Mechanical and Durability Characteristics of Particulate-Filled Recycled Thermoplastic Composites (RTCs): A Comprehensive Review

Abstract

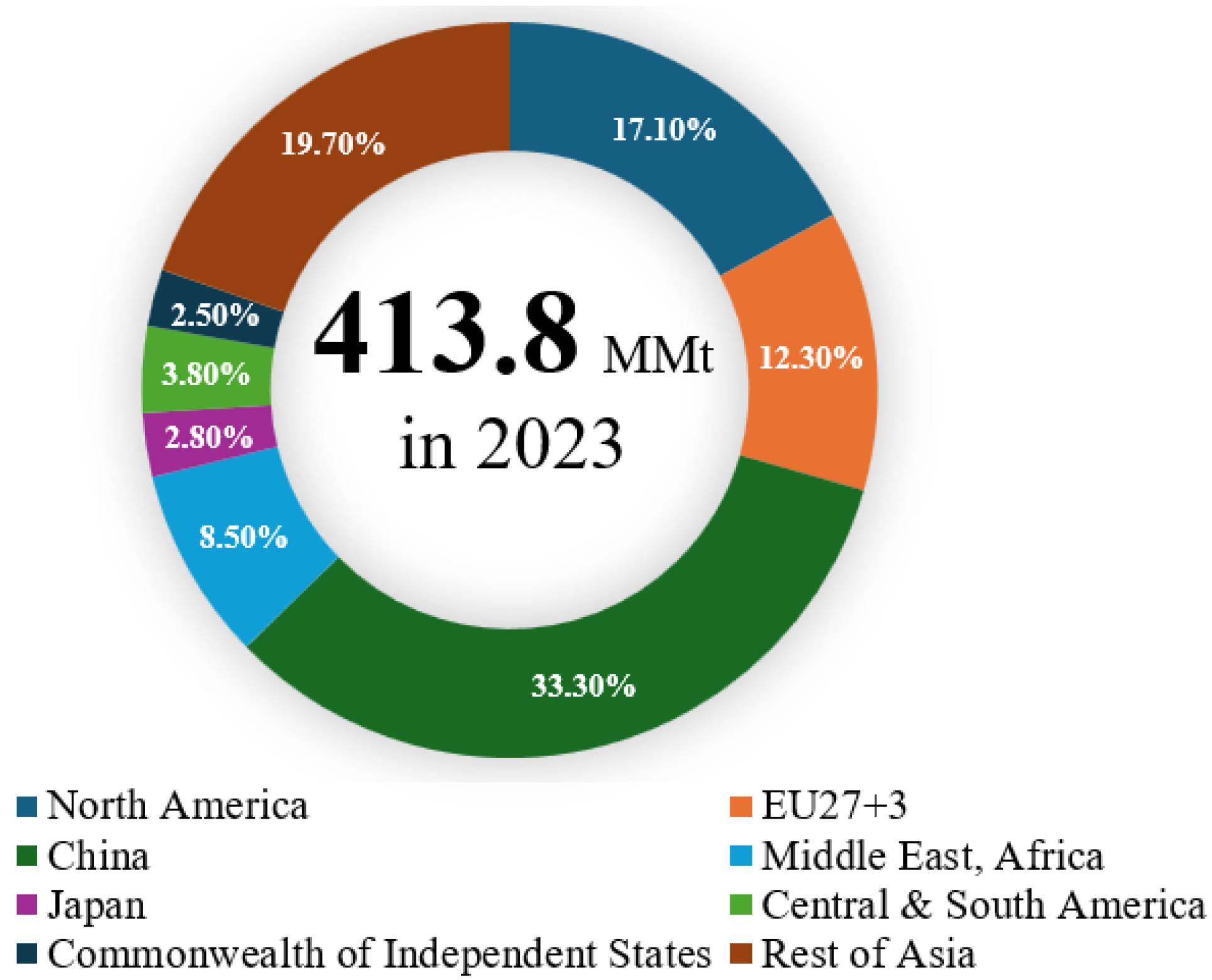

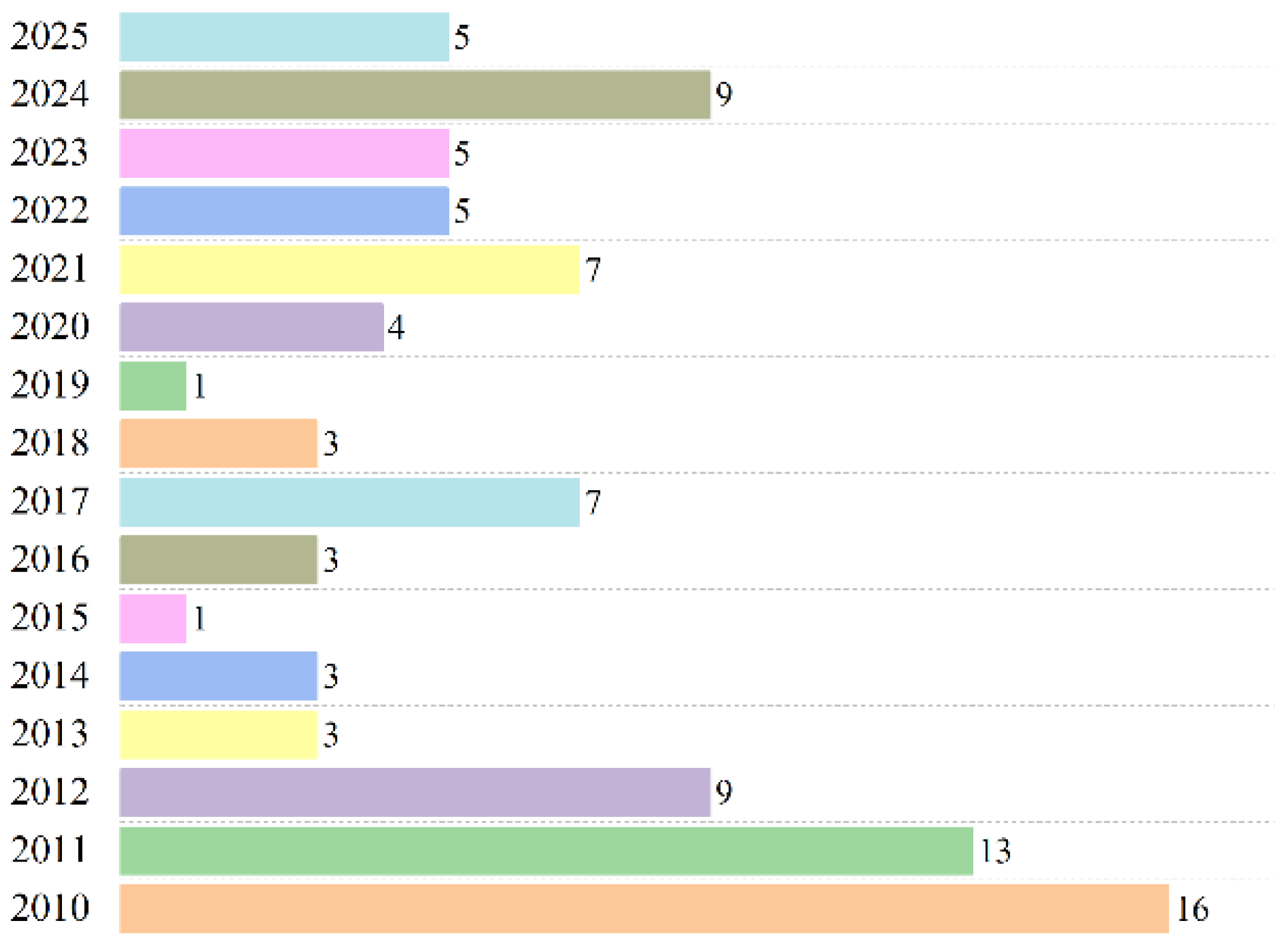

1. Introduction

2. Recycled Thermoplastic Composites (RTCs): Overview

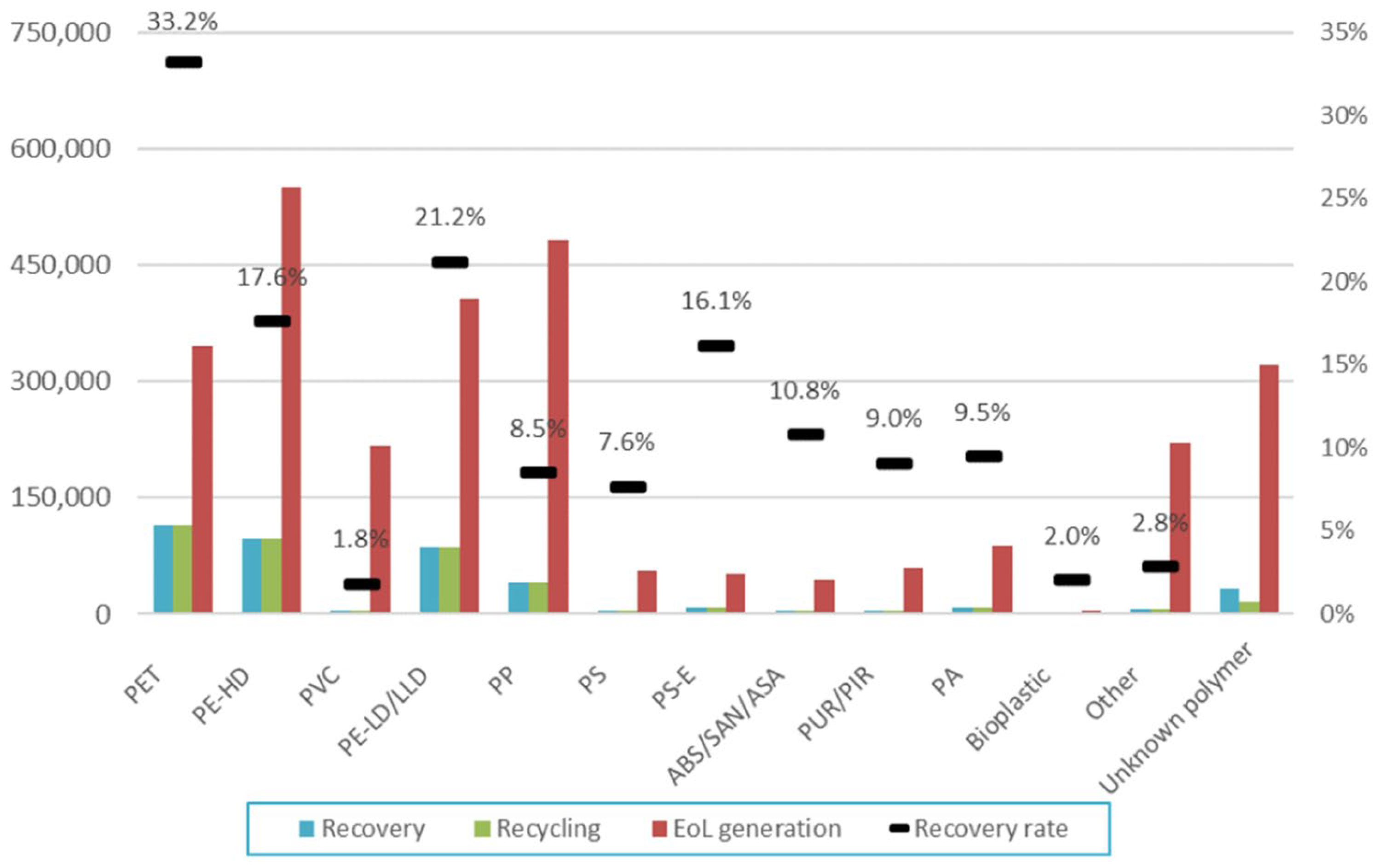

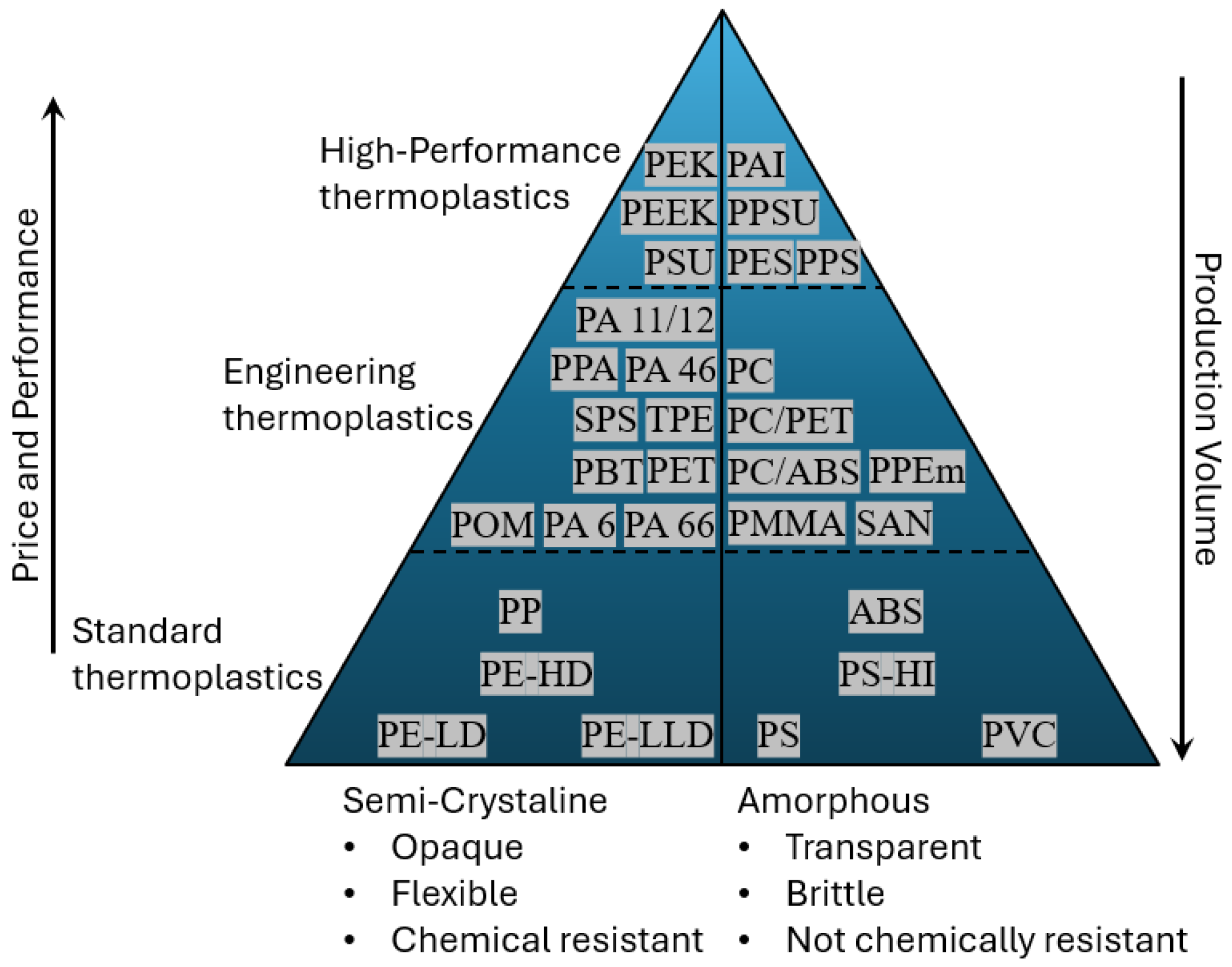

2.1. Types of Recycled Thermoplastics

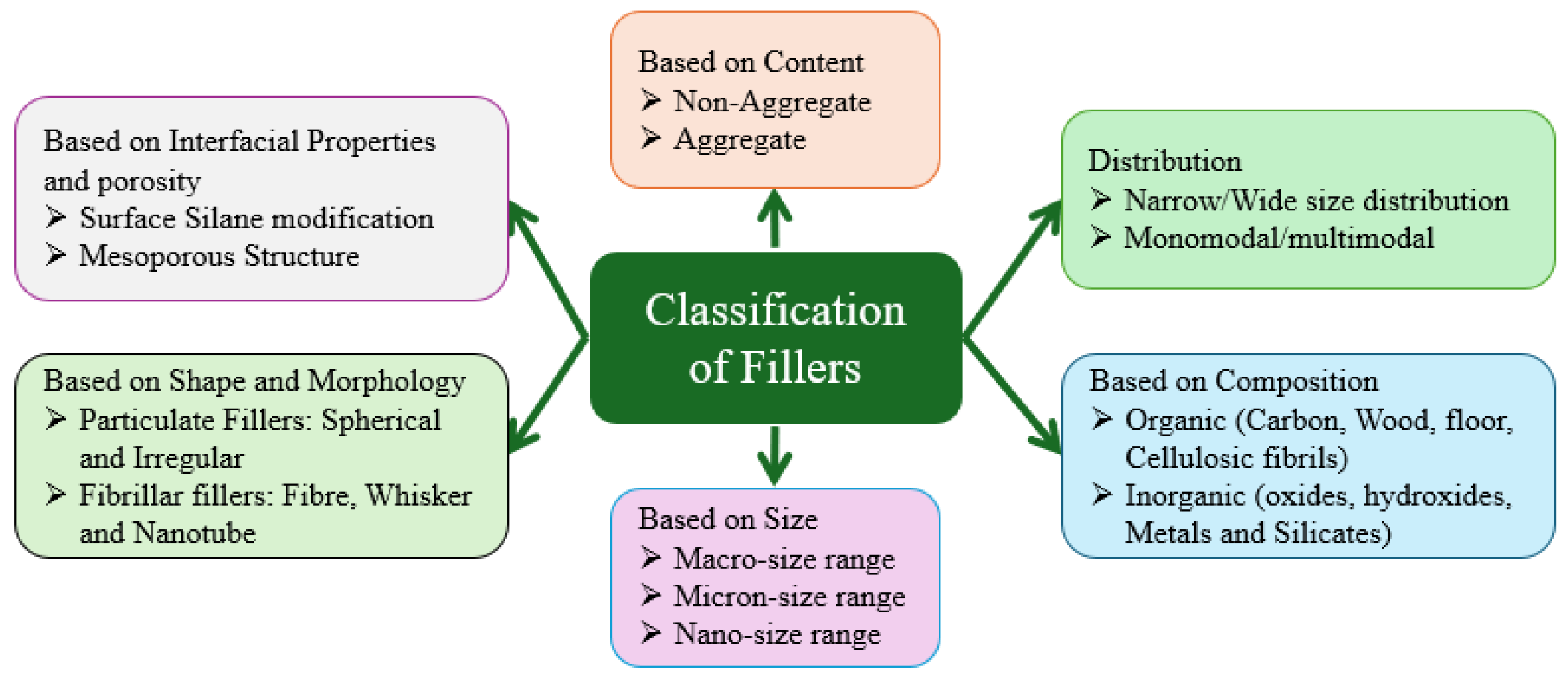

2.2. Classification and Role of Fillers

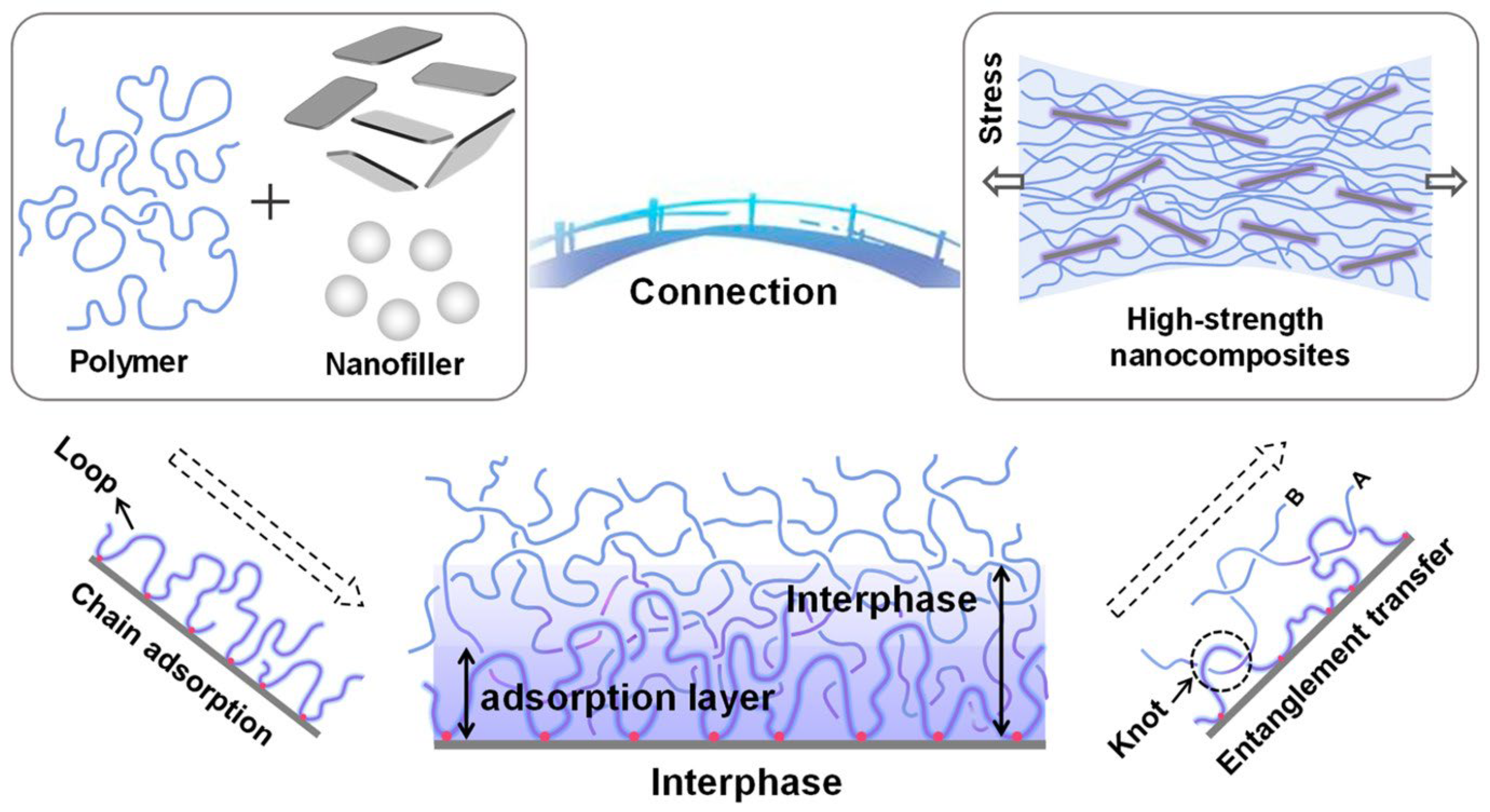

2.3. Composite Mechanisms: Particulate Filler–Matrix Interaction

3. Effect of Fillers on the Manufacturing Process of RTCs

| Matrix Type | Filler Type | Manufacturing Method | Advantages | Limitations | Typical Property Outcomes | Refs. |

|---|---|---|---|---|---|---|

| LDPE/HDPE | Silica sand | Oven Moulding (OMT), Heat Mixing (HMT) | Simple, low-cost processing; suitable for large parts | Poor filler dispersion at low temperature; thermal degradation > 325 °C | Flexural modulus ranged between 0.5 and 0.7 GPa; improved density and stiffness | [86] |

| HDPE | WGP | Melt compounding (two-roll mill) + compression moulding | Good filler distribution; improved stiffness | Increased viscosity and reduced ductility | Modulus ; tensile strength maintained up to 25 MPa with compatibiliser. | [19] |

