Assessment of the Environmental Feasibility of Utilizing Hemp Fibers in Composite Production

Abstract

1. Introduction

2. Materials and Methods

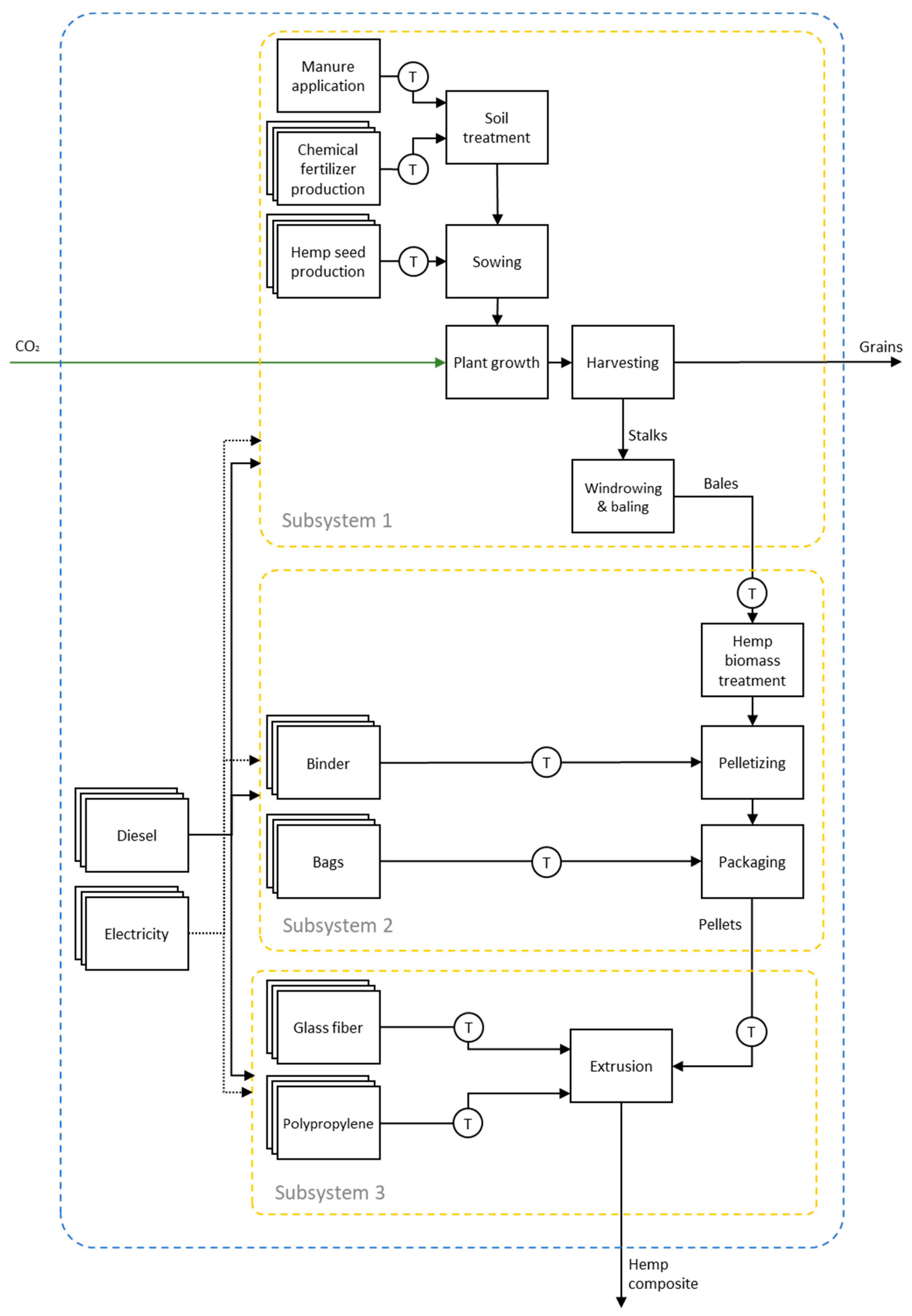

2.1. Specifications of the Study Object

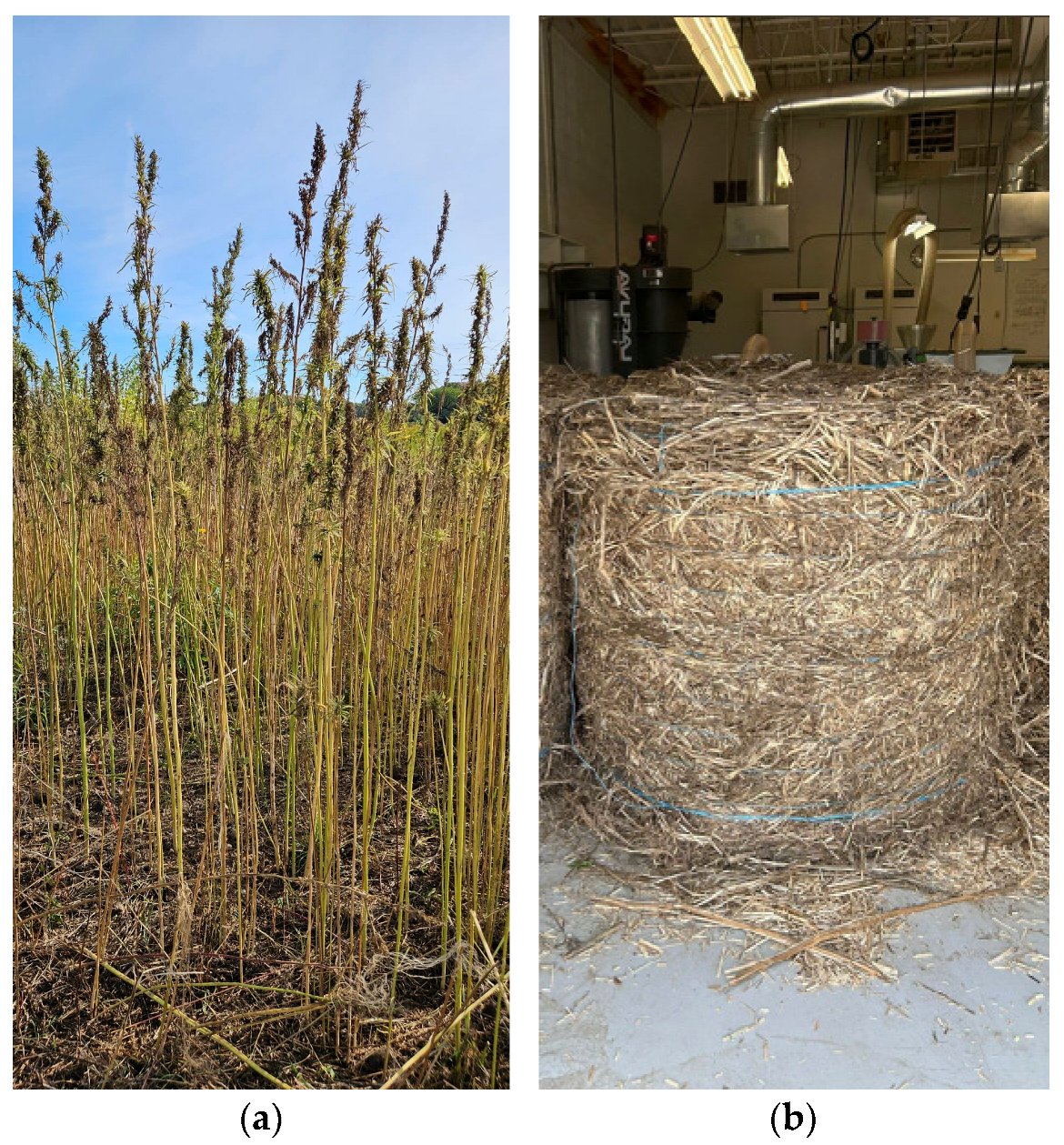

2.1.1. Subsystem 1: Hemp Stalks in Bales

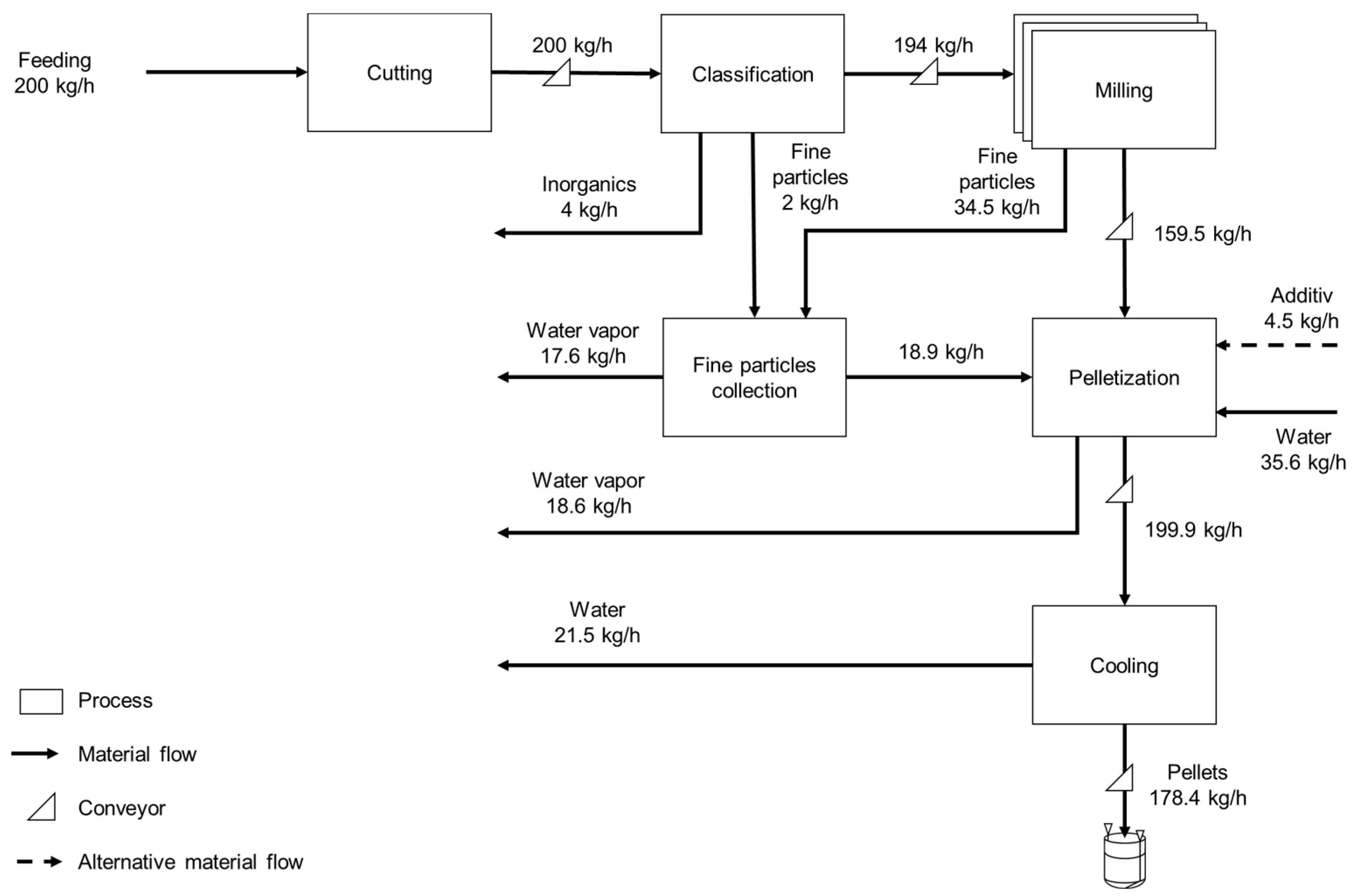

2.1.2. Subsystem 2: Hemp Pellet Production

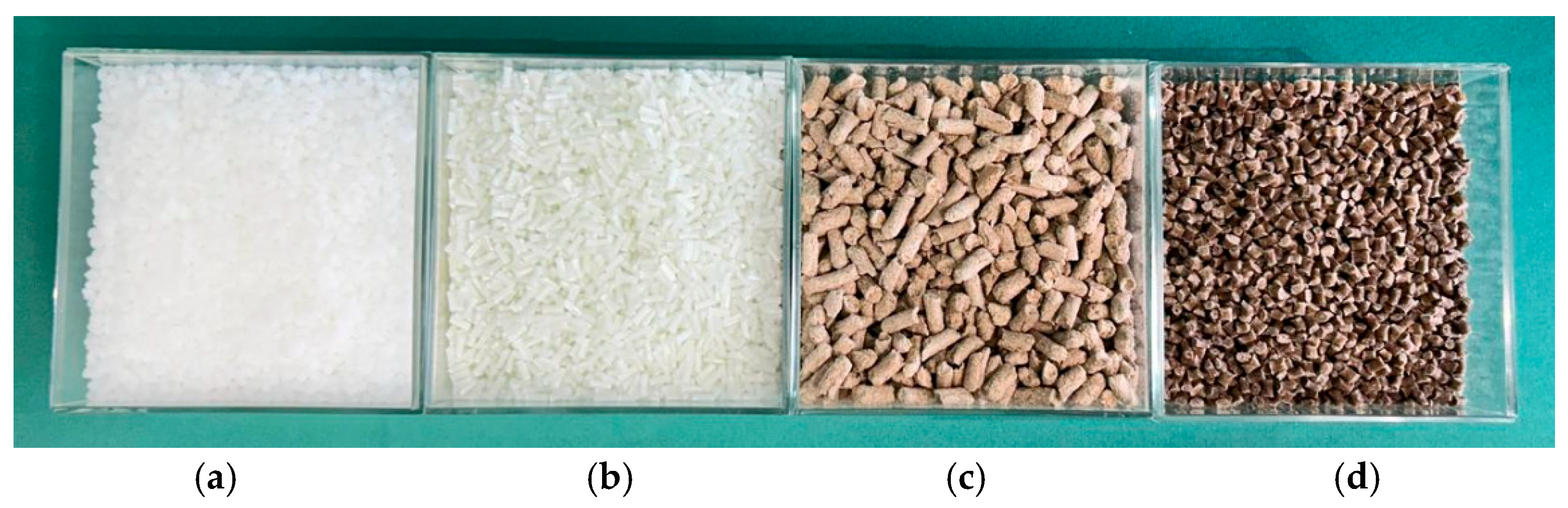

