Experimental Study on the Performance of a Stable Foam System and Its Application Effect Combined with Natural Gas in Natural Foamy Oil Reservoirs

Abstract

1. Introduction

2. Experimental Methodology

2.1. Materials

- Water: Based on the in situ properties of water from the MPE3 block, simulated formation water is replicated using CaCl2, MgCl2, FeCl2, NaCl, and NaHCO3 at quantities of 0.773, 0.602, 0.193, 17.285, and 2.685 g/L, respectively.

- Oil: Heavy oil produced from the MPE3 block was prepared for the experiments using SARA, as listed in Table 1, exhibiting a dead oil viscosity and density of 35,600 mPa·s and 0.96 g/cm3 at 50 °C. Long-term storage caused evaporation of light components in the oil samples. We added light hydrocarbons to replicate crude oil, based on the composition analysis listed in Table 2.

- Gas: Methane (CH4) with a purity of 99.9% was used.

- Basic foaming agents: NKS and SX-117 from Macklin Biochemical Technology Co., Ltd., Shanghai, China.

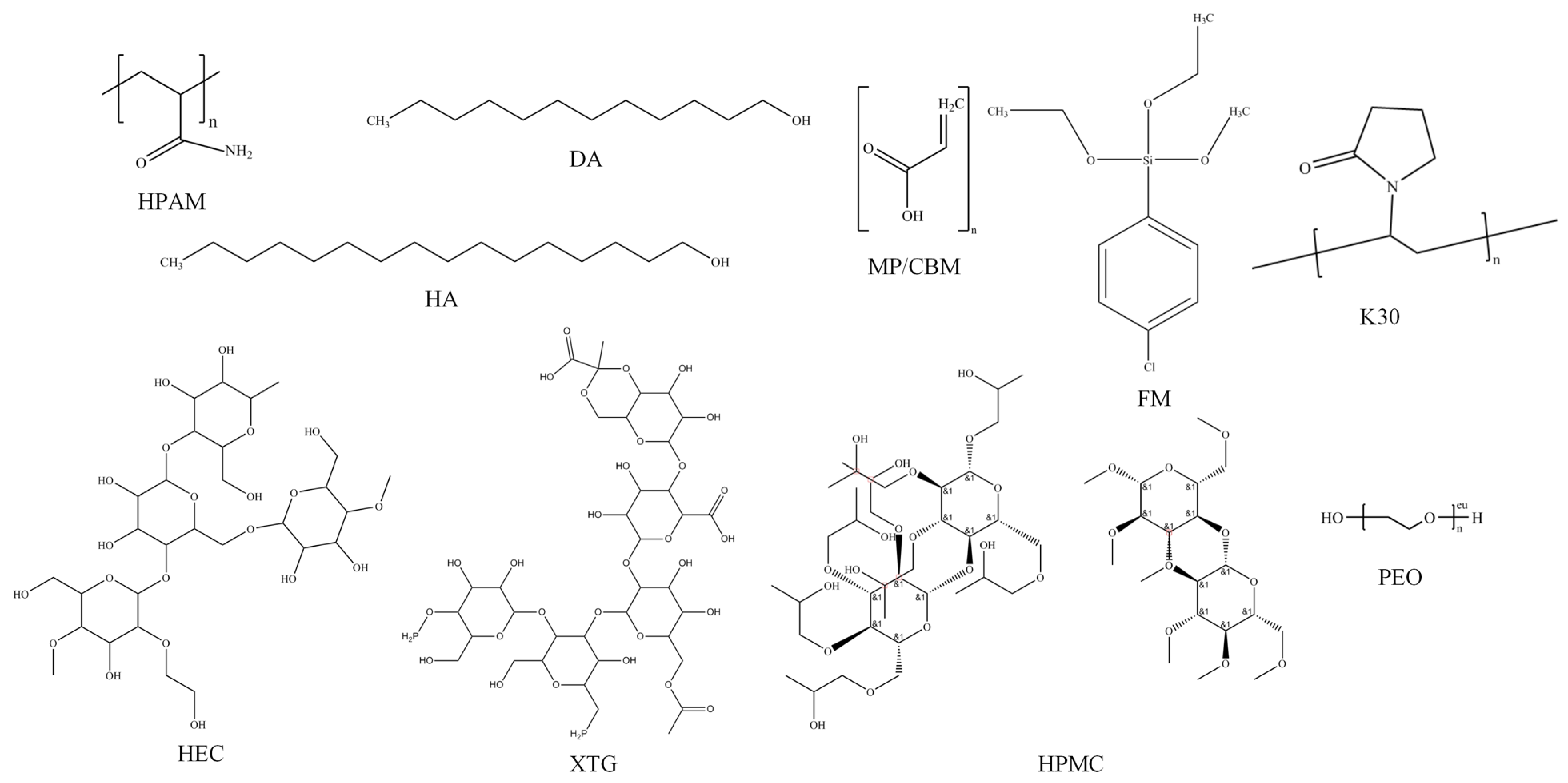

- Foam stabilizers: Polyacrylamide, Dodecanol, Hexadecanol, modified silicone resin polyether, modified silicone resin polyether emulsion, modified acrylic polymer, acrylic polymer film-forming agent, Xanthan gum, acrylic polymer, Hydroxypropyl methyl cellulose type II, Hydroxyethyl cellulose, Polyethylene glycol, Polyvinylpyrrolidone, Nano-silica. All the agents are from Macklin Biochemical Technology Co., Ltd., Shanghai, China.

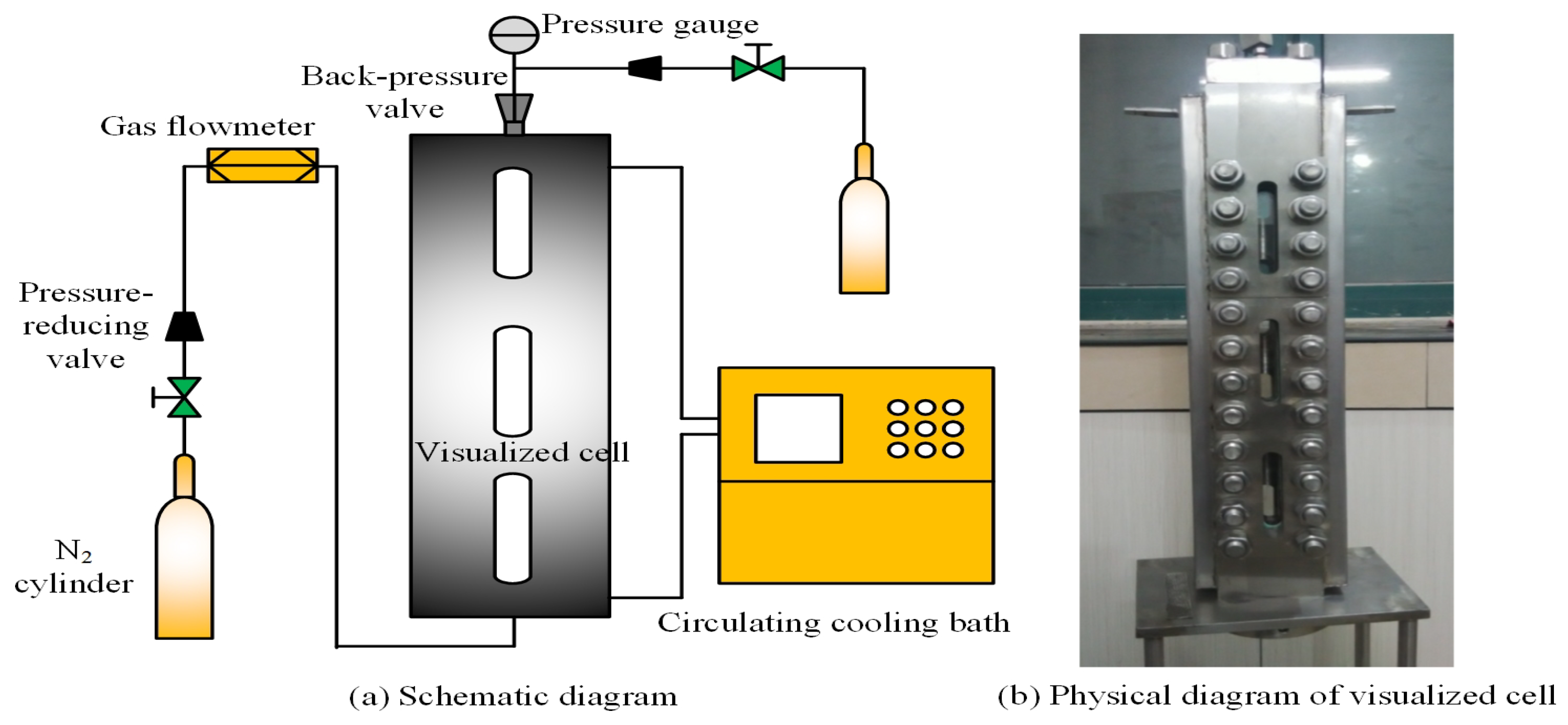

2.2. Experimental Apparatus

2.2.1. High-Temperature Foam Instrument

2.2.2. One-Dimensional Core Model with Visualization Unit

- Injection unit: This consists of a CH4 cylinder, an oil sample dispenser, a chemical tank, two pressure-reducing valves, a gas mass flowmeter, and three ISCO pumps. The oil sample dispenser is used to prepare foamy oil sample consistent with the reservoir condition. The pressure-reducing valve is used to control the injection pressure, and the ISCO pumps are used to inject fluids.