| HDPE | TiO2f, Al2O3f | Magnetic wave-assisted injection moulding | Enhanced filler dispersion; strong interfacial bonding | Requires complex setup and magnetic control | Flexural/tensile strength improved surface uniformity. | [87] |

| PET | Sand | Direct melting and manual mixing | Uses 100% recycled PET; simple processing | Manual blending causes nonuniform dispersion | Flexural strength to 2.55 MPa at 1:3 PET:sand ratio. | [77] |

| LDPE | Sand | Compression moulding | Economical; no high-pressure flow | Limited mechanical interlocking | Moderate tensile strength (8–14 MPa); improved stability. | [88] |

| HDPE | BAG | Melt compounding + extrusion + FFF printing | Excellent control of porosity; strong interlayer bonding | High printing cost, slower productivity | Tensile modulus ; flexural modulus . | [89] |

| HDPE | ZnO | Twin-screw extrusion + injection moulding | Enhanced dispersion; UV stability improvement | Agglomeration at > 2.5 wt.% filler | Tensile strength ; hardness ; improved UV resistance. | [78] |

| rLDPE/LLDPE | Talc | Twin-screw extrusion + blow moulding | High production rate; improved crystallinity | Increased melt viscosity | Improved stiffness and heat resistance; slight strength loss | [11] |

| HDPE | BAG | Dual-head FFF 3D printing | High-resolution fabrication; controlled filler orientation | Limited scalability | Uniform microstructure; tensile/flexural strength /. | [89] |