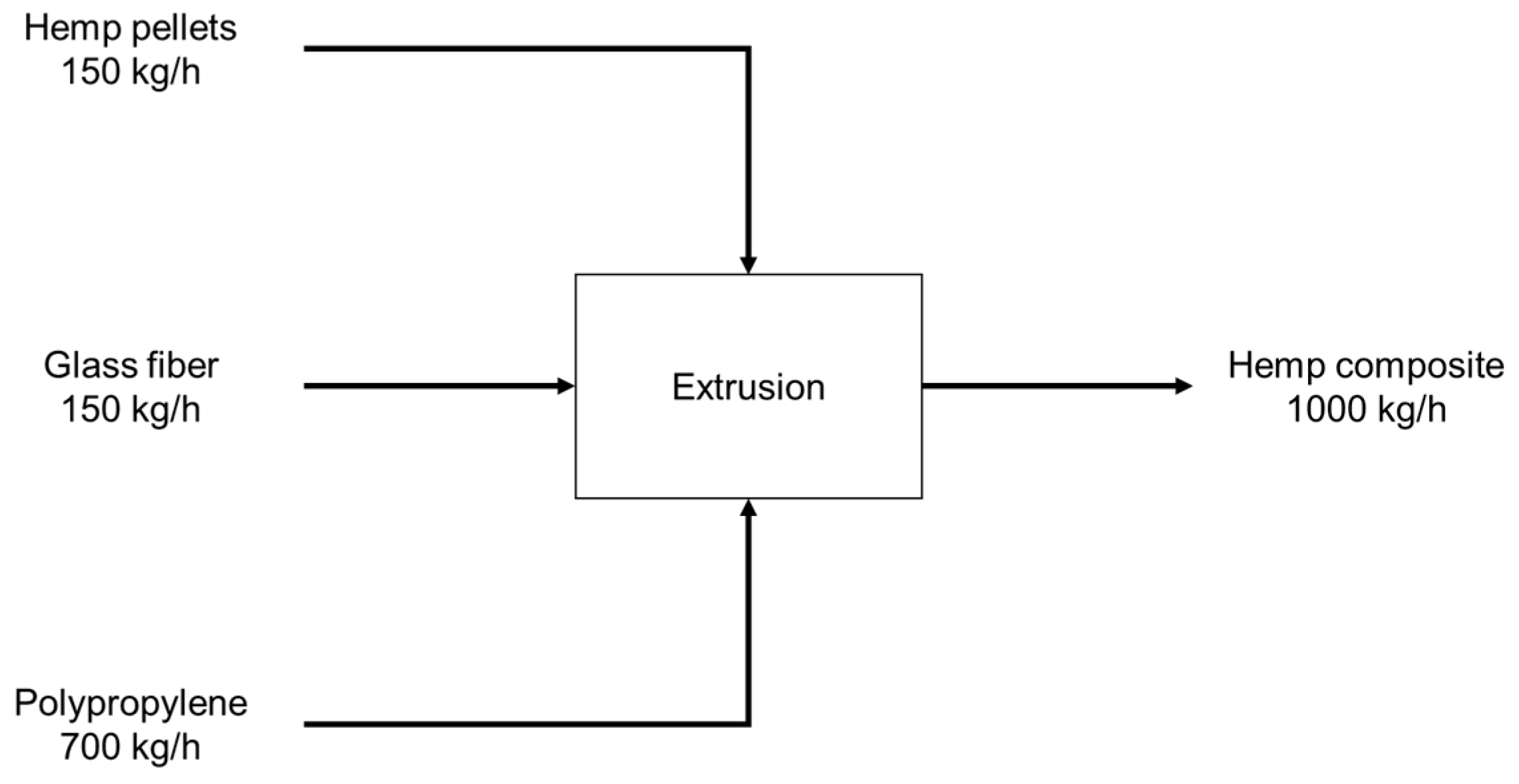

2.1.3. Subsystem 3: Production of Composite Containing Hemp Biomass

2.2. Life Cycle Modeling

2.2.1. LCA Scope Definition

2.2.2. Complementary Assumptions

- The analysis excluded environmental loads from the production of capital goods and labor usage because their contribution rates were minimal, and the data associated with them were significantly uncertain.