- One-dimensional core holder: This is composed of an oven with a core holder diameter of 2.5 cm and a length of 50 cm. The oven is heated to control the temperature of the huff and puff. The core holder is filled with the formation core to simulate the actual reservoir. It has an average porosity of 42.2%, an average permeability of 7.3 μm2, and an initial oil saturation of 97.2.

- Visualization unit: This consists of a thickened explosion-proof glass plate, a flow cell, a stainless-steel holder, an annular pressure pump, and a microscope with a light source. The flow behavior was observed in flow cells using the microscope.

- Production unit: This consists of a vacuum pump, a back-pressure regulator (BPR), a CH4 cylinder, a pressure-reducing valve, a pressure gauge, a gas–liquid separator, a gas flowmeter, an oil collector, and a gas collector. The gas–liquid separator is used to separate produced oil and gas. The vacuum pump is used for saturation, and the BPR is used to adjust the production pressure.

- Data-sensing unit. This is composed of a pressure transducer and a computer, which can transmit and record pressure data in real time.

2.3. Experimental Scenarios

2.3.1. Foam Performance Tests

2.3.2. One-Dimensional Core Experiments of the CCHP

2.4. Experimental Procedure

2.4.1. Foam Performance Tests

- Chemical preparation: Foam agent-stabilizer solutions are prepared in beakers, where stabilizers are finally dispersed into the solution to prevent micelle formation, followed by incubation in a 55 °C thermostatic water bath. Oil samples are prepared using a dispenser by incorporating the missing light hydrocarbons with stock oil. Finally, BPR is adjusted at 3.0 MPa, while cell temperature is maintained at 55 °C.

- Co-injection: Foam agent-stabilizer solutions and oil samples are co-injected into the visualization cell; CH4 is then injected to increase the cell pressure to 3.0 MPa.

- Mixing: The cell rotor is set to rotate at a low speed of 400~500 r/min for 3.0 min, ramping to 1500 r/min sustained shearing for 6.0 min.

- Record: The variations in drainage height and foam height are continuously recorded at designated intervals.

2.4.2. One-Dimensional Core Experiments of the CCHP

- Preparation: Foaming agent-stabilizer solutions are prepared at specified concentrations according to the experimental scenarios, where the corresponding foam stabilizer was formulated based on the performance evaluation tests. Meanwhile, oil samples are prepared using a dispenser by incorporating the missing light hydrocarbons with stock oil. The oven is adjusted to 55 °C to match the reservoir temperature, and the BPR is adjusted to 8.45 MPa to match the reservoir pressure.

- Water saturated: The core is saturated with water at a constant injection rate. The core properties are measured, and the results are shown in Table 5.

- OOIP and depletion: The core is vacuumized to saturate water; the oil sample is then injected to establish the original oil in place (OOIP), shown in Table 5, which closely approximates the in situ oil saturation measured from the original core. After being aged for 24 h, depressurization-depletion production is initiated by gradually reducing the pressure to the experimental scenarios.

- CCHP: CH4 and the foaming agent-stabilizer solutions are alternately injected into the core at the GLR set in the specific scenarios until the pressure reaches 8.45 MPa. Then, all valves are closed to soak the wellbore for 10.0 min. Finally, the BPR is adjusted to the set production pressure (bottom hole pressure) for production. The first cycle of throughput ends when no oil is produced.

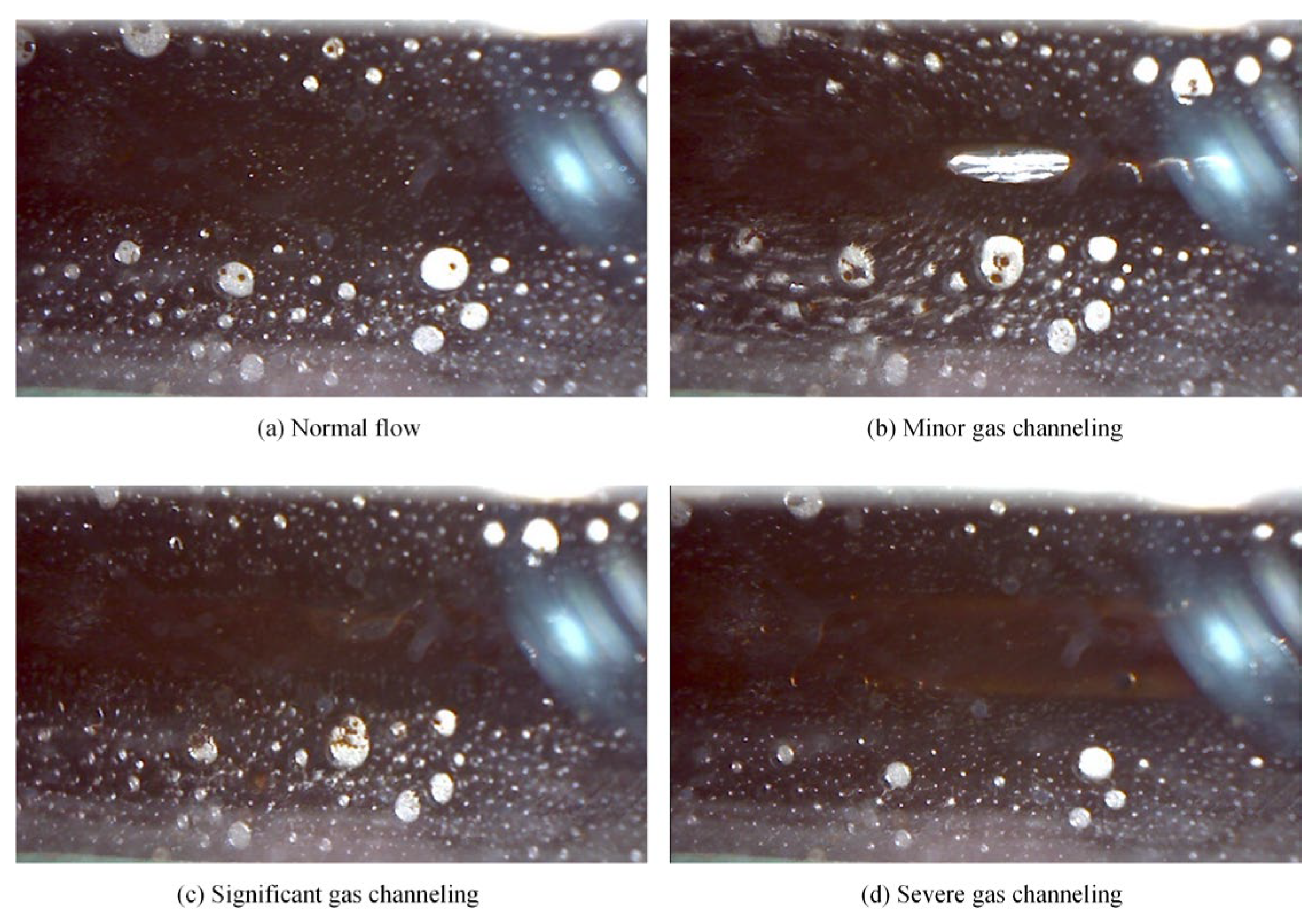

- Visualization: When the water cut in the produced fluid exceeds 98%, the foam morphology in the produced liquid is recorded, as it can effectively reflect the in situ performance of foam in the reservoir.

- Multiple cycles: Repeat step 4 to complete 8 cycles of the CCHP.

