Construction of PVDF/BTO Fibers with High Piezoelectricity for Self-Powered Flexible Pressure Sensing

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of BTO Fillers and PVDF/BTO Fibers

2.3. Characterizations

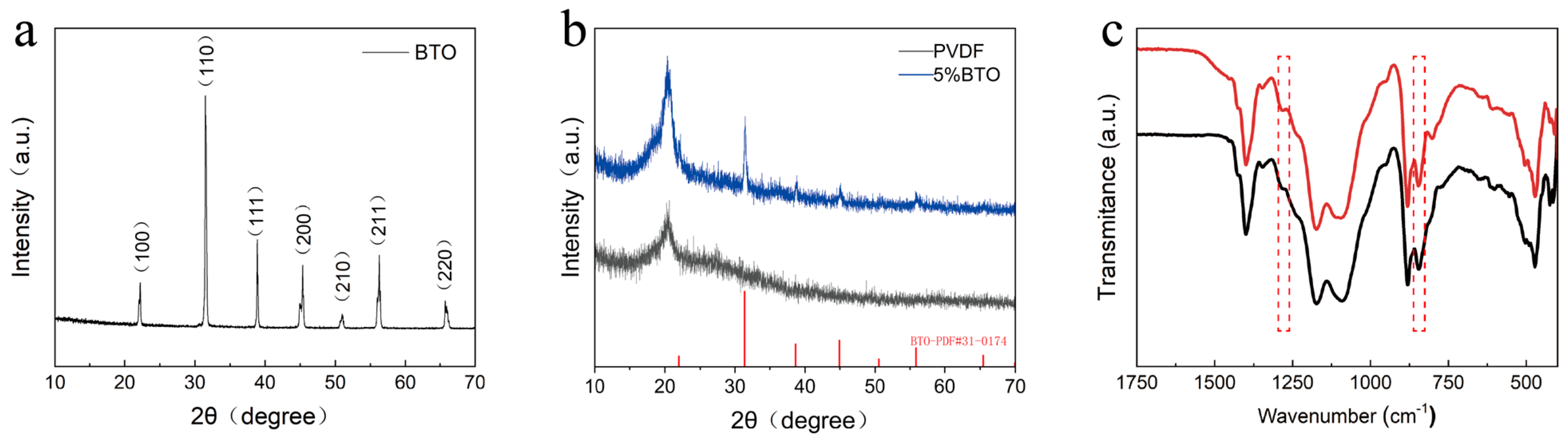

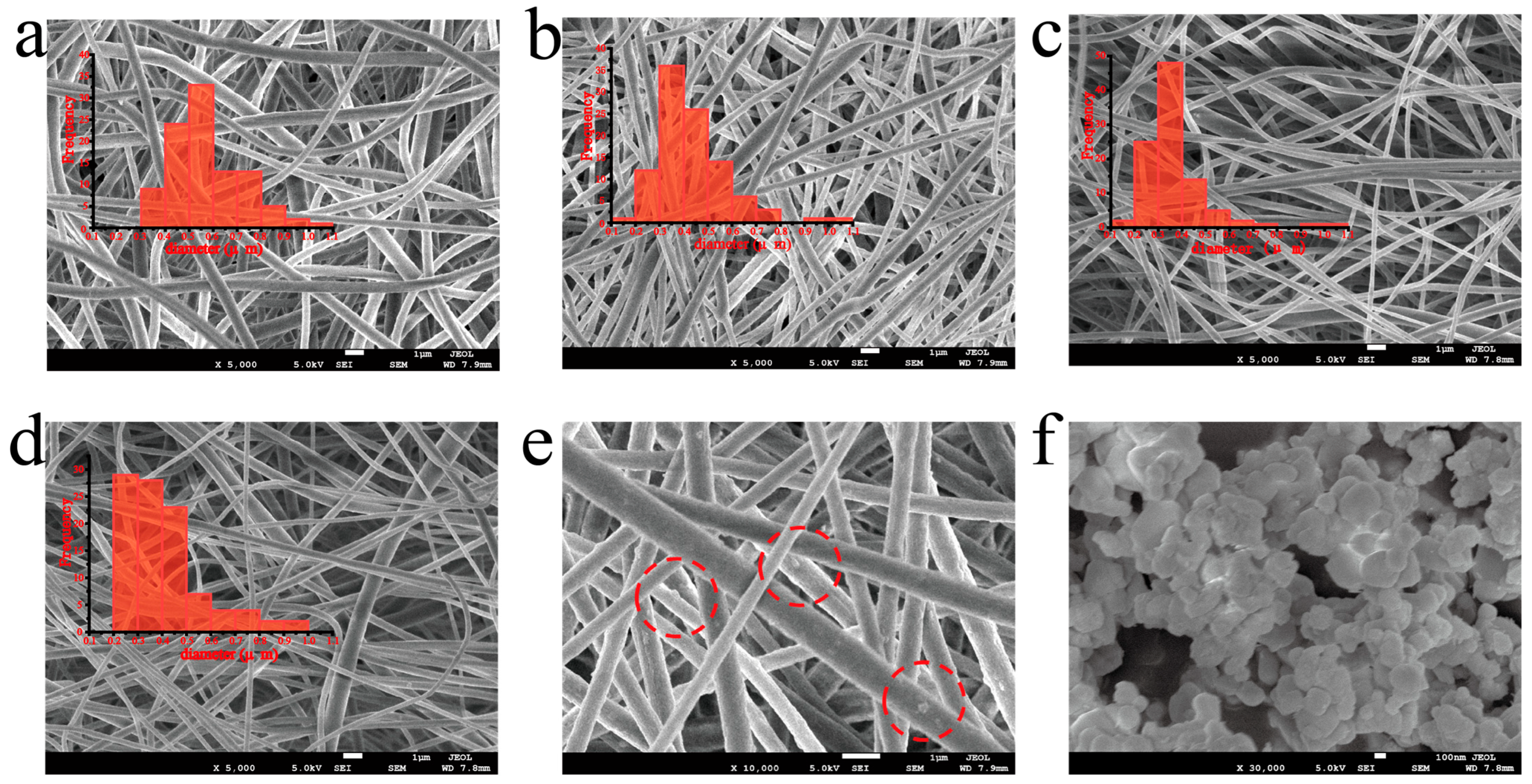

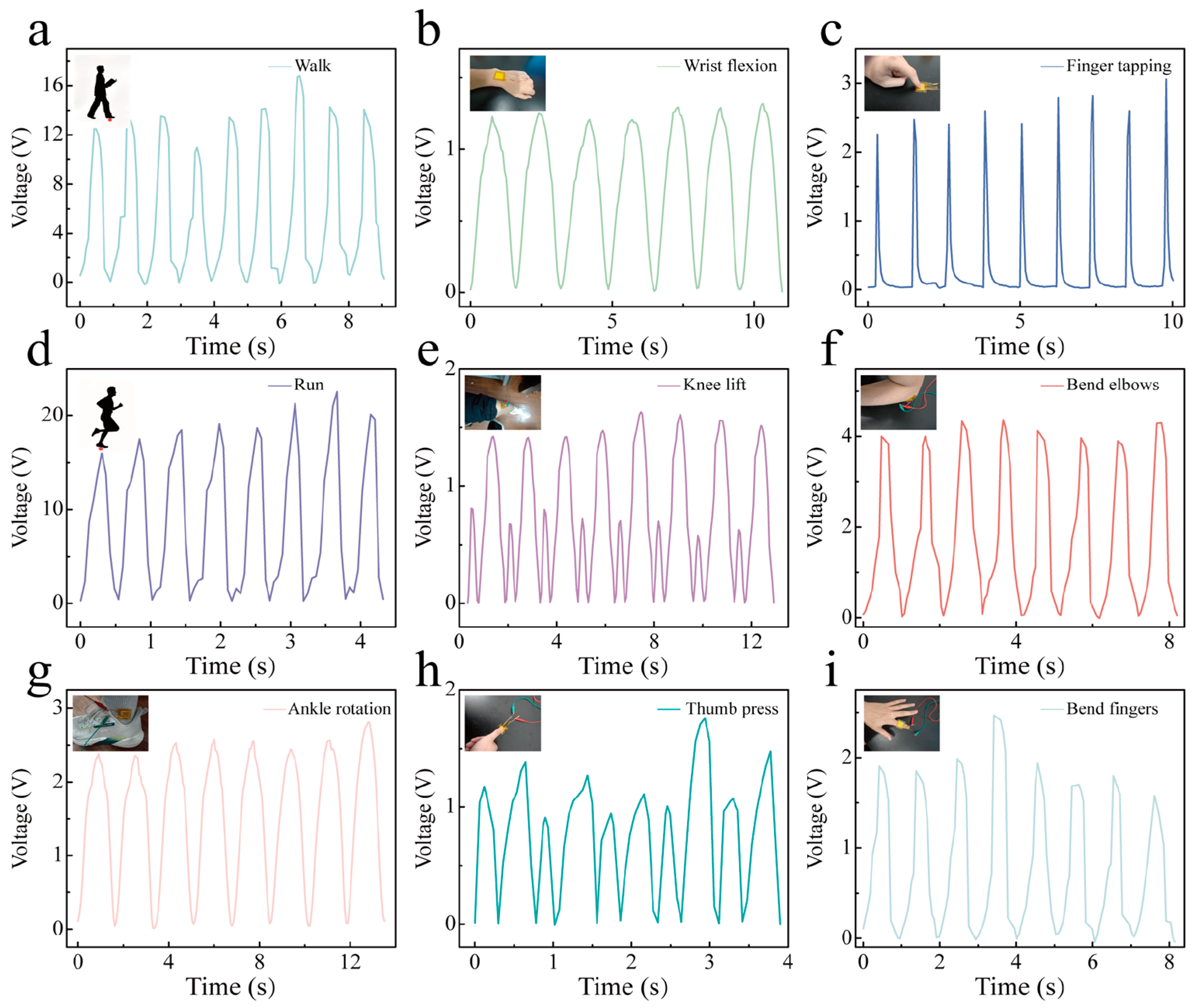

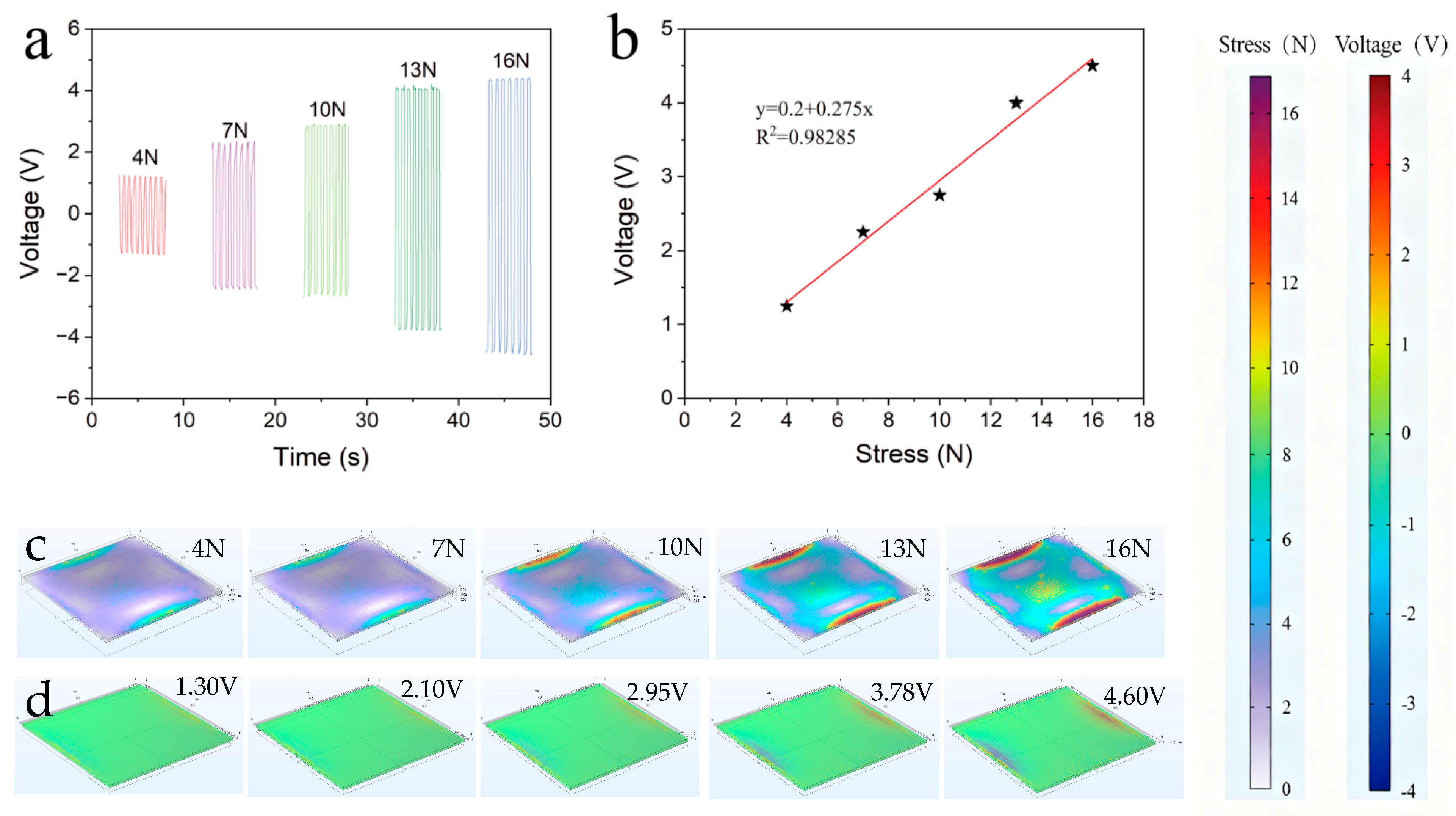

