Polymer Blends of Polyetherimide and Poly(ether ester urethane): Controlling Dielectric Properties for Ultrahigh Energy Storage

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Characterization

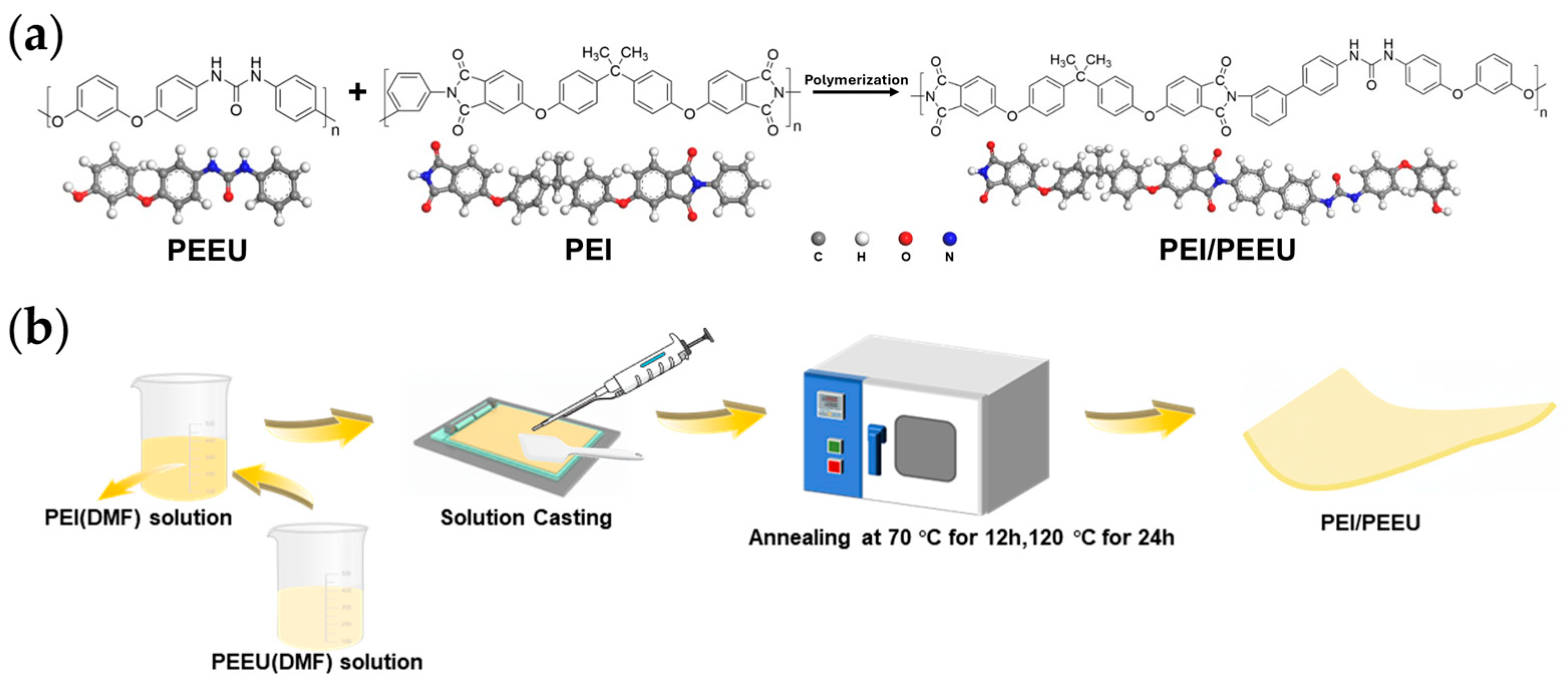

2.2. Preparation of Polymer Films

3. Results and Discussion

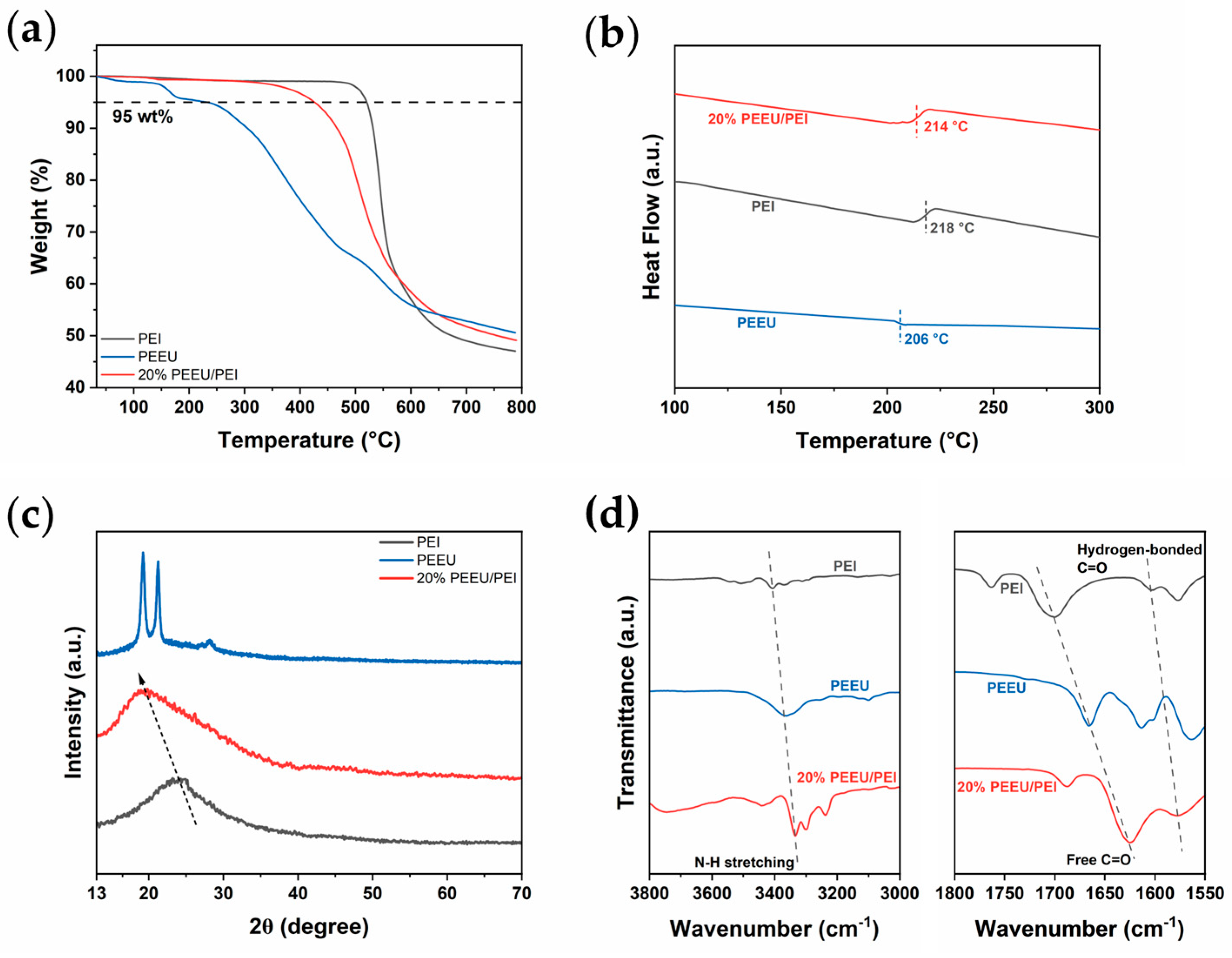

3.1. Structure Characterization