4. Properties of Particulate-Filled RTCs

4.1. Physical Properties of Particulate-Filled RTCs

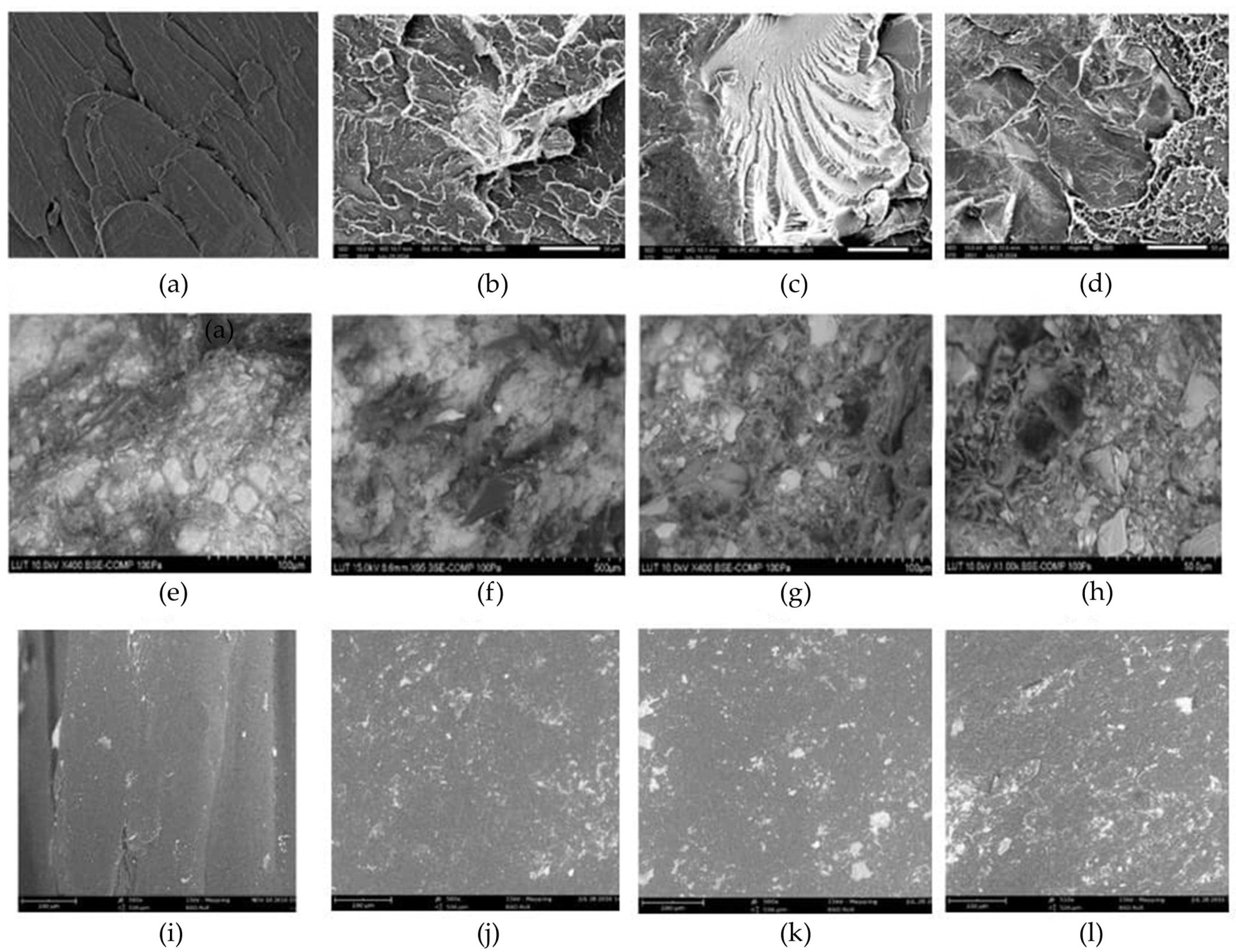

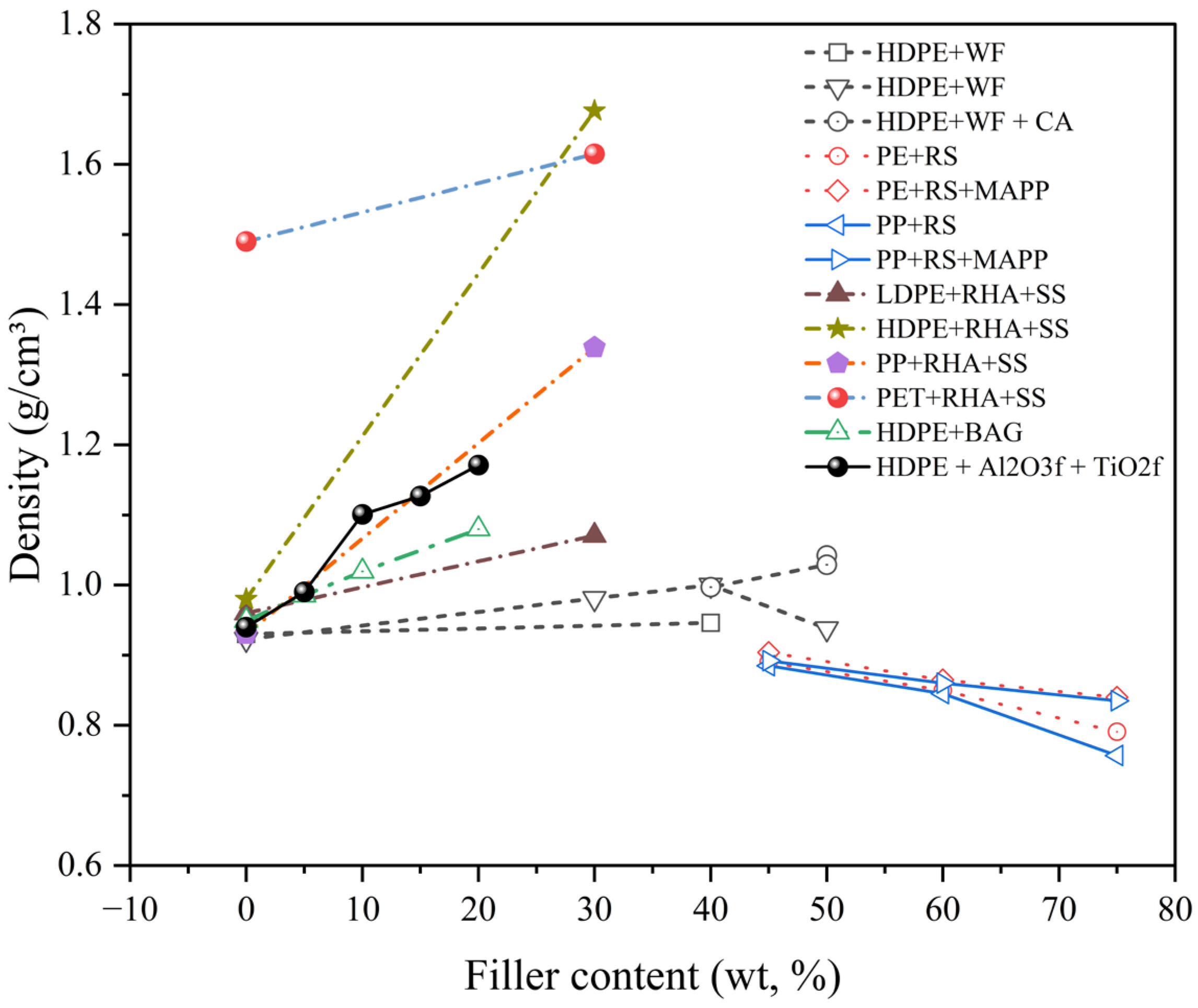

4.1.1. Morphological and Density Properties

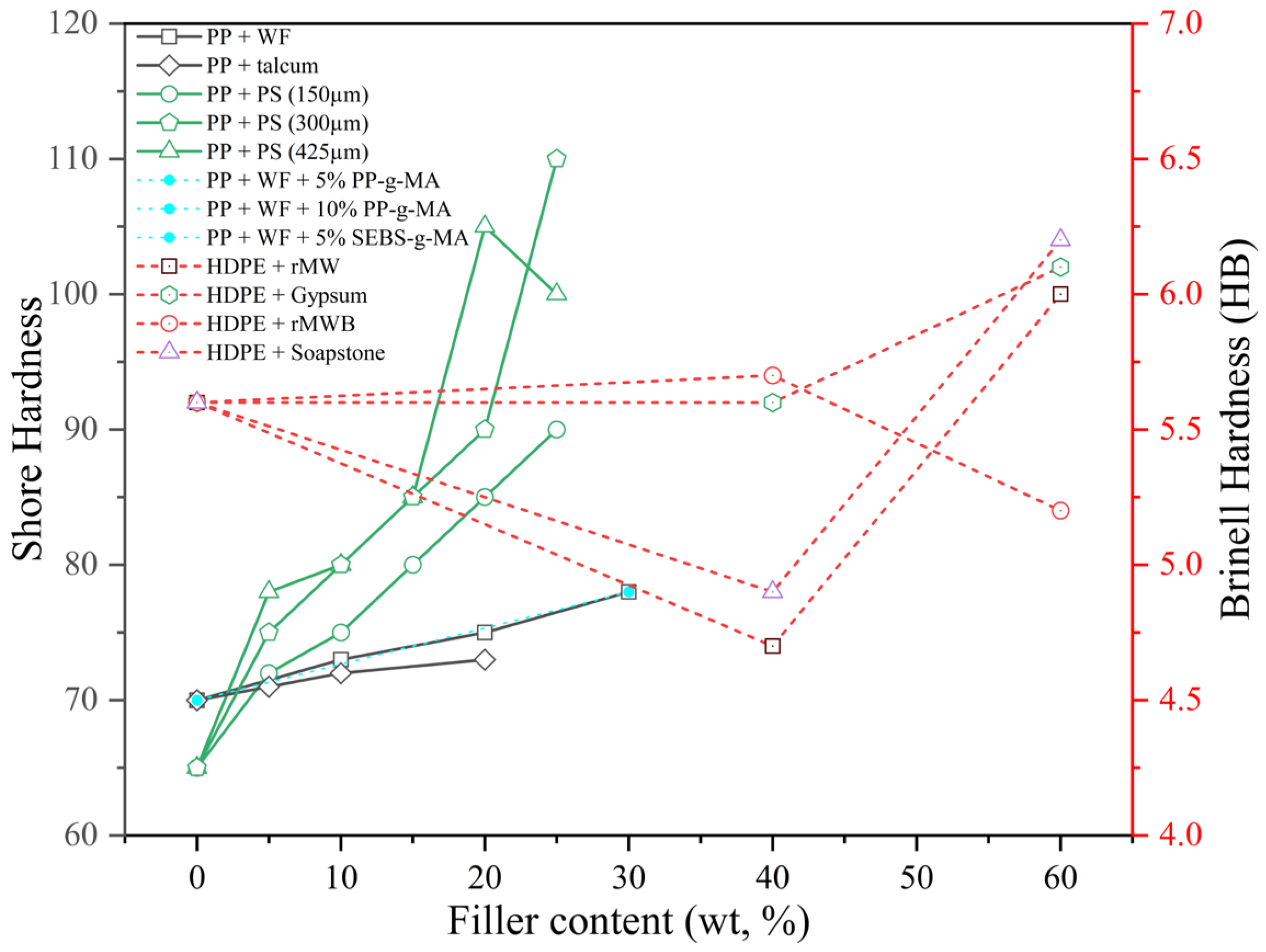

4.1.2. Hardness Properties

4.2. Mechanical Properties of Particulate-Filled RTCs

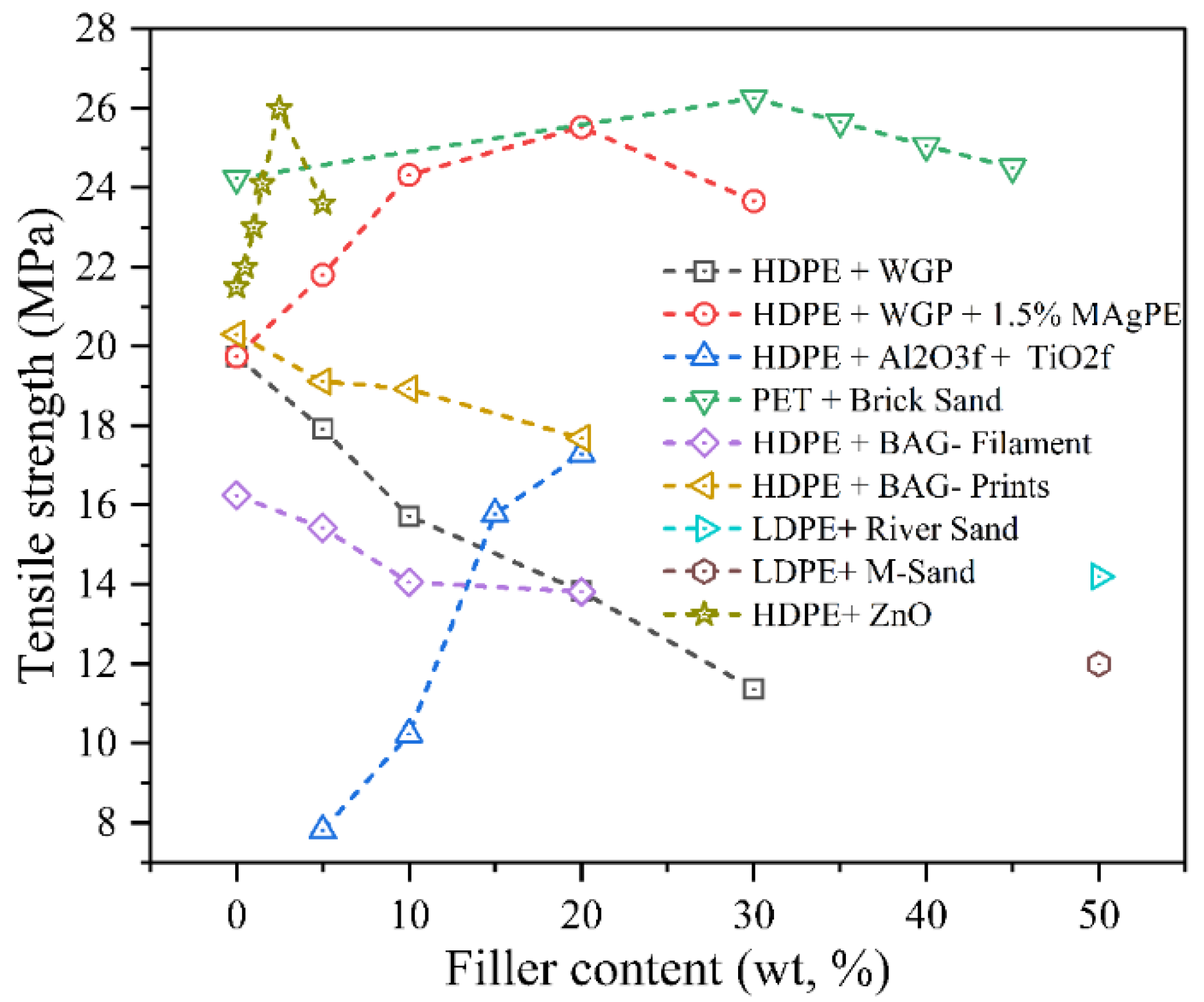

4.2.1. Tensile Strength

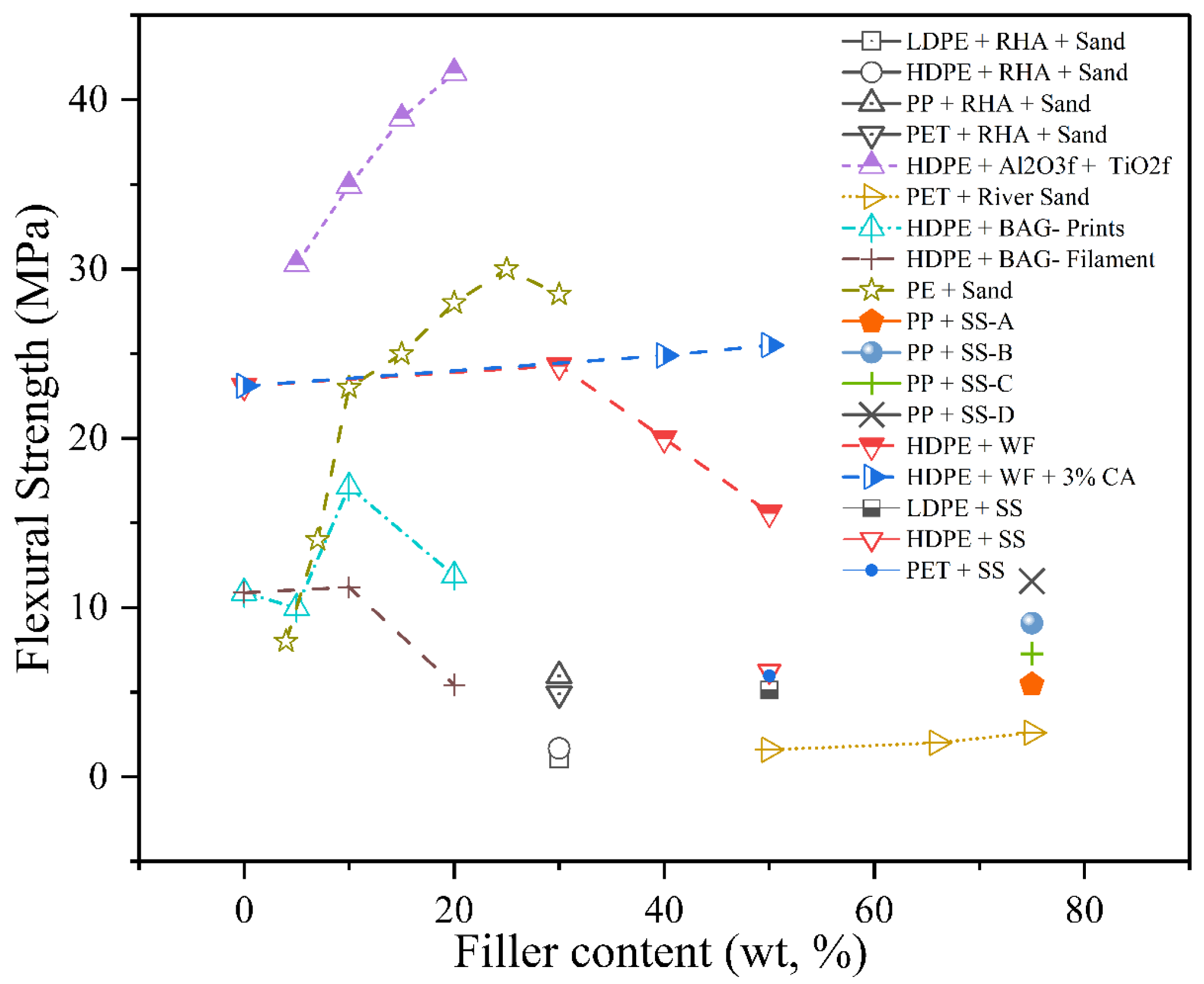

4.2.2. Flexural Strength

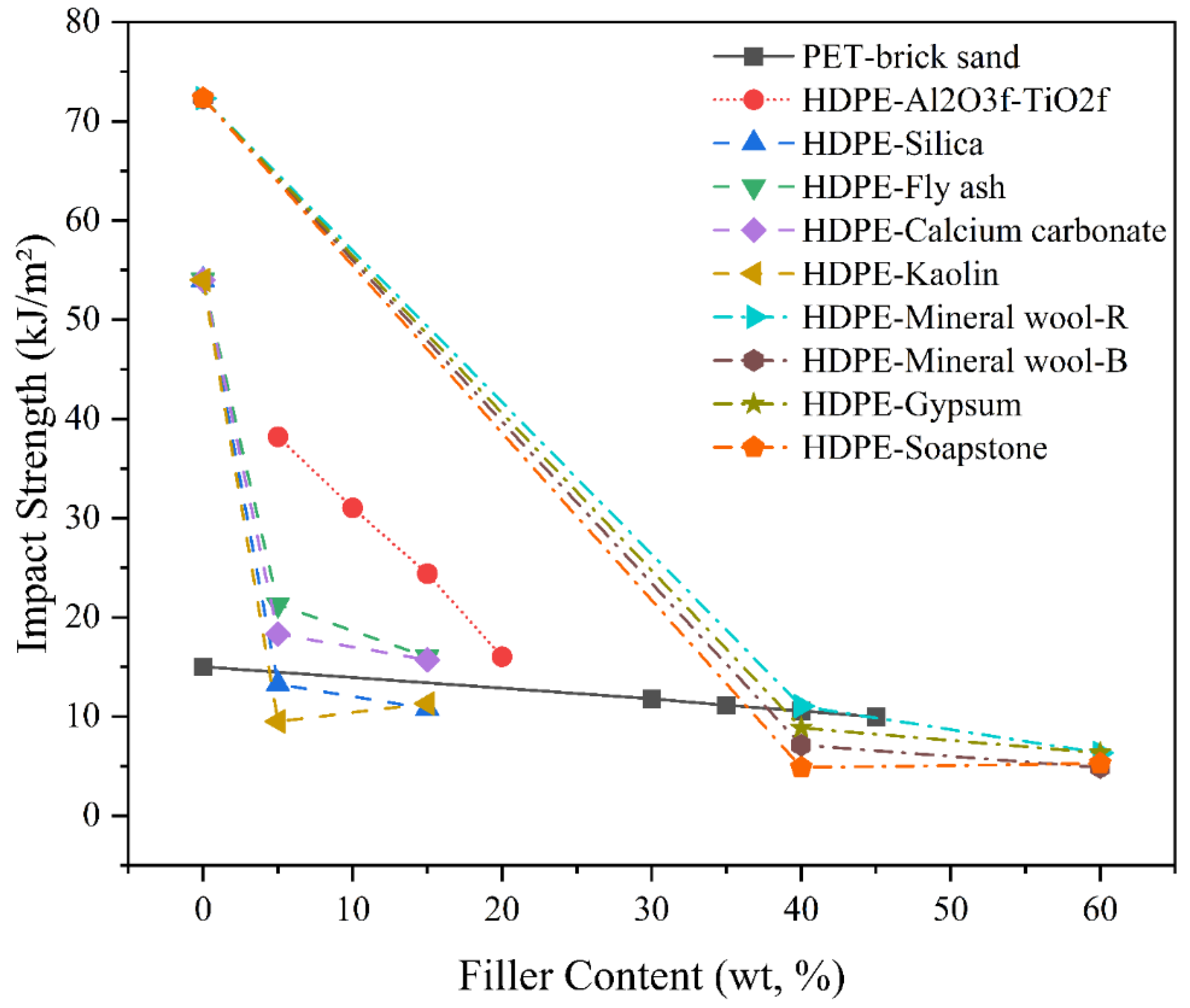

4.2.3. Impact Strength

| Type of Matrix | Type of Filler and Sizes | Content (wt.%) | Objectives of Research | Outcomes | Ref. |

|---|---|---|---|---|---|

| rHDPE | Mineral Wool (0.85–4 mm), Gypsum, Soapstone | 0–60 | Evaluate the mechanical and physical properties of rHDPE composites with various recycled particulate fillers. | Improved rigidity and moisture resistance; Tensile strength decreased by 39.4–66.2% and modulus increased by 24.5–102.1% compared. | [83] |

| rPP | Periwinkle Shell Powder (150–425 µm) | 0–25 | Investigate the effect of filler loading and particle size on mechanical properties of rPP composites | Tensile strength and modulus increased by 72.8% and 19.0% at 15 wt.% (150 µm), flexural strength increased by 40.3% at 20 wt.% (425 µm), and Shore A hardness improved by 69.2% at 25 wt.% (300 µm); excessive filler led to agglomeration and reduced strength | [94] |

| rHPPE/rPP | Silica Sand (100–300 µm) | 60–80 | Investigate the deformation and strength characteristics of highly filled sand–polymer composites derived from reclaimed thermoplastics. | Optimal compressive strength (≥25 MPa) retained up to 75 wt.% filler; surface treatment with stearic acid improved strength by 10–15%; addition of 0.1 wt.% silica nanoparticles enhanced strength by another 15%. | [105] |

| rPP | Fly Ash (76–152 µm) | 1:1 | Utilise industrial waste FA (coated by 0, 1, 2, 3, 5 gm of FP) as filler in rPP composites to enhance sustainability | Demonstrated flexural strength and modulus decreased by 8.3% and 29.6%, respectively, and increased by 6.4% and 1.4%; Impact strength increased by 100% and 53%, but decreased by 14% and 36%. | [106] |