3. Results and Discussing

3.1. Optimization of Foam Stabilizers and Performance of Stable Foam System

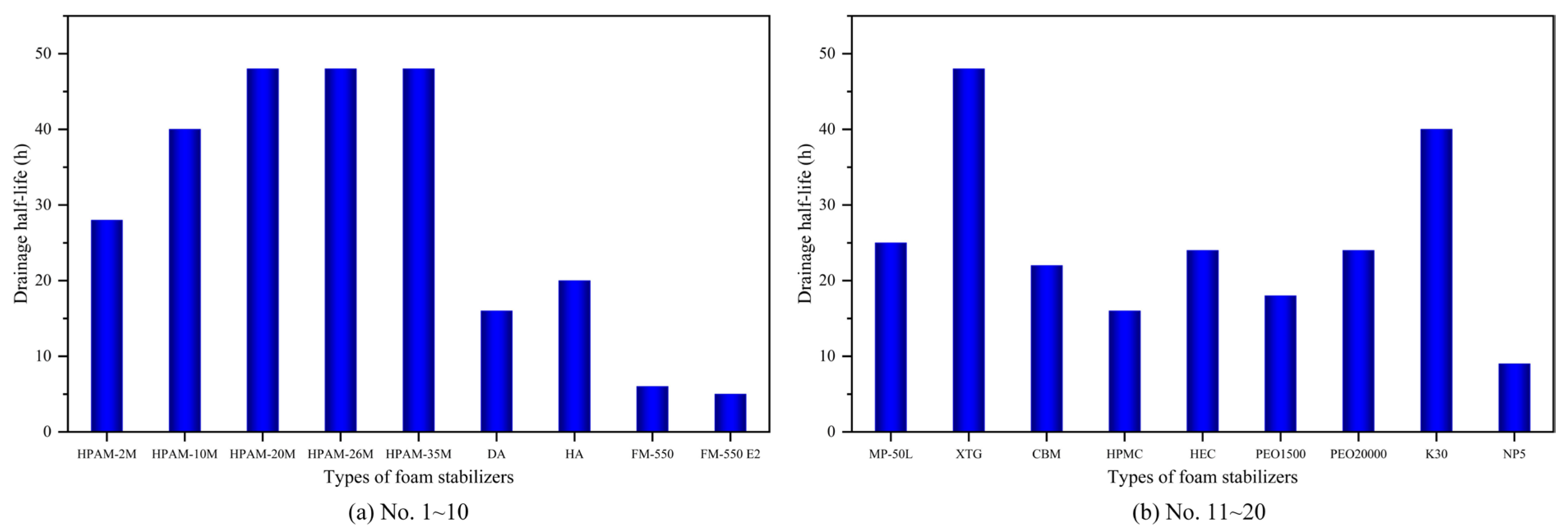

3.1.1. Single Component

3.1.2. Polymer–Surfactant Composite

3.2. Production Performance and Parameters Influence of the CCHP

3.2.1. Pressure After Natural Depletion

3.2.2. Gas–Liquid Ratio of Foam

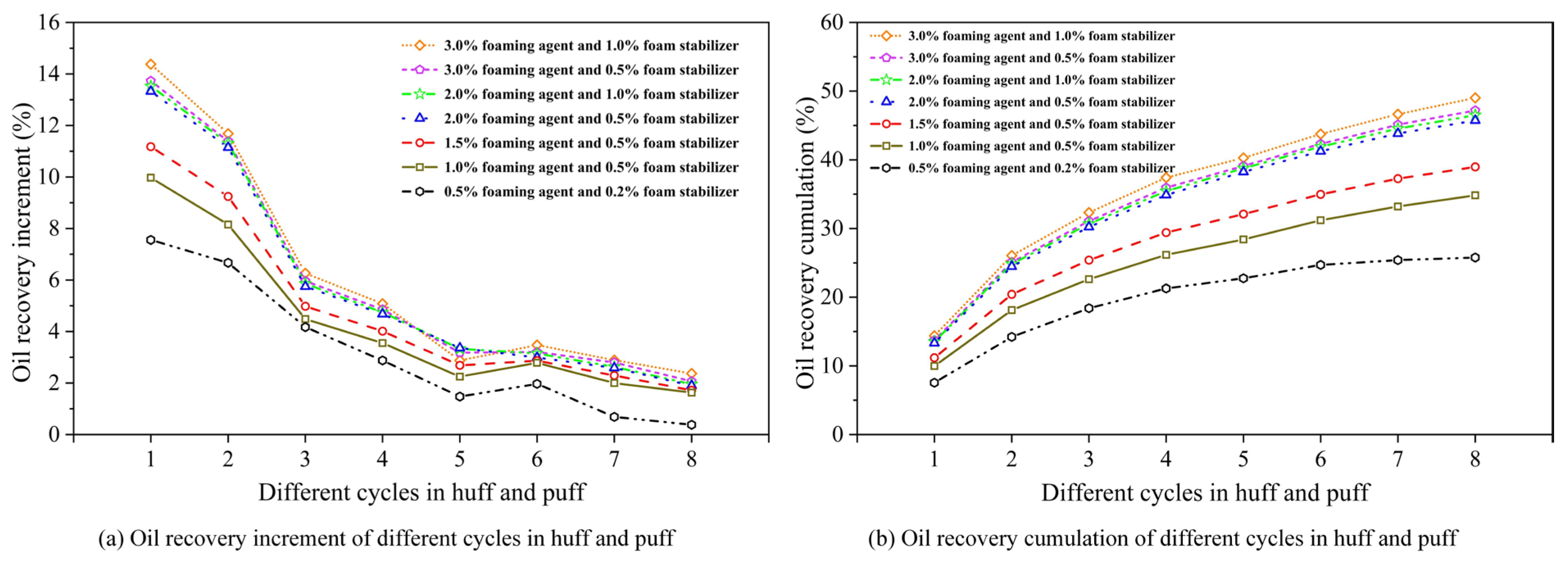

3.2.3. Concentration of Chemical Agent

3.3. Physical Properties of Produced Oil

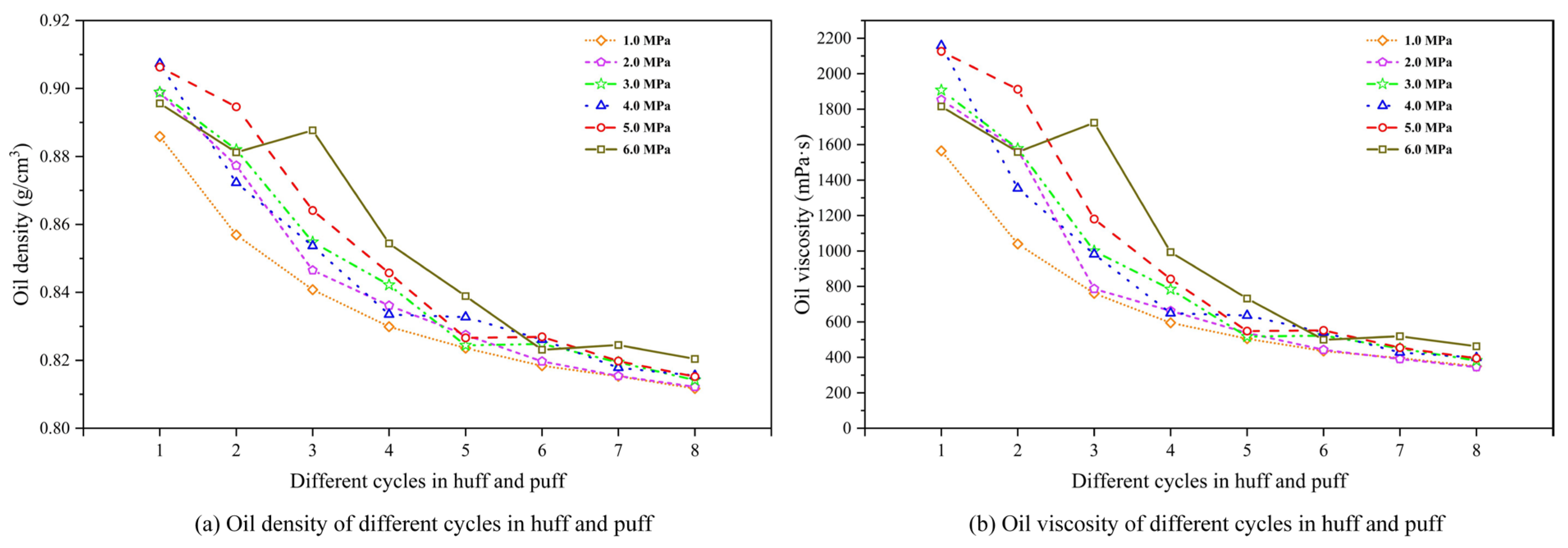

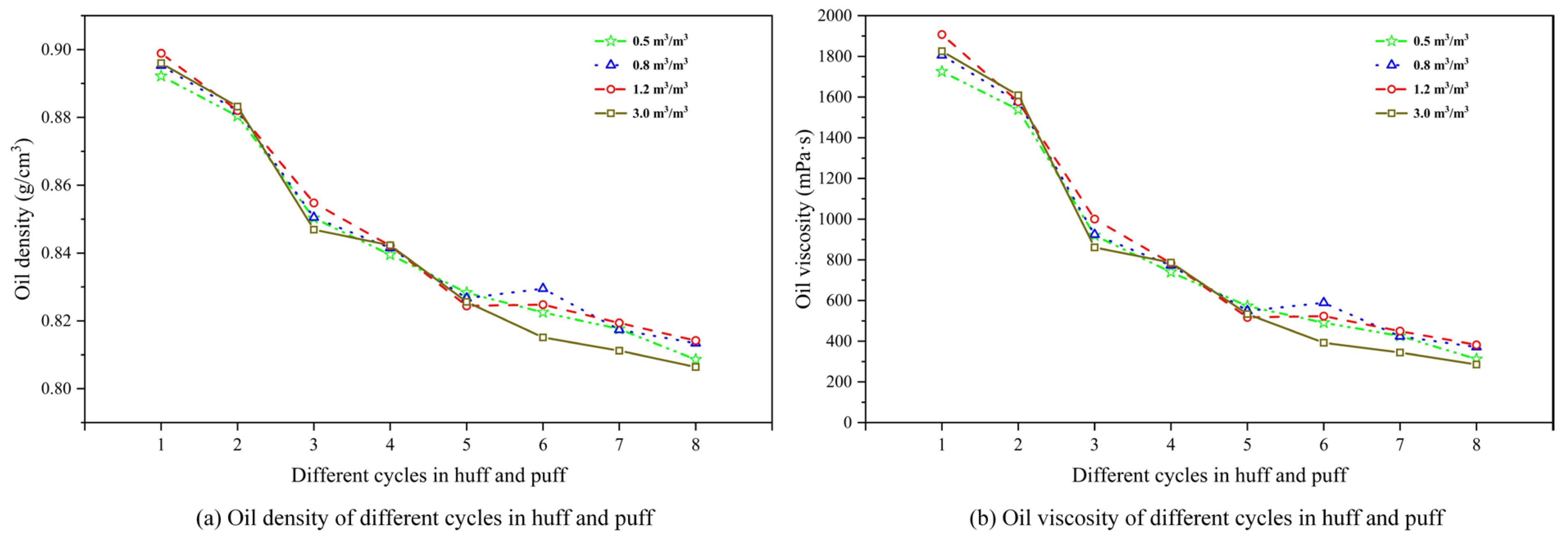

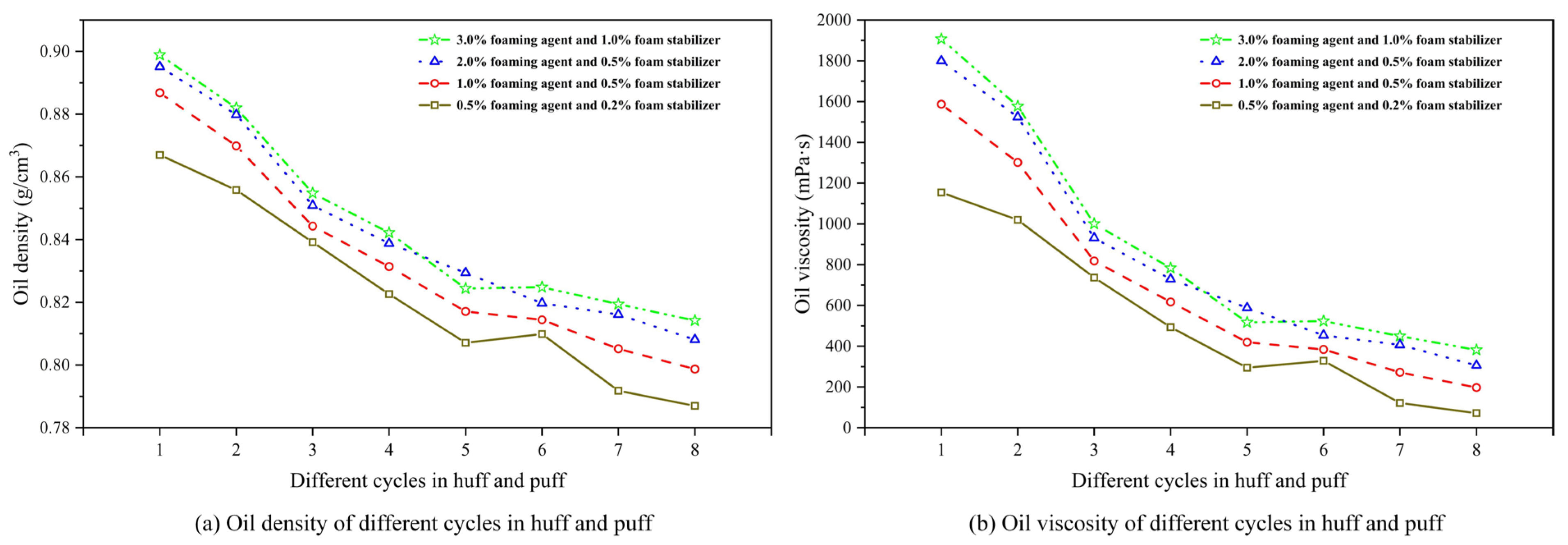

3.3.1. Phase Density and Viscosity of Produced Oil

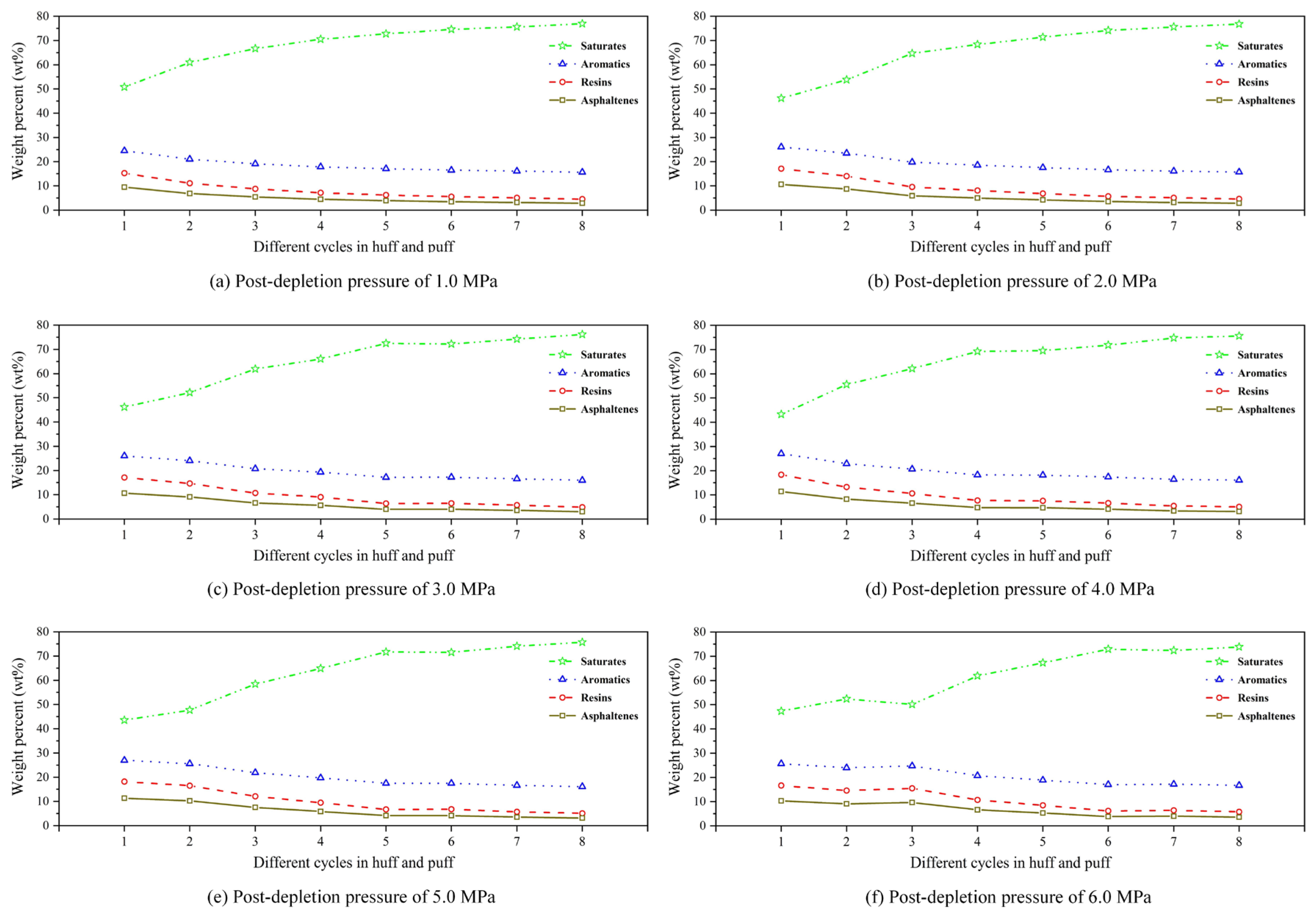

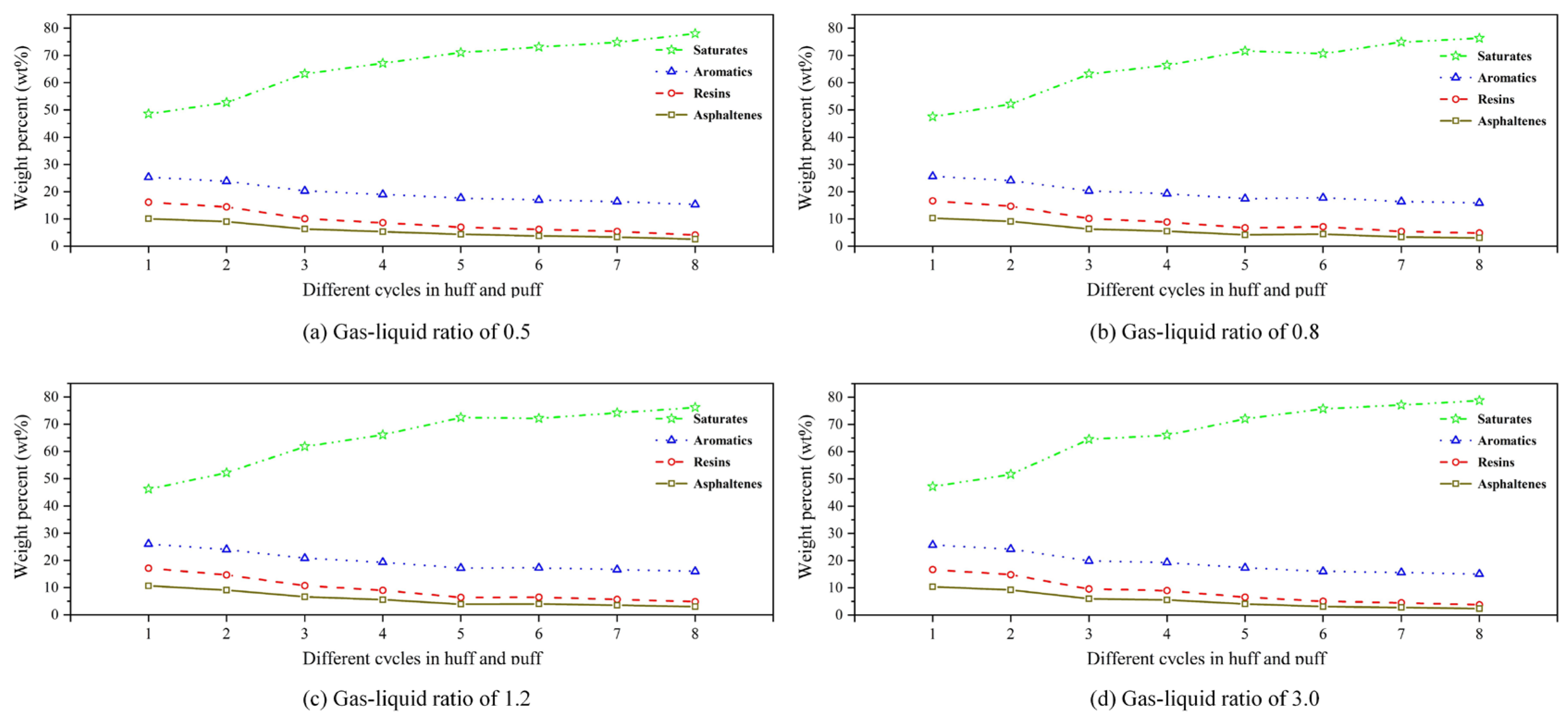

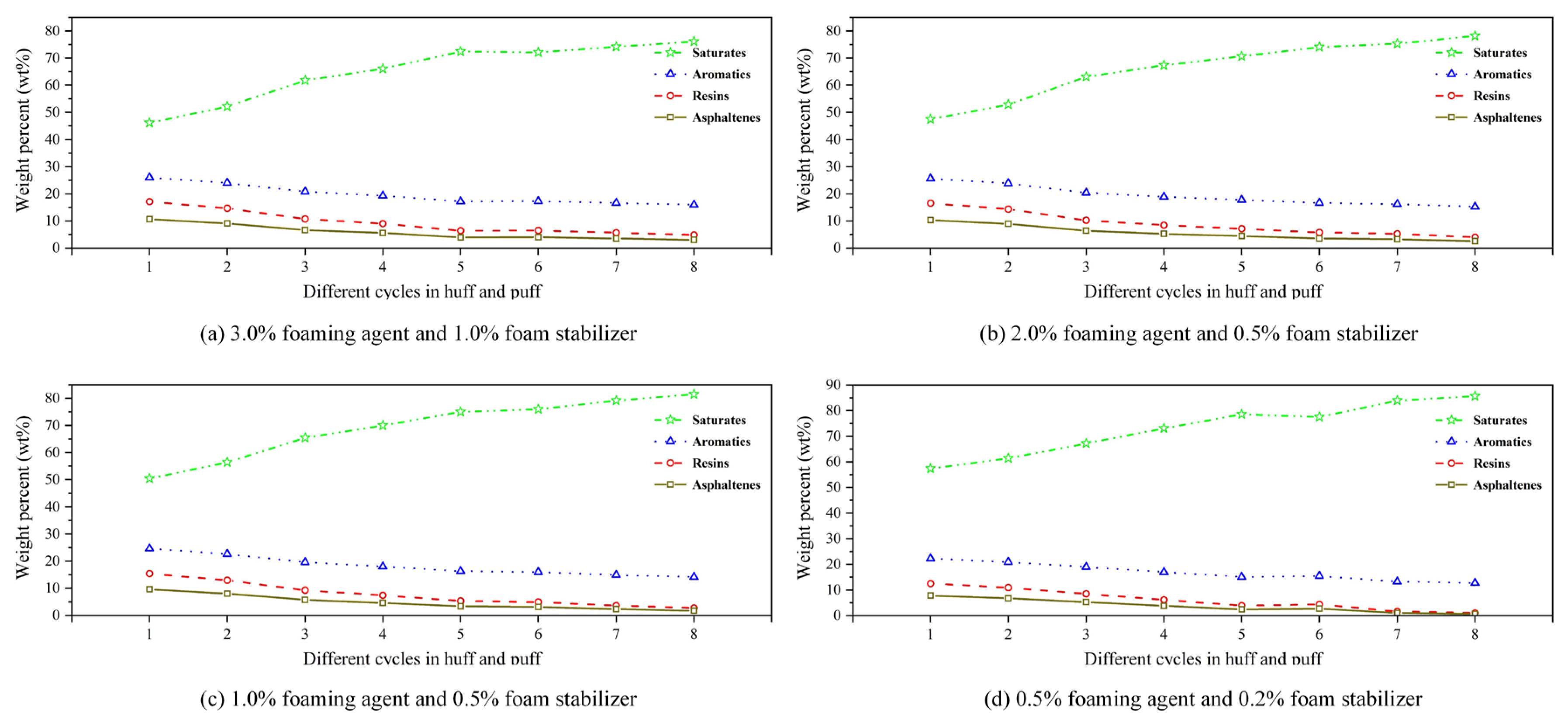

3.3.2. SARA Variation in Produced Oil

3.4. Interplay Between Production Performance and Oil Properties

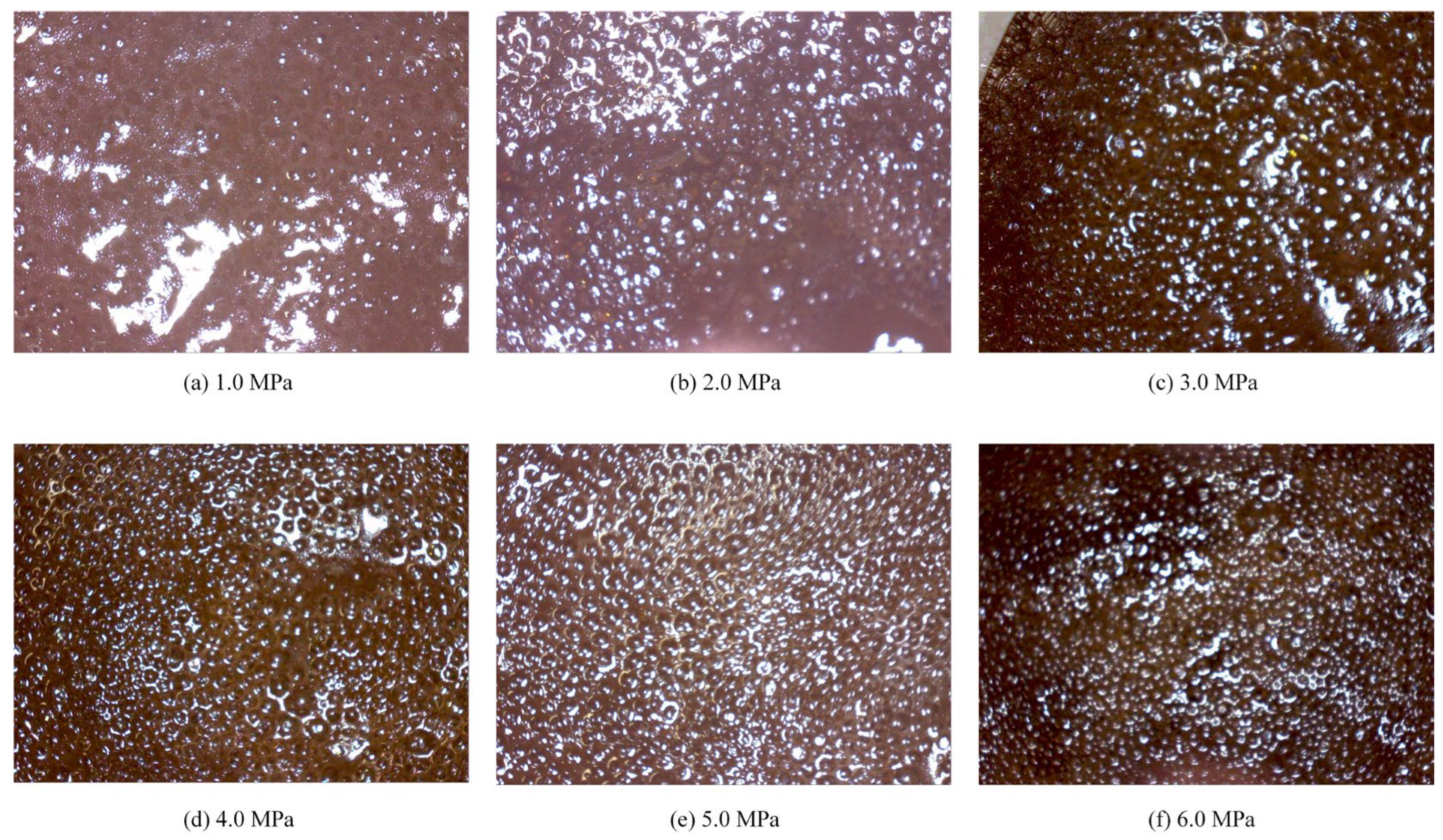