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xu, C.; Chen, J.; Zhu, Z.; Liu, M.; Lan, R.; Chen, X.; Tang, W.; Zhang, Y.; Li, H. Flexible Pressure Sensors in Human–Machine Interface Applications. Small 2024, 20, 2306655. [Google Scholar] [CrossRef] [PubMed]

- Shu, Q.; Pang, Y.; Li, Q.; Gu, Y.; Liu, Z.; Liu, B.; Li, J.; Li, Y. Flexible resistive tactile pressure sensors. J. Mater. Chem. A 2024, 12, 9296–9321. [Google Scholar] [CrossRef]

- Shi, Z.; Meng, L.; Shi, X.; Li, H.; Zhang, J.; Sun, Q.; Liu, X.; Chen, J.; Liu, S. Morphological Engineering of Sensing Materials for Flexible Pressure Sensors and Artificial Intelligence Applications. Nano-Micro Lett. 2022, 14, 141. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.C.; Mun, J.; Kwon, S.Y.; Park, S.; Bao, Z.; Park, S. Electronic Skin: Recent Progress and Future Prospects for Skin-Attachable Devices for Health Monitoring, Robotics, and Prosthetics. Adv. Mater. 2019, 31, 1904765. [Google Scholar] [CrossRef]

- Zhang, H.; Fang, Y.; Lee, J.; Jeong, C.K.; Zhang, Y. Templates-Built Structural Designs for Piezoelectrochemical Pressure Sensors. ACS Appl. Mater. Interfaces 2024, 16, 62617–62626. [Google Scholar] [CrossRef]