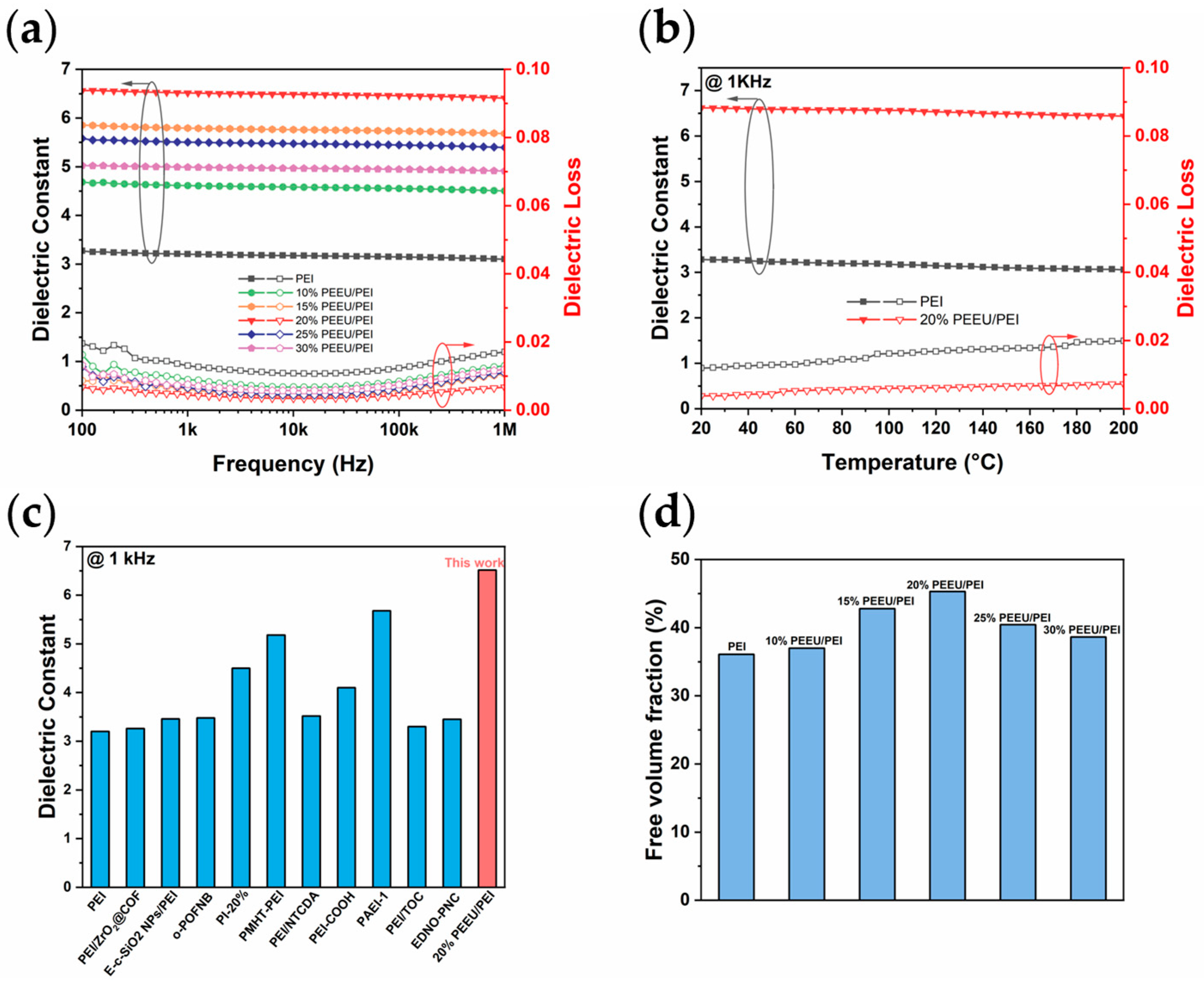

3.2. Dielectric Properties

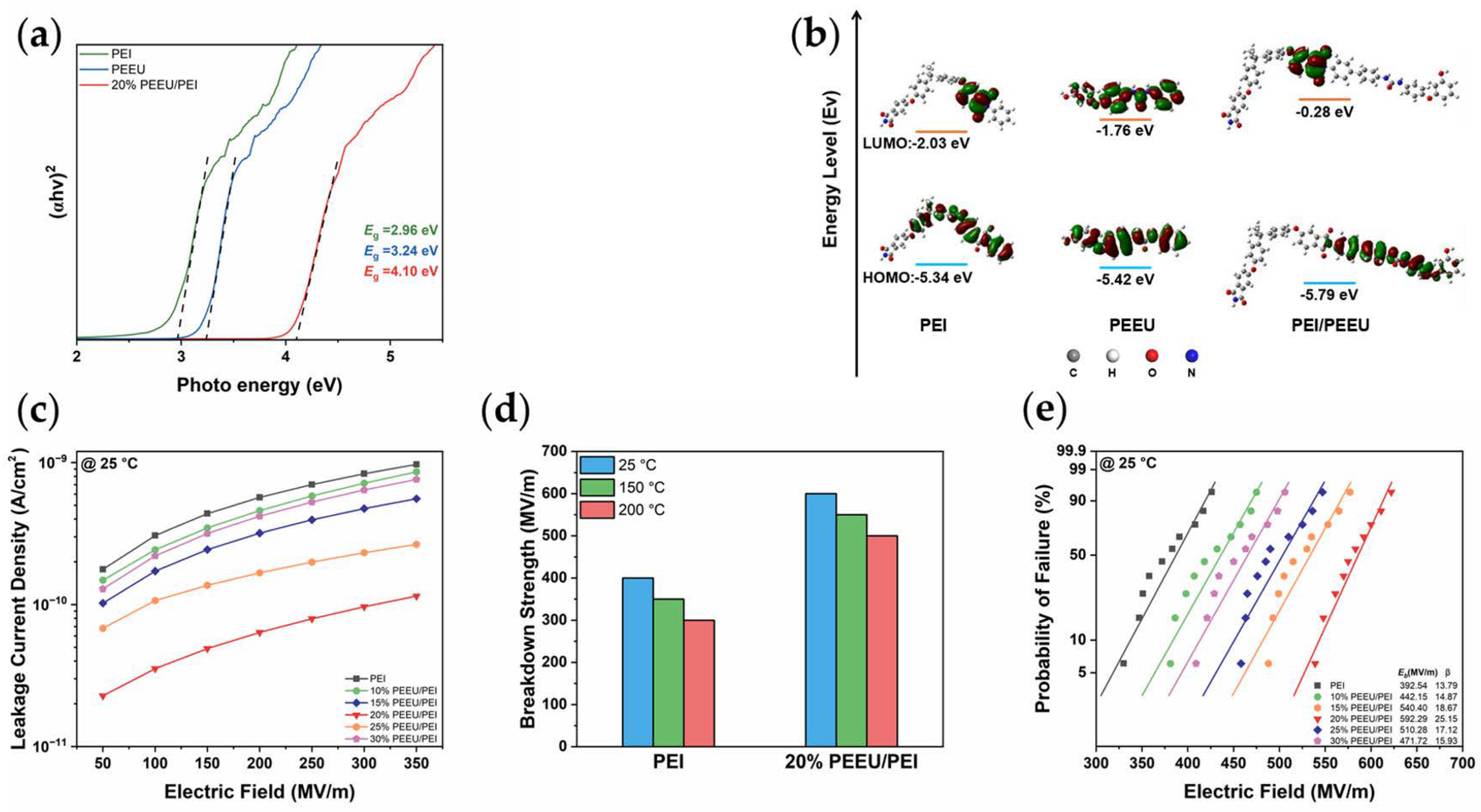

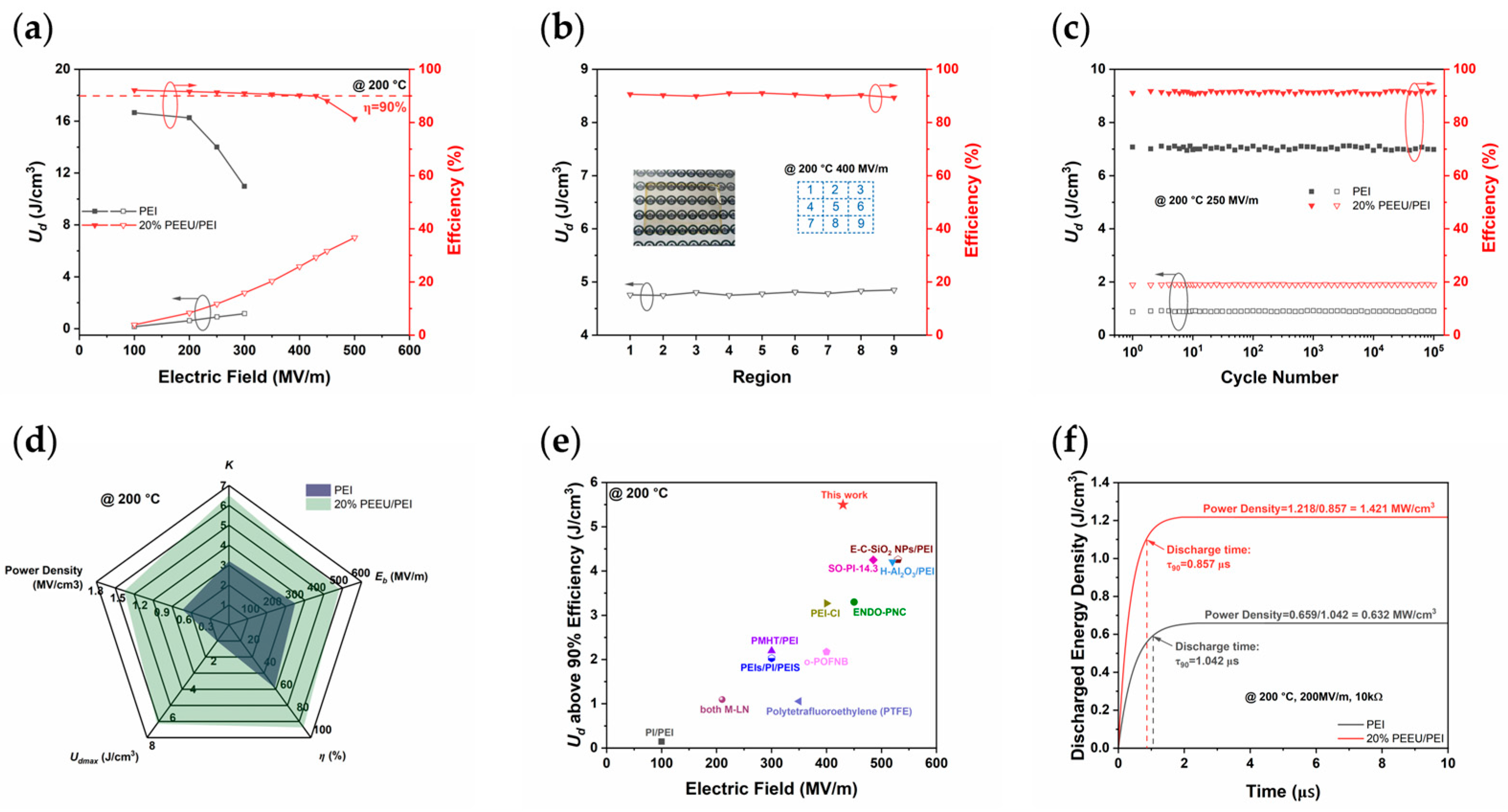

3.3. High-Temperature Energy Storage Capabilities

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Chen, L.; Gadinski, M.R.; Zhang, S.; Zhang, G.; Li, U.; Iagodkine, E.; Haque, A.; Chen, L.Q.; Jackson, N.; et al. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 2015, 523, 576–579. [Google Scholar] [CrossRef] [PubMed]

- Chu, B.; Zhou, X.; Ren, K.; Neese, B.; Lin, M.; Wang, Q.; Bauer, F.; Zhang, Q.M. A dielectric polymer with high electric energy density and fast discharge speed. Science 2006, 313, 334–336. [Google Scholar] [CrossRef]

- Kursumovic, A.; Li, W.-W.; Cho, S.; Curran, P.; Tjhe, D.; MacManus-Driscoll, J. Lead-free relaxor thin films with huge energy density and low loss for high temperature applications. Nano Energy 2020, 71, 104536. [Google Scholar] [CrossRef]

- Qi, H.; Xie, A.; Zuo, R. Local structure engineered lead-free ferroic dielectrics for superior energy-storage capacitors: A review. Energy Storage Mater. 2022, 45, 541–567. [Google Scholar] [CrossRef]