| rPP | Graphene (500 μm) | 0–2 | Predict thermal and mechanical properties of rPP nanocomposites reinforced by graphene-based fillers | Young’s modulus and thermal conductivity showed 5.7–35.4% and 5.84% enhancement, respectively, and a 44.8% decrease in Poisson’s ratio. | [107] |

| rHDPE/ rLDPE | Silica Sand (<0.30 mm 1.35 mm) | 50–83.3 | Investigate the effect of sand particle size and content on mechanical and thermal properties of plastic-bonded sand composite | Produce the highest compressive strength, ranging from 65% and 80%; improved ductility, toughness, and thermal conductivity; suitable for paving tiles and partition walls. | [86] |

| rHDPE | Pine Dust (<250 μm 1000 μm) | 0–30 | Investigate the effect of pine dust particle size and content on the mechanical properties and water absorption of rHDPE composites | Tensile strength increased by 16.9% and 31.2% at 15% (500–1000 µm) and 20 wt.% (250–500 µm) particles; increased by 4.305% water absorption with 30 wt.% (<250) filler. | [97] |

| rPP | Waste printed circuit boards (<1 mm) | 0–30 | Develop sustainable composites using rPP and WPCB | Tensile strength increased and decreased by 0.49% (5 wt.%) and 6.34% to 27.56% (10–30 wt.%), respectively; impact strength decreased by 37.5% and 62.3% with 15% and 30% WPCB; enhanced thermal stability; effective use of electronic waste | [96] |

| rPET | Wollastonite, Mica, Talc (30 µm, 44 µm, 2.7 µm) | 10–20 | To evaluate mechanical, thermal, and morphological properties of rPET with single and hybrid mineral fillers for automotive applications. | Wollastonite- and talc-filled composites at 20 wt.% showed the highest flexural strength improvements of 22.8% and 16.7%, respectively. The addition of Mica (20 wt.%) increased tensile, compression, and flexural modulus by 91.1%, 123.6%, and 129.0%, respectively, while talc addition increased thermal flexural stability by 36.8%. | [108] |

| bPET | Waste Eggshell (66.74, 711.27, and 746.66 μm) | 10 | Evaluate how eggshell particle size affects the mechanical properties of bioPET composites. | Addition of 66.74 μm, 711.27 μm, and 746.66 μm sizes. Eggshell showed tensile strength changes of +5.94%, −0.77%, and −23.23%, with corresponding flexural strength reductions of 31.3%, 13.25%, and 11.78%. Flexural modulus increased by 29.45% (66.74 μm) and 10.46% (711.27 μm), but dropped by 6.77% (746.66 μm). | [93] |