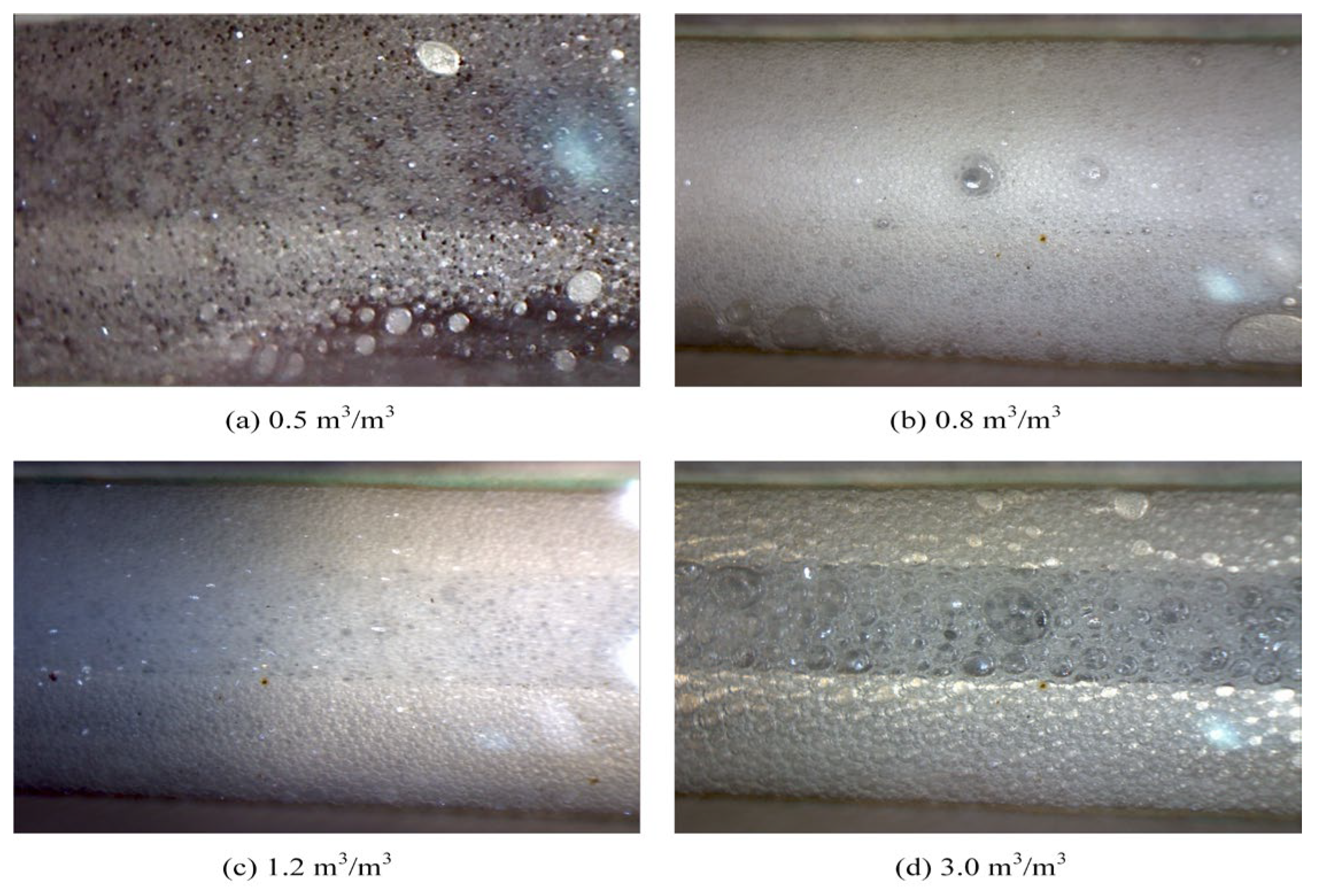

3.5. Characteristics of Foamy Oil and Foam System

4. Application Potential, Limitations and Solutions

5. Conclusions

- (1)

- Compared with surfactants and inorganic nanoparticles, polymers demonstrate superior comprehensive foam stabilization performance. XTG and HPAM-20M exhibit exceptional oil tolerance and salt resistance, achieving optimal foam stability with a drainage half-life of 48 h and an initial foaming volume of 280 mL.

- (2)

- Foam stabilizers with a single component cannot achieve balanced optimization of foam generation and stability. The polymer–surfactant composite of XTG-CBM-DA demonstrates enhanced performance in both its foaming capacity, with an initial foaming volume of 330 mL, and its foam stability, with a drainage half-life of 48 h, effectively improving the overall foam properties.

- (3)