- Su, Y.; Chen, C.; Wang, Y.; Yao, M.; Ma, R.; Zhang, W.; Yuan, Q.; Hu, D. Interface coupling and energy storage of inorganic–organic nanocomposites. J. Mater. Chem. A 2022, 10, 14187–14220. [Google Scholar] [CrossRef]

- Zhang, T.; Chen, X.; Thakur, Y.; Lu, B.; Zhang, Q.; Runt, J.; Zhang, Q.M. A highly scalable dielectric metamaterial with superior capacitor performance over a broad temperature. Sci. Adv. 2020, 6, eaax6622. [Google Scholar] [CrossRef]

- Yuan, C.; Zhou, Y.; Zhu, Y.; Liang, J.; Wang, S.; Peng, S.; Li, Y.; Cheng, S.; Yang, M.; Hu, J.; et al. Polymer/molecular semiconductor all-organic composites for high-temperature dielectric energy storage. Nat. Commun. 2020, 11, 3919. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Wang, Q. Advanced polymer dielectrics for high temperature capacitive energy storage. J. Appl. Phys. 2020, 127, 240902. [Google Scholar] [CrossRef]

- Ho, J.; Jow, R. Characterization of High Temperature Polymer Thin Films for Power Conditioning Capacitors; DTIC: Belvoir, VI, USA, 2009. [Google Scholar]

- Wang, P.; Guo, Y.; Zhou, D.; Li, D.; Pang, L.; Liu, W.; Su, J.; Shi, Z.; Sun, S. High-temperature flexible nanocomposites with ultra-high energy storage density by nanostructured MgO fillers. Adv. Funct. Mater. 2022, 32, 2204155. [Google Scholar] [CrossRef]

- Xu, W.-H.; Tang, Y.-D.; Yao, H.-Y.; Zhang, Y.-H. Dipolar glass polymers for capacitive energy storage at room temperatures and elevated temperatures. Chin. J. Polym. Sci. 2022, 40, 711–725. [Google Scholar] [CrossRef]

- Zeng, T.; Meng, L.; Li, Q.; Liu, D.; Zhou, Q.; He, J.; Li, Q.; Yuan, C. Enhancing energetic disorder in all-organic composite dielectrics for high-temperature capacitive energy storage. Nat. Commun. 2025, 16, 5620. [Google Scholar] [CrossRef] [PubMed]

- Ho, J.S.; Greenbaum, S.G. Polymer Capacitor Dielectrics for High Temperature Applications. ACS Appl. Mater. Interfaces 2018, 10, 29189–29218. [Google Scholar] [CrossRef]

- Kim, G.H.; Lee, D.; Shanker, A.; Shao, L.; Kwon, M.S.; Gidley, D.; Kim, J.; Pipe, K.P. High thermal conductivity in amorphous polymer blends by engineered interchain interactions. Nat. Mater. 2015, 14, 295–300. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Zhou, Y.; Huang, X.; Yu, C.; Han, D.; Wang, A.; Zhu, Y.; Shi, K.; Kang, Q.; Li, P.; et al. Ladderphane copolymers for high-temperature capacitive energy storage. Nature 2023, 615, 62–66. [Google Scholar] [CrossRef]

- Li, H.; Zhou, Y.; Liu, Y.; Li, L.; Liu, Y.; Wang, Q. Dielectric polymers for high-temperature capacitive energy storage. Chem. Soc. Rev. 2021, 50, 6369–6400. [Google Scholar] [CrossRef] [PubMed]

- Zha, J.-W.; Xiao, M.; Wan, B.; Wang, X.; Dang, Z.-M.; Chen, G. Polymer dielectrics for high-temperature energy storage: Constructing carrier traps. Prog. Mater. Sci. 2023, 140, 101208. [Google Scholar] [CrossRef]

- Luo, H.; Zhou, X.; Ellingford, C.; Zhang, Y.; Chen, S.; Zhou, K.; Zhang, D.; Bowen, C.R.; Wan, C. Interface design for high energy density polymer nanocomposites. Chem. Soc. Rev. 2019, 48, 4424–4465. [Google Scholar] [CrossRef]

- Li, J.; Gao, Y.; Jin, Y.; Zhang, T. Ultrahigh Energy Storage of Twisted Structures in Supramolecular Polymers. Adv. Mater. 2025, 37, e2411806. [Google Scholar] [CrossRef]

- Pan, Z.; Li, L.; Wang, L.; Luo, G.; Xu, X.; Jin, F.; Dong, J.; Niu, Y.; Sun, L.; Guo, C.; et al. Tailoring Poly(Styrene-co-maleic anhydride) Networks for All-Polymer Dielectrics Exhibiting Ultrahigh Energy Density and Charge-Discharge Efficiency at Elevated Temperatures. Adv. Mater. 2023, 35, e2207580. [Google Scholar] [CrossRef]

