.M.; Arriaga, A.; Plank, B.; Major, Z. Fiber Orientation Distribution Predictions for an Injection Molded Venturi-Shaped Part Validated Against Experimental Micro-Computed Tomography Characterization. Front. Mater. 2020, 7, 169. [Google Scholar] [CrossRef]

- Oumer, A.N.; Mamat, O. A Review of Effects of Molding Methods, Mold Thickness and Other Processing Parameters on Fiber Orientation in Polymer Composites. Asian J. Sci. Res. 2013, 6, 401–410. [Google Scholar] [CrossRef]

- Kulikowska, D.; Bernat, K.; Wojnowska-Baryła, I.; Pasieczna-Patkowska, S.; Jabłoński, R. Composting as a disposal route of PLA materials: Kinetics of the aerobic biodegradation. Desalination Water Treat. 2020, 206, 153–164. [Google Scholar] [CrossRef]

- Fritz, I.; Hergolitsch, L.; Dalnodar, D.; Zerobin, A. Quantifying the difference between CO2 release and carbon conversion in aerobic aquatic biodegradation tests. bioRxiv 2025. [Google Scholar] [CrossRef]

- Kintzi, A.; Rau, J.; Daturpalli, S.; Battagliarin, G.; Weber, M.; Lott, C.; Zumstein, M. Comparing respirometric systems for standardized biodegradation testing: A case study with polyethylene glycol and activated sludge microbiomes. ChemRxiv 2025. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, W.; Wang, Y.; Liu, Y.; Chen, J.; Li, B.; Su, B.; Song, H. Overestimation of microbial community respiration caused by nitrification, and the identification of keystone groups associated with respiration. Front. Mar. Sci. 2024, 10, 1331680. [Google Scholar] [CrossRef]

- Vaziourakis, K.-M.; Heffernan, L.; Jakobsson, E.; Grasset, C.; Kothawala, D.; Tranvik, L. Controls on the respiratory quotient of organic matter decomposition across ecosystems. Biogeochemistry 2025, 168, 24. [Google Scholar] [CrossRef]

- Fonseca, A.M. Biodegradação de Bioplásticos-Comportamento dos Bioplásticos em Sistemas de Compostagem e Digestão Anaeróbia. Master’s Thesis, Universidade Nova de Lisboa, Caparica, Portugal, 2022. [Google Scholar]

- Momeni, S.; Craplewe, K.; Safder, M.; Luz, S.; Sauvageau, D.; Elias, A. Accelerating the Biodegradation of Poly (lactic acid) through the Inclusion of Plant Fibers: A Review of Recent Advances. ACS Sustain. Chem. Eng. 2023, 11, 15146–15170. [Google Scholar] [CrossRef]

- Jorge, M. Avaliação da Fitotoxicidade de Compostos Orgânicos e da Desintegração de Materiais Contributo para Aferição das Normas Técnicas: EN 16086-1 e ISO 20200. Master’s Thesis, Universidade Nova de Lisboa, Caparica, Portugal, 2018. [Google Scholar]

- Silvestrim, R.G.; Santana, R.M.C.; Moura, A. Avaliação Comparativa da Degradação por Intemperismo Natural e por Compostagem de Compósitos de PLA Reforçado com Fibra Vegetal da Árvore Embira. In Proceedings of the Anais do 15 Congresso Brasileiro de Polímeros (15 CBPOL), Bento Gonçalves, RS, Brazil, 27–31 October 2019; pp. 1083–1087. [Google Scholar]

- Cordeiro, N. Compostagem de Resíduos Verdes e Avaliação da Qualidade dos Compostos Obtidos-Caso de Estudo da Algar S.A. Master’s Thesis, Instituto Superior de Agronomia da Universidade Técnica de Lisboa, Lisboa, Portugal, 2010. [Google Scholar]

- Wittmann, G. Estudo de Estruturas Laminadas com Bioplásticos para o Sistema Produtivo de Embalagens: Dedintegração e Ecotoxicidade em Condições de Compostagem. Master’s Thesis, Centro Estadual de Educação Tecnológica Paula Souza, São Paulo, Brazil, 2020. [Google Scholar]

- Lončarić, Z.; Galić, V.; Nemet, F.; Perić, K.; Galić, L.; Ragályi, P.; Uzinger, N.; Rékási, M. The Evaluation of Compost Maturity and Ammonium Toxicity Using Different Plant Species in a Germination Test. Agronomy 2024, 14, 2636. [Google Scholar] [CrossRef]