- Lower post-depletion pressure correlates with reduced cyclic oil production. The differential production efficacy primarily manifests during the high-pressure stage where dissolved gas exists in crude oil. As the gas–liquid ratio increases, the recovery factor first rises then declines, with an optimal ratio of 1.2 m3/m3. Increasing the concentration of chemical agents progressively enhances production performance; therefore, the early stages of the CCHP require high-concentration foaming systems, considering the formation of adsorption effects.

- (4)

- The density and viscosity of the produced oil progressively decrease with increasing cycles in the CCHP. High-pressure injection yields a slightly higher density and viscosity than low-pressure injection. Both parameters initially increase then decrease with rising gas–liquid ratios, while declining consistently with reduced concentrations of stable foaming systems.

- (5)

- Saturate content gradually increases with additional cycles in the CCHP, while the content of aromatics shows minor decline. The content of resins and asphaltenes decreases significantly. Injection pressure, gas–liquid ratio, and chemical concentrations all exhibit a negative correlation with the content of saturates but a positive correlation with the content of asphaltenes in produced oil.

- (6)

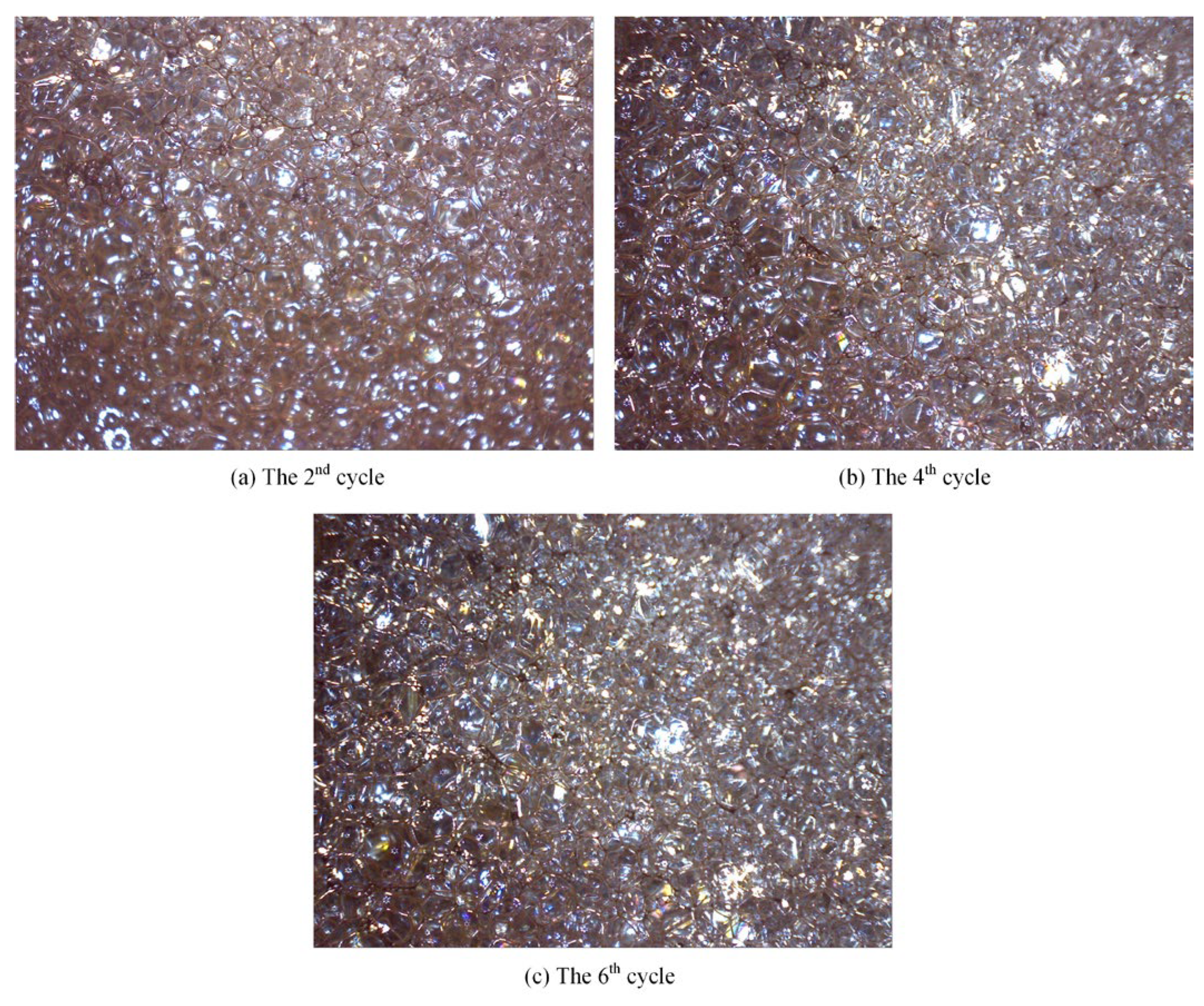

- The stability and performance of foamy oil and foam systems during production critically depend on precise control of key parameters. Insufficient gas–liquid ratios or chemical concentrations will trigger gas channeling, while the foam structure transitions from an oil-rich state to a homogeneous and stable configuration during the CCHP process.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mu, L. Development actualities and characteristics of the Orinoco heavy oil belt, Venezuela. Pet. Explor. Dev. 2010, 37, 338–343. [Google Scholar]