- Du, C.; Zhang, H.; Liu, X.; Zhou, S.; Ma, Y.; Li, S.; Zhang, Y. Flexible and Simply Degradable MXene-Methylcellulose Piezoresistive Sensor for Human Motion Detection. ACS Appl. Mater. Interfaces 2024, 16, 12996–13005. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.X.; Meng, X.S.; Kuang, S.Y.; Wang, X.D.; Pan, C.F.; Zhu, G.; Wang, Z.L. Triboelectrification-enabled touch sensing for self-powered position mapping and dynamic tracking by a flexible and area-scalable sensor array. Nano Energy 2017, 41, 387–393. [Google Scholar] [CrossRef]

- Lin, X.; Yu, F.; Zhang, X.; Li, W.; Zhao, Y.; Fei, X.; Li, Q.; Yang, C.; Huang, S. Wearable Piezoelectric Films Based on MWCNT-BaTiO3/PVDF Composites for Energy Harvesting, Sensing, and Localization. ACS Appl. Nano Mater. 2023, 6, 11955–11965. [Google Scholar] [CrossRef]

- Zhang, Y.; Jeong, C.K.; Wang, J.; Sun, H.; Li, F.; Zhang, G.; Chen, L.-Q.; Zhang, S.; Chen, W.; Wang, Q. Flexible energy harvesting polymer composites based on biofibril-templated 3-dimensional interconnected piezoceramics. Nano Energy 2018, 50, 35–42. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, C.; Li, B.; Shen, Y.; Wang, H.; Ji, K.; Mao, X.; Wei, L.; Sun, R.; Zhou, F. Electrospun PVDF-based piezoelectric nanofibers: Materials, structures, and applications. Nanoscale Adv. 2023, 5, 1043–1059. [Google Scholar] [CrossRef]

- Wang, T.; Gao, Y.; Chen, B.; Crespi, V.H.; van Duin, A.C. Prediction of a Novel Electromechanical Response in Polar Polymers with Rigid Backbones: Contrasting Furan-Derived Nanothreads to Poly (Vinylidene Fluoride). Nano Lett. 2024, 24, 9195–9201. [Google Scholar] [CrossRef]

- Li, W.; Yang, T.; Liu, C.; Huang, Y.; Chen, C.; Pan, H.; Hong, Z. Optimizing piezoelectric nanocomposites by high-throughput phase-field simulation and machine learning. Adv. Sci. 2022, 9, 2105550. [Google Scholar] [CrossRef]

- Li, M.; Zang, H.; Long, J.; Sun, S.; Zhang, Y. Flexible Pressure Sensors Based on Polyvinylidene Fluoride: A Critical Review. Materials 2025, 18, 615. [Google Scholar] [CrossRef]

- Joshi, B.; Seol, J.; Samuel, E.; Lim, W.; Park, C.; Aldalbahi, A.; El-Newehy, M.; Yoon, S.S. Supersonically sprayed PVDF and ZnO flowers with built-in nanocuboids for wearable piezoelectric nano-generators. Nano Energy 2023, 112, 108447. [Google Scholar] [CrossRef]

- Wang, S.; Tang, C.-Y.; Jia, J.; Zha, X.-J.; Liu, J.-H.; Zhao, X.; Ke, K.; Wang, Y.; Yang, W. Liquid Electrolyte-Assisted Electrospinning for Boosting Piezoelectricity of Poly (Vinylidene Fluoride) Fiber Mats. Macromolecules 2023, 56, 7479–7489. [Google Scholar] [CrossRef]

- Morali, A.; Mandal, A.; Skorobogatiy, M.; Bodkhe, S. Unleashing the piezoelectric potential of PVDF: A study on phase transformation from gamma (γ) to beta (β) phase through thermal contact poling. RSC Adv. 2023, 13, 31234–31242. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Sun, H.; Chen, W. Li-modified Ba0.99Ca0.01Zr0.02Ti0.98O3 lead-free ceramics with highly improved piezoelectricity. J. Alloys Compd. 2017, 694, 745–751. [Google Scholar] [CrossRef]

- Korkmaz, S.; Kariper, I.A. BaTiO3-based nanogenerators: Fundamentals and current status. J. Electroceram. 2022, 48, 8–34. [Google Scholar] [CrossRef]