- Nguyen, N.H.A.; Brdlík, P.; Borůvka, M.; Riha, J.; Sevcu, A. Technical note: The influence of controlled thermophilic composting of PLA bio-composites on bacterial community. Bioremediation J. 2025, 29, 182–189. [Google Scholar] [CrossRef]

| Sample | Volatile Solids Content (%) | |

|---|---|---|

| Biocomposite Pellets (BCP) |  | 99.9 ± 0.03 |

| Injected Part 1 (IP1) |  | 99.9 ± 0.04 |

| Injected Part 2 (IP2) |  | 99.2 ± 0.17 |

| Element | Fluoride (F) | Arsenic (As) | Cadmium (Cd) | Lead (Pb) | Cobalt (Co) | Copper (Cu) | Chromium (Cr) | Mercury (Hg) | Molybdenum (Mo) | Nickel (Ni) | Selenium (Se) | Zinc (Zn) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| European Limit (mg/kg) | 100 | 5 | 0.5 | 50 | N.A. 1 | 50 | 50 | 0.5 | 1 | 20 | 0.75 | 150 |

| BCP (mg/kg) | <20 | <1.3 | <0.1 | <0.1 | <2.5 | <2.5 | <2.5 | <0.1 | <0.1 | <2.5 | <0.5 | <2.5 |

| IP1 (mg/kg) | <20 | <0.5 | <0.25 | <0.5 | <0.25 | 0.23 | <0.25 | <0.1 | <0.25 | <0.25 | <0.5 | <2.5 |

| IP2 (mg/kg) | <20 | <0.5 | <0.25 | <0.5 | <0.5 | 0.23 | <0.25 | <0.1 | <0.25 | <0.25 | <0.5 | <0.5 |