- All transportation operations were modeled considering that EURO 6 trucks would be used, featuring load capacities between 7.5 and 16 tons.

- Also, regarding transport, only the atmospheric emissions from fuel combustion during truck movement were considered. Consequently, this study excluded other environmental loads from constructing and maintaining roads and vehicles.

- Data on electricity generation sources and their respective shares in each location within the geographic coverage were also obtained from Ecoinvent Database 9.5 and updated for 2023.

- Mass and energy balances were applied to the data to verify their consistency and representativeness and to harmonize them, reducing discrepancies arising from the diversity of sources.

2.2.3. Sensitivity Analysis

3. Results and Discussion

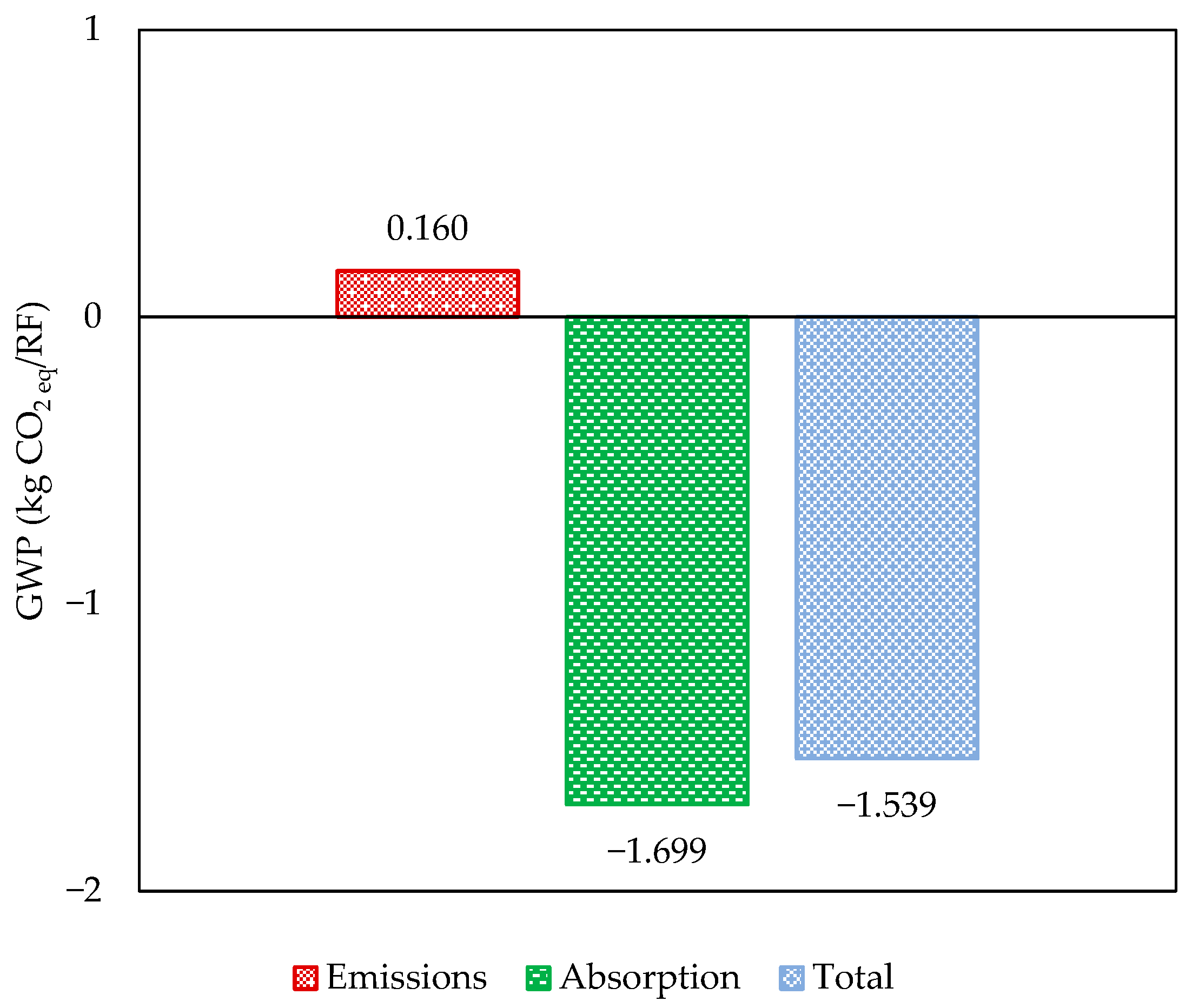

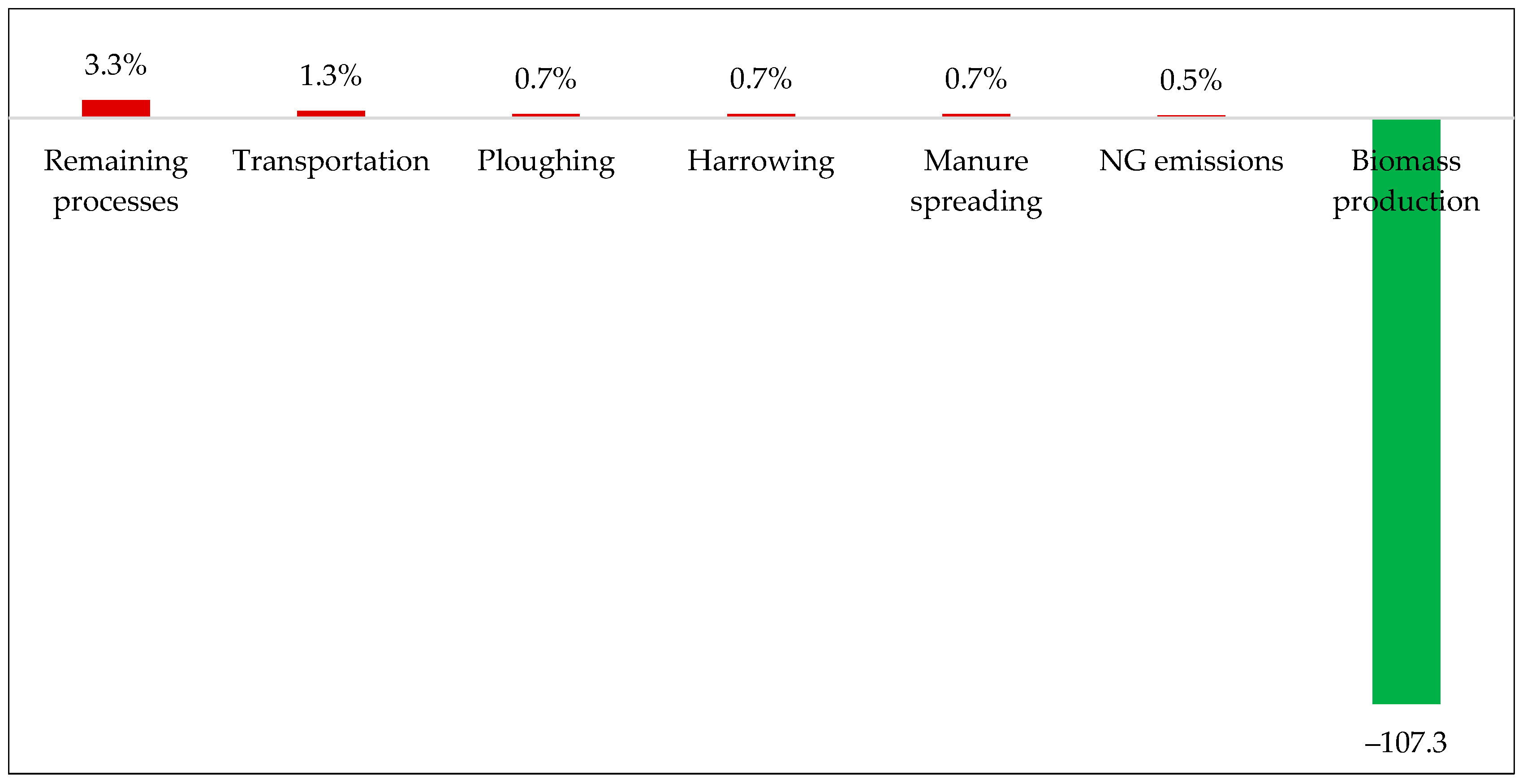

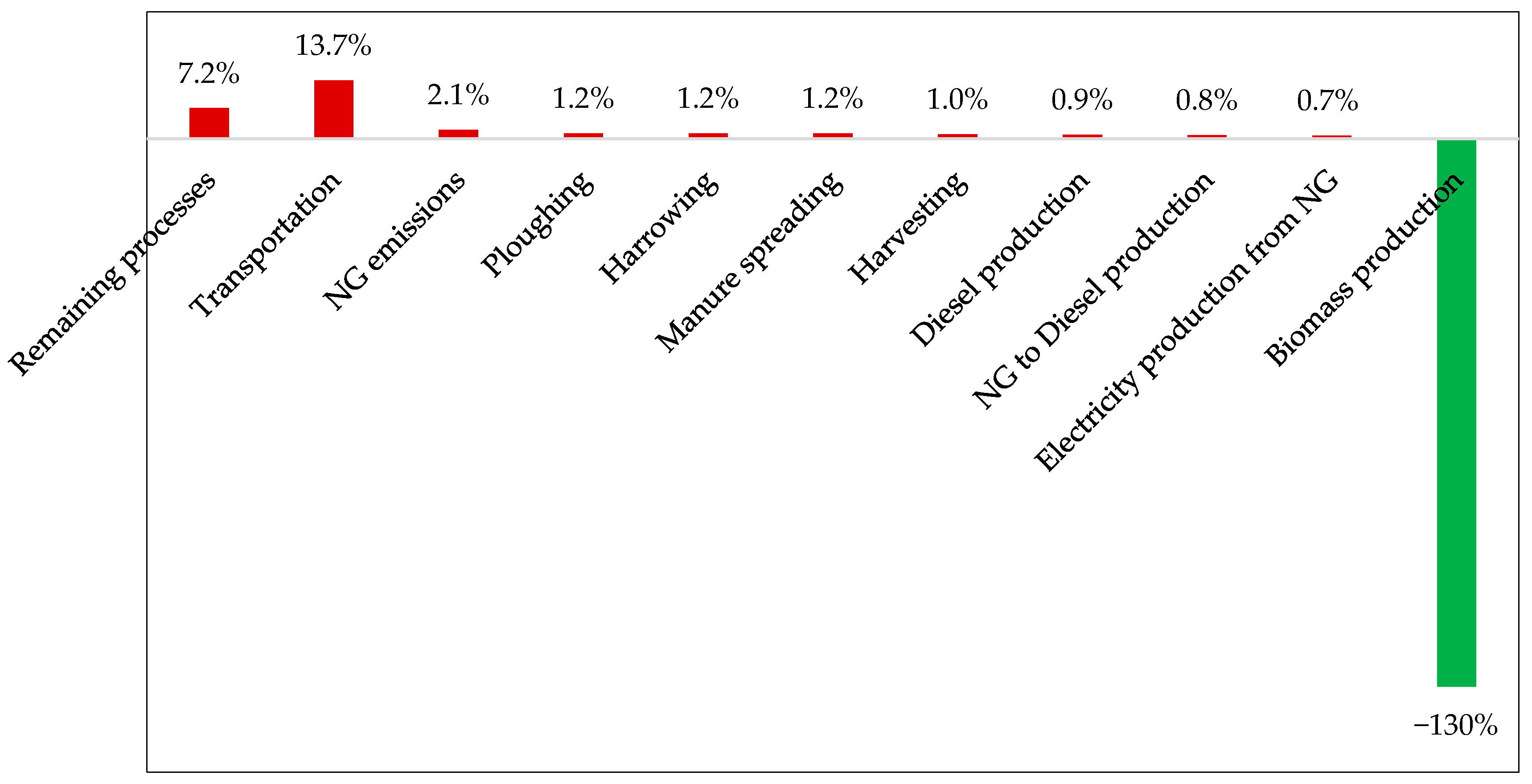

3.1. GWP Associated with Subsystem 1: Hemp Stalks

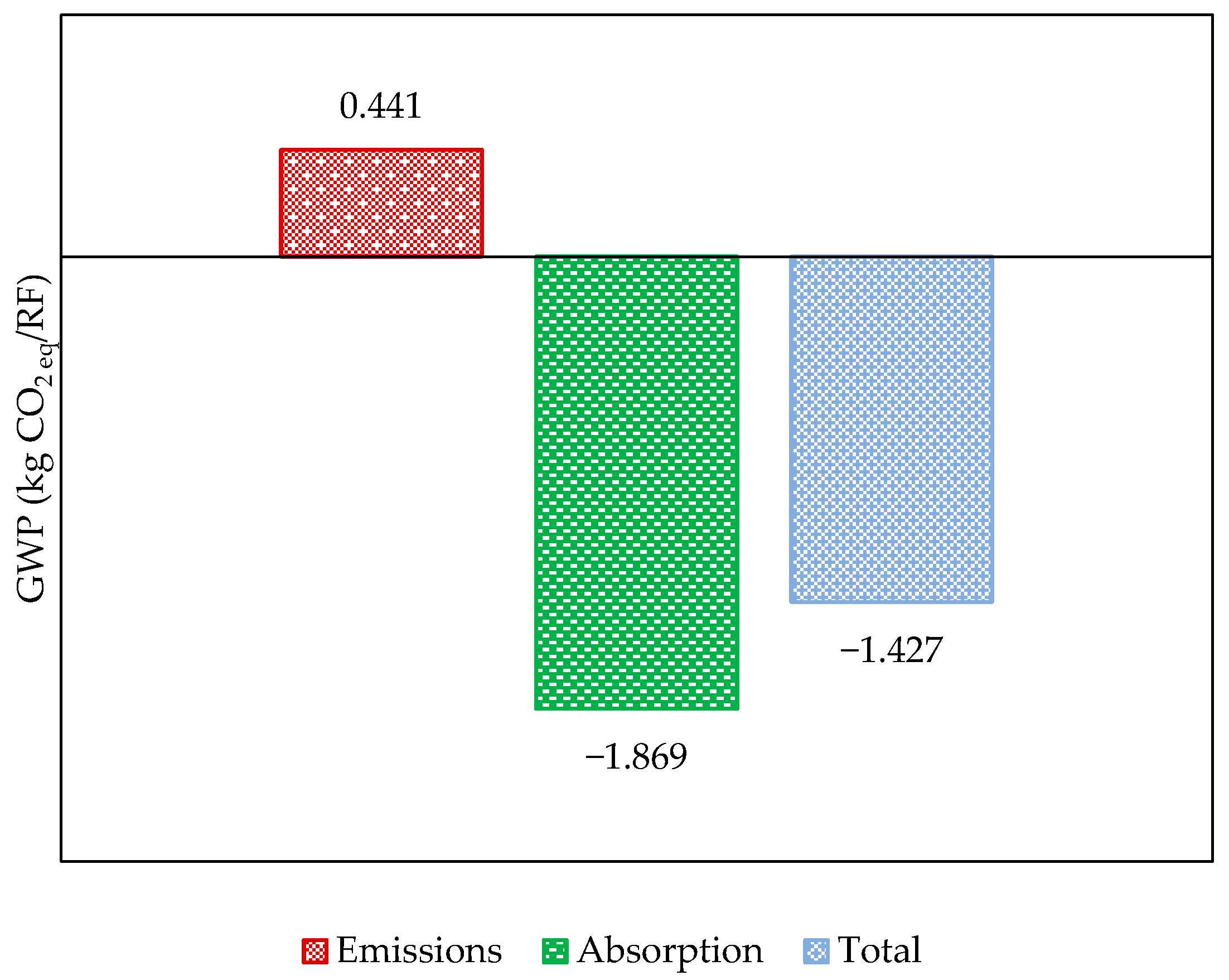

3.2. GWP Associated with Subsystem 2: Hemp Pellets

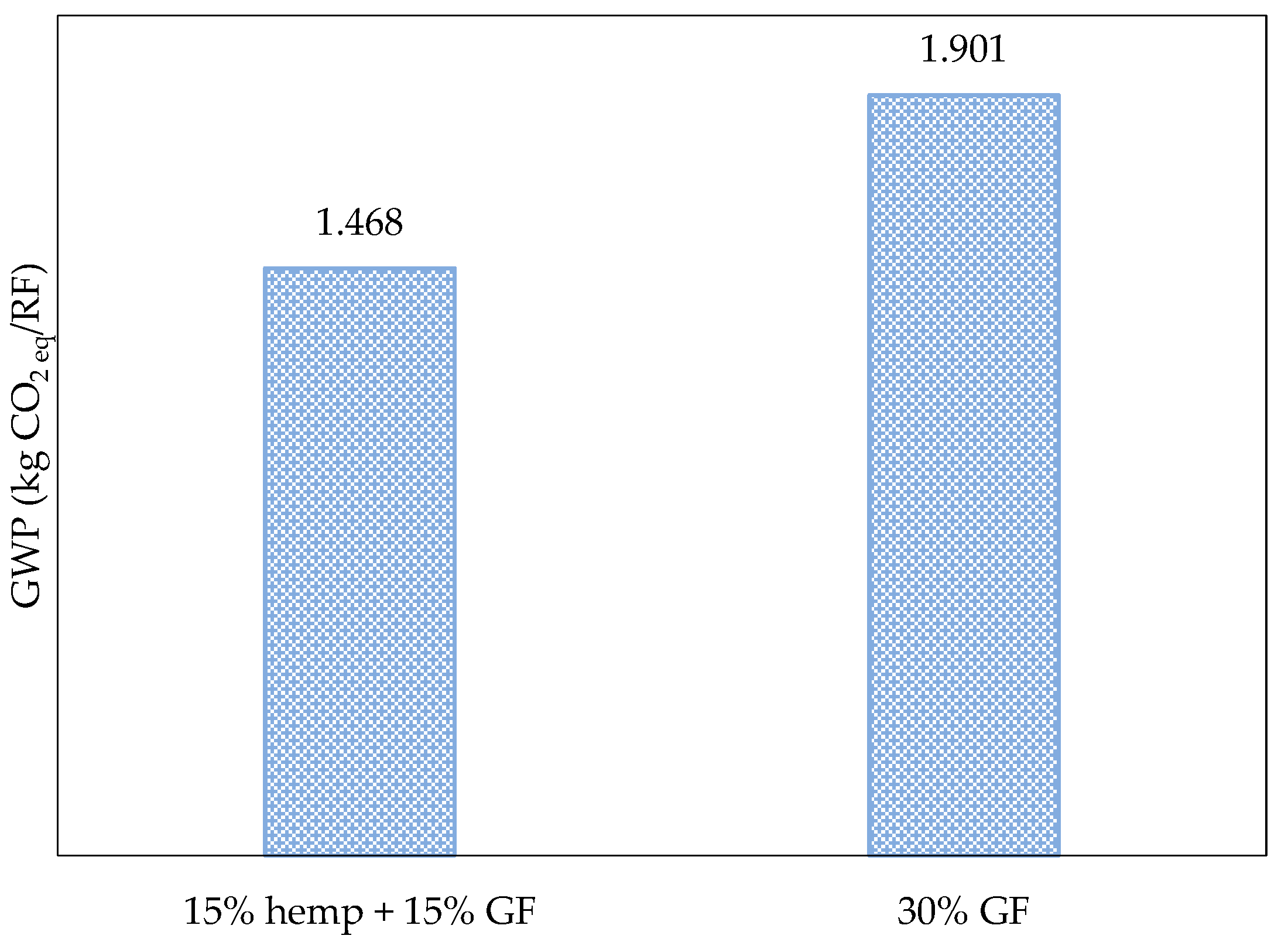

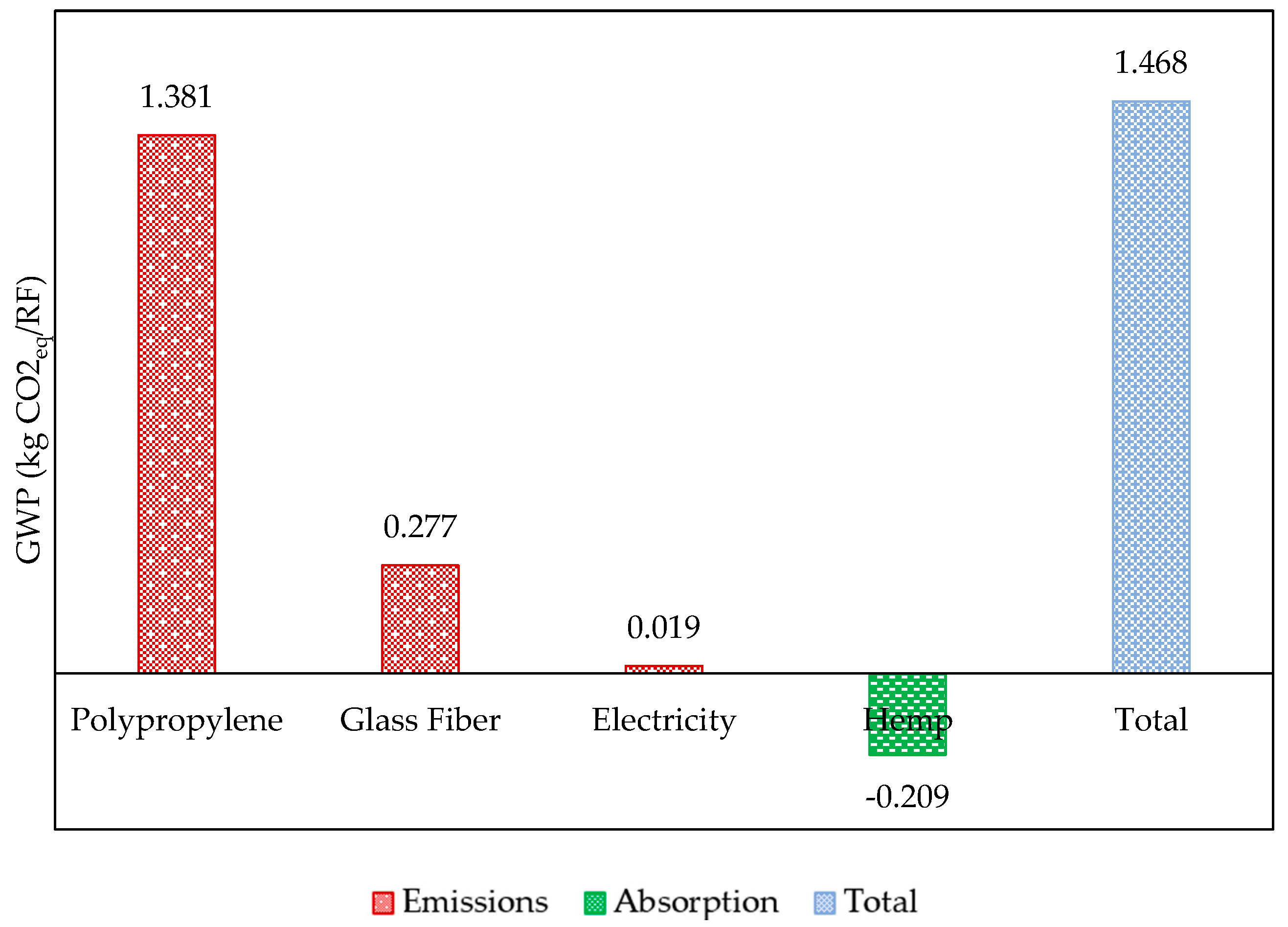

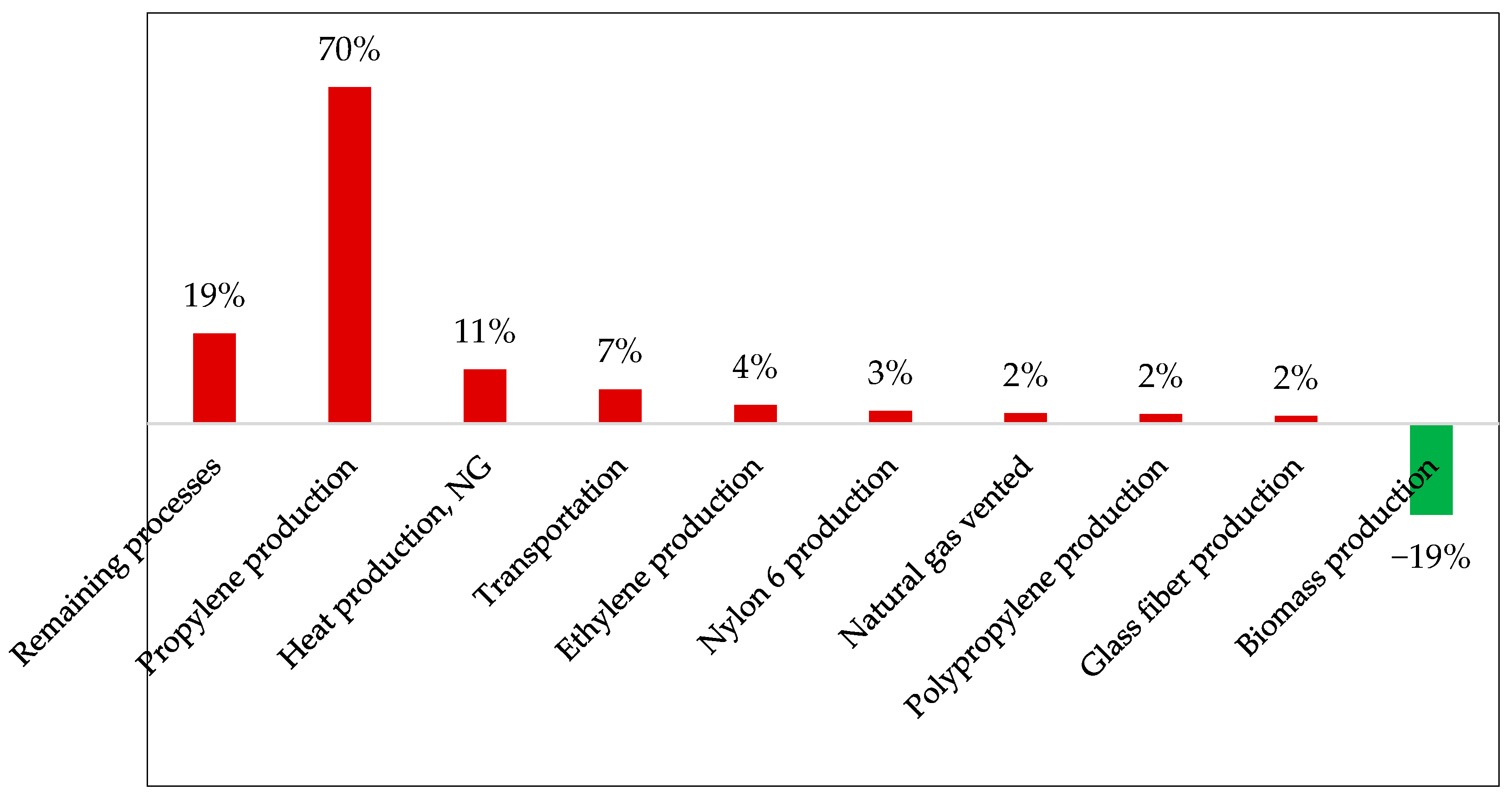

3.3. Comparison of Environmental Performance Between Conventional and Alternative Composites

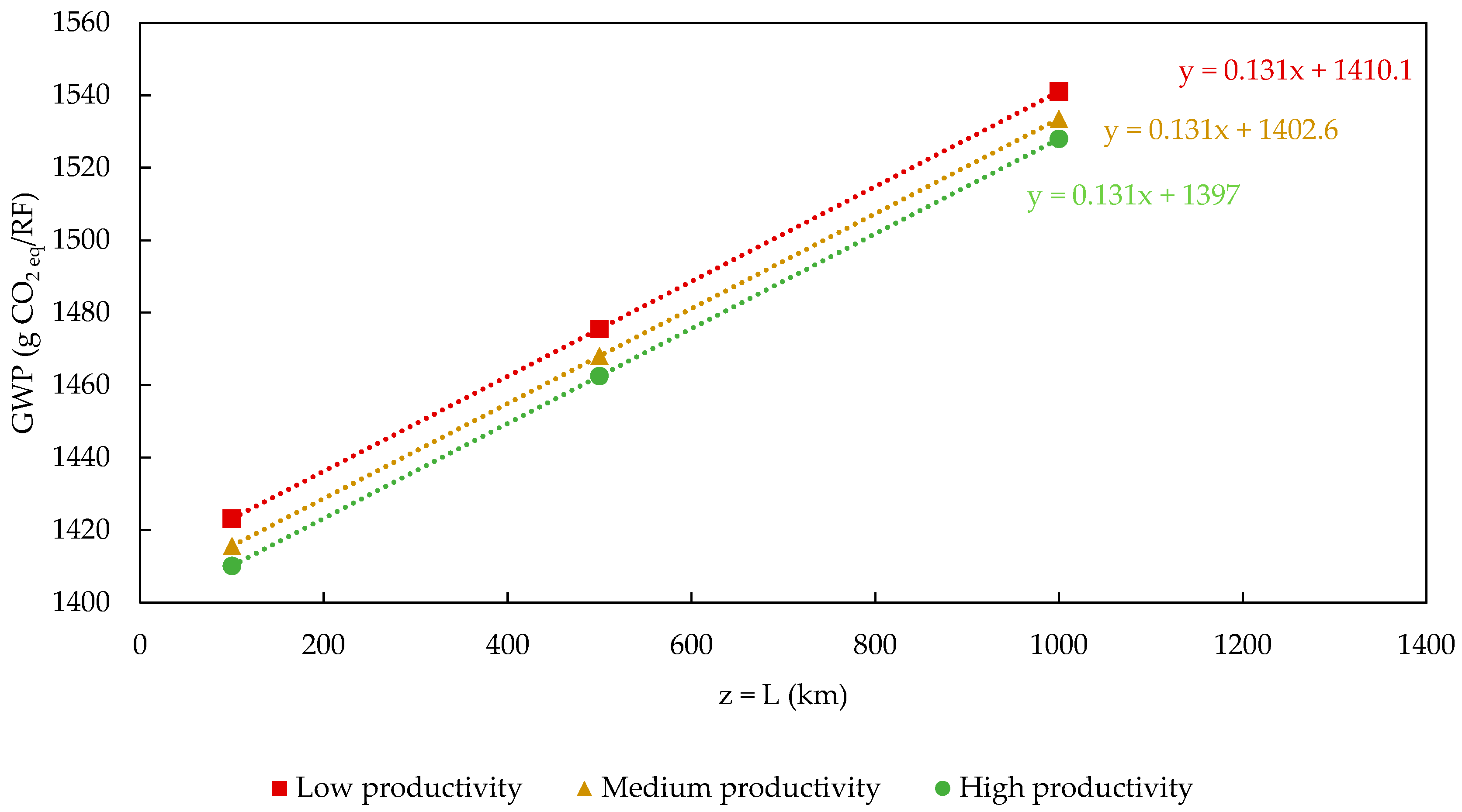

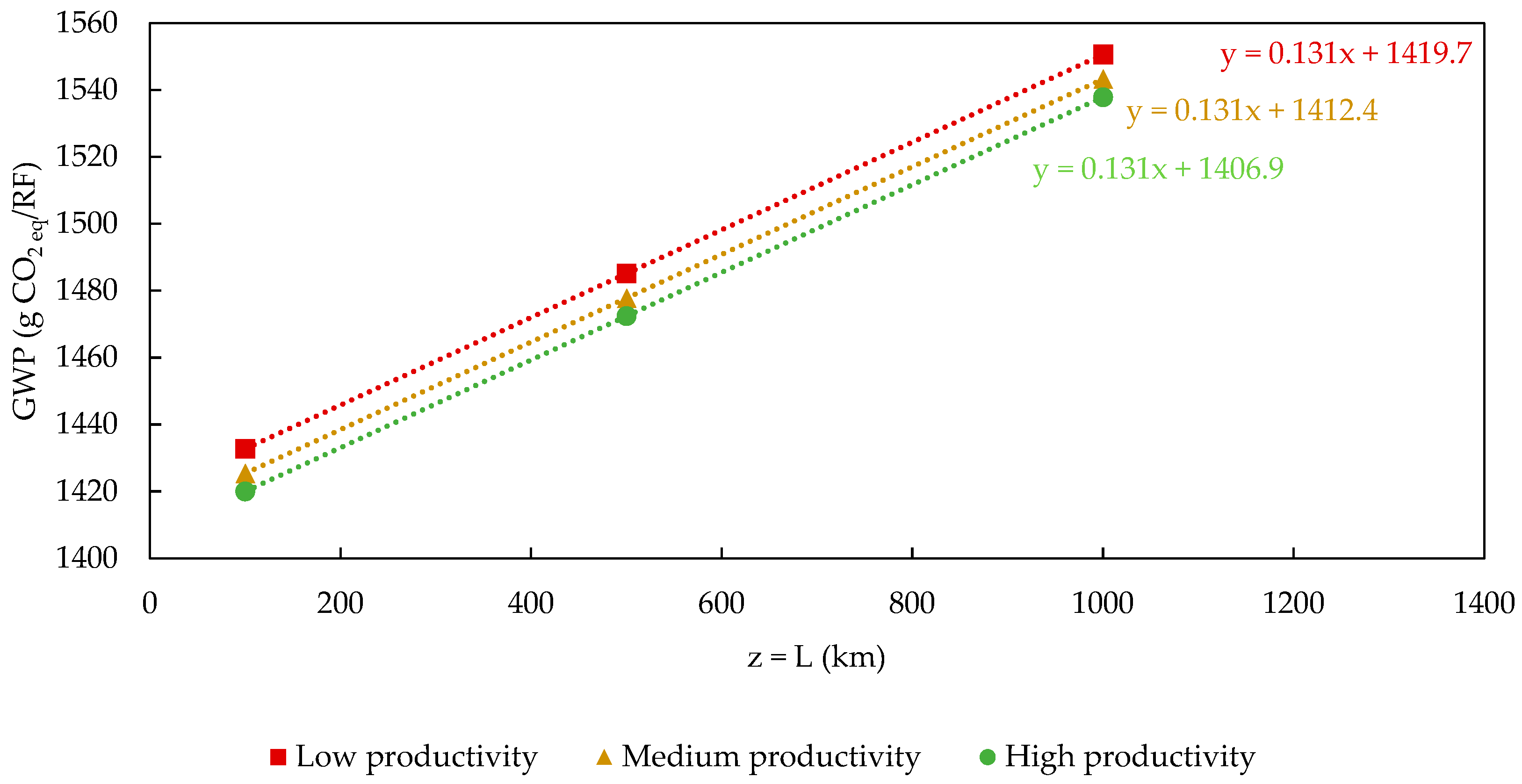

3.4. Findings of Sensitivity Analysis

4. Recommendations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GWP | Global Warming Potential |

