Dynamic Monitoring Method of Polymer Injection Molding Product Quality Based on Operating Condition Drift Detection and Incremental Learning

Abstract

1. Introduction

2. Methodology

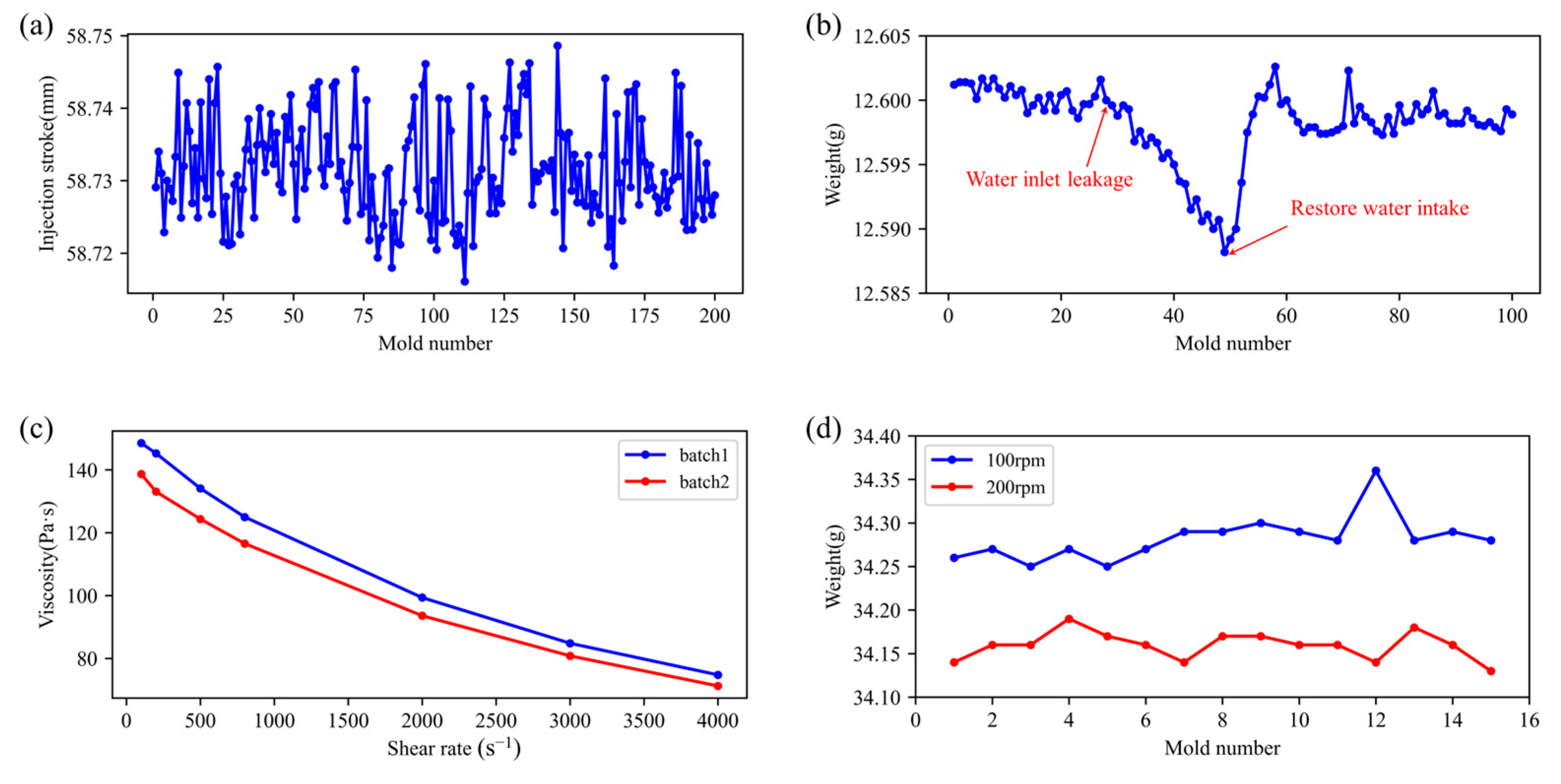

2.1. Operating Condition Drift Factors Affecting Injection Molding Quality

2.1.1. Stability and Operating Status of the Molding Equipment

2.1.2. Variations in Raw Material Properties

2.1.3. Setting of Process Parameters

2.1.4. Manual Operation

2.1.5. Fluctuation of the Production Environment

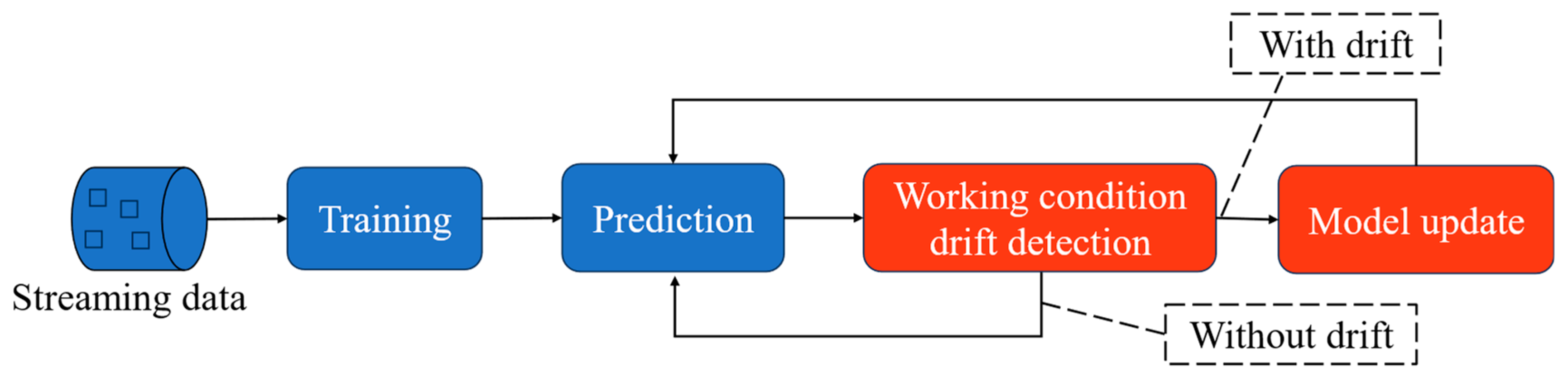

2.2. Operating Condition Drift Detection Method Based on Process Data

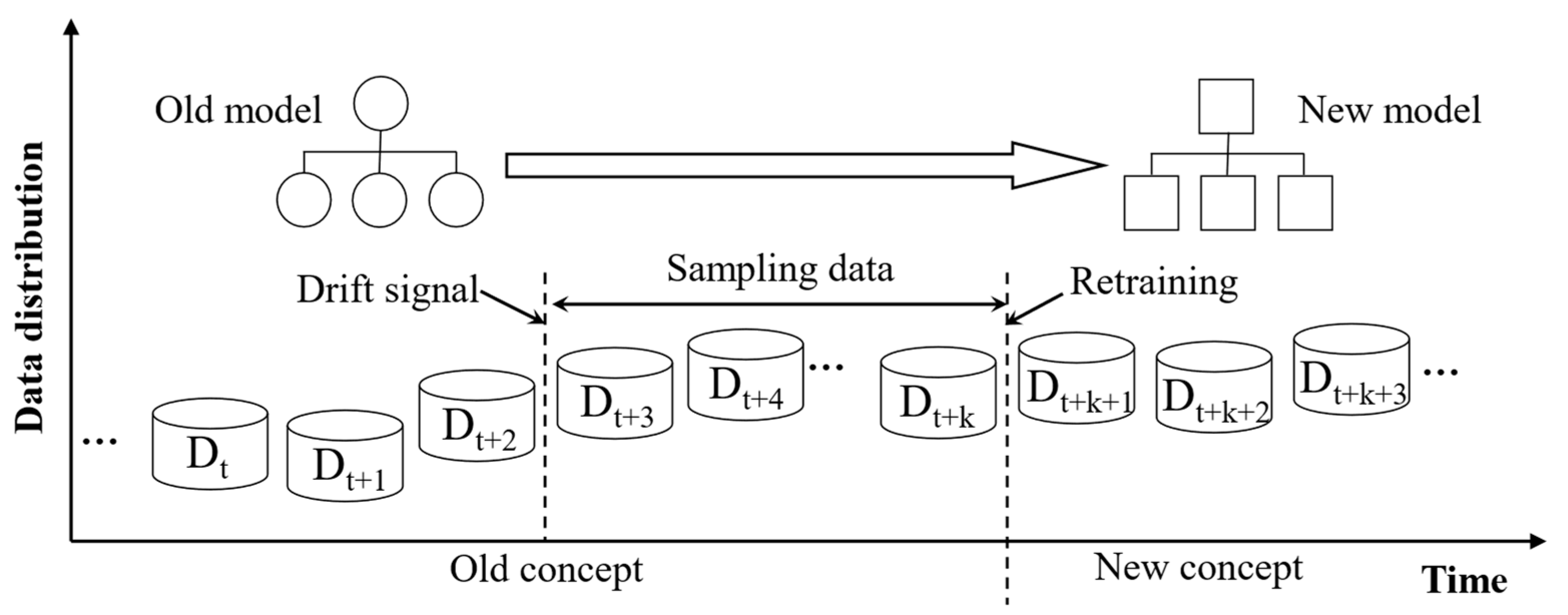

2.3. Model Adaptive Update Method Based on Incremental Data

- (1)