| Reactor | BCP | IP1 | IP2 |

|---|---|---|---|

| I002 (crystalline peak, 2θ ≈ 21–23°) | 1326 | 3098 | 3078 |

| Iam (amorphous region, 2θ ≈ 17–19°) | 1117 | 1475 | 1557 |

| Crystallinity Index (CrI) (%) | 15.8 | 52.4 | 49.4 |

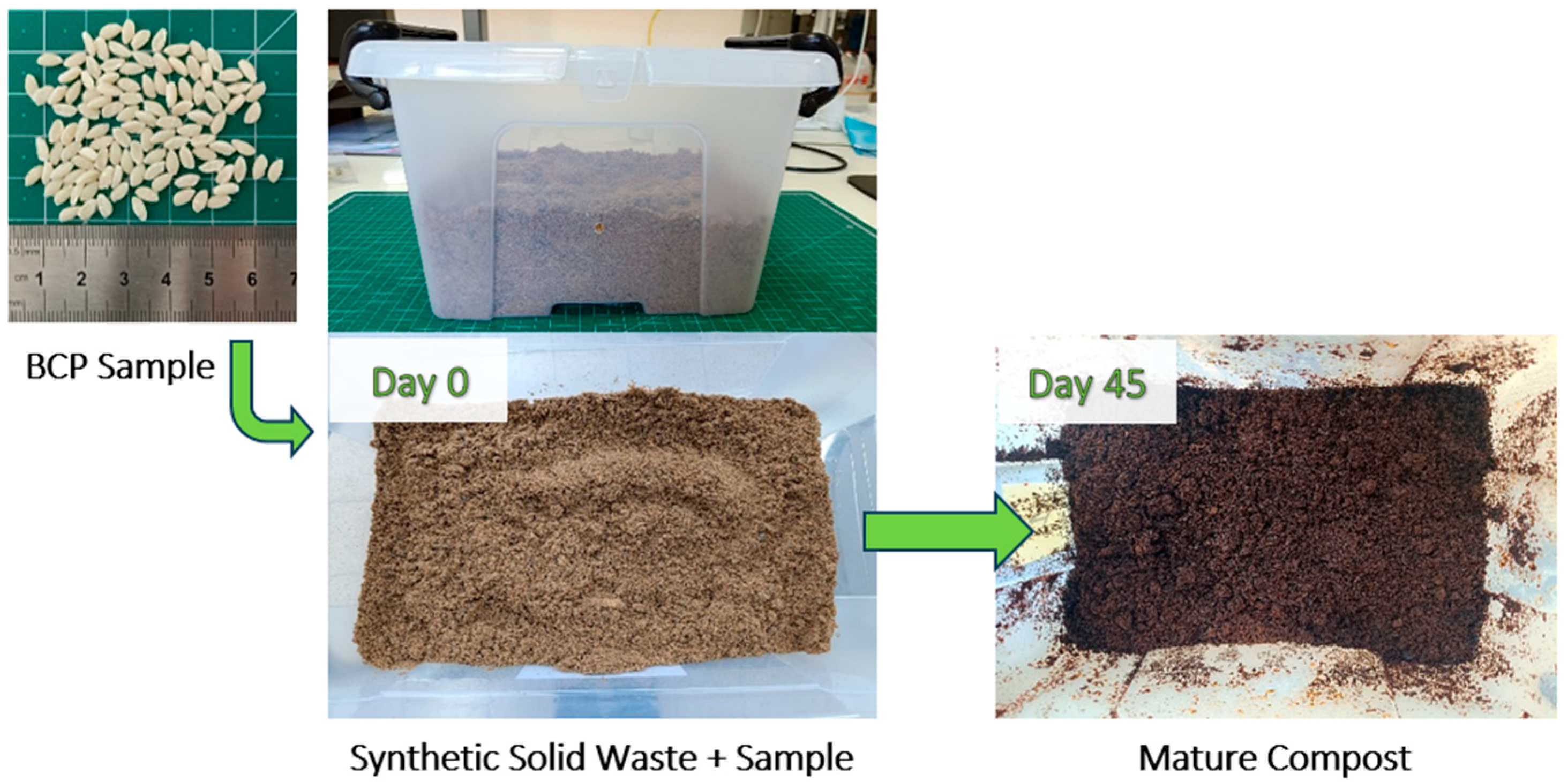

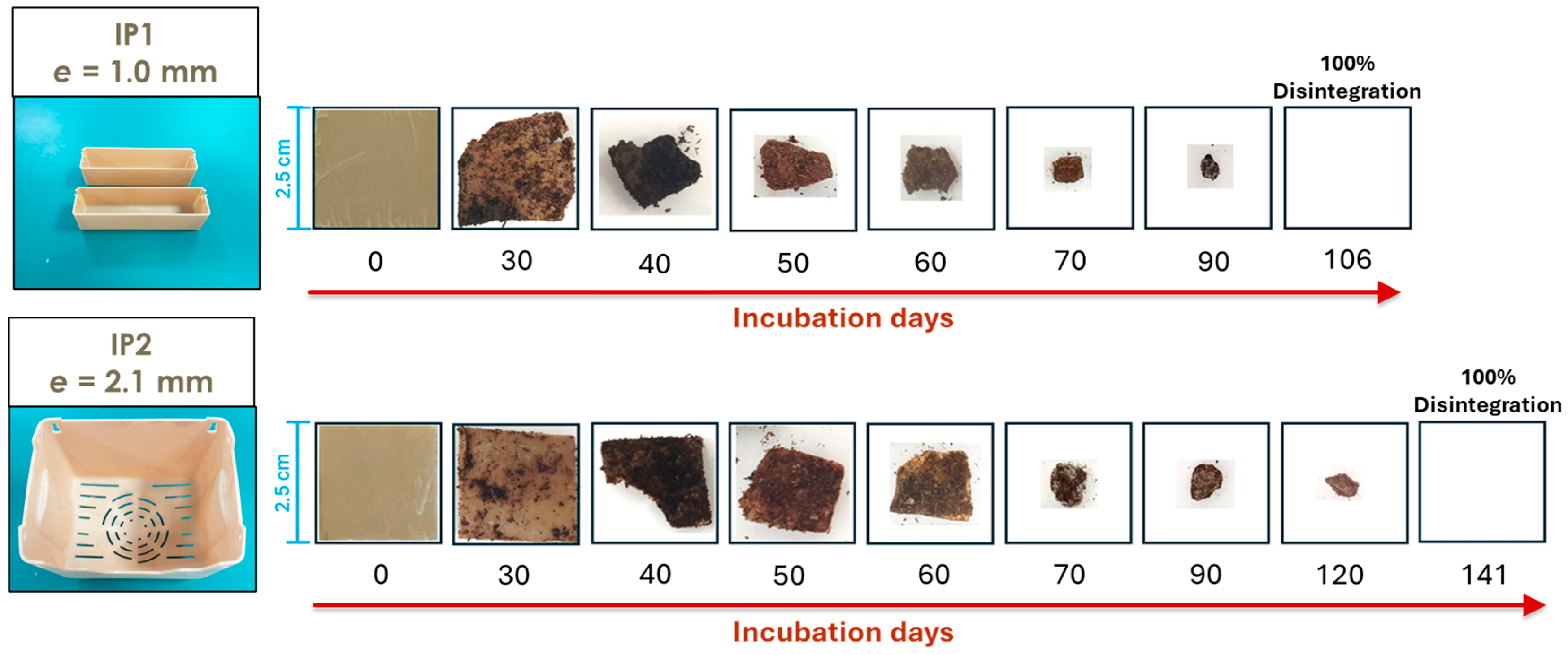

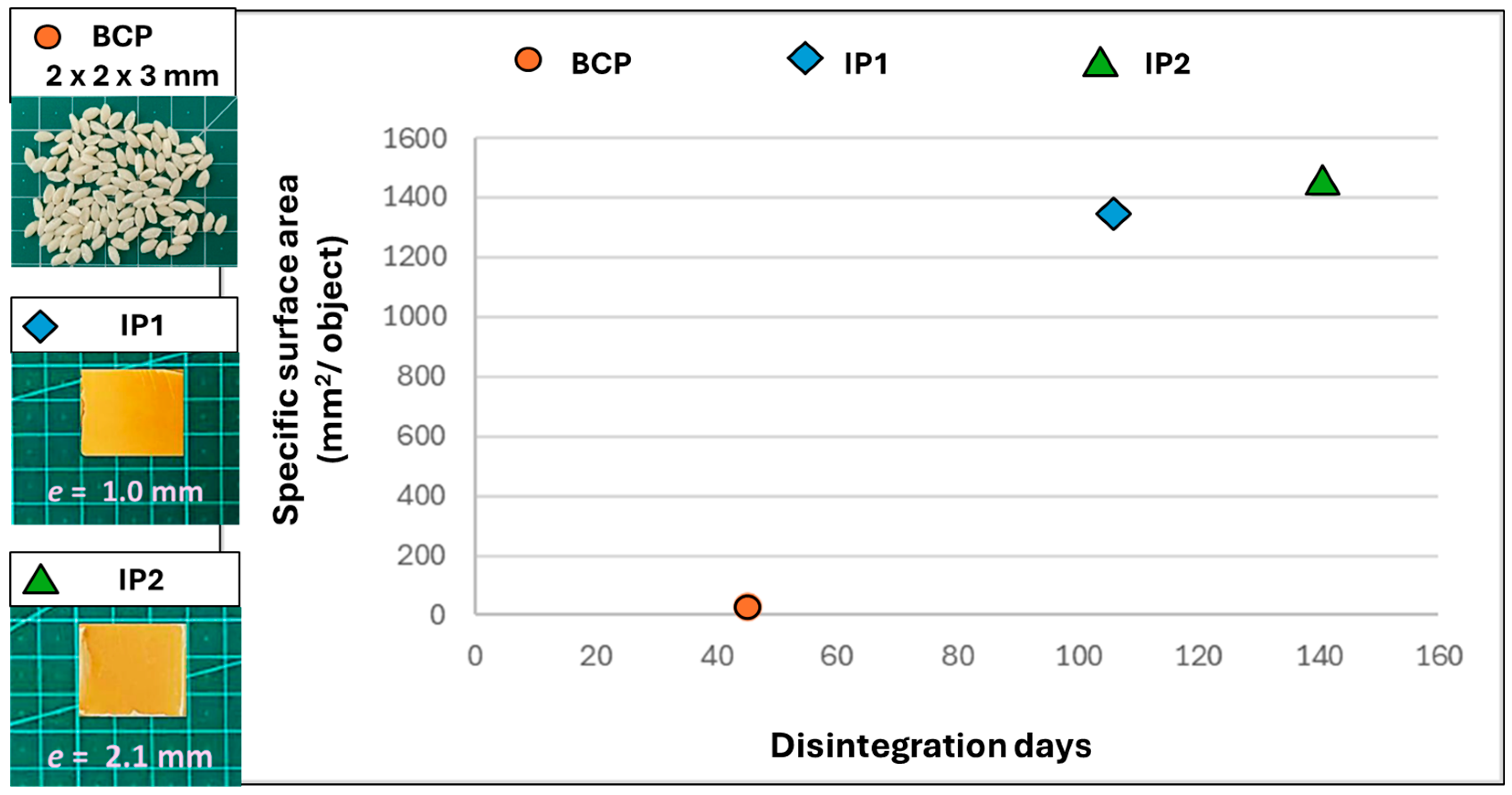

| Reactor | BCP | IP1 | IP2 |

|---|---|---|---|

| Odor | Odorless | Odorless | Odorless |

| Visual Appearance | Earth-like dark color | Earth-like dark color | Earth-like dark color |

| Time (days) | 45 | 106 | 141 |

| pH | 6.85 ± 0.10 | 7.78 ± 0.08 | 7.29 ± 0.08 |

| SSW Volatile Solids Content (%) | 76.4 ± 1.7 | 78.2 ± 1.4 | 77.2 ± 1.4 |