4.3. Durability Properties of Particulate-Filled RTCs

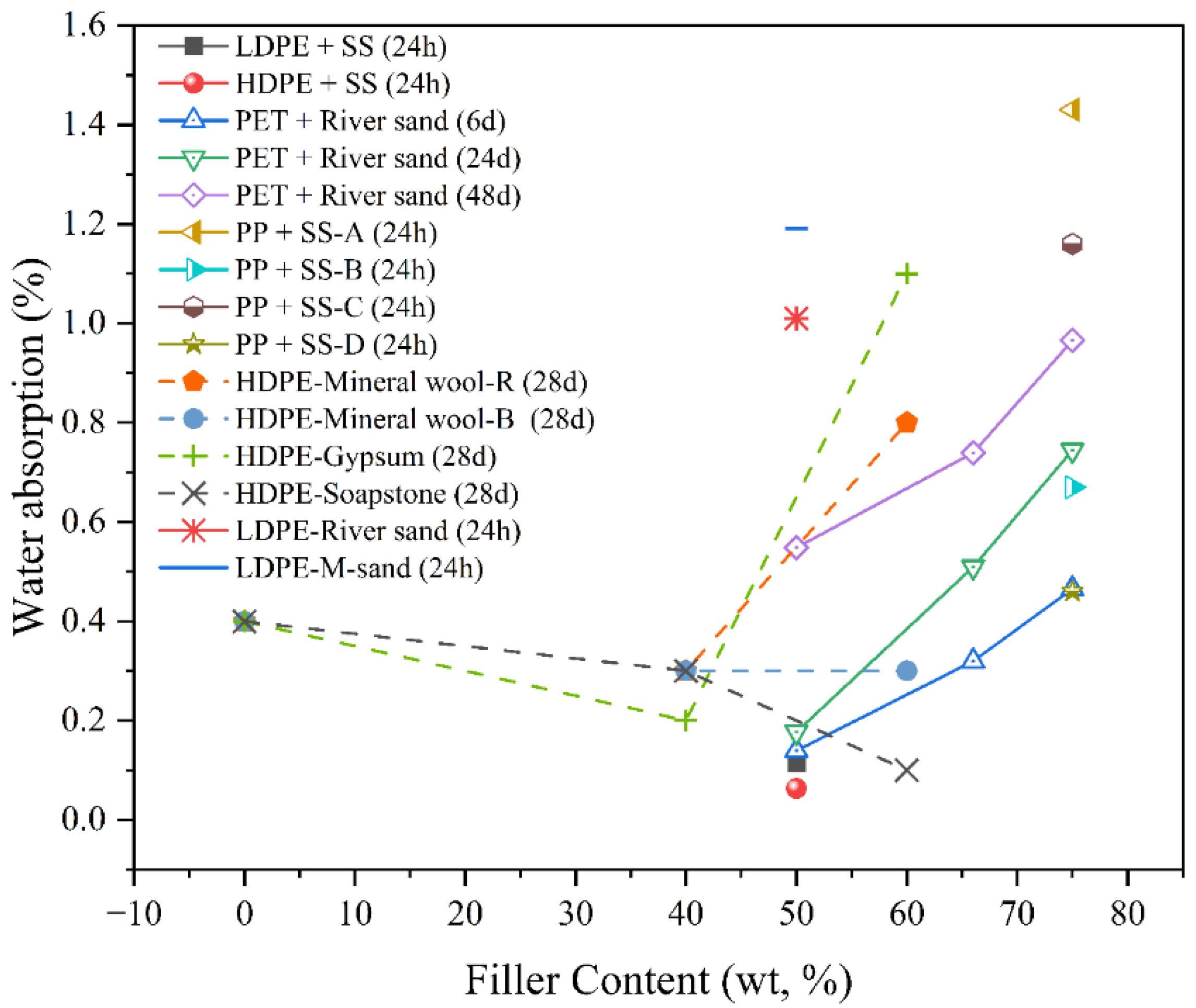

4.3.1. Effect of Water Absorption

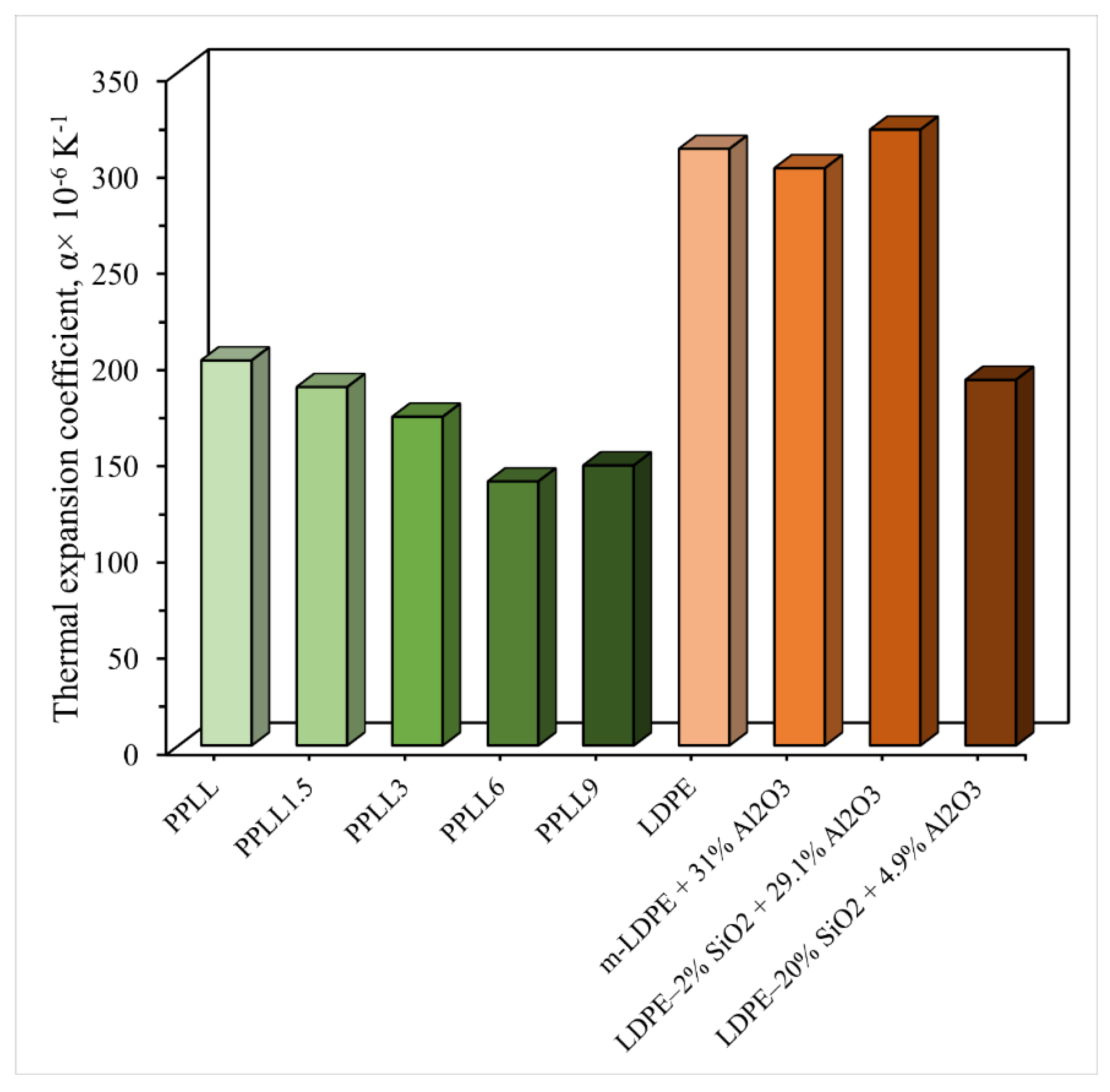

4.3.2. Thermal Durability of Particulate-Filled RTCs

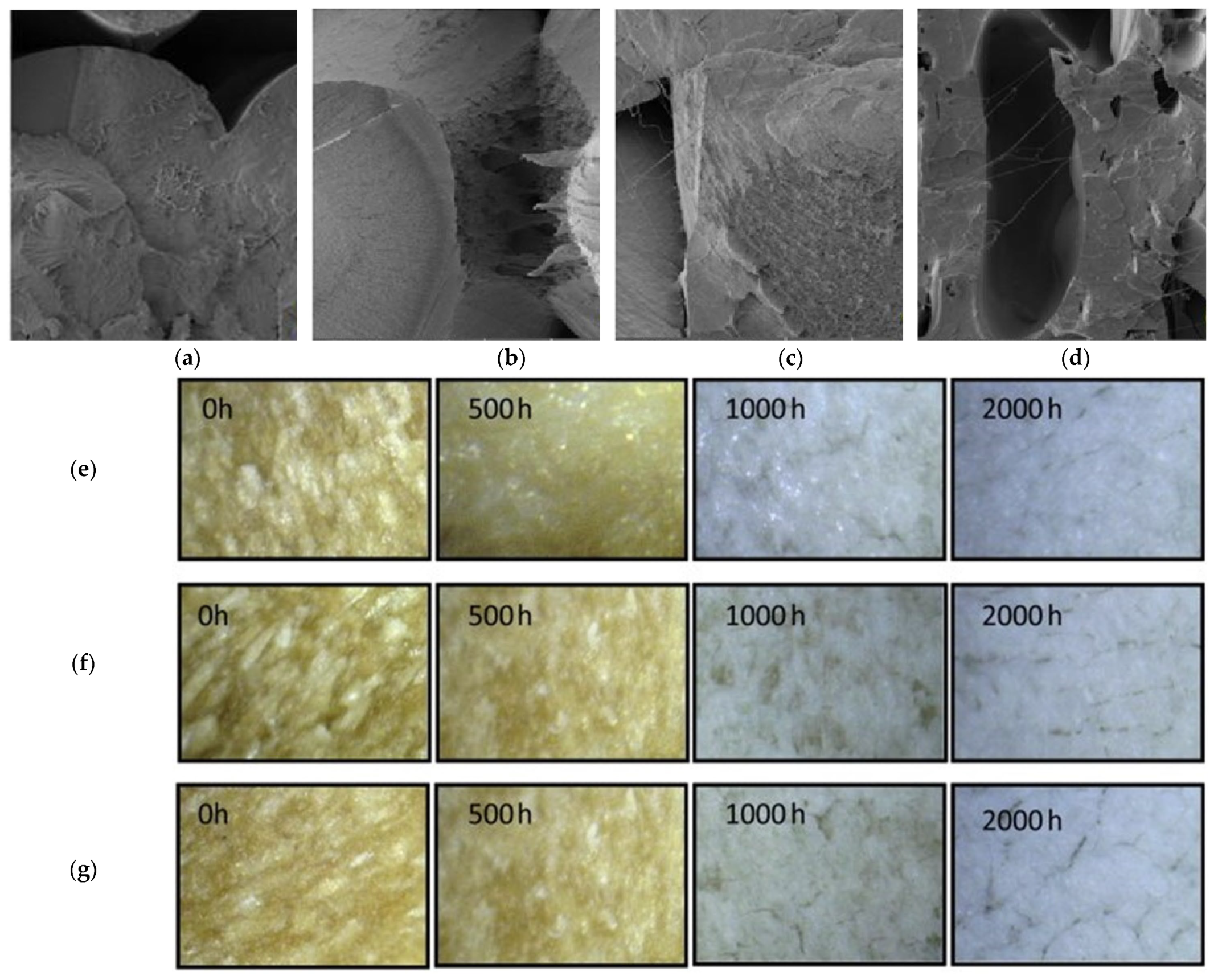

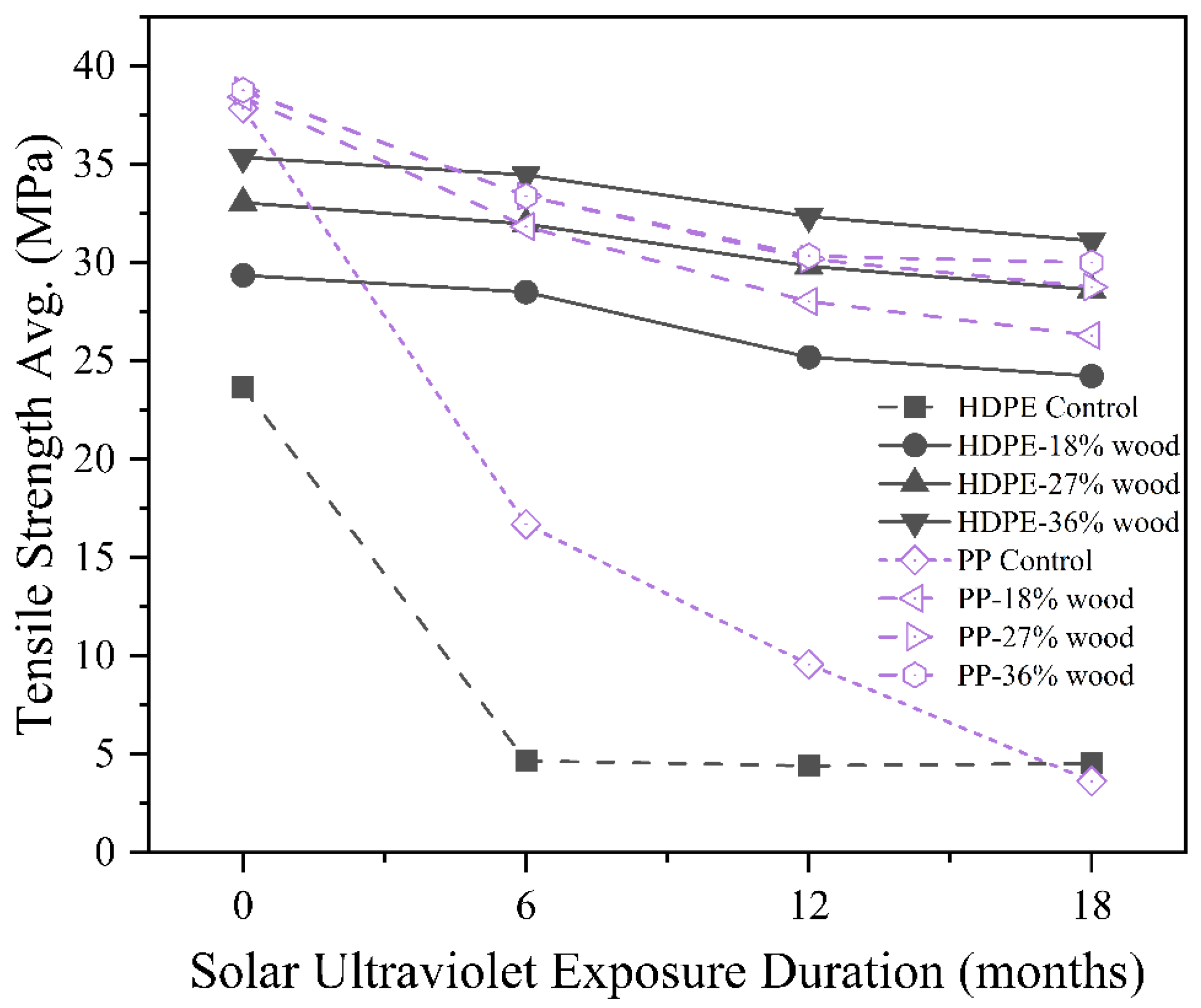

4.3.3. Effect of Solar Ultraviolet (UV) Radiation

5. RTCs in Civil Engineering: Current Applications, Challenges, and Limitations

6. Emerging Applications and Future Recommendations

- Structural elements under dynamic loads: RTCs can be engineered as sustainable alternatives to hardwood and prestressed concrete railway sleepers, where repeated impact and cyclic stresses govern long-term performance.