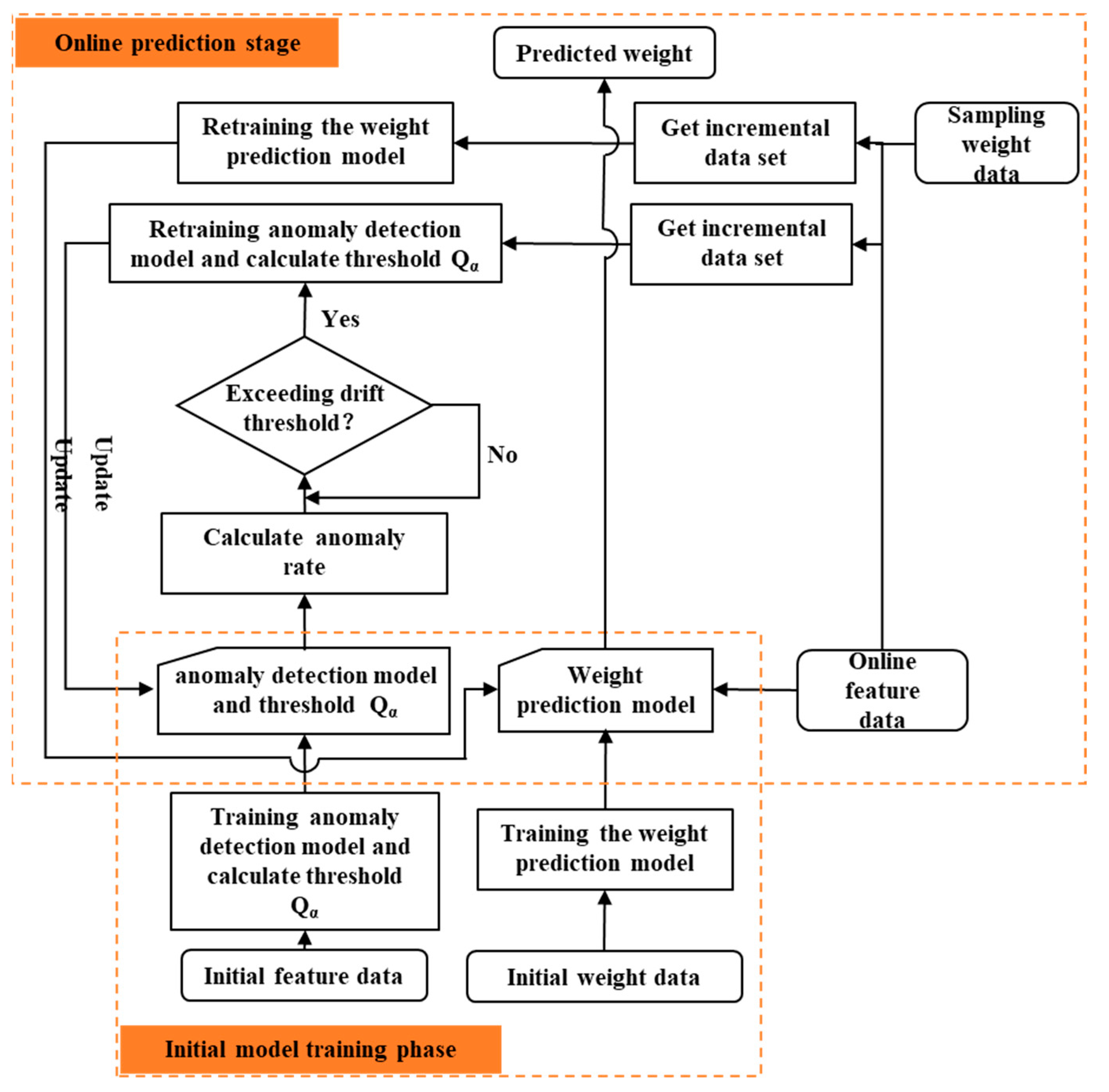

- Initial model training stage: The initial training set includes the first 100 molding cycles, selected as a practical balance between real engineering constraints and sufficient data for initial model learning. Simultaneously, an HFAE-based anomaly detector is trained and its decision threshold established to enable real-time monitoring of operating condition drift. All network architecture and hyperparameters mirror those used in the earlier work.

- (2)