- Zhou, S.; Zhang, H.; Du, C.; Liu, M.; Liu, L.; Zhang, Y. Chitosan-Doped PVDF Film with Enhanced Electroactive β Phase for Piezoelectric Sensing. ACS Appl. Electron. Mater. 2024, 6, 2575–2583. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, H.; Zhou, S.; Du, C.; Liu, M.; Zhang, Y. Boosting the Piezoelectric Response and Interfacial Compatibility in Flexible Piezoelectric Composites via DET-Doping BT Nanoparticles. Polymers 2024, 16, 743. [Google Scholar] [CrossRef]

- Athira, B.S.; George, A.; Priya, K.V.; Hareesh, U.S.; Gowd, E.B.; Surendran, K.P.; Chandran, A. High-Performance Flexible Piezoelectric Nanogenerator Based on Electrospun PVDF-BaTiO3 Nanofibers for Self-Powered Vibration Sensing Applications. ACS Appl. Mater. Interfaces 2022, 14, 44239–44250. [Google Scholar] [CrossRef]

- Kumar, M.; Kulkarni, N.D.; Kumari, P. Fabrication and characterization of PVDF/BaTiO3 nanocomposite for energy harvesting application. Mater. Today Proc. 2022, 56 Pt 3, 1151–1155. [Google Scholar] [CrossRef]

- Vivekananthan, V.; Alluri, N.; Purusothaman, Y.; Chandrasekhar, A.; Kim, S. A flexible, planar energy harvesting device for scavenging road side waste mechanical energy via the synergistic piezoelectric response of K0.5Na0.5NbO3-BaTiO3/PVDF composite films. Nanoscale 2017, 9, 15122–15130. [Google Scholar] [CrossRef]

- Baek, C.; Yun, J.H.; Wang, J.E.; Jeong, C.K.; Lee, K.J.; Park, K.-I.; Kim, D.K. A Flexible Energy Harvester Based on a Lead-Free and Piezoelectric BCTZ Nanoparticle-Polymer Composite. Nanoscale 2016, 8, 17632–17638. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Jeong, C.K.; Shen, Z.; Wang, J.; Sun, H.; Jian, Z.; Chen, W.; Zhang, Y. Ultrahigh Augmentation of Flexible Composite-Based Piezoelectric Energy Harvesting Efficiency via Polymer-Impregnated Nanoparticles Network within 3D Cellulose Scaffold. Compos. Part B 2022, 236, 109813. [Google Scholar] [CrossRef]

- Liu, X.; Ma, J.; Wu, X.; Lin, L.; Wang, X. Polymeric Nanofibers with Ultrahigh Piezoelectricity via Self-Orientation of Nanocrystals. ACS Nano 2017, 11, 1901–1910. [Google Scholar] [CrossRef]

- Ren, J.-Y.; Ouyang, Q.-F.; Ma, G.-Q.; Li, Y.; Lei, J.; Huang, H.-D.; Jia, L.-C.; Lin, H.; Zhong, G.-J.; Li, Z.-M. Enhanced Dielectric and Ferroelectric Properties of Poly (Vinylidene Fluoride) through Annealing Oriented Crystallites under High Pressure. Macromolecules 2022, 55, 2014–2027. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, W.; Jeong, C.K.; Sun, H.; Yang, G.; Chen, W.; Wang, Q. A Microcube-Based Hybrid Piezocomposite as a Flexible Energy Generator. RSC Adv. 2017, 7, 32502–32507. [Google Scholar] [CrossRef]

- Park, K.-I.; Lee, M.; Liu, Y.; Moon, S.; Hwang, G.-T.; Zhu, G.; Kim, J.E.; Kim, S.O.; Kim, D.K.; Wang, Z.L.; et al. Flexible nanocomposite generator made of BaTiO3 nanoparticles and graphitic carbons. Adv. Mater. 2012, 24, 2999–3004. [Google Scholar] [CrossRef] [PubMed]