| GF | Glass fiber |

| PP | Polypropylene |

| LCA | Life Cycle Assessment |

| DfE | Design for Environment |

| MAP | Monoammonium phosphate |

| MCC | Mass contribution criterion |

| CMC | Cumulative mass contribution |

| CEC | Cumulative energy contribution |

| ON | Ontario, Canada |

| RF | Reference flow |

| OLR | Open-loop recycling |

| IPCC | Intergovernmental Panel on Climate Change |

| NG | Natural gas |

References

- OECD. Global Plastics Outlook; OECD: Paris, France, 2022. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, Use, and Fate of All Plastics Ever Made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- MacLeod, M.; Arp, H.P.H.; Tekman, M.B.; Jahnke, A. The global threat from plastic pollution. Science 2021, 373, 61–65. [Google Scholar] [CrossRef] [PubMed]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Shalwan, A.; Yousif, B.F. In state of art: Mechanical and tribological behaviour of polymeric composites based on natural fibres. Mater. Des. 2013, 48, 14–24. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Ben Hamou, K.; Kaddami, H.; Elisabete, F.; Erchiqui, F. Synergistic association of wood /hemp fibers reinforcements on mechanical, physical and thermal properties of polypropylene-based hybrid composites. Ind. Crops Prod. 2023, 192, 116052. [Google Scholar] [CrossRef]

- Wagh, J.; Madgule, M.; Awadhani, L.V. Investigative studies on the mechanical behavior of Jute, Sisal, Hemp, and glass fiber-based composite material. Mater. Today Proc. 2023, 77, 969–976. [Google Scholar] [CrossRef]