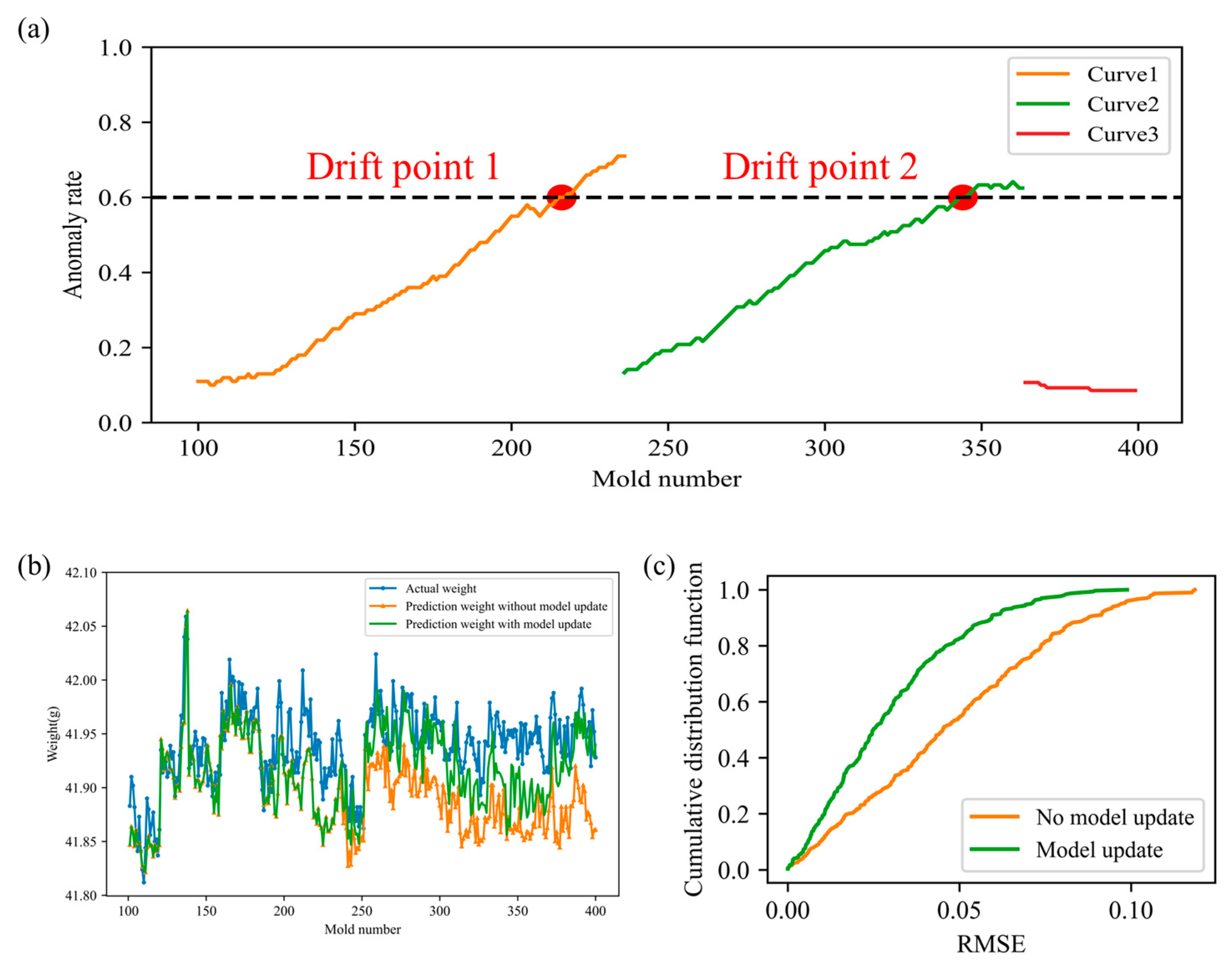

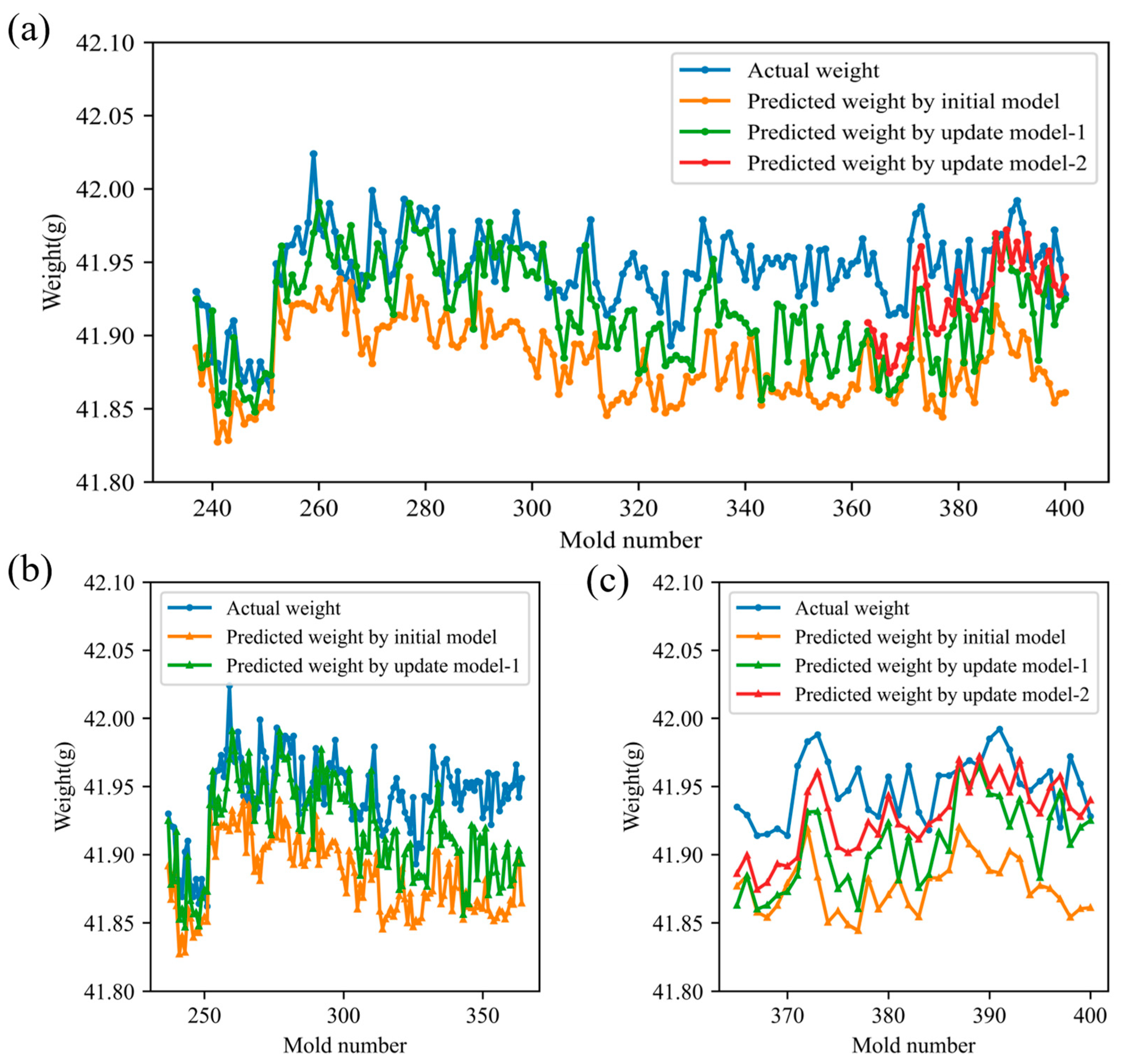

- Online prediction stage: The test data for each model begins immediately after its training range and continues until the next model update is triggered. For example, the initial model is tested from mold 100 to mold 236, and the update model-1 from mold 237 to mold 364, ensuring evaluation under true sequential production conditions. During mass production, the system continuously ingests real-time feature data. Each new data window is processed by the anomaly detector to compute reconstruction errors and an anomaly rate, which is compared against a preset threshold (0.6 in this study). At the same time, the prediction model generates weight estimates. If the anomaly rate exceeds 0.6, indicating an operating condition drift, the system alerts operators to sample 20 molds for quality inspection. After sampling, all accumulated feature data are used to retrain the anomaly detector and update its threshold, while the newly acquired feature-weight pairs are appended to the original training set to retrain the prediction model. Throughout this process, the existing models remain active, ensuring continuous drift detection and prediction until the updated models are ready for seamless deployment.

2.4. Experiments

3. Results and Discussions

3.1. Impact and Types of Operating Condition Drift Phenomenon

3.1.1. Analysis of the Phenomenon of Operating Condition Drift

3.1.2. Analysis of the Types of Operating Drift

- (1)

- Input distribution drift (false drift): The marginal distribution shifts while the conditional distribution remains unchanged. The decision boundary is therefore unaffected, and only feature standardization must be reapplied.

- (2)

- Conditional probability drift (real drift): The marginal distribution stays constant, but the conditional distribution changes. This alters the decision boundary and necessitates retraining of the model.

- (3)

- Both and change simultaneously, combining elements of virtual and real drift. The standardization process needs to be re-performed and the model updated.

- (1)