- Road and bridge construction: Non-structural elements such as formwork, guardrails, deck panels, and retaining walls, where RTCs can replace wood, steel, or concrete.

- Coastal and Hydraulic Structures: Suitable for piers, embankment facings, and flood barriers due to hydrophobicity and biological resistance.

- Urban Furniture and Landscape Design: Used in outdoor furniture, fencing, decking, and boardwalks, especially in parks and recreational zones, because they offer longevity and recyclability.

- Underground Utility Infrastructure: Composite pipes, cable ducts, and drainage systems made from filled RTCs offer resistance to chemical leaching and long-term durability in soil environments.

- Novel waste-derived fillers and hybrids: Beyond conventional waste glass and mineral sand, underexplored fillers such as silica sand, fly ash, ceramic waste, and industrial by-products should be incorporated to enhance stiffness, dimensional stability, and environmental value.

- Optimised filler–matrix interface: Research should focus on compatibilisers, surface modification, and particle tailoring (size, aspect ratio, dispersion) to enhance stress transfer and ensure durability without compromising processability.

- Few studies report fatigue, creep, UV degradation, hygrothermal ageing, or freeze–thaw resistance of RTCs. Moreover, the combined influence of environmental factors—such as UV exposure, moisture absorption, and thermal cycling—remains largely unexplored. Systematic laboratory protocols, incorporating both accelerated and coupled environmental exposure, together with field validation, are needed to establish reliable design safety margins.

- Circular economy integration: Future work should extend beyond mechanical performance to include recyclability after service, embodied CO2, and comprehensive LCA benchmarks for RTCs in real infrastructure.

- Cost-performance optimisation: Innovative processing routes and filler optimisation must be evaluated not only for strength gains but also for economic feasibility relative to timber, steel, and concrete alternatives.

- Standardisation and design guidelines: Development of international standards, testing protocols, and design codes is crucial for the large-scale adoption of RTCs in industry and infrastructure projects.

- Data-driven and modelling-based design: Future studies should integrate AI-assisted optimisation, multiscale modelling, and predictive durability simulations to correlate filler characteristics with composite performance. Machine learning frameworks can accelerate the design of hybrid and surface-activated fillers, enabling tailored interfacial bonding, improved long-term durability, and reduced experimental dependency through model-guided material development.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Plastic Production|Statista. Available online: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed on 20 May 2025).

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mohamed, A.M. Eco-friendly concrete containing recycled plastic as partial replacement for sand. J. Mater. Res. Technol. 2020, 9, 4631–4643. [Google Scholar] [CrossRef]

- Plastics—The Fast FACTS 2024 • Plastics Europe. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-fast-facts-2024/ (accessed on 20 May 2025).

- Ritchie, H.; Samborska, V.; Roser, M. Plastic Pollution, Our World in Data; OECD Publishing: Paris, France, 2023. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Australian Plastic Flows and Fates Study 2021-22 National Report. Available online: https://www.dcceew.gov.au/environment/protection/waste/publications/australian-plastic-flows-and-fates-national-report-2021-22 (accessed on 26 September 2025).

- Georgiou, D.; Sun, D.; Liu, X.; Athanasiou, C.E. Suppressing Mechanical Property Variability in Recycled Plastics via Bio-inspired Design. Proc. Natl. Acad. Sci. USA 2025, 122, e2502613122. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S.; Sanetuntikul, J. Recycling of wood–plastic composites prepared from poly(vinyl chloride) and wood flour. Constr. Build. Mater. 2012, 28, 557–560. [Google Scholar] [CrossRef]

- Wang, K.; Bahlouli, N.; Addiego, F.; Ahzi, S. Elastic and yield behaviors of recycled polypropylene-based composites: Experimental and modeling study. Compos. B Eng. 2016, 99, 132–153. [Google Scholar] [CrossRef]

- Awad, S.A.; Khalaf, E.M. Investigation of improvement of properties of polypropylene modified by nano silica composites. Compos. Commun. 2019, 12, 59–63. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Wiszumirska, K.; Garbacz, T. Manufacturing and Properties of Recycled Polyethylene Films with an Inorganic Filler by the Extrusion Blow Moulding Method, Lecture Notes in Mechanical Engineering; Springer International Publishing: Cham, Switzerland, 2019; pp. 625–638. [Google Scholar] [CrossRef]

- Akhras, M.H.; Langwieser, J.; Czaker, S.; Felgel-Farnholz, A.; Fischer, J. Cascadic degradation of selected polyolefin grades in a simulated closed-loop recycling process. Clean. Technol. Environ. Policy 2024, 26, 3507–3526. [Google Scholar] [CrossRef]

- Akhras, M.H.; Langwieser, J.; Fischer, J. Investigation of the degradative impact of multiple reprocessing loops on the rheological behavior of different polypropylenes. AIP Conf. Proc. 2023, 2884, 180005. [Google Scholar] [CrossRef]

- DeArmitt, C. Functional Fillers for Plastics. In Applied Plastics Engineering Handbook: Processing and Materials; William Andrew Publishing: Norwich, NY, USA, 2011; pp. 455–468. [Google Scholar] [CrossRef]

- Kanna, M.R.R.; Jerusha, E.; Bhattacharya, S.; Pore, S.B.; Ahamed, S.B.I.; Dixit, C.K.; Rajkumar, S. Mechanical properties of micro and Nano-Filler content on polypropylene composites. Mater. Today Proc. 2022, 59, 1261–1265. [Google Scholar] [CrossRef]

- Muthukutti, G.P.; Singh, M.K.; Palaniappan, S.K.; Vijayananth, K.; Rangappa, S.M.; Siengchin, S. Value-added polymer composites using non-metallic industrial waste: A concise review. Chem. Eng. J. 2025, 512, 162344. [Google Scholar] [CrossRef]

- Ghosh, A. Performance modifying techniques for recycled thermoplastics. Resour. Conserv. Recycl. 2021, 175, 105887. [Google Scholar] [CrossRef]

- Scopus—Document Search Results|Signed in. Available online: https://www.scopus.com/results/results.uri?st1=recycled+thermoplastics&st2=&s=KEY%28recycled+thermoplastics%29&limit=10&origin=resultslist&sort=plf-f&src=s&sot=b&sdt=cl&sessionSearchId=a774387e8323c989e48b3060845fa507&cluster=scosubtype%2C%22ar%22%2Ct%2Bscosubjabbr%2C%22ENGI%22%2Ct%2Bscolang%2C%22English%22%2Ct%2Bscoexactkeywords%2C%22Recycling%22%2Ct%2C%22Thermoplastics%22%2Ct%2C%22Reinforced+Plastics%22%2Ct&yearFrom=2010&yearTo=2025 (accessed on 2 June 2025).

- Sadik, W.A.; El-Demerdash, A.G.M.; Abokhateeb, A.E.A.; Elessawy, N.A. Innovative high-density polyethylene/waste glass powder composite with remarkable mechanical, thermal and recyclable properties for technical applications. Heliyon 2021, 7, e06627. [Google Scholar] [CrossRef] [PubMed]

- Chaturvedi, R.; Tyagi, P.; Gupta, M.K.; Pappu, A. Sustainable approach toward novel poly(vinyl chloride) composite using calcite-rich waste particulates. J. Vinyl Addit. Technol. 2022, 28, 649–658. [Google Scholar] [CrossRef]

- Friedrich, K.; Zhang, Z.; Schlarb, A.K. Effects of various fillers on the sliding wear of polymer composites. Compos. Sci. Technol. 2005, 65, 2329–2343. [Google Scholar] [CrossRef]

- Jabu, M.A.; Alugongo, A.A.; Nkomo, N.Z. A Review of Composites Sleepers Used in the Railway Structure. Int. J. Eng. Trends Technol. 2024, 72, 360–366. [Google Scholar] [CrossRef]

- Salih, C.; Manalo, A.; Ferdous, W.; Yu, P.; Abousnina, R.; Heyer, T.; Schubel, P. Effect of bending and compressive modulus of elasticity on the behaviour of timber-alternative railway sleepers supported by ballast. Case Stud. Constr. Mater. 2021, 15, e00597. [Google Scholar] [CrossRef]

- Lai, P.H.; Hall, S.L.; Lan, Y.C.; Ai, J.R.; Jaberi, A.; Sheikhi, A.; Shi, R.; Vogt, B.D.; Gomez, E.D. Upcycling plastic waste into fully recyclable composites through cold sintering. Mater. Horiz. 2024, 11, 2718–2728. [Google Scholar] [CrossRef]

- Rosli, N.A.; Ahmad, I. Mechanical Properties of Recycled Plastics; Springer: Singapore, 2021; pp. 239–258. [Google Scholar] [CrossRef]

- Zhang, J.; Hirschberg, V.; Goecke, A.; Wilhelm, M.; Yu, W.; Orfgen, M.; Rodrigue, D. Effect of mechanical recycling on molecular structure and rheological properties of high-density polyethylene (HDPE). Polymer 2024, 297, 126866. [Google Scholar] [CrossRef]

- Krueger, R.; Bergan, A. Advances in Thermoplastic Composites Over Three Decades-A Literature Review. 2024. Available online: http://www.sti.nasa.gov (accessed on 27 May 2025).

- Ferdous, W.; Manalo, A.; Van Erp, G.; Aravinthan, T.; Kaewunruen, S.; Remennikov, A. Composite railway sleepers—Recent developments, challenges and future prospects. Compos. Struct. 2015, 134, 158–168. [Google Scholar] [CrossRef]

- Kazemi, M.; Kabir, S.F.; Fini, E.H. State of the art in recycling waste thermoplastics and thermosets and their applications in construction. Resour. Conserv. Recycl. 2021, 174, 105776. [Google Scholar] [CrossRef]

- Parker, D.; Bussink, J.; van de Grampel, H.T.; Wheatley, G.W.; Dorf, E.-U.; Ostlinning, E.; Reinking, K.; Schubert, F.; Jünger, O. Polymers, High-Temperature, Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH: Weinheim, Germany, 2012. [Google Scholar] [CrossRef]

- de Leon, A.C.C.; da Silva, Í.G.M.; Pangilinan, K.D.; Chen, Q.; Caldona, E.B.; Advincula, R.C. High performance polymers for oil and gas applications. React. Funct. Polym. 2021, 162, 104878. [Google Scholar] [CrossRef]

- Grigore, M.E. Methods of Recycling, Properties and Applications of Recycled Thermoplastic Polymers. Recycling 2017, 2, 24. [Google Scholar] [CrossRef]

- Nicholson, J.W. The Chemistry of Polymers; The Royal Society of Chemistry: Cambridge, UK, 2017; p. 210. Available online: https://books.google.com/books/about/The_Chemistry_of_Polymers.html?id=9JHpDQAAQBAJ (accessed on 29 September 2025).

- Erkuş, Y.; Kök, B.V. Comparison of physical and rheological properties of calcium carbonate-polypropylene composite and SBS modified bitumen. Constr. Build. Mater. 2023, 366, 130196. [Google Scholar] [CrossRef]

- Ajith, A.; Swapna, M.S.; Sankararaman, S. Clay-plastic-biodegradable waste composite as low carbon construction material: A way to sustainable development. Constr. Build. Mater. 2025, 488, 142151. [Google Scholar] [CrossRef]

- Chu, J.; Zhou, Y.; Cai, Y.; Wang, X.; Li, C.; Liu, Q. Flows and waste reduction strategies of PE, PP, and PET plastics under plastic limit order in China. Resour. Conserv. Recycl. 2023, 188, 106668. [Google Scholar] [CrossRef]

- Uzosike, C.C.; Yee, L.H.; Padilla, R.V. Small-Scale Mechanical Recycling of Solid Thermoplastic Wastes: A Review of PET, PEs, and PP. Energies 2023, 16, 1406. [Google Scholar] [CrossRef]

- Tai, C.M.; Li, R.K.Y.; Ng, C.N. Impact behaviour of polypropylene/polyethylene blends. Polym. Test. 2000, 19, 143–154. [Google Scholar] [CrossRef]

- Seymour, R.B. Polymers for Engineering Applications; OSTI: Albuquerque, NM, USA, 1987. [Google Scholar]

- Van De Velde, K.; Kiekens, P. Thermoplastic polymers: Overview of several properties and their consequences in flax fibre reinforced composites. Polym. Test. 2001, 20, 885–893. [Google Scholar] [CrossRef]

- Targor Polypropylene data sheet. Novolen 1100 H. CAM-PUS 4.1, 1999. Available online: https://personales.upv.es/sasanca/Master/files/caracteristicas%20polipropileno.pdf (accessed on 23 November 2025).

- Cogswell, F.N. Thermoplastic Aromatic Polymer Composites: A Study of the Structure, Processing and Properties of Carbon Fibre Reinforced Polyetheretherketone and Related Materials; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Kale, D.D.; Bopardikar, N.B. Effect of rheology on melt-spinning of polymer blends. IJFRET 1988, 13, 146–150. [Google Scholar]

- Agenda, I. The New Plastics Economy Rethinking the Future of Plastics; Economic Forum: Geneva, Switzerland, 2016. [Google Scholar]

- Wilson, M.L.; Buckley, J.D.; Dickerson, G.E.; Johnson, G.S.; Taylor, E.C.; Covington, E.W. Pultrusion Process Development of a Graphite Reinforced Polyetherimide Thermoplastic Composite. J. Thermoplast. Compos. Mater. 1989, 2, 230–246. [Google Scholar] [CrossRef]

- Callister, W.D., Jr.; Rethwisch, D.G. Materials Science and Engineering: An Introduction; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Menachem, L.; Pearce, E.M. Handbook of Fiber Chemistry, 2nd ed.; Marcel Dekker: New York NY, USA, 1998. [Google Scholar]

- Miller, E. Plastics Products Design Handbook. Part A. Materials and Components, 1st ed.; Marcel Dekker: New York, NY, USA; Basel, Switzerland, 1981. [Google Scholar]

- Internal Results from Earlier Research at the Department of Textiles, Ghent University. Available online: https://www.ugent.be/ea/match/textiles/en/research (accessed on 23 November 2025).