- Aubin, M.; Seguin, P.; Vanasse, A.; Tremblay, G.F.; Mustafa, A.F.; Charron, J. Industrial Hemp Response to Nitrogen, Phosphorus, and Potassium Fertilization. Crop Forage Turfgrass Manag. 2015, 1, 1–10. [Google Scholar] [CrossRef]

- Moscariello, C.; Matassa, S.; Esposito, G.; Papirio, S. From residue to resource: The multifaceted environmental and bioeconomy potential of industrial hemp (Cannabis sativa L.). Resour. Conserv. Recycl. 2021, 175, 105864. [Google Scholar] [CrossRef]

- Harvest New York. Industrial HEMP from Seed to Market. 2017. Available online: https://bpb-us-e1.wpmucdn.com/blogs.cornell.edu/dist/a/7491/files/2019/10/Industrial-Hemp_from-seed-to-market_FINALv2.pdf (accessed on 16 July 2025).

- Lanzoni, D.; Skrivanova, E.; Pinotti, L.; Rebucci, R.; Baldi, A.; Giromini, C. Review: Nutritional aspects of hemp-based products and their effects on health and performance of monogastric animals. Animal 2024, 18, 101058. [Google Scholar] [CrossRef]

- Steinmetz, F.P.; Nahler, G.; Wakefield, J.C. How safe are hemp-based food products? A review and risk assessment of analytical data from Germany. Nutr. Food Sci. 2023, 53, 489–499. [Google Scholar] [CrossRef]

- Ramesh, M.; Bhoopathi, R. Chapter 10—Hemp fibers, their composites and applications. In Plant Fibers, Their Composites, and Applications; Mavinkere Rangappa, S., Parameswaranpillai, J., Siengchin, S., Ozbakkaloglu, T., Wang, H., Eds.; Woodhead: Cambridge, MA, USA, 2022; pp. 233–252. Available online: https://www.sciencedirect.com/science/article/pii/B9780128245286000138 (accessed on 16 July 2025).