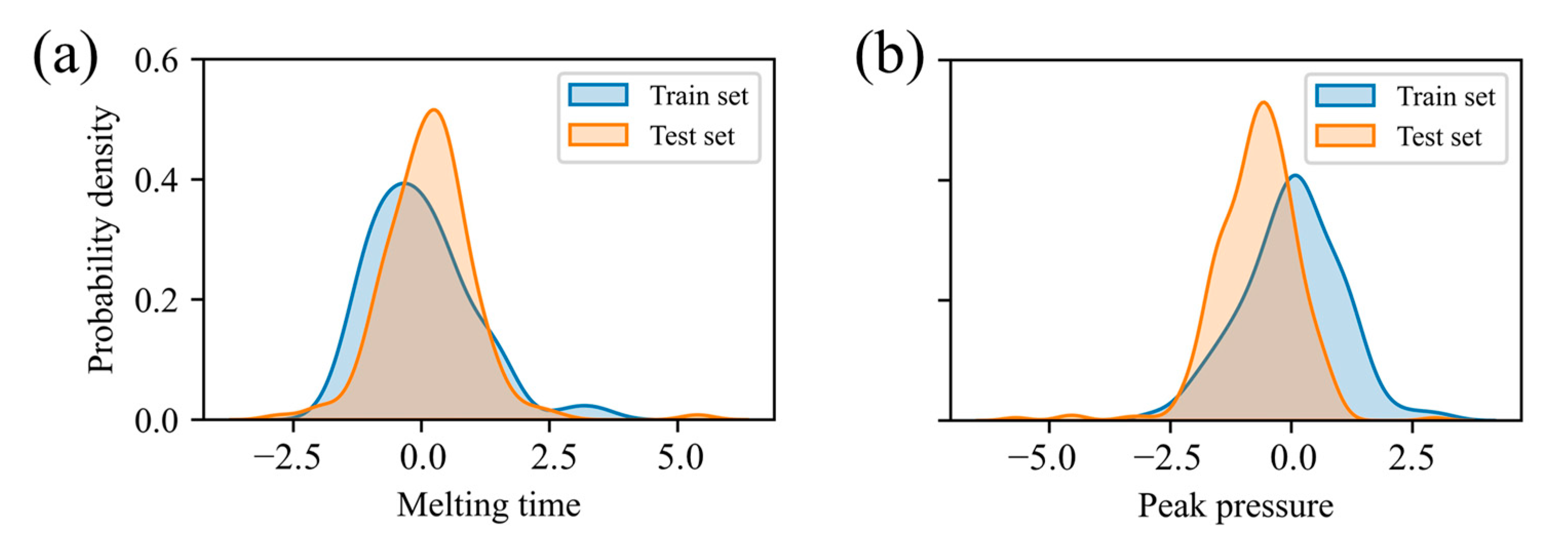

- Input distribution drift analysis

- (2)