- Dym, J.B. Product Design with Plastics, 2nd ed.; Industrial Press: New York, NY, USA, 1983. [Google Scholar]

- Hostalen Data Sheet. Hostalen Produkttyp GF 7740 F2. 1999. Available online: https://hongrunplastics.com/public/uploads/images/20250609/LyondellBasell%20HDPE%20Hostalen%20GF%207740%20F2.pdf (accessed on 23 November 2025).

- Kroschwitz, J.I. Encyclopedia of Polymer Science and Engineering; Wiley-Interscience: Hoboken, NJ, USA, 1990. [Google Scholar]

- O’Conner, J.E.; Ma, C.C.M.; Lou, A.Y. Proceedings of the 39th Annual Conference, Reinforced Plastics/Composites Institute; Session 11-E; The Society of the Plastics Industry: Washington, DC, USA, 1984; pp. 1–5. [Google Scholar]

- Lee, A.; Liew, M.S. Tertiary recycling of plastics waste: An analysis of feedstock, chemical and biological degradation methods. J. Mater. Cycles Waste Manag. 2021, 23, 32–43. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.N.; Srinivasan, N.; Kumar, D.V.; Balaji, D. Influence of filler material on properties of fiber-reinforced polymer composites: A review. E-Polymer 2022, 22, 898–916. [Google Scholar] [CrossRef]

- Zhao, L.; Su, C.; Wang, Q.; Fan, C.; Fang, Y.; Bai, Y.; Ren, X.; Zhang, H.; Long, H. Fabrication modified pressurized-hot steel slag using stearic acid coupling agent to enhance the mechanical properties of wood-plastic composites. Constr. Build. Mater. 2025, 458, 139571. [Google Scholar] [CrossRef]

- Ganapathy, T.; Uthayakumar, G.; Raja, P.; Divakaran, D.; Suyambulingam, I. Eco-Friendly Fillers for Polymer Composites: A Comprehensive Review 2000–2024. Springer Proc. Mater. 2024, 60, 839–864. [Google Scholar] [CrossRef]

- Katz, H.S.; Milewski, J.V. Handbook of Fillers for Plastics; Springer: Berlin/Heidelberg, Germany, 1987; p. 467. Available online: https://books.google.com/books/about/Handbook_Of_Fillers_For_Plastics.html?id=zKMiAEVWgUIC (accessed on 27 May 2025).

- Leidner, J.; Woodhams, R.T. The strength of polymeric composites containing spherical fillers. J. Appl. Polym. Sci. 1974, 18, 1639–1654. [Google Scholar] [CrossRef]

- Gent, A.N. Detachment of an elastic matrix from a rigid spherical inclusion. J. Mater. Sci. 1980, 15, 2884–2888. [Google Scholar] [CrossRef]

- Needleman, A. A Continuum Model for Void Nucleation by Inclusion Debonding. J. Appl. Mech. 1987, 54, 525–531. [Google Scholar] [CrossRef]

- Gent, A.N.; Park, B. Failure processes in elastomers at or near a rigid spherical inclusion. J. Mater. Sci. 1984, 19, 1947–1956. [Google Scholar] [CrossRef]

- Dubnikova, I.L.; Oshmyan, V.G.; Gorenberg, A.Y. Mechanisms of participate filled polypropylene finite plastic deformation and fracture. J. Mater. Sci. 1997, 32, 1613–1622. [Google Scholar] [CrossRef]

- Mekideche, S.; Rokbi, M.; Rahmouni, Z.E.A.; Phiri, R.; Rangappa, S.M.; Siengchin, S. Manufacture and characterization of lightweight sand-plastic composites made of plastic waste and sand: Effect of sand types. Int. J. Lightweight Mater. Manuf. 2025, 8, 53–65. [Google Scholar] [CrossRef]

- Kant, S.; Urmila, J.K.; Pundir, G. Study of talc filled polypropylene-a concept for improving mechanical properties of polypropylene. Int. J. Res. Eng. Technol. 2013, 2, 411–415. [Google Scholar]

- Wu, P.; Liu, X.; Zhang, Z.; Wei, C. Properties of red mud-filled and modified resin composites. Constr. Build. Mater. 2023, 409, 133984. [Google Scholar] [CrossRef]

- Brydson, J.A. Plastics Materials, 7th ed.; Elsevier: Amsterdam, The Netherlands, 1999; Volume 7, p. 920. [Google Scholar]

- Essabir, H.; Bensalah, M.O.; Rodrigue, D.; Bouhfid, R.; el kacem Qaiss, A. A comparison between bio- and mineral calcium carbonate on the properties of polypropylene composites. Constr. Build. Mater. 2017, 134, 549–555. [Google Scholar] [CrossRef]

- Wieme, T.; Duan, L.; Mys, N.; Cardon, L.; D’hooge, D.R. Effect of Matrix and Graphite Filler on Thermal Conductivity of Industrially Feasible Injection Molded Thermoplastic Composites. Polymers 2019, 11, 87. [Google Scholar] [CrossRef] [PubMed]

- Jordan, M.M.; Montero, M.A.; Meseguer, S.; Sanfeliu, T. Influence of firing temperature and mineralogical composition on bending strength and porosity of ceramic tile bodies. Appl. Clay Sci. 2008, 42, 266–271. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Michailidis, N.; Mountakis, N.; Argyros, A.; Spiridaki, M.; Moutsopoulou, A.; Papadakis, V.; Charitidis, C. High-Density Polyethylene/Carbon Black Composites in Material Extrusion Additive Manufacturing: Conductivity, Thermal, Rheological, and Mechanical Responses. Polymers 2023, 15, 4717. [Google Scholar] [CrossRef]

- Urtekin, G.; Ullah, M.S.; Yildirim, R.; Ozkoc, G.; Kodal, M. A comprehensive review of the recent developments in thermoplastics and rubber blends-based composites and nanocomposites. Polym. Compos. 2023, 44, 8303–8329. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Ismail, H.; Saeed, A.M. A Review: Metal Filled Thermoplastic Composites. Polym. Plast. Technol. Mater. 2021, 60, 1033–1050. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Reihmane, S.; Gassan, J. Thermoplastics Reinforced with Wood Fillers: A Literature Review. Polym. Technol. Eng. 1998, 37, 451–468. [Google Scholar] [CrossRef]

- Nitz, H.; Reichert, P.; Römling, H.; Mülhaupt, R. Influence of compatibilizers on the surface hardness, water uptake and the mechanical properties of poly(propylene) wood flour composites prepared by reactive extrusion. Macromol. Mater. Eng. 2000, 276–277, 51–58. [Google Scholar] [CrossRef]

- Babatunde, Y.O.; Ibrahim, R.A.; Oguntayo, D.O. Effect of mix proportion on the strength and durability of plastic and sand composite for construction applications. Innov. Infrastruct. Solut. 2022, 7, 333. [Google Scholar] [CrossRef]

- Abou-Kandil, A.I.; Awad, A.; Mwafy, E. Polymer nanocomposites part 2: Optimization of zinc oxide/high-density polyethylene nanocomposite for ultraviolet radiation shielding. J. Thermoplast. Compos. Mater. 2015, 28, 1583–1598. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, J.; Liu, M. Interphase in Polymer Nanocomposites. JACS Au 2022, 2, 280–291. [Google Scholar] [CrossRef]

- Singh, V.P.; Kumar, R.; Singh, P.; Samanta, S.; Banerjee, S. Melt rheological behaviour of high-density polyethylene/ montmorillonite nanocomposites. Polym. Polym. Compos. 2021, 29, S511–S520. [Google Scholar] [CrossRef]

- Hafiz, H.M.; Al Rashid, A.; Koç, M. Recent advancements in sustainable production and consumption: Recycling processes and impacts for additive manufacturing. Sustain. Chem. Pharm. 2024, 42, 101778. [Google Scholar] [CrossRef]

- Landolfi, L.; Detry, A.L.H.S.; Cozzolino, E.; Tammaro, D.; Squillace, A. Energy-saving approach for mechanical properties enhancement of recycled PET additively manufactured by MEX. Sustain. Mater. Technol. 2024, 41, e01038. [Google Scholar] [CrossRef]

- Sormunen, P.; Kärki, T. Compression Molded Thermoplastic Composites Entirely Made of Recycled Materials. Sustainability 2019, 11, 631. [Google Scholar] [CrossRef]

- Apichartpattanasiri, S.; Hay, J.N.; Kukureka, S.N. A study of the tribological behaviour of polyamide 66 with varying injection-moulding parameters. Wear 2001, 251, 1557–1566. [Google Scholar] [CrossRef]

- Reinicke, R.; Haupert, F.; Friedrich, K. On the tribological behaviour of selected, injection moulded thermoplastic composites. Compos. Part A Appl. Sci. Manuf. 1998, 29, 763–771. [Google Scholar] [CrossRef]

- Jnr, A.K.-L.; Galpin, R.; Manjula, S.; Lenkiewicz, Z.; Cheeseman, C. Reuse of Waste Plastics in Developing Countries: Properties of Waste Plastic-Sand Composites. Waste Biomass Valorization 2022, 13, 3821–3834. [Google Scholar] [CrossRef]

- Periasamy, K.; M, K.; Venkatesh, R.; Padmavathy, S. Enhancement of high density polyethylene (HDPE) composite behavior by using TiO2f and Al2O3f bio ceramic fillers. J. Polym. Res. 2023, 30, 339. [Google Scholar] [CrossRef]

- Zahran, R.R. Effect of sand addition on the tensile properties of compression moulded sand/polyethylene composite system. Mater. Lett. 1998, 34, 161–167. [Google Scholar] [CrossRef]

- Jeyachandran, P.; Bontha, S.; Bodhak, S.; Balla, V.K.; Kundu, B.; Doddamani, M. Mechanical behaviour of additively manufactured bioactive glass/high density polyethylene composites. J. Mech. Behav. Biomed. Mater. 2020, 108, 103830. [Google Scholar] [CrossRef] [PubMed]

- Adhikary, K.B.; Pang, S.; Staiger, M.P. Dimensional stability and mechanical behaviour of wood–plastic composites based on recycled and virgin high-density polyethylene (HDPE). Compos. B Eng. 2008, 39, 807–815. [Google Scholar] [CrossRef]

- Mohammadi, H.; Mirmehdi, S.; Hugen, L.N. Rice Straw/Thermoplastic Composite: Effect Of Filler Loading, Polymer Type And Moisture Absorption On The Performance. Cerne 2016, 22, 449–456. [Google Scholar] [CrossRef]

- Khan, S.; Khondoker, M.; Soni, A.; Das, P.K.; Gupta, S.K.; Alam, M.A.; Yusuf, M.; Ibrahim, H. Development of Filler-Reinforced Sustainable Polymeric Composites for the Implementation of Green Technology in Building Construction. Eng. Proc. 2025, 76, 109. [Google Scholar] [CrossRef]

- Kuciel, S.; Rusin-Żurek, K.; Kurańska, M. The Influence of Filler Particle Size on the Strength Properties and Mechanical Energy Dissipation Capacity of Biopoly(Ethylene Terephthalate) BioPET/Eggshell Biocomposites. Recycling 2024, 9, 88. [Google Scholar] [CrossRef]

- Onuoha, C.; Onyemaobi, O.O.; Anyakwo, C.N.; Onuegbu, G.C. Effect of filler loading and particle size on the mechanical properties of periwinkle shell-filled recycled polypropylene composites, American Journal of Engineering Research. Available online: www.ajer.org (accessed on 26 October 2025).