| Mature compost Volatile Solids Content (%) | 73.3 ± 0.8 | 66.2 ± 2.5 | 62.7 ± 0.4 |

| C/N ratio | 36.6 ± 0.4 | 33.1 ± 1.2 | 31.3 ± 0.2 |

| Dry Mass of Residual Sample (g) | 0 | 0 | 0 |

| Degree of Disintegration (%) | 100 | 100 | 100 |

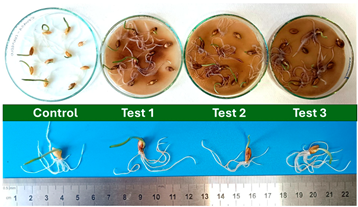

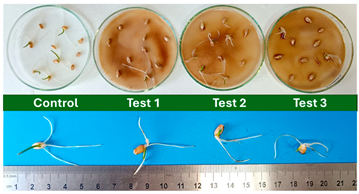

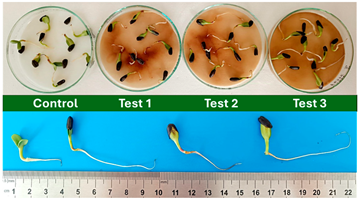

| Germination Seed Test | Image at 72 h | Germination Index (%) | Evaluation |

|---|---|---|---|

| Barley |  | 96.2 | 80 < GI < 100 → Not phytotoxic mature compost |

| Wheat |  | 174.2 | GI > 100 → The compost enhances the germination and growth of the plant’s roots (strong fertilizer effect) |