- Shen, Z.; Tiruta-Barna, L.; Hamelin, L. From hemp grown on carbon-vulnerable lands to long-lasting bio-based products: Uncovering trade-offs between overall environmental impacts, sequestration in soil, and dynamic influences on global temperature. Sci. Total Environ. 2022, 846, 157331. [Google Scholar] [CrossRef]

- Akampumuza, O.; Wambua, P.M.; Ahmed, A.; Li, W.; Qin, X.H. Review of the applications of biocomposites in the automotive industry. Polym. Compos. 2017, 38, 2553–2569. [Google Scholar] [CrossRef]

- Katsourinis, D.; Giannopoulos, D.; Founti, M. Fischer–Tropsch Biofuel Production from Supercritical Water Gasification of Lignocellulosic Biomass: Process Modelling and Life-Cycle Assessment. Processes 2025, 13, 895. [Google Scholar] [CrossRef]

- Miranda, D.d.S.; Martins, L.P.; Teles, B.A.d.S.; Cunha, I.L.C.; Menezes, N.d.A.; Sakamoto, H.; Kulay, L. Alternative Integrated Ethanol, Urea, and Acetic Acid Processing Routes Employing CCU: A Prospective Study through a Life Cycle Perspective. Sustainability 2023, 15, 15937. [Google Scholar] [CrossRef]

- Paes, M.X.; Mancini, S.D.; De Medeiros, G.A.; Bortoleto, A.P.; Kulay, L.A. Life cycle assessment as a diagnostic and planning tool for waste management-a case study in a Brazilian municipality. J. Solid Waste Technol. Manag. 2018, 44, 259–269. [Google Scholar] [CrossRef]