- Tufa, M.; Tafesse, D.; Tolosa, S.; Murgan, S. Study of sand-plastic composite using optimal mixture design of experiments for best compressive strength. Mater. Today Proc. 2021, 47, 480–487. [Google Scholar] [CrossRef]

- Grigorescu, R.M.; Ghioca, P.; Iancu, L.; David, M.E.; Andrei, E.R.; Filipescu, M.I.; Ion, R.M.; Vuluga, Z.; Anghel, I.; Sofran, I.E.; et al. Development of thermoplastic composites based on recycled polypropylene and waste printed circuit boards. Waste Manag. 2020, 118, 391–401. [Google Scholar] [CrossRef]

- Adhikari, S.P.; Pandey, U.; Adhikari, R. Effect of filler particle size on of pine dust-filled recycled HDPE composites. UNEC J. Eng. Appl. Sci. 2024, 4, 91–99. [Google Scholar] [CrossRef]

- Psyanchin, A.A.; Zakharova, E.M.; Zakharov, V.P. Effect of Melt Flow Modifier on Physical and Mechanical Properties of Polymer Composite Based on Recycled Polypropylene and Aluminosilicate Microspheres. Inorg. Mater. Appl. Res. 2023, 14, 408–411. [Google Scholar] [CrossRef]

- Rubiano-Navarrete, A.F.; Sandoval, P.R.; Pérez, Y.T.; Gómez-Pachón, E.Y. Effect of Fiber Loading on Green Composites of Recycled HDPE Reinforced with Banana Short Fiber: Physical, Mechanical and Morphological Properties. Polymers 2024, 16, 3299. [Google Scholar] [CrossRef]

- Arbi, Y.M.; Mahmoudi, N.; Djebli, A. Manufacturing and testing of waste PET reinforced with sand bricks. J. Compos. Mater. 2023, 57, 2513–2526. [Google Scholar] [CrossRef]

- Mohan, H.T.; Whitaker, F.; Gaskell, D.; Mohan, R.; Mini, K.M. Performance assessment of recycled LDPE with sand fillers. Mater. Today Proc. 2021, 42, 1526–1530. [Google Scholar] [CrossRef]

- Yi, H.; Oh, K.; Kou, R.; Qiao, Y. Sand-filler structural material with a low content of polyethylene binder. Sustain. Mater. Technol. 2020, 25, e00194. [Google Scholar] [CrossRef]

- Soni, A.; Das, P.K.; Yusuf, M.; Kamyab, H.; Chelliapan, S. Development of sand-plastic composites as floor tiles using silica sand and recycled thermoplastics: A sustainable approach for cleaner production. Sci. Rep. 2022, 12, 18921. [Google Scholar] [CrossRef]

- Rasib, S.Z.M.; Mariatti, M.; Atay, H.Y. Effect of waste fillers addition on properties of high-density polyethylene composites: Mechanical properties, burning rate, and water absorption. Polym. Bull. 2021, 78, 6777–6795. [Google Scholar] [CrossRef]

- Yurchenko, V.; Haiduk, V.; Skaskevich, A.; Zharkevich, O.; Zhetessova, G.; Reshetnikova, O.; Smagulov, A.; Mussayev, M. Study of Deformation and Strength Characteristics of Highly Filled Sand–Polymer Composites Based on Regenerated Thermoplastics. J. Compos. Sci. 2025, 9, 206. [Google Scholar] [CrossRef]

- Sengupta, S.; Pal, K.; Ray, D.; Mukhopadhyay, A. Furfuryl palmitate coated fly ash used as filler in recycled polypropylene matrix composites. Compos. B Eng. 2011, 42, 1834–1839. [Google Scholar] [CrossRef]

- Muhammad, A.; Srivastava, R.; Koutroumanis, N.; Semitekolos, D.; Chiavazzo, E.; Pappas, P.-N.; Galiotis, C.; Asinari, P.; Charitidis, C.A.; Fasano, M. Mesoscopic modeling and experimental validation of thermal and mechanical properties of polypropylene nanocomposites reinforced by graphene-based fillers. Macromolecules 2022, 56, 9969–9982. [Google Scholar] [CrossRef]

- Droß, M.; Ehleben, M.; Dröder, K. Mineral Filler Hybridization in Recycled Polyethylene Terephthalate. Polymers 2025, 259, 17. [Google Scholar] [CrossRef]

- Srivabut, C.; Ratanawilai, T.; Hiziroglu, S. Effect of nanoclay, talcum, and calcium carbonate as filler on properties of composites manufactured from recycled polypropylene and rubberwood fiber. Constr. Build. Mater. 2018, 162, 450–458. [Google Scholar] [CrossRef]

- Sahani, K.; Timsina, A.P.; Tuladhar, B.; Sahani, S.K.; Das, A.K. Low cost upcycling of non-segregated plastic waste as building materials in Nepal: Experimental investigation and microstructural analysis. Constr. Build. Mater. 2025, 492, 142955. [Google Scholar] [CrossRef]

- Salih, W.K. Flame retardancy properties and thermomechanical behavior of the nanocomposite of thermoplastic Polypropylene/Linear Low-density Polyethylene blend filled with nano calcium carbonate. J. Phys. Conf. Ser. 2019, 1294, 052020. [Google Scholar] [CrossRef]

- Olmos, D.; Martínez, F.; González-Gaitano, G.; González-Benito, J. Effect of the presence of silica nanoparticles in the coefficient of thermal expansion of LDPE. Eur. Polym. J. 2011, 47, 1495–1502. [Google Scholar] [CrossRef]

- Zhao, Q.; Zhang, B.; Quan, H.; Yam, R.C.M.; Yuen, R.K.K.; Li, R.K.Y. Flame retardancy of rice husk-filled high-density polyethylene ecocomposites. Compos. Sci. Technol. 2009, 69, 2675–2681. [Google Scholar] [CrossRef]

- Iñiguez, M.E.; Conesa, J.A.; Fullana, A. Recyclability of four types of plastics exposed to UV irradiation in a marine environment. Waste Manag. 2018, 79, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Jirků, P.; Muller, M.; Mishra, R.K.; Svobodová, J. Effect of Recycling and UV Ageing on the Properties of PLA-Based Materials Used in Additive Manufacturing. Polymers 2025, 17, 1862. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.; Mishra, A.; Thakur, V.K.; Pappu, A. Towards sustainable wood–plastic composites: Polymer types, properties, processing and future prospects. RSC Sustain. 2025, 3, 2833–2862. [Google Scholar] [CrossRef]

- Siddiqui, M.N.; Redhwi, H.H.; Andrady, A.L.; Furquan, S.A.; Hussain, S. Effect of Extensive Solar Ultra-Violet Irradiation on the Durability of High-Density Polyethylene- and Polypropylene-Based Wood–Plastic Composites. Polymers 2024, 17, 74. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhang, J.; Liu, L.; Yang, F.; Zhang, Y. Evaluation of cooling property of high density polyethylene (HDPE)/titanium dioxide (TiO2) composites after accelerated ultraviolet (UV) irradiation. Sol. Energy Mater. Sol. Cells 2015, 143, 120–127. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Muttashar, M.; Yu, P.; Kakarla, R.; Salih, C.; Schubel, P. Composites for alternative railway sleepers. Lect. Notes Civ. Eng. 2021, 101, 267–276. [Google Scholar] [CrossRef]

- Shanmugam, D.; Thiruchitrambalam, M. Static and dynamic mechanical properties of alkali treated unidirectional continuous Palmyra Palm Leaf Stalk Fiber/jute fiber reinforced hybrid polyester composites. Mater. Des. 2013, 50, 533–542. [Google Scholar] [CrossRef]

- Wimalasuriya, L.; Gunasekara, C.; Robert, D.; Setunge, S.; O’Donnell, B. Waste-Derived High-Density Polyethylene-Glass Composites: A Pathway to Sustainable Structural Materials. Polymers 2024, 17, 35. [Google Scholar] [CrossRef]

- Valdés, M.; Trulli, N.; De Nicolo, B. From Plastic Waste to Building Material: Mechanical Properties of Recycled Thermoplastic Timber. Int. J. Struct. Glass Adv. Mater. Res. 2018, 2, 55–65. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, M. Recycled tyre rubber-thermoplastic composites through interface optimization. RSC Adv. 2017, 7, 29263–29270. [Google Scholar] [CrossRef]

- Ju, S.; Yoon, J.; Sung, D.; Pyo, S. Mechanical Properties of Coal Ash Particle-Reinforced Recycled Plastic-Based Composites for Sustainable Railway Sleepers. Polymers 2020, 12, 2287. [Google Scholar] [CrossRef]

- Zhao, X.; Copenhaver, K.; Wang, L.; Korey, M.; Gardner, D.J.; Li, K.; Lamm, M.E.; Kishore, V.; Bhagia, S.; Tajvidi, M.; et al. Recycling of natural fiber composites: Challenges and opportunities. Resour. Conserv. Recycl. 2022, 177, 105962. [Google Scholar] [CrossRef]

- Oladele, I.O.; Omotosho, T.F.; Adediran, A.A. Polymer-Based Composites: An Indispensable Material for Present and Future Applications. Int. J. Polym. Sci. 2020, 2020, 8834518. [Google Scholar] [CrossRef]

- Thermoplastic Composites Market Size & Forecast [Latest]. Available online: https://www.marketsandmarkets.com/Market-Reports/thermoplastic-composite-market-111944669.html (accessed on 21 March 2025).

| Polymers | (g/cm3) | E (GPa) | Tg (°C) | Tm (°C) | Tp (°C) |

|---|---|---|---|---|---|

| PP | 0.899–0.920 | 0.95–1.776 | −23 to −10 | 160–176 | 200–290 |

| LDPE | 0.910–0.925 | 0.1–0.38 | –125 | 105–116 | 150–230 |

| HDPE | 0.941–1.000 | 0.41–1.49 | −133 to −100 | 120–140 | 150–290 |

| PA-6 | 1.09–1.14 | 2.9 | 40–48 | 215–216 | 215–270 |

| PA-66 | 1.08–1.14 | 2.5–3.9 | 50–80 | 250–269 | 250–320 |

| PC | 1.19–1.24 | 2.3–3.0 | 140.5–150 | – | 260–330 |

| PBT | 1.23–1.35 | 2.37 | 20–45 | 224–240 | 246–290 |

| PET | 1.30–1.40 | 2.7–4.0 | 69–110 | 246–265 | 256–310 |

| PEEK | 1.264–1.32 | 3.1–3.8 | 139–153 | 334–343 | 370–400 |

| PPS | 1.30–1.40 | 2.6–3.9 | 85–95 | 275–290 | 300–340 |

| PEI | 1.27–1.28 | 3 | 215–225 | – | 330–420 |

| PAI | 1.38–1.45 | 2.8–4.4 | 244–290 | – | 340–400 |

| Matrix Types | Filler Types and Sizes | Applications | Key Findings | Challenges and Limitations | Refs. |

|---|---|---|---|---|---|

| rHDPE | Waste glass (<50 μm and <200 μm) | Marine structures such as docks and sea barriers | At this optimum ratio, flexural, tensile, and compressive strengths of 33.3 MPa, 19.6 MPa, and 12.8 MPa, respectively; compatibilisers improved filler dispersion. | Processing limits with high filler content; Durability: UV radiation, temperature fluctuations, and long-term loading remain unproven; limited field validation. | [121] |

| Recycled PET, PE-HD, PE-LD, PP and PS | Steel-strengthened and un-strengthened | Wall panels, non-load-bearing materials, and Eco-building materials | Steel reinforcement enhanced strength and stiffness by over 300% without loss of ductility, achieving suitable panel performance, though still lower than traditional materials like timber. | Low bearing capacity; not suitable for major load-bearing applications. | [122] |

| rPE | Recycled tyre (0.25–0.5 mm) | Road and paving materials | Si69 treatment improved tensile stress by 34% and strain by 70%, while MAPE enhanced strain by 47% with negligible strength change. VTMS treatment slightly reduced both stress and modulus compared to untreated samples. | Difficulties in consistent blending; thermal degradation risk. | [123] |

| rPE | Sand (>2 mm) | Structural blocks, precast, and Modular construction materials. | Flexural strength increased from 8 MPa at 4% filler to 30 MPa at 25% filler, representing a 275% improvement, exceeding that of many steel-reinforced concretes. | Brittle failure at low binder ratios; thermal expansion mismatch. | [102] |

| rHDPE | Mineral fillers (wool, gypsum, soapstone) | Structural construction boards | Enhanced stiffness and moisture resistance; usable for semi-structural applications. | Poor tensile strength; filler incompatibility; not suitable for heavy structural loads; variation in filler properties impacts consistency. | [83] |

| Municipal waste plastic | Coal ash (0.1–1000 μm) | Sustainable Railway sleepers | Tensile stress and modulus improved from 6.8 MPa to 19.0 MPa, and from 755 MPa to 2281 MPa, a 179% and 202% increase; Compressive and flexural strength improved by 74% and 66%, respectively. Up to 60% coal ash filler yielded suitable mechanical strength for sleeper use. | Long-term durability and creep under load remain concerns; it requires more field validation. | [124] |

| Recycled plastic composites (Type-1) | Particle filler | Railway sleepers | Recycled plastic sleepers offer environmental benefits and ease of handling, but new Australian hardwood sleepers show a MoR of 47–110 MPa, while most composite sleepers exhibit much lower strength and stiffness. | Low anchorage capability, void formation, creep deformation, UV and moisture degradation, and absence of long-term performance standards. | [28] |

| Alternative railway sleepers | Recycled plastic sleepers with a bending modulus below 1.0 GPa showed W-shaped deflection and ~42% higher rail seat deformation compared with timber sleepers (MoE = 13.0 GPa). | Low MoE sleepers cause stress concentrations and unstable deflection; recycled plastic sleepers deform excessively. | [23] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sabbrojjaman, M.; Manalo, A.; Ferdous, W.; Alajarmeh, O. Mechanical and Durability Characteristics of Particulate-Filled Recycled Thermoplastic Composites (RTCs): A Comprehensive Review. Polymers 2025, 17, 3161. https://doi.org/10.3390/polym17233161

Sabbrojjaman M, Manalo A, Ferdous W, Alajarmeh O. Mechanical and Durability Characteristics of Particulate-Filled Recycled Thermoplastic Composites (RTCs): A Comprehensive Review. Polymers. 2025; 17(23):3161. https://doi.org/10.3390/polym17233161

Chicago/Turabian StyleSabbrojjaman, Md, Allan Manalo, Wahid Ferdous, and Omar Alajarmeh. 2025. "Mechanical and Durability Characteristics of Particulate-Filled Recycled Thermoplastic Composites (RTCs): A Comprehensive Review" Polymers 17, no. 23: 3161. https://doi.org/10.3390/polym17233161

APA StyleSabbrojjaman, M., Manalo, A., Ferdous, W., & Alajarmeh, O. (2025). Mechanical and Durability Characteristics of Particulate-Filled Recycled Thermoplastic Composites (RTCs): A Comprehensive Review. Polymers, 17(23), 3161. https://doi.org/10.3390/polym17233161