| Sunflower |  | 77.8 | 60 < GI < 80 → Moderately phytotoxic mature compost |

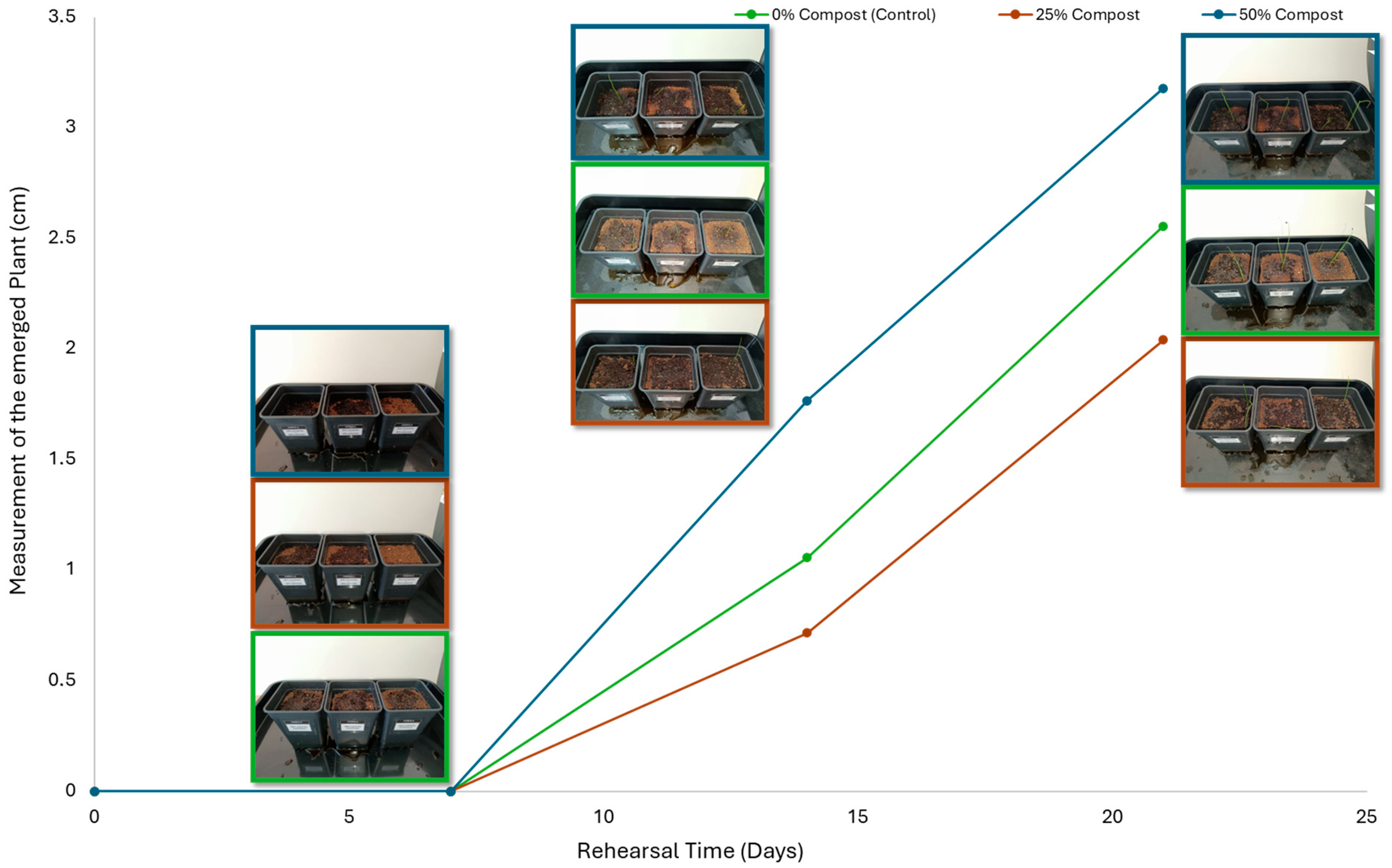

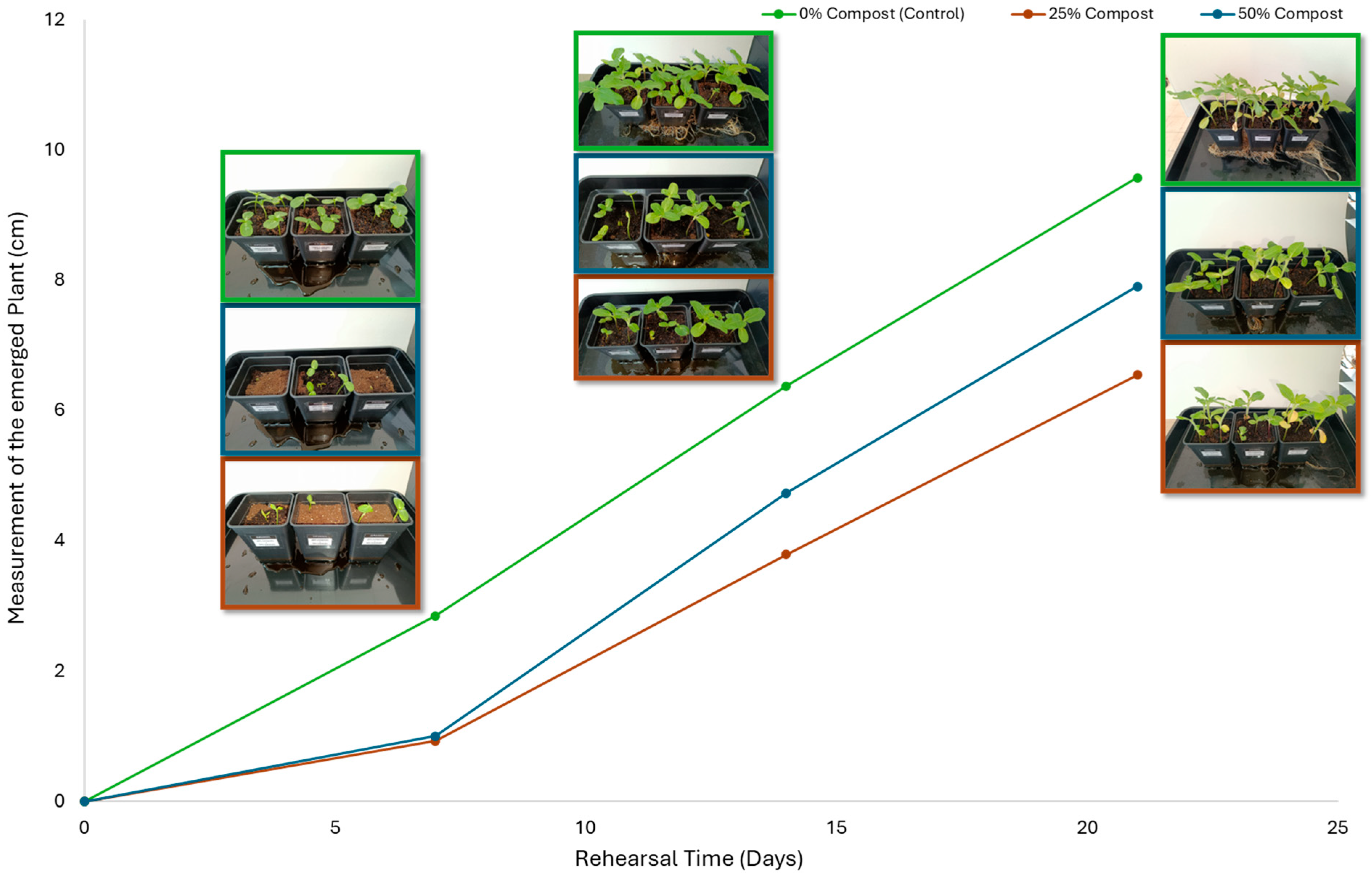

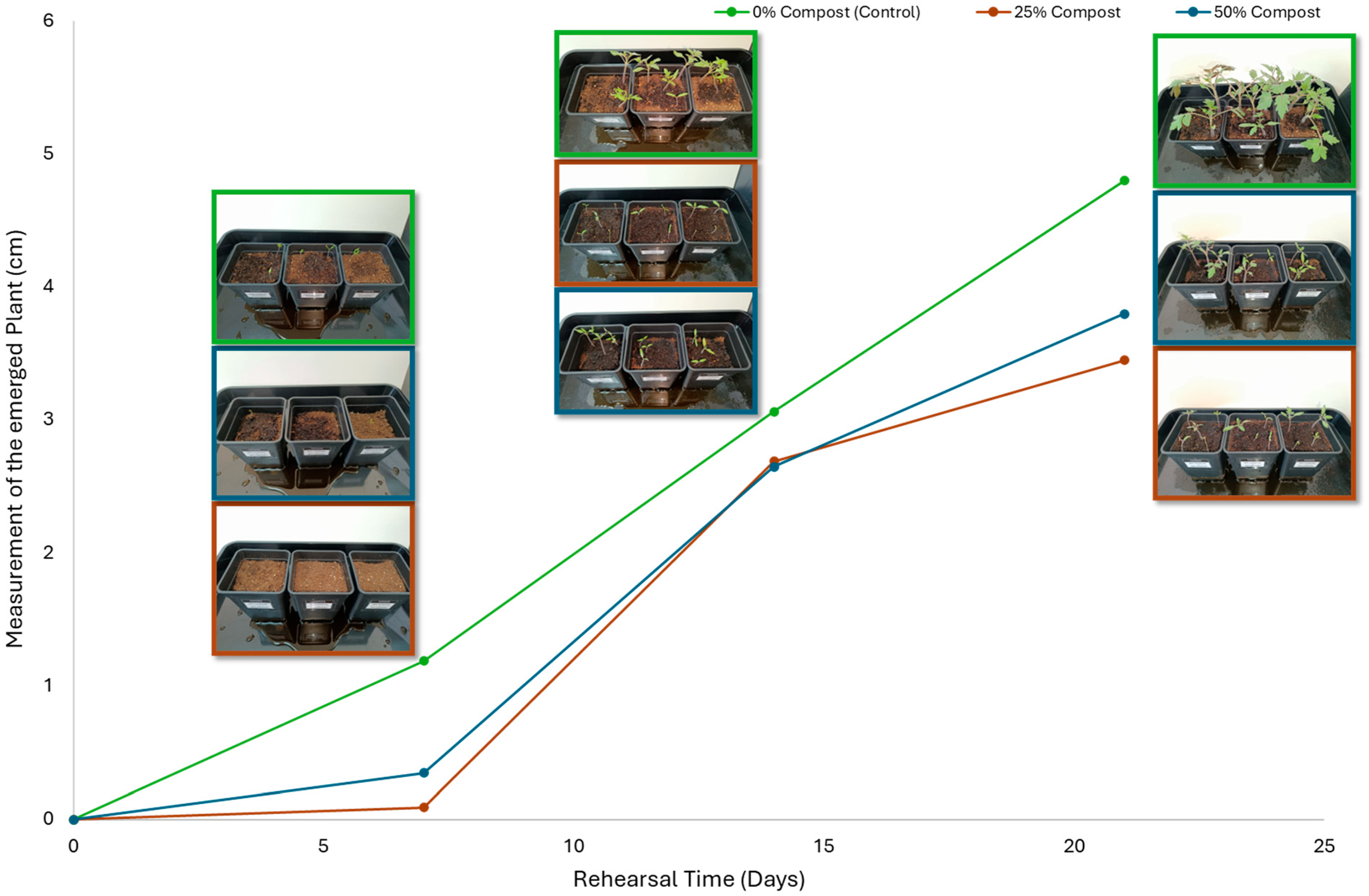

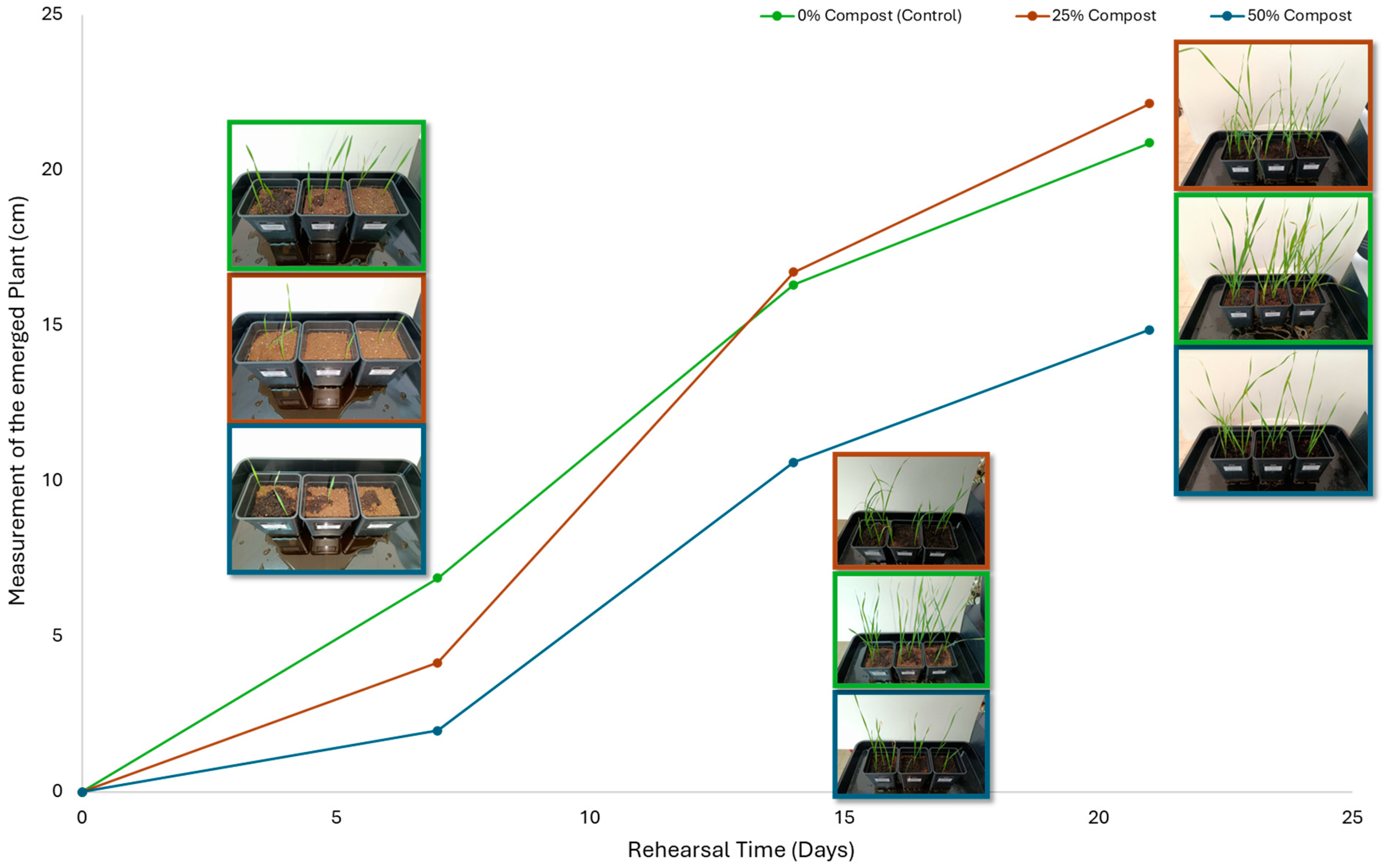

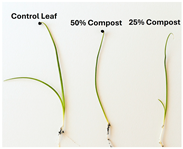

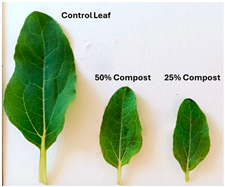

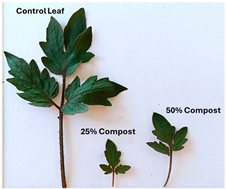

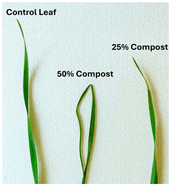

| Growth Plant Test | Compost | Growth Rate (%) | Survival Rate (%) | Photo 1st True Leaves | Phytotoxic Effects |

|---|---|---|---|---|---|

| Barley | 0% (Control) | 100 | 100 |  |

|

| 25% | 74.5 | ||||

| 50% | 78.0 | ||||