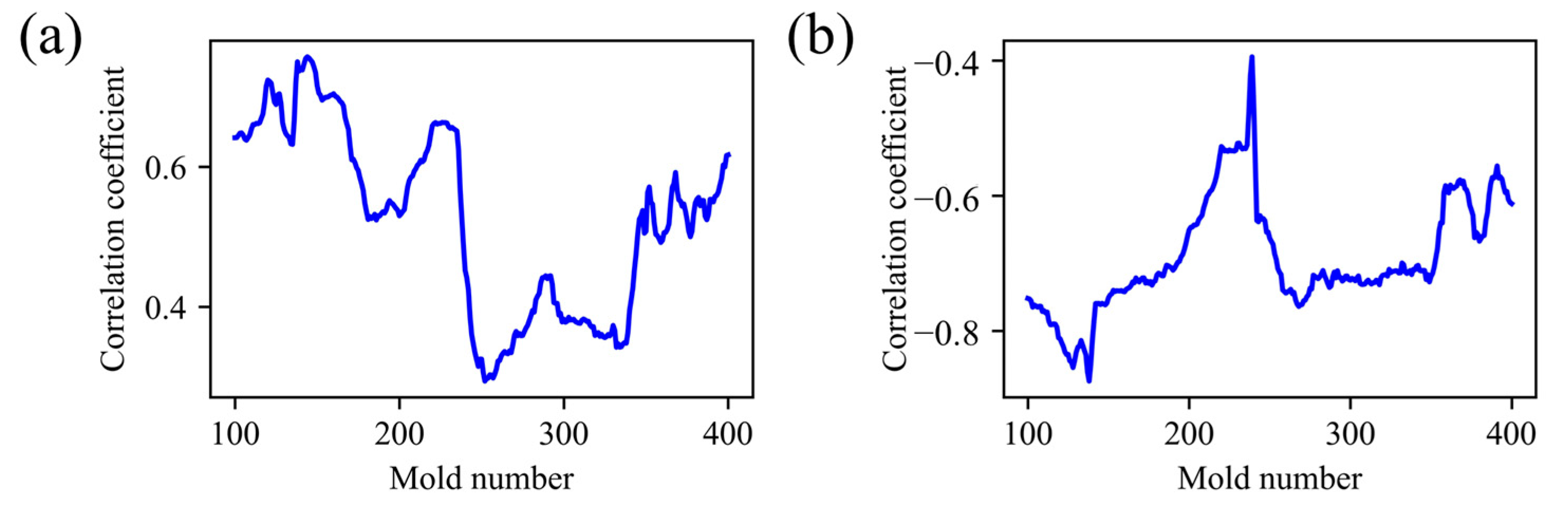

- Conditional probability drift analysis

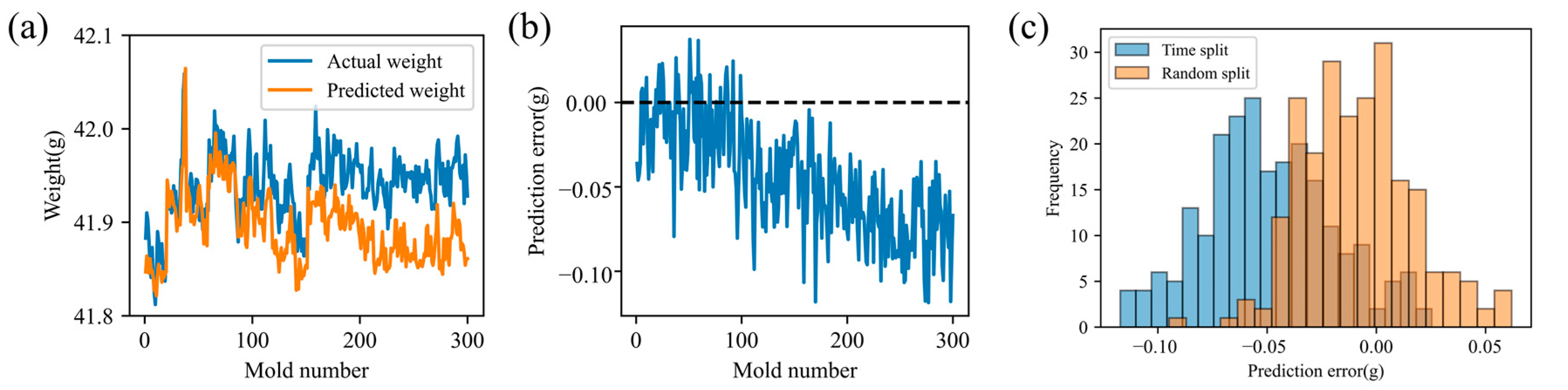

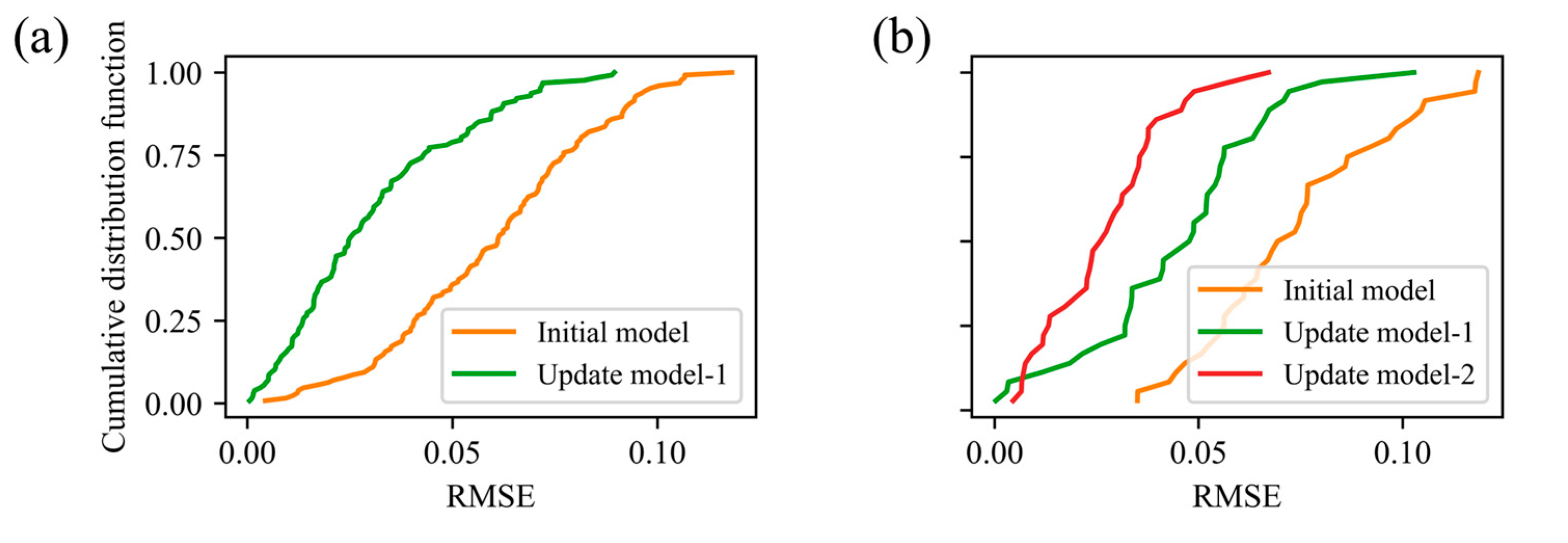

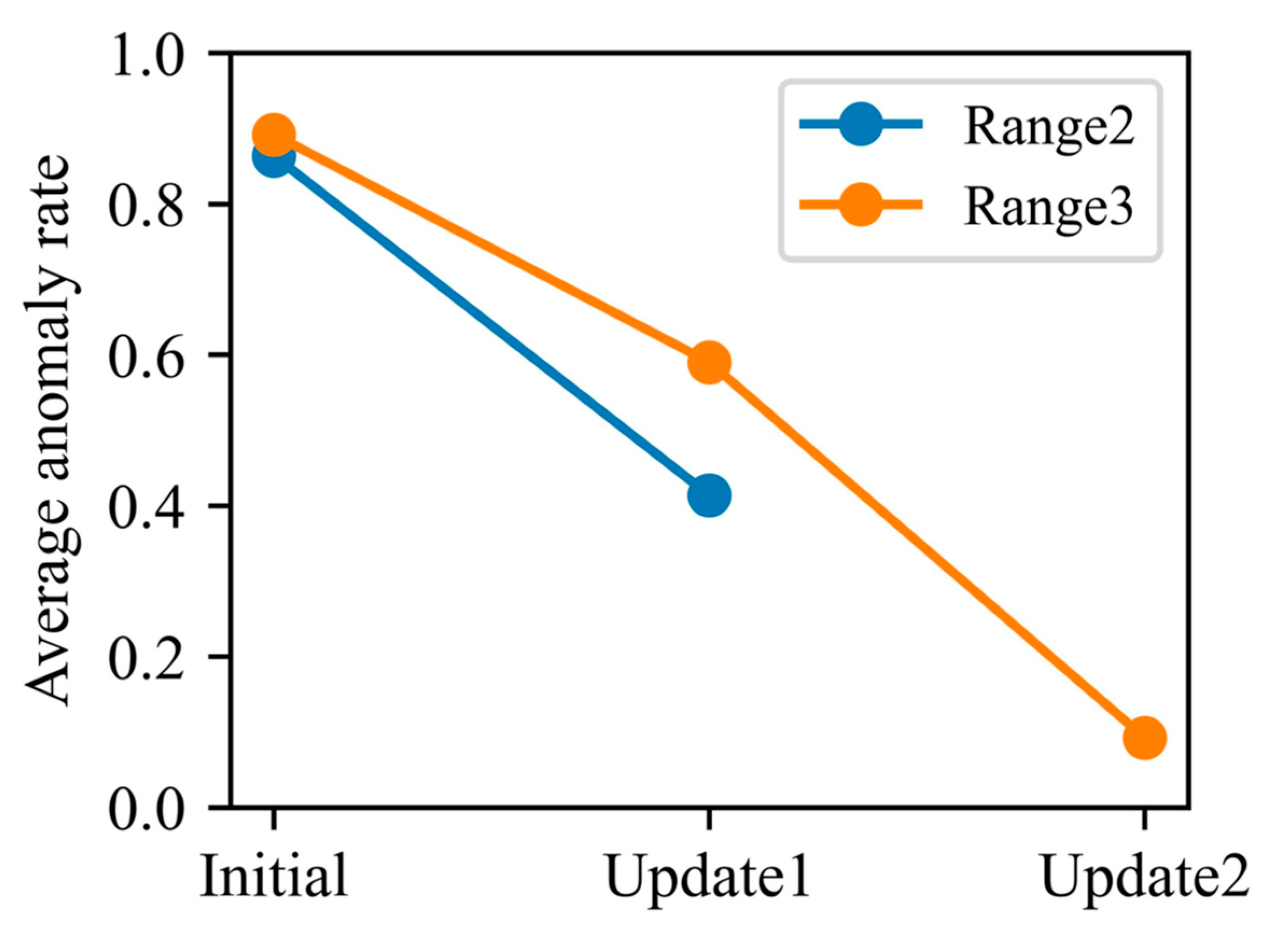

3.2. Effectiveness of Adaptive Updating Methods for Prediction Models

3.3. Adaptive Dynamic Updating Process of Prediction Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gim, J.; Lin, C.-Y.; Turng, L.-S.J.J.o.M.S. In-mold condition-centered and explainable artificial intelligence-based (IMC-XAI) process optimization for injection molding. J. Manuf. Syst. 2024, 72, 196–213. [Google Scholar] [CrossRef]