- Dai, Z.; Bao, Z.; Ding, S.; Liu, C.; Sun, H.; Wang, H.; Zhou, X.; Wang, Y.; Yin, Y.; Li, X. Scalable Polyimide-Poly(Amic Acid) Copolymer Based Nanocomposites for High-Temperature Capacitive Energy Storage. Adv. Mater. 2022, 34, e2101976. [Google Scholar] [CrossRef]

- Dong, J.; Li, L.; Qiu, P.; Pan, Y.; Niu, Y.; Sun, L.; Pan, Z.; Liu, Y.; Tan, L.; Xu, X.; et al. Scalable Polyimide-Organosilicate Hybrid Films for High-Temperature Capacitive Energy Storage. Adv. Mater. 2023, 35, e2211487. [Google Scholar] [CrossRef]

- Wang, F.; Wang, H.; Shi, X.; Diao, C.; Li, C.; Li, W.; Liu, X.; Zheng, H.; Huang, H.; Li, X. Polyimide composites crosslinked by aromatic molecules for high-temperature capacitive energy storage. Chem. Eng. J. 2024, 485, 149972. [Google Scholar] [CrossRef]

- Wang, R.; Zhu, Y.; Fu, J.; Yang, M.; Ran, Z.; Li, J.; Li, M.; Hu, J.; He, J.; Li, Q. Designing tailored combinations of structural units in polymer dielectrics for high-temperature capacitive energy storage. Nat. Commun. 2023, 14, 2406. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, S.; Zhao, J. Simultaneously improving the optical, dielectric, and solubility properties of fluorene-based polyimide with silyl ether side groups. ACS Omega 2022, 7, 11939–11945. [Google Scholar] [CrossRef]

- Alamri, A.; Wu, C.; Mishra, A.; Chen, L.; Li, Z.; Deshmukh, A.; Zhou, J.; Yassin, O.; Ramprasad, R.; Vashishta, P.; et al. Improving the Rotational Freedom of Polyetherimide: Enhancement of the Dielectric Properties of a Commodity High-Temperature Polymer Using a Structural Defect. Chem. Mater. 2022, 34, 6553–6558. [Google Scholar] [CrossRef]

- Yue, D.; Yin, J.H.; Zhang, W.C.; Cheng, X.X.; Zhang, M.H.; Wang, J.J.; Feng, Y. Computational simulation for breakdown and energy storage performances with optimization in polymer dielectrics. Adv. Funct. Mater. 2023, 33, 2300658. [Google Scholar] [CrossRef]

- Chen, H.; Pan, Z.; Wang, W.; Chen, Y.; Xing, S.; Cheng, Y.; Ding, X.; Liu, J.; Zhai, J.; Yu, J. Ultrahigh discharge efficiency and improved energy density in polymer-based nanocomposite for high-temperature capacitors application. Compos. Part A Appl. Sci. Manuf. 2021, 142, 106266. [Google Scholar] [CrossRef]

- Kumar, S.; Supriya, S.; Kar, M. Enhancement of dielectric constant in polymer-ceramic nanocomposite for flexible electronics and energy storage applications. Compos. Sci. Technol. 2018, 157, 48–56. [Google Scholar] [CrossRef]

- Cheng, Z.; Lin, M.; Wu, S.; Thakur, Y.; Zhou, Y.; Jeong, D.-Y.; Shen, Q.; Zhang, Q. Aromatic poly (arylene ether urea) with high dipole moment for high thermal stability and high energy density capacitors. Appl. Phys. Lett. 2015, 106, 20. [Google Scholar] [CrossRef]

- Meijer, H.E.; Govaert, L.E. Mechanical performance of polymer systems: The relation between structure and properties. Prog. Polym. Sci. 2005, 30, 915–938. [Google Scholar] [CrossRef]

- Androulaki, K.; Chrissopoulou, K.; Prevosto, D.; Labardi, M.; Anastasiadis, S.H. Dynamics of hyperbranched polymers under confinement: A dielectric relaxation study. ACS Appl. Mater. Interfaces 2015, 7, 12387–12398. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhu, Y.; Xu, W.; Wang, Q. Molecular trap engineering enables superior high-temperature capacitive energy storage performance in all-organic composite at 200 °C. Adv. Energy Mater. 2023, 13, 2203961. [Google Scholar] [CrossRef]

- Zhou, F.; Tian, C.; Huang, L.; Jiang, Y.; Zhao, F.; Yang, N.; Yuan, D.; Cai, X.-f. Tailoring Dielectric Performance via Dipole Density and Hydrogen Bonding Interaction Towards High-Temperature Capacitive Energy Storage Polymer. J. Mater. Chem. A 2025, 13, 24868–24879. [Google Scholar] [CrossRef]

- Kuo, S.-W. Hydrogen-bonding in polymer blends. J. Polym. Res. 2008, 15, 459–486. [Google Scholar] [CrossRef]

- Xie, Z.; Le, K.; Li, H.; Pang, X.; Xu, T.; Altoé, V.; Klivansky, L.M.; Wang, Y.; Huang, Z.; Shelton, S.W. Interfacial engineering using covalent organic frameworks in polymer composites for high-temperature electrostatic energy storage. Adv. Funct. Mater. 2024, 34, 2314910. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, Y.; Yang, M.; Yan, H.; Xu, C.; Tian, B.; Zhang, C.; Xie, Q.; Dang, Z.M. Surface Strengthening of Polymer Composite Dielectrics for Superior High-Temperature Capacitive Energy Storage. Adv. Energy Mater. 2025, 15, 2405411. [Google Scholar] [CrossRef]