- Chen, H.; Chen, H.; Li, C.; Wang, Y.; Li, J.; Huang, R.; Tian, C.; Hou, Q. Logging response characteristics and formation process of flushed zone in the Orinoco heavy oil belt, Venezuela. Pet. Explor. Dev. 2020, 47, 585–593. [Google Scholar] [CrossRef]

- Gipson, L.J.; Owen, R.; Robertson, C.R. Hamaca heavy oil project: Lessons learned and an evolving development strategy. In Proceedings of the SPE International Thermal Operations and Heavy Oil Symposium and International Horizontal Well Technology Conference, Calgary, AB, Canada, 4–7 November 2002. [Google Scholar]

- Smith, G.E. Fluid flow and sand production in heavy-oil reservoirs under solution-gas drive. SPE Prod. Eng. 1988, 3, 169–180. [Google Scholar] [CrossRef]

- Bennion, D.B.; Mastmann, M.; Moustakis, M.L. A case study of foamy oil recovery in the Patos-Marinza Reservoir, Driza Sand, Albania. J. Can. Pet. Technol. 2003, 42, PETSOC-03-03-01. [Google Scholar] [CrossRef]

- Mu, L.X.; Han, G.Q.; Xu, B.J. Geology and reserve of the Orinoco heavy oil belt, Venezuela. Pet. Explor. Dev. 2009, 36, 784–789. [Google Scholar]

- Li, S.; Li, Z. Effect of temperature on the gas/oil relative permeability of Orinoco Belt Foamy Oil. SPE J. 2016, 21, 170–179. [Google Scholar] [CrossRef]

- Turta, A.T.; Maini, B.B.; Jackson, C. Mobility of gas-in-oil dispersions in enhanced solution gas drive (foamy oil) exploitation of heavy oil reservoirs. J. Can. Pet. Technol. 2003, 42, PETSOC-03-03-05. [Google Scholar] [CrossRef]

- Lu, T.; Li, Z.; Li, S.; Li, B.; Liu, S. Performances of different recovery methods for Orinoco Belt heavy oil after solution gas drive. Energy Fuels 2013, 27, 3499–3507. [Google Scholar] [CrossRef]

- Kumar, R.; Pooladi-Darvish, M.; Okazawa, T. Effect of depletion rate on gas mobility and solution gas drive in heavy oil. SPE J. 2002, 7, 213–220. [Google Scholar] [CrossRef]

- Li, S.Y.; Li, Z.M.; Lu, T.; Li, B. Experimental study on foamy oil flow in porous media with Orinoco Belt heavy oil. Energy Fuels 2012, 26, 6332–6342. [Google Scholar] [CrossRef]

- Ma, H.; Yu, G.; She, Y.; Gu, Y. An analytical production model for primary production and cyclic solvent injection in a heavy-oil reservoir. SPE J. 2019, 24, 2695–2710. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Z.; Lu, T. Experimental study and mechanism analysis of the effect of oil viscosity and asphaltene on foamy oil. Energies 2019, 12, 761. [Google Scholar] [CrossRef]

- Kudapa, V.K.; Krishna, S.K. Heavy oil recovery using gas injection methods and its challenges and opportunities. Mater. Today Proc. 2024, 102, 247–256. [Google Scholar] [CrossRef]

- Guan, W.; Wu, S.; Zhao, J.; Zhang, X.; Liang, J.; Ma, X. Utilizing natural gas huff and puff to enhance production in heavy oil reservoir. In Proceedings of the SPE International Thermal Operation and Heavy Oil Symposium, Calgary, AB, Canada, 20–23 October 2008. [Google Scholar]

- Sun, X.; Zhang, Y.; Cui, G.; Duan, X.; Zhao, C. Feasibility study of enhanced foamy oil recovery of the Orinoco Belt using natural gas. J. Pet. Sci. Eng. 2014, 122, 94–107. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, K.; Li, A.; Sun, C. Phase characteristics of the miscible zone in natural gas miscible flooding and the gas channeling identification method. ACS Omega 2022, 7, 34286–34295. [Google Scholar] [CrossRef] [PubMed]

- Gu, Z.; Zhang, C.; Li, P.; Li, Z.; Wang, M.; Li, Z. CO2-induced in-situ targeted precipitation of asphaltene in heavy oil reservoirs: Balancing formation gas channeling regulation and wellbore asphaltene blockage prevention. SPE J. 2024, 29, 6138–6154. [Google Scholar] [CrossRef]

- Zhang, B.; Zhou, Y.; Wang, B.; Xi, C.; Lv, W.; Liu, P. Experimental investigation on improving sweep efficiency through temperature-resistant gel foam in heavy oil reservoirs. Geoenergy Sci. Eng. 2025, 255, 214117. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, Y.; Liu, P.; Wang, C.; Liu, P.; Xi, C. Experimental investigation on enhanced oil recovery and carbon storage by multimedia synergistic electrical heating-assisted CO2 stimulation in developing medium-deep heavy oil reservoirs. SPE J. 2025, 30, 6406–6427. [Google Scholar] [CrossRef]

- Jawad, A.D.; Murtada, S.A.; Muhammad, S.K.; Mohamed, M.; Shabeeb, A.; Dhafer, A.S. CO2 foam stabilized by viscoelastic surfactant: Effects of chelating agents’ type, pH, and water chemistry on microstructure, stability, and rheology of foam. SPE J. 2025, 30, 976–994. [Google Scholar]

- Wang, K.; Yue, Q.; Zhang, J.; Chen, P.; Wang, Z.; Wang, W.; Zhou, Y.; Zhou, B. Temperature effects of the artificial accelerated ageing of aqueous film-forming foam agent on the foam structural stability. Therm. Sci. Eng. Prog. 2025, 64, 103819. [Google Scholar] [CrossRef]

- Zheng, N.; Zhu, J.; Yang, Z.; Li, X.; Li, Q.; Wen, Y.; Chen, G.; Su, H. Research on the viscoelastic scCO2 foam systems synergistically stabilized by nonionic/zwitterionic mixed surfactants. Colloids Surf. A Physicochem. Eng. Asp. 2024, 697, 134462. [Google Scholar] [CrossRef]

- Bai, Y.; Xu, M.; Liu, G.; Yao, S.; Yan, P.; Yu, F. Molecular dynamics insights into spacer chain length effect on foam stability of mixed amine Gemini surfactant/octanol systems. Colloids Surf. A Physicochem. Eng. Asp. 2025, 725, 137536. [Google Scholar] [CrossRef]

- Aibike, T.; Azza, H.A.; Sonny, I.; Peyman, P. Investigation of natural surfactant for oil recovery potential. Petroleum, 2025; in press. [Google Scholar] [CrossRef]

- Chen, X.; Patel, V.; Liu, J.; Trivedi, J. Surfactant synergy on rheological properties, injectivity, and enhanced oil recovery of viscoelastic polymers. Phys. Fluids 2025, 37, 23107. [Google Scholar] [CrossRef]

- Du, Z.; Xv, J.; Wang, J.; Zhang, J.; Zhao, K.; Wang, Q.; Zheng, Q.; Wang, J.; Li, J.; Liao, B. The microscopic mechanism of high temperature resistant core-shell nano-blocking agent: Molecular dynamics simulations. Polymers 2025, 17, 1969. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Shi, L.; Luo, Y.; Chen, M.; Jin, C.; Guo, Y.; Yuan, N. A surfactant-polymer and macromolecular surfactant compound system for enhancing heavy oil recovery: Synthesis, characterization and mechanism. Colloid Polym. Sci. 2025, 303, 637–653. [Google Scholar] [CrossRef]

- Mohamed, M.H.; Mohyaldinn, M.E. Polyacrylamide-based solutions: A comprehensive review on nanomaterial integration, supramolecular design, and sustainable approaches for integrated reservoir management. Polymers 2025, 17, 2202. [Google Scholar] [CrossRef]

- Yang, J.; Wu, T.; Yang, L.; Zhou, P.; Tang, Y.; Huang, H.; Chen, G. One-pot method to prepare betaine surfactant from rapeseed oil and its application for enhanced oil recovery. Fuel 2025, 398, 135560. [Google Scholar] [CrossRef]

- Shokrollahi, A.; Ghazanfari, M.H.; Badakhshan, A. Application of foam floods for enhancing heavy oil recovery through stability analysis and core flood experiments. Can. J. Chem. Eng. 2014, 92, 1975–1987. [Google Scholar] [CrossRef]

- Oseibonsu, K.; Grassia, P.; Shokri, N. Relationship between bulk foam stability, surfactant formulation and oil displacement efficiency in porous media. Fuel 2017, 203, 403–410. [Google Scholar] [CrossRef]

- Zhao, J.; Torabi, F.; Yang, J. The role of emulsification and IFT reduction in recovering heavy oil during alkaline-surfactant-assisted CO2 foam flooding: An experimental study. Fuel 2022, 313, 122942. [Google Scholar] [CrossRef]

- Arifur, R.; Farshid, T.; Ezeddin, S. Surfactant and nanoparticle synergy: Towards improved foam stability. Petroleum 2023, 9, 255–264. [Google Scholar] [CrossRef]

- Yi, T.; Lu, Y.; Chen, B.; Wang, X.; Zhang, M.; Frostad, J.M.; Xu, Z. Pseudo-Gemini surfactants as switchable surfactants for foams. Colloids Surf. A Physicochem. Eng. Asp. 2026, 728, 138711. [Google Scholar] [CrossRef]