- Chen, J.C.; Guo, G.; Wang, W.-N. Artificial neural network-based online defect detection system with in-mold temperature and pressure sensors for high precision injection molding. Int. J. Adv. Manuf. Technol. 2020, 110, 2023–2033. [Google Scholar] [CrossRef]

- Zhao, N.-Y.; Liu, J.-F.; Su, M.-Y.; Xu, Z.-B.J.M. Measurement techniques in injection molding: A comprehensive review of machine status detection, molten resin flow state characterization, and component quality adjustment. Measurement 2024, 226, 114163. [Google Scholar] [CrossRef]

- Rahmani, K.; Thapa, R.; Tsou, P.; Chetty, S.C.; Barnes, G.; Lam, C.; Tso, C.F. Assessing the effects of data drift on the performance of machine learning models used in clinical sepsis prediction. Int. J. Med. Inform. 2023, 173, 104930. [Google Scholar] [CrossRef] [PubMed]

- Gama, J.; Žliobaitė, I.; Bifet, A.; Pechenizkiy, M.; Bouchachia, A. A survey on concept drift adaptation. ACM Comput. Surv. (CSUR) 2014, 46, 1–37. [Google Scholar] [CrossRef]

- Bengio, Y. Learning deep architectures for AI. Found. Trends® Mach. Learn. 2009, 2, 1–127. [Google Scholar] [CrossRef]

- Yu, H.; Webb, G.I. Adaptive online extreme learning machine by regulating forgetting factor by concept drift map. Neurocomputing 2019, 343, 141–153. [Google Scholar] [CrossRef]

- Wiederkehr, P.; Finkeldey, F.; Siebrecht, T. Reduction of experimental efforts for predicting milling stability affected by concept drift using transfer learning on multiple machine tools. CIRP Ann. 2024, 73, 301–304. [Google Scholar] [CrossRef]

- Yu, H.; Zhang, Q.; Liu, T.; Lu, J.; Wen, Y.; Zhang, G. Meta-ADD: A meta-learning based pre-trained model for concept drift active detection. Inf. Sci. 2022, 608, 996–1009. [Google Scholar] [CrossRef]

- Gemaque, R.N.; Costa, A.F.J.; Giusti, R.; dos Santos, E.M. An overview of unsupervised drift detection methods. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2020, 10, e1381. [Google Scholar] [CrossRef]

- Gama, J.; Medas, P.; Castillo, G.; Rodrigues, P. Learning with drift detection. In Proceedings of the Advances in Artificial Intelligence–SBIA 2004, Berlin, Germany, 29 September–1 October 2004; pp. 286–295. [Google Scholar]

- Baena-Garcıa, M.; del Campo-Ávila, J.; Fidalgo, R.; Bifet, A.; Gavalda, R.; Morales-Bueno, R. Early drift detection method. In Proceedings of the Fourth International Workshop on Knowledge Discovery from Data Streams, Philadelphia, PA, USA, 20 August 2006; pp. 77–86. [Google Scholar]

- Munirathinam, S. Drift Detection Analytics for IoT Sensors. Procedia Comput. Sci. 2021, 180, 903–912. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, W.; Pan, M.; Loo, C.K.; Pasupa, K. Weighted error-output recurrent Xavier echo state network for concept drift handling in water level prediction. Appl. Soft Comput. 2024, 165, 112055. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Z.; Su, Y. Adaptive short-term wind power forecasting with concept drifts. Renew. Energy 2023, 217, 119146. [Google Scholar] [CrossRef]

- Sun, Y.; Dai, H. Constructing accuracy and diversity ensemble using Pareto-based multi-objective learning for evolving data streams. Neural Comput. Appl. 2021, 33, 6119–6132. [Google Scholar] [CrossRef]

- Jain, M.; Kaur, G.; Saxena, V. A K-Means clustering and SVM based hybrid concept drift detection technique for network anomaly detection. Expert Syst. Appl. 2022, 193, 116510. [Google Scholar] [CrossRef]

- Castellani, A.; Schmitt, S.; Hammer, B. Task-Sensitive Concept Drift Detector with Constraint Embedding. In Proceedings of the IEEE Symposium Series on Computational Intelligence (IEEE SSCI), Orlando, FL, USA, 5–7 December 2021; pp. 1–8. [Google Scholar]

- Liu, A.; Lu, J.; Liu, F.; Zhang, G. Accumulating regional density dissimilarity for concept drift detection in data streams. Pattern Recognit. 2018, 76, 256–272. [Google Scholar] [CrossRef]

- Wahab, O.A. Intrusion Detection in the IoT Under Data and Concept Drifts: Online Deep Learning Approach. IEEE Internet Things J. 2022, 9, 19706–19716. [Google Scholar] [CrossRef]

- Hinder, F.; Vaquet, V.; Hammer, B. Feature-based analyses of concept drift. Neurocomputing 2024, 600, 127968. [Google Scholar] [CrossRef]

- Gim, J.; Turng, L.-S. A review of current advancements in high surface quality injection molding: Measurement, influencing factors, prediction, and control. Polym. Test. 2022, 115, 107718. [Google Scholar] [CrossRef]

- Wang, X.; Ma, Y.; Dang, K.; Zhao, B.; Chen, A.; Yang, W.; Xie, P. Fault diagnosis of injection molding machine non-return valve based on data-driven model. J. Manuf. Process. 2024, 117, 145–153. [Google Scholar] [CrossRef]

- Bach, S.H.; Maloof, M.A. Paired Learners for Concept Drift. In Proceedings of the 2008 Eighth IEEE International Conference on Data Mining, Pisa, Italy, 15–19 December 2008; pp. 23–32. [Google Scholar]