- Deshmukh, A.A.; Wu, C.; Yassin, O.; Mishra, A.; Chen, L.; Alamri, A.; Li, Z.; Zhou, J.; Mutlu, Z.; Sotzing, M. Flexible polyolefin dielectric by strategic design of organic modules for harsh condition electrification. Energy Environ. Sci. 2022, 15, 1307–1314. [Google Scholar] [CrossRef]

- Li, T.; Liu, J.; Yu, S.; Zhang, X.; Chen, Z. Polyimide Modified with Different Types and Contents of Polar/Nonpolar Groups: Synthesis, Structure, and Dielectric Properties. Polymers 2025, 17, 753. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Wan, Y.; Long, H.; Luo, H.; Liu, X.; Luo, H.; Chen, S. Improved capacitive energy storage at high temperature via constructing physical cross-link and electron–hole pairs based on p-type semiconductive polymer filler. Adv. Funct. Mater. 2024, 34, 2312238. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, X.m.; Pan, Z.; Liu, P.; Mao, M.; Song, K.; Mao, Z.; Sun, R.; Wang, D.; Zhang, S. Superior high-temperature energy density in molecular semiconductor/polymer all-organic composites. Adv. Funct. Mater. 2023, 33, 2210050. [Google Scholar] [CrossRef]

- Li, X.; Weng, L.; Wang, X.; Li, Z.; Li, Y.; Zhang, X.; Guan, L.; Wu, Z. 200 °C-Stable Dielectric Polymer Enabled by Molecular-Scale Carrier Trapping: Synergy of Steric Hindrance and Deep Energy Level Engineering. Adv. Funct. Mater. 2025, e12257. [Google Scholar] [CrossRef]

- Hou, S.; Liu, Y.; Hao, Y.; Zhu, W.; Xu, Y.; Gao, J.; Lou, X.; Zhong, L. Side group induced steric hindrance effect in polyetherimide derived polymers for high-temperature capacitive energy storage performance. Chem. Eng. J. 2025, 519, 165324. [Google Scholar] [CrossRef]

- Zhao, S.; Peng, W.; Zhou, L.; Dai, S.; Ren, W.; Xu, E.; Xiao, Y.; Zhang, M.; Huang, M.; Shen, Y. Metal-organic cage crosslinked nanocomposites with enhanced high-temperature capacitive energy storage performance. Nat. Commun. 2025, 16, 769. [Google Scholar] [CrossRef] [PubMed]

- Qin, H.; Liu, M.; Qin, S.; Zhang, S.; Zhou, X.; Li, C.; Wei, Y.; Chen, D.; Fan, R.; Wang, S. Stereoisomerically enhanced polynorbornene-imide dielectric energy storage performance. Chem. Eng. J. 2024, 483, 149244. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, X.; Zhang, T.; Zhang, Q. Giant permittivity materials with low dielectric loss over a broad temperature range enabled by weakening intermolecular hydrogen bonds. Nano Energy 2019, 64, 103916. [Google Scholar] [CrossRef]

- Thakur, Y.; Zhang, B.; Dong, R.; Lu, W.; Iacob, C.; Runt, J.; Bernholc, J.; Zhang, Q. Generating high dielectric constant blends from lower dielectric constant dipolar polymers using nanostructure engineering. Nano Energy 2017, 32, 73–79. [Google Scholar] [CrossRef]

- Ran, Z.; Wang, R.; Fu, J.; Yang, M.; Li, M.; Hu, J.; He, J.; Li, Q. Spiral-structured dielectric polymers exhibiting ultrahigh energy density and charge–discharge efficiency at high temperatures. Adv. Mater. 2023, 35, 2303849. [Google Scholar] [CrossRef]

- Sarjeant, W.J.; Zirnheld, J.; MacDougall, F.; Bowers, J.; Clark, N.; Clelland, I.; Price, R.; Hudis, M.; Kohlberg, I.; McDuff, G. Capacitors—Past, present, and future. In Handbook of Low and High Dielectric Constant Materials and Their Applications; Elsevier: Amsterdam, The Netherlands, 1999; pp. 423–491. [Google Scholar]

- Huan, T.D.; Boggs, S.; Teyssedre, G.; Laurent, C.; Cakmak, M.; Kumar, S.; Ramprasad, R. Advanced polymeric dielectrics for high energy density applications. Prog. Mater. Sci. 2016, 83, 236–269. [Google Scholar] [CrossRef]

- An, L.; Boggs, S.A.; Calame, J.P. Energy storage in polymer films with high dielectric constant fillers. IEEE Electr. Insul. Mag. 2008, 24, 5–10. [Google Scholar] [CrossRef]