- Ekta, S.; Suraj, B.; Philipp, B.; Shi, X.; Wu, J.Y.; David, M.; Gerald, G.F. Foam stabilization in salt solutions: The role of capillary drainage and Marangoni stresses. J. Colloid Interface Sci. 2025, 693, 137535. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Lv, Z.; Wang, L.; Feng, C.; Wang, J.; Xu, Z.; Huang, Y.; Li, Z.; Kang, W. Stability mechanism of controlled acid-resistant hydrophobic polymer nanospheres on CO2 foam. Fuel 2023, 346, 128332. [Google Scholar] [CrossRef]

- Wu, M.; Li, B.; Ruan, L.; Tang, Y.; Li, Z. Study on the control of steam front mobility in high-temperature and high-salinity conditions using polymer-enhanced foam. Polymers 2024, 16, 2478. [Google Scholar] [CrossRef]

- Alvarenga, B.G.; Lopes, L.F.; Ribeiro, F.R.T.; Pérez-Gramatges, A. Challenges in screening nanoparticles for CO2-foam stabilization: From atmospheric to high-pressure conditions. Colloids Surf. A Physicochem. Eng. Asp. 2025, 720, 137165. [Google Scholar] [CrossRef]

- Amr, G.; Shanker, K.; Ahmed, A.Y. Polymer formulations with binary biosurfactants and zinc oxide nanoparticles for enhanced oil recovery. Fuel 2025, 400, 135733. [Google Scholar] [CrossRef]

- Dinesh, J.; Dadi, N.R.; Shubham, P.; Rohit, K.S.; Neetish, K.M.; Kiran, B.R.; Sujit, M.; Sinha, O.P.; Prem, K.B.; Ajay, M. Formulation and characterization of polymer and nanoparticle-stabilized anionic surfactant foam for application in enhanced oil recovery. Surf. Interfaces 2025, 56, 105615. [Google Scholar]

- Wu, Q.; Ding, L.; Zhang, L.; Ge, J.; Rahman, M.A.; Economou, I.G.; Guérillot, D. Polymer enhanced foam for improving oil recovery in oil-wet carbonate reservoirs: A proof of concept and insights into the polymer-surfactant interactions. Energy 2023, 264, 126256. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, Y.; Khan, N.; Zhu, C.; Gao, Y. Effects of the surfactant, polymer, and crude oil properties on the formation and stabilization of oil-based foam liquid films: Insights from the microscale. J. Mol. Liq. 2023, 373, 121194. [Google Scholar] [CrossRef]

- Li, X.; Sun, X.; Yang, Z.; Gong, H.; Li, T.; Shi, X. Experimental study on chemical-assisted methane flooding for foamy oil reservoirs after primary production. J. Pet. Sci. Eng. 2022, 216, 110803. [Google Scholar] [CrossRef]

- Sun, X.; Cai, L.; Zhang, Y.; Li, T.; Song, Z.; Teng, Z. Comprehensive investigation of non-equilibrium properties of foamy oil induced by different types of gases. Fuel 2022, 316, 123296. [Google Scholar] [CrossRef]

- Ahmed, S.; Hanamertani, S.A.; Elraies, A.K.; Shafian, M. Enhanced CO2 trapping by hydrophobically modified polymer stabilized foam: Significance for CO2 geo-storage. Energy 2025, 314, 1133839. [Google Scholar] [CrossRef]

- Chen, Q.; Liu, D.; Nie, X.; Wang, D.; Pu, W.; Wei, B. Influence of different reservoir conditions on the stability and decay mechanism of the polymer-enhanced foam. Energy Fuels 2024, 38, 18. [Google Scholar] [CrossRef]

- Baigadilov, A.; Stéfan, C.; Omirbekov, S.; Cochennec, M.; Davarzani, D.; Lion, F.; Bodiguel, H.; Oxarango, L. Stability and flow behavior of polymer-enhanced foams for improved in-situ remediation of hydrocarbons: Effect of polymer-surfactant interactions. J. Hazard. Mater. 2025, 486, 137004. [Google Scholar] [CrossRef]

| Oil from MPE3 | Saturates | Aromatics | Resins | Asphaltenes |

|---|---|---|---|---|

| Mass fraction (%) | 6.02 | 39.64 | 33.5 | 20.84 |

| Components | n-Pentane | Isopentane | n-Hexane | n-Heptane | n-Octane | n-Nonane |

|---|---|---|---|---|---|---|

| Mass fraction (%) | 0.01 | 0.01 | 0.04 | 0.05 | 0.08 | 0.15 |

| No. | Foam Stabilizers | Abbreviation-Specification | Types |

|---|---|---|---|

| 1 | Polyacrylamide | HPAM-2M | Polymer |

| 2 | Polyacrylamide | HPAM-10M | Polymer |

| 3 | Polyacrylamide | HPAM-20M | Polymer |

| 4 | Polyacrylamide | HPAM-26M | Polymer |

| 5 | Polyacrylamide | HPAM-35M | Polymer |

| 6 | Dodecanol | DA | Surfactant |

| 7 | Hexadecanol | HA | Surfactant |

| 8 | Modified silicone resin polyether microemulsion | FM-550 | Surfactant |

| 9 | Modified silicone resin polyether emulsion | FM-550 E2 | Surfactant |

| 10 | Modified acrylic polymer | MP-3000S | Polymer |

| 11 | Acrylic polymer film-forming agent | MP-50L | Polymer |

| 12 | Xanthan gum | XTG | Polymer |

| 13 | Acrylic polymer (Carbomer) | CBM | Polymer |

| 14 | Hydroxypropyl methyl cellulose type II | HPMC | Polymer |

| 15 | Hydroxyethyl cellulose | HEC | Polymer |

| 16 | Polyethylene glycol | PEO1500 | Polymer |

| 17 | Polyethylene glycol | PEO20000 | Polymer |

| 18 | Polyvinylpyrrolidone | K30 | Polymer |

| 19 | Nano-silica | 5 nm | Inorganic nanoparticle |

| 20 | Nano-silica | 30 nm | Inorganic nanoparticle |

| 21 | Xanthan gum and Dodecanol | XTG-DA | Polymer–surfactant |

| 22 | Xanthan gum, acrylic polymer, and Dodecanol | XTG-CBM-DA | Polymer–surfactant |

| 23 | Polyacrylamide and Dodecanol | HPAM-DA | Polymer–surfactant |

| 24 | Polyacrylamide, Acrylic polymer, and Dodecanol | HPAM-CBM-DA | Polymer–surfactant |

| Schemes No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Post-depletion pressure (MPa) | 1.0 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 |

| Production pressure in the CCHP (MPa) | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 |

| Gas–liquid ratio (m3/m3) | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 0.5 | 0.8 | 3.0 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 |

| Concentration of foaming agent (%) | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 3.0 | 2.0 | 2.0 | 1.5 | 1.0 | 0.5 |

| Concentration of foam stabilizer (%) | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 0.5 | 1.0 | 0.5 | 0.5 | 0.5 | 0.2 |

| Schemes No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

|---|---|---|---|---|---|---|---|---|

| Porosity (%) | 42.1 | 43.3 | 42.5 | 41.1 | 42.9 | 43.8 | 42.2 | 41.6 |

| Permeability (um2) | 7.3 | 7.2 | 7.4 | 7.6 | 7.2 | 7.0 | 7.6 | 7.3 |

| Original oil in place (m3/m3) | 98.8 | 97.9 | 97.5 | 97.0 | 98.1 | 96.8 | 97.3 | 99.0 |

| Schemes No. | 9 | 10 | 11 | 12 | 13 | 14 | 15 | |

| Porosity (%) | 43.0 | 42.6 | 42.0 | 45.1 | 43.9 | 42.7 | 42.9 | |

| Permeability (um2) | 7.2 | 7.3 | 7.3 | 7.7 | 7.4 | 7.4 | 7.7 | |

| Original oil in place (m3/m3) | 97.5 | 97.1 | 98.0 | 98.5 | 96.3 | 98.2 | 98.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Wu, Y.; Li, X.; Wang, C.; Liu, P. Experimental Study on the Performance of a Stable Foam System and Its Application Effect Combined with Natural Gas in Natural Foamy Oil Reservoirs. Polymers 2025, 17, 2966. https://doi.org/10.3390/polym17222966

Zhang J, Wu Y, Li X, Wang C, Liu P. Experimental Study on the Performance of a Stable Foam System and Its Application Effect Combined with Natural Gas in Natural Foamy Oil Reservoirs. Polymers. 2025; 17(22):2966. https://doi.org/10.3390/polym17222966

Chicago/Turabian StyleZhang, Jipeng, Yongbin Wu, Xingmin Li, Chao Wang, and Pengcheng Liu. 2025. "Experimental Study on the Performance of a Stable Foam System and Its Application Effect Combined with Natural Gas in Natural Foamy Oil Reservoirs" Polymers 17, no. 22: 2966. https://doi.org/10.3390/polym17222966

APA StyleZhang, J., Wu, Y., Li, X., Wang, C., & Liu, P. (2025). Experimental Study on the Performance of a Stable Foam System and Its Application Effect Combined with Natural Gas in Natural Foamy Oil Reservoirs. Polymers, 17(22), 2966. https://doi.org/10.3390/polym17222966