| Onion | 0% (Control) | 100 | 100 |  |

|

| 25% | 92.2 | ||||

| 50% | 89.4 | ||||

| Sunflower | 0% (Control) | 100 | 100 |  |

|

| 25% | 78.9 | ||||

| 50% | 82.6 | ||||

| Tomato | 0% (Control) | 100 | 100 |  |

|

| 25% | 60.3 | ||||

| 50% | 72.0 | ||||

| Wheat | 0% (Control) | 100 | 100 |  |

|

| 25% | 86.8 | ||||

| 50% | 74.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, V.L.D.; Videira, P.E.M.; Mendes, A.d.O.; Duarte, T.; Valente, B.F.A.; Pinto, P.; Gaspar, A.; Viana, T.; Fiadeiro, P.T.; Curto, J.M.R.; et al. Evaluating Environmental Performance of PLA–Cellulose-Based Biocomposites: A Comprehensive Study on Biodegradability, Compostability, and Ecotoxicity. Polymers 2025, 17, 3232. https://doi.org/10.3390/polym17233232

Costa VLD, Videira PEM, Mendes AdO, Duarte T, Valente BFA, Pinto P, Gaspar A, Viana T, Fiadeiro PT, Curto JMR, et al. Evaluating Environmental Performance of PLA–Cellulose-Based Biocomposites: A Comprehensive Study on Biodegradability, Compostability, and Ecotoxicity. Polymers. 2025; 17(23):3232. https://doi.org/10.3390/polym17233232

Chicago/Turabian StyleCosta, Vera L. D., Pedro E. M. Videira, António de O. Mendes, Tomás Duarte, Bruno F. A. Valente, Paula Pinto, Alexandre Gaspar, Tânia Viana, Paulo T. Fiadeiro, Joana M. R. Curto, and et al. 2025. "Evaluating Environmental Performance of PLA–Cellulose-Based Biocomposites: A Comprehensive Study on Biodegradability, Compostability, and Ecotoxicity" Polymers 17, no. 23: 3232. https://doi.org/10.3390/polym17233232

APA StyleCosta, V. L. D., Videira, P. E. M., Mendes, A. d. O., Duarte, T., Valente, B. F. A., Pinto, P., Gaspar, A., Viana, T., Fiadeiro, P. T., Curto, J. M. R., Amaral, M. E., Costa, A. P., & Vieira, J. C. (2025). Evaluating Environmental Performance of PLA–Cellulose-Based Biocomposites: A Comprehensive Study on Biodegradability, Compostability, and Ecotoxicity. Polymers, 17(23), 3232. https://doi.org/10.3390/polym17233232