- Zarafshani, H.; Watjanatepin, P.; Lepelaar, M.; Verbruggen, J.; Ouagne, P.; De Luca, R.; Li, Q.; Scarpa, F.; Placet, V.; Van Acker, K. Environmental assessment of woven hemp fibre reinforced epoxy composites and potential applications in aerospace and electric scooter industries. Results Mater. 2023, 1, 20. [Google Scholar]

- Recupido, F.; Lama, G.C.; Ammendola, M.; Bossa, F.D.L.; Minigher, A.; Campaner, P.; Morena, A.G.; Tzanov, T.; Ornelas, M.; Barros, A.; et al. Rigid composite bio-based polyurethane foams: From synthesis to LCA analysis. Polymer 2023, 13, 267. [Google Scholar] [CrossRef]

- Iucolano, F.; Boccarusso, L.; Langella, A. Hemp as eco-friendly substitute of glass fibres for gypsum reinforcement: Impact and flexural behaviour. Compos. B Eng. 2019, 15, 175. [Google Scholar] [CrossRef]

- La Rosa, A.D.; Cozzo, G.; Latteri, A.; Recca, A.; Björklund, A.; Parrinello, E.; Cicala, G. Life cycle assessment of a novel hybrid glass-hemp/thermoset composite. J. Clean Prod. 2013, 44, 69–76. [Google Scholar] [CrossRef]

- Heidari, M.D.; Lawrence, M.; Blanchet, P.; Amor, B. Regionalised life cycle assessment of bio-based materials in construction; the case of hemp shiv treated with sol-gel coatings. Materials 2019, 12, 2987. [Google Scholar] [CrossRef]

- Ganesarajan, D.; Simon, L.; Tamrakar, S.; Kiziltas, A.; Mielewski, D.; Behabtu, N.; Lenges, C. Hybrid composites with engineered polysaccharides for automotive lightweight. Compos. Part C Open Access 2022, 7, 100222. [Google Scholar] [CrossRef]

- Hemp Fiber Manufacturing and Use in Polymer Composites. PCT/US2025/30511, 23 May 2025.