- Park, K.-I.; Jeong, C.K.; Ryu, J.; Hwang, G.-T.; Lee, K.J. Flexible and Large-Area Nanocomposite Generators Based on Lead Zirconate Titanate Particles and Carbon Nanotubes. Adv. Energy Mater. 2013, 3, 1539–1544. [Google Scholar] [CrossRef]

- Li, Y.; Su, X.; Liang, K.; Luo, C.; Li, P.; Hu, J.; Li, G.; Jiang, H.; Wang, K. Multi-layered BTO/PVDF Nanogenerator with Highly Enhanced Performance Induced by Interlaminar Electric Field. Microelectron. Eng. 2021, 244–246, 111557. [Google Scholar] [CrossRef]

- Pei, H.; Shi, S.; Chen, Y.; Xiong, Y.; Lv, Q. Combining Solid-State Shear Milling and FFF 3D-Printing Strategy to Fabricate High-Performance Biomimetic Wearable Fish-Scale PVDF-Based Piezoelectric Energy Harvesters. ACS Appl. Mater. Interfaces 2022, 14, 15346–15359. [Google Scholar] [CrossRef]

- Kim, S.-R.; Yoo, J.-H.; Kim, J.H.; Cho, Y.S.; Park, J.-W. Mechanical and Piezoelectric Properties of Surface Modified (Na,K)NbO3-Based Nanoparticle-Embedded Piezoelectric Polymer Composite Nanofibers for Flexible Piezoelectric Nanogenerators. Nano Energy 2021, 79, 105445. [Google Scholar] [CrossRef]

- Xue, H.; Zheng, T.; Wu, J. Understanding the Nature of Temperature Stability in Potassium Sodium Niobate Based Ceramics from Structure Evolution under External Field. ACS Appl. Mater. Interfaces 2020, 12, 32925–32934. [Google Scholar] [CrossRef]

- Su, H.; Wang, X.; Li, C.; Wang, Z.; Wu, Y.; Zhang, J.; Zhang, Y.; Zhao, C.; Wu, J.; Zheng, H. Enhanced Energy Harvesting Ability of Polydimethylsiloxane-BaTiO3-Based Flexible Piezoelectric Nanogenerator for Tactile Imitation Application. Nano Energy 2021, 83, 105809. [Google Scholar] [CrossRef]

- Yang, L.; Zhao, Q.; Chen, K.; Ma, Y.; Wu, Y.; Ji, H.; Qiu, J. PVDF-Based Composition-Gradient Multilayered Nanocomposites for Flexible High-Performance Piezoelectric Nanogenerators. ACS Appl. Mater. Interfaces 2020, 12, 11045–11054. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Shao, H.-Q.; Liu, Y.; Tang, C.-Y.; Zhao, X.; Ke, K.; Bao, R.-Y.; Yang, M.-B.; Yang, W. Boosting Piezoelectric Response of PVDF-TrFE via MXene for Self-Powered Linear Pressure Sensor. Compos. Sci. Technol. 2021, 202, 108600. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Zhang, H. Construction of PVDF/BTO Fibers with High Piezoelectricity for Self-Powered Flexible Pressure Sensing. Polymers 2025, 17, 3043. https://doi.org/10.3390/polym17223043

Liu Z, Zhang H. Construction of PVDF/BTO Fibers with High Piezoelectricity for Self-Powered Flexible Pressure Sensing. Polymers. 2025; 17(22):3043. https://doi.org/10.3390/polym17223043

Chicago/Turabian StyleLiu, Zao, and Hongjian Zhang. 2025. "Construction of PVDF/BTO Fibers with High Piezoelectricity for Self-Powered Flexible Pressure Sensing" Polymers 17, no. 22: 3043. https://doi.org/10.3390/polym17223043

APA StyleLiu, Z., & Zhang, H. (2025). Construction of PVDF/BTO Fibers with High Piezoelectricity for Self-Powered Flexible Pressure Sensing. Polymers, 17(22), 3043. https://doi.org/10.3390/polym17223043