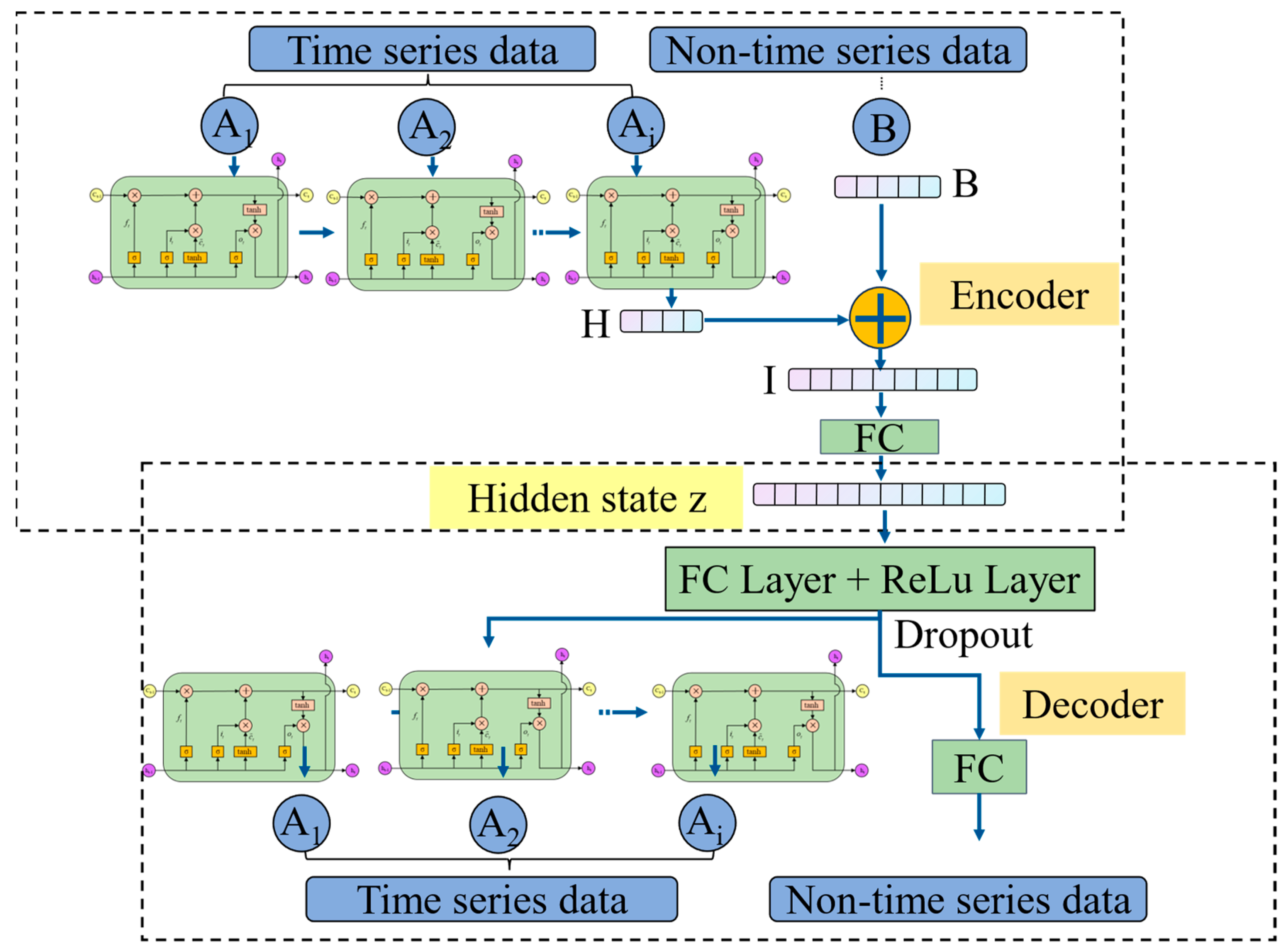

- Li, M.; Li, S.; Shen, G.; Zhang, Y.; Zhou, H. Online high-precision prediction method for injection molding product weight by integrating time series/non-time series mixed features and feature attention mechanism. arXiv 2025, arXiv:2506.18950. [Google Scholar]

| Process Parameters | Unit | Values |

|---|---|---|

| Injection pressure | MPa | 150; 150; 150 |

| Injection speed | mm/s | 150; 130; 110 |

| Injection position | mm | 70; 35 |

| VP switch position | mm | 15 |

| Holding pressure | MPa | 30 |

| Holding time | s | 0.5 |

| Cooling time | s | 25 |

| Barrel temperature | °C | 200; 210; 205; 175 |

| Mold temperature controller temperature | °C | 45 |

| Interval 1 | Interval 2 | Interval 3 | |

|---|---|---|---|

| Initial model | 0.0356 | 0.0650 | 0.0771 |

| Update model-1 | × | 0.0375 | 0.0500 |

| Update model-2 | × | × | 0.0309 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, G.; Li, S.; Zhang, Y.; Zhou, H.; Li, M. Dynamic Monitoring Method of Polymer Injection Molding Product Quality Based on Operating Condition Drift Detection and Incremental Learning. Polymers 2025, 17, 3025. https://doi.org/10.3390/polym17223025

Shen G, Li S, Zhang Y, Zhou H, Li M. Dynamic Monitoring Method of Polymer Injection Molding Product Quality Based on Operating Condition Drift Detection and Incremental Learning. Polymers. 2025; 17(22):3025. https://doi.org/10.3390/polym17223025

Chicago/Turabian StyleShen, Guancheng, Sihong Li, Yun Zhang, Huamin Zhou, and Maoyuan Li. 2025. "Dynamic Monitoring Method of Polymer Injection Molding Product Quality Based on Operating Condition Drift Detection and Incremental Learning" Polymers 17, no. 22: 3025. https://doi.org/10.3390/polym17223025

APA StyleShen, G., Li, S., Zhang, Y., Zhou, H., & Li, M. (2025). Dynamic Monitoring Method of Polymer Injection Molding Product Quality Based on Operating Condition Drift Detection and Incremental Learning. Polymers, 17(22), 3025. https://doi.org/10.3390/polym17223025