- Scrucca, F.; Ingrao, C.; Maalouf, C.; Moussa, T.; Polidori, G.; Messineo, A.; Arcidiacono, C.; Asdrubali, F. Energy and carbon footprint assessment of production of hemp hurds for application in buildings. Environ. Impact Assess Rev. 2020, 84, 106417. [Google Scholar] [CrossRef]

- Pretot, S.; Collet, F.; Garnier, C. Life cycle assessment of a hemp concrete wall: Impact of thickness and coating. Build Environ. 2014, 72, 223–231. [Google Scholar] [CrossRef]

- Ip, K.; Miller, A. Life cycle greenhouse gas emissions of hemp–lime wall constructions in the UK. Resour. Conserv. Recycl. 2012, 69, 1–9. [Google Scholar] [CrossRef]

- Zampori, L.; Dotelli, G.; Vernelli, V. Life Cycle Assessment of Hemp Cultivation and Use of Hemp-Based Thermal Insulator Materials in Buildings. Environ. Sci. Technol. 2013, 47, 7413–7420. [Google Scholar] [CrossRef] [PubMed]

- Sinka, M.; Van den Heede, P.; De Belie, N.; Bajare, D.; Sahmenko, G.; Korjakins, A. Comparative life cycle assessment of magnesium binders as an alternative for hemp concrete. Resour. Conserv. Recycl. 2018, 133, 288–299. [Google Scholar] [CrossRef]

- Arrigoni, A.; Pelosato, R.; Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Life cycle assessment of natural building materials: The role of carbonation, mixture components and transport in the environmental impacts of hempcrete blocks. J. Clean. Prod. 2017, 149, 1051–1061. [Google Scholar] [CrossRef]

- Boutin, M.P.; Flamin, C.; Quinton, S.; Gosse, G.; Inra, L. Etude des Caractéristiques Environnementales du Chanvre par l’Analyse de Son Cycle de Vie; Ministere de l′Agricolture et de la Peche Paris: Paris, France, 2006.

- ISO 14040; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2006.

- Canada Energy Regulator. Provincial and Territorial Energy Profiles—Ontario 2024. Available online: https://www.cer-rec.gc.ca/en/data-analysis/energy-markets/provincial-territorial-energy-profiles/provincial-territorial-energy-profiles-ontario.html#:~:text=Ontario’s%20motor%20gasoline%20demand%20in,of%20855%20litres%20per%20capita (accessed on 11 July 2025).

- Curran, M.A. (Ed.) Goal and Scope Definition in Life Cycle Assessment; Springer: Dordrecht, The Netherlands, 2017. [Google Scholar]

- Curran, M.A. (Ed.) Interpretation, Critical Review and Reporting in Life Cycle Assessment; Springer International Publishing: Cham, Switzerland, 2023. [Google Scholar]

- Forster, P.; Storelvm, T.; Armour, K.; Collins, W.; Dufresne, J.-L.; Frame, D.; Lunt, D.J.; Mauritsen, T.; Palmer, M.D.; Watanabe, M.; et al. The Earth’s Energy Budget, Climate Feedbacks, and Climate Sensitivity. In Climate Change 2021: The Physical Science Basis. Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Masson-Delmotte, V., Zhai, P., Pirani, A., Connors, S.L., Péan, C., Berger, S., Caud, N., Chen, Y., Goldfarb, L., Gomis, M.I., et al., Eds.; Cambridge University Press: Cambridge, UK, 2021. [Google Scholar]

- Liu, W.; Zhang, Z.; Xie, X.; Yu, Z.; von Gadow, K.; Xu, J.; Zhao, S.; Yang, Y. Analysis of the Global Warming Potential of Biogenic CO2 Emission in Life Cycle Assessments. Sci. Rep. 2017, 7, 39857. [Google Scholar] [CrossRef]

- Tao, Z.; Jain, A.K. Modeling of global biogenic emissions for key indirect greenhouse gases and their response to atmospheric CO2 increases and changes in land cover and climate. J. Geophys. Res. Atmos. 2005, 16, 110. [Google Scholar] [CrossRef]

- Seile, A.; Spurina, E.; Sinka, M. Reducing Global Warming Potential Impact of Bio-Based Composites Based of LCA. Fibers 2022, 10, 79. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Kumar, L.R.; Sanjay, M.; Siengchin, S. Life-cycle and environmental impact assessments on processing of plant fibres and its bio-composites: A Crit review. J. Ind. Text. 2022, 51, 5518S–5542S. [Google Scholar] [CrossRef]

- Le Duigou, A.; Baley, C. Coupled micromechanical analysis and life cycle assessment as an integrated tool for natural fibre composites development. J. Clean. Prod. 2014, 83, 61–69. [Google Scholar] [CrossRef]

- Amghizar, I.; Vandewalle, L.A.; Van Geem, K.M.; Marin, G.B. New Trends in Olefin Production. Engineering 2017, 3, 171–178. [Google Scholar] [CrossRef]

- Zimmermann, H.; Walzl, R. Ethylene. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co: Weinheim, Germany, 2009. [Google Scholar]

- Akbarian-Saravi, N.; Sowlati, T.; Ahmad, H.; Hewage, K.; Sadiq, R.; Milani, A.S. Life cycle assessment of hemp-based biocomposites production for agricultural emission mitigation strategies: A case study. In Biocomposites and the Circular Economy; Elsevier: Amsterdam, The Netherlands, 2025; pp. 261–285. [Google Scholar]

| Reference | Reference CO2 Uptake Rate (kg CO2 /kg Biomass) |

|---|---|

| [27] | 1.29 |

| [28] | 1.47 |

| [29] | 1.53 |

| [30] | 1.73 |

| [31] | 1.84 |

| [32] | 1.85 |

| [33] | 2.10 |

| Average value | 1.69 |

| Operation | Electrical Power (kW) |

|---|---|

| Cutting | 0.80–4.00 |

| Classification | 0.75–5.00 |

| Milling | 15.0–50.0 |

| Fine collection | 10.0–18.0 |

| Pelletization | 9.00–16.0 |

| Cooling | 0.50–3.50 |

| Belt conveying | 5.00–12.0 |

| Sample | Relative Composition (% *) | Tensile Modulus (MPa—23 °C) | Flexural Modulus (MPa—23 °C) | Impact Notched (kJ/m2—23 °C) | Density (g/cm3) |

|---|---|---|---|---|---|

| 30GF–PP (regular) | 30% GF + 70% PP | 4000 ± 514 | 4000 ± 232 | 6.00 ± 0.15 | 1.21 ± 0.23 |

| 15H–15GF–PP (alternative) | 15% hemp + 15% + GF + 70% PP | 4648 ± 159 | 4364 ± 208 | 5.10 ± 0.59 | 1.05 ± 0.42 |

| Parameter | Hemp Productivity | Addition of Binder | Distance Between Plants (PP—Composite) |

|---|---|---|---|

| Code/Unit | (kg/ha) | – | (km) |

| 2471 | – | 100 | |

| 3707 | No | 500 | |

| 4942 | Yes | 1000 |

| = 0 | ||||

|---|---|---|---|---|

| Parameters/Codes | ||||

| Spacing between plants: | 1.423 | 1.416 | 1.410 | |

| 0 | 1.476 | 1.468 | 1.463 | |

| 1.541 | 1.534 | 1.528 | ||

| = +1 | ||||

|---|---|---|---|---|

| Parameters/Codes | ||||

| Spacing between plants: | 1.433 | 1.425 | 1.420 | |

| 0 | 1.485 | 1.478 | 1.472 | |

| 1.551 | 1.543 | 1.538 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miranda, D.d.S.; Casetta, D.A.; Simon, L.C.; Kulay, L. Assessment of the Environmental Feasibility of Utilizing Hemp Fibers in Composite Production. Polymers 2025, 17, 2103. https://doi.org/10.3390/polym17152103

Miranda DdS, Casetta DA, Simon LC, Kulay L. Assessment of the Environmental Feasibility of Utilizing Hemp Fibers in Composite Production. Polymers. 2025; 17(15):2103. https://doi.org/10.3390/polym17152103

Chicago/Turabian StyleMiranda, Denis da Silva, Douglas Alexandre Casetta, Leonardo Coelho Simon, and Luiz Kulay. 2025. "Assessment of the Environmental Feasibility of Utilizing Hemp Fibers in Composite Production" Polymers 17, no. 15: 2103. https://doi.org/10.3390/polym17152103

APA StyleMiranda, D. d. S., Casetta, D. A., Simon, L. C., & Kulay, L. (2025). Assessment of the Environmental Feasibility of Utilizing Hemp Fibers in Composite Production. Polymers, 17(15), 2103. https://doi.org/10.3390/polym17152103