- Azizi, A.; Gadinski, M.R.; Li, Q.; AlSaud, M.A.; Wang, J.; Wang, Y.; Wang, B.; Liu, F.; Chen, L.Q.; Alem, N. High-performance polymers sandwiched with chemical vapor deposited hexagonal boron nitrides as scalable high-temperature dielectric materials. Adv. Mater. 2017, 29, 1701864. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, X.; Zhang, B.; Zhang, T.; Lu, W.; Chen, Z.; Liu, Z.; Kim, S.H.; Donovan, B.; Warzoha, R.J. High-temperature polymers with record-high breakdown strength enabled by rationally designed chain-packing behavior in blends. Matter 2021, 4, 2448–2459. [Google Scholar] [CrossRef]

- Meng, Z.; Zhang, T.; Zhang, C.; Dang, Z.M.; Chi, Q. Optimizing energy storage performance in polymer dielectrics through dual strategies: Constructing “peaked” barrieras and enhancing carrier scattering. Adv. Funct. Mater. 2024, 34, 2403402. [Google Scholar] [CrossRef]

- Dong, X.; Wang, Y.; Cao, Y.; Li, N.; Fu, J.; Yu, J.; Hu, Z. Enhanced high-temperature energy storage performance in all-organic dielectric films through synergistic crosslinking of chemical and physical interaction. Chem. Eng. J. 2024, 500, 157312. [Google Scholar] [CrossRef]

- Wang, F.; Cai, J.; Yang, C.; Luo, H.; Li, X.; Hou, H.; Zou, G.; Zhang, D. Improved capacitive energy storage nanocomposites at high temperature utilizing ultralow loading of bimetallic MOF. Small 2023, 19, 2300510. [Google Scholar] [CrossRef] [PubMed]

- Niu, Y.; Dong, J.; He, Y.; Xu, X.; Li, S.; Wu, K.; Wang, Q.; Wang, H. Significantly enhancing the discharge efficiency of sandwich-structured polymer dielectrics at elevated temperature by building carrier blocking interface. Nano Energy 2022, 97, 107215. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Z.; Moran, T.J.; Ortiz, L.A.; Wu, C.; Konstantinou, A.C.; Nguyen, H.; Zhou, J.; Huo, J.; Davis-Amendola, K. Interfacial 2D montmorillonite nanocoatings enable sandwiched polymer nanocomposites to exhibit ultrahigh capacitive energy storage performance at elevated temperatures. Adv. Sci. 2022, 9, 2204760. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Zhao, Y.; Wang, Z.; Yan, H.; Liu, Z.; Li, Q.; Dang, Z.-M. Surface ion-activated polymer composite dielectrics for superior high-temperature capacitive energy storage. Energy Environ. Sci. 2024, 17, 1592–1602. [Google Scholar] [CrossRef]

- Dong, J.; Li, L.; Niu, Y.; Pan, Z.; Pan, Y.; Sun, L.; Tan, L.; Liu, Y.; Xu, X.; Guo, X. Scalable high-permittivity polyimide copolymer with ultrahigh high-temperature capacitive performance enabled by molecular engineering. Adv. Energy Mater. 2024, 14, 2303732. [Google Scholar] [CrossRef]

- Boshoman, S.; Fatoba, O.; Dada, O.; Jen, T. Transition metal oxide catalytic abilities for fuel cell applications: Density functional theory (DFT) studies. Mater. Today Commun. 2024, 39, 109125. [Google Scholar] [CrossRef]

- Wu, Q.; Deng, D.; Zhou, R.; Zhang, J.; Zou, W.; Liu, L.; Wu, S.; Lu, K.; Wei, Z. Modulation of donor alkyl terminal chains with the shifting branching point leads to the optimized morphology and efficient all-small-molecule organic solar cells. ACS Appl. Mater. Interfaces 2020, 12, 25100–25107. [Google Scholar] [CrossRef]

- Kim, H.; Shi, F. Thickness dependent dielectric strength of a low-permittivity dielectric film. IEEE Trans. Dielectr. Electr. Insul. 2002, 8, 248–252. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, T.; Wang, S.; Li, J.; Zhang, T. Polymer Blends of Polyetherimide and Poly(ether ester urethane): Controlling Dielectric Properties for Ultrahigh Energy Storage. Polymers 2025, 17, 3100. https://doi.org/10.3390/polym17233100

Lu T, Wang S, Li J, Zhang T. Polymer Blends of Polyetherimide and Poly(ether ester urethane): Controlling Dielectric Properties for Ultrahigh Energy Storage. Polymers. 2025; 17(23):3100. https://doi.org/10.3390/polym17233100

Chicago/Turabian StyleLu, Tao, Shiqi Wang, Jinfeng Li, and Tian Zhang. 2025. "Polymer Blends of Polyetherimide and Poly(ether ester urethane): Controlling Dielectric Properties for Ultrahigh Energy Storage" Polymers 17, no. 23: 3100. https://doi.org/10.3390/polym17233100

APA StyleLu, T., Wang, S., Li, J., & Zhang, T. (2025). Polymer Blends of Polyetherimide and Poly(ether ester urethane): Controlling Dielectric Properties for Ultrahigh Energy Storage. Polymers, 17(23), 3100. https://doi.org/10.3390/polym17233100